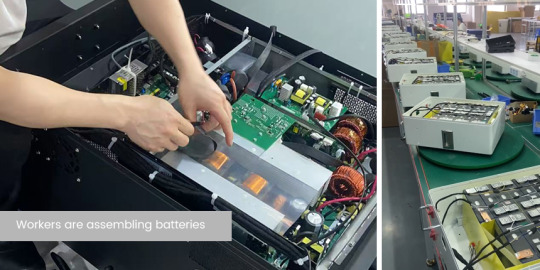

#Battery module assembly process

Explore tagged Tumblr posts

Text

Discover the meticulous process of lithium-ion battery pack manufacturing, where individual cells are sorted, grouped, and assembled into high-performance modules. Key stages include battery sorting and grouping, spot welding, module assembly, and rigorous testing for safety and reliability. Learn how advanced techniques ensure optimal performance, safety, and adherence to industry standards in applications like electric vehicles and energy storage systems.

#Lithium-ion battery pack manufacturing#Battery module assembly process#Battery pack production stages#Cell sorting and grouping techniques#Spot welding for battery assembly#BMS integration in lithium batteries#Lithium-ion battery quality control#EV battery manufacturing process#Battery pack safety standards#Testing in battery pack manufacturing

0 notes

Text

The Role of PCB Assembly in Med-Tech and Automotive Sectors

As global industries evolve with smarter, smaller, and more powerful devices, the demand for precision-engineered PCB assembly has skyrocketed — especially in the medical technology (med-tech) and automotive sectors. These industries demand not just high-quality electronics but also speed, reliability, and regulatory compliance. This is where Aimtron Electronics plays a vital role.

Why PCB Assembly Is Critical in Med-Tech

Modern medical devices — from portable ECG machines to imaging systems and wearable diagnostics — rely on compact and high-performance PCBs. In this sector, zero-failure tolerance is a must, as even a minor malfunction can affect patient health and safety.

At Aimtron Electronics, our quick-turn PCB prototyping, BGA assembly expertise, and precision testing services support med-tech innovators in rapidly developing and scaling their products. Our assembly processes are developed in the USA and implemented in India, ensuring global quality standards with local agility.

Automotive Electronics: Reliability Under Pressure

The automotive industry is undergoing a major transformation, driven by electric vehicles (EVs), ADAS (Advanced Driver Assistance Systems), and in-vehicle infotainment. These applications require PCBs that can withstand harsh environments, thermal cycling, and mechanical stress.

Aimtron supports this with:

High-volume SMT and thru-hole PCB assembly

Robust testing procedures to ensure durability and consistency

Electromechanical integration for complete module assembly

Whether it’s battery management systems or advanced lighting controls, Aimtron’s engineering and manufacturing expertise deliver consistent performance for automotive applications.

Global Expertise, Local Execution

With our flagship manufacturing facility in the United States and advanced production lines in Vadodara, Gujarat, Aimtron Electronics offers a seamless global supply chain. Our clients benefit from:

USA-grade quality

Faster development cycles

Cost-effective scalability

Supporting Innovation with Trusted Partnership

Aimtron is more than just a PCB assembly company — we’re your ESDM partner, offering turnkey solutions across product design, manufacturing, and testing. For med-tech and automotive companies looking to bring high-impact electronics to market, Aimtron provides the technical strength, speed, and global reliability you need.

0 notes

Text

Cutting-Edge EV Trends Impacting Automotive OEM Services in Grand Rapids MI

The automotive landscape is shifting at lightning speed as electric vehicles (EVs) redefine performance and sustainability. For companies in Michigan’s booming manufacturing corridor, adapting quickly isn’t optional—it’s essential. In this article, we’ll dive into the hottest trends transforming Automotive OEM Services Grand Rapids MI, showcase real‑world success, and share how you can leverage these insights to outpace competitors.

Lightweight Materials for Extended Range

Reducing vehicle mass directly increases battery efficiency and range. Advanced composites—like carbon-fiber–reinforced polymers—and high-strength aluminum alloys are in high demand. Local Automotive OEM Suppliers Grand Rapids MI have invested in state‑of‑the‑art CNC equipment and automated fiber placement to deliver these precision components. In fact, Arrow Manufacturing helped a regional EV startup cut chassis weight by 15%, boosting range by 8%—a game‑changer on consumer test drives.

Smart Factory Integration (Industry 4.0)

Data-driven production is the backbone of modern manufacturing. Sensors across assembly lines feed live analytics into predictive‑maintenance platforms, slashing downtime and scrap rates. By partnering with an experienced Automotive OEM Services Grand Rapids MI provider, you gain turnkey IoT integration, from PLC configuration to dashboard visualization. This approach led one automotive tier‑1 supplier to improve OEE (Overall Equipment Effectiveness) by 12% within six months.

Digital Twin Technology for Rapid Validation

Imagine testing thermal loads, vibration profiles, and electromagnetic interference in a virtual environment—before building a single prototype. That’s the power of digital twins. With this tool, engineers can iterate designs in hours instead of weeks, driving down development costs. Forward‑thinking Automotive OEM Suppliers Grand Rapids MI now include digital‑twin services in their portfolios, helping clients compress time‑to‑market by up to 30%.

Circular Manufacturing & Green Practices

Sustainability isn’t a buzzword—it’s a mandate. OEMs are adopting closed-loop recycling for aluminum extrusions and switching to water‑based cleaning agents to reduce VOC emissions. Arrow Manufacturing’s facility reclaims over 90% of machining scrap, translating to a 20% reduction in material spend year‑over‑year. By choosing a Automotive OEM Services Grand Rapids MI partner with green credentials, you not only meet regulatory targets but also appeal to eco-conscious consumers.

Collaborative Robots (Cobots) and Human‑Centric Automation

Cobots are transforming small‑batch and precision tasks, working safely alongside operators without extensive guarding. They handle repetitive duties—like fastening EV battery modules—while humans focus on quality assurance and complex assembly. Our recent cobot deployment reduced cycle times by 25% on a high‑voltage harness line, demonstrating how Automotive OEM Suppliers Grand Rapids MI can deliver both speed and precision.

Augmented Reality (AR) for Training & Maintenance

AR headsets overlay digital instructions on physical components, guiding technicians through complex EV assemblies and safety checks. This technology cut onboarding time by 40% for new hires at one Grand Rapids facility. When you engage Automotive OEM Services Grand Rapids MI experts who integrate AR workflows, you’ll minimize errors and maintain consistent quality—especially critical when dealing with high‑voltage systems.

Get Your Free EV Component Checklist

To help you implement these trends effectively, we’ve created a complimentary EV Component Checklist—covering material selection, digital‑twin best practices, and cobot integration tips. Download your copy now and start benchmarking your processes against industry leaders.

Ready to Accelerate Your EV Program?

Whether you’re launching a new model or scaling production, partnering with a seasoned Automotive OEM Suppliers Grand Rapids MI provider is the fastest path to success. Contact Arrow Manufacturing & Assembly today for a free consultation, and discover how our proven solutions can optimize your manufacturing footprint, improve efficiency, and drive down costs.

