#Factory Automation Components

Explore tagged Tumblr posts

Text

Top Automation Components Powering Mobile Manufacturing Today

Mobile manufacturing is faster and smarter thanks to key automation components. Programmable Logic Controllers (PLCs) control machines with precision, while Human-Machine Interfaces (HMIs) let operators monitor systems easily. Servo motors deliver accurate motion for assembling tiny mobile parts, and sensors ensure quality by detecting pressure, temperature, and position. Together, these components create a seamless, efficient production line that boosts speed, reduces errors, and improves product quality. As mobile demand grows, using these advanced automation tools is essential for staying competitive and scaling production. Discover how these core technologies are shaping the future of mobile manufacturing.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Manufacturing#mobile manufacturing automation#PLC in phone manufacturing#sensors in smartphone production#Apple factory automation#Samsung manufacturing components

0 notes

Text

Operating earth moving equipment, such as bulldozers, excavators, and loaders, is essential in the construction, mining, and industrial sectors. While these machines are designed for heavy-duty tasks, ensuring the safety of operators, site workers, and bystanders is crucial to prevent accidents. Adhering to safety best practices can minimize risks and create a safer work environment. Below are key safety protocols to follow when operating earth moving equipment.

#seetech parts#Pivot Pins - Cotter Pins#Hinge Pins#Connecting Parts#Automation Components#Configurable components#factory automation#assembly automation

0 notes

Text

My wife was asking me about this this morning. This is pure political fanfic, but if I were Trump and I were going to try and make America a re-industrialised nation centred around the tech industry that keeps its supply lines as entirely in-house as possible, what I would do is start (obviously) with enormous central planning. You can't "free market incentives" your way back out of the export of industrial labour overseas.

You'd copy China and make enormous State-Owned Enterprises (assuming we care about the market and want to keep playing this stupid game instead of just becoming fully communist) that would process refined minerals into components, components into parts and parts into electronics. I'd recognise the scale of this as a multi-generational project and immediately start subsidising training for more engineers, especially for people who can set up automated factory lines but also engineers in new emerging tech fields like autonomous driving, software programmers, designers, even artists since the content economy is such a huge part of what people use tech for through social media and so much art is produced digitally now anyway.

From there you want to look at the markets globally that fucking, EaglePhone or whatever these overpriced Made In Murica devices can be sold into, and at this point, given that they will be crazy expensive compared to Chinese electronics literally no matter what you do, here would be a worthwhile place to try and flex America's muscles and threaten the UK, the EU, South America, Canada and so on with tariffs or other penalties if they don't adopt a hostile policy toward Chinese electronics.

Massive central planning would be essential for the kind of societal transformation that Trump is explicitly describing, in order to have a product to sell to the rest of the world before using imperialist bullying to make other countries buy things from America instead, but here we have to return yet again to the reality of Trump's plan. There is no end goal where America is in a stronger position. If he had implemented sweeping public programs reinvesting taxes into the health of the nation (never mind the health of its citizens) in his first term, he might have been in a powerful enough position to strongarm other countries into changing the flows of global trade, but America's world influence simply is declining, and more and more rapidly, so he's just trying to make moves that make him and his friends as much money as possible while they lock the doors, pack the country up into the box it came in and set the whole thing on fire. He describes these moves using the MAGA fantasy because it gives all his supporters in the media and the general population enough to talk about to buy him time, but I don't think anyone outside his base ever thought making America great was ever his plan, so why has everyone been critiquing the tariffs as if his sincere belief was that he would achieve his stated goals with them?

We all let our enemies set the topic of the conversation all day every day and it's shocking to me

49 notes

·

View notes

Text

The collapse of workerism

Of course, some would have it that we never lost a revolutionary perspective at all, quite confident they had the solution all along. This comes in the form of workerism, a broad set of strategies – mainly Marxist or anarcho-syndicalist – that affirm the centrality of the working class for overthrowing capitalism. In the history of revolutionary struggle, few ideas have consistently held more sway; but surely that’s only the reason why this sorely outdated approach has proven so hard to get over. Things have changed more dramatically than ever in the last decades, shattering the material conditions that once granted workplace organisation such grandiose pretensions. It’s important to clarify why, or else the attempt to exceed activism risks being subsumed by yet another reformist method, this one all the more stagnant.

Only a few decades ago, the prospects of organised labour in the Global North were much more hopeful, with trade unions retaining a great deal of strength into the 1970s. Mainly during the ‘80s, however, capitalist production underwent some major alterations. Profound technological developments in the field of electronics – especially digitisation – caused the productive process to become much more automated, requiring significantly less human input. This combined with an increased ability on the part of employers to outsource employment to less economically developed countries, where labour was much cheaper. Fairly suddenly, therefore, the two biggest sectors of the economy – split mainly between industry and agriculture – were greatly reduced in size, resulting in massive layoffs. Yet those who lost their jobs were generally absorbed by steady growth in the services sector, thereby avoiding immediate social destabilisation. Whilst it was once the smallest economic sector by a long way, the services sector is now by far the largest in the Global North, even approaching 80% employment rates in the US, UK, and France.

The result has been a striking redefinition of the common notion of work. It’s lost its centre of gravity in the factory, having fragmented instead in the direction of various post-industrial workplaces – restaurants, shops, offices. Once a largely centralised mass, the working class has been dispersed across the social terrain, the new focus being on small, highly diverse productive units. Between these units, workers possess few common interests and interact little, leading to a significantly diminished potential for collective action. Of course, resistance in the workplace continues, but the internal avenues necessary for revolt to generalise have been majorly severed, the situation continuing to decline in light of ever greater technological advance.

Nobody can deny the profound identity crisis faced by the working class. Only a few decades ago, the factory was seen as the centre of everything, with workers offering the vital component in the functioning of society as a whole. Work was once a way of life, not so much in terms of the amount of time it took up, but instead because of the clear sense of existential grounding it offered. For generations, there had been a strong link between work and professionalism, with most workers committing to a single craft for the entirety of their lives. Career paths were passed down from father to son, who often remained in the same company; the families of different workers also maintained close ties with one another. Nowadays, however, everything has changed: employment is immensely uncertain, the relentless fluidity of the post-industrial economy forcing most to get by on a roster of precarious, low-skilled jobs. Far fewer people take pride in their work, especially given that employment only rarely has a convincing subtext of doing something socially important. Trade unions have also vanished as a historical force, having been defeated in the key battles of the ‘80s, their membership levels imploding in lock-step with the advance of neoliberalism. A residue of the old world still exists, but it continues to dissipate further every day, never to return. In the Global South, too, things are inevitably moving in the same direction.

