#Cobots

Explore tagged Tumblr posts

Text

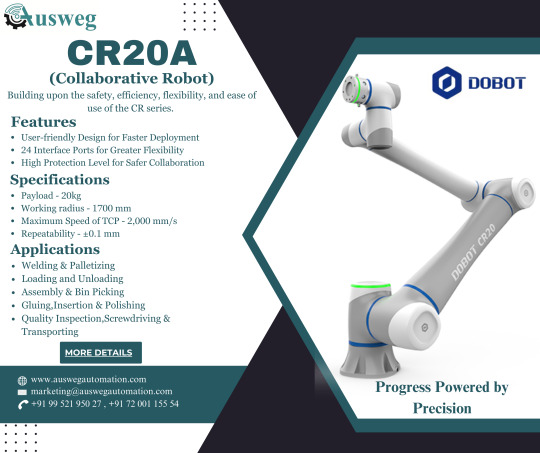

DOBOT CR20A Performance Unleashed With High Payload and Wide Radius

www.auswegautomation.com [email protected] +91 99 521 950 27, +91 72 001 155 54

#cobots#collabrativerobots#automation#industry40#robotics#manufacturing#ai#roboticstechno#digitaltransformation#innovation#techtrends#futureofwork#smartfactory#industrialautomation#productivity#workplacesafety#efficiency#humanrobotcollabration#roboticsindustry#advancedmanufacturing

2 notes

·

View notes

Text

#SmartManufacturing#IndustrialRobotics#Cobots#Automation#Industry40#ManufacturingInnovation#RoboticsFuture#Timestech#electronicsnews#technologynews

0 notes

Text

🤝 Collaborative Robot Market — Next-Gen Automation 🤝

The global #CollaborativeRobot market was valued at 💲979.6M in 2020 and is projected to grow from 💲1,358.2M in 2021 to a massive 💲16,387.3M by 2028 🚀, showing a robust CAGR of 42.7%! 📈 #AsiaPacific led with a 23.26% share in 2020.

Despite a dip to 38.1% growth in 2020 (vs. 2017–2019), cobots are booming thanks to rising automation, seamless human-robot collaboration, and high ROI for SMEs. 🤖✨ From manufacturing lines to precision tasks, cobots are redefining productivity and safety.

🌟 Latest Trends: ✅ Easy integration with existing systems ✅ AI-driven vision & smart sensors ✅ User-friendly programming for SMEs ✅ Growing role in electronics, automotive & healthcare

🔮 Future Outlook: ➡️ More affordable solutions for small businesses ➡️ Enhanced safety standards for human-robot teams ➡️ Increased adoption in emerging economies ➡️ Strong push for Industry 4.0 transformation

Cobots are the future of smart, flexible, and efficient production! ⚙️🤝

🔗 https://www.fortunebusinessinsights.com/industry-reports/collaborative-robots-market-101692

0 notes

Text

Robotics & Patents: India’s Rise and Global Trends

From precision-driven manufacturing to life-saving medical treatments, the robotics industry is transforming various sectors. AI-powered systems, collaborative robots (cobots), and autonomous drones are now essential tools that enhance productivity and creativity. Protecting intellectual property (IP) through patents is vital for innovators to safeguard their work and maintain a competitive edge as robotics continues to evolve.

#Robotics#einfolge#Patents#Robotics patents#Robotics innovation#AI-powered robots#cobots#Artificial Intelligence in robotics#Global robotics market trends