By embracing lightweight materials, Industry 4.0 technologies, and sustainable practices, you’ll not only stay competitive—you’ll lead the pack in the next generation of automotive innovation.

0 notes

Text

Mastering Disassembly and Assembly Techniques in Mobile Repairing

In the world of smartphones, breakdowns and damages are common. A skilled mobile technician must know how to properly disassemble and assemble a mobile phone without causing damage to internal components. At our Mobile Repairing Institute, we place strong emphasis on mastering these essential techniques as part of our mobile repairing training course.

Why Are Disassembly and Assembly Skills Important?

Every mobile phone consists of delicate components like the motherboard, screen, battery, cameras, speakers, and connectors. Improper handling during disassembly can damage these parts, making the repair more difficult or even impossible. Assembly is just as critical — poor reassembly can lead to loose connections, dust accumulation, and even device failure.

🔧 Essential Tools for Disassembly and Assembly

In our practical classes at the mobile repairing institute, students are trained to use:

Precision screwdrivers

Plastic pry tools and spudgers

Anti-static tweezers

Suction cups

Magnetic project mats

ESD protection gear

Understanding each tool's role helps prevent damage during mobile repair.

🔍 Step-by-Step Disassembly Process

Here’s a simplified version of how we teach mobile disassembly in our classes:

Power Off the Device Always begin by turning off the phone to avoid short circuits.

Remove SIM and SD Card Trays Eject these before opening the case to avoid breaking internal connections.

Unscrew the Back Panel Using appropriate screwdrivers, remove all visible screws while keeping track of each.

Open the Housing Safely Use pry tools to gently lift the back cover. Never forcefully pull or twist.

Disconnect Battery First Always disconnect the battery before touching any other internal components.

Disconnect Cables and Modules Carefully detach display, charging port, and other connectors using tweezers or spudgers.

Remove Components Sequentially We teach students to remove and label parts in the correct order to ensure easy reassembly.

🛠️ Assembly Tips for Mobile Technicians

Once repairs or inspections are done, reassembly begins. Our mobile repairing training program teaches students:

Double-check connections before screwing anything back

Clean internal parts using isopropyl alcohol and a brush

Ensure camera lenses and sensors are dust-free

Apply the right amount of pressure while placing back the screen

Test the device before completely closing the housing

📚 Learn From Experts at Our Mobile Repairing Institute

At our Mobile Repairing Institute in Kochi, students receive hands-on experience under expert guidance. Whether you're a beginner or looking to upgrade your skills, our course offers:

Real device training (Android & iPhone)

Latest disassembly techniques (including Edge Display and Foldables)

Practical sessions for troubleshooting

Industry-recognized certifications

🚀 Start Your Mobile Repairing Career Today

Disassembly and assembly techniques are just the beginning. Our mobile repairing training prepares students for careers in service centers, retail shops, or their own repair businesses.

👉 Ready to master the art of mobile repairing? Join our expert-led training program today. 🔗 Visit: https://nexgeninstitute.in

0 notes

Text

Why the E-PRO BRLSSFN-1 Brushless Fan is the Ideal Choice for Advanced Cooling

Introduction to E-PRO BRLSSFN-1 Brushless Fan

In the evolving world of electronics and thermal control, the demand for efficient and reliable cooling solutions is critical. The E-PRO BRLSSFN-1 Brushless Fan is a high-performance solution engineered to manage heat in systems packed with sensitive electronic components. It ensures thermal stability in applications involving microprocessors, controllers, LEDs, capacitors, and sensors. Designed for reliability and durability, this fan is suitable for both industrial and consumer-grade systems where effective airflow is a priority.

What Makes Brushless Fans Stand Out?

Brushless fans have become increasingly popular due to their mechanical efficiency and electronic advantages. They operate without brushes, which significantly reduces friction and wear. This leads to longer operational life and quieter performance compared to traditional brushed fans.

Advantages of the E-PRO BRLSSFN-1

Delivers powerful airflow while maintaining low noise levels

Reduces energy consumption in long-term applications

Offers a long service life due to minimal mechanical wear

Compatible with various enclosures, including compact electronics and laptops

Prevents overheating in sensitive parts like thermal pads, switches, and fuses

Application Versatility of the BRLSSFN-1 Fan

The E-PRO BRLSSFN-1 Brushless Fan is widely adaptable, making it useful in many types of systems and electronic assemblies. Its compact structure and powerful performance enable it to be used in devices requiring consistent cooling.

Where It Can Be Used

Laptops, PCs, and embedded computers

Electrical control panels and PLC enclosures

Industrial machines housing contactors, relays, and microcontrollers

LED lighting units and smart lighting drivers

Communication and networking hardware including routers and switches

Server racks and IT equipment that rely on regulated thermal environments

Test benches using microprocessors, connectors, cables, and sensors

Enhanced Thermal Management Capabilities

Maintaining optimal operating temperatures is essential for electronic longevity and performance. The E-PRO BRLSSFN-1 excels in rapid heat dissipation and airflow consistency, keeping internal electronics cool and efficient.

Key Thermal Features

Effective cooling of capacitors, microchips, and power supplies

Maintains ideal temperatures for tools, controllers, and power modules

Supports systems with dense cabling and thermal-sensitive layouts

Protects delicate components from heat-related degradation

Ideal for systems that use oils, thermal pads, and insulators

Benefits in Industrial and Commercial Electronics

From small desktop devices to heavy-duty industrial controllers, the BRLSSFN-1 supports broad integration. Its performance stability and low power draw make it suitable for multiple industries.

Reasons to Consider This Fan

Reduces risk of thermal failure in mission-critical equipment

Easy installation in enclosures with cables, grips, and sensor arrays

Designed for environments where safety and thermal reliability are key

Contributes to energy-efficient operation over prolonged periods

Built with strong materials for use in harsh environments

Integration with Modern Electronic Components

The E-PRO BRLSSFN-1 Brushless Fan is designed to work seamlessly with modern components, from basic circuit designs to advanced electronic systems. It ensures that components like LEDs, fuses, switches, and microcontrollers operate within safe thermal limits.

Perfect Match for Compact and High-Tech Systems

Compact enough for use in laptops and tablets

Supports active cooling for embedded boards and IoT systems

Assists in thermal regulation for high-speed processing units

Works alongside capacitors, connectors, and digital sensors

Ensures longevity in battery-powered devices and portable equipment

Why You Should Choose E-PRO BRLSSFN-1

Choosing a high-quality cooling fan impacts the overall performance and lifespan of your electronic equipment. The E-PRO BRLSSFN-1 provides an edge by balancing performance, energy savings, and versatility.

