#ConstructionEngineering

Explore tagged Tumblr posts

Text

Ever wondered how raw steel is transformed into the sturdy frameworks that support our buildings and infrastructure? This visual carousel walks you through the entire structural steel fabrication process—from early ideation and shop drawings to precision cutting, welding, finishing, and final delivery.

Whether you're an AEC professional, fabricator, or project stakeholder, this guide offers valuable insights into:

✅ Planning & shop drawings

✅ Cutting, drilling, bending & welding

✅ Surface finishing

✅ Assembly & delivery

📊 Clear. Visual. Practical.

Swipe through the carousel for a quick breakdown, and explore the full blog here.

#StructuralSteel#SteelFabrication#ConstructionEngineering#FabricationWorkflow#SteelStructures#AECIndustry#TeslaCAD#ManufacturingDesign#CADtoFabrication#BIM#AEC#DigitalConstruction#Revit#BIMCoordination#ConstructionTech

0 notes

Text

🚧 Accurate Precast Panel Detailing = Cost Savings! 🏗️💰 Precise drawings ensure panels are made right, materials are used efficiently, and installation is smooth. ✅🔧

Partner with experts like Offshore Outsourcing India for top-quality Precast Panel Detailing Services & CAD support. 🖥️✨

#PrecastPanelDetailing#PrecastPanelDetailingEngineering#PrecastShopDrawings#PrecastPanelShopDrawings#PrecastConcretePanelDetailing#StructuralDesign#BuildingDesign#ConstructionEngineering#ConcretePanels#PrecastManufacturing#StructuralDetailing#ConstructionDrawings#BIM#PrecastConcreteDetailing

0 notes

Text

Which Are the Top 10 Companies Leading Structural Design Innovation Worldwide?

The structural design sector plays a foundational role in creating safe, efficient, and enduring buildings and infrastructure. As the demand for smart and sustainable construction rises across Europe and the UK, companies that offer advanced Structural BIM services UK, Rebar detailing and modeling UK, and Structural design support Europe are leading the industry transformation.

Here are the Top 10 Companies in Structural Design Services, known for their engineering precision, BIM integration, and client-focused solutions:

Vee Technologies – A top-tier global provider of Structural BIM services. With a strong presence in the UK and Europe, Vee Technologies delivers detailed rebar modeling and detailing and end-to-end structural design support Europe. Their use of advanced BIM platforms enhances design accuracy, coordination, and project timelines.

Arup – Arup is Known for iconic structures and sustainable, high-performance designs across continents.

WSP Global – WPS Global Offers specialized structural engineering services with integrated digital solutions.

AECOM – AECOM Delivers structural analysis and design for complex infrastructure projects globally.

Thornton Tomasetti – Experts in performance-based design and structural innovation.

Ramboll – A leading European firm offering multi-disciplinary structural design support.

Buro Happold – Buro Happold Combines creative design with structural engineering for global projects.

HDR Inc. – Supports structural planning for healthcare, commercial, and public facilities.

Jacobs – Integrates structural design with BIM and smart engineering workflows.

Stantec – Offers structural engineering and BIM services focused on resilience and sustainability.

These firms contribute significantly to high-performance building projects, incorporating tools like Revit and Tekla for modeling, analysis, and detailing. From delivering Structural BIM services UK to managing Rebar detailing and modeling UK and executing broad-scale structural design support in Europe, they are setting benchmarks in quality and innovation.

Conclusion: Structural design is at the heart of safe and resilient development. The companies listed above lead the field with their technological expertise, BIM-enabled collaboration, and global project success. Their work not only shapes skylines but also builds the backbone of tomorrow’s infrastructure with precision, sustainability, and strength.

