#Brass Washers – Machined Type

Explore tagged Tumblr posts

Text

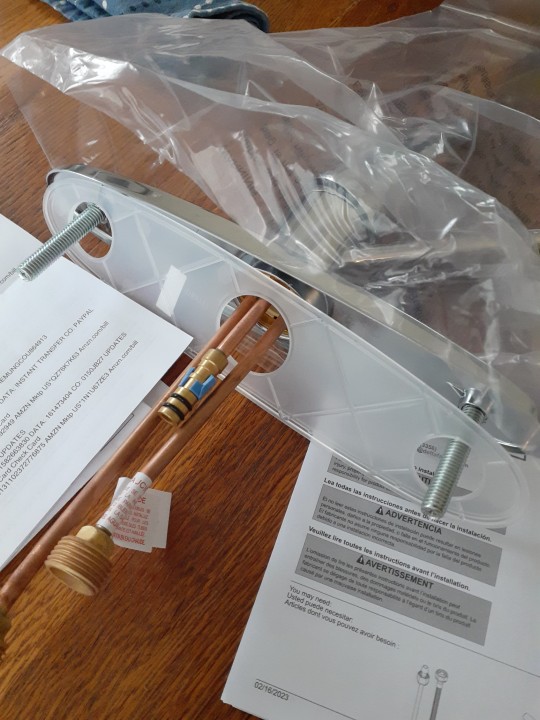

Today's adventure in homeownership... Plumbing...

The old Moen faucet had been leaking and upon inspection it was a cartridge type with a lot of broken plastics and the o-rings had flat spots too... It was junk. It's possible it was junk to start.... The previous owner was into the DIY stuff but by all accounts the neighbors have the most common description remains "cheap and dumb."

Well, ol'Cheap&dumb stacked about 3/8" of big steel flat washers up and sandwiched them with the brass nut to make the old faucet work.

What happens when we mix steel and brass children? Especially in a nice damp environment with a solid earth ground.....

I had to chisel through the brass to break it off as there was no room for a saw.... That's what...

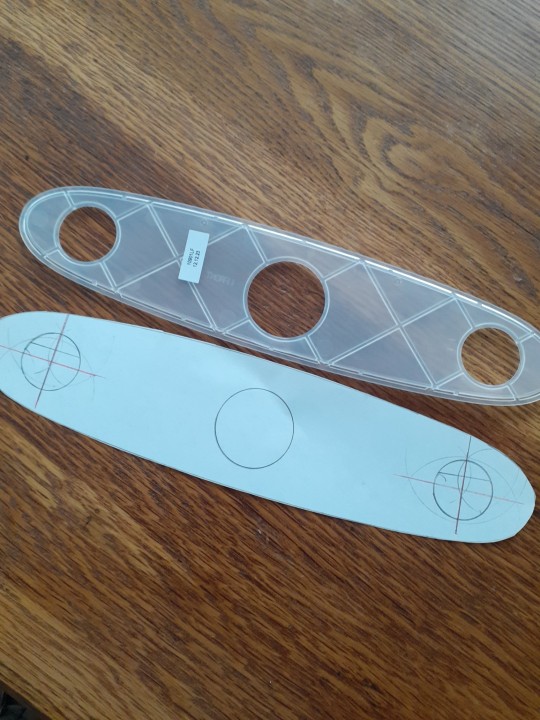

To add a little insult to injury, Delta is sellig single hole faucets that bolt down like toilets now rather than the large flange but we've all grown accustomed to over the last oh .... 65 years.... So I had to machine a few holes in the countertop too. On top of that, they aren't even centered in the gasket for the base, so my template (no Delta didn't provide that) was only helpful to a point.

Today's lessons. Don't be cheap and dumb. When you realize you're in over your head call someone. And don't expect anything to be like it was the last time you did it.

2 notes

·

View notes

Text

Washers Manufacturers in India – Akbar Fasteners

Introduction to Washers and Their Industrial Importance

Washers are simple yet critical components used in almost every industry where fasteners are applied. They act as a supporting element between fasteners and surfaces, helping distribute the load evenly, prevent loosening due to vibration, and protect surfaces from damage. Without washers, the integrity of assemblies in mechanical, structural, and industrial applications could be compromised. Industries like construction, oil and gas, automotive, petrochemical, power generation, and shipbuilding rely heavily on washers for smooth functioning. Among the leading names in this field, Akbar Fasteners stands as one of the most trusted Washers Manufacturers in India because of their expertise in producing high-quality, precise, and reliable washers.

Akbar Fasteners – A Trusted Name in Fasteners

Akbarali Fasteners has earned a strong reputation as a prominent fastener manufacturer in India by combining decades of experience with modern technology. Based in Mumbai, the company focuses on meeting global quality standards while ensuring customer satisfaction. From manufacturing bolts, nuts, screws, and stud bolts to specialized components like washers, every product is designed with accuracy and tested rigorously. This commitment to innovation and excellence has allowed Akbar Fasteners to serve clients worldwide.

For inquiries or product requirements, customers can contact Akbar Fasteners at Barkat: +91 99192 04560, Email: [email protected], Address: Kurla West, CST Road, India, 400070.

Range of Washers Offered by Akbar Fasteners

The company specializes in producing different types of washers, including plain washers, spring washers, locking washers, and custom-designed special washers. Each type is made to meet specific functional requirements across industries. The availability of washers in a wide range of materials, including carbon steel, stainless steel, brass, silicon bronze, and special alloys, ensures their performance even in harsh operating environments.

Plain Washers – Precision and Strength

Among their wide range of products, Plain Washers Manufacturers in India from Akbar Fasteners stand out for their quality. These washers are essential in applications where the load needs to be distributed evenly to prevent the fastener from damaging the surface. They are extensively used in automotive parts, heavy equipment, construction projects, and even in delicate assemblies where surface protection is important. Manufactured with advanced CNC machining, these plain washers meet international standards such as ASTM, DIN, and ISO, ensuring consistency in thickness, dimensions, and strength.

Commitment to Quality and Performance

Akbar Fasteners employs state-of-the-art testing methods such as hardness testing, tensile strength testing, and corrosion resistance testing to ensure the reliability of their washers. The company believes that quality is not just about meeting standards but exceeding expectations. As a best quality washers manufacturer, supplier and exporter, Akbar Fasteners has consistently provided products that withstand high-pressure environments and offer durability.

Material Excellence – Stainless Steel and Beyond

In industries where resistance to rust and harsh chemicals is necessary, stainless steel washers are the first choice. Akbar Fasteners is a leading ss washer manufacturer in Mumbai, producing washers in stainless steel grades like 304, 304L, 316, and duplex steel. These washers are highly popular in marine, food processing, chemical plants, and outdoor structures due to their long service life and resistance to corrosion. Apart from stainless steel, the company also manufactures washers from exotic materials such as silicon bronze, Monel, and Hastelloy, offering solutions for highly specific needs.

Why Choose Akbar Fasteners for Washers in India

There are several reasons why Akbar Fasteners has become a preferred name for washers:

Customization: The company can design washers as per customer drawings and specifications.

Global Standards: Products conform to ASTM, ASME, ISO, DIN, and UNI standards.

Fast Delivery: With an efficient manufacturing setup in Mumbai, they ensure timely delivery.

Wide Range: From standard sizes to special large-diameter washers, everything is available under one roof.

Competitive Pricing: The company combines quality with cost-effectiveness.

These factors make Akbar Fasteners one of the top washer manufacturer in India – Akbar Fasteners trusted by industries across India and globally.

Leading Washers Exporter from India

Over the years, Akbar Fasteners has also established itself as a major exporter of washers to several countries in the Middle East, Europe, Africa, and Asia. Their products are used in offshore projects, heavy machinery manufacturing, petrochemical plants, and large-scale construction activities. This international recognition highlights their position as a leading washers exporter delivering consistent quality at competitive rates.

Washers Suppliers with a Strong Network

The company has built a reliable supply chain network to ensure clients in different parts of India and abroad receive timely deliveries. This is why Akbar Fasteners is regarded as one of the top washers suppliers in the country. Whether the requirement is small or bulk, the company ensures seamless supply with clear documentation and quality certifications.

Applications of Washers in Modern Industries

Washers have a wide range of uses in industries, such as:

Construction: Preventing fastener loosening in buildings and infrastructure projects.

Automotive: Enhancing load distribution in engines and vehicle assemblies.

