#Factory Automation Display

Explore tagged Tumblr posts

Text

Digital VGA STN PCB Card | High-Performance Industrial Automation Module | Ram Automations

Level up your industrial and marine automation systems with the Digital VGA STN PCB Card, now available at Ram Automations. Designed for high-precision signal processing and industrial-grade visual outputs, this PCB card ensures seamless communication between your control hardware and visualization systems.

Built to support mission-critical automation environments, the Digital VGA STN PCB Card is ideal for upgrading your system’s display interfaces, ensuring clear communication, real-time monitoring, and system stability across industrial setups.

🛒 Buy Now: 👉 https://ramautomations.com/products/digital-vga-stn-pcb-card

🌐 Explore More Premium Industrial Products: 👉 https://ramautomations.com

🔧 Product Overview:

• 📦 Product Name: Digital VGA STN PCB Card • 🏢 Brand: Digital (Digital Equipment Corporation) • 🧩 Type: Printed Circuit Board (PCB) — VGA Signal and Display Interface Module • 📌 Condition: Fully Tested • 🛠 Applications: Factory floor systems, marine automation displays, process control panels, SCADA visualization, machine interfaces

✅ Key Features:

✔️ Genuine Digital Equipment Corporation board ✔️ High-quality VGA signal output for industrial monitors ✔️ Seamless integration into control and automation systems ✔️ Strong signal stability and display clarity ✔️ Reliable design for demanding industrial environments ✔️ Fully verified for performance and longevity

🏭 Ideal Applications:

✔️ Industrial visualization systems ✔️ Automation cabinets and control panels ✔️ Marine navigation displays ✔️ SCADA workstations ✔️ OEM equipment visualization ✔️ Factory production monitoring systems

Whether you’re upgrading your automation displays or maintaining OEM equipment, the Digital VGA STN PCB Card offers the best combination of durability, quality, and precision output.

🛠 Why Choose Ram Automations?

At Ram Automations, we stock tested, genuine, and hard-to-find industrial parts from over 1000 global brands, ready to ship worldwide.

✔️ 1000+ Global Brands in Inventory ✔️ Fully Tested, Reliable Automation Components ✔️ Fast Worldwide Delivery ✔️ Bulk and OEM Support Available ✔️ Expert Technical Assistance

📽️ In This Video You Will Learn:

🔎 Full Visual Overview of Digital VGA STN PCB Card ⚙️ How to integrate it into industrial visualization systems 📈 Applications in SCADA and process control ⚡ Why visualization modules are crucial for system monitoring 🌍 Benefits of trusted brands like Digital Equipment Corporation in industrial automation

📣 Subscribe and Stay Updated:

🔔 Subscribe to Ram Automations YouTube Channel for weekly videos featuring industrial spare parts, system integration tips, and rare automation components. 💬 Drop your questions in the comments — we respond fast! 👍 Like this video if you found it helpful

#Digital VGA STN PCB Card#VGA PCB Board#Industrial Display Module#Automation Visualization Card#SCADA Display Card#Industrial PCB for Displays#Ram Automations#Digital Equipment Corporation Board#Automation Visual Module#VGA Industrial Control Board#Marine Display Board#SCADA Panel Board#Factory Automation Display#VGA Signal Module#Automation Display Module#OEM Display Parts#Industrial Automation Board#Industrial Signal Processing#Industrial Electronics Board

1 note

·

View note

Text

B-2 Gets Big Upgrade with New Open Mission Systems Capability

July 18, 2024 | By John A. Tirpak

The B-2 Spirit stealth bomber has been upgraded with a new open missions systems (OMS) software capability and other improvements to keep it relevant and credible until it’s succeeded by the B-21 Raider, Northrop Grumman announced. The changes accelerate the rate at which new weapons can be added to the B-2; allow it to accept constant software updates, and adapt it to changing conditions.

“The B-2 program recently achieved a major milestone by providing the bomber with its first fieldable, agile integrated functional capability called Spirit Realm 1 (SR 1),” the company said in a release. It announced the upgrade going operational on July 17, the 35th anniversary of the B-2’s first flight.

SR 1 was developed inside the Spirit Realm software factory codeveloped by the Air Force and Northrop to facilitate software improvements for the B-2. “Open mission systems” means that the aircraft has a non-proprietary software architecture that simplifies software refresh and enhances interoperability with other systems.

“SR 1 provides mission-critical capability upgrades to the communications and weapons systems via an open mission systems architecture, directly enhancing combat capability and allowing the fleet to initiate a new phase of agile software releases,” Northrop said in its release.

The system is intended to deliver problem-free software on the first go—but should they arise, correct software issues much earlier in the process.

The SR 1 was “fully developed inside the B-2 Spirit Realm software factory that was established through a partnership with Air Force Global Strike Command and the B-2 Systems Program Office,” Northrop said.

The Spirit Realm software factory came into being less than two years ago, with four goals: to reduce flight test risk and testing time through high-fidelity ground testing; to capture more data test points through targeted upgrades; to improve the B-2’s functional capabilities through more frequent, automated testing; and to facilitate more capability upgrades to the jet.

The Air Force said B-2 software updates which used to take two years can now be implemented in less than three months.

In addition to B61 or B83 nuclear weapons, the B-2 can carry a large number of precision-guided conventional munitions. However, the Air Force is preparing to introduce a slate of new weapons that will require near-constant target updates and the ability to integrate with USAF’s evolving long-range kill chain. A quicker process for integrating these new weapons with the B-2’s onboard communications, navigation, and sensor systems was needed.

The upgrade also includes improved displays, flight hardware and other enhancements to the B-2’s survivability, Northrop said.

“We are rapidly fielding capabilities with zero software defects through the software factory development ecosystem and further enhancing the B-2 fleet’s mission effectiveness,” said Jerry McBrearty, Northrop’s acting B-2 program manager.

The upgrade makes the B-2 the first legacy nuclear weapons platform “to utilize the Department of Defense’s DevSecOps [development, security, and operations] processes and digital toolsets,” it added.

The software factory approach accelerates adding new and future weapons to the stealth bomber, and thus improve deterrence, said Air Force Col. Frank Marino, senior materiel leader for the B-2.

The B-2 was not designed using digital methods—the way its younger stablemate, the B-21 Raider was—but the SR 1 leverages digital technology “to design, manage, build and test B-2 software more efficiently than ever before,” the company said.

The digital tools can also link with those developed for other legacy systems to accomplish “more rapid testing and fielding and help identify and fix potential risks earlier in the software development process.”

Following two crashes in recent years, the stealthy B-2 fleet comprises 19 aircraft, which are the only penetrating aircraft in the Air Force’s bomber fleet until the first B-21s are declared to have achieved initial operational capability at Ellsworth Air Force Base, S.D. A timeline for IOC has not been disclosed.

The B-2 is a stealthy, long-range, penetrating nuclear and conventional strike bomber. It is based on a flying wing design combining LO with high aerodynamic efficiency. The aircraft’s blended fuselage/wing holds two weapons bays capable of carrying nearly 60,000 lb in various combinations.

