#CMP Cables

Explore tagged Tumblr posts

Text

Knowing the nonsense that went on at old CW and Nextar CW, not just with spn, but many shows that affected by systemic linear broadcast network shenanigans at CW in all eras, I gotta say, I am relieved spn is free of the CW. I know it's a systemic tv industry problem and it's not like it's a paradise on other platforms either, broadcast or streaming. But still I'm glad that the spn franchise is free of CW and will have a chance to tell its stories on another platform. Most likely streaming. I honestly can't picture spn winding up on linear broadcast or basic cable right now. Genre has vanished from linear broadcast, and I read that studios prefer to put genre or more unusual scripts onto streaming.

Rolling the dice on which platform.

Netflix: What happens when spn's old netflix contract runs out in 2025? Does netflix and WBD renew and Netflix becomes the platform for spn and the spn universe? The main series has done well there so far.

Max: At one point I'd be thinking WBD might want a franchise like spn on their own platform Max, but WBD has been licensing things out more and more often.

Amazon Prime: also a big contender given the excellent relationship Jensen and CMP has with them, plus there's the Eric Kripke link, and spn is on Amazon Prime in the UK (last I heard).

22 notes

·

View notes

Text

hey online websites that use dumbass algorithms to include "related" products in search results rather than only displaying products using the exact terms that users search for: super fucked that you're doing this to mix up CMR and CMP cables. those two have very different fire safety ratings.

14 notes

·

View notes

Text

Nylon Cable Gland Market: Trends, Growth, and Forecast 2025–2032

Nylon Cable Gland Market, Trends, Business Strategies 2025-2032

Nylon Cable Gland Market size was valued at US$ 456.9 million in 2024 and is projected to reach US$ 623.4 million by 2032, at a CAGR of 3.9% during the forecast period 2025-2032.

Our comprehensive Market report is ready with the latest trends, growth opportunities, and strategic analysis https://semiconductorinsight.com/download-sample-report/?product_id=103394

MARKET INSIGHTS

The global Nylon Cable Gland Market size was valued at US$ 456.9 million in 2024 and is projected to reach US$ 623.4 million by 2032, at a CAGR of 3.9% during the forecast period 2025-2032. China’s market is anticipated to grow at 6.2% CAGR, while the U.S. remains the dominant regional market with estimated 2024 revenue of USD 420 million.

Nylon cable glands are specialized mechanical components designed to securely fasten and protect cables entering electrical equipment. These devices provide strain relief, environmental sealing, and EMI shielding through their durable nylon construction. Key product variants include elbows and straight-head configurations, with material innovations improving flame retardancy and UV resistance.

Market expansion is driven by increasing industrialization, stringent safety regulations, and rising demand from energy infrastructure projects. The oil & gas sector accounted for 28% of 2024 applications, followed by power generation (22%) and mining (18%). Recent developments include Heyco’s 2023 launch of explosion-proof nylon glands meeting ATEX/IECEx standards, reflecting industry emphasis on hazardous environment solutions. Leading manufacturers like HUMMEL and Essentra Components are expanding production capacities in Asia-Pacific to capitalize on regional growth.

List of Prominent Nylon Cable Gland Manufacturers

Heyco (U.S.)

HUMMEL (Germany)

By Carpel (China)

Hont Electrical (China)

Essentra Components (UK)

DEMOELE (Spain)

B.M.P (Italy)

DSE HIBOX (India)

Jacob (Germany)

ITALWEBER (Italy)

PANOZZO (Brazil)

PLASTEM (France)

Utility Electrical (Australia)

Vital Parts (South Africa)

ZHEJIANG DERXIN CONNECTOR (China)

CMP Products (UK)

Segment Analysis:

By Type

Elbows Segment Gains Traction for Enhanced Cable Routing in Complex Installations

The market is segmented based on type into:

Elbows

Subtypes: 90-degree elbow, 45-degree elbow, and others

Straight Head

Subtypes: Single-entry, double-entry, and others

Waterproof

Explosion-proof

Others

By Application

Oil and Gas Sector Leads Owing to Rigorous Safety Standards and Harsh Environment Demands

The market is segmented based on application into:

Oil and Gas

Mining

Chemical Industry

Aerospace

Power and Energy

Others

By Material Grade

Standard Nylon Dominates Due to Cost-Effectiveness and General-Purpose Applications

The market is segmented based on material grade into:

Standard Nylon

Reinforced Nylon

UV-Resistant Nylon

Flame-Retardant Nylon

Others

By Installation Type

Threaded Installations Preferred for Their Reliability in Industrial Settings

The market is segmented based on installation type into:

Threaded

Compression

Push-fit

Others

Regional Analysis: Nylon Cable Gland Market

North America The North American nylon cable gland market benefits from stringent safety regulations and significant industrial automation investments, particularly in sectors like oil & gas and power generation. The U.S. dominates demand, accounting for over 60% of regional market share, driven by strict NEC (National Electrical Code) compliance requirements for cable management systems. While traditional metal glands still hold relevance in hazardous environments, thermoplastic nylon variants gain traction due to their corrosion resistance and cost-effectiveness. The region’s focus on renewable energy projects, such as offshore wind farms, presents new opportunities for waterproof cable gland solutions.

Europe Europe maintains a strong position in the nylon cable gland market, with Germany and the U.K. leading adoption due to advanced manufacturing sectors and ATEX directive compliance for explosive atmospheres. The region shows increasing preference for halogen-free flame retardant (HFFR) nylon products, particularly in Scandinavia’s maritime applications. While price sensitivity restricts growth in Southern Europe, Western European markets demonstrate willingness to pay premium prices for IP68-rated cable glands with enhanced UV stability. The EU’s circular economy action plan may impact future material formulations and recycling protocols.

Asia-Pacific As the fastest-growing market, Asia-Pacific demonstrates voracious demand from China’s industrial expansion and India’s infrastructure development. China alone accounts for nearly 45% of global nylon cable gland production, though quality differentiation remains a challenge. Japan and South Korea prefer high-end precision components for electronics manufacturing, while Southeast Asian nations show growing appetite for weatherproof glands in construction applications. The region’s competitive landscape features intense price competition between domestic manufacturers and international brands, with local players gradually improving technical capabilities.