0 notes

Text

Düsseldorf, 10. Juni 2025 – Epson, ein führender Anbieter von Roboter- und Automatisierungstechnik, stellt auf der automatica 2025 seine erste kollaborative Industrieroboterlösung vor. Diese ermöglicht in Branchen wie Fertigung, Logistik und dem sich schnell entwickelnden Life-Science-Sektor eine wirkungsvolle Interaktion zwischen Mensch und Maschine und steigert so die Effizienz und Produktivität. Die Lösung wird ab Herbst 2025 als erstes kollaboratives Roboter-Komplettpaket von Epson angeboten, welches den neuen, aus Carbon-Leichtbau bestehenden 6-Achs-Roboter AX6-A901S sowie die kompakte Epson RC-A101-Steuerung inklusive dem Programmiersystem AX-Portal umfasst. „In den stark wachsenden Bereichen Biowissenschaften und pharmazeutische Industrie sind präzise Arbeitsabläufe und ein strenges Hygienemanagement von größter Bedeutung“, erklärt Volker Spanier, Head of Manufacturing Solutions von Epson. „Um auch diese Anforderungen zu erfüllen, ist der neue kollaborative Roboter von Epson reinraumtauglich. Dank seiner präzisen Bewegungen erlaubt die Maschine daher auch in Laboren und pharmazeutischen Einrichtungen die Verrichtung selbst komplizierter Aufgaben.“ Wichtige Produktmerkmale des kollaborativen Roboters AX6-A901S von Epson: Ausbalanciertes Design: Der AX6-A901S bewegt eine Nutzlast von bis zu 6 kg bei einer Armlänge von 900 mm. Er besitzt ein besonders leichtes und kompaktes Design, sodass sowohl sein Transport als auch seine Integration in bestehende Produktionslinien sehr einfach sind. Dank der kompakten Abmessungen lässt er sich auch in beengten Umgebungen einsetzen. Kompakter und leichter Controller: Der Epson RC-A101-Controller ist für die Installation auf fahrerlosen Transportfahrzeugen (AGVs) und autonomen, mobilen Robotern (AMRs) geeignet. Er hat die Abmessungen B 440 x T 205 x H 135 mm und wiegt weniger als 6 kg. Auch dieses kompakte Design ermöglicht eine sehr platzsparende Installation. Kompatibel zu verschiedenen Stromquellen: Der kollaborative Roboter ist mit Stromquellen von 100 bis 230 VAC bzw. 48 VDC kompatibel, sodass er in Umgebungen mit verschiedenen Stromquellen installiert werden kann. Reinraumkompatibilität: Der AX6-A901S besitzt die Reinraumklasse 5 nach ISO 14644-1 und die Schutzart IP54. Das glatte Gehäusedesign ohne Schraubenlöcher und scharfe Kanten minimiert die Staubansammlung und damit das Kontaminationsrisiko in Reinraumumgebungen. Python-Programmierung: Die Programmierumgebung unterstützt die weit verbreitete Programmiersprache Python. Diese Kompatibilität vereinfacht die Integration in alle F&E-Umgebungen und die Inbetriebnahme. Auch wird so das Erlernen einer neuen Programmiersprache unnötig. Spanier fasst zusammen: „Epsons Engagement für die Weiterentwicklung der Robotik resultiert in diesem kollaborativen Roboter, der auch sehr komplexe Aufgaben sicher ausführt. Damit erfüllen wir die wachsende Nachfrage der Labor- und Pharmaindustrie und weiteren Branchen. Diese Maschine stellt einen bedeutenden Fortschritt auf dem Weg zur Verbesserung des Epson Angebotes im Bereich der industriellen Automatisierung dar. Unsere Roboter erfüllen dabei auch die strikten Anforderungen des Life-Science-Sektors und gewährleisten Sicherheit und Präzision bei jeder Interaktion zwischen Mensch und Maschine.“ Zu den neuen Robotern gibt es am 24. Juni eine Pressekonferenz am Epson Stand 311 in Halle B5 Weitere Informationen zu den Robotiklösungen von Epson: automatica 2025 | Epson Europe

#Cobots#Development#Events#General#German#Hardware#IndustrialRobots#2025#6AchsRoboter#automatica#AXPortal#AX6A901S#Cobot#Düsseldorf#Epson#kollaborativesRoboterKomplettpaket#RCA101#Reinraum#Roboter#Roboterarm

0 notes

Text

Robótica avanzada: los asistentes del futuro ya están aquí

Santo Domingo. – La imagen de un robot torpe y metálico de las películas de ciencia ficción ha quedado en el pasado. Hoy, la robótica avanzada es una realidad que está transformando nuestras vidas. Esto ocurre de formas que apenas comenzamos a entender. Más que simples máquinas, los nuevos robots son asistentes inteligentes que colaboran con nosotros en el trabajo, en el hogar y hasta en las…

0 notes

Text

Explorando el Universo de la Robótica y la Automatización: Líderes y Tecnologías Clave

¿Qué es la Robótica y la Automatización y Para Qué Sirven? La robótica y la automatización son dos conceptos tecnológicos estrechamente relacionados que están transformando radicalmente industrias enteras y, cada vez más, aspectos de nuestra vida cotidiana. Aunque a menudo se usan indistintamente, tienen matices distintos: Robótica: Se centra específicamente en el diseño, construcción, operación…