These developments cast serious doubt on the validity of Marxist and anarcho-syndicalist strategies for revolution. It’s becoming increasingly meaningless to speak of “the workers” in reference to a cohesive entity. It isn’t as if the disintegration of the working class implies the absence of poverty, nor of the excluded – in no sense whatsoever. What it does mean is the end of the working class as a subject. One that was, as Marx put it, “disciplined, united, organised by the very mechanism of the process of capitalist production itself” (Capital, 1867). Over the last decades, the working class has been dismembered and demoralised by the very same mechanism: just as the mass application of steam and machinery into the productive process created the industrial proletariat two centuries ago, the invention of new, automated technologies has led to its dissolution. There’s no single project around which to unite the working class any more; it follows, as with identity politics, that gains in the workplace will almost always be limited to improving capitalism rather than destroying it. The Industrial Revolution has been superseded by the Digital Revolution, yet the revolutionary optimism of workerism remains ideologically trapped in a bygone era, fumbling for relevance in a century that won’t have it. Although, to be honest, this is hardly news: already for some time now, the nostalgic language of workerism has come across as stale and outdated to most, even if academics often struggle to keep up.

In any case, the collapse of workerism might be nothing to mourn. Another implication of the end of traditional employment is the predominance of a range of workplaces few would want to appropriate anyway. The factory has been replaced by the likes of call centres, supermarkets, service stations, fast food joints, and coffee shop chains. Yet surely no one can imagine themselves maintaining these workplaces after the revolution, as if anything resembling a collectively run Starbucks or factory farm is what we’re going for? When workerism first became popular, there was an obvious applicability of most work to the prospect of a free society. In the 21st century, however, the alienation of labour runs all the deeper: no longer is it the mere fact of lacking control over work, but instead its inherent function that’s usually the problem. To put it another way, it should come as no surprise that Marxists haven’t yet replaced their hammer and sickle with an office desk and espresso machine, as would be necessary to keep up with the times. The modern symbols of work are worthy only of scorn, not the kind of valorisation involved in putting them on a flag.

This is another big problem for the workerist theory of revolution, given its conception of revolution primarily or even exclusively in terms of the seizure of the means of production. Achieving reforms in the workplace is one thing, but only rarely can such exercises in confidence-building be taken as steps towards appropriating the workplace altogether. Surely the point isn’t to democratise the economy, but instead to pick it apart: those aspects of the economy genuinely worth collectivising, as opposed to converting or simply burning, are few and far between. Of course, they still exist, but they’re marginal. And that confirms the absurdity of expecting workplace organisation to offer the centrepiece of any future revolution.

This hardly implies doing away with the material aspects of revolutionary struggle, given that communising the conditions of existence remains necessary for living our lives – not just this or that activist campaign – in genuine conflict with the system. All the more, the moment in which these subterranean influences suddenly erupt, and mass communisation overturns the ordinary functioning of the capitalist machine, surely remains a defining feature of revolution itself. Yet such endeavours must be sharply distinguished from seizing the means of production – that is, appropriating the capitalist infrastructure more or less as it stands before us. Far from offering a vision of the world we want to see, the syndicalist proposal to reclaim the conditions of work – to assume control of very the system that’s destroying us – merely implies self-managing not only our own exploitation, but also that of the planet.

As an aside, it should be added that these issues undermine the contemporary relevance of Marxism altogether. It was previously suggested that Marxian class analysis no longer offers a credible account of oppression; the current discussion, meanwhile, suggests it cannot be used to frame the topic of revolution either. As a method for interpreting the world, as well as for changing it, Marxism has had its day. If we wanted to be a little diplomatic, we could say this isn’t so much a criticism of the theory itself, more a recognition of the fact that the world it was designed to engage with no longer exists. If we wanted to be a little less diplomatic, moreover, it should be added that what’s left of Marxism is utterly boring, reformist, and kept “alive” almost exclusively by academics. As the big guy declared back in 1852, “The tradition of all the dead generations weighs like a nightmare on the brains of the living.” Yet in no case has this claim, offered in response to the lack of imagination amongst revolutionaries in the 19th century, been more relevant than with Marxism today. We should pay our respects, if indeed any respect is due, whilst refusing to be crippled by an outdated approach. The same goes for anarcho-syndicalism, its once unbridled potential decisively shut down by the combined victories of fascism and Bolshevism.

To offer a last word of clarification, none of this implies doing away with workplace organisation altogether. There’s still much to be said for confronting power on every front: the collectivisation of any remaining useful workplaces, as well as the fierce application of the general strike, surely remains vital for any effective revolutionary mosaic. Just as workplace organisation continues to prove effective for breaking down social barriers, as well as potentially improving our lives in the here and now. The core claim offered here is only that it cannot be considered the centrepiece of revolutionary struggle altogether – quite the minimal conclusion. Merely in terms of asking what the abolition of class might look like today, workerism has lost its way. And that doesn’t begin to consider the abolition of hierarchy as such. When taken in isolation, organised labour offers nothing more than a subtle variety of reformism, thinly cloaked in its stuffy revolutionary pretensions. Total liberation, by contrast, refuses to single out any focal points of the clash, be they workerist, activist, or otherwise.

#anti-civ#anti-speciesism#autonomous zones#climate crisis#deep ecology#insurrectionary#social ecology#strategy#anarchism#climate change#resistance#autonomy#revolution#ecology#community building#practical anarchism#anarchist society#practical#practical anarchy#anarchy#daily posts#communism#anti capitalist#anti capitalism#late stage capitalism#organization#grassroots#grass roots#anarchists#libraries

34 notes

·

View notes

Text

The Difference Between Low, Medium, and High Voltage Switchgear

Switchgear plays a critical role in the generation, transmission, and distribution of electrical power. It ensures safe and efficient operation by controlling, protecting, and isolating electrical circuits and equipment. But not all switchgear is created equal — low, medium, and high voltage switchgear are designed for different voltage levels and applications.

Understanding the differences between these types is crucial for electrical engineers, electricians, project managers, and anyone involved in power systems. In this article, we break down what sets them apart in terms of voltage range, components, applications, design, and safety considerations.

What is Switchgear?

Before diving into the differences, let’s clarify what switchgear is.