South America Market growth in South America remains constrained by economic volatility, though Brazil and Argentina show steady demand from mining and agriculture sectors. The lack of standardized certification requirements creates quality inconsistencies across the region. While multinational corporations prefer imported high-specification glands, local manufacturers dominate price-sensitive segments with basic nylon offerings. Recent investments in renewable energy projects, particularly in Chile’s solar sector, could spur demand for specialized cable management solutions in coming years.

Middle East & Africa The MEA region presents diverging trends – Gulf Cooperation Council (GCC) countries demand high-performance cable glands for oil refineries and desalination plants, while African markets focus on affordable solutions for basic electrification projects. Saudi Arabia’s Vision 2030 industrial diversification strategy drives demand in industrial cities, whereas North African auto manufacturing clusters require precision components. The lack of local manufacturing capabilities creates import dependency, though some UAE-based companies are establishing regional production facilities to serve adjacent markets.

MARKET DYNAMICS

The lack of uniform certification requirements across regions complicates product development and compliance efforts. Manufacturers must navigate varying regional standards including UL, CE, CSA, and CCC approvals, each with different testing protocols. These diverging requirements force companies to maintain multiple product variants, increasing complexity in production planning and inventory management. The certification process itself represents substantial time and cost investments, particularly for smaller players entering new geographic markets.As cable systems become more sophisticated with integrated sensors and smart monitoring capabilities, cable glands must evolve accordingly. Developing next-generation glands that accommodate emerging technologies while maintaining traditional performance characteristics requires significant engineering resources. These development challenges slow product innovation cycles and delay time-to-market for advanced solutions.

The rapid global transition toward renewable energy creates substantial opportunities for nylon cable gland suppliers. Solar farms, wind turbines, and energy storage installations all require weather-resistant cable management solutions. Nylon glands are particularly well-suited for photovoltaic applications due to their UV stability and corrosion resistance. The growing emphasis on offshore wind energy further expands potential, with projects requiring marine-grade components that withstand saltwater exposure. Industry projections indicate renewable energy capacity additions will drive double-digit annual growth in specialized cable gland demand through the decade.

Urban infrastructure modernization programs worldwide are incorporating intelligent transportation systems, smart grids, and IoT sensor networks – all requiring robust cable protection. Municipalities prioritizing future-proof infrastructure favor nylon glands for their longevity and maintenance advantages. The integration of 5G small cell networks and edge computing in urban environments further multiplies cable management needs. Strategic partnerships with smart city solution providers allow cable gland manufacturers to participate in large-scale infrastructure rollouts with predictable, long-term demand cycles.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies https://semiconductorinsight.com/download-sample-report/?product_id=103394

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global Nylon Cable Gland Market?

Which key companies operate in Global Nylon Cable Gland Market?

What are the key growth drivers?

Which region dominates the market?

What are the emerging trends?

Related Reports:

CONTACT US: City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014 [+91 8087992013] [email protected]

0 notes

Text

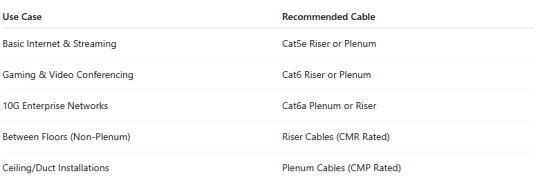

Beyond the Jacket: Cat6a Riser vs Plenum – Which One Should You Choose in 2025?

When you're planning your next network installation, selecting the right Ethernet Cable goes beyond just speed and bandwidth. Sure, Cat6a cables are built for high-performance data transfer, supporting speeds up to 10 Gbps and a bandwidth of 750 MHz. But choosing between Cat6a plenum and Cat6a riser jackets can make a big difference in safety, compliance, and cost.

In this guide, we’ll break down everything you need to know about Cat6a riser vs plenum cables, how they compare, and when to use each in residential and commercial network environments.

Understanding Cat6a Ethernet Cable Jackets

Cat6a Ethernet cables, short for Category 6 Augmented, are built to deliver superior performance compared to Cat5e and Cat6. Whether you’re wiring a smart home, outfitting a corporate office, or managing a data center, Cat6a is a reliable, future-proof choice.

But not all Cat6a cables are created equal. The “jacket” type—either riser (CMR) or plenum (CMP)—isn’t just about outer appearance. It determines where the cable can be safely installed based on fire codes and building regulations.

Comparing Cat6a Plenum and Riser Cables

Choosing between riser and plenum cables depends on where you're installing them. Here’s how they compare across key characteristics:

Each cable is certified to meet specific fire safety standards set by the National Electrical Code (NEC). Plenum cable, though more expensive, is designed for maximum safety in air circulation areas.

When to Use Cat6a Plenum Cable

Plenum cable is engineered for use in plenum spaces—areas within buildings that facilitate air circulation for heating and air conditioning systems. These areas tend to be more vulnerable to fire spread, so the cable installed there must be made of materials that minimize toxic smoke and resist flame propagation.

Common installation points include:

Drop ceilings

Raised floors

HVAC ducts and plenum shafts

Air returns in data centers

Attics and basements in commercial settings

In these spaces, Cat6a plenum cable offers both performance and peace of mind, helping meet safety codes while delivering reliable 10 Gigabit Ethernet.

⚠️ Note: Never substitute a riser cable for a plenum-rated one in these spaces. Not only is it a violation of code—it’s a major fire hazard.

When to Use Cat6a Riser Cable

Cat6a riser cables are intended for vertical runs between floors in non-plenum environments, such as inside walls or between server rooms on different levels of a building. They’re fire-resistant to a degree but produce more toxic smoke when ignited.

Cat6a riser cable is a great option for:

Residential homes

Multi-story buildings (within wall runs)

Offices with contained vertical shafts

Non-air-handling vertical pathways

They’re also more affordable than plenum cables, making them a cost-effective choice when full plenum compliance isn’t required.