Spirit entered combat during Allied Force on March 24, 1999, striking Serbian targets. Production was completed in three blocks, and all aircraft were upgraded to Block 30 standard with AESA radar. Production was limited to 21 aircraft due to cost, and a single B-2 was subsequently lost in a crash at Andersen, Feb. 23, 2008.

Modernization is focused on safeguarding the B-2A’s penetrating strike capability in high-end threat environments and integrating advanced weapons.

The B-2 achieved a major milestone in 2022 with the integration of a Radar Aided Targeting System (RATS), enabling delivery of the modernized B61-12 precision-guided thermonuclear freefall weapon. RATS uses the aircraft’s radar to guide the weapon in GPS-denied conditions, while additional Flex Strike upgrades feed GPS data to weapons prerelease to thwart jamming. A B-2A successfully dropped an inert B61-12 using RATS on June 14, 2022, and successfully employed the longer-range JASSM-ER cruise missile in a test launch last December.

Ongoing upgrades include replacing the primary cockpit displays, the Adaptable Communications Suite (ACS) to provide Link 16-based jam-resistant in-flight retasking, advanced IFF, crash-survivable data recorders, and weapons integration. USAF is also working to enhance the fleet’s maintainability with LO signature improvements to coatings, materials, and radar-absorptive structures such as the radome and engine inlets/exhausts.

Two B-2s were damaged in separate landing accidents at Whiteman on Sept. 14, 2021, and Dec. 10, 2022, the latter prompting an indefinite fleetwide stand-down until May 18, 2023. USAF plans to retire the fleet once the B-21 Raider enters service in sufficient numbers around 2032.

Contractors: Northrop Grumman; Boeing; Vought.

First Flight: July 17, 1989.

Delivered: December 1993-December 1997.

IOC: April 1997, Whiteman AFB, Mo.

Production: 21.

Inventory: 20.

Operator: AFGSC, AFMC, ANG (associate).

Aircraft Location: Edwards AFB, Calif.; Whiteman AFB, Mo.

Active Variant: •B-2A. Production aircraft upgraded to Block 30 standards.

Dimensions: Span 172 ft, length 69 ft, height 17 ft.

Weight: Max T-O 336,500 lb.

Power Plant: Four GE Aviation F118-GE-100 turbofans, each 17,300 lb thrust.

Performance: Speed high subsonic, range 6,900 miles (further with air refueling).

Ceiling: 50,000 ft.

Armament: Nuclear: 16 B61-7, B61-12, B83, or eight B61-11 bombs (on rotary launchers). Conventional: 80 Mk 62 (500-lb) sea mines, 80 Mk 82 (500-lb) bombs, 80 GBU-38 JDAMs, or 34 CBU-87/89 munitions (on rack assemblies); or 16 GBU-31 JDAMs, 16 Mk 84 (2,000-lb) bombs, 16 AGM-154 JSOWs, 16 AGM-158 JASSMs, or eight GBU-28 LGBs.

Accommodation: Two pilots on ACES II zero/zero ejection seats.

21 notes

·

View notes

Text

The Shadow of Khansar (Salaar Fic)

Part 6 - Wrought Iron

Part 5 | Part 7

The first thing that Deva notices when he starts to gain consciousness is the rhythmic clang of metal meeting metal. A part of him believes that in the state he is in, the constant clashing should be annoying and more than enough to give him a headache. If anything it feels reassuring, as if he was back in his forge in Bharuch. It starts to dawn on him just how much he’s missed his routine of grinding away in the stifling heat as he works to create intricate shapes out of metal.

Not many people would enjoy the hassle of blacksmithing, not in a day and age where everything was automated. To this day he can hear the advice provided to him by older colleagues who urged him to leave the forge and work in the factories where work would be just a little less strenuous and the pay just slightly higher. Deva couldn’t initially pinpoint why he liked his trade enough that he refuted their advice and spent years dedicated to honing his craft despite how niche it seemed.

With age however, come epiphanies that should have been obvious from the start. Some of his best childhood memories included his time in the forges of Khansar, where his father and him spent hours working in the grueling temperatures. Dhaara was a busy man said to have been taken under the wing of Sivamannaar for his unmatched wit and integrity. He was almost never home and Deva couldn’t remember Amma and him faulting Dhaara for not being around. Probably because even during the short periods of time he was available, he would shower them with love in the only way he knew how.

While Amma situated herself in the back of the workspace to share with Dhaara the instances of everyday life he couldn’t participate in, Deva would stand next to his father, watching as he used his brute strength to create mesmerizing works of art that would later be displayed in their home, or in the homes of their loved ones. Once, when Deva begged his father to let him make something too, his father smiled warmly, pride shining in his eyes as he led them to the forge. He remembered just how often he messed up that day, his still developing body not used to the strain of handling such bulky tools. Yet, Dhaara patiently stood by his side, correcting any mistakes along the way. The final result of their time was a small trinket in the shape of a wonky letter D, if it could even be considered that.

When he dropped the piece of metal into Amma’s hands later that day, she ruffled his hair telling him just how much she loved it. It wasn’t till much later, after the death of his father, that the misshapen D returned to him. His mother had taken the time to thread the pendant, along with some smaller pieces of metal from their workshop, to a leather cord and hung it around his neck when they celebrated his first birthday away from Khansar. His first birthday without his father.

As his body begins to adjust to the sounds, he tries to pry open his eyes despite the heaviness that strains to keep them lidded. As they open, Deva observes something yellow shining through a haze of green. He blinks a few times, trying to clear the blurriness and is able to successfully deduce that he’s in a green tent facing towards a large fire. Behind it seems to be a large, looming statue that he can’t quite make out through the brightness, so he turns his gaze down towards his body and holds in a sigh of frustration when he sees the shackles binding his limbs.

The other part of living in Bharuch he misses is not being tied down every few days. A luxury he never considered he would miss.

“Finally, you’re awake.” Deva looks up in confusion when he hears the obvious relief pouring out of a stranger’s voice. The man standing in front of him looks vaguely familiar, though he can’t exactly place from where. His long curls are gathered into a bun that rests loose at the back of his neck, drawing attention to his striking facial features. The length of him is draped in gray fabrics that hang loosely over his torso and he is void of any distinct marks or jewelry that would explain his descent or affiliation. Despite this, there is an aura of power that radiates off of him, symbolizing the status of a leader who knows his place.

“I was worried that we had miscalculated the dose for the sedative.” He goes on to explain, pulling up a chair in front of Deva and taking a seat. “Are you doing okay? Can I get you anything? Water?”

“This might be an obvious series of questions from my side, but I’m going to go ahead and ask anyway. Who are you? Where am I? Why am I here?” Deva’s eyes flick to the pitcher of water on the side table and hesitates for a second before choosing to concede. “And I’ll have that glass of water now, if the offer is still on the table.”

“Yes, of course.” The man nods, standing up to fill up the glass before handing it over to Deva. “I’m not surprised that you don’t recognize me. It’s been 25 years after all and even back then, we didn’t know each other too well. You were always with Varadha.” At the mention of his name, Deva tenses, eyes narrowing immediately as he considers the possibility of a threat. “Even now, you’re choosing to focus on him instead of the bigger picture I’m trying to provide you with. Do you remember Agira? I’m his son.”