#ABB Robotics#automatización#Automatización Industrial#Boston Dynamics#Cobots#Denso Robotics#Fabricación Avanzada#Fanuc Robotics#Festo#Industria 4.0#inteligencia artificial#KUKA Robotics#Logística Automatizada#Mitsubishi Electric Automation#Omron Adept Technologies#robótica#Robotiq#Robots Colaborativos#Robots Industriales#Robots Móviles#Rockwell Automation#Siemens Digital Industries#SoftBank Robotics#Staubli Robotics#tecnología#Universal Robots#Yaskawa Motoman

0 notes

Text

#Industry40#SmartManufacturing#AI#Automation#Robotics#SupplyChain#DigitalTransformation#FutureOfWork#Innovation#TechRevolution#IoT#Sustainability#Logistics#Cobots#AMRs

0 notes

Text

How can AI unlock human potential in the supply chain?

New Post has been published on https://thedigitalinsider.com/how-can-ai-unlock-human-potential-in-the-supply-chain/

How can AI unlock human potential in the supply chain?

AI is driving a new revolution across a number of industries and the supply chain is no exception. AI has been the most transformative technology of the decade, and it’s no secret it has helped supply chains become more efficient, resilient, and responsive, while allowing organisations to become more efficient and ensuring workforces to focus on more strategic growth.

However despite the benefits of the technology, many businesses are slow to adopt the technology, with recent statistics showing only one in ten of SME’s regularly use AI technology, indicating companies and employees are still not operating at their full potential, thus missing out on opportunities for growth and optimisation.

Transforming the supply chain through AI

The potential that AI has in the supply chain is undeniable, with some estimating that AI helps businesses reduce logistics costs by 15%, reduce inventory levels by 35% and raise service levels by 65%. In contrast, failure to implement AI tools could set companies back, leave employees feeling unmotivated and unproductive and result in a weak supply chain and poor staff retention.

Now, more than ever, it’s time for businesses to not just pay lip service to AI – they must start using it within their supply chains to truly enhance operations. Due to the evolving market dynamics, AI is not just a competitive advantage; it’s essential for business agility and profitability. Here are two ways in which organisations can use AI to improve their supply chains.

Automating the supply chain & harnessing the power of AI for resilience

AI allows businesses to tackle supply chain challenges head-on by automating time-consuming manual processes, such as data-logging whilst reducing errors. By taking over repetitive and potentially hazardous tasks, AI frees up employees to focus on strategic initiatives that drive business value. For example, a recent report highlighted that nearly three quarters of warehouse staff surveyed are excited about the possibilities of generative AI and robotics improving their job roles.

Needless to say, a supply chain still can’t operate at its peak without resilience – which is the capacity of a supply chain to withstand and recover from disruptions – ensuring uninterrupted operations and minimal impact to businesses and customers.

As global markets continue to evolve & expand, businesses are challenged to adapt swiftly to unforeseen disruptions. AI enables businesses to provide real time data analysis, providing unprecedented insights into the web of supply chain dynamics and acting as the eyes and ears of a supply chain. This empowers each component with the ability to make informed decisions quickly to meet supply chain demands. Allowing insights into every aspect of their warehouse operations, real time data enables visibility which permits precise monitoring, enhanced customer service and reduced downtime – identifying potential issues before they become a major problem.

At the heart of the supply chain is communication between all stakeholders, with technology such as AI providing real time data, seamless collaboration is enabled by providing a shared platform where suppliers, manufacturers, and distributors can exchange information instantaneously. Enhanced communication leads to quicker issue resolution, enabling the supply chain to adapt rapidly to changing circumstances. Robotics, AI and real-time data introduce an all-encompassing visibility of the good’s journey, which leads to resilience.

Human expertise with robot precision

Building on the theme of resilience, in the next couple of years the industry will witness AI-integrated robots becoming collaborative partners to their human co-workers. Particularly in environments requiring vast coverage and extensive data capture, robots that are equipped with groundbreaking sensor technologies will navigate, adapt and work with greater levels of autonomy along with other machinery and people in busy environments. This will result in speed of data acquisition and most importantly, allowing companies to make decisions based on actionable insights a lot faster than ever before.