Performance Matters: Not Just the Jacket

Regardless of jacket type, Cat6a cables offer impressive specs that make them an excellent upgrade in 2025:

10 Gbps transmission over 100 meters (328 ft)

Up to 750 MHz bandwidth

Backward compatible with Cat6 and Cat5e

Improved crosstalk protection with tight twists and spline separator

Ideal for high-speed internet, gaming, streaming, and enterprise-grade networks

Whether you're using a Cat6a plenum or riser cable, the internal construction remains nearly identical—the difference lies in how and where you install them.

How to Identify Plenum vs Riser Cable

At first glance, it’s hard to tell them apart. Always check the jacket labeling. Manufacturers clearly mark cable jackets with terms like “CMP,” “CMR,” “PLENUM,” or “RISER” to identify compliance. Some brands may also use codes like “PL,” “PLM,” or “FEP” for plenum cables and “PVC” for riser cables.

If you’re unsure, consult the manufacturer’s spec sheet or reach out to a licensed installer.

Can You Use Riser Cable in Plenum Spaces?

This is one of the most asked questions—and the answer is no.

Riser cables are not designed to be fire-safe in air handling spaces. Using them in plenum areas violates building codes and poses a serious risk of fire and toxic smoke. Only CMP-rated cables are permitted in such environments.

If budget is a concern, you can use a combination of cables—plenum for necessary areas and riser for wall runs—just be sure they’re installed in the right locations.

Longevity of Cat6a Plenum and Riser Cables

Ethernet cables don’t wear out quickly, but over time, they can degrade due to environmental factors and technological advancements. A well-installed Cat6a cable can last 8–10 years, sometimes longer, depending on how and where it's used.

When to Consider Replacing:

Visible wear or damaged jacket

Network performance drops (latency, speed loss)

Major building renovations or rewiring projects

Fire inspections requiring upgrades

Transition to newer standards or PoE systems

Follow best practices during installation—such as avoiding tight bends and using shielded connectors when needed—to extend the life of your cable infrastructure.

Which One Wins? Final Thoughts

So, who wins in the Cat6a Riser vs Plenum debate?

If you’re looking for cost savings in standard installations like wall runs or between floors, Cat6a riser cable is the logical pick.

But if safety, code compliance, and future-proofing your infrastructure matter most—especially in commercial or large residential buildings—Cat6a plenum cable is worth every penny.

In 2025, with high-speed connectivity and building safety taking center stage, knowing when and where to use each type of Cat6a cable will ensure your network is not only fast but also secure and code-compliant.

0 notes

Text

EMC Cable Glands Market Forecast: A CAGR of 6.50% Expected, Expanding from USD 2.61 Billion in 2024 to USD 4.32 Billion by 2032

The EMC (Electromagnetic Compatibility) cable glands market is experiencing steady growth, driven by the increasing need for effective shielding and grounding solutions to prevent electromagnetic interference (EMI) in various industrial and electronic applications. EMC cable glands are critical components used to provide secure cable entry while maintaining electromagnetic shielding, ensuring that electrical and electronic systems function properly without interference from external electromagnetic fields.

The EMC Cable Glands Market was valued at USD 2.45 billion in 2023. It is projected to grow from USD 2.61 billion in 2024 to USD 4.32 billion by 2032, reflecting a compound annual growth rate (CAGR) of 6.50% during the forecast period from 2024 to 2032.

As industries become more reliant on complex electronic systems, particularly in sectors such as telecommunications, automotive, aerospace, industrial automation, and energy, the demand for EMC cable glands is rising. These glands are designed to ensure the safe and efficient transmission of signals and power while protecting sensitive equipment from EMI, which can cause malfunctions, signal disruptions, or even damage to devices.

The growth of the EMC cable glands market is also influenced by the increasing adoption of automation and digitalization in industries like manufacturing, where EMI issues can disrupt automated systems and lead to costly downtime. Furthermore, the expansion of telecommunications infrastructure, including 5G networks, and the growing emphasis on renewable energy projects are fueling the demand for advanced EMC solutions to ensure signal integrity and system reliability.

Get Sample PDF EMC Cable Glands Market with Complete TOC, Tables & Figures @

EMC Cable Glands Market Companies Are:

Amphenol, Emerson, ABB, TE Connectivity, Jacob GmbH, Cortem, Eaton, Hubbell Incorporated, Axis Communications, PFLITSCH GmbH, CMP Products, Lapp Group, Hummel AG, WISKA, Weidmüller Interface, BARTEC Group, and others

With the rising implementation of stringent regulatory standards regarding EMC in various regions, industries are increasingly investing in EMC cable glands to comply with these regulations and avoid the potential for costly disruptions. Additionally, advancements in materials and design are contributing to the development of more efficient and durable EMC cable glands that meet the specific needs of different industries.

DROC (Drivers, Restraints, Opportunities, and Challenges) of the EMC Cable Glands Market:

Drivers:

Increasing Need for Electromagnetic Compatibility in Industrial Applications: As industries across the globe rely more on advanced electronics and communication systems, there is a growing need for EMC solutions to prevent electromagnetic interference that can disrupt sensitive equipment. EMC cable glands are essential for maintaining the functionality and safety of these systems.

Rising Demand from the Telecommunications and Data Center Sectors: The expansion of the telecommunications industry, especially with the rollout of 5G networks, has significantly increased the demand for EMC cable glands. These glands help protect critical infrastructure from EMI, ensuring uninterrupted data transmission and reliable network performance.

Growth in Automation and Industrial IoT: The proliferation of automation, robotics, and the Industrial Internet of Things (IIoT) in manufacturing and other industrial sectors is driving the demand for EMC cable glands. These environments often have numerous electronic devices operating in close proximity, making EMI protection crucial to avoid equipment malfunctions and signal disruptions.

Restraints:

High Cost of Advanced EMC Cable Glands: While EMC cable glands provide critical protection against EMI, their advanced design and materials can make them more expensive than standard cable glands. For small and medium-sized enterprises (SMEs), the high cost of EMC cable glands may act as a deterrent, limiting their adoption in cost-sensitive markets.

Complex Installation Process: Installing EMC cable glands requires specialized knowledge and skills to ensure proper grounding and shielding. Improper installation can compromise the effectiveness of the EMI protection, leading to system failures. This complexity may discourage some companies from adopting EMC cable glands or lead to increased installation costs.