The blood in Deva’s system runs cold as the implication of what this means washes over him. “You can’t be. All of the Shouryangas were–”

“No, not all of us.” He gestures outside of the tent, where Deva can make out the forms of blue-covered bodies wandering around the fire. His gaze is once again drawn to the statue located directly behind the flame and all at once, the shape of it registers in his head. The wolf. Their wolf. “We survived. Our parents made sure we survived.”

“So that means that you’re–”

“Bhaarava. I go by Bhaarava now. You’ve seen me before at Velamgadi. Well… maybe you caught a glimpse.” Then he waves towards Deva’s body. “It might make me sound crazy to you, but don’t take any of this to heart. It’s all for our own safety. With everything you’ve done since stepping foot in Khansar, I figured it’d be best to take all the precautions necessary. You aren’t in harm's way though. I just want to talk.”

“Funny. I’ve been away for so many years that I forgot the traditions of our land. I can’t believe I ever found more comfort in a regular conversation than in one where I am chained against my will.” Bhaarava doesn’t seem amused by the dry humor.

“You’re not alone anymore Devaratha. You’re people are here. We are alive despite the injustice that was inflicted upon us. We’ve spent the last decade plotting our revenge against the crown that took so much for us. We’ve changed our identities, infiltrated the government, and spent years plotting to destroy our enemies. Now is the time for us to take back what belongs to us. To burn the throne and make way for a new empire.” He leans closer, a fire burning bright in his eyes. “The Shouryanaga Empire. Join us in our battle for justice. Avenge your father and the people we have lost. Stake your claim to the throne that is your birthright.”

Deva stares at Bhaarava, unable to move. The emotion that flows through him is too much to handle as his memories flash back to that night. He doesn’t remember much other than the fact that he was terrified. He startled awake at the sounds of shrill screams. One look out his window showcased his neighborhood encapsulated in flames and people running out in hoards only to be murdered viciously on the streets. Later, of course, there were the men. There was him trying to save his mother as best as he could, fear crushing his heart when he realized he had failed, and then there was Varadha.

Varadha who had sacrificed his birthright to save Deva and Amma. Who faced the burden of humiliation at every turn, unappreciated in a society that idolized power over kindness. Who cared for Deva enough not to come calling even in his deepest moments of despair because he wanted him to live a good and happy life.

“No.” Deva utters, meeting Bhaarava’s gaze. To his credit, Bhaarava doesn’t look surprised. He takes a deep breath, crossing his arms over his chest as he leans back.

“So you what? Promised the throne to the son of the man who murdered our people?” Deva’s skin prickles.

“You said so yourself. It was a decision made by his father, not him.”

“The throne in his hands is no better than the throne in his father’s. The Mannarsi cannot be trusted, Devaratha. The throne belongs in the hands of our people because we are the only ones who can do right by Khansar.”

“So your solution is to put power over the kingdom in the hands of a man who hasn’t even lived within the confines of Khansar for twenty-five years?” Deva scratches at his temple. “You realize how insane that is right. The kingdom would be in better hands if Varadha ruled than I did. He’s the leader this city deserves. And since none of you bothered to ask for my opinion regarding the matter of birthright, let me clarify right now that I don’t want the throne.”

“A part of me hoped you wouldn’t do this,” Bhaarava stands wiping his hands across the fabric of his thighs. “I hoped you would realize where your loyalties should lie and that you would join us in our quest for a better, brighter future. I should’ve known though, that hope is useless in a land confined to the virtues of revenge and enmity.”

“Where are you going?” Deva sneers as Bhaarava stands, his back facing towards him. Slowly, Bhaarava looks over his shoulder at Deva, his face painted with disapproval.

“If you haven’t noticed, we’re in the middle of a war. It’s time I lead my troops to battle. I trust you’ll stay here if you know what’s good for you.”

“And if I don’t?” Deva can’t help but to challenge.

“Trust me Devaratha Raisaar, you don’t want to make an enemy out of me. You have too much to lose.” With that final statement, Bhaarava swoops out of the tent and begins to call out to his troops, leaving Deva to sit by himself in the confines of a green tent.

~*~

Deva’s not proud of how long it takes, but he’s finally able to break himself out of the cuffs once the camp has been cleared of everyone but two guards stationed outside his tent.

During the span of his childhood, he’d heard the many merits of the Shauryanga tribe. Overall, of course, they were known for their strength, intelligence, and camaraderie. What they actually should have been known for, in Deva’s opinion, is their superior craftsmanship because those shackles were the first ones in Khansar that he hadn’t been able to break himself out of. No wonder why Bhaarava had left him behind with such confidence.

He silently thanks his mother for the small pieces of metal she attached to his necklace that allowed him to pick those locks.

As Deva carefully plots his escape, he hopes that he can get around the guards without creating a scene, but the stars must not be aligned that night because before he knows it, the guards are crumpled to the ground and are thoroughly unconscious. Deva makes out the form of a jeep parked not far away and searches the guards’ pockets, sending a prayer of thanks to Kateramma when his fingers wrap around the sharp edges of a key.

He peels off the license plate before he hops into the car, opening the GPS to see where he’s located and how to make his way out of the remote forest. Once he has the location set, he adjusts the mirrors, catching a glimpse of the wolf statue in the background. A feeling of unease settles within him as he looks into the eyes of the creature and he has to force himself out of the stupor.

Right now, he needs to get back to Varadha. He can worry about everything else later.

And with that final thought, Deva zips out of the forest, making his way home.

~*~

Deva stands in front of the mansion in Pathran, nausea overtaking him as he tries to process the scene around him.

It all feels too familiar. The suffocating smoke twists, turns, and fills the space around him, taking with it any illusion of freedom as it confines him to the reality of battle. Loud sirens ring in the background but with how panicked Deva is, he can’t register them as being anything more than a small nuisance. The streets are lined with the bodies of men, their blood pooling through the streets, gathering to form a sickening river that drowns everything in its path. Deva knows that the wise thing to do would be to glance at the faces of the dead men so he could gauge what exactly happened in the time he was gone. But fear grips at his throat and he worries just what he’ll find there. He worries that one of those faces could be Varadha’s, and the thought itself is enough to bring him to his knees.

He doesn’t know how much time passes by when he tucks his face into his knees, breathing deeply and cowering in on himself, the tang of rust filling his lungs. An abrupt tap on his shoulder forces him out of his reprieve. He grabs the hand and turns sharply, fist raised in defense.

It falls to his side however, when he notices the face of Chintu standing in front of him, eyes wide with fear and full of tears. Once again, nausea overtakes him as he realizes just how horrifying this scene must be for the child, and he pulls him into an unyielding hug. Chintu cries into him, arms grasping tighter, looking for any kind of comfort. Deva doesn’t know what he can do to provide him with it.

Finally, once his sobs have settled into low hiccups, Deva leans back and signs to him. It’s a little choppy but Chintu understands and signs back at him slowly.

I don’t know where they are. I was with Surabhi and her family. When I came back…

It’s okay, we’ll find them. You’re safe with me.

Deva knows for certain, if nothing else, that part is true. The determination must show through on his face because Chintu nods, taking a sniff as he gathers himself.