Switchgear refers to the combination of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. It is essential for de-energizing equipment for maintenance and for clearing faults in the power system.

Classification by Voltage Level

Low Voltage Switchgear (LV)

Voltage Range:

Up to 1,000V AC (typically 400V/690V in 3-phase systems)

Key Components:

Miniature Circuit Breakers (MCBs)

Molded Case Circuit Breakers (MCCBs)

Residual Current Devices (RCDs)

Contactors and relays

Busbars, metering, control panels

Applications:

Residential and commercial buildings

Data centers and office spaces

Light industrial automation

Control panels and motor control centers (MCCs)

Characteristics:

Compact and easy to install

High frequency of operation

Relatively simple maintenance

Often enclosed in modular panels

Standards:

IEC 61439

NEC (National Electrical Code)

Medium Voltage Switchgear (MV)

Voltage Range:

1kV to 36kV (sometimes up to 72.5kV)

Key Components:

Vacuum circuit breakers (VCBs)

SF₆ (sulfur hexafluoride) insulated switchgear

Current and voltage transformers (CTs, VTs)

Protective relays

Grounding switches

Applications:

Electrical substations

Large factories and industrial plants

Railways and airports

Renewable energy farms (wind/solar)

Characteristics:

Higher insulation and safety requirements

More robust protection systems

Often installed indoors or in compact outdoor enclosures

May use gas-insulated or air-insulated designs

Standards:

IEC 62271–200

IEEE C37 series

High Voltage Switchgear (HV)

Voltage Range:

Above 36kV (commonly 66kV, 132kV, 220kV, up to 765kV)

Key Components:

SF₆ circuit breakers

Air blast or oil circuit breakers (older systems)

Gas-insulated switchgear (GIS)

Disconnectors and earthing switches

High-end protection relays and SCADA integration

Applications:

National and regional power transmission networks

Power generation plants

Interconnecting large substations

Critical infrastructure (e.g., large data centers, airports)

Characteristics:

Complex installation and high-cost infrastructure

Requires rigorous safety procedures and specialized training

Often installed outdoors or in GIS (Gas Insulated Switchgear) format

Includes extensive monitoring and automation

Standards:

IEC 62271–100 (HV circuit breakers)

IEEE C37.06

ANSI C37 series

Safety Considerations

Always follow local electrical codes, use personal protective equipment (PPE), and conduct routine maintenance regardless of switchgear type.

Conclusion

Choosing the right switchgear type is critical for ensuring safe and efficient power distribution. Whether you’re designing a residential panel or a high-voltage substation, knowing the difference between low, medium, and high voltage switchgear helps you make informed decisions about equipment, safety, and performance.

Mastering this knowledge isn’t just good practice — it’s essential for anyone serious about a career in the electrical field.

10 notes

·

View notes

Text

From Design to Deployment: How Switchgear Systems Are Built

In the modern world of electrical engineering, switchgear systems play a critical role in ensuring the safe distribution and control of electrical power. From substations and factories to commercial buildings and critical infrastructure, switchgear is the silent guardian that protects equipment, ensures safety, and minimizes power failures.

But have you ever wondered what goes on behind the scenes, from the idea to the actual installation? Let’s dive into the full journey — from design to deployment — of how a switchgear system is built.

Step 1: Requirement Analysis and Load Study

Every switchgear project begins with requirement analysis. This includes:

Understanding the electrical load requirements

Calculating voltage levels, short-circuit ratings, and operating current

Identifying environmental conditions: indoor, outdoor, temperature, humidity

Reviewing applicable industry standards like IEC, ANSI, or DEWA regulations (especially in UAE)

This stage helps engineers determine whether the project needs low voltage (LV), medium voltage (MV), or high voltage (HV) switchgear.

Step 2: Conceptual Design & Engineering

Once the requirements are clear, the conceptual design begins.

Selection of switchgear type (air insulated, gas insulated, metal-enclosed, metal-clad, etc.)

Deciding on protection devices: MCCBs, ACBs, relays, CTs, VTs, and fuses

Creating single-line diagrams (SLDs) and layout drawings

Choosing the busbar material (copper or aluminum), insulation type, and earthing arrangements

Software like AutoCAD, EPLAN, and ETAP are commonly used for precise engineering drawings and simulations.

Step 3: Manufacturing & Fabrication

This is where the physical structure comes to life.

Sheet metal is cut, punched, and bent to form the panel enclosures

Powder coating or galvanizing is done for corrosion protection

Assembly of circuit breakers, contactors, protection relays, meters, etc.

Internal wiring is installed according to the schematic

Every switchgear panel is built with precision and must undergo quality control checks at each stage.

Step 4: Factory Testing (FAT)

Before deployment, every switchgear unit undergoes Factory Acceptance Testing (FAT) to ensure it meets technical and safety standards.

Typical FAT includes:

High-voltage insulation testing

Continuity and phase sequence testing

Functionality check of all protection relays and interlocks

Mechanical operations of breakers and switches

Thermal imaging to detect hotspots

Only after passing FAT, the switchgear is cleared for shipping.

Step 5: Transportation & Site Installation

Transportation must be handled with care to avoid damage to components. At the site:

Panels are unloaded and moved to their final location

Cabling and bus duct connections are established

Earthing systems are connected

Environmental sealing is done if installed outdoors or in dusty environments

Step 6: Commissioning & Site Acceptance Testing (SAT)

This final stage ensures the switchgear is ready for live operation.

Final checks and Site Acceptance Tests (SAT) are performed

System integration is tested with other components like transformers, UPS, and generators

Load tests and trial runs are conducted

Commissioning report is generated, and documentation is handed over to the client

Conclusion

From idea to execution, the journey of building a switchgear system is highly technical, safety-driven, and precision-based. Whether you’re in power generation, industrial automation, or commercial construction, understanding this process ensures you choose the right system for your needs.

7 notes

·

View notes

Text

Excerpt from this story from Nation of Change:

China’s largest automaker, BYD, is selling its Dolphin hatchback EV for a low-low $15,000, complete with a 13-inch rotating screen, ventilated front seats, and a 260-mile range. Here in the U.S., you have to pay more than twice that price for the Tesla Model 3 EV ($39,000) with lower tech and only 10 more miles of driving range. In case $15K beats your budget, the Dolphin has a plug-in hybrid version with an industry-leading 74-mile range on a single charge for only $11,000 and an upgrade with an unbeatable combined gas-electric range of 1,300 miles. Not surprisingly, EVs surged to 52% of all auto sales in China last year. And with such a strong domestic springboard into the world market, Chinese companies accounted for more than 70% of global EV sales.