Opportunities:

Expansion of Renewable Energy Projects: The increasing focus on renewable energy sources such as wind and solar power presents significant opportunities for the EMC cable glands market. In renewable energy installations, especially in harsh environments, EMC cable glands are necessary to protect sensitive electrical systems from EMI and ensure the reliable operation of power generation equipment.

Development of Smart Cities and Infrastructure: The growing trend of smart cities, which rely on interconnected systems for transportation, communication, and energy, is creating a demand for advanced EMC solutions. EMC cable glands are crucial in protecting the communication and control systems that enable the smooth operation of smart city infrastructure.

Challenges:

Intense Competition and Price Pressure: The EMC cable glands market is highly competitive, with many players offering a variety of products. This competition can lead to price pressure, which may reduce profit margins for manufacturers. Companies need to focus on differentiating their products through technological innovations and quality improvements to remain competitive.

Difficulty in Retrofitting Existing Systems: In some industries, retrofitting existing systems with EMC cable glands can be challenging, particularly in older installations that were not designed with EMC protection in mind. Upgrading these systems may require significant investments and complex modifications, posing a challenge for companies looking to enhance their EMI protection.

Browse Related Report:

About Market Research Future: At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), & Consulting Services. MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients.

Contact us: Market Research Future (part of Wantstats Research and Media Private Limited), 99 Hudson Street, 5Th Floor, New York, New York 10013 United States of America +1 628 258 0071 Email: [email protected] Website: https://www.marketresearchfuture.com

0 notes

Text

Cable Gland Manufacturing in India: Driving Connectivity and Safety

Cable glands are essential components in electrical and instrumentation systems, serving as crucial elements for providing secure cable entry points while ensuring protection against environmental factors such as dust, moisture, and vibrations. In India, the manufacturing of cable glands has seen significant growth, with companies producing a wide range of high-quality products to meet domestic and international demands. This article explores the landscape of cable gland manufacturing in India, key players in the industry, technological advancements, market trends, and the importance of cable glands in ensuring connectivity and safety in various applications.

Overview of Cable Gland Manufacturing in India:

India has emerged as a prominent hub for cable gland manufacturing, with several companies specializing in the production of a diverse range of cable glands for different industries and applications. These manufacturers leverage advanced technologies, stringent quality standards, and skilled labor to produce reliable and efficient cable gland solutions that meet the requirements of both domestic and global markets.

Significance of Cable Glands:

Secure Cable Management: Cable glands provide a secure and reliable method for routing cables through enclosures, panels, or equipment while maintaining ingress protection against dust, water, and other contaminants.

Electrical Safety: By ensuring proper cable termination and grounding, cable glands help prevent electrical hazards such as short circuits and shocks, enhancing overall safety in electrical installations.

Environmental Protection: Cable glands offer protection against environmental factors like moisture, chemicals, and mechanical stress, ensuring the longevity and performance of electrical systems in diverse operating conditions.

Key Players in the Cable Gland Industry in India:

CMP Products India: CMP Products India is a leading manufacturer of cable glands, cable cleats, and associated products, known for its high-quality offerings and innovative solutions.

Rajputana Engineering Works: Rajputana Engineering Works specializes in the production of cable glands, conduit fittings, and accessories, catering to a wide range of industrial applications.

Dowells Cable Gland Pvt. Ltd.: Dowells Cable Gland Pvt. Ltd. is a well-established manufacturer of cable glands and electrical connectors, recognized for its reliability and product quality.

Hex Cable Accessories Pvt. Ltd.: Hex Cable Accessories Pvt. Ltd. is a trusted supplier of cable glands, lugs, and other electrical accessories, offering a comprehensive range of products for various industries.

Braco Electricals India Pvt. Ltd.: Braco Electricals India Pvt. Ltd. specializes in the manufacturing of cable glands, cable ties, and cable accessories, providing solutions for industrial and commercial applications.

Technological Advancements and Market Trends:

Material Innovations: Manufacturers are exploring advanced materials such as stainless steel, brass, and aluminum alloys to enhance the durability and performance of cable glands in challenging environments.

IP Ratings Compliance: Emphasis on designing cable glands that meet international Ingress Protection (IP) ratings to ensure reliable protection against dust and moisture ingress.

Customization and Specialization: Offering customized cable gland solutions tailored to specific industry requirements and applications, providing flexibility and adaptability in cable management.

Automation and Robotics: Integration of automation and robotics in manufacturing processes to improve efficiency, precision, and consistency in producing cable glands of high quality.

Global Expansion: Indian cable gland manufacturers are increasingly expanding their presence in international markets, leveraging competitive pricing and quality offerings to cater to a global customer base.

Importance of Cable Glands in Connectivity and Safety:

Cable glands are integral components in electrical installations across various sectors, ensuring reliable connectivity, cable management, and safety. By providing secure cable entry points, strain relief, and environmental protection, cable glands play a critical role in maintaining the integrity and efficiency of electrical systems, thereby reducing the risk of electrical faults, downtime, and safety hazards.

In conclusion, the cable gland manufacturing in India continues to thrive, driven by technological advancements, quality standards, and a focus on innovation. With a diverse range of products, customized solutions, and a commitment to meeting industry requirements, Indian cable gland manufacturers contribute significantly to ensuring connectivity and safety in electrical and instrumentation systems both domestically and globally. As the demand for reliable cable management solutions grows, the role of cable glands in facilitating secure and efficient cable routing remains paramount in enhancing the performance and longevity of electrical installations.

0 notes

Text

Glands Market Size, Type, segmentation, growth and forecast 2023-2030

Cable Glands Market Scenario and Scope

Cable glands are crucial components used for sealing and securing the ends of electrical cables as they pass through enclosures, such as junction boxes. These devices are vital in various industries for ensuring cable protection and management, enhancing safety, and maintaining the integrity of electrical systems. The global Cable Glands Market was valued at USD 2.20 billion in 2022 and is projected to reach USD 3.80 billion by 2030, registering a CAGR of 8.20% during the forecast period. The market's growth is driven by the increasing demand for cable protection and management systems, particularly in industries such as oil and gas, telecommunications, and construction.