These advancements will transform robots into true cobots and will take human-robot teamwork to an unprecedented level. We will also see that robots will become better with understanding nuanced human gestures and intentions. This evolution in collaboration with technology will redefine what humans and machines can accomplish together.

What’s next for the industry?

In theory implementing AI and advanced technology in the supply chain has the potential to bring significant benefits. However, we will only begin to see substantial results once these innovations are widely adopted in practice. By automating the supply chain and using data to fuel predictions, these technologies are the foundations for a new industrial revolution that will shape the future of the industries for years to come. Those that delay starting their journeys will risk being left behind.

Photo by Miltiadis Fragkidis on Unsplash

Want to learn more about AI and big data from industry leaders? Check out AI & Big Data Expo taking place in Amsterdam, California, and London. The comprehensive event is co-located with other leading events including Intelligent Automation Conference, BlockX, Digital Transformation Week, and Cyber Security & Cloud Expo.

Explore other upcoming enterprise technology events and webinars powered by TechForge here.

#acquisition#ai#ai & big data expo#AI technology#ai tools#amp#Analysis#Artificial Intelligence#automation#Big Data#Building#Business#california#Capture#Cloud#Cobots#Collaboration#collaborative#communication#Companies#comprehensive#conference#customer service#cyber#cyber security#data#data analysis#Data Capture#Delay#Digital Transformation

1 note

·

View note

Text

#Collaborative Robots Market#Collaborative Robots#Cobots#Robotics & Automation#Semiconductor and Electronics#Industrial Robots

0 notes

Text

The Revolution of Collaborative Robotics: Humans and Machines Working Together

Industrial automation has evolved rapidly in recent decades, and one of the most groundbreaking innovations is collaborative robotics. Known as "cobots," these robots are designed to work alongside humans safely and efficiently, transforming various industries.

What is Collaborative Robotics?

Unlike traditional industrial robots, which operate in enclosed spaces for safety reasons, cobots can share the same workspace with humans. Thanks to advanced sensors and vision technology, they can detect human presence and adjust their behavior in real-time, stopping if necessary to prevent accidents.

Another key advantage is their flexibility. Cobots are smaller, lighter, and easier to program than traditional robots. Workers can teach them new tasks simply by guiding them manually, reducing the need for complex programming.

Applications of Collaborative Robotics

Cobots are making a significant impact across various industries:

Manufacturing: Assisting in assembly, quality control, and material handling, increasing productivity without entirely replacing human workers.

Logistics: Streamlining packaging and shipping processes, reducing wait times, and improving supply chain efficiency.

Healthcare: Used in surgeries to enhance precision and reduce human error.

Agriculture: Optimizing tasks such as planting and harvesting, decreasing reliance on manual labor.

Collaborative Robotics in Technological Development

In technological development, cobots play a key role in creating new automated solutions. Their ease of programming allows developers and tech companies to integrate artificial intelligence and machine learning, enhancing their performance and adaptability in dynamic environments.

Additionally, cobots are driving Industry 4.0 forward by connecting with IoT (Internet of Things) systems and cloud platforms to collect real-time data, optimize processes, and predict failures before they occur.

The Future of Work with Cobots

Rather than replacing humans, cobots are redefining how we collaborate with machines. Their ability to integrate safely into workplaces and their ease of programming make them a crucial tool for industrial innovation and efficiency.

Collaborative robotics is paving the way for a more human-centered automation era, where technology complements and enhances human skills instead of replacing them.

Learn more about collaborative robotics: Discovering Collaborative Robotics: The Fusion of Humans and Machines.

1 note

·

View note

Text

Future of Collaborative Robots: Automation and AI Integration

The global collaborative robot market size is anticipated to reach USD 11.64 billion by 2030, exhibiting a CAGR of 31.6% over the forecast period, according to a new report published by Grand View Research, Inc. The growth can be credited to the growing inclination of industries toward collaborative robots or cobots to automate manufacturing processes.

Over the past few years, the growing interest in robot technology across various industries has positively impacted the collaborative robots industry. Unlike conventional industrial robots, cobots are developed to operate at par with their human counterparts. They are mobile and can be easily moved from one area of a manufacturing facility to another. Moreover, they can be programmed with ease, are more cost-effective than their fixed counterparts, and can be used in a wide range of low-speed, repetitive applications.