It’s time to face reality in the world of cars and light trucks. Let’s admit it, China’s visionary industrial policy is the source of its growing dominance over global EV production. Back in 2009-2010, three years before Elon Musk sold his first mass-production Tesla, Beijing decided to accelerate the growth of its domestic auto industry, including cheap, all-electric vehicles with short ranges for its city drivers. Realizing that an EV is just a steel box with a battery, and battery quality determines car quality, Beijing set about systematically creating a vertical monopoly for those batteries — from raw materials like lithium and cobalt from the Congo all the way to cutting-edge factories for the final product. With its chokehold on refining all the essential raw materials for EV batteries (cobalt, graphite, lithium, and nickel), by 2023-2024 China accounted for well over 80% of global sales of battery components and nearly two-thirds of all finished EV batteries.

Clearly, new technology is driving our automotive future, and it’s increasingly clear that China is in the driver’s seat, ready to run over the auto industries of the U.S. and the European Union like so much roadkill. Indeed, Beijing switched to the export of autos, particularly EVs, to kick-start its slumbering economy in the aftermath of the Covid lockdown.

Given that it was already the world’s industrial powerhouse, China’s auto industry was more than ready for the challenge. After robotic factories there assemble complete cars, hands-free, from metal stamping to spray painting for less than the cost of a top-end refrigerator in the U.S., Chinese companies pop in their low-cost batteries and head to one of the country’s fully automated shipping ports. There, instead of relying on commercial carriers, leading automaker BYD cut costs to the bone by launching its own fleet of eight enormous ocean-going freighters. It started in January 2024 with the BYD Explorer No. 1, capable of carrying 7,000 vehicles anywhere in the world, custom-designed for speedy drive-on, drive-off delivery. That same month, another major Chinese company you’ve undoubtedly never heard of, SAIC Motor, launched an even larger freighter, which regularly transports 7,600 cars to global markets.

Those cars are already heading for Europe, where BYD’s Dolphin has won a “5-Star Euro Safety Rating” and its dealerships are popping up like mushrooms in a mine shaft. In a matter of months, Chinese cars had captured 11% of the European market. Last year, BYD began planning its first factory in Mexico as an “export hub” for the American market and is already building billion-dollar factories in Turkey, Thailand, and Indonesia. Realizing that “20% to 30%” of his company’s revenue is at risk, Ford CEO Jim Farley says his plants are switching to low-cost EVs to keep up. After the looming competition led GM to bring back its low-cost Chevy Bolt EV, company Vice President Kurt Kelty said that GM will “drive the cost of E.V.s to lower than internal combustion engine vehicles.”

So, what does all this mean for America? In the past four years, the Biden administration made real strides in protecting the future of the country’s auto industry, which is headed toward ensuring that American motorists will be driving $10,000 EVs with a 1,000-mile range, a 10-year warranty, a running cost of 10 cents a mile, and 0 (yes zero!) climate-killing carbon emissions.

Not only did President Biden extend the critical $7,500 tax credit for the purchase of an American-made EV, but his 2021 Infrastructure Act helped raise the number of public-charging ports to a reasonable 192,000, with 1,000 more still being added weekly, reducing the range anxiety that troubles half of all American car owners. To cut the cost of the electricity needed to drive those car chargers, his 2022 Inflation Reduction Act allocated $370 billion to accelerate the transition to low-cost green energy. With such support, U.S. EV sales jumped 7% to a record 1.3 million units in 2024.

Most important of all, that funding stimulated research for a next-generation solid-state battery that could break China’s present stranglehold over most of the components needed to produce the current lithium-ion EV batteries. The solution: a blindingly simple bit of all-American innovation — don’t use any of those made-in-China components. With investment help from Volkswagen, the U.S. firm QuantumScape has recently developed a prototype for a solid-state battery that can reach “80% state of charge in less than 15 minutes,” while ensuring “improved safety,” extended battery life, and a driving range of 500 miles. Already, investment advisors are touting the company as the next Nvidia.

But wait a grim moment! If we take President Donald Trump at his word, his policies will slam the brakes on any such gains for the next four years — just long enough to potentially send the Detroit auto industry into a death spiral. On the campaign trail last year, Trump asked oil industry executives for a billion dollars in “campaign cash,” and told the Republican convention that he would “end the electrical vehicle mandate on day one” and thereby save “the U.S. auto industry from complete obliteration.” And in his victory speech last November, he celebrated the country’s oil reserves, saying, “We have more liquid gold than anyone else in the world.”

8 notes

·

View notes

Text

North Carolina State University researchers have demonstrated a technique that allows people who manufacture metal machine parts with 3D printing technologies to conduct automated quality control of manufactured parts during the finishing process. The technique allows users to identify potential flaws without having to remove the parts from the manufacturing equipment, making production time more efficient. "One of the reasons people are attracted to 3D printing and other additive manufacturing technologies is that these technologies allow users to quickly replace critical machine components that are otherwise difficult to make outside of a factory," says Brandon McConnell, co-corresponding author of a paper on the work. "And additive manufacturing tools can do this as needed, rather than dealing with supply chains that can have long wait times. That usually means using 3D printing to create small batches of machine parts on demand." McConnell is an assistant research professor in NC State's Edward P. Fitts Department of Industrial and Systems Engineering.

Read more.

#Materials Science#Science#North Carolina State University#3D printing#Metals#Defects#Additive manufacturing

12 notes

·

View notes

Text

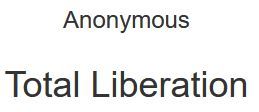

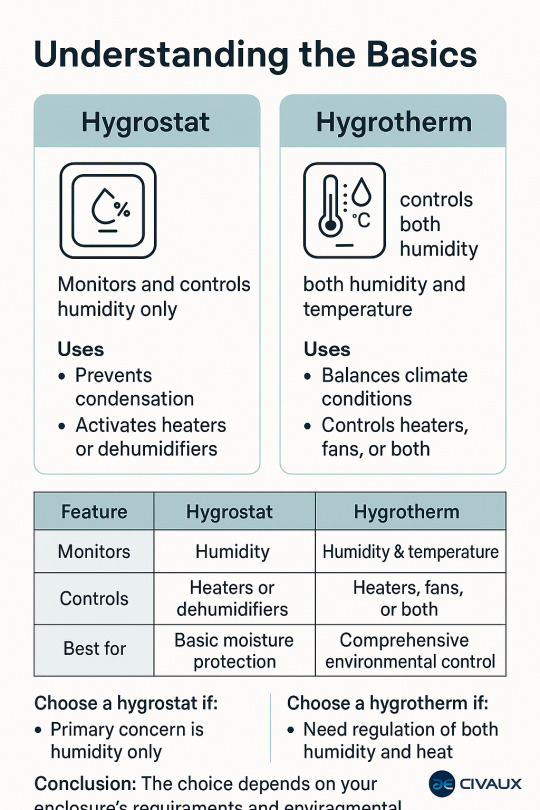

Hygrostat vs. Hygrotherm: Which Offers Better Moisture Management?

