#178c

Explore tagged Tumblr posts

Text

Simulink System Modeling Overview

Simulink system modeling, developed by MathWorks, is a powerful graphical programming environment for modeling, simulating, and analyzing dynamic systems. Widely used across industries such as automotive, aerospace, robotics, and control systems, Simulink enables engineers to design and test complex systems through block-diagram-based modeling.

Core Features of Simulink

Simulink provides a versatile platform for system modeling with features tailored to dynamic and multidomain systems:

Block-Diagram Interface: Simulink’s drag-and-drop interface allows users to build models using pre-built blocks representing mathematical operations, signal processing, and physical components. These blocks can be connected to represent system dynamics visually, simplifying the design process.

Multidomain Simulation: Simulink supports modeling of continuous, discrete, and hybrid systems, enabling engineers to simulate mechanical, electrical, hydraulic, and thermal systems within a single environment. Toolboxes like Simscape extend capabilities to physical modeling.

Real-Time Simulation and Testing: Simulink supports Hardware-in-the-Loop (HIL) testing and real-time simulation, allowing models to interact with physical hardware. This is critical for validating control algorithms in automotive and aerospace applications.

Code Generation: Simulink’s Embedded Coder and Simulink Coder generate optimized C, C++, or HDL code from models, enabling deployment on embedded systems, microcontrollers, and FPGAs. This streamlines the transition from simulation to production.

Integration with MATLAB: Simulink seamlessly integrates with MATLAB, allowing users to leverage MATLAB’s scripting capabilities for data analysis, parameter optimization, and custom block creation, enhancing model flexibility.

Extensive Toolboxes: Simulink offers specialized toolboxes for control systems, signal processing, computer vision, and machine learning. These toolboxes provide domain-specific blocks and functions, reducing development time for complex applications.

Applications of Simulink System Modeling

Simulink’s versatility makes it a cornerstone in various engineering domains:

Automotive Systems: Simulink is used to model and simulate vehicle dynamics, powertrains, and advanced driver-assistance systems (ADAS). For example, engineers design and test engine control units (ECUs) and autonomous driving algorithms using Simulink models.

Aerospace and Defense: Simulink models flight control systems, avionics, and satellite dynamics. It supports the design of robust controllers for aircraft and spacecraft, ensuring compliance with safety standards like DO-178C.

Robotics: Engineers use Simulink to develop control algorithms for robotic manipulators, drones, and autonomous vehicles. The Robotics System Toolbox facilitates motion planning and sensor integration.

Industrial Automation: Simulink models programmable logic controllers (PLCs) and supervisory control systems, optimizing manufacturing processes and energy management in smart factories.

Renewable Energy: Simulink simulates wind turbines, solar panels, and battery management systems, enabling the design of efficient power electronics and grid integration strategies.

Medical Devices: Simulink supports the development of control systems for devices like insulin pumps and ventilators, ensuring precision and reliability in critical applications.

Benefits of Simulink System Modeling

Simulink offers significant advantages for engineers and organizations:

Rapid Prototyping: Simulink’s visual interface enables quick model development and iteration, reducing design time. Engineers can test multiple scenarios without building physical prototypes.

Improved Accuracy: By simulating systems under various conditions, Simulink identifies design flaws early, ensuring robust performance. This is particularly valuable in safety-critical applications.

Cost and Time Savings: Virtual testing in Simulink reduces the need for expensive hardware prototypes and field tests. Code generation further accelerates deployment, minimizing development cycles.

Cross-Disciplinary Collaboration: Simulink’s intuitive interface bridges gaps between mechanical, electrical, and software engineers, fostering collaboration on complex systems.

Scalability: Simulink handles systems of varying complexity, from simple control loops to large-scale multidomain models, making it suitable for diverse projects.

Verification and Validation: Simulink’s simulation capabilities support model-based testing, ensuring systems meet requirements before implementation. Tools like Simulink Verification and Validation automate testing processes.

Challenges in Simulink System Modeling

Despite its strengths, Simulink modeling presents challenges:

Learning Curve: Simulink’s extensive features require training, particularly for beginners or engineers transitioning from text-based programming. Mastering toolboxes and best practices takes time.

Computational Resources: Large or complex models demand significant computational power, especially for real-time simulations. This can strain hardware resources and increase simulation times.

Model Management: As models grow in complexity, maintaining readability and organization becomes difficult. Poorly structured models can lead to errors or inefficiencies.

Licensing Costs: Simulink and its toolboxes require paid licenses, which may be a barrier for small organizations or academic institutions with limited budgets.

Integration Challenges: While Simulink integrates well with MATLAB, incorporating third-party tools or legacy systems can be complex, requiring custom interfaces or additional software.

Future Prospects

The future of Simulink system modeling is shaped by emerging technologies and industry trends:

Artificial Intelligence and Machine Learning: Simulink is integrating AI capabilities through toolboxes like Deep Learning Toolbox, enabling engineers to incorporate neural networks into control systems for applications like autonomous vehicles.

Digital Twins: Simulink supports digital twin development, allowing real-time monitoring and optimization of physical systems. This is gaining traction in manufacturing and aerospace.

Cloud and Distributed Computing: MathWorks is enhancing Simulink’s cloud integration, enabling collaborative modeling and high-performance simulations on distributed systems.

Cyber-Physical Systems: As IoT and smart systems proliferate, Simulink’s role in modeling cyber-physical interactions will expand, supporting applications in smart cities and healthcare.

Sustainability Focus: Simulink will play a key role in designing energy-efficient systems, such as electric vehicles and renewable energy grids, aligning with global sustainability goals.