Top Reasons to Buy

Trusted by electronics professionals for thermal reliability

Suitable for integration into complex systems with minimal modifications

Helps extend service life of devices by preventing overheating

Reduces maintenance needs and replacement frequency

Compatible with modern components like microprocessors, contactors, and tools

Conclusion

As electronics continue to evolve, so must the cooling systems that support them. The E-PRO BRLSSFN-1 Brushless Fan is a dependable choice for maintaining thermal balance across a wide range of systems—from industrial controllers and thermal pads to laptops and LED circuits. Whether you're upgrading your thermal management system or designing a new one from scratch, this fan provides long-term value, performance, and peace of mind.

0 notes

Text

Electric Vehicle Battery Adhesive Market Expands Amid Lightweighting Trends and Enhanced Safety Requirements

The Electric Vehicle Battery Adhesive Market is experiencing significant growth, fueled by ongoing innovations in vehicle design, increasing electric vehicle adoption, and stringent safety and environmental regulations. As automakers strive to reduce vehicle weight and enhance battery pack safety, demand for high-performance adhesives is surging. These adhesives are no longer just optional components in EV battery assembly—they are now essential enablers of structural integrity, thermal management, and crash resistance.

Lightweighting Drives Adhesive Innovation

One of the primary drivers of the electric vehicle battery adhesive market is the automotive industry's commitment to lightweighting. Reducing the overall weight of EVs extends driving range and improves energy efficiency—both of which are critical selling points for consumers and regulators alike. To achieve this, manufacturers are replacing traditional mechanical fasteners such as bolts, screws, and welds with structural adhesives that bond dissimilar materials like aluminum, composites, and plastics.

Battery adhesives help to join battery pack components—cells, modules, casings, and cooling systems—while minimizing the need for heavy mechanical joining techniques. These adhesives also distribute stress more evenly across bonded surfaces, improving structural performance and crash safety. As a result, EV manufacturers are increasingly relying on adhesives for pack assembly, particularly as they shift to cell-to-pack and cell-to-chassis configurations that demand both durability and weight reduction.

Safety Regulations Bolster Demand

Safety remains a top priority in EV battery design, especially given the risks associated with thermal runaway and high-voltage systems. Battery adhesives play a crucial role in mitigating these risks by providing thermal management, vibration damping, and fire resistance. Advanced adhesives can help contain battery fires, delay heat transfer, and maintain pack integrity during crashes.

Global safety standards such as UNECE R100 and U.S. Federal Motor Vehicle Safety Standards (FMVSS) are pushing manufacturers to adopt high-performance adhesives that meet strict safety and performance criteria. In particular, thermal interface materials (TIMs) and flame-retardant adhesives are in high demand for their role in protecting battery cells and modules from overheating and mechanical failure.

Moreover, automakers are under pressure to comply with extended producer responsibility (EPR) and recyclability mandates, further elevating the need for adhesives that are not only strong and durable but also easy to remove or process at end-of-life.

Key Adhesive Technologies and Material Trends

The EV battery adhesive market encompasses a range of adhesive technologies, each tailored to specific application areas such as cell bonding, module encapsulation, battery cover sealing, and thermal interface layering. Key adhesive chemistries include:

Epoxy adhesives: Known for their high strength, chemical resistance, and durability, epoxy adhesives are commonly used for structural bonding and thermal management.

Polyurethane adhesives: Valued for flexibility and impact resistance, these are often employed where vibration damping is required.

Silicone adhesives: Offering excellent thermal stability and electrical insulation, silicones are ideal for sealing and gasketing in high-temperature areas.

Acrylic adhesives: These provide rapid curing and good adhesion to various substrates, making them useful for high-throughput battery assembly lines.

In addition to adhesive types, material innovations such as low-VOC (volatile organic compound) and solvent-free formulations are gaining traction. As environmental regulations become stricter, manufacturers are prioritizing eco-friendly, sustainable adhesives that reduce emissions and improve workplace safety.

Regional Market Dynamics

The Asia-Pacific region dominates the electric vehicle battery adhesive market, led by EV manufacturing hubs such as China, South Korea, and Japan. China, in particular, accounts for the largest share due to its vast EV production volume, battery manufacturing capacity, and government incentives for clean energy vehicles. Major Chinese battery manufacturers such as CATL and BYD are heavily investing in advanced adhesives to support high-density battery packs.

Europe is another critical region, driven by stringent CO₂ emission regulations and aggressive EV targets under the European Green Deal. German automakers like Volkswagen, BMW, and Daimler are investing in next-generation battery systems and sourcing adhesives that align with their performance and sustainability goals.

In North America, the United States is seeing a resurgence in EV investments due to the Inflation Reduction Act (IRA), which offers tax credits and grants for EV and battery production. U.S.-based players are increasingly focused on domestic supply chains for adhesives and related materials, offering growth opportunities for regional manufacturers.

Competitive Landscape and Strategic Developments

The EV battery adhesive market is characterized by intense competition among chemical and adhesive giants such as Henkel, 3M, Sika, H.B. Fuller, Dow, Parker Lord, and Arkema. These companies are expanding their EV-specific adhesive portfolios, partnering with automakers and battery OEMs, and investing in R&D to develop next-generation materials.

For example, Henkel has launched a range of thermal interface materials and structural adhesives tailored for EV batteries, while Sika has focused on flame-retardant sealing solutions and bonding systems optimized for automated production lines. M&A activity is also prevalent, as companies look to consolidate expertise and strengthen their global presence.

Future Outlook

The electric vehicle battery adhesive market is poised for robust growth over the next decade, with analysts projecting a CAGR in the high single to double digits. Key trends that will shape the market include:

Greater adoption of solid-state batteries requiring new adhesive formulations

Rising importance of fast-curing adhesives for high-speed automated assembly

Growth in battery-as-a-service (BaaS) models emphasizing easy disassembly and recyclability

Emphasis on multifunctional adhesives that combine bonding, thermal management, and flame resistance

As EV architectures evolve and manufacturers seek more efficient, safe, and sustainable battery solutions, adhesives will remain at the core of innovation—bonding together not only battery packs but the future of electric mobility itself.

0 notes

Text

What Sets a Wholesale Wheelchair Manufacturer Apart

Across the international healthcare and rehabilitation sectors, the search for a dependable Wholesale Wheelchair Manufacturer has become a critical component of meeting mobility demands in hospitals, clinics, and elder care environments. In the center of this expanding market, Suzhou Xinxin Vehicle Science and Technology Co., Ltd.—known globally as Sweetrich—has established itself as a trusted production base that delivers durability, safety, and customized functionality to partners worldwide.

Located in Suzhou, China, Sweetrich integrates advanced manufacturing with responsive customer support, giving wholesale buyers access to a variety of wheelchair models ranging from manual and lightweight designs to electric, foldable units for long-term mobility use. The company operates an intelligent production system that includes CNC processing, aluminum alloy welding, electronic component assembly, and multiple inspection points���all designed to ensure stability and comfort for end users.

What makes Sweetrich stand out is its attention to ergonomics and long-use practicality. Every wheelchair model is designed with patient and caregiver needs in mind. From adjustable footrests and anti-slip hand rims to breathable back cushions and puncture-resistant tires, the details are refined to deliver optimal support in home care, hospital, and institutional settings. The engineering team frequently collaborates with physical therapists and international clients to adjust seating angles, frame weight, and mobility accessories.