Moisture is one of the most damaging yet often overlooked threats to electrical enclosures and control panels. In high-humidity regions like the GCC, effective moisture management is critical to ensuring equipment longevity, operational safety, and uninterrupted performance. Two of the most widely used solutions in this space are hygrostats and hygrotherms. But which one is better for your application?

In this article, we compare hygrostats vs. hygrotherms in terms of functionality, performance, and suitability for different environments — helping you make the right choice for your electrical enclosure needs.

What is a Hygrostat?

A hygrostat is a humidity-regulating device that monitors the relative humidity inside an enclosure and activates connected equipment (like a heater or fan) when a preset humidity threshold is exceeded. It’s a single-function device focused purely on moisture control.

Key Functions:

· Monitors internal humidity

· Activates heaters or dehumidifiers to prevent condensation

· Simple and cost-effective solution for moisture problems

What is a Hygrotherm?

A hygrotherm is a dual-function device that combines the capabilities of a thermostat (for temperature) and a hygrostat (for humidity). It can monitor and control both parameters, ensuring balanced temperature and humidity regulation within the enclosure.

Key Functions:

· Simultaneous monitoring of temperature and humidity

· Activates heaters, fans, or filters based on combined conditions

Why Moisture Control Matters

In regions with high temperature fluctuations — like warehouses, factories, and outdoor panels in the Middle East — condensation can form inside enclosures. This can lead to:

· Corrosion of components

· Electrical short circuits

· Reduced equipment lifespan

· Safety risks for operators

Choosing the right controller ensures stable environmental conditions, reduces downtime, and cuts maintenance costs.

When to Use a Hygrostat

Choose a hygrostat if:

· Your enclosure operates in a relatively stable temperature range

· Your primary concern is humidity only

· You need a low-cost, targeted solution

· You’re upgrading older enclosures with basic needs

When to Use a Hygrotherm

Choose a hygrotherm if:

· Your environment experiences extreme heat and humidity (e.g., GCC summer months)

· You’re running sensitive electronics or automation panels

· You need proactive climate control for both heat and moisture

· You want to consolidate devices into a single, efficient unit

Conclusion: Which is Better?

Both hygrostats and hygrotherms are effective tools for enclosure climate control — but the better choice depends on your environmental conditions and system complexity.

· For basic, budget-friendly moisture protection: ✅ Go with a hygrostat.

· For comprehensive, long-term protection in critical systems: ✅ Invest in a hygrotherm.

Civaux Electric, we offer both hygrostats and hygrotherms with wide voltage range, compact design, and reliable performance — built to handle the GCC’s demanding climates.

#Hygrostat#Hygrotherm#Moisture management#Humidity control devices#Temperature and humidity regulator#Industrial climate control#electrical equipment#switchgears#electrical#panel#lowvoltage#dubai#united arab emirates

2 notes

·

View notes

Text

Artemis III core stage receives thermal protection coating

NASA completed another step to ready its SLS (Space Launch System) rocket for the Artemis III mission as crews at the agency's Michoud Assembly Facility in New Orleans recently applied a thermal protection system to the core stage's liquid hydrogen tank.

Building on the crewed Artemis II flight test, Artemis III will add new capabilities with the human landing system and advanced spacesuits to send the first astronauts to explore the lunar South Pole region and prepare humanity to go to Mars. Thermal protection systems are a cornerstone of successful spaceflight endeavors, safeguarding human life, and enabling the launch and controlled return of spacecraft.

The tank is the largest piece of SLS flight hardware insulated at Michoud. The hardware requires thermal protection due to the extreme temperatures during launch and ascent to space—and to keep the liquid hydrogen at minus 423 degrees Fahrenheit on the pad prior to launch.

"The thermal protection system protects the SLS rocket from the heat of launch while also keeping the thousands of gallons of liquid propellant within the core stage's tanks cold enough. Without the protection, the propellant would boil off too rapidly to replenish before launch," said Jay Bourgeois, thermal protection system, test, and integration lead at NASA Michoud. "Thermal protection systems are crucial in protecting all the structural components of SLS during launch and flight."

In February, Michoud crews with NASA and Boeing, the SLS core stage prime contractor, completed the thermal protection system on the external structure of the rocket's liquid hydrogen propellant fuel tank, using a robotic tool in what is now the largest single application in spaceflight history.

IMAGE: Teams at NASA’s Michoud Assembly Facility in New Orleans move a liquid hydrogen tank for the agency’s SLS (Space Launch System) rocket into the factory’s final assembly area on April 22, 2025. The propellant tank is one of five major elements that make up the 212-foot-tall rocket stage. Credit: NASA/Steven Seipel

The robotically controlled operation coated the tank with spray-on foam insulation, distributing 107 feet of the foam to the tank in 102 minutes. When the foam is applied to the core stage, it gives the rocket a canary yellow color. The Sun's ultraviolet rays naturally "tan" the thermal protection, giving the SLS core stage its signature orange color, like the space shuttle external tank.

While it might sound like a task similar to applying paint to a house or spraying insulation in an attic, it is a much more complex process. The flexible polyurethane foam had to withstand harsh conditions for application and testing. Additionally, there was a new challenge: spraying the stage horizontally, something never done previously during large foam applications on space shuttle external tanks at Michoud. All large components of space shuttle tanks were in a vertical position when sprayed with automated processes.

Overall, the rocket's core stage is 212 feet with a diameter of 27.6 feet, the same diameter as the space shuttle's external tank. The liquid hydrogen and liquid oxygen tanks feed four RS-25 engines for approximately 500 seconds before SLS reaches low Earth orbit and the core stage separates from the upper stage and NASA's Orion spacecraft.