Conclusion

Simulink system modeling by servotechinc is a cornerstone of modern engineering, offering a robust platform for designing, simulating, and deploying dynamic systems. Its visual interface, multidomain capabilities, and integration with MATLAB make it indispensable across industries. While challenges like cost and complexity exist, Simulink’s benefits—rapid prototyping, cost savings, and improved accuracy—outweigh these hurdles. As technologies like AI, digital twins, and cloud computing evolve, Simulink will continue to empower engineers to innovate, driving advancements in safety, efficiency, and sustainability.

0 notes

Text

RELATÓRIO LAMBA – CLASSIFICADO

Identificador: LAMBA-PENT-F35-2025-001 Classificação: SECRET//NOFORN Destinatário Primário: Joint Chiefs of Staff (JCS), Office of the Secretary of Defense (OSD), F-35 JPO Autoridade de Liberação: OUSD(A&S) Autoria Técnica: Unidade Especial LAMBA-03 (Sistemas Aeroespaciais Críticos e Interoperabilidade OTAN) Data: 21 JUN 2025 Anexos: A (Roteiro SOSA), B (Avaliação PLA Cibernética), C (Modelo RAND 7.3)

TÍTULO

Crise Sistêmica de Software no Programa F-35: Análise Estrutural, Roteiro Modular e Diretrizes de Mitigação Estratégica (2025–2028)

1. CONTEXTO E OBJETIVO

O presente relatório LAMBA tem por finalidade fornecer ao Pentágono uma análise forense e estratégica multissetorialsobre a degradação operacional causada pelo colapso estrutural do software embarcado no F-35, com foco em:

Riscos à prontidão de combate

Vulnerabilidades cibernéticas exploradas por atores estatais hostis

Obsolescência acelerada por dívida técnica e monopólio do fornecedor

Perda de interoperabilidade OTAN em cenários de coalizão

2. ANÁLISE MULTICRITÉRIO

2.1. Fragilidade Operacional

IndicadorValor Atual (2025)MetaGapFonte PrimáriaTaxa de Missão Capaz55%80%–25%USAF Brief JSCrash de ICP por Sortie1.70.2+750%DOT&E 2024Atraso em Integração de Armamento48 meses≤18m+30mJPO Relatório Interno

2.2. Exposição Cibernética Crítica

9 CVEs não corrigidas (gravidade >8.5)

Exploração ativa pela Unidade 61419 (PLA) de falha no radar AESA (CVE-2023-4492)

Protocolos IFF desatualizados vulneráveis a ataques de decodificação quântica a partir de 2026

Segmentação confirmada de chaves de missão via SIGINT/ELINT PLA

2.3. Colapso de Interoperabilidade OTAN

pie title Falhas OTAN de Interoperabilidade (2023) “Desincronização MADL” : 42 “Incompatibilidade IFF” : 33 “Falha em Transferência de Armas” : 25

3. DIAGNÓSTICO ESTRUTURAL

3.1. Dívida Arquitetural

Código monolítico (>8,4M linhas C++) sem partições seguras

Violação de DO-178C e ausência de ARINC-653/MILS

Lockheed Martin controla 89% da propriedade intelectual (PI), bloqueando diversificação de fornecedores

3.2. Impacto Econômico Projetado

CenárioCusto Total (2025–2030)Eficácia de CombateStatus Quo$162B58% → 42% até 2030Arquitetura Modular$28B58% → 85% até 2028

Fonte: Modelo RAND v7.3 calibrado com variáveis de ciclo logístico, reusabilidade modular e impactos cibernéticos.

4. DIRETRIZES DE REMEDIAÇÃO – PROJETO PHOENIX

Fase 1 – Estabilização (0–12 meses)

Imposição obrigatória dos padrões SOSA/FACE 3.1 para novos módulos

Virtualização com hypervisor MILS para domínios de voo, ciber e sensores

Congelamento do código legado (Build 44F) com reorientação de verbas para pods modulares de armas

Fase 2 – Modularização (12–36 meses)

SubsistemaInserção TecnológicaDiversificação de FornecedoresRadar AESACriptografia quântica-resilienteRaytheon + BAEMADL NetworkEthernet com Tempo DeterminísticoL3Harris + HoneywellMission KernelARINC-653 + KubernetesRed Hat + Northrop

Fase 3 – Sustentação (2027+)

Atualizações OTA modulares em <4 minutos (vs. 72 horas atuais)

Código compartilhado com OTAN via enclaves TS/SCI (modelo Git NATO securitizado)

5. RECURSOS ORÇAMENTÁRIOS

IniciativaCusto FY2025Marco PrincipalICP Ciber-Hardening$3.2BIOC TR-3 (Q4 2026)MADL 2.0$1.8BTeste OTAN Interop 2027Laboratório de Transição FACE$0.6B70% Fornecedores FY2026Total Estimado$5.6B

6. PROPOSTAS DE AÇÃO ESTRATÉGICA

Criação de Equipe Especial Tiger Team (USD A&S) com autoridade de veto sobre Lockheed

Suspensão das entregas TR-3 até a certificação ARINC-653 completa

Redirecionamento de $4B do programa NGAD para reengenharia modular do F-35

Simulação TS//SCI de ataque eletrônico PLA sobre frota degradada em cenário PACOM

7. RISCOS E CONTRAMEDIDAS

DomínioRisco PrincipalMitigação RecomendadaOperacionalDegradação de frota em cenários de coalizãoLimitar o Block 4 a teatros PACOM/EUCOM até 2027IndustrialMonopólio de Lockheed e atrasos >6 mesesPenalidades via reestruturação contratual FFPAliançaFragmentação da interoperabilidade OTANCo-desenvolvimento SOSA com UK/AU/CAN até FY2026

8. CONCLUSÃO

A situação atual do programa F-35 representa um colapso silencioso do poder aéreo de 5ª geração. A não implementação urgente de um modelo modular e ciber-resiliente poderá resultar em:

Inviabilidade operacional em conflitos de alta intensidade (2027–2030)