Get a Sample PDF of the Report: https://www.reportprime.com/enquiry/sample-report/368

Market Trends Influencing the Cable Glands Market

Rising Demand for Cable Protection Systems: The need for effective cable protection in industries such as oil and gas, telecommunications, and construction is a significant driver of the Cable Glands Market.

Growth in Industrial Development: Established infrastructure in North America and Europe makes these regions the largest markets for cable glands. However, the Asia Pacific region is expected to experience the highest growth rate, driven by rapid industrialization in developing countries like China and India.

Technological Advancements: Innovations in materials and design are leading to more durable and efficient cable glands, further boosting market demand.

Focus on Safety and Compliance: The market is also driven by stringent safety regulations and the need for compliance with international standards, particularly in hazardous environments.

Request a Free Sample PDF Brochure of Cable Glands Market: https://www.reportprime.com/enquiry/sample-report/368

Cable Glands Segment Analysis

Cable Glands Market, by Type:

Plastic and Polymer Glands

Metal Glands

Plastic and polymer glands are widely used in various applications due to their cost-effectiveness and resistance to corrosion. However, metal glands are preferred in environments requiring higher durability and strength, such as in the oil and gas industry.

Inquire or Share Your Questions If Any Before Purchasing This Report: https://www.reportprime.com/enquiry/pre-order/368

Cable Glands Market, by Application:

Oil and Gas

Mining

Construction

Railway

Chemical

Aerospace

Power and Energy

Others

The oil and gas industry is a significant segment within the Cable Glands Market, due to the need for secure and durable cable management solutions in challenging environments. The construction and telecommunications sectors also represent substantial market segments, driven by ongoing infrastructure projects and the expansion of communication networks.

Cable Glands Competitive Analysis

Amphenol

Emerson

ABB

TE Connectivity

Eaton

Hubbell Incorporated

Axis Communications

PFLITSCH GmbH

CMP Products

Lapp Group

Hummel AG

WISKA

Weidmüller Interface

BARTEC Group

R.Stahl AG

Warom Group

Bimed Teknik

El Sewedy Electric

CCG Cable Terminations

Beisit Electric Tech

Jacob GmbH

Cortem

Metal Craft Industries

Caledonian Cables

Sealcon

The competitive landscape of the Cable Glands Market is marked by the presence of key players such as Amphenol, Emerson, and ABB, who are focusing on expanding their product portfolios and investing in research and development to enhance product performance. The Asia Pacific region is a critical area of focus for these companies, due to the rapidly growing demand for cable management solutions in developing economies.

Regulatory and Legal Factors

Regulatory and legal factors play a vital role in the Cable Glands Market, especially concerning safety regulations and standards. Key regulations include:

ATEX Directive: This European directive lays down requirements for equipment and protective systems intended for use in potentially explosive atmospheres. Compliance with ATEX is essential for cable glands used in hazardous environments, such as oil and gas facilities.

IECEx Certification: This international certification ensures that electrical equipment, including cable glands, is safe for use in explosive atmospheres.

RoHS Compliance: The Restriction of Hazardous Substances (RoHS) directive restricts the use of specific hazardous materials in electrical and electronic products, impacting the materials used in cable glands.

ISO Certifications: Adherence to ISO standards ensures that cable glands meet global quality and safety requirements, which is crucial for market acceptance.

Ensuring compliance with these regulations is essential for companies operating in the Cable Glands Market to avoid legal challenges, enhance product safety, and maintain a competitive edge.

Buy now: https://www.reportprime.com/checkout?id=368&price=3590

0 notes

Text

Laminate Wood Flooring Market Size, Share, Growth, Trends [2032]

Laminate Wood Flooring Market provides in-depth analysis of the market state of Laminate Wood Flooring manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Laminate Wood Flooring in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Laminate Wood Flooring Market Report:

The report offers a comprehensive and broad perspective on the global Laminate Wood Flooring Market.

The market statistics represented in different Laminate Wood Flooring segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Laminate Wood Flooring are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Laminate Wood Flooring.

Major stakeholders, key companies Laminate Wood Flooring, investment feasibility and new market entrants study is offered.

Development scope of Laminate Wood Flooring in each market segment is covered in this report. The macro and micro-economic factors affecting the Laminate Wood Flooring Market

Advancement is elaborated in this report. The upstream and downstream components of Laminate Wood Flooring and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/laminate-wood-flooring-market-100005

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Global Hydrogenated Bisphenol A MarketMarket Size

Global Blood Clot Retrieval Devices MarketMarket Growth

Global Swimming Pool Treatment Chemicals MarketMarket Size

Global Membrane Pressure Vessel MarketMarket Growth

Global Defibrillator MarketMarket Size

Global Semiconductor Production Equipment MarketMarket Growth

Global Shale Gas Processing Equipment MarketMarket Size

Global Digital Experience Platform MarketMarket Growth

Global RFID Smart Cabinets MarketMarket Size

Global Desktop CNC Machines MarketMarket Growth

Global CMP Pad Regulator MarketMarket Size

Global Unmanned Surface Vessels (Usv) MarketMarket Growth

Global Fresh Avocado MarketMarket Size

Global Heat Pump Water Heater MarketMarket Growth

Global Motor For Robots MarketMarket Size

Global Personalized Hydration Solutions MarketMarket Growth

Global Silver Powders And Flakes MarketMarket Size

Global Depaneling Machine MarketMarket Growth

Global Pv Solar Energy Charge Controller MarketMarket Size

Global Fleece Knitting Yarn MarketMarket Growth

Global Super Capacitor MarketMarket Size

Global Bird Detection System MarketMarket Growth

Global Predictive Genetic Testing and Consumer Genomics MarketMarket Size

Global Recreation Management Software MarketMarket Growth

Global Analog Cheese MarketMarket Size

Global Artificial Intelligence Software MarketMarket Growth

Global EV Charging Cables MarketMarket Size

Global Remote Sensing Services MarketMarket Growth

Global Education Technology (EdTech) MarketMarket Size

Global Transcatheter Heart Valve Replacement and Repair MarketMarket Growth

Global Cervical Total Disc Replacement Device MarketMarket Size

Global Biomass Boiler MarketMarket Growth

Global Door Closers MarketMarket Size

Global Silicone Elastomers For Medical Applications MarketMarket Growth

Global Energy Recovery Ventilation System MarketMarket Size

Pegaspargase Drugs MarketMarket Analysis

0 notes

Text

0 notes

Text

Discounted Cables

Cat6 Plenum Ethernet Solid Copper Cable is an indispensable tool for data and media networking projects. This cable has a CMP rating. The Cat6 cable is specially designed to reduce crosstalk, is up to 550Mhz with 23 AWG, and is Fluke Tested and TIA compliant.