Oil and Gas: Providing stable fastening in pipelines and equipment that undergo vibration.

Marine Industry: Protecting surfaces in ship structures from corrosion damage.

Power Plants: Assisting in heavy-duty machinery and turbines where secure fastening is critical.

These applications underline the importance of choosing reliable washers manufacturers in India who can deliver quality and precision.

Innovation and Research in Washer Manufacturing

Akbar Fasteners continues to invest in research and development to improve its product offerings. They are working on advanced coating technologies for washers to enhance corrosion resistance and extend lifespan, making them suitable for even more demanding environments. This focus on innovation ensures that customers always receive the latest and best fastening solutions.

Conclusion – A Reliable Partner for Washers in India

If you are looking for high-quality washers that combine strength, accuracy, and reliability, Akbar Fasteners is the name you can trust. With decades of expertise, a strong focus on global quality standards, and a customer-oriented approach, the company continues to serve industries with excellence.

To place an order or for any inquiries related to washers manufacturers in India, you can contact Akbar Fasteners at: Phone: +91 99192 04560 Email: [email protected] Address: Kurla West, CST Road, India, 400070

0 notes

Text

60055987 UNP Sealing Ring for SANY machinery

60055987 UNP Sealing Ring SANY spare parts Mail:[email protected] 10254570 Crane, crawler, SCC7500 21030401 SANY PARTS 160102070032A077 Turbocharger line 10266163 Plate 10245303 SANY PARTS 67324543938 Lifting cyclinder SPUP-0370B Boom110-70- 10019205 槽钢料坯QY50Ⅱ.20-4(L) 21016545 Reinforced plate 160102130004A009 Connecting Rod Lower Bearing Shell 180101051169A Turning Blade 10432787 穿线管CP12.5.4-39 10241232L SANY PARTS 22004978 Power support SP301TH22-A 160101050018A004 Plumbing, Exhaust 10049368 SANY PARTS 22007615 End plate SP402G2203 160602050026A Housing 9190305000012 水泵3200/3/8/TA2/75 轴流泵 10417132 Web-plate 10424791 Front face covering parts 10025997 Handle box 59100078 羊T骨散装 59011969 红菜苔 10023717L Pull Plate 10016169 Flange 181500000224A Electric tractor cab right door rear pa 10122513 Connecting plate 160101090121A043 Remote Start and Stop Function Module 10234017 板2RC1Z.4.1.3.3-2 10692950 Top board 21006143 Strut 180399000148A brass 522677 THRUST SPACER 180106060120A Boring Blade 160102160022B452 Engine Oil Position Sensor 10245738 SANY PARTS 22053726 Guide sleeve assemlby SPPCH040KA41 10662935 SANY PARTS 61028330 Clamp 10030515 Caution board 22066097 Crane SPZJ00085 10434229 Jointed board 1 21026184 SANY PARTS 61008738 Plug 10201477 摆放架��木垫FG-237 61008285 防护铸帽AD600-1 61005193 Brace,Tube 160102050053B340 Fan Plate 22051927 Balance Weight SPHX-0464 245760008 销轴A-90F7x490x456-M30(AMS) 180101020113A Inner Round Turning Tools 180101010150A Cutting Tools 22064191 Cutting plate SP400A0504_6_HG70 Default 534210 CC Load Sensor Harness 10114460 Socket 160102070202A128 Plug 160101020001A128 Seal Ring 10266269 SANY PARTS 10268117 SANY PARTS 10118647 Weight Block 160101070011B047 Gasket 24997442 Convertible spanner 10165035 SANY PARTS 180106040110A Full type Boring Tool 22043090 Pipe SPHLR-11500001 160101090060A081 Screw plug M22×1.5 9181218000099 Gearmotor 10079390255 Crawler crane assembly 526520 AMGU5-246R BASE ANGLE-REAR 160102030060B249 Camshaft and Idle Gear Shaft 22014149 The shaft components SPKMG-000108A 传动 160104000463A Lubric. Oil Filter 10183649328 Crawler Crane assemly 168899000717A Flywheel Housing 21009869 Web member 61015968 Piston 21032820 SANY PARTS 10683522 End Cover 181500002409A Decal 61012542 Contactor 181299000416A Engraving Machine Tool Chuck 22065926 bottom plate SPFXE-1692 [email protected] 59011935 莴笋头 10207093M Cylinder bottom 67325239702 Pressure sensor harness SPEEA-0632 Ë«Êä 180605000841A Filter 61016747 贴片按键0155C 10238776L SANY PARTS 10182607 SANY PARTS 10468844 SANY PARTS 160102100027B019 Water Draining Valve 59013029 玩具娃娃 160102050021B130 Secondary Balance Mechanism Shaft 24914362 Piston rod ear ring 160102120008A085 Secondary Lock 59009983 SANY PARTS 160102030041A023 VENTILATION SYSTEM 160801010274A SANY PARTS 10198251 B81A工艺其他小件包见图 24914846 SANY PARTS 920021500023A 医用普通口罩鼻梁条单芯2.5mm×100mm 61009971 L-oil tube 59001364 SANY PARTS 10669022 SANY PARTS 10472463 SANY PARTS 24916685 SANY PARTS 160801090156A Shroud 160102020019A283 Spring 169900000258B Mount, Engine 10681370 筋板Z11.6-15 10139174 Steel Wire Ring 10484147 Flat plate 21002996 Pipe connector 10493444 SANY PARTS 10254870 Lower Portion of Frame 10033526L - 51000613 SANY PARTS 923111400002A Power Module 10142595 SANY PARTS 10687168 LB2000C Asphalt mixing plant with Base-l 10028877 Pressure cover 10078675 column nest Z2.9-7 10010621 Reinforced plate 10641444 底座Z10.14 21023179 Web member 21008056 Air cleaner 61013084 Gasket 67328466740 SPEFA-0511 10241227 收尘袋HZS120MDL.9.1 160801040030A007 Air Deflector 22050594 Limit lever SPHI-0566 10112067 Rope stop rod support 10184466 Reinforced Plate(4) 10269444 Front vertical oil cylinder 10079389376 SCC800-R8 0301030201履带起重机总成 10131943 Movable boom cylinder steel tube 22002740 Slide block SPHF-0078 160102070109A053 Fuel Filter Pipeline 10213859 Connecting boot 160102230002A584 Plain Washer 160801030111B001 Core Body of Radiator 10113096L 角钢料坯HQC5290JB.22A-41(L) 59003328 SANY PARTS 22032702 TUBE JC10EP28W-1 A 10209188 导向套PY1.3.6-3 22005964 Stablizerassembly SP404AU02A 10459713 UPPER WEB-PLATE Ⅲ 160102130005B033 Fitting 59002023 JS1500强制式双卧轴搅拌机英文零部件图册(2 10265202 SANY PARTS 10456301 Top Plate 10209773B SANY PARTS 21005073 Screw 61004205 管夹213.5 PP IS M W3 10258185 - 160102090086A012 Plumbing, Exhaust 10505577 SANY PARTS 168807000468A Valve Seal 10467311L SANY PARTS 160507030024A Urea Pipe 67341650440 Unload Valve Core Cover Assembly SPYS-13 180103021098A Solid Carbid Bits 21030530 Carrier Roller 24907629 Rubber plate 160101090032A149 FUEL RETURN PIPE ASSY, LOW PRESSURE 24919747 Sun wheel 10677268 Side board 61021490 piston ring assembly 59005516 SANY PARTS 160102050031A333 Pulley idler 10683786 Plate 520019 Fitting-Hydraulic 3/4 BSPPx45 Elbow 22021551 Pin assembly SPHI-0216 /HI2345A 10698956 Flange 160102120008A121 other vehicle function modules 61020639 扭矩扳手梅花头16配NB100 准达 21035404 Supporting Plate 59004523 SANY PARTS 10505031 SANY PARTS 160801010164B002 Auxiliary Water Tank Assembly 10017877L 上槽板料坯QY50A.1.1.1-1(L) 160102050035B020 Cylinder Block Assembly 10459454 左中腹板Z8.3-16 10659022 SY5296THB/37D concrete truck-mounted con 160102030041B015 Gear, Idle Read the full article

0 notes

Text

Plain Washer Manufacturers In Ludhiana

When it comes to fasteners and assembly hardware, washers may seem like minor components—but their role is crucial. Among the various types, plain washers are the most commonly used due to their simplicity and effectiveness. These small, flat discs are found in almost every mechanical system, from industrial machines to household furniture. In this blog, we’ll explore what plain washers are, their functions, benefits, materials, and typical applications.