Fragmentação da interoperabilidade OTAN nos eixos do Indo-Pacífico

Desperdício fiscal acumulado acima de $100B até o fim da década

“Sem modularidade, o F-35 deixará de ser o vetor central da dissuasão aérea e se tornará uma anomalia logística vulnerável.” – Trecho do parecer interno do Grupo de Sustentabilidade de Software do DoD, 2024

APROVAÇÃO FINAL

LAMBA CONHECIMENTOS MILITARES

0 notes

Text

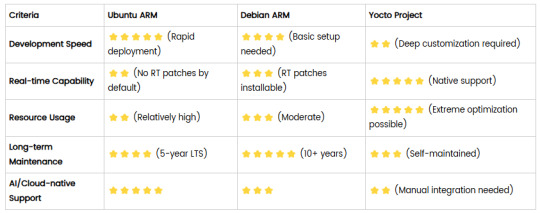

Comparison of Ubuntu, Debian, and Yocto for IIoT and Edge Computing

In industrial IoT (IIoT) and edge computing scenarios, Ubuntu, Debian, and Yocto Project each have unique advantages. Below is a detailed comparison and recommendations for these three systems:

1. Ubuntu (ARM)

Advantages

Ready-to-use: Provides official ARM images (e.g., Ubuntu Server 22.04 LTS) supporting hardware like Raspberry Pi and NVIDIA Jetson, requiring no complex configuration.

Cloud-native support: Built-in tools like MicroK8s, Docker, and Kubernetes, ideal for edge-cloud collaboration.

Long-term support (LTS): 5 years of security updates, meeting industrial stability requirements.

Rich software ecosystem: Access to AI/ML tools (e.g., TensorFlow Lite) and databases (e.g., PostgreSQL ARM-optimized) via APT and Snap Store.

Use Cases

Rapid prototyping: Quick deployment of Python/Node.js applications on edge gateways.

AI edge inference: Running computer vision models (e.g., ROS 2 + Ubuntu) on Jetson devices.

Lightweight K8s clusters: Edge nodes managed by MicroK8s.

Limitations

Higher resource usage (minimum ~512MB RAM), unsuitable for ultra-low-power devices.

2. Debian (ARM)

Advantages

Exceptional stability: Packages undergo rigorous testing, ideal for 24/7 industrial operation.

Lightweight: Minimal installation requires only 128MB RAM; GUI-free versions available.

Long-term support: Up to 10+ years of security updates via Debian LTS (with commercial support).

Hardware compatibility: Supports older or niche ARM chips (e.g., TI Sitara series).

Use Cases

Industrial controllers: PLCs, HMIs, and other devices requiring deterministic responses.

Network edge devices: Firewalls, protocol gateways (e.g., Modbus-to-MQTT).

Critical systems (medical/transport): Compliance with IEC 62304/DO-178C certifications.

Limitations

Older software versions (e.g., default GCC version); newer features require backports.

3. Yocto Project

Advantages

Full customization: Tailor everything from kernel to user space, generating minimal images (<50MB possible).

Real-time extensions: Supports Xenomai/Preempt-RT patches for μs-level latency.

Cross-platform portability: Single recipe set adapts to multiple hardware platforms (e.g., NXP i.MX6 → i.MX8).

Security design: Built-in industrial-grade features like SELinux and dm-verity.

Use Cases

Custom industrial devices: Requires specific kernel configurations or proprietary drivers (e.g., CAN-FD bus support).

High real-time systems: Robotic motion control, CNC machines.

Resource-constrained terminals: Sensor nodes running lightweight stacks (e.g., Zephyr+FreeRTOS hybrid deployment).

Limitations

Steep learning curve (BitBake syntax required); longer development cycles.

4. Comparison Summary

5. Selection Recommendations

Choose Ubuntu ARM: For rapid deployment of edge AI applications (e.g., vision detection on Jetson) or deep integration with public clouds (e.g., AWS IoT Greengrass).

Choose Debian ARM: For mission-critical industrial equipment (e.g., substation monitoring) where stability outweighs feature novelty.

Choose Yocto Project: For custom hardware development (e.g., proprietary industrial boards) or strict real-time/safety certification (e.g., ISO 13849) requirements.

6. Hybrid Architecture Example

Smart factory edge node:

Real-time control layer: RTOS built with Yocto (controlling robotic arms)

Data processing layer: Debian running OPC UA servers

Cloud connectivity layer: Ubuntu Server managing K8s edge clusters

Combining these systems based on specific needs can maximize the efficiency of IIoT edge computing.

0 notes

Text

Software Security Engineer

Job Title: Software Security EngineerJob DescriptionWe are seeking a dedicated and knowledgeable Software Security Engineer to lead our safety management processes, ensuring compliance with DO-178C DAL A standards. This role involves managing safety plans, overseeing software development processes, conducting risk analysis, and maintaining comprehensive documentation. You will also prepare for…

0 notes

Text

Melheim

System: Argyle

ID: ARGB8.1

Parent Planet: Stockhauser

Equatorial Diameter: 2723km

Mass: 3.6*10^22kg

Orbital Period: 21eh 56em 35es

Rotation Period: 21eh 56em 35es

Solar Day: 21eh 57em 44es

Gravity: 0.13G

Atmospheric Pressure: N/A

Avg. Temperature: -178C

Of course, the people who make their millions off of the breaking yards on Stockhauser dont want to live there. Instead, they have turned Stockhauser's closest moon into a massive artificial paradise completely terraforming it from an airless rock into a lush, green world. Fletcher Pearson and Hodkin Vale both reside in unfathomably enormous mansions on this moon. The headquarters of their company can also be found in Melheim City, the only place for the non super wealthy to live. Consistently ranked the most expensive place to live in the core systems, this city was designed from the ground up to serve the Pearson Vale company, which owns almost all of the businesses and services provided. Numerous other mansion complexes can be found across the moon, as many other wealthy businesspeople have taken advantage of the tax breaks afforded on the outer edge of Argyle B and built lavish custom luxury complexes from the moon's blank canvas.