cat6e plenum

1 note

·

View note

Text

#etekcables#ethernetcables#usa#installation#voip phone#voipservices#structuredcabling#teledata#cat5ecables#cat6plenum

0 notes

Text

Cat6 Plenum Cables 1000ft CMP Rated in a Different Colors

BNCables also offers a diverse selection of Cat6 plenum cable in various colors. This allows you to not only meet your networking requirements but also add a touch of organization and simplicity to your cable management.

Read More: https://bncables.com/product/cat6-plenum-cables-1000ft/

0 notes

Text

CAT6A Plenum Pure Copper 750Mhz 1000ft UTP Bulk Ethernet Cable

Cat6 Ethernet cables is 8 conductors (4-Pairs) of solid bare copper with a high-density polyethylene (HDPE) insulation and a CMP rated Jacket (fire-resistant). Our Category 6A Un-Shielded CMP Rated Plenum Cable is designed for residential/commercial LAN applications and is resistant to fire and heat, making it the best solution for installation runs that require plenum rated.

Read More: https://atscables.com/cat6a-bulk-cables/cat6a-plenum-pure-copper-750mhz-1000ft-utp-bulk-ethernet-cable/

Cat6Cables #Cat6EthernetCables #Cat6Plenum #PureCables

0 notes

Text

Tired of Slow Internet? Try Our Premium Ethernet Cables

In today’s hyper-connected world, dealing with slow internet isn’t just annoying — it’s disruptive. Whether you’re working from home, streaming high-definition content, gaming online, or running a business network, your connection speed matters.

One of the most overlooked culprits behind sluggish internet is poor cabling. If you’re still relying on outdated or low-quality ethernet cables, you’re simply not getting the performance you should. The solution? Upgrading to high-quality bulk ethernet cables designed to support fast, stable, and interference-free data transmission.

Let’s explore how the right cable — Cat5e, Cat6, or Cat6a in riser or plenum variants — can completely change the game for your network.

What Makes a Good Ethernet Cable?

Before we dive into types, it’s important to understand what defines a good ethernet cable.

A premium ethernet cable must:

Support high-speed data transmission

Resist electromagnetic interference (EMI)

Be made with pure copper (not CCA)

Meet building codes (riser or plenum rated)

Deliver long-term reliability

If you're shopping for ethernet cables in bulk, these traits aren't optional — they're essential.

Understanding Ethernet Cable Categories

The most common ethernet cable categories today are Cat5e, Cat6, and Cat6a. Each is designed for different performance needs. Let’s break them down so you can choose what fits your setup.

Cat5e – Affordable and Reliable for Everyday Use

Cat5e (Category 5e) is the most budget-friendly option still widely used today. It supports:

Speeds up to 1 Gbps

Bandwidth up to 100 MHz

Up to 100 meters in distance

For basic networking — like web browsing, video calls, and light data transfer — Cat5e bulk ethernet cables get the job done. They're especially popular for residential installs and small offices.

Available in:

Cat5e Plenum Cable – Ideal for commercial spaces with air handling requirements

Cat5e Riser Cable – Perfect for vertical runs between floors in non-plenum environments

If you're looking to buy ethernet cables for basic networking, Cat5e is a solid, cost-effective choice.

Cat6 – The Sweet Spot of Speed and Affordability

Cat6 (Category 6) offers a major performance boost over Cat5e, without a huge price jump. It supports:

Speeds up to 10 Gbps (over short distances)

Bandwidth up to 250 MHz

Enhanced shielding against EMI

Cat6 ethernet cables are great for modern homes, startups, and mid-size offices handling more demanding traffic — think video conferencing, cloud computing, and HD streaming.

Available in:

Cat6 Plenum Cable – Fire-retardant and low-smoke; required in ceilings and HVAC spaces

Cat6 Riser Cable – Perfect for structured cabling between floors or through walls

If you're setting up a smart home, gaming setup, or small server room, Cat6 bulk ethernet cables deliver impressive value.

Cat6a – Built for High-Density, High-Speed Networks

Cat6a (Category 6 Augmented) is the heavy-duty performer in copper cabling. Designed for large networks and bandwidth-hungry applications, it supports:

10 Gbps up to 100 meters

Bandwidth up to 500 MHz

Superior shielding for interference-free performance

Cat6a ethernet cables are ideal for enterprise networks, hospitals, universities, data centers, and high-tech homes where future-proofing is a priority.

Available in:

Cat6a Plenum Cable – UL-listed, ETL-verified for use in air circulation areas

Cat6a Riser Cable – Strong, high-speed solution for vertical runs in buildings

If you're planning to buy ethernet cables in bulk for a growing or mission-critical network, Cat6a is the top-tier choice.

Riser vs Plenum: What’s the Difference?

If you’re browsing ethernet cables, you’ll often see “riser” and “plenum” types. Here’s the quick breakdown:

Riser Cables (CMR)

Used in walls, between floors, or vertical shafts

Flame-resistant but not rated for air handling spaces

Affordable for most building installations

Plenum Cables (CMP)

Designed for use in plenum spaces (like ceilings, ducts)

Built with low-smoke, flame-retardant jackets

Required by NFPA 70 (NEC) in many commercial settings

For safety and code compliance, always choose the right jacket type for your environment. Bulk ethernet cables are available in both riser and plenum variants across all categories — Cat5e, Cat6, and Cat6a.

Bulk Ethernet Cables: Why Buying in Bulk Is Better

When setting up a network — whether it’s a home office, smart building, or enterprise infrastructure — buying ethernet cables in bulk saves money and time.