What is a Plain Washer?

A plain washer, also known as a flat washer, is a thin, circular metal or plastic disc with a central hole. It is typically placed under a nut or the head of a bolt to distribute the load evenly over a surface. The design is intentionally simple: it doesn’t feature any locks, teeth, or shapes. Its main purpose is to provide a smooth bearing surface and prevent damage to the assembly material.

Functions of Plain Washers

Despite their simplicity, plain washers serve multiple important functions:

Load Distribution: One of the primary roles of a plain washer is to spread the load of the fastener across a wider area. This prevents the bolt or nut from embedding into softer materials.

Surface Protection: Plain washers act as a buffer, reducing the risk of scratching, denting, or otherwise damaging the assembly surface.

Prevents Loosening: While not as effective as lock washers, plain washers can help reduce loosening from vibration by providing consistent pressure on the fastener.

Improved Torque Accuracy: By offering a smooth surface for torque application, plain washers help maintain a consistent clamping force.

Common Materials Used

Plain washers are made from various materials, each chosen based on the application's demands:

Steel: Most common for general-purpose applications, often zinc-plated to prevent corrosion.

Stainless Steel: Ideal for high-corrosion environments like marine or chemical industries.

Brass and Copper: Used for conductivity or aesthetic purposes, often found in electronics.

Plastic and Nylon: Non-conductive, corrosion-resistant, and useful in light-load or sensitive applications.

Standard Sizes and Dimensions

Plain washers come in standard sizes based on the inner diameter (hole size) and outer diameter. The thickness may also vary based on the intended load or material type. Standards like DIN 125, ISO 7089, and ASME B18.22.1 define these dimensions across different global markets.

Applications of Plain Washers

Plain washers are incredibly versatile and used in:

Construction: In structural assemblies, they ensure bolt loads are evenly distributed over surfaces like wood, metal, and concrete.

Automotive Industry: Used in engine parts and frames to reduce wear and vibration.

Machinery: Installed in equipment to prevent surface damage and ensure even tightening.

Electronics: Non-metallic washers are ideal for insulating and spacing components.

DIY Projects: Furniture, household appliances, and shelving often include washers for better performance and longevity.

Benefits of Using Plain Washers

Prevents long-term wear and tear on both the fastener and the material.

Reduces maintenance costs by preventing loosening and damage.

Improves safety and reliability in load-bearing and vibration-prone assemblies.

Cost-effective solution that enhances the performance of fasteners in almost every application.

Conclusion

When it comes to choosing a reliable Plain Washer Manufacturer In Ludhiana, Shri L.G. Hindustan emerges as a name synonymous with trust, quality, and performance. Backed by decades of experience and a strong manufacturing backbone, the company continues to deliver value to industries that rely on precision-engineered fastening solutions. Whether you are a large OEM or a growing enterprise, Shri L.G. Hindustan promises unmatched service, product excellence, and enduring partnerships.

0 notes

Text

Fixing a Leaking Faucet: DIY Overview

Fixing a Leaking Tap: Do It Yourself Overview

If you have actually ever taken care of the nuisance of a dripping tap, you recognize how it can interrupt your tranquility. The constant drip, drip, drip can be frustrating, as well as the drainage and increased expenses. But anxiety not, there's a method to tackle this problem head-on and bring back serenity to your home. By following a few simple steps, you can become the hero of your family and banish that pesky leak permanently. So, are you all set to take charge and solution that touch at last?

Secret Takeaways Identify tap type for proper repair service: round, cartridge, compression, ceramic disk. Gather essential devices like wrench, screwdrivers, washing machines, and O-rings. Shut off water system making use of sink or main shut-off shutoff. Disassemble faucet meticulously after switching off water. Inspect, choose right dimension, and change worn washing machines promptly. Recognizing the Kind Of Tap

To identify the type of tap, start by analyzing the layout and framework of the tap. Tap products play a critical role in determining the kind plumbing line of tap you have. Common tap products include brass, stainless steel, and chrome. Each product calls for details upkeep to guarantee the faucet functions properly. Regular cleansing and staying clear of severe chemicals are necessary for maintaining the faucet's appearance and performance.

youtube

Tap layout also provides clues regarding the kind of tap you are managing. Various tap styles, such as round faucets, cartridge faucets, compression taps, and ceramic disk taps, have distinct capabilities. Sphere taps are typically found in older homes and are identifiable by their single take care of design. Cartridge faucets utilize a cartridge to regulate the water circulation and temperature level. Compression faucets have separate hot and cold deals with that need to be twisted to transform the water on. Ceramic disk faucets are modern-day and feature a solitary bar for both cold and hot water control. Recognizing the tap's layout and products is essential for effective repair work and maintenance.

Collecting the Essential Tools

Check your faucet thoroughly to establish the details devices needed for the repair work procedure. As soon as you have identified the type of tap, it's sittingbourneplumber.co.uk crucial to gather the essential devices for an effective fixing. Correct device organization and maintenance are vital for finishing the job successfully. Make certain your devices are in good problem, as harmed tools can lead to crashes or ineffective repairs. Prior to making use of any tool, make sure you comprehend its safety and security standards and correct use to avoid injuries.

For fixing a dripping faucet, usual devices you may need consist of an adjustable wrench, screwdrivers, pliers, and a washer and O-ring selection. These devices will assist you disassemble the tap, replace any damaged parts, and rebuild it effectively. Keep your tools organized in a toolbox or assigned area to conveniently access them when required. Regular device upkeep, such as cleaning and lubricating, will certainly extend their lifespan and ensure they carry out properly throughout the repair work procedure. Bear in mind, safety should always be a priority when using tools to repair your leaking faucet.

youtube

Shutting down the Water Supply

Guarantee the water is totally s

1 note

·

View note

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description Package Contain : 1 Pcs Single Socket With Switch Extension Cord , 3 Meter Long Cable , Upto 2500W, 15A 16A 20A 3 Pin 1 Socket 1 Switch Wire Length: 3 Meter | Size: 2.5MM 3 Core Cable | Material Type: Pure Copper ISI Certified Wire | Brand: Vrct | Color: White | Features: Heavy Duty, Triple Pvc Insulation with earthing Our Extension Board Is Specifically Engineered To Accommodate A Wide Range Of Low & High-Wattage Home, Office, And Kitchen Appliances, Such As Toasters, Coffee Makers, Blenders, Mixers, Kettles, Water Purifiers, Chimneys, Televisions, Vacuum Cleaners, Ovens, Dishwashers, Treadmills, Dryers, Washing Machines, Refrigerators, Air Conditioners, Pressure Washers, Grills, Microwaves, Ev Chargers, And Electric Vehicles. Furthermore, This Extension Board Is Also Suitable For Commercial applications. To Ensure Safe And Efficient Use Of The Extension Cord, It Is Important To Verify Both The Total Power Consumption (In Watts) Of The Device You Wish To Plug Into It, As Well As The Maximum Load Capacity Of The Extension Board You Intend To Purchase. This Will Help Ensure That The Cord Can Safely Accommodate The Power Requirements Of Your Device, Without Exceeding The Maximum Load Capacity Of The Extension Board Prior To Making Purchase. Our Extension Board Is A Cut Above The Rest With Its Impressive Features. | It Has A Load-Bearing Capacity That Is Twice That Of Standard Extension Boards And Is Equipped With Silver-Coated Brass Pins And Connectors That Guarantee Seamless Power Supply. | Its Flexible And Durable Soft Pvc Wire Is Accompanied By Surge And Overload Protection For Added Safety. | It Is Proudly Made In India | Package Includes One Extension Board, A Set Of Wall Plugs, And Screws For Easy installation. [ad_2]

0 notes

Text

Top Reasons Brass and Naval Brass Sheets Dominate Industry

In the world of metalworking and industrial design, few materials are as widely used and respected as Brass Sheet and Naval Brass Sheet. These copper-based alloys combine durability, workability, and corrosion resistance, making them indispensable across sectors like architecture, marine engineering, plumbing, and electrical manufacturing.

In this blog, we explore the top reasons why these two metal sheets continue to dominate various industries and why you should consider them for your next project.

What is Brass Sheet?