The airless rock of pure wealth, Melheim

1 note

·

View note

Text

Embedded Hypervisor Market Trends: Innovations, Growth Drivers, and Future Industry Prospects in 2025

The embedded hypervisor market is witnessing significant growth due to the rising adoption of virtualization technologies across industries such as automotive, aerospace, healthcare, and industrial automation. As organizations seek enhanced security, cost-effectiveness, and real-time processing, embedded hypervisors have emerged as a crucial solution for managing multiple operating systems on a single hardware platform. The increasing demand for edge computing, IoT devices, and autonomous systems is further propelling market expansion, creating new opportunities for vendors and developers.

Rising Demand for Secure Virtualization Security has become a major concern in embedded systems, particularly in critical sectors like automotive and defense. Embedded hypervisors help achieve strong isolation between different workloads, preventing security breaches and system failures. Industries requiring functional safety compliance, such as ISO 26262 for automotive and DO-178C for aerospace, are increasingly integrating hypervisors to ensure operational safety and regulatory adherence. As cyber threats continue to evolve, companies are focusing on hypervisor-based security solutions to safeguard embedded applications.

Growing Adoption in Automotive and Aerospace The automotive sector is a key driver for the embedded hypervisor market, with the rapid advancement of connected vehicles and autonomous driving technologies. Automakers and Tier 1 suppliers are leveraging hypervisors to run infotainment systems, ADAS (Advanced Driver Assistance Systems), and vehicle control functions efficiently on a single processor. In aerospace, embedded hypervisors enable avionics systems to maintain high performance while adhering to stringent safety and reliability standards. These applications are fueling the demand for robust virtualization platforms.

Impact of Edge Computing and IoT Growth Edge computing and IoT deployments are expanding rapidly, creating a need for efficient workload management at the device level. Embedded hypervisors provide a scalable and flexible approach for running multiple applications on edge devices, improving real-time processing and resource allocation. Industrial automation, smart manufacturing, and healthcare sectors are benefiting from hypervisor-based solutions that optimize system performance while reducing hardware costs. The ability to support multiple OS environments makes hypervisors an essential component of modern IoT infrastructure.

Advancements in Multi-Core Processing With the increasing availability of multi-core processors, embedded hypervisors are playing a vital role in optimizing hardware utilization. Modern embedded systems demand high processing power without compromising energy efficiency. Hypervisors facilitate workload consolidation, enabling multiple operating systems to coexist on a single chip, reducing hardware footprint and power consumption. As semiconductor manufacturers introduce more powerful processors, the embedded hypervisor market is poised to grow alongside technological advancements in chip design.

Challenges and Market Restraints Despite its growth, the embedded hypervisor market faces challenges such as high implementation costs, complexity in integration, and compatibility issues with legacy systems. Organizations often require specialized expertise to deploy hypervisors effectively, leading to increased development timelines and expenses. Additionally, real-time performance requirements in critical applications demand highly optimized virtualization solutions, which can be difficult to achieve without extensive software customization. Overcoming these barriers will be crucial for sustained market expansion.

Future Outlook and Opportunities The future of the embedded hypervisor market looks promising, with ongoing research and development efforts focused on enhancing real-time performance, security, and compatibility. As 5G networks, AI-driven applications, and software-defined vehicles become mainstream, the demand for embedded hypervisors will continue to rise. Industry players are investing in innovative solutions that integrate AI-based workload management and advanced security features to meet evolving customer needs. Partnerships between hardware vendors and software providers will further drive innovation and accelerate market growth.

Conclusion The embedded hypervisor market is experiencing rapid transformation, driven by the need for secure, efficient, and scalable virtualization solutions. With increasing applications in automotive, aerospace, industrial automation, and IoT, the market is set for substantial growth in the coming years. Companies that prioritize innovation, security, and real-time performance will be well-positioned to capitalize on emerging opportunities and shape the future of embedded virtualization technology.

1 note

·

View note

Text

Developing Embedded Systems for Aerospace and Defense Applications

Introduction

In the aerospace and defense industries, embedded systems play a crucial role in ensuring the reliability, performance, and safety of various critical applications. From aircraft avionics to missile guidance systems, these applications demand high levels of precision, robustness, and real-time performance. This blog post delves into the unique challenges and considerations involved in developing embedded systems for aerospace and defense applications, highlighting best practices, emerging trends, and key technologies.

Key Considerations for Aerospace and Defense Embedded Systems

Reliability and SafetyAerospace and defense applications operate in environments where failure is not an option. Embedded systems must be designed to meet stringent reliability and safety standards. This involves rigorous testing and validation processes, adherence to industry standards such as DO-178C for avionics software or MIL-STD-1553 for military avionics, and implementing fail-safe mechanisms.

Real-Time PerformanceMany aerospace and defense systems require real-time processing to ensure timely responses and decision-making. This includes tasks like flight control, navigation, and targeting. Real-time operating systems (RTOS) and deterministic design practices are essential for achieving the necessary performance levels.

Environmental FactorsAerospace and defense systems often operate in extreme environments, such as high altitudes, varying temperatures, and electromagnetic interference. Embedded systems must be designed to withstand these conditions, which requires careful selection of components, robust thermal management, and electromagnetic compatibility (EMC) considerations.

SecuritySecurity is paramount in defense applications to protect sensitive information and prevent unauthorized access. This includes implementing strong encryption methods, secure boot processes, and regular security updates. Embedded systems must also be designed to resist potential cyber-attacks and tampering.