As a Wholesale Wheelchair Manufacturer, Sweetrich places great emphasis on OEM and ODM flexibility. Bulk buyers have the ability to select features such as seat width, wheel size, controller type, and even upholstery patterns. Products can also be co-branded, labeled for specific retail chains, or adapted to meet country-specific regulations like CE, ISO 13485, or FDA standards. Each unit comes with technical documentation, multi-language manuals, and after-sales support information for quick integration into local markets.

Sweetrich’s electric wheelchair lines are designed with modern control systems and extended battery range. Intelligent braking, joystick interfaces, electromagnetic motors, and foldable structures enable them to be used both indoors and outdoors with confidence. For manual designs, the factory uses ultra-light yet reinforced aluminum frames to maintain maneuverability without compromising weight capacity.

The company also leads in logistics coordination. Its global export team offers tailored shipping schedules, container optimization, and documentation services. Whether a client is managing private label distribution or fulfilling public procurement contracts, Sweetrich supports streamlined fulfillment, including pre-assembled units and spare part supply guarantees.

In response to increasing demand for mobility devices in emerging markets, Sweetrich has ramped up its monthly production output and upgraded testing facilities. Each wheelchair undergoes endurance testing for stress, vibration, and corrosion resistance. Frame fatigue is tested using dynamic load machines, while braking systems and motor response are inspected under simulated user conditions.

Beyond production, Sweetrich maintains technical training channels and a multilingual customer service portal. Wholesale clients are provided with ongoing product updates, maintenance tips, and remote diagnostics for electric models. Support for warranty claims and spare parts dispatches are prioritized to minimize equipment downtime for local service providers.

Sweetrich continues to innovate in material sourcing and component integration. Lightweight magnesium alloys, sustainable fabrics, and lithium battery modules are now under review for upcoming models. The R&D team also explores smart add-ons such as app connectivity, voice control, and compact travel conversion kits for future market expansion.For more details on collaboration and product catalogs from a trusted Wholesale Wheelchair Manufacturer, please visit: https://www.sweetrichmobility.com/ .

0 notes

Text

https://calonev.com/why-cal-on-evs-manufacturing-standards-set-a-new-benchmark-in-e-mobility/

Driving the Future of Green Mobility

India’s electric vehicle (EV) market is undergoing a revolutionary transformation, and at the heart of this shift stands CAL-ON EV, a company committed to reimagining mobility through precision, innovation, and sustainability. In an industry increasingly defined by performance, safety, and eco-consciousness, CAL-ON EV Manufacturing Standards have set an extraordinary benchmark in e-mobility manufacturing excellence.

This blog explores how CAL-ON EV’s quality assurance practices, cutting-edge production facilities, and relentless pursuit of sustainable electric vehicle manufacturing are elevating the brand as a symbol of reliable electric vehicles in India and global competitiveness.

1. The Foundation of Excellence: High-Quality EV Manufacturing in India

When it comes to high-quality EV manufacturing, CAL-ON EV Manufacturing Standards lead the charge by combining advanced automation, smart technologies, and precision engineering in EVs. The company leverages a state-of-the-art EV plant in India, equipped with AI-driven quality checks, robotic assembly lines, and lean production techniques that prioritize zero defects.

This focus on best practices in EV production has enabled CAL-ON to meet and exceed the most stringent EV safety standards in India, ensuring not only world-class performance but also driver and passenger safety.

2. Quality Assurance Beyond Industry Norms

CAL-ON EV quality assurance begins at the design table and continues through every stage of production. From component sourcing to final testing, CAL-ON integrates next-gen EV manufacturing systems that facilitate real-time feedback and automated quality control checkpoints.

Such robust quality control in EV production has helped CAL-ON build trust among its customers and industry partners. The rigorous inspection process—covering electrical safety, battery endurance, structural integrity, and software calibration—ensures that every vehicle meets benchmark EV production in India.

3. Innovation at the Core of CAL-ON EV Manufacturing Standards

Innovation isn’t just a buzzword at CAL-ON—it’s a philosophy. The brand’s R&D teams are constantly testing and implementing cutting-edge EV technology in India, including regenerative braking systems, advanced battery management, and IoT-enabled smart dashboards.

This spirit of CAL-ON electric vehicle innovation keeps the company ahead of the curve in delivering future-ready electric vehicles. It also fuels its mission of green technology in EVs, using lightweight composite materials, recyclable components, and energy-efficient assembly lines.

4. Smart Manufacturing in E-Mobility: An Industry Benchmark

Smart manufacturing in e-mobility is not just about digitizing processes—it’s about creating a connected ecosystem where every component, sensor, and module communicates seamlessly. CAL-ON EV Manufacturing Standards utilize predictive analytics, digital twins, and cloud-connected monitoring systems to anticipate issues before they arise and optimize production in real time.

This integration of technology and talent supports superior EV design and testing, enabling quicker prototyping, reduced production time, and improved reliability of end products.

5. Sustainability Built Into Every EV

The journey toward sustainable electric vehicle manufacturing involves minimizing carbon footprints and maximizing energy efficiency. CAL-ON’s facilities are designed for solar integration, rainwater harvesting, and responsible waste management. Its supply chain is curated to include vendors who align with green technology in EVs and follow ethical sourcing.

From eco-friendly paints to recyclable battery packs, sustainability is an integral part of CAL-ON EV Manufacturing Standards, underscoring their role as leaders in the Indian electric vehicle manufacturing benchmarks space.

6. Setting the Gold Standard for EV Safety in India

In the arena of EV safety standards in India, CAL-ON is a name synonymous with trust. Vehicles undergo over 200 individual safety tests, including frontal and side impact simulations, battery explosion resistance, and water-wading performance.

The company’s approach to best practices in EV production ensures all vehicles meet or exceed Bharat NCAP and AIS 038 safety requirements. Safety features like advanced driver-assistance systems (ADAS), traction control, and fail-safe battery cut-offs highlight their commitment to building reliable electric vehicles in India.

7. Precision Engineering in Every Bolt and Circuit

One of the defining traits of CAL-ON EV Manufacturing Standards is the company’s dedication to precision engineering in EVs. Whether it’s a bolt, wire, or sensor, every component is meticulously tested and positioned to achieve optimum performance and durability.

Such a focus on detail allows CAL-ON to perfect the balance between performance and economy, shaping vehicles that are both exhilarating to drive and cost-efficient to own.

8. The Indian EV Industry Growth and CAL-ON’s Role

The rapid Indian EV industry growth has been fueled by supportive policies, urbanization, and environmental awareness. But it’s brands like CAL-ON that are setting tangible benchmarks in EV manufacturing standards in India.

By aligning their processes with international certifications and constantly upgrading to newer technologies, CAL-ON is not just keeping pace—it is leading. The brand’s strategy is a case study in e-mobility manufacturing excellence, showcasing what’s possible when vision, technology, and talent converge.