Brass Sheet is an alloy made primarily of copper and zinc, celebrated for its bright gold-like appearance, excellent formability, and corrosion resistance. It is often chosen for both functional and decorative applications.

👉 View high-grade Brass Sheet options ideal for interiors, electrical, and plumbing uses.

What is Naval Brass Sheet?

Naval Brass Sheet is a specialized form of brass alloyed with a small percentage of tin (about 1%) to increase its strength and corrosion resistance—especially in marine or chemical-rich environments.

👉 Explore long-lasting Naval Brass Sheet designed for heavy-duty marine and industrial applications.

1. Superior Corrosion Resistance

One of the leading reasons these sheets dominate is their exceptional resistance to corrosion:

Brass Sheet resists tarnishing and oxidation in air and freshwater.

Naval Brass Sheet performs in the most demanding environments, including saltwater, steam, and chemicals, without degrading.

This makes them top picks for plumbing, marine hardware, and exterior architectural elements.

2. Outstanding Machinability

These metals are known for how easily they can be shaped, cut, and joined:

Brass Sheet is extremely malleable, suitable for fine detailing, intricate forms, and artistic projects.

Naval Brass Sheet is more rigid but still offers great machining characteristics, ideal for parts requiring precision and strength.

✅ Applications include custom fittings, panels, heat exchanger plates, and decorative work.

3. Strong Yet Lightweight

Both metals offer a high strength-to-weight ratio, a critical feature in applications where durability and weight must be balanced: MaterialStrengthCommon UsesBrass SheetModerateFurniture, fixtures, electronicsNaval Brass SheetHighPropeller shafts, condenser plates, valves

Unlike heavier materials like stainless steel, these sheets provide strength without excessive bulk.

4. Aesthetic Appeal

Brass Sheet has a naturally luxurious appearance. Its gold-like finish is widely used in:

Hotels and luxury interiors

Museums and galleries

High-end furniture and fittings

Signage and nameplates

While Naval Brass Sheet is used more for function, it still holds a subtle gold tone and can be polished to achieve a clean, sophisticated finish.

5. Excellent Thermal and Electrical Conductivity

Both brass types are excellent conductors of heat and electricity, which is why they are chosen for:

Electrical terminals

Heat exchanger fins

Connectors and grounding plates

Radiator and boiler components

Brass provides an advantage over many ferrous metals due to its anti-sparking properties, especially valuable in hazardous environments.

6. Resistance to Wear and Fatigue

Naval Brass Sheet, in particular, is widely used in mechanical parts that face constant friction or load. Its resistance to wear makes it perfect for:

Bearings

Thrust washers

Bushings

Seawater pump parts

Brass also performs well in moving parts but is better suited for moderate-stress environments.

7. Easy Joining and Finishing

Brass and naval brass are both easy to solder, braze, and weld, giving fabricators and engineers flexibility in construction. Common joining methods include:

Soft soldering (ideal for electrical)

Brazing (for strong, leak-proof joints)

TIG welding (used with skill and care)

Both materials can also be:

Polished to a mirror finish

Brushed for texture

Patinated for an antique look

Lacquered for corrosion protection

8. Versatility Across Industries

Here’s a quick look at how both materials are used in various fields: IndustryBrass Sheet UsageNaval Brass Sheet UsageArchitecturePanels, trims, railingsMarine-grade fixtures, exterior claddingMarine-Propellers, keels, hull platesPlumbingPipe joints, valves, faucetsUnderwater valves, pump rodsElectricalTerminals, connectors, switchesGrounding plates, fuse componentsIndustrialGaskets, brackets, small gearsBushings, condenser plates, wear surfacesFurniture/DesignDrawer pulls, knobs, metal inlaysCoastal-themed furniture elements

9. Longevity and Low Maintenance

Once fabricated, these metals require minimal upkeep:

Brass can be polished or lacquered to maintain its appearance

Naval brass naturally resists corrosion and usually needs only rinsing in marine conditions

Their long service life reduces replacement and maintenance costs—making them cost-effective over time.

10. Sustainable and Recyclable

Both brass and naval brass are:

♻️ Fully recyclable

🔁 Reusable without property loss

🌱 Environmentally responsible choices for green manufacturing

This makes them not only efficient but also eco-friendly—a major plus in today's market.

Final Thoughts

Whether you’re working in construction, interior design, marine engineering, or electrical manufacturing, Brass Sheet and Naval Brass Sheet continue to dominate due to their unmatched combination of aesthetic appeal, mechanical strength, workability, and corrosion resistance.

0 notes

Text

The Ultimate Guide to Industrial Fasteners: Types, Uses & Materials

Akbarali Enterprises is the leading Fasteners Manufacturer in India, Industrial fasteners are essential components used in almost every type of manufacturing, construction, and engineering project. They may seem small, but they play a big role in holding structures, machines, and equipment together. In this blog, we’ll explore what fasteners are, the types available, common materials used, and how to choose the right one for your needs.

Whether you are a buyer, engineer, or contractor, understanding fasteners helps ensure safety, strength, and durability in your projects.

What Are Industrial Fasteners?

Industrial fasteners are hardware devices used to join two or more components together securely. These components can be made of metal, wood, plastic, or composite materials. Fasteners create a mechanical bond, and depending on the type, this connection can be either temporary (like bolts and screws) or permanent (like rivets). They are used in a wide range of industries including construction, automotive, aerospace, machinery, and electronics.

Fasteners come in many forms such as bolts, screws, nuts, washers, and rivets. Each type serves a specific function and is selected based on factors like load strength, environmental conditions, and the materials being joined. Choosing the right fastener is important to ensure safety, durability, and the overall performance of the structure or product.

Common Types of Fasteners

Here are some widely used types of industrial fasteners:

1. Bolts and Nuts

Bolts are threaded fasteners used with nuts to hold two components together. They are available in many sizes and thread types. This combination is used in construction, machinery, and automotive industries.

2. Screws

Screws are similar to bolts but can be used without nuts. They are widely used in wood, metal, and plastic. Types include wood screws, machine screws, and self-tapping screws.

3. Washers

Washers are thin plates used under nuts or bolt heads to distribute pressure and prevent surface damage. They also help keep the fastener in place.

4. Rivets

Rivets are permanent fasteners used when welding is not an option. Once installed, they cannot be removed without destroying the rivet.

5. Anchors

Anchors are used to attach fasteners to materials that are brittle or soft, like drywall or concrete.

Many Fasteners Suppliers in India offer all these types in various sizes, coatings, and materials based on your industrial requirements.

Materials Used in Fasteners

Choosing the right material is important for durability, corrosion resistance, and strength. Common materials include:

Stainless Steel

Resistant to corrosion and rust, making it ideal for outdoor and marine applications.

Carbon Steel

Strong and affordable. It’s widely used in construction and general manufacturing.

Brass

Corrosion-resistant and visually appealing, often used in plumbing and decorative fixtures.

Aluminum

Lightweight and resistant to corrosion, suitable for aerospace and automotive industries.

Alloy Steel

High strength and toughness, used in heavy-duty applications.

A professional Fasteners Manufacturer will help you choose the right material depending on your environment, load requirements, and budget.

Common Uses of Industrial Fasteners

Fasteners are used in many industries, such as:

Construction: For joining structural components like beams, metal sheets, and frames.

Automotive: To secure engine parts, panels, and suspension systems.

Electronics: For assembling casings and internal parts.

Oil & Gas: For pipeline assembly and structural supports in extreme environments.

Furniture & Woodworking: Screws and bolts are used for easy assembly and disassembly.

Choosing the Right Fasteners Supplier in India

When selecting a Fasteners Supplier, look for:

Consistent quality

On-time delivery

ISO or other quality certifications

Ability to customize as per your specifications

Good customer service

Partnering with a reputable Fasteners Manufacturer in India ensures your projects are built on strong and reliable components.

Conclusion

Fasteners are more than just small metal parts—they are the backbone of strong and safe constructions. Understanding their types, materials, and uses helps you choose the right product for your industry. Whether you're building a bridge or assembling a machine, always trust a reliable Fasteners Manufacturer or Fasteners Supplier in India to get the job done right.

#FastenersManufacturerInIndia#FastenersSupplierInIndia#Fasteners#FastenersManufacturer#FastenersSupplier

0 notes

Text

The Versatility and Value of Custom Brass Parts and Brass Washers

In today’s fast-paced manufacturing and engineering sectors, precision and durability are key. Among the many materials used in custom component fabrication, brass stands out as a preferred choice due to its excellent mechanical properties, corrosion resistance, and aesthetic appeal. Whether you're designing industrial machinery, plumbing systems, or electrical components, custom brass parts and brass washers offer reliable performance and long-term value.