Collaborative Robot Market Report Highlights

By payload capacity, the up to 5kg segment accounted for the largest market share of over 43% in 2024. The growth is attributable to the increasing demand for enhanced in-building wireless connectivity catalyzed by the burgeoning number of smartphone users and data-intensive applications.

The assembly segment accounted for the largest market share in 2024, driven by the increasing adoption of collaborative robots (cobots) for tasks such as nut driving, bolting, and part fitting.

The automotive segment dominated the market in 2024, owing to its extensive adoption of automation technologies. Collaborative robots are particularly valuable in this sector for tasks such as assembly, welding, and painting, where they enhance productivity and ensure precision.

The European collaborative robots is expected to grow at the significant CAGR of over 30% from 2025 to 2030, driven by government initiatives promoting industrial automation and sustainability.

For More Details or Sample Copy please visit link @: Collaborative Robots Market Report

The increasing need for highly efficient and user-friendly robots that do not require highly skilled experts for deployment and functioning has created a significant demand for software platforms. These platforms allow the integration of robots, motion control, and the generation of an interface that enables the programming of such robots. For instance, Mitsubishi Electric Corporation has launched a cobot named MELFA ASSISTA equipped with RT VisualBox, the company’s engineering software. This software allows the intuitive creation of operating sequences by connecting block diagrams in a chain of events, including linking with other devices, such as cameras and the hands of the robot.

The increasing demand from industrial customers, researchers, and engineers further strengthens the outlook of the collaborative robots industry. These robots are being deployed across various industries and have been highly influential in addressing the challenges faced by the logistics sector, such as complex work processes, and managing several tasks in different combinations and compact spaces.

List of Key Players in Collaborative Robot Market

ABB Group

DENSO Corporation

Epson America Inc.

AUBO (BEIJING) ROBOTICS TECHNOLOGY CO., LTD

Comau S.p.A.

Energid Technologies Corporation

Fanuc Corporation

KUKA AG

Rethink Robotics GmbH

Robert Bosch GmbH

We have segmented the global collaborative robot market report based on payload capacity, application, industry vertical, and region

#CollaborativeRobots#Cobots#RoboticsMarket#Automation#IndustrialRobots#SmartManufacturing#AIinRobotics#CobotsIndustry#RobotAutomation#Industry40#ManufacturingTrends#RobotTechnology#FutureOfWork#IoTRobotics#GlobalMarket

0 notes

Text

🤖🌐 Service Robotics Market: Size, Regional Trends & Future Growth

✅ The global service robotics market was valued at USD 22.40 billion in 2024 and is projected to grow from USD 26.35 billion in 2025 to USD 90.09 billion by 2032, showcasing a robust CAGR of 19.2% during the forecast period.

🌏 Asia Pacific continues to lead, holding a dominant 36.6% market share in 2024. Rapid urbanization, aging populations, and a strong focus on smart automation are fueling growth across this region.

🇺🇸 The U.S. market is also set for significant expansion, projected to reach USD 16.27 billion by 2032. This surge is driven by the widespread adoption of IoT in robotics, enabling predictive maintenance and cost efficiencies that boost overall operational performance.

🔍 Key Trends:

🤝 Collaborative robots (cobots) gaining popularity in healthcare, logistics & domestic applications

📡 Integration of AI and IoT for smarter, self-learning robots

🌱 Increased demand for service robots that support sustainability and labor shortages

🚀 As industries, homes, and cities get smarter, service robotics will transform how tasks are performed — from healthcare and retail to smart homes and industrial facilities.

👉 Read the Full Market Report & Insights: https://www.fortunebusinessinsights.com/industry-reports/service-robotics-market-101805

#ServiceRobotics#Robots#SmartAutomation#IoT#Cobots#RoboticsMarket#MarketGrowth#AsiaPacific#USMarket#FutureTrends#CAGR

0 notes

Text

EMO Hanover 2025: A Global Hub for Innovation in Metalworking and Production Technology

South Korea to Showcase Cutting-Edge Technology at EMO Hanover 2025 EMO Hanover 2025 – World’s leading trade fair for production technology offers innovations, discussions and networking for South Korean production experts (image. EMO) The world’s premier trade fair for production technology, EMO Hanover 2025, is set to take place under the theme Innovate Manufacturing. This global event,…