9. Future-Ready and Built to Last

Future-ready electric vehicles are more than just EVs with modern tech-they are designed to evolve. With over-the-air (OTA) updates, modular battery architecture, and smart connectivity features, CAL-ON’s vehicles are built with tomorrow in mind.

Such a forward-thinking approach is embedded in CAL-ON EV Manufacturing Standards, ensuring longevity, scalability, and upgradability—traits that will be crucial as India transitions toward full-scale e-mobility.

10. The Benchmark for the EV Ecosystem in India

In a highly competitive market, CAL-ON EV Manufacturing Standards are helping redefine what it means to build an electric vehicle in India. Their model inspires confidence across stakeholders-customers, investors, government bodies, and supply chain partners.

This has led to the emergence of a new standard for benchmark EV production in India, paving the way for an ecosystem that’s not only profitable but also sustainable and socially responsible.

Conclusion: CAL-ON is the Future of EV Manufacturing in India

In conclusion, CAL-ON EV Manufacturing Standards represent more than just technical superiority-they embody a vision for smart manufacturing in e-mobility, rooted in sustainability, safety, and innovation. By consistently adhering to high-quality EV manufacturing, maintaining rigorous EV safety standards in India, and driving CAL-ON EV quality assurance, the company is spearheading a future where green mobility solutions in India are the norm, not the exception.

Whether you are an EV enthusiast, a policymaker, or a business looking to invest in the Indian electric vehicle manufacturing benchmarks, CAL-ON’s journey offers a roadmap to success. Their relentless commitment to next-gen EV manufacturing in India makes them the brand to watch in the electrified era ahead.

Also Read: Made in India, Built for the Future: The Manufacturing Journey of CAL-ON EV

📘 Facebook || �� Instagram || 💼 LinkedIn || 🎯 YouTube

#electric vehicles#electric vehicle sales#sustainable transportation#calonev#electric scooters#electric vehicle innovation

0 notes

Text

Technological Advancements Drive Significant Growth in the Global Welding Guns Market by 2030

The global welding guns market is experiencing a significant surge, driven by industrial automation, advanced manufacturing practices, and growing infrastructure development across emerging economies. Welding guns, essential tools in various metal fabrication and construction activities, are evolving with technological advancements that enhance efficiency, precision, and operator safety. This blog explores the current landscape of the welding guns market, key trends shaping its future, and the sectors driving its rapid expansion.

Market Overview

Welding guns serve as critical components in both manual and robotic welding systems. These devices are used to direct filler metal into the weld joint and are available in multiple types such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and spot welding guns. The selection depends on the welding process, material type, and production environment.

With the steady growth of the automotive, aerospace, construction, and heavy machinery sectors, demand for high-performance and durable welding guns is rising. As of recent industry reports, the market is poised to grow at a CAGR of over 5% through 2030, with Asia-Pacific leading in terms of demand and production.

Key Drivers of Market Growth

Rise of Industrial Automation Automation is no longer a competitive edge; it’s a necessity. Robotic welding systems that use programmable welding guns have become standard in large-scale production lines, particularly in automotive and aerospace industries. These guns not only reduce human error but also increase the speed and consistency of welds.

Infrastructure and Urbanization Boom Developing economies such as India, Brazil, and Southeast Asian countries are witnessing an infrastructure boom. Bridges, railways, ports, and urban housing projects require substantial metal fabrication, propelling the demand for reliable welding equipment, including advanced welding guns.

Technological Advancements The welding guns market is seeing innovations such as lightweight and ergonomic designs, improved cooling systems, and better electrical conductivity. Manufacturers are integrating features like wireless controls and smart sensors to monitor performance and optimize operations in real time.

Shift Towards Energy Efficiency and Safety Modern welding guns are increasingly designed to meet strict energy efficiency norms and ensure operator safety. Features like thermal overload protection, insulated handles, and minimal spatter contribute to safer and cleaner work environments.

Growth in Electric Vehicles and Renewable Energy The global push for sustainability and reduced emissions is creating fresh demand for welding guns in sectors like electric vehicle (EV) manufacturing and renewable energy installations. From battery module welding to assembling wind turbine components, welding guns are central to achieving high-quality, reliable joints in new-age technologies.

Challenges in the Welding Guns Market

Despite its promising outlook, the market does face certain challenges. The high initial investment for advanced welding systems can be a barrier for small and medium-sized enterprises. Additionally, the industry is facing a shortage of skilled welders, which places even more pressure on automation and easy-to-operate welding equipment.

Environmental regulations are also becoming stricter. Welding operations, especially those not equipped with modern filtration and exhaust systems, can contribute to harmful emissions. This is pushing manufacturers to innovate further in the direction of eco-friendly welding solutions.

Regional Market Insights

The Asia-Pacific region dominates the global welding guns market, led by China, India, and Japan. The region benefits from large-scale manufacturing units, a growing construction industry, and government support for industrial expansion.

North America and Europe also represent significant market shares, especially in terms of technological advancements and adoption of robotic welding systems. The U.S., Germany, and Italy are at the forefront of developing high-efficiency, automated welding solutions for industries like automotive and aerospace.

Meanwhile, Latin America, the Middle East, and Africa are emerging markets, with steady growth driven by construction, mining, and energy infrastructure development.

Competitive Landscape

The welding guns market is moderately fragmented, with a mix of global giants and regional players. Key companies such as Lincoln Electric, ESAB, Fronius International, Miller Electric, and Panasonic Welding Systems are leading the charge with new product developments, mergers, and global expansion strategies.

To stay competitive, many manufacturers are investing heavily in R&D, exploring materials such as composite polymers and heat-resistant alloys to enhance gun durability and reduce maintenance downtime. Some are also exploring AI integration for predictive maintenance and fault detection.

Future Outlook

The future of the welding guns market looks robust and innovation-driven. As smart manufacturing and Industry 4.0 continue to shape the industrial landscape, welding guns are expected to become more intelligent, adaptable, and integrated into digital factory ecosystems.

Moreover, sustainability goals and worker safety will likely dictate the design and functionality of next-generation welding guns. Market players that can offer smart, energy-efficient, and ergonomic solutions are poised to gain a competitive edge in the coming decade.

Conclusion

The welding guns market is at the intersection of tradition and transformation. While the fundamental purpose of welding remains unchanged, the tools and technologies enabling it are undergoing a paradigm shift. From advanced robotic arms to eco-conscious designs, welding guns are becoming smarter, safer, and more efficient. As industries worldwide continue to build and innovate, the demand for reliable welding equipment will remain strong, keeping this market on a path of sustained growth.

0 notes

Text

How Lithium-ion Battery Packs Are Assembled: Techniques, Testing & Key Challenges?

The manufacturing of lithium-ion battery packs is a crucial step in delivering high-performance, reliable power solutions. It involves combining individual lithium-ion cells into functional battery modules, integrated with safety and monitoring systems.

These battery packs power a range of modern applications, including electric vehicles (EVs), renewable energy storage systems, and portable electronics.