Why Choose Brass?

Brass, an alloy primarily composed of copper and zinc, offers a unique combination of strength, conductivity, and resistance to tarnish. It’s easily machinable, making it ideal for creating custom parts tailored to exact specifications. This flexibility has led to a growing demand for custom brass parts across a wide range of industries, including automotive, marine, aerospace, and electronics.

Custom brass components can be manufactured in virtually any shape or size. Whether you need connectors, spacers, terminals, fittings, or bushings, brass can be formed and finished to meet high precision standards. The ability to customize these parts ensures compatibility with complex systems and improves overall product efficiency.

The Role of Brass Washers

A brass washer may seem like a small, insignificant part, but it plays a crucial role in many mechanical and electrical applications. Typically used to distribute the load of a threaded fastener like a screw or nut, brass washers also help prevent damage to surfaces and ensure a secure fit.

In electrical setups, brass washers are especially beneficial due to their excellent conductivity and corrosion resistance. They are frequently used in terminal assemblies, circuit boards, and electrical enclosures. Unlike steel or plastic alternatives, brass washers provide a longer lifespan and superior reliability under varying environmental conditions.

Benefits of Customization

Opting for custom brass parts means you get components that are tailored to your exact requirements—no more compromising on size, thread type, or shape. This level of customization not only improves performance but also reduces wear and tear, minimizing the risk of system failure.

Additionally, custom parts can be finished in a variety of ways—plating, polishing, or coating—to meet specific industry standards or aesthetic preferences. Whether it's a matte finish for electronic components or a polished look for decorative fittings, customization adds both function and form.

Conclusion

Whether you’re working on a specialized engineering project or a high-performance electrical system, using custom brass parts and brass washers can elevate your results. Their combination of strength, precision, and reliability makes them an indispensable choice across multiple industries. By investing in quality brass components, you're ensuring performance that stands the test of time.

0 notes

Text

Silicon Bronze Fasteners — A Complete Guide

Silicon Bronze Fasteners are widely recognized for their excellent corrosion resistance, strength, and aesthetic appeal. Commonly used in marine environments, architecture, and electrical applications, these fasteners are a staple in industries that require durability and resistance to harsh elements. In this comprehensive guide, we will explore everything you need to know about Silicon Bronze Fasteners, including their composition, properties, types, applications, advantages, and why Ananka Group is your go-to manufacturer and supplier.

What Are Silicon Bronze Fasteners?

Silicon Bronze Fasteners are made primarily from copper and silicon, with small amounts of other elements such as manganese, iron, or zinc. The typical composition is:

Copper (Cu): 94–96%

Silicon (Si): 2.5–3.5%

Other elements: Iron, Manganese, Zinc (trace amounts)

This alloy is part of the broader bronze family and is especially known for its ability to withstand corrosive environments, making it a favorite in marine and coastal installations.

Key Properties of Silicon Bronze Fasteners

1. Corrosion Resistance

Silicon bronze has excellent resistance to corrosion, particularly from saltwater and most acids. This makes it ideal for outdoor and marine use.

2. High Strength

These fasteners offer greater strength compared to regular brass or pure copper fasteners, making them suitable for heavy-duty applications.

3. Non-Magnetic

Silicon bronze is non-magnetic, making it ideal for sensitive electrical and electronic applications.

4. Excellent Conductivity

The copper base ensures good thermal and electrical conductivity, useful in electrical systems.

5. Aesthetic Appeal

The natural golden-reddish hue of silicon bronze adds an attractive, vintage look to structures and exposed hardware.

Common Types of Silicon Bronze Fasteners

Silicon Bronze Hex Bolts

Silicon Bronze Machine Screws

Silicon Bronze Wood Screws

Silicon Bronze Carriage Bolts

Silicon Bronze Nuts and Washers

Silicon Bronze Threaded Rods

Silicon Bronze Nails and Rivets

Applications of Silicon Bronze Fasteners

Due to their superior resistance and durability, Silicon Bronze Fasteners are used across various industries:

◾ Marine Industry

Boat building

Docks and piers

Underwater structures

◾ Construction and Architecture

Roofing

Exterior woodwork

Decorative features

◾ Electrical and Electronics

Electrical connectors

Power distribution systems

◾ Automotive and Aerospace

Non-corrosive fasteners for specialty vehicles

◾ Furniture and Woodworking

High-end furniture assembly

Outdoor wooden decks

Advantages of Silicon Bronze Fasteners

Comparison: Silicon Bronze vs. Other Fastener Materials

Standard Specifications

Silicon Bronze Fasteners are typically manufactured under the following standards:

ASTM B98 – Specification for Silicon Bronze Rods for Fastener Use

ASTM F468 – Standard for Non-Ferrous Fastener Materials

ASTM B150 – For high-strength silicon bronze alloys

SAE J463 / UNS C65100 / C65500 / C66100 – Common alloy designations

Ananka Group – Trusted Silicon Bronze Fasteners Manufacturer & Supplier

Ananka Group is a leading Silicon Bronze Fasteners Manufacturer in India, offering a wide range of bolts, screws, nuts, washers, and custom fasteners tailored to your application needs. With state-of-the-art manufacturing units, stringent quality checks, and worldwide supply capabilities, we ensure top-tier performance and reliability for every product.

Why Choose Ananka Group?

In-house quality testing & inspection

Wide range of fastener grades and dimensions

Worldwide delivery & packaging

Compliance with international standards (ASTM, DIN, ISO)

Expert team for custom solutions

Conclusion

Silicon Bronze Fasteners are a top choice for applications where corrosion resistance, durability, and appearance are essential. From boat building to electrical systems and premium furniture, these fasteners deliver exceptional performance in even the most demanding conditions. Whether you need standard sizes or customized fasteners, Ananka Group is your trusted partner for Silicon Bronze solutions.

Frequently Asked Questions (FAQs)

What is the main advantage of silicon bronze fasteners?

Silicon bronze fasteners offer superior corrosion resistance and strength, making them ideal for marine and outdoor applications.

Are silicon bronze fasteners suitable for electrical applications?

Yes, due to their good electrical conductivity and non-magnetic nature, they are commonly used in electrical systems.

How do silicon bronze fasteners compare to stainless steel?

Silicon bronze offers better electrical conductivity and aesthetic appeal, while stainless steel typically has higher tensile strength and is more cost-effective.

Can I use silicon bronze fasteners in wood?

Absolutely. They're often used in premium woodworking and boat construction where both strength and corrosion resistance are essential.

Do silicon bronze fasteners patina over time?

Yes, they develop a rich patina that enhances their visual appeal, especially in architectural applications.

#ananka#anankafasteners#silicon#siliconbronzefasteners#bronzefasteners#articles#blog#siliconbronze#fasteners#manufacturer#supplier#mumbai#tumblr#blog tumblr

0 notes

Text

European Standard EU Fasteners Manufacturer & Supplier in India – Akbarali Enterprises

Introduction to European Standard Fasteners

Fasteners are the backbone of countless engineering and construction applications. They play a crucial role in maintaining the strength, stability, and durability of mechanical and structural assemblies. When it comes to international quality and compatibility, European Standard fasteners stand out. As a reputed European Standard EU Fasteners Manufacturer & Supplier in India, Akbarali Enterprises delivers a comprehensive range of fasteners engineered to meet DIN, EN, and ISO standards with utmost precision.

What Are EU Fasteners?

European Standard fasteners, commonly referred to as EU fasteners, are components manufactured as per standardized specifications used throughout Europe. These include the DIN (German Institute for Standardization), EN (European Norm), and ISO (International Organization for Standardization) systems. They ensure that bolts, nuts, washers, and screws manufactured in one country can seamlessly fit and function in another, promoting interchangeability and global compatibility.

Importance of DIN, EN, ISO Standards

These standards are vital for ensuring product quality, safety, and reliability. They define not only the dimensions but also the mechanical properties, tolerances, and material requirements of each fastener type. This helps eliminate ambiguity and ensures uniform performance across projects, whether in manufacturing, construction, or transportation.

Benefits of European Standard Fasteners

Interchangeability Across Projects

Because EU fasteners are manufactured according to strict international guidelines, they can be used confidently in projects spanning multiple countries and industries. This is especially important for Indian manufacturers and exporters who need their components to match global expectations.