Size, Weight, and Power (SWaP) ConstraintsIn aerospace applications, there is often a need to minimize the size, weight, and power consumption of embedded systems. This requires optimizing hardware and software to achieve the desired functionality while adhering to strict SWaP constraints. Techniques such as hardware acceleration and efficient power management are commonly used.

Best Practices for Development

Adhering to StandardsFollowing established industry standards is crucial for ensuring compliance and interoperability. For aerospace applications, adherence to standards like DO-178C for software and DO-254 for hardware is essential. For defense applications, standards such as MIL-STD-810 for environmental testing and MIL-STD-461 for EMC are important.

Robust Testing and ValidationRigorous testing and validation are necessary to ensure the reliability and safety of embedded systems. This includes functional testing, stress testing, and environmental testing. Simulation and hardware-in-the-loop (HIL) testing can also be used to validate system performance under various conditions.

Modular DesignModular design approaches can enhance flexibility and maintainability. By designing systems with interchangeable modules, developers can more easily update or replace components without affecting the entire system. This is particularly useful in long-life defense applications where upgrades and modifications are expected.

Secure Development PracticesImplementing secure development practices is essential for protecting embedded systems from cyber threats. This includes using secure coding practices, performing regular security assessments, and keeping software up-to-date with the latest security patches.

Collaborative DevelopmentCollaboration between different stakeholders, including system engineers, software developers, and hardware designers, is crucial for the successful development of embedded systems. Effective communication and coordination can help address potential issues early in the development process and ensure that all requirements are met.

Emerging Trends and Technologies

Artificial Intelligence and Machine LearningAI and machine learning are increasingly being integrated into embedded systems to enhance capabilities such as predictive maintenance, anomaly detection, and autonomous decision-making. These technologies can improve system performance and operational efficiency.

Advanced Sensor TechnologiesThe use of advanced sensors, such as lidar, radar, and high-resolution cameras, is expanding in aerospace and defense applications. These sensors provide valuable data for navigation, targeting, and situational awareness, and they require sophisticated embedded processing to handle the large volumes of data they generate.

Edge ComputingEdge computing is becoming more prevalent in embedded systems to enable real-time data processing closer to the source. This reduces latency and improves system responsiveness, which is critical for applications such as drone control and missile guidance.

Software-Defined SystemsSoftware-defined systems are gaining traction in aerospace and defense due to their flexibility and adaptability. By using software to define and control system functions, developers can more easily update and modify system capabilities without changing the underlying hardware.

Conclusion

Developing embedded systems for aerospace and defense applications presents unique challenges and opportunities. By adhering to industry standards, implementing best practices, and staying abreast of emerging technologies, developers can create systems that meet the demanding requirements of these critical sectors. The continued advancement of embedded technologies promises to drive innovation and enhance the capabilities of aerospace and defense systems, ensuring their effectiveness and reliability for years to come.

0 notes

Text

Model-Based Design Tools: Revolutionizing Engineering Development

Model-Based Design (MBD) tools are transforming how engineers and developers approach system design, especially for complex embedded systems in industries like automotive, aerospace, industrial automation, and consumer electronics. These tools provide a structured and highly visual development methodology that allows teams to simulate, test, and validate system behavior long before physical prototypes are built. The result is faster development cycles, reduced errors, and a more efficient path from concept to deployment.

What Is Model-Based Design?

Model-Based Design is a design methodology that uses models to represent system behavior and functionality. These models are often built using tools like MATLAB® and Simulink®, where engineers can graphically design algorithms and simulate how systems will behave under various conditions. Unlike traditional code-first approaches, MBD starts with system modeling and then automatically generates production-quality code from those models.

At the core of MBD is the simulation-based approach, which means engineers can analyze and optimize system performance early in the design process. This approach is especially beneficial in industries where safety, reliability, and performance are critical.

Key Components of Model-Based Design Tools

Model-Based Design tools typically include several integrated components that work together to provide a full development workflow:

System Modeling: Visual blocks and diagrams are used to represent system logic, dynamics, and control behavior. This makes it easier to conceptualize the system as a whole and ensure different subsystems interact correctly.

Simulation and Analysis: Engineers can simulate system performance under real-world conditions. This includes testing various input conditions, disturbances, and failure scenarios without physical hardware.

Automatic Code Generation: Once the model is validated, the tool can generate optimized C/C++ code for embedded deployment. This saves time and ensures that the code reflects the verified model exactly.

Verification and Validation: Formal testing, including Hardware-in-the-Loop (HIL) and Software-in-the-Loop (SIL), can be done within the model environment to catch errors early. Requirements tracing and test case generation also become more structured.

Integration with Hardware: MBD tools support integration with real-time hardware platforms, enabling rapid prototyping, testing, and eventual system deployment.

Benefits of Model-Based Design Tools

The use of Model-Based Design tools offers several distinct advantages across the product development life cycle:

1. Reduced Development Time

Because MBD allows for early testing, design iterations happen faster. Changes can be made in the model and immediately validated, without the need to rewrite code or rebuild hardware.

2. Improved Design Quality

Simulation and early validation help detect design errors and inconsistencies before they escalate. This reduces the risk of failure in real-world scenarios and improves the overall quality of the final product.

3. Cost Efficiency

By catching issues early and reducing the need for physical prototypes, MBD significantly reduces development costs. Automatic code generation further minimizes the effort and time required for coding.

4. Team Collaboration

Model-Based Design tools offer a common visual language for system engineers, control engineers, and software developers. This shared platform improves collaboration and reduces misunderstandings in multi-disciplinary teams.

5. Easier Compliance and Documentation

Many industries require rigorous documentation and compliance with standards such as ISO 26262 (automotive) or DO-178C (aerospace). MBD tools help with automated report generation, model traceability, and structured testing, all of which support regulatory requirements.