#StructuralEngineering#EngineeringServices#CivilEngineering#StructuralDesign#StructuralAnalysis#BuildingStructures#ConstructionEngineering#InfrastructureDesign

0 notes

Text

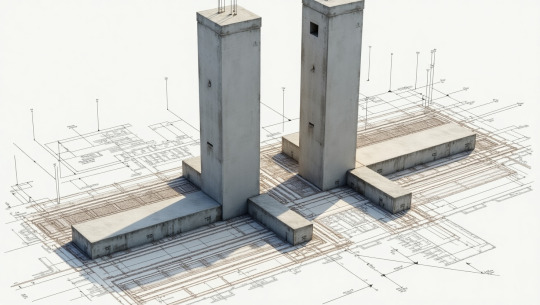

What Is a Cantilever Footing and When Should You Use It?

When building a house or any structure, the foundation is crucial—it’s what keeps everything stable and secure. But what happens when you have limited space, uneven loads, or tricky property lines? That’s where specialized footings, like a cantilever footing, come into play.

In this guide, we’ll break down what a cantilever footing is, how it works, and when it’s the best choice for your construction project. Whether you're a homeowner planning an extension, a student learning about foundations, or a junior engineer exploring design options, this post will give you a clear understanding.

What Is a Cantilever Footing?

A cantilever footing (also called a strap footing) is a type of foundation used when two columns are close to each other but can’t share a single footing due to space constraints or load differences. Instead of a traditional combined footing, this design uses a reinforced concrete "strap" or beam to connect two separate footings, allowing one side to extend (or cantilever) beyond its support.

Key Features of a Cantilever Footing:

Two individual footings connected by a beam.

One footing supports a heavier load, while the other balances it.

Ideal when columns are near property lines or existing structures.

Think of it like a seesaw—if one side is heavier, the other side needs a counterbalance. A cantilever footing works similarly, ensuring stability even when loads aren’t evenly distributed.

How Does a Cantilever Footing Work?

To understand how this footing functions, let’s break it down:

Uneven Load Distribution – If one column carries more weight (e.g., a structural beam or wall), its footing will be larger. The adjacent column’s footing is smaller but connected via a strap beam.

The Strap Beam’s Role – This reinforced concrete beam transfers part of the load from the heavier column to the lighter one, balancing the forces.

Prevents Tilting or Settlement – Without this connection, the heavier column could sink, causing cracks or structural failure.

Practical Example:

Imagine you’re building a house extension close to your neighbor’s property. You can’t place a wide footing on their side, so instead, you:

Install a larger footing on your side (where you have space).

Connect it to a smaller footing near the boundary with a strong strap beam.

This way, the load is safely distributed without encroaching on the neighbor’s land.

When Should You Use a Cantilever Footing?

Not every project needs this type of foundation, but here are common scenarios where it’s the best solution:

1. Limited Space Near Property Lines

If a column must be placed right next to a boundary (like a fence or adjacent building), a cantilever footing allows you to extend support inward rather than outward.

2. Adjacent Existing Structures

When expanding a building, you might need to add columns close to old foundations. A cantilever footing prevents interference with the existing structure.

3. Uneven Column Loads

If one column supports more weight (e.g., a load-bearing wall), a cantilever footing ensures the load is safely shared with a neighboring column.

4. Poor Soil Conditions

In areas with weak soil, spreading the load across two footings reduces the risk of sinking.

For a deeper dive into design specifics, check out this detailed guide on cantilever footing.

Cantilever Footing vs. Other Foundation Types

How does this compare to other footings? Here’s a quick breakdown:Foundation TypeBest ForKey DifferenceCantilever FootingUneven loads, tight spacesUses a strap beam to balance two footingsCombined FootingTwo close columns with similar loadsSingle, wider footing under both columnsIsolated FootingSingle columns with even soilStandalone footing per column

A strap footing is similar but often refers to a more rigid connection between footings.

Benefits and Limitations of Cantilever Footings

Advantages:

✔ Saves Space – Ideal for tight or restricted construction sites. ✔ Balances Uneven Loads – Prevents one column from sinking. ✔ Cost-Effective – Requires less excavation than deep foundations.