Precision Engineering and Quality

From thread pitch to tensile strength, European standards guarantee tight tolerances and consistent quality. This ensures durability, reduces failure risk, and enhances the efficiency of installations, making them ideal for critical applications like automotive and aerospace assemblies.

Types of European Fasteners Offered by Akbarali

Bolts, Nuts, Screws, Washers

Akbarali Enterprises provides a full range of fasteners including hex bolts, socket head cap screws, pan head machine screws, hex nuts, and flat and spring washers. Each product is manufactured to match precise DIN/ISO specifications for seamless integration.

Specialty Fasteners for Custom Applications

In addition to standard items, we also supply specialized fasteners like anchor bolts, flange nuts, tamper-proof screws, and high-temperature washers that meet unique engineering requirements. As a Top European Standard EU Fasteners Manufacturer, we ensure versatility and quality in every order.

Materials and Grades Available

Stainless Steel, Carbon Steel, Brass, Alloy Steel

Our fasteners are available in a range of materials tailored to different industry demands. Stainless steel offers corrosion resistance, carbon steel ensures strength, brass provides conductivity, and alloy steels deliver high performance in heavy-duty operations.

Surface Finishing and Coating Options

To further enhance durability and appearance, we offer several finishes including zinc plating, hot-dip galvanizing, black oxide, and nickel coating. These options ensure that your European Standard Fastener, Coated, Plated, EU Standard performs well in corrosive and high-stress environments.

Applications of EU Fasteners in Various Industries

Automotive

Vehicles require consistent, durable fastening solutions. Our fasteners are widely used in engines, chassis, brakes, and body panels where they ensure long-lasting performance and safety.

Construction and Infrastructure

For bridges, buildings, railways, and airports, European standard fasteners offer high load-bearing capacity and weather resistance. Their reliability under dynamic loads makes them the preferred choice for critical structural joints.

Aerospace and Engineering

In aerospace and precision engineering, fasteners must meet the highest levels of accuracy and strength. Our EU fasteners ensure exceptional performance even in extreme conditions of pressure, vibration, and temperature.

Why Choose Akbarali for EU Fasteners

Consistency with Global Standards

We follow a strict quality management system aligned with ISO 9001:2015. Every fastener that leaves our facility meets the required DIN, EN, or ISO standard, ensuring compatibility and dependability in international markets.

Certified Manufacturing and Exports

Our factory is equipped with modern CNC machines, heat treatment units, and automated quality inspection systems. We are a reputed European Standard EU Fasteners Exporter with a growing footprint in Europe, the Middle East, and Southeast Asia.

Manufacturing Process and Quality Assurance

CNC Machining and Cold Forging

We use precision CNC machines and cold forging techniques to produce fasteners with flawless dimensions and high mechanical strength. This method ensures the threads are clean, uniform, and consistent in every piece.

In-House Testing and ISO Certification

Every batch of fasteners undergoes rigorous testing, including tensile strength, hardness, salt spray corrosion resistance, and dimensional checks. Our in-house lab ensures that only flawless products make their way to clients.

Global Reach and Export Capabilities

Serving European Clients from India

We serve clients across Germany, France, the UK, Spain, and Italy with high-quality fasteners manufactured in India. By maintaining European standards at Indian costs, we offer unmatched value to global buyers.

Logistics and Custom Documentation Support

Our export team handles complete documentation including material test certificates, compliance declarations, packing lists, and bills of lading. With dependable freight partnerships, we guarantee on-time global deliveries.

Customization and Bulk Supply Options

Tailored Sizes and Threads

From M4 to M48, we offer custom-sized fasteners with fine or coarse threads, based on your technical drawings or application needs. Whether you're building machines or skyscrapers, we deliver as per specification.

OEM Branding and Packaging

We support OEMs with branded packaging, barcoding, and labeling services to help enhance their market identity. Bulk orders are shipped with robust industrial packaging to ensure product integrity during transit.

Standards Followed in EU Fastener Production

DIN Standards (Germany)

Our DIN-compliant fasteners include DIN 933 hex bolts, DIN 934 hex nuts, and DIN 912 socket cap screws. These are widely used in European engineering systems.

EN and ISO Conformity

We also comply with the EN and ISO standards which harmonize fastener specifications across Europe and globally. These standards cover performance, dimensions, materials, and tolerances.

Client Testimonials and Global Trust

We’ve worked with numerous companies in automotive, infrastructure, and equipment manufacturing sectors who rely on Akbarali fasteners for consistent quality and timely supply. Our dedication to quality has earned us repeat business and long-term trust across global markets.

Frequently Asked Questions (FAQs)

1. What are the benefits of EU standard fasteners? They offer global compatibility, high accuracy, and durability in both standard and critical applications.

2. Do you offer fasteners with anti-corrosion coating? Yes, we provide coated, plated, and hot-dip galvanized fasteners for added corrosion protection.

3. Can you export fasteners to Europe and the UK? Absolutely. We are an experienced European Standard EU Fasteners Exporter with full compliance to shipping and product norms.

4. Do you manufacture non-standard fasteners? Yes, we offer complete customization including non-standard threads, heads, and finishes.

5. How do I ensure I’m getting the best pricing? Contact our team to receive quotes tailored to your quantity and delivery schedule. We are known for offering European Standard EU Fasteners Manufacturer & Supplier at best price in India.

6. What industries do you serve the most? Automotive, construction, aerospace, railways, and heavy engineering.

How to Contact Akbarali Enterprises

For product inquiries, technical support, or bulk order quotes, please reach out using the details below:

Contact Person: Barkat Phone: +91 99192 04560 Email: [email protected] Address: Kurla West, CST Road, India, India 400070

You can also visit the Akbarali Fasteners website for product catalogs and detailed specifications.

Conclusion

If you’re seeking reliable fastening solutions that meet international engineering benchmarks, Akbarali Enterprises is your trusted partner. As a premier European Standard EU Fasteners Manufacturer & Supplier in India, we deliver precision, performance, and professionalism in every batch. Whether you’re a local contractor or a global distributor, our fasteners are built to meet your standards.