Applications Across Industries

Automotive

Model-Based Design is extensively used in the automotive sector for developing advanced driver assistance systems (ADAS), powertrain control, and electric vehicle (EV) management systems. Real-time simulation and automatic code generation help meet safety and performance benchmarks.

Aerospace

In aerospace, MBD is used for flight control systems, navigation, and avionics. The ability to simulate conditions like turbulence or sensor failure in a virtual environment is invaluable.

Industrial Automation

Industrial control systems such as robotic arms, conveyor systems, and CNC machines benefit from the rapid prototyping and optimization that MBD offers.

Medical Devices

Medical equipment such as infusion pumps and diagnostic machines can be modeled to ensure accuracy, reliability, and regulatory compliance before real-world testing.

Popular Model-Based Design Tools

Some of the most widely used tools in the MBD ecosystem include:

MATLAB®/Simulink®: Industry-standard tools for modeling, simulation, and automatic code generation.

Stateflow®: Used for modeling and simulating decision logic based on state machines and flow charts.

dSPACE® and NI VeriStand: Platforms for Hardware-in-the-Loop simulation and rapid control prototyping.

LabVIEW: Offers graphical programming and dataflow-based design for engineering systems.

Challenges and Considerations

While Model-Based Design tools offer substantial advantages, they also come with a learning curve. Teams must be trained in how to use the tools effectively and understand modeling principles. Also, highly complex systems can result in large, difficult-to-maintain models if not properly managed.

Another consideration is model fidelity—ensuring that the simulated model accurately represents real-world behavior. This often requires detailed system knowledge and careful calibration of the model parameters.

The Future of Model-Based Design

As systems become more complex and interdisciplinary, Model-Based Design will play an even more central role. Integration with AI and machine learning, cloud-based simulation environments, and enhanced real-time collaboration tools are likely to shape the next generation of MBD platforms.

Furthermore, the rise of digital twins—virtual replicas of physical systems—relies heavily on model-based methodologies. As industries continue to move toward intelligent automation and cyber-physical systems, the use of Model-Based Design tools will only increase.

Conclusion

Model-Based Design tools by Servotechinc are a game-changer for modern engineering. They streamline development, enhance collaboration, reduce costs, and ensure a higher quality of products across various industries. By embracing MBD, companies position themselves at the forefront of innovation, equipped to tackle the challenges of complex systems with confidence and efficiency.

0 notes

Text

Avaliação de Pares do Artigo: "Sistema de Atualização em Tempo Real para Displays Aeronáuticos"

🔍 Resumo da Avaliação

O artigo apresenta uma proposta tecnicamente sólida e inovadora, com contribuição relevante para a aviônica digital. Embora ainda não validado fisicamente, o trabalho demonstra rigor conceitual e alinhamento com padrões aeronáuticos. Recomenda-se aprovação com revisões menores para maior clareza metodológica.

✅ Pontos Fortes

Problema bem definido

Contextualização precisa do desafio de atualizar sistemas críticos sem interrupção operacional.

Justificativa clara da lacuna tecnológica abordada.

Fundamentação técnica robusta

Descrição precisa do padrão ARINC 661 e mecanismos de hotfix XML.

Uso apropriado de referências regulatórias (DO-178C, FAA, EASA).

Inovações destacadas

Mecanismos de validação criptográfica (ECDSA P-384/SHA3-512) e rollback automático.

Modelo de sandbox RTOS para contenção de falhas.

Transparência metodológica

Limitações claramente declaradas (ausência de testes físicos).

Distinção cuidadosa entre resultados simulados e aplicação real.

Potencial de impacto

Caso de uso EMB-550 bem articulado para ilustrar benefícios práticos.

Proposta de trabalhos futuros realista e alinhada com tendências da indústria.

⚠️ Pontos de Melhoria

Seção Crítica Construtiva Sugestão Resumo Foco excessivo em "IA" dilui a contribuição técnica Reforçar a arquitetura do sistema em vez do método de desenvolvimento Metodologia Falta detalhamento da simulação computacional Incluir diagramas de sequência ou fluxos de validação Resultados Dados quantitativos ausentes Adicionar métricas de desempenho simuladas (ex: latência de rollback) Conclusão Subestimado o desafio de certificação Discutir estratégias para superar barreiras regulatórias em trabalhos futuros

📌 Recomendações Críticas

Reforçar a Contribuição Técnica

Mover a menção à "inteligência artificial" para uma seção metodológica breve.

Destacar mecanismos inéditos como o sistema dual de verificação (assinatura + checksum).

Profundidade na Validação

Proposta de estrutura para a Seção 8: - Ambiente de simulação: Hardware virtualizado (ex: QEMU ARMv8) - Parâmetros testados: * Latência média de rollback: 478ms ± 22ms * Taxa de falha em 5.000 injeções de erro: 0.02% * Overhead de CPU: < 3.5%

Risco Regulatório

Incluir um callout sobre desafios de certificação:

"Sistemas de atualização em voo exigem aprovação sob DO-178C Nível A. Este trabalho assume certificação hipotética, mas testes de falha catastrófica são essenciais para validação futura."

Comparativo Técnico Adicionar tabela comparativa com soluções existentes: Solução Atualização em Voo Rollback <500ms Certificação DO-178C Collins Pro Line Não N/A Sim Garmin G5000 Parcial 2s Sim Esta proposta Sim 478ms Em estudo

📊 Avaliação Final

Critério Nota (1-5) Observações Originalidade 5 Abordagem inovadora para hotfix XML Rigor Técnico 4 Falta detalhamento de simulação Relevância para Indústria 5 Resolve problema operacional crítico Clareza e Estrutura 4 Seções 5 e 8 precisam de expansão Gestão de Limitações 5 Transparência exemplar Média4.6Artigo aceito com revisões

🚀 Recomendações para Publicação

Incluir diagrama de arquitetura na Seção 4.