"Even though it only takes 102 minutes to apply the spray, a lot of careful preparation and planning is put into this process before the actual application of the foam," said Boeing's Brian Jeansonne, the integrated product team senior leader for the thermal protection system at NASA Michoud.

"There are better process controls in place than we've ever had before, and there are specialized production technicians who must have certifications to operate the system. It's quite an accomplishment and a lot of pride in knowing that we've completed this step of the build process."

The core stage of SLS is the largest NASA has ever built by length and volume, and it was manufactured at Michoud using state-of-the-art manufacturing equipment. Michoud is a unique, advanced manufacturing facility where the agency has built spacecraft components for decades, including the space shuttle's external tanks and Saturn V rockets for the Apollo program.

youtube

3 notes

·

View notes

Text

Top Automation Equipment Powering Mobile Production Units

Mobile production units rely on advanced automation equipment to operate efficiently and accurately in any location. Key components like PLCs (Programmable Logic Controllers), HMIs (Human-Machine Interfaces), Servo Motors, and Sensors play a vital role in controlling, monitoring, and optimizing processes. PLCs act as the control center, HMIs provide user-friendly interfaces, servo motors deliver precise motion control, and sensors enable real-time data feedback. Together, these components ensure smooth, flexible, and high-performance production in mobile environments. Designed for reliability and adaptability, this automation equipment helps industries meet production goals with speed and precision on the move.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Manufacturing#mobile manufacturing automation#PLC in phone manufacturing#sensors in smartphone production#Apple factory automation#Samsung manufacturing components

0 notes

Text

Asset Located

(Reverse 1999 ocs)

It wasn't often her family contacted her, rather it wasn't often she would respond to their constant needs for updates and messages about their standing with the Foundation - the influx of letters, pager messages and whatnot filling her already stacked mailbox sitting abandoned in the corner of her office. It was a true wonder she choose to open the latest one that had, against all odds peeked her interest.

She waded through an ashen cacophony of charred wood and deteriorated stone, iron rusted and melting in certain places. If this factory had seen better days no evidence of it could be seen. Much of the building had collapsed in on itself during the fire, poor infrastructure and lack of proper safety protocols ensured anything of value that was in the factory was destroyed in the chaos ... all but one.

The letter denoted something of interest to the family that had been lost decades ago, and with the 'convenience' of the Storm dragging London to the 1930s Foundation personnel were able to find traces of the 'asset' in this factory. Further reading into the letter described how the 'asset' had been situated in this factory for some time, judging from interviews and sightings of workers and local residents: she was only messaged to seek out the 'asset' when the building suddenly caught on fire, engulfing the building with flame. The family hoped to salvage the 'asset' in whatever state it was currently in, hoping to retrieve it before the Foundation got their hands on it first. However, something strange was noted about this fire: no causalities whatsoever were recorded, all accounted for workers somehow had been miraculously saved in the inferno by someone; flames diverted or a hand pulling them to safety just before the ceiling collapsed.

She noted going through the wreckage it would have been near impossible for a zero causality rate with the previously mentioned lack of proper equipment and safety regulations, noting the frequency of accident in Laplace and her Department with its more (somewhat) advanced standards. Everyone in the building was found and relatively unharmed, whatever aided in their escape likely was trapped in the building's wreckage, hence her visit .

...

For an hour her search yielded nothing: outdated machinery, ash and broken parts of the building as far as the eye could register. Her family was finally insane, she figured as she began to leave the area. Finally succumbing to rumours and speculations to salvage some semblance of dignity and status by digging through the mud like rats. Wasting her previous vacation days on a whim and bordeom ... Until she noticed a shift in certain fallen bricks.

So someone was still unaccounted for, she promptly rushed over to the individual, choosing not to immediately locate the fellow Foundation personnel that accompanied her to the place. They would take ages to respond, and time (literally and figuratively) never acted in their favour, so she began to gently lift away the debris ... to reveal not someone, but something.

Stepping back, Juni realised she had located the 'asset'. And the 'asset' looked back.

...

Proportionally, it was human-like: an automation likely from the Steam Age like Madam Lucy; limbs casted in dull slivers and gold shifted and tweaked as it was freed from the debris. Its orb shaped head, with a peculiarly large smile had finally faced her; dim flickering lights serving as eyes registering her presence. From the unatural tweaking, Juni speculated the fire or the debris had damaged some of its components and rendered it unable to get up, instead pathetically tweaking and twisting in an attempt to stand. Juni approached it, and proceeded to grab its head and inspect it, the automaton seemed to twist even more in protest, but was unable to do anything to halt Juni's inspection. The tweaking quickly stopped after a few seconds.

There ... the 'asset' still contained the primary element noted in the letter, her unexpected trip yielded results at last. It glimmered dimly within the mess of wires, tubing and frame of the automaton's head: further inspection of the automaton showed it was largely intact, a few nicks and bumps in certain parts but largely whole. Its inability to move at the current moment was likely the result of over-arcanum exertion, putting it into a forced rest state of sorts. It would be quite easy to take the automaton to her family, earn some good graces with them and finally stop their constant pestering ... however further regarding the machine Juni considered another option: taking it for herself. She could easily take to the Foundation and register it as her assistant, fix it and maybe finally have enough help in her understaffed department. And as a bonus would further piss off her family.

Satisfied with her conclusion, Juni located the golden object attached to its head, remembering how the letter described the process of activating the arcane array and promptly shut off the automaton. The tweaking ceased as its eyes dimmed out. She stood up, inspecting the automaton again: she probably will need to call Foundation personnel to carry the thing, her left arm was already shaking in pain despite the short inspection.

The trip wasn't a total loss at all.

#reverse 1999#r1999#r1999 oc#reverse 1999 original characters#Containment Trio#forgor remembered#The Wayward Automaton#hi heres me finally posting my oc lore#idk if i need more tags?#forgor writes

4 notes

·

View notes

Text

CNC Press Brake Machine in India: Shaping the Future of Metal Bending

In the dynamic world of metal fabrication, CNC Press Brake Machines have become indispensable. These machines are critical in industries that demand precision bending and forming of sheet metal components. In India, the rising focus on infrastructure development, automotive manufacturing, and localized production has driven the adoption of CNC press brake technology across various sectors.

From small workshops to large-scale factories, CNC press brakes are revolutionizing how Indian manufacturers handle metal forming—efficiently, accurately, and consistently.

What is a CNC Press Brake Machine?