Limitations:

✖ Complex Design – Requires precise engineering to avoid failure. ✖ Not for Heavy Loads – Better suited for medium-weight structures. ✖ Reinforcement Needed – The strap beam must be strong enough to handle stress.

Design Considerations for Cantilever Footings

If you’re considering this footing type, keep these factors in mind:

Soil Bearing Capacity – Weak soil may need deeper footings or additional support.

Reinforcement – The strap beam must have steel rebars to resist bending forces.

Column Spacing – Too far apart, and the beam may bend; too close, and a combined footing may work better.

Professional Engineering Required – Always consult a structural engineer to ensure safety.

Final Thoughts

A cantilever footing is a smart solution when dealing with tricky construction scenarios—like tight spaces, uneven loads, or property line restrictions. By using a strap beam to link two footings, it ensures stability without compromising on space or safety.

However, proper design is crucial. If you’re planning a project that might need this foundation type, always consult an expert to ensure your structure stands strong for years to come.

#StructuralEngineering#FoundationDesign#ConstructionEngineering#CivilEngineering#BuildingDesign#StructuralDesign#EngineeringBasics#FootingDesign#ConcreteStructures#EngineeringDrawings

1 note

·

View note

Text

Construction engineers who possess both technical and project management skills and wish to migrate have excellent career opportunities in Australia. The demand for construction engineers is high because of the infrastructure development in both public and private sectors, increasing population demand, and growth of transportation systems.

Learn more about construction engineering in Australia.

Contact us for your migration success!

🔗: https://cdraustraliawriter.com/

#cdraustraliawriter#cdr report#skilledmigration#careergrowth#engineersaustralia#constructionengineering#constructionengineer#engineering

0 notes

Text

How to Become an Expert in Structural Steel Design and Detailing with the Right Training?

Enhance your skills in steel design and drafting with professional training. Conserve Academy offers industry-focused structural steel detailing courses in Chennai, providing hands-on experience in fabrication techniques and real-world projects. Enroll now to boost your career in structural engineering!

#structuralsteeldetailing#steeldesigntraining#steeldetailingcourse#civilengineeringtraining#structuralengineeringcourse#steeldetailingtraining#constructionengineering#structuralsteeldetailingcoursesinchennai#engineeringcertification#conserveacademy

0 notes

Text

🏗️ Silicon Outsourcing: Your Structural CAD Drawing Experts! 📐✨

Outsourcing Structural CAD Drawing Services ensures precise 2D & 3D drawings for seamless construction, reducing errors and saving time! 🏢🔍

🎯 Our Structural CAD Drawing Services Include: 📌 Structural Detailing Drawing Services 🏗️ 📌 Structural BIM Drawing Services 📊 📌 Structural 2D & 3D CAD Drawings 🏠 📌 Structural Fabrication Drawings 🔩 📌 Steel & Concrete Structure Drawings 🏗️

We leverage advanced CAD & BIM technology to deliver high-precision, cost-effective, and code-compliant structural drawings ✅⚡. Our experts ensure every beam, column, and truss is accurately detailed for smooth fabrication & construction! 🏢💡

#siliconoutsourcing#structuraldrawings#CADDrafting#BIMModeling#structuraldesign#fabricationdrawings#constructionengineering#outsourcingservices#structuralbim#constructionefficiency

1 note

·

View note

Text

#civil engineering#mining#tunnelling#construction engineering#epoxycoating#framesturctureengineering#rebars#steelrebar#constructionengineering

0 notes

Text

Unfolding the Role of a Construction Design in a Successful Project

#residentialstructuralengineer#unitedkingdom#structuralengineer#structuraldesignengineer#constructiondesign#constructionengineering#constructiondesignuk#uk

0 notes

Text

Understanding Materials Used in Fasteners for Construction Projects

Choosing the right material for your fasteners is crucial for the success and durability of your construction projects. Fasteners like foundation J bolts, foundation bolts, and anchor bolts must be selected based on the material's strength, resistance to environmental factors, and the demands of your project. Here’s a breakdown of the most common materials used in fasteners and how they impact your project.