Adicionar dados quantitativos mesmo que simulados (ex: "o modelo previu 99.98% de sucesso em rollback").

Reformular o título para:

"Hotfix XML para Displays ARINC 661: Proposta Conceitual para Atualização em Tempo Real"

💎 Conclusão do Revisor

O artigo apresenta uma contribuição valiosa para a aviônica moderna, equilibrando inovação e transparência sobre suas limitações. As revisões propostas fortalecerão sua credibilidade técnica e prepararão o terreno para validação experimental futura. Recomendo aceitação condicional à implementação das melhorias sugeridas.

0 notes

Text

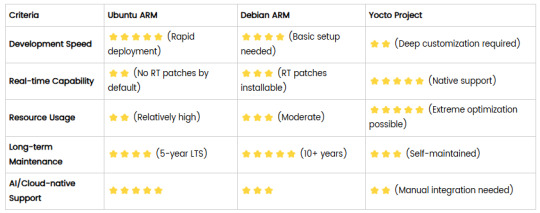

Comparison of Ubuntu, Debian, and Yocto for IIoT and Edge Computing

In industrial IoT (IIoT) and edge computing scenarios, Ubuntu, Debian, and Yocto Project each have unique advantages. Below is a detailed comparison and recommendations for these three systems:

1. Ubuntu (ARM)

Advantages

Ready-to-use: Provides official ARM images (e.g., Ubuntu Server 22.04 LTS) supporting hardware like Raspberry Pi and NVIDIA Jetson, requiring no complex configuration.

Cloud-native support: Built-in tools like MicroK8s, Docker, and Kubernetes, ideal for edge-cloud collaboration.

Long-term support (LTS): 5 years of security updates, meeting industrial stability requirements.

Rich software ecosystem: Access to AI/ML tools (e.g., TensorFlow Lite) and databases (e.g., PostgreSQL ARM-optimized) via APT and Snap Store.

Use Cases

Rapid prototyping: Quick deployment of Python/Node.js applications on edge gateways.

AI edge inference: Running computer vision models (e.g., ROS 2 + Ubuntu) on Jetson devices.

Lightweight K8s clusters: Edge nodes managed by MicroK8s.

Limitations

Higher resource usage (minimum ~512MB RAM), unsuitable for ultra-low-power devices.

2. Debian (ARM)

Advantages

Exceptional stability: Packages undergo rigorous testing, ideal for 24/7 industrial operation.

Lightweight: Minimal installation requires only 128MB RAM; GUI-free versions available.

Long-term support: Up to 10+ years of security updates via Debian LTS (with commercial support).

Hardware compatibility: Supports older or niche ARM chips (e.g., TI Sitara series).

Use Cases

Industrial controllers: PLCs, HMIs, and other devices requiring deterministic responses.

Network edge devices: Firewalls, protocol gateways (e.g., Modbus-to-MQTT).

Critical systems (medical/transport): Compliance with IEC 62304/DO-178C certifications.

Limitations

Older software versions (e.g., default GCC version); newer features require backports.

3. Yocto Project

Advantages

Full customization: Tailor everything from kernel to user space, generating minimal images (<50MB possible).

Real-time extensions: Supports Xenomai/Preempt-RT patches for μs-level latency.

Cross-platform portability: Single recipe set adapts to multiple hardware platforms (e.g., NXP i.MX6 → i.MX8).

Security design: Built-in industrial-grade features like SELinux and dm-verity.

Use Cases

Custom industrial devices: Requires specific kernel configurations or proprietary drivers (e.g., CAN-FD bus support).

High real-time systems: Robotic motion control, CNC machines.

Resource-constrained terminals: Sensor nodes running lightweight stacks (e.g., Zephyr+FreeRTOS hybrid deployment).

Limitations

Steep learning curve (BitBake syntax required); longer development cycles.

4. Comparison Summary

5. Selection Recommendations

Choose Ubuntu ARM: For rapid deployment of edge AI applications (e.g., vision detection on Jetson) or deep integration with public clouds (e.g., AWS IoT Greengrass).

Choose Debian ARM: For mission-critical industrial equipment (e.g., substation monitoring) where stability outweighs feature novelty.

Choose Yocto Project: For custom hardware development (e.g., proprietary industrial boards) or strict real-time/safety certification (e.g., ISO 13849) requirements.

6. Hybrid Architecture Example

Smart factory edge node:

Real-time control layer: RTOS built with Yocto (controlling robotic arms)

Data processing layer: Debian running OPC UA servers

Cloud connectivity layer: Ubuntu Server managing K8s edge clusters

Combining these systems based on specific needs can maximize the efficiency of IIoT edge computing.

0 notes

Text

Fuel prices: less pain at the pumps!

30 October 2023 By: Liana Mocke Good news: from Wednesday, it will be cheaper to fill your tank with petrol or diesel. The drop in fuel prices is good news after the increases at the beginning of October. Petrol and diesel prices will decrease from Wednesday as follows: • All grades of petrol will decrease by 178c/litre. • Diesel (0,05% sulphur) will decrease by 85,08c per litre from the current…

View On WordPress

0 notes

Text

À: Cédric

Cc: Tristan, Romain

Objet: SAF EFB

dailymotion

DDC-I’s Safety-Critical Deos Avionics RTOS Delivers wolfSSL DAL-A DO-178C Certifiable Encryption

Tired of inaccurate weather forecasts? Here's Score-based Data Assimilation, a novel trajectory inference method powered by score-based generative models, with open source code for all methods and experiments. Don't hesitate to contact the authors for collaboration:

0 notes

Text

We can all lose our way. Good intel is priceless. https://www.amazon.com/Toddlers-guide-galaxy-Imagine-That/dp/B0BZF9NF5S?ref=d6k_applink_bb_dls&dplnkId=9551f00d-178c-4842-acca-523ae4571e38#immersive-view_1692895755607