Key Stages in Lithium-ion Battery Pack Manufacturing

1. Battery Cell Sorting and Grouping

Selection: Match cells with similar internal resistance, voltage, and capacity.

Grouping: Uniform cell groups promote balanced performance and longevity.

Testing: Evaluate cell capacity, voltage drop, and charge/discharge cycles.

2. Cell Assembly and Spot Welding

Fixture Placement: Accurately arrange cells using designated tools.

Spot Welding: Use automatic battery welding machines for strong, clean joints.

Quality Inspection: Check weld integrity to avoid electrical faults.

3. Battery Module Assembly

Module Connection: Configure cells in series or parallel for target voltage/capacity.

BMS Integration: Install a Battery Management System (BMS) to monitor temperature, voltage, and current flow.

4. Battery Pack Testing and Quality Control

Functional Testing: Validate module safety, performance, and reliability.

Leakage Testing: Ensure airtight, leak-free construction.

Visual Inspection: Spot physical defects or structural inconsistencies.

Challenges and Considerations in Battery Pack Manufacturing

Cell Consistency: Inconsistent cells can destabilize battery module performance.

Welding Quality: Poor welds may lead to short circuits and thermal hazards.

BMS Configuration: A well-calibrated BMS ensures safe energy management.

Compliance: Must meet global safety standards like UN 38.3, UL 2580, ISO 26262.

Conclusion

From cell sorting to final testing, every stage in lithium-ion battery pack assembly ensures the product is safe, efficient, and ready for deployment. When done correctly, this process delivers durable energy solutions for EVs, solar systems, and industrial battery applications.

#lithium-ion battery pack assembly#battery pack manufacturing process#lithium battery pack testing#battery pack assembly techniques#battery module assembly

0 notes

Text

What design features make the Tesla Model Y stand out compared to traditional SUVs and even other EVs?

Tesla Model Y stands out from traditional SUVs and even other electric vehicles with its revolutionary design, efficiency, practicality and manufacturing innovation. Here is a breakdown of its key differentiators:

🔋 1. Structural Battery Pack and Gigacast Functional Impact

Gigacast Chassis System: One-piece front and rear chassis castings (using a 6,000-ton press) → 14% lighter and 10% longer range than competitors.

Structural Battery Pack: Battery cells form the vehicle structure → Lower center of gravity, increased rigidity, and more than 370 parts reduction.

Result: Class-leading drag coefficient Cd value of 0.23 (Audi e-tron and Mercedes EQC are above 0.30).

🚙 2. Minimalist packaging No engine/tank: Frees up front trunk (frunk) and rear sub-trunk space → 68 cu. ft. (~177 L/32 cu. ft.) total storage space (~30 cu. ft./32 cu. ft. for Ford Mustang Mach-E).

Flat rear floor: Battery-integrated chassis → No transmission bulge, enabling true stadium seating (raised rear seats, wide view).

Double-layer trunk: Adjustable load floor with underfloor storage → Two carry-on luggage can be stacked vertically.

🔧 3. Proprietary manufacturing technology Innovation of traditional SUV/EV approach Tesla Model Y

Reduces wiring harnesses by more than 1 mile, about 330 feet (~90 meters) (70% reduction) through regional controller wiring. Body assembly 400+ welded panels, 2-4 Gigabit Ethernet components → 30% reduction in production time.

Painting process: multi-stage primer/coating, seven layers of "Tesla Red" + automatic painting robot → 50% reduction in defect rate.

⚡ 4. Thermal energy and power system Eight valves + heat pump: Recycle heat from motor/battery to warm the cabin → Range loss in cold weather is reduced to about 15% (Volkswagen ID.4 has a range loss of 30-40%).

16V lithium-ion auxiliary battery: replaces 12V lead-acid battery → longer life and OTA upgradeable.

Integrated power module: integrates charging, DC-DC and BMS into one unit → Reduce wiring and improve reliability.

🖥️ 5. Software-defined architecture Centralized computing: One computer (AMD Ryzen) runs infotainment, Autopilot and vehicle control (competitors use separate ECUs).

OTA updates: new features (e.g. matrix headlights, torque vectoring), recalls, aftermarket performance improvements.

Camera-first perception: no radar or USS → Tesla Vision uses 8 cameras for Autopilot and safety systems.

📦 6. Aerodynamics & Shape Design Elements Function

Smooth roofline Fastback profile → Reduces drag without sacrificing headroom (unlike Audi Q4 e-tron).

Active grille shutters Close at high speed → Reduces drag coefficient by 0.01 Cd.

Aerodynamic wheels Sculpted wheels → Increases range by 3-5% compared to traditional alloy wheels.

🚗 7. Safety Innovations Giga Press castings: 20% more efficient in absorbing crash energy (IIHS 5-star crash test rating).

Front impact beam + side impact beam: Reinforced aluminum profile → Prevents intrusion at speeds above 70 mph.

Battery shield: 3mm bulletproof aluminum plate → Withstands impact from road debris.

⚙️ Practical highlights Power tailgate: 50% wider opening width than Mach-E/Rivian R1S → Can hold a 55-inch TV upright.

Camping mode: Maintains interior temperature/battery charge at night → Turns vehicle into sleeping space (not available on Hyundai Ioniq 5).

Towing mode: Software-controlled towing mode → Adjusts regenerative braking and torque limit (up to 3,500 lbs).

📊 Model Y vs. Key Competitors Featured Models: Tesla Model Y Ford Mustang Mach-E Volkswagen ID.4 Storage (cubic feet): 68 (max) 60 64 0-60 mph: 3.5 sec (Performance) 3.7 sec (GT) 5.7 sec (Pro S) Range (EPA): 330 miles 312 miles 275 miles DC Fast Charging: 250 kW (V3 Supercharger) 150 kW 135 kW Over-the-air updates✅ (monthly)❌ (dealers only)⚠️ (base maps only)

💎 What Stands Out:

Model Y rethinks SUV design: Removes traditional components (e.g., starting battery, wiring).

Prioritizes functionality (aerodynamics, cargo versatility).

Rapidly iterates through software and manufacturing breakthroughs.

Its one-piece castings, powertrain integration, and OTA capabilities will be hard for legacy automakers to match, even in electric vehicles launching in 2025. While competitors excel in material quality (e.g., Audi) or ride comfort (e.g., Genesis), no gas-powered car can match Tesla’s system efficiency.

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#race cars#electric cars#classic cars#car#cars#carlos sainz#porsche#truck#lamborghini#automobile#bmw#sabrina carpenter#car light#autonomous vehicle headlights#overtake another vehicle#older vehicles#vehicle#auto mode#automobiles#auto

1 note

·

View note

Text

WPC Registration Services in India and BIS Registration Support

In today’s fast-growing electronics and wireless product market, regulatory compliance is essential for legal manufacturing, import, and sales within India. Two critical approvals required for most electronic and wireless-enabled products are WPC Registration and BIS Registration. These certifications ensure that the products meet Indian technical standards and operate safely without interfering with existing communication networks.