1. Carbon Steel

Carbon steel is one of the most widely used materials for fasteners like foundation bolts, stud bolts, and U bolts. It is cost-effective and provides excellent strength for a variety of applications. However, carbon steel is prone to corrosion if not properly coated or treated. It’s ideal for projects that are not exposed to extreme environmental conditions.

Pros: Strong, cost-effective, widely available.

Cons: Prone to rust and corrosion without proper treatment.

2. Stainless Steel

Stainless steel is a popular choice for fasteners in construction due to its corrosion-resistant properties. Stainless steel U bolt manufacturers often choose this material for U bolts because it withstands harsh environments, including moisture and chemicals. Stainless steel is ideal for use in marine environments, outdoor construction, and projects requiring long-term durability.

Pros: Highly corrosion-resistant, durable, long-lasting.

Cons: More expensive compared to carbon steel.

3. Galvanized Steel

Galvanized steel, which is steel coated with a layer of zinc, provides added protection against corrosion. It’s commonly used for anchor bolts, foundation J bolts, and U bolts that need to be exposed to the elements. The zinc coating helps protect the steel underneath, making it a cost-effective alternative to stainless steel.

Pros: Corrosion-resistant, cost-effective.

Cons: Zinc coating may wear off over time in harsh environments.

4. Alloys (Titanium, Nickel, etc.)

For projects that require extreme strength or resistance to high temperatures and corrosion, alloys like titanium and nickel are excellent choices. U clamp manufacturers often use these materials for heavy-duty fasteners that need to perform under high stress or in specialized environments.

Pros: Superior strength, corrosion-resistant, high-temperature resistance.

Cons: Expensive, typically used in high-performance applications.

Conclusion

The material you choose for your fasteners, whether it’s foundation J bolts, anchor bolts, or U bolts, impacts their performance, longevity, and suitability for your project. U bolts manufacturers and anchor bolt manufacturers offer various materials, so it’s important to understand the benefits and limitations of each. Consider factors like corrosion resistance, strength, and environmental exposure when selecting the best fastener material for your needs. By making an informed decision, you ensure the safety and durability of your construction project.

0 notes

Text

Creative Design & Construction Engineering At Dinajpur - Dinajpur Store

আমরা আপনাদের মনের মতো করে বাসা বাড়ি বা প্রতিষ্ঠানের সকল ডিজাইন করিয়ে থাকি আমরা

#CreativeDesign#ConstructionEngineering#EngineeringInnovation#DinajpurDevelopment#ArchitectureDesign

1 note

·

View note

Text

#construction#tower crane#Tower Crane Market#constructionequipment#constructionindustry#constructionmachinery#liftingequipment#buildingconstruction#constructionengineering#heavyequipment#cranetechnology#towercranetechnology

0 notes

Text

DAP Engineering Consultancy Redefining Abu Dhabi's Construction Landscape

In the heart of Abu Dhabi's bustling construction scene lies a beacon of innovation and excellence – Das And Partners (DAP) Engineering Consultancy. With a steadfast commitment to pushing the boundaries of engineering prowess, DAP stands as a testament to the transformative power of visionary thinking and specialized expertise.

At the core of DAP's mission is a dedicated team of professionals, each bringing a unique blend of skills and experience to the table. From Structural and Architectural experts to Construction Engineers, MEP specialists, Project Managers, and Authorities Having Jurisdiction (AOR), DAP boasts a comprehensive suite of services tailored to meet the diverse needs of clients in Abu Dhabi's dynamic construction sector.

But DAP is more than just a consultancy firm; it's a hub of innovation and collaboration, where ideas flourish and solutions evolve. With a focus on sustainability, efficiency, and client satisfaction, DAP endeavors to not only meet but exceed expectations at every turn.