0 notes

Text

60055987 UNP Sealing Ring for SANY machinery

60055987 UNP Sealing Ring SANY spare parts Mail:[email protected] 10254570 Crane, crawler, SCC7500 21030401 SANY PARTS 160102070032A077 Turbocharger line 10266163 Plate 10245303 SANY PARTS 67324543938 Lifting cyclinder SPUP-0370B Boom110-70- 10019205 槽钢料坯QY50Ⅱ.20-4(L) 21016545 Reinforced plate 160102130004A009 Connecting Rod Lower Bearing Shell 180101051169A Turning Blade 10432787 穿线管CP12.5.4-39 10241232L SANY PARTS 22004978 Power support SP301TH22-A 160101050018A004 Plumbing, Exhaust 10049368 SANY PARTS 22007615 End plate SP402G2203 160602050026A Housing 9190305000012 水泵3200/3/8/TA2/75 轴流泵 10417132 Web-plate 10424791 Front face covering parts 10025997 Handle box 59100078 羊T骨散装 59011969 红菜苔 10023717L Pull Plate 10016169 Flange 181500000224A Electric tractor cab right door rear pa 10122513 Connecting plate 160101090121A043 Remote Start and Stop Function Module 10234017 板2RC1Z.4.1.3.3-2 10692950 Top board 21006143 Strut 180399000148A brass 522677 THRUST SPACER 180106060120A Boring Blade 160102160022B452 Engine Oil Position Sensor 10245738 SANY PARTS 22053726 Guide sleeve assemlby SPPCH040KA41 10662935 SANY PARTS 61028330 Clamp 10030515 Caution board 22066097 Crane SPZJ00085 10434229 Jointed board 1 21026184 SANY PARTS 61008738 Plug 10201477 摆放架枕木垫FG-237 61008285 防护铸帽AD600-1 61005193 Brace,Tube 160102050053B340 Fan Plate 22051927 Balance Weight SPHX-0464 245760008 销轴A-90F7x490x456-M30(AMS) 180101020113A Inner Round Turning Tools 180101010150A Cutting Tools 22064191 Cutting plate SP400A0504_6_HG70 Default 534210 CC Load Sensor Harness 10114460 Socket 160102070202A128 Plug 160101020001A128 Seal Ring 10266269 SANY PARTS 10268117 SANY PARTS 10118647 Weight Block 160101070011B047 Gasket 24997442 Convertible spanner 10165035 SANY PARTS 180106040110A Full type Boring Tool 22043090 Pipe SPHLR-11500001 160101090060A081 Screw plug M22×1.5 9181218000099 Gearmotor 10079390255 Crawler crane assembly 526520 AMGU5-246R BASE ANGLE-REAR 160102030060B249 Camshaft and Idle Gear Shaft 22014149 The shaft components SPKMG-000108A 传动 160104000463A Lubric. Oil Filter 10183649328 Crawler Crane assemly 168899000717A Flywheel Housing 21009869 Web member 61015968 Piston 21032820 SANY PARTS 10683522 End Cover 181500002409A Decal 61012542 Contactor 181299000416A Engraving Machine Tool Chuck 22065926 bottom plate SPFXE-1692 [email protected] 59011935 莴笋头 10207093M Cylinder bottom 67325239702 Pressure sensor harness SPEEA-0632 Ë«Êä 180605000841A Filter 61016747 贴片按键0155C 10238776L SANY PARTS 10182607 SANY PARTS 10468844 SANY PARTS 160102100027B019 Water Draining Valve 59013029 玩具娃娃 160102050021B130 Secondary Balance Mechanism Shaft 24914362 Piston rod ear ring 160102120008A085 Secondary Lock 59009983 SANY PARTS 160102030041A023 VENTILATION SYSTEM 160801010274A SANY PARTS 10198251 B81A工艺其他小件包见图 24914846 SANY PARTS 920021500023A 医用普通口罩鼻梁条单芯2.5mm×100mm 61009971 L-oil tube 59001364 SANY PARTS 10669022 SANY PARTS 10472463 SANY PARTS 24916685 SANY PARTS 160801090156A Shroud 160102020019A283 Spring 169900000258B Mount, Engine 10681370 筋板Z11.6-15 10139174 Steel Wire Ring 10484147 Flat plate 21002996 Pipe connector 10493444 SANY PARTS 10254870 Lower Portion of Frame 10033526L - 51000613 SANY PARTS 923111400002A Power Module 10142595 SANY PARTS 10687168 LB2000C Asphalt mixing plant with Base-l 10028877 Pressure cover 10078675 column nest Z2.9-7 10010621 Reinforced plate 10641444 底座Z10.14 21023179 Web member 21008056 Air cleaner 61013084 Gasket 67328466740 SPEFA-0511 10241227 收尘袋HZS120MDL.9.1 160801040030A007 Air Deflector 22050594 Limit lever SPHI-0566 10112067 Rope stop rod support 10184466 Reinforced Plate(4) 10269444 Front vertical oil cylinder 10079389376 SCC800-R8 0301030201履带起重机总成 10131943 Movable boom cylinder steel tube 22002740 Slide block SPHF-0078 160102070109A053 Fuel Filter Pipeline 10213859 Connecting boot 160102230002A584 Plain Washer 160801030111B001 Core Body of Radiator 10113096L 角钢料坯HQC5290JB.22A-41(L) 59003328 SANY PARTS 22032702 TUBE JC10EP28W-1 A 10209188 导向套PY1.3.6-3 22005964 Stablizerassembly SP404AU02A 10459713 UPPER WEB-PLATE Ⅲ 160102130005B033 Fitting 59002023 JS1500强制式双卧轴搅拌机英文零部件图册(2 10265202 SANY PARTS 10456301 Top Plate 10209773B SANY PARTS 21005073 Screw 61004205 管夹213.5 PP IS M W3 10258185 - 160102090086A012 Plumbing, Exhaust 10505577 SANY PARTS 168807000468A Valve Seal 10467311L SANY PARTS 160507030024A Urea Pipe 67341650440 Unload Valve Core Cover Assembly SPYS-13 180103021098A Solid Carbid Bits 21030530 Carrier Roller 24907629 Rubber plate 160101090032A149 FUEL RETURN PIPE ASSY, LOW PRESSURE 24919747 Sun wheel 10677268 Side board 61021490 piston ring assembly 59005516 SANY PARTS 160102050031A333 Pulley idler 10683786 Plate 520019 Fitting-Hydraulic 3/4 BSPPx45 Elbow 22021551 Pin assembly SPHI-0216 /HI2345A 10698956 Flange 160102120008A121 other vehicle function modules 61020639 扭矩扳手梅花头16配NB100 准达 21035404 Supporting Plate 59004523 SANY PARTS 10505031 SANY PARTS 160801010164B002 Auxiliary Water Tank Assembly 10017877L 上槽板料坯QY50A.1.1.1-1(L) 160102050035B020 Cylinder Block Assembly 10459454 左中腹板Z8.3-16 10659022 SY5296THB/37D concrete truck-mounted con 160102030041B015 Gear, Idle Read the full article

0 notes

Text

Everything You Should Know About Washers and Their Applications

Washers may seem like small and simple components, but they play a vital role in many mechanical assemblies. Positioned between a fastener and the surface it’s securing, washers distribute load, reduce wear, and prevent damage. They are widely used in industries ranging from construction and automotive to electronics and aerospace.

In this blog, we’ll explore what washers are, their various types, and how they’re applied across different sectors.

What is a Washer?

A washer is a thin plate with a hole (typically in the center) that is used in conjunction with a threaded fastener, such as a bolt or nut. The primary purpose of a washer is to distribute the load of the fastener evenly and to prevent surface damage. Additionally, washers can help prevent loosening due to vibration and can serve as spacers, springs, or locking devices.

Types of Washers

Washers come in several types, each designed to meet specific functional requirements:

1. Flat Washers

Flat washers are the most common type. They are typically used to spread the load of a bolt or screw over a larger area, reducing surface wear and protecting the material beneath.

2. Spring Washers

Also known as lock washers, these are designed to prevent loosening due to vibration or torque. They exert a spring force between the fastener’s head and the surface.

3. Fender Washers

These have a larger outer diameter compared to flat washers. They’re ideal for use in soft materials or oversized holes to provide greater load distribution.

4. Lock Washers

Lock washers include several designs such as split, toothed, or serrated. They are used to keep fasteners secure and prevent movement during operation.

5. Shoulder Washers

Made often from plastic or nylon, these washers provide electrical insulation in electronic assemblies and act as spacers.

6. Sealing Washers

Used in plumbing and automotive industries, sealing washers (often made with rubber or neoprene) provide a tight seal to prevent leaks.

Applications of Washers

Washers are essential across a wide range of industries and functions:

• Construction

Washers ensure bolts are securely fastened and evenly load-distributed on beams, panels, and structural components.

• Automotive

In vehicles, washers reduce vibration, prevent loosening of bolts and nuts, and protect engine and body components.

• Electronics

Insulating washers prevent electrical conductivity where it's not needed and offer thermal protection.

• Aerospace

Specialty washers with high strength and heat resistance are used to secure aircraft parts and reduce the risk of mechanical failure.

• Household Appliances

From washing machines to furniture assembly, washers help extend the life of fixtures by reducing wear and loosening.

Factors to Consider When Choosing a Washer

When selecting the right washer for your project, consider the following:

Material: Washers can be made from steel, stainless steel, brass, plastic, rubber, and more, depending on the application.

Load Requirements: Determine the amount of load the washer will need to handle.

Environmental Conditions: For corrosive or high-heat environments, stainless steel or coated washers are recommended.

Compatibility: Ensure the washer matches the size and type of bolt or screw being used.

Conclusion

Washers may seem like a minor component, but their contribution to structural integrity, performance, and safety is significant. Understanding their types and applications helps engineers and buyers make informed decisions.

At Shri LG Hindustan, we are committed to delivering reliable fastening solutions backed by technical expertise and consistent quality. For premium-grade washers suited for every application, trust the name that industries rely on.

Connect with Shri LG Hindustan today for expert advice and top-quality washers.

0 notes

Text

Fixing a Leaking Tap: Do It Yourself Guide

Repairing a Leaking Tap: DIY Guide

If you've ever managed the annoyance of a leaking tap, you understand just how it can interrupt your tranquility. The continuous drip, drip, drip can be maddening, not to mention the drainage and raised expenses. However fear not, there's a means to tackle this issue head-on and recover harmony to your home. By following a couple of straightforward steps, you can come to be the hero of your household and eliminate that pesky leakage for good. So, are you prepared to take fee and solution that tap finally?