WPC Registration Services in India

The Wireless Planning and Coordination (WPC) Wing, under the Ministry of Communications, is responsible for regulating wireless devices in India. WPC registration services in India is mandatory for any wireless product that operates in the de-licensed frequency bands like Bluetooth, Wi-Fi, Zigbee, or RFID.

Manufacturers and importers must obtain Equipment Type Approval (ETA) from the WPC before marketing or distributing such products in the country. This certification ensures that the equipment operates within prescribed radio frequency limits and does not cause harmful interference.

WPC Registration is required for:

Wireless devices like Wi-Fi routers, Bluetooth speakers, smartwatches, IoT modules, RFID scanners, and wireless cameras

Importers bringing wireless-enabled products to India

Manufacturers producing or assembling devices with wireless functionality

WPC ETA certification can be obtained through RF testing of the product from a NABL-accredited lab in India, followed by application submission to WPC along with technical documents and test reports.

BIS Registration in India

The Bureau of Indian Standards (BIS) is the national standards body in India responsible for maintaining product quality and safety. Under the Compulsory Registration Scheme (CRS), BIS mandates certification for over 70 categories of electronic and IT goods. BIS Registration is compulsory before such products can be sold in the Indian market.

Products that need BIS Registration include:

LED lights, mobile phones, power adapters, laptops, smartwatches, UPS, batteries, and other IT and electronic devices

Foreign and domestic manufacturers seeking to enter the Indian market

Under BIS-CRS, manufacturers must submit their products for safety testing at a BIS-approved lab. Based on the test results and verification of documents, the BIS issues a registration number. The manufacturer must then affix the Standard Mark with the registration number on the product packaging.

Why Compliance is Important

Without proper WPC or BIS certification, products are subject to seizure by Indian Customs or regulatory authorities. Additionally, non-compliance can result in heavy penalties and a ban on sales. Obtaining both registrations not only ensures legal entry into the Indian market but also boosts customer trust and brand credibility.

How Fusion Compliance Services Can Help

At Fusion Compliance Services, we offer complete support for obtaining WPC ETA Approval and BIS Registration in India. From product testing, documentation, and online application filing to liaising with government departments, our experts ensure a smooth, transparent, and timely certification process.

Whether you are an Indian manufacturer, foreign brand, or importer, our team ensures your products meet all regulatory standards for a seamless market entry and long-term business success.

Contact Fusion Compliance Services

Phone: +91-9289082890

Email: [email protected]

Website: www.fusioncomplianceservices.com

Office Address: C-44, First Floor, Sector-2, Noida, Uttar Pradesh – 201301, India

#WPCRegistration#BISRegistration#WPCApproval#ETACertification#BISCRS#WirelessComplianceIndia#ElectronicsCertificationIndia#ImportRegulationsIndia#WPCConsultants#BISConsultants#FusionComplianceServices

0 notes

Text

Aerogel for EV Battery: Enhancing Smart Home and Electric Vehicle Technologies with Jiepu’s Precision Die Cut Solutions

As technology advances rapidly in both smart home devices and electric vehicles (EVs), manufacturers face growing challenges in optimizing performance, safety, and durability. One cutting-edge material gaining significant attention is aerogel, especially in applications like thermal insulation for EV batteries. Jiepu offers specialized die cut solutions tailored for smart home products and emerging sectors such as electric vehicles, providing precision and quality that enhance product fit, function, and durability. In this article, we will explore how aerogel is revolutionizing EV battery technology and how Jiepu’s die cutting expertise supports the integration of aerogel components for superior performance.

What Is Aerogel and Why Is It Important for EV Batteries?

Aerogel is a unique material known for its extraordinary insulating properties, light weight, and durability. Often referred to as “frozen smoke” or “solid air” due to its translucent appearance and extremely low density, aerogel consists mostly of air trapped in a solid silica or polymer matrix.

When it comes to electric vehicles, aerogel for EV battery insulation offers several key benefits:

Superior Thermal Insulation: Aerogel effectively manages heat generated during battery charging and discharging, protecting battery cells from overheating or freezing.

Lightweight: Its ultra-low density helps reduce the overall weight of EV battery packs, contributing to improved vehicle efficiency and range.

Durability: Aerogel withstands harsh conditions, including vibration and mechanical stress, crucial for EV battery longevity.

Safety Enhancement: Maintaining battery temperature within optimal ranges reduces risks of thermal runaway and fire.

Due to these advantages, aerogel is becoming a preferred choice for thermal management in EV battery systems.

The Role of Die Cutting Solutions in Aerogel Integration for EV Batteries

Although aerogel offers outstanding properties, its practical application in EV batteries requires precise manufacturing techniques to fit the tight, complex spaces within battery packs. This is where Jiepu’s specialized die cutting solutions come into play.

Our advanced die cutting technology allows us to cut aerogel materials into exact shapes and sizes with micron-level accuracy, ensuring a perfect fit inside battery modules without compromising insulation performance.

Jiepu’s Expertise in Die Cutting Aerogel Components

Jiepu is a leader in providing customized die cut solutions for high-tech materials like aerogel. Our approach includes:

Precision Cutting for Optimal Fit

EV battery packs are intricate assemblies with limited space for insulation. Jiepu’s precision die cutting ensures aerogel components fit perfectly around battery cells, connectors, and cooling systems, maximizing thermal protection without adding bulk.

Material Handling and Preservation

Aerogel is fragile and prone to cracking if mishandled. Jiepu’s processes are designed to minimize material stress during cutting, preserving the aerogel’s structure and insulating properties.

Versatility Across Smart Home and EV Applications

While aerogel is critical for EV battery insulation, it is also used in smart home devices requiring thermal management or soundproofing. Jiepu’s die cutting expertise spans multiple industries, providing consistent quality for diverse needs.

Benefits of Using Aerogel for EV Battery Applications with Jiepu’s Die Cutting Solutions

By combining the advantages of aerogel with Jiepu’s precision die cutting, manufacturers can expect:

Improved Battery Efficiency: Better thermal regulation helps maintain consistent battery performance under various environmental conditions.

Reduced Weight: Lightweight aerogel insulation contributes to lighter battery packs and overall vehicle weight reduction, enhancing driving range.

Enhanced Safety: Effective insulation reduces overheating risks and improves battery safety standards.

Custom Solutions: Tailored aerogel shapes and sizes that fit seamlessly into specific battery designs, improving assembly efficiency.

Sustainability: Aerogel’s insulation helps increase battery lifespan, reducing replacement frequency and environmental impact.

Why Choose Jiepu for Aerogel Die Cutting Solutions?

Jiepu’s commitment to precision, quality, and innovation makes us a trusted partner for manufacturers integrating aerogel in EV batteries and smart home products. Our key strengths include:

Advanced Die Cutting Technology: Utilizing the latest equipment capable of handling delicate materials like aerogel with precision and care.

Experienced Engineering Team: Collaborating with clients to develop custom die solutions that meet exact design specifications.