Benefits of Buying Ethernet Cables in Bulk

Cost-Effective: Per-foot pricing is much lower than buying pre-cut cables

Custom Lengths: Cut only what you need, reducing waste and clutter

Clean Installations: Perfect for structured cabling setups

Better Performance: Use high-quality connectors and terminations to suit your exact needs

Whether you're an installer, IT manager, or homeowner, bulk cable gives you flexibility and professional results.

Why Cheap Ethernet Cables Can Cost You More

Not all ethernet cables are made equal. Some sellers cut corners by offering CCA (Copper-Clad Aluminum) cables instead of 100% pure copper.

Here’s why you should avoid CCA cables:

Higher electrical resistance = weaker signal

Increased risk of heat build-up and fire hazards

Not TIA/EIA or NEC compliant

Shorter lifespan and higher failure rate

For reliable data transmission and long-term safety, always choose UL-listed, ETL-verified, pure copper ethernet cables.

How to Choose the Right Cable for Your Network

Still not sure which cable is right for your setup? Our support team is here to help — we’ll guide you through it based on your space, devices, and budget.

Ready to Experience the Internet at Full Speed?

Upgrading your ethernet cables is one of the simplest, most effective ways to fix slow internet issues. It’s not just about speed — it’s about stability, security, and future-proofing your network.

At [Your Brand], we offer:

✅ Premium Cat5e, Cat6, and Cat6a cables

✅ Bulk ethernet cables for custom installations

✅ Both riser and plenum rated options

✅ Fast shipping and volume discounts

✅ Expert support

Don’t let outdated cabling hold you back. Buy ethernet cables today and experience the difference of high-quality network performance.

Still Tired of Slow Internet?

Make the smart switch to our premium ethernet cables — because your network deserves better.

Shop Now and elevate your speed, security, and signal quality — once and for all.

0 notes

Text

Top 5 Heavy-Duty Cable Cleats for Extreme Industrial Conditions

In industrial environments, the need for reliable cable management solutions is non-negotiable. Among the various options available, heavy-duty cable cleats stand out as indispensable components for ensuring electrical safety and maintaining the integrity of cable installations. To know about cable cleats for electrical safety is to understand their role in safeguarding critical systems, especially in extreme conditions. In this blog, we’ll explore the top 5 heavy-duty cable cleats for industrial applications, with a spotlight on products that have earned their reputation for reliability and durability.

What Are Heavy-Duty Cable Cleats?

Cable cleats are devices designed to secure and support cables, especially in high-voltage and high-temperature environments. Their primary function is to prevent cable displacement during electrical faults, mechanical vibrations, or environmental stress. In extreme industrial conditions, heavy-duty cable cleats ensure that electrical systems remain operational and safe.

If you’re looking to know about cable cleats for electrical safety, it’s essential to choose products that meet international standards like IEC 61914, which specifies performance requirements for cable cleats.

Why Heavy-Duty Cable Cleats Matter in Extreme Conditions

Extreme industrial conditions demand cable cleats that can withstand:

High mechanical stress: Sudden forces caused by electrical faults can displace cables without proper support.

Harsh environments: Exposure to extreme temperatures, chemicals, or moisture requires corrosion-resistant materials.

Electrical safety compliance: Cable cleats ensure that cables remain securely positioned, reducing the risk of accidents or system failures.

Top 5 Heavy-Duty Cable Cleats for Extreme Industrial Conditions

1. Ellis Patents Vulcan+ Cleats

The Ellis Patents Vulcan+ cleats are renowned for their robust construction and versatility. Designed for medium to high-voltage cables, these cleats are made from corrosion-resistant stainless steel and feature a low-profile design for compact installations.

Key Features:

High short-circuit ratings

UV and corrosion-resistant materials

Easy installation with pre-fitted liners

Why It’s a Top Pick:

The Vulcan+ cleats are ideal for industries like oil and gas, where reliability is paramount. Their compliance with IEC 61914 ensures electrical safety in critical applications.

2. Prysmian BICON® Cleats

Prysmian’s BICON® heavy-duty cleats are engineered for durability and precision. They are perfect for environments requiring robust short-circuit protection.

Key Features:

High-strength aluminium construction

Temperature resistance up to 120°C

Available in a range of sizes to suit different cable diameters

Why It’s a Top Pick:

The Prysmian BICON® cleats are widely used in utilities and infrastructure projects, making them a trusted choice for extreme industrial conditions.

3. CMP Products Heavy-Duty Cleats

CMP Products offers an extensive range of heavy-duty cable cleats designed for superior performance in harsh environments. Their innovative designs focus on both safety and ease of installation.

Key Features:

Short-circuit tested and certified

Materials include stainless steel and aluminum

Anti-corrosive coatings for enhanced longevity

Why It’s a Top Pick:

CMP’s cleats combine strength and versatility, making them suitable for applications in marine, mining, and petrochemical industries.

4. North American Sales Company Cable Cleats

As a leader in cable management solutions, North American Sales Company provides heavy-duty cleats tailored to North American standards. Their cleats are built to endure the toughest industrial challenges.

Key Features:

Exceptional mechanical strength

Resistant to UV, moisture, and chemicals

Designed for easy installation and maintenance

Why It’s a Top Pick:

North American Sales Company’s cleats are a reliable choice for industries across the continent, offering superior performance and compliance with regional standards. Their focus on customer-driven solutions makes them stand out.

5. Panduit Heavy-Duty Cleats

Panduit’s heavy-duty cable cleats are known for their innovative designs and high-performance materials. These cleats are ideal for large-scale industrial setups.

Key Features:

High short-circuit withstand capabilities

Flame-retardant and UV-stabilized materials

Easy to install with minimal tools required

Why It’s a Top Pick:

Panduit’s cleats provide unmatched reliability in high-voltage applications, making them a go-to solution for utility companies and manufacturing plants.

Factors to Consider When Choosing Heavy-Duty Cable Cleats

When selecting cable cleats for extreme industrial conditions, consider the following:

Material: Opt for corrosion-resistant materials like stainless steel or aluminum.

Compliance: Ensure the cleats meet standards such as IEC 61914 for performance and safety.