“Come on,” Deva says aloud, more so for himself than Chintu, leading them into the mansion. He is careful to keep the boy tucked into his side, a hand covering his eyes as a precaution and Chintu doesn’t protest. Soon, they are in Varadha’s room and it takes all of Deva’s willpower not to scream in frustration at the sight in front of him. The room is a wreck. Antique furniture that Varadha had inherited from his mother’s family is broken or damaged beyond repair. All of his belongings are scattered across the room in enough of a state of disarray that they almost distract him from the bullets lodged into the walls.

He continues to examine the room looking desperately for any sign that would indicate Varadha was okay. That’s when he sees it. Hidden away in the corner of the room, was a wrought iron dog ornament. It was something he had made for Varadha when they were children and he was able to refine his skill enough to create something more intricate than his previous works. Not that it was amazing of course, or anything to brag about for that matter. It was just a small frame of a dog that was too heavy on one side and would keep falling over, never able to stand on its own. Deva had offered many times in the months following to take it back into the shop so that he could adjust it and gift it back. Varadha would always refuse, not willing to part with it, and saying that he liked it exactly as it was.

It was leaning up against the wall, a small piece of paper rolled into the curve of its paw. Within seconds, Deva makes his way over, pulling out the piece and reading through it. The distress drains away immediately and Deva is filled with the comfort of knowing that everything might be okay after all.

Chintu taps at him from behind, a curious tilt to his head as he gestures at the paper.

They’re okay. We found them.

43 notes

·

View notes

Text

IFC to 3DTiles conversion has evolved to this extent with GISBox

Free on-premise cesium ion alternative

As the next generation of spatial information is used in smart cities, digital twins, infrastructure management, etc., the fusion of BIM (Building Information Modeling) and GIS (Geographic Information System) is now an inevitable trend. However, the barrier of interoperability between systems and formats stands between developers and users.

That’s where GISBox comes in. As a new generation 3D spatial data integration platform, it has the industry’s leading IFC to 3DTiles conversion function, and dramatically accelerates data integration and utilization in the fields of architecture, civil engineering, urban planning, and metaverse.

1 | From IFC to 3DTiles: Technology that fills the last step in “BIM x GIS fusion” IFC (Industry Foundation Classes) is an international standard format for BIM that holds geometric information and attribute data (materials, construction history, management numbers, etc.) of architectural structures. On the other hand, 3DTiles is a lightweight format optimized for real-time display that is used in GIS platforms such as Cesium.

There are structural differences between these two, and the following issues frequently occurred in the conventional conversion process:

✅ Missing metadata: BIM attributes such as materials and specifications are lost during conversion

✅ Performance limitations: If IFC is directly loaded into GIS, the display is heavy and it is not suitable for city-level scenes

✅ Compatibility issues: Problems such as display failure and hierarchy collapse due to differences in IFC versions

GISBox tackles these problems head-on, achieving the industry’s first high-precision conversion + attribute preservation + lightweighting at the same time.

2 | No-code & visualization, a conversion experience that is friendly to non-engineers

Conventional conversion tools require specialized knowledge (GLTF, B3DM, etc.), so the reality was that only a limited number of engineers could use them. GISBox provides a UI/UX that anyone can use, such as:

🖱️ Import IFC files by dragging and dropping

👀 Preview LOD settings, materials, and hierarchy display in real time

🚀 One-click OGC-compliant 3DTiles data output (compatible with Cesium, SuperMap, Mapbox)

🔧 API that can be linked with Python and JavaScript is also provided, allowing developers to automate processing

3 | Supports a wide range of use cases, from architecture to urban scale GISBox’s IFC to 3DTiles conversion is being used in a wide range of fields, from visualization of individual buildings to urban scale:

🏙️ Smart building management Integrate IoT sensor information into BIM models to visualize building interior condition monitoring and maintenance forecasts.

🌇 Urban planning simulation Convert hundreds of IFC building models into 3DTiles at once and use them for evaluations such as visibility analysis and sunshine analysis.

🛤️ Inspection and maintenance of infrastructure facilities

Convert civil engineering structures such as bridges and tunnels into 3DTiles while retaining their construction history. A digital foundation for maintenance.

🕹️ Metaverse construction

By outputting models in lightweight 3DTiles format, they can be quickly deployed in virtual exhibition spaces and virtual factories.

4|GISBox as a common language for spatial information

GISBox’s conversion engine is not just a technical tool.

It is a bridge between the different cultures of BIM and GIS,

and a common language for digital space that connects design, construction, and management.

In Japan’s accelerating smart city concept, architectural digital transformation, and urban disaster prevention and mitigation measures,

GISBox is expected to be the key to realizing the “democratization of spatial data.”

GISBox Official Teams: https://teams.live.com/l/invite/FEAr12sInvEVy4hFQE Official Teams Group: https://teams.live.com/l/invite/FBAFp0pbqhqlpe1BQI

Contact us to get 7-day Team Plan

2 notes

·

View notes

Text

More updates on the factory!

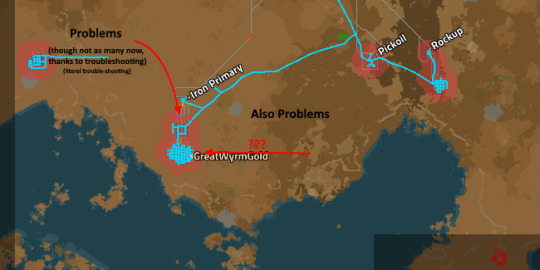

First, a weird problem I was having: Attacks from the rear. Allow me to diagram how I expected things to go with my iron outpost.

("Rockup" is the stone brick pick-up station for that stone outpost I mentioned needing to build.)

Here's how it actually went.

Experienced Factorio players can probably guess where this is going, but I didn't see it coming.

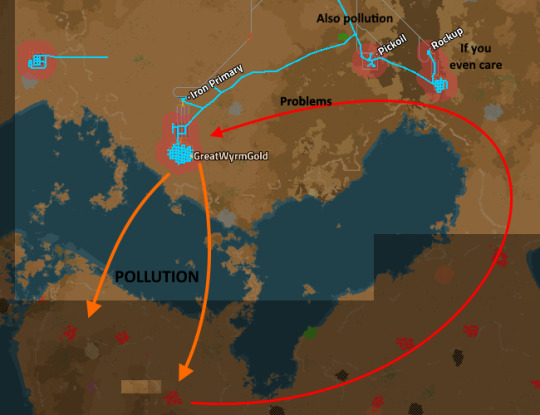

It turns out, Problems will just path to whatever machines caused the pollution they're reacting to, instead of attacking whatever miners or pumpjacks they come across. If I'd figured that out before covering the backside of the iron outpost with turrets, I could have just fortified that path Problems would need to take, which would have been a more elegant solution. But I had other problems.

First, power outages. Second, plastic shortages. Third, copper smelting. Fourth, grenades (for military science). What do all of these have in common? Coal.