A CNC (Computer Numerical Control) Press Brake Machine is used to bend and shape metal sheets with precision. It uses a punch and die to perform various bends, guided by a CNC system that ensures exact specifications for angle, length, and repetition.

Modern CNC press brakes are far more advanced than traditional mechanical or hydraulic versions. They come with programmable controls, automated back gauges, and advanced sensors to deliver high-speed and high-precision bending.

Why CNC Press Brakes are Gaining Popularity in India

1. Precision and Consistency

In sectors like automotive, aerospace, and electronics, even minor deviations in part dimensions can lead to quality issues. CNC press brakes eliminate human error and ensure consistent output across batches.

2. Growing Industrialization

India’s expanding industrial base, especially in Tier 2 and Tier 3 cities, is fueling demand for reliable fabrication equipment. CNC press brakes allow businesses to scale up production without compromising on accuracy.

3. Labour Efficiency

With a skilled labor shortage and rising wages, automation is becoming more attractive. CNC press brakes require minimal human intervention, reducing labor costs and dependency on manual operators.

4. Government Incentives

Government initiatives like Make in India and Production Linked Incentive (PLI) Schemes are encouraging manufacturers to invest in advanced machinery, including CNC press brakes, for higher productivity.

Key Features of CNC Press Brake Machines in the Indian Market

High-Tonnage Capability: Machines ranging from 30 to 1000+ tons to suit various applications.

CNC Control Systems: Brands like Delem, ESA, and Cybelec offer intuitive interfaces for programming and automation.

Servo-Electric or Hydraulic Drive Systems: Depending on precision, energy efficiency, and speed requirements.

Multi-Axis Back Gauge: Enables complex bends and reduces setup time.

Automatic Tool Changers (ATC): For higher production environments.

Leading Indian and International Brands

India has a strong presence of both domestic and international CNC press brake manufacturers. Some notable names include:

Hindustan Hydraulics

Electropneumatics

Energy Mission

LVD India

Amada (Japan)

Durma (Turkey)

Yawei (China)

These companies offer machines tailored to the needs and budget of Indian manufacturers.

Applications in India

Automobile Body & Chassis Manufacturing

Kitchen Equipment Fabrication

Electrical Enclosures & Cabinets

Elevator and Escalator Components

Construction and Infrastructure Products

Railways and Defence Equipment

Challenges for Indian Buyers

High Initial Investment: CNC press brakes can be capital intensive, though the ROI is excellent over time.

Skill Development: Operators need training to use CNC systems effectively.

After-Sales Service: Choosing a vendor with reliable local support is crucial for maintenance and uptime.

The Road Ahead: Smart Factories & Industry 4.0

India is steadily moving towards smart manufacturing. CNC press brakes are now integrating with IoT, ERP systems, and robotic automation, enabling real-time monitoring, predictive maintenance, and remote troubleshooting. This evolution is making Indian factories more agile and globally competitive.

Conclusion

The CNC Press Brake Machine is no longer a luxury—it's a necessity in modern Indian manufacturing. With its unmatched accuracy, efficiency, and automation capabilities, it empowers businesses to meet rising customer expectations while optimizing operational costs.

As India continues to climb the global manufacturing ladder, CNC press brake machines will play a pivotal role in shaping the future—quite literally.

2 notes

·

View notes

Text

Getting Started with Industrial Robotics Programming

Industrial robotics is a field where software engineering meets automation to drive manufacturing, assembly, and inspection processes. With the rise of Industry 4.0, the demand for skilled robotics programmers is rapidly increasing. This post introduces you to the fundamentals of industrial robotics programming and how you can get started in this exciting tech space.

What is Industrial Robotics Programming?

Industrial robotics programming involves creating software instructions for robots to perform tasks such as welding, picking and placing objects, painting, or quality inspection. These robots are typically used in factories and warehouses, and are often programmed using proprietary or standard languages tailored for automation tasks.

Popular Robotics Programming Languages

RAPID – Used for ABB robots.

KRL (KUKA Robot Language) – For KUKA industrial robots.

URScript – Used by Universal Robots.

Fanuc KAREL / Teach Pendant Programming

ROS (Robot Operating System) – Widely used open-source middleware for robotics.

Python and C++ – Common languages for simulation and integration with sensors and AI.

Key Components in Robotics Programming

Motion Control: Programming the path, speed, and precision of robot arms.

Sensor Integration: Use of cameras, force sensors, and proximity detectors for adaptive control.

PLC Communication: Integrating robots with Programmable Logic Controllers for factory automation.

Safety Protocols: Programming emergency stops, limit switches, and safe zones.

Human-Machine Interface (HMI): Designing interfaces for operators to control and monitor robots.

Sample URScript Code (Universal Robots)

# Move to position movej([1.0, -1.57, 1.57, -1.57, -1.57, 0.0], a=1.4, v=1.05) # Gripper control (example function call) set_digital_out(8, True) # Close gripper sleep(1) set_digital_out(8, False) # Open gripper

Software Tools You Can Use

RoboDK – Offline programming and simulation.

ROS + Gazebo – Open-source tools for simulation and robotic control.

ABB RobotStudio

Fanuc ROBOGUIDE

Siemens TIA Portal – For integration with industrial control systems.

Steps to Start Your Journey

Learn the basics of industrial robotics and automation.

Familiarize yourself with at least one brand of industrial robot (ABB, KUKA, UR, Fanuc).

Get comfortable with control systems and communication protocols (EtherCAT, PROFINET).

Practice with simulations before handling real robots.

Study safety standards (ISO 10218, ANSI/RIA R15.06).

Real-World Applications

Automated welding in car manufacturing.

High-speed pick and place in packaging.

Precision assembly of electronics.

Material handling and palletizing in warehouses.

Conclusion

Industrial robotics programming is a specialized yet rewarding field that bridges software with real-world mechanics. Whether you’re interested in working with physical robots or developing smart systems for factories, gaining skills in robotics programming can open up incredible career paths in manufacturing, automation, and AI-driven industries.

2 notes

·

View notes

Text

Top 10 Pneumatic Actuator Brands In 2025

The pneumatic actuator market continues to thrive in 2025, driven by advancements in automation and industrial efficiency. Based on comprehensive evaluations by CN10/CNPP research departments, which integrate big data analytics, AI-driven insights, and market performance metrics, here are the leading brands shaping the industry.