View On WordPress

0 notes

Text

Düsseldorf, 10. Juni 2025 – Epson, ein führender Anbieter von Roboter- und Automatisierungstechnik, stellt auf der automatica 2025 seine erste kollaborative Industrieroboterlösung vor. Diese ermöglicht in Branchen wie Fertigung, Logistik und dem sich schnell entwickelnden Life-Science-Sektor eine wirkungsvolle Interaktion zwischen Mensch und Maschine und steigert so die Effizienz und Produktivität. Die Lösung wird ab Herbst 2025 als erstes kollaboratives Roboter-Komplettpaket von Epson angeboten, welches den neuen, aus Carbon-Leichtbau bestehenden 6-Achs-Roboter AX6-A901S sowie die kompakte Epson RC-A101-Steuerung inklusive dem Programmiersystem AX-Portal umfasst. „In den stark wachsenden Bereichen Biowissenschaften und pharmazeutische Industrie sind präzise Arbeitsabläufe und ein strenges Hygienemanagement von größter Bedeutung“, erklärt Volker Spanier, Head of Manufacturing Solutions von Epson. „Um auch diese Anforderungen zu erfüllen, ist der neue kollaborative Roboter von Epson reinraumtauglich. Dank seiner präzisen Bewegungen erlaubt die Maschine daher auch in Laboren und pharmazeutischen Einrichtungen die Verrichtung selbst komplizierter Aufgaben.“ Wichtige Produktmerkmale des kollaborativen Roboters AX6-A901S von Epson: Ausbalanciertes Design: Der AX6-A901S bewegt eine Nutzlast von bis zu 6 kg bei einer Armlänge von 900 mm. Er besitzt ein besonders leichtes und kompaktes Design, sodass sowohl sein Transport als auch seine Integration in bestehende Produktionslinien sehr einfach sind. Dank der kompakten Abmessungen lässt er sich auch in beengten Umgebungen einsetzen. Kompakter und leichter Controller: Der Epson RC-A101-Controller ist für die Installation auf fahrerlosen Transportfahrzeugen (AGVs) und autonomen, mobilen Robotern (AMRs) geeignet. Er hat die Abmessungen B 440 x T 205 x H 135 mm und wiegt weniger als 6 kg. Auch dieses kompakte Design ermöglicht eine sehr platzsparende Installation. Kompatibel zu verschiedenen Stromquellen: Der kollaborative Roboter ist mit Stromquellen von 100 bis 230 VAC bzw. 48 VDC kompatibel, sodass er in Umgebungen mit verschiedenen Stromquellen installiert werden kann. Reinraumkompatibilität: Der AX6-A901S besitzt die Reinraumklasse 5 nach ISO 14644-1 und die Schutzart IP54. Das glatte Gehäusedesign ohne Schraubenlöcher und scharfe Kanten minimiert die Staubansammlung und damit das Kontaminationsrisiko in Reinraumumgebungen. Python-Programmierung: Die Programmierumgebung unterstützt die weit verbreitete Programmiersprache Python. Diese Kompatibilität vereinfacht die Integration in alle F&E-Umgebungen und die Inbetriebnahme. Auch wird so das Erlernen einer neuen Programmiersprache unnötig. Spanier fasst zusammen: „Epsons Engagement für die Weiterentwicklung der Robotik resultiert in diesem kollaborativen Roboter, der auch sehr komplexe Aufgaben sicher ausführt. Damit erfüllen wir die wachsende Nachfrage der Labor- und Pharmaindustrie und weiteren Branchen. Diese Maschine stellt einen bedeutenden Fortschritt auf dem Weg zur Verbesserung des Epson Angebotes im Bereich der industriellen Automatisierung dar. Unsere Roboter erfüllen dabei auch die strikten Anforderungen des Life-Science-Sektors und gewährleisten Sicherheit und Präzision bei jeder Interaktion zwischen Mensch und Maschine.“ Zu den neuen Robotern gibt es am 24. Juni eine Pressekonferenz am Epson Stand 311 in Halle B5 Weitere Informationen zu den Robotiklösungen von Epson: automatica 2025 | Epson Europe

#Cobots#Development#Events#General#German#Hardware#IndustrialRobots#2025#6AchsRoboter#automatica#AXPortal#AX6A901S#Cobot#Düsseldorf#Epson#kollaborativesRoboterKomplettpaket#RCA101#Reinraum#Roboter#Roboterarm

0 notes