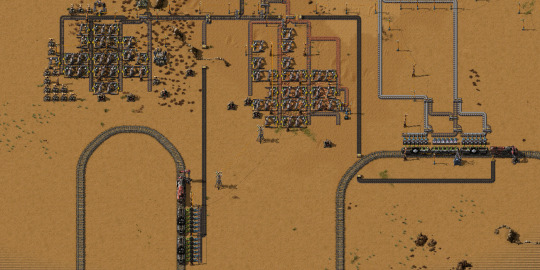

Part of the problem is, unsurprisingly, power. The power outages came shortly after I expanded power production, ironically enough. And since I did so in a slightly spaghetti-ish manner...might as well share.

Anyways, the coal outpost is simple. Miners, laser turrets, a few gun turrets I slapped down in case biters came before I plugged in the laser turrets, train station. The interesting bit there is that I ran out of rails before I could finish the train.

I had some semi-automated rail production at the old stone mine; I had to feed it steel and iron manually, but it handled the rest while I wandered around doing other stuff. That was fine for a while, but I'll need to automate rails soon for purple science anyway, so I might as well set up a proper solution. Especially since stone and iron products are so far from each other.

I was going to set up a train car to deliver iron and steel to the stone outpost, when I noticed something.

There's iron on-site. And an advantage of using this iron ore instead of shipping in metal is that I can put aside some iron ore and stone to make concrete! Of course, for the actual rails I'll need to smelt a lot of that iron ore into iron (and most of that iron into steel), and concrete needs water, and this is quickly turning into a big project that will bring me even closer to biter territory...

...but before I think of setting up a decent defensive perimeter of some kind, I need to remind myself why I'm doing this. I need to make rails, so that I can connect the coal to the main base, which has barely enough coal to maintain its power supply but not enough for production.

I don't need to set up a big defensive line to protect a multi-product outpost to support large-scale rail production. Right now, what I need is enough rails to fix the coal supply, and feeding a temporary assembler array with all the steel in my inventory and half the iron makes more than enough.

Though feeding it all my steel and not returning to the main base to resupply has consequences. Like not being able to put chests in the coal loading station.

The inserters are doing fine for now, I guess. I can fill in the chests once I've finished the dropoff station.

To the left is the preexisting coal dropoff system, to the right is iron. In the middle is the old copper patch, still supplying the base with more copper than it needs. Certainly more than it could smelt!

With these basic resources, plus oil and bricks (not displayed), the base has everything it needs to produce the first four tiers of science pack. And while I'm sure I could bolt the last three into the spaghetti somewhere, this spaghetti was supposed to be a starter base.

And blue science unlocks most of the basic production stuff. There's still Kovarex enrichment and better modules and weapons and power armor and numerical bonuses and space, but for the core factory-designing stuff? I've got it all.

So I guess I need to start designing a real base.

19 notes

·

View notes

Text

Popular Commercial RO Plant Manufacturers in Delhi

Delhi essentially needs clean and pure water for commercial premises, industries, and commercial houses. Commercial RO plants have emerged as the most popular and successful water purification solution. Most of the leading manufacturer’s design and develop these important water treatment systems in Delhi. It removes dissolved solids, chemicals, and other impurities by making them safe for various uses of water in the respective commercial institutions. Be it a hotel, a hospital, a factory, or any other business, the right RO plant manufacturer is sought for water purification purposes. In this blog we discuss the Commercial RO Plant Manufacturers in Delhi, highlighting their efficiency, products, and services.

1. Netsol Water

Netsol Water is a major Delhi-based Commercial RO Plant Manufacturer that has more than 15 years of experience providing water treatment solutions. Netsol Water is known for offering industrial quality water purification systems made in its in-house manufacturing unit at Delhi's industrial area.

The company manufactures commercial RO plants in capacities ranging from 100 LPH to 100,000 LPH that are offered for use by various industries. The plants are made of high-grade stainless steel and other premium components sourced from the best brands available in the market. Each plant undergoes a full-fledged test for quality before it is actually delivered so that it offers prime performance and long use.

What sets Netsol Water apart is their comprehensive approach to customer service. They offer free consultation services, helping businesses choose the right RO plant capacity based on their specific requirements. Their team of experienced engineers provides detailed site surveys and water quality analysis before recommending solutions.

The company's commercial RO plants come with advanced features like automatic operation, digital display panels, and remote monitoring capabilities. They use energy-efficient pumps and motors, helping businesses save on electricity costs. All plants include pre-treatment systems like multimedia filters, activated carbon filters, and antiscalant dosing systems for complete water purification.

Netsol Water's after-sales support is particularly noteworthy. They provide annual maintenance contracts, emergency repair services, and regular performance monitoring. Their spare parts inventory ensures quick replacements when needed, minimizing downtime.

The company has successfully installed RO plants in numerous hotels, hospitals, schools, manufacturing units, and residential complexes across Delhi NCR. Their plants are certified by relevant authorities and come with warranties on major components. They also offer flexible payment options and competitive pricing, making quality water treatment solutions accessible to businesses of all sizes.

For businesses considering a commercial RO plant purchase, Netsol Water offers several advantages:

- Extensive experience in water treatment solutions

- Wide range of plant capacities to suit different needs

- High-quality components and durable construction

- Comprehensive pre and post-sale support

- Energy-efficient designs

- Competitive pricing and flexible payment options

- Quick installation and professional maintenance services

- Proven track record with numerous successful installations

- Advanced monitoring and control systems

- Complete water analysis and customized solutions

2. Pure Aqua Technologies

Pure Aqua Technologies has established itself as a reliable Commercial RO Plant Manufacturer in Delhi. With over a decade of experience, they specialize in medium to large-capacity plants suitable for industrial applications. Their systems feature automated operations and come with comprehensive warranty packages. The company offers installation services and regular maintenance support to ensure optimal plant performance.

3. Waterkraft Systems

Waterkraft Systems rounds out the top three manufacturers, known for their innovative approach to water treatment solutions. They focus on energy-efficient designs and user-friendly interfaces in their RO plants. The company provides customized solutions based on input water quality and client requirements. Their after-sales service includes operator training and quarterly maintenance checks.

Bottom-line

When planning to invest in a commercial RO plant, customers should consider factors like water quality requirements, daily consumption needs, available space, and budget constraints. Netsol Water's expert team can help analyze these factors and recommend the most suitable solution. They also provide detailed project proposals including technical specifications, installation requirements, and maintenance schedules, helping customers make informed decisions.

Contact Netsol Water for a free consultation to discuss your commercial water purification needs and find the perfect RO plant solution for your business in Delhi.

#environment#manufacturer#industries#water#environmental#manufacturers#industrial#netsolwater#purifier#manufacturing#industry#wastewater#filter#delhi

2 notes

·

View notes

Text

Genio 510: Redefining the Future of Smart Retail Experiences

Genio IoT Platform by MediaTek

Genio 510

Manufacturers of consumer, business, and industrial devices can benefit from MediaTek Genio IoT Platform’s innovation, quicker market access, and more than a decade of longevity. A range of IoT chipsets called MediaTek Genio IoT is designed to enable and lead the way for innovative gadgets. to cooperation and support from conception to design and production, MediaTek guarantees success. MediaTek can pivot, scale, and adjust to needs thanks to their global network of reliable distributors and business partners.