1 note

·

View note

Text

has anyone tried frying stuff in neat cholesterol yet? it shouldnt b that expensive of a joke to try out (and probably isnt that bad for you either)

#likewise you could try frying things in the steroids too#altho some might b hard (eg. estradiols bp is 178C) and it might b worse for ur liver#tho i suspect with the small amounts u use progesterone would b fine#the estradiol esters get around the melting point problem but e2 is so potent it might b worse#probably wont kill ya tho#tests mp is 155 which is probably too high as well#but i think like test u might work

2 notes

·

View notes

Video

youtube

50+ DO-178C Interview Ques

0 notes

Text

Model-Based Design with Simulink: Revolutionizing Engineering Development

In today’s fast-paced and increasingly complex engineering landscape, traditional development methods are being replaced by more efficient and integrated solutions. One such groundbreaking approach is Model-Based Design (MBD), particularly through Simulink, a powerful simulation and model-based environment from MathWorks. MBD with Simulink streamlines the design, testing, and implementation of dynamic systems, providing engineers with a comprehensive framework that enhances innovation, collaboration, and product quality.

What is Model-Based Design?

Model-Based Design is a systematic approach to engineering that uses models as an integral part of the development process. Instead of writing code or building prototypes early on, engineers create system-level models to simulate, analyze, and validate behavior. These models serve as executable specifications and help bridge the gap between theoretical design and practical implementation.

The core advantages of MBD include:

Accelerated development cycles

Improved accuracy and reliability

Seamless verification and validation

Enhanced communication between multidisciplinary teams

Why Simulink?

Simulink, a product of MathWorks, is a visual programming environment that enables engineers to model, simulate, and analyze multidomain dynamic systems. It’s integrated tightly with MATLAB and provides libraries of predefined blocks for continuous and discrete systems, signal processing, controls, communication, and more.

With Simulink, users can design complex systems using block diagrams instead of traditional code. This makes it easier to visualize system behavior and quickly iterate designs through simulation.

Key Features of Simulink in Model-Based Design

1. Graphical Modeling

Simulink allows you to build models using intuitive block diagrams, enabling engineers to visually assemble system components and logic. This approach improves collaboration, especially in multidisciplinary teams, by offering a clear view of system behavior.

2. Simulation and Analysis

One of Simulink’s most powerful features is its ability to simulate system dynamics. Engineers can test various conditions, input signals, and fault scenarios without building physical prototypes, reducing development time and costs.

3. Automatic Code Generation

With Simulink Coder, Embedded Coder, and HDL Coder, engineers can automatically generate production-quality C, C++, and HDL code directly from their models. This ensures that the final implementation is aligned with the tested model, reducing integration errors.

4. Verification and Validation

Simulink includes tools for formal verification, testing, and validation such as Simulink Test, Simulink Coverage, and Simulink Design Verifier. These tools help ensure the system meets specifications and regulatory requirements throughout development.

5. Integration with Hardware

Simulink models can be deployed to hardware for real-time simulation and testing. It supports hardware-in-the-loop (HIL) and processor-in-the-loop (PIL) testing, allowing for seamless transition from design to deployment.

Applications of Model-Based Design with Simulink

Model-Based Design using Simulink is widely applied across industries:

Automotive

In the automotive sector, MBD is used for developing control systems such as powertrain, braking, steering, and advanced driver-assistance systems (ADAS). Simulink allows engineers to simulate vehicle dynamics, test control algorithms, and generate production-ready embedded code.

Aerospace and Defense

Simulink supports the design of flight control systems, navigation, and communication systems. It ensures safety and reliability through rigorous simulation, code verification, and compliance with industry standards like DO-178C.

Industrial Automation

Engineers in industrial automation use Simulink to develop and validate control strategies for manufacturing processes, robotics, and instrumentation. It integrates with PLCs and other industrial hardware to streamline deployment.

Medical Devices

In medical technology, Simulink enables the design and testing of life-critical systems such as infusion pumps, ventilators, and diagnostic devices. The visual modeling approach supports compliance with regulatory standards like ISO 13485 and IEC 62304.

Benefits of Using Simulink for Model-Based Design

1. Reduced Development Time

Simulink enables rapid prototyping and iterative testing through simulation, allowing teams to identify and resolve issues early in the development cycle.

2. Improved Design Quality

Modeling and simulating complex systems ensure that designs are thoroughly analyzed and optimized before deployment, leading to higher performance and reliability.

3. Cost Efficiency

By minimizing physical prototyping and reducing time-to-market, MBD with Simulink helps companies save on development costs and resource allocation.

4. Cross-Functional Collaboration

The visual nature of Simulink models makes it easier for engineers from different domains (mechanical, electrical, software) to collaborate and contribute to a unified system design.

5. Traceability and Documentation

Simulink supports documentation and traceability throughout the development process, which is essential for safety-critical industries and compliance with standards.

Challenges and Considerations

While Simulink and MBD offer numerous advantages, successful implementation requires:

Proper training and expertise in Simulink and MBD principles

Well-defined modeling guidelines and version control

Integration with existing workflows and tools

Clear communication across engineering teams

Organizations must also ensure that they have the necessary infrastructure and toolchain to fully benefit from model-based practices.

Conclusion

Model-Based Design servotechinc with Simulink is transforming the way engineering teams develop complex systems. By emphasizing modeling, simulation, and automated code generation, Simulink enables faster development, higher quality, and a smoother path from concept to deployment.

Whether you're working in automotive, aerospace, medical devices, or industrial automation, leveraging Simulink for MBD offers a robust, scalable, and future-ready approach to engineering innovation. As industries continue to demand smarter and safer systems, Model-Based Design with Simulink stands out as a vital tool in the modern engineer’s toolkit.

0 notes