Quality Assurance: Strict testing and inspection to ensure every die cut component meets performance and durability standards.

Flexible Production Capabilities: From prototypes to large-scale production runs, we scale our services to fit your needs.

Cross-Industry Expertise: Experience in both smart home and automotive sectors ensures comprehensive understanding of application requirements.

The Future of Aerogel in EV Battery Technology

As electric vehicles become more prevalent, the demand for advanced battery technologies continues to grow. Aerogel insulation, paired with precise die cut components, will play an increasingly critical role in addressing thermal management challenges.

Manufacturers who invest in high-quality aerogel parts and reliable die cutting solutions position themselves at the forefront of innovation, delivering safer, more efficient, and longer-lasting EV batteries.

Conclusion

The integration of aerogel for EV battery insulation is a game-changer in electric vehicle technology, offering unmatched thermal protection, lightweight advantages, and enhanced safety. Jiepu’s specialized die cutting solutions ensure that these advanced materials are perfectly tailored to fit your product’s design, improving fit, function, and durability.

Whether you are developing cutting-edge smart home devices or pioneering EV battery packs, Jiepu provides the precision and quality needed for seamless integration of aerogel and other high-performance materials.

Partner with Jiepu to leverage our expertise in die cutting and elevate your product’s performance with innovative aerogel solutions designed for the future of technology.

0 notes

Text

Empowering the Future: Refurbished Li-ion Battery Application and Lithium-Ion Battery Life Cycle Assessment

The world is racing towards electrified mobility—from scooters and motorcycles to electric buses, trucks, and even airplanes. At the heart of this revolution is the lithium-ion battery, a powerhouse that enables sustainable energy storage for electric vehicles (EVs), renewable energy grids, and consumer electronics. However, with the surge in demand for EVs—projected to rise by 35% in 2023 alone—comes an inevitable wave of retired batteries. Analysts predict that by 2030, retirements could exceed half a million vehicles annually, translating to over 2 million metric tonnes of batteries per year.

The question arises: How do we manage this massive influx of end-of-life batteries sustainably? At LOHUM, we believe that the answer lies in innovation and responsible lifecycle management—through Refurbished Li-ion Battery Application and lithium-ion battery life cycle assessment.

The Growing Need for Lithium-Ion Battery Recycling

According to the Environmental Protection Agency (EPA), recycling lithium-ion batteries is crucial not just for environmental reasons but also for resource optimization. These batteries contain valuable minerals like lithium, cobalt, nickel, and manganese, which are critical for the clean energy transition. Despite this, only about 5% of lithium-ion batteries are recycled globally, compared to the 99% recycling rate of lead-acid batteries.

The disparity is rooted in the complexity and cost of lithium battery recycling. Lithium is highly reactive, making the process delicate and demanding specialized recycling facilities. However, ignoring this issue is not an option. With EVs, solar grids, and energy storage solutions rapidly expanding, the demand for lithium is set to outpace mining capabilities. Establishing new mines is both costly and environmentally taxing, often leading to depleted water resources and polluted ecosystems.

This is where LOHUM steps in—not just as a recycler but as a leader in lithium-ion battery life cycle assessment. We aim to optimize every stage of a battery's life, from initial application to second-life usage and, eventually, recycling.

Refurbished Li-ion Battery Application: Extending the Lifecycle

At LOHUM, we are reimagining the life of lithium-ion batteries through Refurbished Li-ion Battery Application. Most EV batteries are considered "end-of-life" when their capacity drops below 80% of their original power. However, that remaining 80% is still substantial for less demanding applications. Through refurbishment, these batteries are repurposed for uses like:

Stationary energy storage for solar power systems.

Backup power for telecommunications and IT infrastructures.

Grid stabilization to enhance energy efficiency.

This second-life usage not only extends the lifecycle of the battery but also reduces the demand for freshly mined materials. In fact, batteries repurposed for stationary energy storage can last an additional 6 to 10 years, contributing significantly to sustainability goals.

LOHUM’s innovative refurbishment process involves:

Discharging and Safety Checks: Ensuring the battery is fully discharged and evaluated for safe handling.

Module and Cell Assessment: Identifying viable cells for repurposing.

Reconditioning and Reassembly: Assembling functional cells into new configurations suitable for secondary applications.

This model is a testament to LOHUM's commitment to lithium-ion battery life cycle assessment, optimizing every phase for maximum efficiency and minimum waste.

The Economics and Environmental Impact of Recycling

The economic incentive for lithium battery recycling is compelling. The three most expensive ingredients in a battery—cobalt, nickel, and lithium—represent nearly 50% of the total manufacturing cost. Global price volatility, sometimes fluctuating by 300% in a single year, adds even more pressure to find sustainable sources of these materials. Recycling not only helps stabilize costs but also reduces dependency on mining, which is often linked to conflict zones and harmful environmental practices.

LOHUM’s process involves:

Pyrometallurgy and Hydrometallurgy: For material recovery through high-temperature melting and chemical dissolution.

Direct Recycling Techniques: Retaining the cathode's structural integrity to reduce the need for energy-intensive refining.

In recent advancements, direct recycling methods have shown promise by refurbishing the cathode without breaking it down entirely, resulting in better battery performance and faster charging times. This method preserves the engineered structure of the cathode, making it as good as, if not better than, newly manufactured materials.

Policy and the Path Forward

The importance of sustainable recycling is increasingly recognized by governments. States like California are working on policies to ensure 100% of EV batteries are recycled or reused. At LOHUM, we are aligned with these global sustainability goals, leading the charge with innovative recycling technologies and efficient life cycle assessment.

Our approach to lithium-ion battery life cycle assessment is not just about recycling—it's about building a circular economy. With state-of-the-art technology and a forward-thinking mindset, LOHUM is redefining what it means to manage battery life sustainably.

LOHUM: Pioneering the Circular Economy of Lithium-Ion Batteries

At LOHUM, we are not merely recyclers—we are sustainability innovators. Our commitment to Refurbished Li-ion Battery Application and thorough lithium-ion battery life cycle assessment enables us to extend the life of valuable materials, reduce environmental impact, and contribute to the global push for cleaner energy.

By closing the loop on lithium-ion battery usage, LOHUM is empowering the shift towards electrified mobility with sustainable solutions that are not just good for business but essential for the planet.

Visit us at: Lithium-ion battery reuse value

Originally published on: Wix

#lohum#critical minerals#li-ion battery waste management#lithium battery reusing and recycling#battery waste management#lithium battery waste recycling#3 wheeler ev battery#reverse logistics for lithium-ion batteries

0 notes

Text

Energy Storage Battery Assembly Process

Cell Sorting – Match cells by voltage/capacity for consistency.

Module Assembly – Connect cells in series/parallel with BMS wiring.

Packing – Secure modules in a robust casing with thermal management.

Testing – Verify performance, safety, and cycle life.

Final Inspection – Quality check before shipping.

Efficient. Reliable. Ready to Power Your Needs.

0 notes