Genio 510 features

Excellent work

Broad range of third-party modules and power-efficient, high-performing IoT SoCs

AI-driven sophisticated multimedia AI accelerators and cores that improve peripheral intelligent autonomous capabilities

Interaction

Sub-6GHz 5G technologies and Wi-Fi protocols for consumer, business, and industrial use

Both powerful and energy-efficient

Adaptable, quick interfaces

Global 5G modem supported by carriers

Superior assistance

From idea to design to manufacture, MediaTek works with clients, sharing experience and offering thorough documentation, in-depth training, and reliable developer tools.

Safety

IoT SoC with high security and intelligent modules to create goods

Several applications on one common platform

Developing industry, commercial, and enterprise IoT applications on a single platform that works with all SoCs can save development costs and accelerate time to market.

MediaTek Genio 510

Smart retail, industrial, factory automation, and many more Internet of things applications are powered by MediaTek’s Genio 510. Leading manufacturer of fabless semiconductors worldwide, MediaTek will be present at Embedded World 2024, which takes place in Nuremberg this week, along with a number of other firms. Their most recent IoT innovations are on display at the event, and They’ll be talking about how these MediaTek-powered products help a variety of market sectors.

They will be showcasing the recently released MediaTek Genio 510 SoC in one of their demos. The Genio 510 will offer high-efficiency solutions in AI performance, CPU and graphics, 4K display, rich input/output, and 5G and Wi-Fi 6 connection for popular IoT applications. With the Genio 510 and Genio 700 chips being pin-compatible, product developers may now better segment and diversify their designs for different markets without having to pay for a redesign.

Numerous applications, such as digital menus and table service displays, kiosks, smart home displays, point of sale (PoS) devices, and various advertising and public domain HMI applications, are best suited for the MediaTek Genio 510. Industrial HMI covers ruggedized tablets for smart agriculture, healthcare, EV charging infrastructure, factory automation, transportation, warehousing, and logistics. It also includes ruggedized tablets for commercial and industrial vehicles.

The fully integrated, extensive feature set of Genio 510 makes such diversity possible:

Support for two displays, such as an FHD and 4K display

Modern visual quality support for two cameras built on MediaTek’s tried-and-true technologies

For a wide range of computer vision applications, such as facial recognition, object/people identification, collision warning, driver monitoring, gesture and posture detection, and image segmentation, a powerful multi-core AI processor with a dedicated visual processing engine

Rich input/output for peripherals, such as network connectivity, manufacturing equipment, scanners, card readers, and sensors

4K encoding engine (camera recording) and 4K video decoding (multimedia playback for advertising)

Exceptionally power-efficient 6nm SoC

Ready for MediaTek NeuroPilot AI SDK and multitasking OS (time to market accelerated by familiar development environment)

Support for fanless design and industrial grade temperature operation (-40 to 105C)

10-year supply guarantee (one-stop shop supported by a top semiconductor manufacturer in the world)

To what extent does it surpass the alternatives?

The Genio 510 uses more than 50% less power and provides over 250% more CPU performance than the direct alternative!

The MediaTek Genio 510 is an effective IoT platform designed for Edge AI, interactive retail, smart homes, industrial, and commercial uses. It offers multitasking OS, sophisticated multimedia, extremely rapid edge processing, and more. intended for goods that work well with off-grid power systems and fanless enclosure designs.

EVK MediaTek Genio 510

The highly competent Genio 510 (MT8370) edge-AI IoT platform for smart homes, interactive retail, industrial, and commercial applications comes with an evaluation kit called the MediaTek Genio 510 EVK. It offers many multitasking operating systems, a variety of networking choices, very responsive edge processing, and sophisticated multimedia capabilities.

SoC: MediaTek Genio 510

This Edge AI platform, which was created utilising an incredibly efficient 6nm technology, combines an integrated APU (AI processor), DSP, Arm Mali-G57 MC2 GPU, and six cores (2×2.2 GHz Arm Cortex-A78& 4×2.0 GHz Arm Cortex-A55) into a single chip. Video recorded with attached cameras can be converted at up to Full HD resolution while using the least amount of space possible thanks to a HEVC encoding acceleration engine.

FAQS

What is the MediaTek Genio 510?

A chipset intended for a broad spectrum of Internet of Things (IoT) applications is the Genio 510.

What kind of IoT applications is the Genio 510 suited for?

Because of its adaptability, the Genio 510 may be utilised in a wide range of applications, including smart homes, healthcare, transportation, and agriculture, as well as industrial automation (rugged tablets, manufacturing machinery, and point-of-sale systems).

What are the benefits of using the Genio 510?

Rich input/output choices, powerful CPU and graphics processing, compatibility for 4K screens, high-efficiency AI performance, and networking capabilities like 5G and Wi-Fi 6 are all included with the Genio 510.

Read more on Govindhtech.com

#genio#genio510#MediaTek#govindhtech#IoT#AIAccelerator#WIFI#5gtechnologies#CPU#processors#mediatekprocessor#news#technews#technology#technologytrends#technologynews

2 notes

·

View notes

Text

Check your surroundings for safety

It was either late night or early morning, the difference between the two is so arbitrary and thin. I had just turned the office lights off and locked the door. These twilight hours were nice though, I found an odd comfort to the sound of my steps echoing in the nearly barren car park. Setting my things down in the passenger seat I closed the door and buckled up, safety first. My car is not the newest thing off the factory floor but it does have some nice bells and whistles. The center console lights up and the display is overtaken with the camera feed. A little yellow triangle with an exclamation point and some little white text “check your surroundings for safety”.

Watching the segmented yellow lines curve with my wheels my eyes drift up and around. A harsh chime snaps my attention back and my foot down on the break. Nearly avoiding an annoying collision with a support column. Thanks little camera. Luckily given the hour of the day I and the security guard were the only witnesses, and he wasn’t much of a talker. Shifting into drive the screen changes to the radio, I leave it off for now. The nice thing about being the last one out is you can kind of do whatever at your own pace. So I grabbed my phone and, keeping a leisurely roll, checked up on anything I’ve missed.

She had been texting me. Nothing serious, I had told her these nights were going to be pretty late. Just something about what the cats were doing, the show she was watching, and a loving goodnight. Checking the time on the phone I figured it was best to not text back. I’d be home soon enough anyway. The most I would do now would be wake her up- a flash of orange causes me once again to slam the brakes. Another wonderful safety feature; my side mirrors light up when something is too close and could also cause a collision. It was Dave. Sheepishly I nodded and waved. He chuckled and returned the wave.

Setting the phone face down on the passenger seat; I ought to invest in a phone holder. I made my way out of the car park with no more distractions. The barriers were raised high and the automated voices wished me a good night.

The city roads were illuminated in an orange glow. Steam rising from the sewer vents and road alike; it must have rained while I was working. Lots of blinking yellow signals made the exit of the concrete jungle swift and painless. The freeway was also empty. I couldn’t be happier. Leaning back in my seat my eyelids were feeling heavy. Really heavy. So I turned the air on and set it to biting cold. I also turned the radio over to something a little more upbeat and heart pumping. Tapping the drums on my wheel it was only a split second of darkness until an alarm snapped my eyes back open and the orange indicators flooded the car.