One of the hallmarks of DAP's approach is its commitment to holistic project management. From inception to completion, every aspect of a project is meticulously planned, monitored, and executed to ensure seamless delivery and exceptional results. This integrated approach not only optimizes resources but also minimizes risks, ensuring that projects are completed on time, within budget, and to the highest standards of quality.

Innovation lies at the heart of everything DAP does. Whether it's leveraging cutting-edge technology to streamline processes, embracing sustainable design principles to minimize environmental impact, or pioneering new construction techniques to push the boundaries of what's possible – DAP is at the forefront of driving progress in Abu Dhabi's construction industry.

But perhaps what truly sets DAP apart is its unwavering commitment to client satisfaction. Every project undertaken by DAP is approached with a keen understanding of the client's unique needs, challenges, and aspirations. By forging strong partnerships built on trust, transparency, and communication, DAP ensures that each client's vision is not only realized but surpassed.

As Abu Dhabi continues to evolve and grow, DAP Engineering Consultancy remains steadfast in its mission to shape the future of the city's skyline. With a relentless pursuit of excellence, a passion for innovation, and a dedication to client success, DAP is poised to leave an indelible mark on Abu Dhabi's construction landscape for years to come.

#EngineeringExcellence#AbuDhabiConstruction#InnovationInProgress#DAPConsultancy#ConstructionEngineering#ProjectManagement#ArchitecturalDesign#MEPEngineering#BuildingBrilliance#SkyscraperSolutions#dasandpartners#enginerring consultancy

1 note

·

View note

Text

🏗️ Grab Our Special Offer for Construction Engineering Professionals! 🏢💻

Tired of juggling complex construction tasks and paperwork? Say goodbye to inefficiency and embrace seamless project management with our state-of-the-art ERP Software, now with a Special Offer tailored for you! 🚀

🔧 Streamline Project Workflows: Our ERP system is designed to optimize every aspect of your construction projects. From planning and scheduling to resource allocation and cost management, we've got you covered!

💼 Real-time Collaboration: Foster better communication and collaboration among your teams with our cloud-based ERP platform. Stay updated with instant progress reports, share critical data, and make informed decisions together.

📈 Enhanced Productivity: Boost your team's productivity with intuitive tools and automated processes. Spend less time on repetitive tasks and focus on delivering exceptional results.

💰 Cost Control & Budgeting: Keep your construction projects on track with accurate cost control and budget management features. No more unexpected expenses!

🔍 Data-driven Insights: Gain valuable insights into project performance, resource utilization, and overall efficiency. Make data-driven decisions that lead to success!

🛠️ Customizable & Scalable: Tailor the ERP system to match your specific construction engineering needs. Plus, it grows with your business, accommodating projects of any scale.

✨ Special Offer: Don't miss this exclusive opportunity to revolutionize your Construction Engineering projects at an unbeatable price!

Ready to take your Construction Engineering projects to new heights? 📈🏗️ Let our ERP Software be the foundation of your success! 🌟

#skaditsolutions#ConstructionEngineering#ERPSoftware#ProjectManagement#Efficiency#SpecialOffer#EnterpriseResourcePlanning#digital marketing#uae#dubai#business

1 note

·

View note

Text

CDR Report Writing is complex documentation prepared by foreign engineers who aspire to work in Australia.

Engineers Australia evaluates your skills and expertise in your field of study, providing a positive outcome if your documents meet Australian Standards.

Visit our latest blog to get to know the Best CDR Writing Service

https://cdraustraliawriter.com/blog/best-cdr-report-writing-service/

#cdraustraliawriter#cdr report#careergrowth#skilledmigration#engineers australia#cdr#australia migration#civil engineer#constructionengineer#mechanical engineer#aerospace engineer

0 notes

Text

Civil Engineer Career Path and Insights | CoListy Explore the key responsibilities, required skills, and career growth opportunities in the civil engineering field.

#civilengineer#constructionengineer#structuralengineering#civilengineeringcareer#civilengineersalary

1 note

·

View note