Application: Match the cleat design to your specific cable configuration and environmental conditions.

Ease of Installation: Choose cleats that are simple to install and maintain to save time and labor costs.

Final Thoughts

Heavy-duty cable cleats are an essential component in maintaining electrical safety and system integrity in extreme industrial conditions. Whether you’re working in oil and gas, utilities, or manufacturing, the right cable cleats can make all the difference. To know about cable cleats for electrical safety is to prioritize products that offer durability, compliance, and reliability.

From Ellis Patents to North American Sales Company, the cleats highlighted here represent the best in the industry. By investing in high-quality cable cleats, you’re not only protecting your infrastructure but also ensuring a safer working environment.

If you’re interested in learning more about heavy-duty cable cleats or need help choosing the right product, feel free to reach out to our experts today!

0 notes

Text

EMC Cable Glands Market Forecast: A CAGR of 6.50% Expected, Expanding from USD 2.61 Billion in 2024 to USD 4.32 Billion by 2032

The EMC (Electromagnetic Compatibility) cable glands market is experiencing steady growth, driven by the increasing need for effective shielding and grounding solutions to prevent electromagnetic interference (EMI) in various industrial and electronic applications. EMC cable glands are critical components used to provide secure cable entry while maintaining electromagnetic shielding, ensuring that electrical and electronic systems function properly without interference from external electromagnetic fields.

The EMC Cable Glands Market was valued at USD 2.45 billion in 2023. It is projected to grow from USD 2.61 billion in 2024 to USD 4.32 billion by 2032, reflecting a compound annual growth rate (CAGR) of 6.50% during the forecast period from 2024 to 2032.

As industries become more reliant on complex electronic systems, particularly in sectors such as telecommunications, automotive, aerospace, industrial automation, and energy, the demand for EMC cable glands is rising. These glands are designed to ensure the safe and efficient transmission of signals and power while protecting sensitive equipment from EMI, which can cause malfunctions, signal disruptions, or even damage to devices.

The growth of the EMC cable glands market is also influenced by the increasing adoption of automation and digitalization in industries like manufacturing, where EMI issues can disrupt automated systems and lead to costly downtime. Furthermore, the expansion of telecommunications infrastructure, including 5G networks, and the growing emphasis on renewable energy projects are fueling the demand for advanced EMC solutions to ensure signal integrity and system reliability.

Get Sample PDF EMC Cable Glands Market with Complete TOC, Tables & Figures @

EMC Cable Glands Market Companies Are:

Amphenol, Emerson, ABB, TE Connectivity, Jacob GmbH, Cortem, Eaton, Hubbell Incorporated, Axis Communications, PFLITSCH GmbH, CMP Products, Lapp Group, Hummel AG, WISKA, Weidmüller Interface, BARTEC Group, and others

With the rising implementation of stringent regulatory standards regarding EMC in various regions, industries are increasingly investing in EMC cable glands to comply with these regulations and avoid the potential for costly disruptions. Additionally, advancements in materials and design are contributing to the development of more efficient and durable EMC cable glands that meet the specific needs of different industries.

DROC (Drivers, Restraints, Opportunities, and Challenges) of the EMC Cable Glands Market:

Drivers:

Increasing Need for Electromagnetic Compatibility in Industrial Applications: As industries across the globe rely more on advanced electronics and communication systems, there is a growing need for EMC solutions to prevent electromagnetic interference that can disrupt sensitive equipment. EMC cable glands are essential for maintaining the functionality and safety of these systems.

Rising Demand from the Telecommunications and Data Center Sectors: The expansion of the telecommunications industry, especially with the rollout of 5G networks, has significantly increased the demand for EMC cable glands. These glands help protect critical infrastructure from EMI, ensuring uninterrupted data transmission and reliable network performance.

Growth in Automation and Industrial IoT: The proliferation of automation, robotics, and the Industrial Internet of Things (IIoT) in manufacturing and other industrial sectors is driving the demand for EMC cable glands. These environments often have numerous electronic devices operating in close proximity, making EMI protection crucial to avoid equipment malfunctions and signal disruptions.

Restraints:

High Cost of Advanced EMC Cable Glands: While EMC cable glands provide critical protection against EMI, their advanced design and materials can make them more expensive than standard cable glands. For small and medium-sized enterprises (SMEs), the high cost of EMC cable glands may act as a deterrent, limiting their adoption in cost-sensitive markets.

Complex Installation Process: Installing EMC cable glands requires specialized knowledge and skills to ensure proper grounding and shielding. Improper installation can compromise the effectiveness of the EMI protection, leading to system failures. This complexity may discourage some companies from adopting EMC cable glands or lead to increased installation costs.

Opportunities:

Expansion of Renewable Energy Projects: The increasing focus on renewable energy sources such as wind and solar power presents significant opportunities for the EMC cable glands market. In renewable energy installations, especially in harsh environments, EMC cable glands are necessary to protect sensitive electrical systems from EMI and ensure the reliable operation of power generation equipment.

Development of Smart Cities and Infrastructure: The growing trend of smart cities, which rely on interconnected systems for transportation, communication, and energy, is creating a demand for advanced EMC solutions. EMC cable glands are crucial in protecting the communication and control systems that enable the smooth operation of smart city infrastructure.

Challenges:

Intense Competition and Price Pressure: The EMC cable glands market is highly competitive, with many players offering a variety of products. This competition can lead to price pressure, which may reduce profit margins for manufacturers. Companies need to focus on differentiating their products through technological innovations and quality improvements to remain competitive.

Difficulty in Retrofitting Existing Systems: In some industries, retrofitting existing systems with EMC cable glands can be challenging, particularly in older installations that were not designed with EMC protection in mind. Upgrading these systems may require significant investments and complex modifications, posing a challenge for companies looking to enhance their EMI protection.

Browse Related Report:

About Market Research Future: At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), & Consulting Services. MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients.

Contact us: Market Research Future (part of Wantstats Research and Media Private Limited), 99 Hudson Street, 5Th Floor, New York, New York 10013 United States of America +1 628 258 0071 Email: [email protected] Website: https://www.marketresearchfuture.com

0 notes