Jerking the wheel to the left I narrowly avoided the guard rail. My heart was racing. Had I really fallen asleep? Muffled noises were becoming more crisp as the alarm subsided and an automated voice took over. It was a test of the emergency broadcast system, what wonderful timing. After confirming that no cops were going to make an easy meal of me I noticed the passenger seat glowing white. She was calling me?

Answering the phone she sounded relieved. I apologized for not texting back as I figured she was asleep. She mentioned I was coming home later than normal and she was getting worried. There wasn’t a big fight or anything, we were both adults. We did have a nice little chat and exchanged “I love you” before I hung up. My heart was pumping and eyes firmly opened now. So it was clear the car was darker than normal.

Normally, and I swear it just had been, the center console would give off some bits of light displaying the radio and the information about what was playing yadda yadda yadda. It was dark however, but like, that dark when a screen is on but not showing anything. I’m no tech wiz but something must have happened during my impromptu nap as it was back on the camera feed. Nothing was being shown other than that little triangle and the little white text. Maybe my quick movements got some wires crossed?

The rest of the freeway was uneventful; thank God. I turned off onto a little back road. I didn’t live super far away from the city, but enough where I could enjoy the night sky every once in a while. I pulled to the side of the road and put the car into park and got out. She hummed softly as I leaned against her and pulled out a smoke. Talking to myself I improved a lecture about the constellations that I knew and made up what I didn’t. I was halfway into the discussion of the bull when an alarm in the car caught my attention. Dropping the little nub and snuffing it out with my heel I slumped back inside.

It was the backup camera? Man I must have really did a number on it. The best thing I could think was to turn the car off and back on again. It didn’t fix it. Still a black screen with the fun little pyramid and text. This was a problem for a mechanic and a different day. So ignoring the warning sounds I put her back into drive and took off down the road. She kept beeping but I could eventually tune it out. What I couldn’t ignore was now my side mirrors were flickering like crazy. Normally it’s a solid light but they were strobing something fierce. It was really distracting. The radio turned itself back on too! What the hell was going on with my car?

My heart was pounding, the hair on the back of my neck standing on end. Why though? It didn’t matter, I could see the house now. The engine was roaring as I tore down the dirt road like a bat out of hell. Why the hell was I so on edge? Closer and closer. The lights were going crazy and the alarm was so damn loud! I gripped the wheel tight, white knuckled. C’mon c’mon almost home. How had I not reached home by no-

I started going backwards.

I looked down at the center console.

Little yellow triangle and small white text.

Check your surroundings for safety.

I could see the road.

#writing#writeblr#original fiction#original writing#original work#just a little one off#Had a little glitch this morning and was inspired#creative writing

5 notes

·

View notes

Text

Crowcon GMC-1002-SS Gasmaster Four Channel Display Board | Gas Detection Excellence | Ram Automations

Crowcon GMC-1002-SS Gasmaster Four Channel Display Board | Gas Detection Excellence | Ram Automations

Description:

Discover reliable gas monitoring technology with the Crowcon GMC-1002-SS Gasmaster Four Channel Display Board, crafted to deliver precision and safety in critical environments. This versatile four-channel display board ensures constant and accurate gas detection, providing peace of mind in industrial, marine, and commercial applications. Trust the Crowcon Gasmaster for enhanced safety, quick response, and dependable performance.

At Ram Automations, we proudly offer genuine automation products from globally renowned brands to help you achieve seamless operations.

🛒 Order Now - Crowcon GMC-1002-SS Gasmaster Display Board 👉 https://ramautomations.com/products/crowcon-gmc-1002-ss-gasmaster-four-channel-display-board-used

🌐 Explore Our Full Product Range: 👉 https://ramautomations.com

#Crowcon Gasmaster Display Board#GMC-1002-SS Display Board#Industrial Gas Monitoring System#Industrial Gas Detection Board#Marine Gas Detection Solutions#Process Automation Equipment#Industrial Automation Safety#Gas Detection Board#Gas Monitoring Systems#Crowcon Gas Detection#Industrial Process Safety#Marine Safety Equipment#Emergency Response Systems#Automation Control Systems#Safety Equipment for Factories#Gas Plant Monitoring Equipment#Crowcon Monitoring Equipment

1 note

·

View note

Text

Boost Productivity with ValanoIPC's High-Performance Industrial Touchscreen PC

Discover the ultimate Industrial Touchscreen PC solution from ValanoIPC, designed for manufacturing excellence. At ValanoIPC, innovation meets durability – our rugged touchscreen PCs deliver seamless performance in harsh industrial environments. Whether you need real-time data acquisition, HMI operations, or automation control, our Industrial Touchscreen PC lineup offers high-resolution displays, multi-touch capabilities, and fanless cooling systems to minimize maintenance. Built with IP65-rated enclosures and wide temperature range support, they ensure reliability on factory floors. Plus, easy integration with PLCs and SCADA systems makes ValanoIPC’s industrial PCs the smart choice for production efficiency. For more information, please feel free to contact us today at +86 13556025664 or email us at [email protected], and you can also visit us here: https://tinyurl.com/2553zra7

0 notes

Text

Top Servo Stabilizer Suppliers: Ensuring Voltage Stability with ABP Powers

In today's industrial and commercial landscape, voltage fluctuations are more than just an inconvenience—they're a threat to sensitive equipment, productivity, and operational efficiency. Machines shut down unexpectedly, electronics fail prematurely, and critical systems risk malfunctioning. The solution? A reliable servo voltage stabilizer. And when it comes to sourcing these devices, partnering with a trusted supplier becomes just as important as choosing the right product. One such name that stands out in India’s power conditioning sector is ABP Powers, a leading supplier of high-performance servo stabilizers suppliers.

Why Servo Stabilizers Are Essential

Servo stabilizers are electrical devices designed to regulate fluctuating voltage levels and deliver consistent output voltage to equipment. Unlike basic stabilizers, servo-controlled voltage stabilizers operate with high precision and are capable of handling wide input voltage variations. This makes them ideal for industries that rely on sensitive or high-end equipment, such as manufacturing units, medical facilities, telecom stations, IT infrastructure, and educational institutions.

Frequent voltage variations, common in many regions, can degrade performance and reduce the life span of devices. Servo stabilizers prevent these issues by maintaining a steady voltage supply, ensuring optimal equipment performance, and minimizing power-related failures.

ABP Powers: A Name Synonymous with Stability

Among the prominent servo stabilizer suppliers in India, ABP Powers has earned a reputation for delivering technologically advanced and durable power conditioning solutions. With years of experience in the field, the company offers a range of servo voltage stabilizers designed to meet the diverse requirements of commercial, industrial, and institutional clients.

What makes ABP Powers a preferred choice is their consistent focus on quality, performance, and customer satisfaction. Their stabilizers are engineered for long-term reliability, even under harsh electrical and environmental conditions.

Key Strengths of ABP Powers’ Servo Stabilizers

Precision Voltage Control: ABP Powers’ servo stabilizers ensure accurate voltage regulation, typically within ±1% of the desired output. This level of precision protects even the most sensitive equipment from damage due to voltage instability.

Wide Input Range: Designed to function effectively across a broad voltage spectrum, their stabilizers can handle extreme power conditions—something especially useful in rural or industrial areas with unpredictable grid behavior.