Secret Takeaways Recognize tap kind for proper fixing: ball, cartridge, compression, ceramic disk. Collect essential devices like wrench, screwdrivers, washers, and O-rings. Turn off water system using sink or main shut-off valve. Take apart faucet very carefully after turning off water. Inspect, select right dimension, and change worn washers quickly. Determining the Type of Tap

To identify the type of tap, beginning by checking out the style and structure of the faucet. Tap materials play an essential role in identifying the sort of tap you have. Typical faucet materials consist of brass, stainless steel, and chrome. Each product needs particular upkeep to guarantee the faucet works correctly. Normal cleansing and preventing rough chemicals are necessary for keeping the tap's look and capability.

Faucet style additionally gives ideas about the type of faucet you are dealing with. Various tap designs, such as ball faucets, cartridge taps, compression taps, and ceramic disk taps, have distinctive capabilities. Ball taps are frequently located in older homes and are well-known by their single handle style. Cartridge taps utilize a cartridge to control the water flow and temperature. Compression faucets have separate hot and cold takes care of that need to be twisted to transform the water on. Ceramic disk taps are contemporary and feature a single lever for both hot and cold water control. Understanding the faucet's style and materials is crucial for reliable repair work and upkeep.

Collecting the Necessary Tools

Check your tap thoroughly to determine the certain devices needed for the repair procedure. When you have recognized the sort of faucet, it's vital to collect the required tools for a successful repair work. Proper device company and upkeep are crucial for finishing the task effectively. Make sure your devices remain in great condition, as harmed tools can bring about accidents or inadequate repair work. Prior to utilizing any kind of tool, make sure you comprehend its safety and security standards and correct use to stop injuries.

For repairing a leaking faucet, common devices you could require consist of a flexible Browse around this site wrench, screwdrivers, pliers, and a washing machine and O-ring assortment. These tools will help you dismantle the tap, replace any kind of damaged components, and reassemble it correctly. Keep your devices arranged in a toolbox or marked location to easily access them when needed. Regular tool upkeep, such as cleansing and lubricating, will certainly extend their life-span and guarantee they carry out effectively throughout the repair work procedure. Keep in mind, https://medwayplumber.co.uk safety ought to constantly be a top priority when making use of tools to repair your leaking tap.

youtube

Turning off the Water System

Make certain the water supply is totally turned off before comme

0 notes

Text

Machined Washers: Types, Materials, Benefits and Supplier India

The CNC Machining Process Behind Precision Washers

Ever wondered how a CNC Machined Washer is made? The process begins with a solid metal bar—like stainless steel, aluminum, or brass—which is loaded into a CNC lathe or milling machine. Guided by a digital blueprint, the machine cuts the washer to exact dimensions, ensuring smooth edges and precise thickness. Compared to stamping or laser-cutting, this method offers far better control over tolerances and finish.

One of the biggest perks of CNC machining is repeatability. Whether you’re producing one Custom Machined Washer or a thousand, each one will be identical. This is crucial in industries where component uniformity is critical—like aerospace, automotive, and precision instruments. Plus, CNC machines allow for rapid prototyping and quick adjustments, which makes them ideal for both low-volume custom orders and high-volume production runs of CNC Machined Washers.

0 notes

Text

How to Use Brass and Naval Brass Sheets in Industrial Projects ?

When it comes to choosing the right metal for durability, corrosion resistance, and versatility, brass sheets and naval brass sheets are two of the most reliable options available. But how do you use them in real-world industrial applications, and what makes them different?

In this guide, we’ll explore the functional advantages, use cases, and buying tips for both materials to help engineers, designers, and manufacturers make informed decisions.

What Is a Brass Sheet and Where Is It Used?

A brass sheet is a flat rolled alloy made from a combination of copper and zinc. The proportions of these metals can vary depending on the desired strength, color, and flexibility. Brass sheets are available in various thicknesses and widths, making them suitable for multiple industries.

You can find high-quality Brass Sheet options for industrial, commercial, and decorative purposes.

Common Industrial Uses of Brass Sheet

Brass sheets are chosen for a variety of applications due to their machinability and corrosion resistance:

Electrical terminals and contact points

Heat exchangers and radiator cores

Decorative panels and architecture detailing

Industrial equipment parts

Fasteners, hinges, and nameplates

Because of its visual appeal and practical strength, brass is one of the few metals that work equally well in technical and decorative contexts.

Why Is Brass Sheet Preferred in Manufacturing?

Brass offers a unique combination of properties that are ideal for forming and machining:

Corrosion Resistance

Brass performs well in wet or moderately corrosive environments, making it useful in plumbing and outdoor applications.

Electrical Conductivity

While not as conductive as copper, brass offers good electrical performance, ideal for connectors and low-voltage systems.

Ductility and Formability

Brass is easy to punch, stamp, bend, and roll without cracking, which is why it’s widely used in hardware fabrication.

Aesthetic Finish

Brass has a natural golden shine that does not require plating, which reduces cost and processing time in decorative applications.

What Is Naval Brass Sheet and How Is It Different?

Naval brass is a specific type of brass alloy that includes around 1% tin. This addition enhances its resistance to saltwater corrosion and stress cracking. As a result, naval brass sheet is widely used in marine and heavy industrial environments.

Check out the best-grade Naval Brass Sheet solutions for your marine engineering needs.

How Is Naval Brass Sheet Used in Marine and Industrial Sectors?

Naval brass is a preferred material where regular brass may fall short, especially in aggressive environments.

Shipbuilding and Marine Engineering

Naval brass sheets are used to fabricate rudders, shaft linings, propeller components, and other seawater-exposed parts.

Heat Exchangers and Condensers

Due to its superior corrosion resistance, naval brass is frequently used in oil and gas systems, condensers, and cooling units.

Hydraulic and Pneumatic Systems

In systems where exposure to water or chemicals is high, naval brass ensures durability and operational integrity.

Industrial Hardware and Fasteners

Bolts, washers, and nuts made from naval brass offer a longer lifespan in corrosive or coastal industrial setups.

How to Choose Between Brass and Naval Brass Sheet?

While both types of sheets are useful, the right choice depends on your specific application.

Choose Brass Sheet If:

You need material for decorative or light structural use

Cost is a primary concern, and exposure to harsh environments is low

You want good machinability for precision metal work

Choose Naval Brass Sheet If:

Your project involves constant or long-term exposure to water, especially saltwater

You need a stronger alloy with added durability

You require material suitable for outdoor, marine, or chemical-prone environments

How to Cut and Work with Brass and Naval Brass Sheets

Working with brass or naval brass sheets doesn’t require overly complex tools, but certain best practices can help ensure precision and safety.

Use the Right Tools

Brass can be cut using tin snips for thin sheets or a jigsaw/metal shear for thicker material. Naval brass may require more durable cutting equipment due to its strength.

Wear Safety Gear

Always use safety gloves and eye protection when cutting or shaping sheets, especially with power tools.

Deburr the Edges

After cutting, use a metal file or deburring tool to smooth sharp edges and ensure a clean finish.

Use a Template or Guide

For repeated industrial cuts or fabrication, templates can increase efficiency and reduce error rates.

Brass vs. Naval Brass: Cost and Availability

Brass sheets are more readily available and often less expensive than naval brass. However, in applications where failure is not an option—like marine engineering or power generation—naval brass justifies its higher cost with added durability.

When budgeting for large-scale industrial projects, factor in not just the material cost, but also maintenance and longevity. A slightly higher upfront investment in naval brass can result in lower maintenance over time.

Where to Buy High-Quality Brass and Naval Brass Sheets?

Look for suppliers that offer:

Certified material specifications

Dimensional customizations

Fast shipping and stock availability

Technical support for applications and cutting

You can explore both Brass Sheet and Naval Brass Sheet options with guaranteed quality from a trusted industrial metals supplier.

Final Thoughts

Brass sheet and naval brass sheet are two powerful allies in the world of metalwork. While one offers versatility and elegance, the other delivers unmatched strength in hostile conditions. Understanding their differences and use cases ensures better design, improved performance, and cost efficiency for your projects.

When in doubt, consider the environment in which the material will operate. If it’s decorative or lightly functional, brass sheet is ideal. If it involves moisture, pressure, or saltwater, naval brass sheet is the better choice.

Still unsure which one suits your requirement best? Speak to a metal specialist or request samples from a reputable supplier to make the most informed decision.

0 notes