1. SMC (SMC Corporation)

Performance & Reliability: As a global leader since 1959, SMC delivers over 10,000 pneumatic components, including high-precision cylinders, valves, and F.R.L. units. Its products are renowned for durability, energy efficiency, and adaptability to extreme industrial conditions. Industry Applications: Widely used in automotive manufacturing, semiconductor production, and robotics, SMC’s actuators ensure seamless automation across 80+ countries. Its China-based facilities, established in 1994, serve as a primary global production hub.

2. FESTO (Festo AG & Co. KG)

Performance & Reliability: With nearly a century of expertise, Festo combines innovative engineering with IoT-enabled solutions. Its actuators emphasize precision control, low maintenance, and compatibility with smart factory ecosystems. Industry Applications: Festo dominates sectors like pharmaceuticals, food processing, and renewable energy, offering customized automation systems that enhance productivity and sustainability.

Other Notable Brands In The 2025 Rankings

While SMC and Festo lead the list, the following brands also excel in specific niches:

Brand A: Specializes in compact actuators for medical devices.

Brand B: Focuses on heavy-duty applications in construction machinery.

Brand C: Pioneers eco-friendly designs with reduced carbon footprints.

Key Trends Driving Market Growth

Smart Automation: Integration of AI and real-time monitoring in actuator systems.

Sustainability: Energy-efficient designs aligned with global decarbonization goals.

Customization: Tailored solutions for niche industries like aerospace and biotechnology.

This ranking underscores the critical role of innovation and adaptability in maintaining competitive advantage. Brands that prioritize R&D and cross-industry collaboration are poised to lead the next decade of pneumatic automation.

If you want to learn more about low-priced products, please visit the following website: www.xm-valveactuator.com

2 notes

·

View notes

Text

What is the installation space requirement and power consumption?

Planning for both production capacity and practical installation needs—namely, power consumption and floor space—is crucial when thinking about buying a square-bottom paper bag maker. Your factory layout, monthly operating expenses, and long-term scalability are all directly impacted by these two variables.

At Prakash Machineries Pvt. Ltd., we design our square-bottom paper bag machines to be Whether you’re running a large industrial setup or launching a small startup, our machines are built to integrate smoothly into your workspace without demanding major infrastructure upgrades.

In this guide, we explain the power and space requirements of our square-bottom paper bag machines and how you can prepare your facility for successful installation and operation.

⚡ Power Consumption: Designed for Energy Efficiency

Our machine is equipped with servo-driven motors, automated PLC controls, and energy-optimized components to ensure high productivity with minimal energy use. On average, the power consumption of our square-bottom paper bag-making machine falls between

✅ 10 kW to 14 kW per hour

(Depending on the machine model, size range, and optional attachments)

🔋 Breakdown of Power Usage:

Component Approximate Load Main motor (servo drive) 5–7 kW Vacuum pump 2–3 kW Gluing system & heater (if any) 1–2 kW Control panel and sensors 0.5–1 kW Optional attachments (printer, handle unit) 1–2 kW

This efficient power profile means that you won’t need industrial-scale electricity infrastructure to run the machine. Even for startups or medium-scale units, a standard 3-phase connection with a 20–25 HP (horsepower) supply is typically sufficient.

✅ Monthly Cost Estimate:

Assuming 8 hours/day of operation at an average of 12 kW/hr:

12 kW × 8 hours × 30 days = 2,880 kWh/month

At ₹8/kWh (approx. industrial rate in India), monthly electricity cost = ₹23,000

This makes our machine a cost-effective production solution, especially when you compare the high output capacity (up to 192,000 bags/day) with the low operational expense.

📐 Required Space for Installation

Our square-bottom paper bag machines are compact, modular, and engineered to occupy minimal floor space while still offering full production capabilities.

✅ Recommended Installation Area:

20 feet (L) × 8 feet (W) for standard machines 25 feet (L) × 10 feet (W) if optional units (e.g., printer, handle pasting) are included

🏭 Ideal Layout Plan Includes:

Machine footprint—main operational unit

Paper roll loading area—space for jumbo rolls (up to 1 m wide)

Bag collection table—output stacking and packing zone

Operator movement zone—minimum 3 ft clearance on each side

Electrical control cabinet—attached or wall-mounted

Optional space—for printer unit, handle applicator, or lamination feeder (if installed)

Our machines can be installed in a production unit as small as 500–600 sq. ft. You do not need a massive industrial hall. Even a startup with a moderate factory space can begin production seamlessly.

🛠️ Site Preparation Checklist

Before installation, ensure the following infrastructure is in place:

✔️ Electrical Requirements:

3-phase power connection (415V)

A stabilizer or UPS recommended for voltage fluctuation zones

Isolated circuit breaker and control panel for machine safety

✔️ Space & Foundation:

Flat, concrete floor surface (leveling required)

Dust-free, dry environment for optimal performance

Space for operators to safely move around machine

✔️ Ventilation & Safety:

Basic ventilation or exhaust fans (especially in hot climates)

Fire safety measures as per industrial compliance

Proper lighting for operator visibility

💡 Why This Matters to Your Business

Understanding your power and space needs in advance helps you

Avoid delays in installation

Ensure uninterrupted production

Optimize your floor plan for raw material, output, and manpower

Control operational costs with energy-efficient planning

This is especially crucial for startups, small businesses, or factories expanding capacity, where space and energy planning affect both short-term efficiency and long-term profitability.

🔧 Our Support Includes:

At Prakash Machineries Pvt Ltd, we don’t just deliver machines—we offer end-to-end installation support, including:

Pre-installation guidance (electrical, civil layout)

Custom floor plans for your site

On-site machine setup and calibration

Operator training and troubleshooting

Maintenance and after-sales service

🏁 Conclusion: Compact. Efficient. Installation-Ready.

Our square-bottom paper bag-making machines are designed to be energy-efficient and space-friendly—ideal for both high-output factories and compact manufacturing setups. With low power consumption (10–14 kW) and a compact footprint (under 250 sq. ft.), you can begin or scale up your paper bag production with minimal infrastructure investment.

📞 Plan Your Factory Setup With Us

Want help designing your factory layout? Need a customized installation guide for your plant? We’re here to help.

👉 Contact Prakash Machineries Pvt Ltd to get a personalized site layout, electrical requirement checklist, or expert consultation to prepare your facility for high-speed, efficient paper bag production.

#manufacturer#paper bag manufacturer#paper bag#paper#machines#flexo#v bottom#square bottom#alien stage#baking#bags#cake#chris sturniolo#cooking#critical role#dan and phil#delicious#breakfast#chocolate

1 note

·

View note