Heavy-Duty Build Quality: Built using high-grade components, ABP Powers’ stabilizers offer superior durability and efficiency. Their robust construction allows them to operate continuously without overheating or failure.

Customizable Solutions: Every business has different power requirements. ABP Powers offers custom-built servo stabilizers based on load capacity, application type, and site-specific voltage conditions, ensuring a perfect match for every customer.

Digital Monitoring and Protection: Many of ABP Powers’ stabilizers come with digital displays and advanced protective features like overload protection, phase failure protection, and short circuit safeguards, adding another layer of reliability and safety.

Efficient After-Sales Service: ABP Powers is known not just for product excellence but also for strong service support. Their team of skilled technicians provides quick installation, preventive maintenance, and responsive customer service across various regions.

Applications Across Industries

ABP Powers serves a wide range of industries including:

Textile and garment factories

Printing and packaging units

CNC and automation machinery

Hospitals and diagnostic centers

Educational institutions and labs

Banks, data centers, and corporate offices

Each of these sectors requires stable power to maintain productivity, and ABP Powers delivers solutions that meet these critical demands.

Conclusion

Voltage instability is a silent enemy of productivity and equipment health. Investing in a high-quality servo stabilizer suppliers is not just about protecting machinery—it’s about ensuring uninterrupted operations and long-term cost savings. For businesses seeking a trusted supplier that combines product reliability with technical expertise, ABP Powers is a standout choice. Their servo stabilizers are engineered for performance, built for longevity, and backed by service that customers can count on.

Visit:- https://www.abppowers.com/servo_voltage_stabilizer.html

0 notes

Text

Fume Absorber and Extractors: Clean Air Solutions for Safer Workspaces

At Ascomp Inc, we believe that a healthy workspace is a productive one. Whether you're soldering, welding, laser engraving, or working with chemicals, airborne contaminants pose serious risks to both workers and equipment. That’s why we offer high-performance fume absorber and extractors—engineered to remove harmful particles, gases, and odors directly at the source.

Our systems are designed for precision environments, from electronics labs to industrial production floors. With multi-stage filtration, adjustable airflow, and compact designs, our extractors ensure clean air without disrupting your workflow.

Key Features of Ascomp’s Fume Absorber and Extractors

🌬️ High Suction Power: Up to 330m³/h airflow for rapid fume removal

🧠 Smart Control Panel: Adjustable speed, filter alerts, and digital display

🧼 Multi-Stage Filtration: HEPA + activated carbon filters for particles and VOCs

🔧 Flexible Hose & Hood: Positionable arms for targeted extraction

🛡️ ESD-Safe Design: Ideal for electronics and sensitive components

📐 Compact Footprint: Fits seamlessly into workbenches and cleanrooms

🔌 Universal Voltage Support: Operates on 110V–220V for global compatibility

🧪 Low Noise Operation: Quiet fans for uninterrupted focus

📦 Replaceable Filters: Easy maintenance and long service life

🌐 Smart Factory Integration: Optional connectivity for automation and monitoring

Applications Across Industries

Our fume absorber and extractors are trusted by professionals in:

🖥️ Electronics Manufacturing: Soldering, PCB rework, and component assembly

✈️ Aerospace & Defense: Precision welding and avionics repair

🚗 Automotive Systems: Sensor calibration and ECU servicing

🏥 Medical Devices: Cleanroom soldering and diagnostics

🧪 R&D Labs: Chemical testing and prototyping

🎨 Laser Engraving & 3D Printing: Smoke and particle control

Why Choose Ascomp Inc?

✅ IPC-Compliant Air Safety Standards

✅ Expert Consultation & Setup Support

✅ Custom Extraction Solutions

✅ Fast Turnaround & Nationwide Delivery

✅ End-to-End Workspace Safety Systems

At Ascomp Inc, we don’t just extract fumes—we protect your people, your products, and your performance. If you're looking for reliable fume absorber and extractors, we’re ready to help you breathe easy and work smarter.

#FumeAbsorberAndExtractors#AscompInc#AirQualitySolutions#ElectronicsSafety#SmartFactoryTools#ESDSafeEquipment#CleanroomTechnology#SolderingSafety#IndustrialFumeControl#WorkspaceWellness

0 notes

Text

Choosing the Right LCD Panel: A Key Component in Modern Display Solutions

In today’s digital world, LCD panels have become a cornerstone of countless industries—from consumer electronics and automotive systems to medical devices and industrial machinery. These thin, efficient, and high-resolution displays power everything from your smartphone to factory control screens, and understanding their structure and benefits is essential for any business sourcing display modules.

At the core of any visual device lies the LCD display module, which includes the panel LCD, TFT screen, and sometimes a touch interface or LCD driver board. The choice of an LCD module depends on the specific use-case requirements, such as brightness, resolution, durability, and interface compatibility.

Advantages of TFT LCD Modules

A TFT LCD module (Thin-Film Transistor) enhances traditional LCD performance by giving each pixel its own transistor. This results in faster response times, brighter displays, and superior color accuracy. TFT technology is especially popular in applications demanding real-time data and precision—such as POS systems, test equipment, and automotive dashboards.

For businesses needing durable and reliable displays in challenging environments, TFT LCD modules provide optimal visibility and performance under varied lighting and temperature conditions.

Customization and Versatility in Display Modules

From small handhelds to large touch terminals, the display module is more than just a screen—it's an integrated solution. Modern LCD display modules can be customized with capacitive or resistive touchscreens, wide viewing angles, extended temperature ranges, and anti-glare coatings. This adaptability makes them suitable for industrial automation, kiosks, HMI (human-machine interface) systems, and more.

The growing need for visual interaction in devices has also led to increased demand for high-quality screen displays. OEMs and system integrators often rely on replacement LCD screens to extend the lifecycle of existing products, reduce maintenance costs, and ensure consistent performance over time.

Selecting the Right LCD Display Module

When selecting an LCD display screen, consider the application environment. Is it exposed to sunlight? Will it need glove touch? Should it resist shock, dust, or moisture? These factors determine whether a basic screen module or a ruggedized TFT LCD screen is the better fit.

Manufacturers like INNOLUX, BOE, AUO, and LG produce a wide range of LCD display modules that serve industries such as medical equipment, transportation, and smart home devices.

Conclusion

Whether you're sourcing a replacement LCD screen, designing a new device, or upgrading your product line, choosing the right TFT LCD module or LCD panel is crucial. With advances in brightness, responsiveness, and durability, modern display LCD technology continues to enhance how users interact with digital content—making it an essential component of innovation across industries.

At Shenzhen Zhiyan Optronics Co., Ltd., we specialize in helping businesses source high-quality LCD screens at competitive factory prices. Whether you need touch panels or complete LCD modules, we offer fast service, reliable stock, and tailored support. Explore more at zylcdshop.com.

#lcd driver board#display module#touch display#touch lcd screen#LCD Module Display#Lcd touch#TFT LCD display#tft lcd display module#lcd module old#inch lcd screen#oled panel#tft lcd screen#tft lcd module#lcddisplays

0 notes

Text

IPS vs OLED: What’s the Best Display Tech for Industrial Use?

IPS vs OLED: Which Display Technology Is Better for Industrial Use?

When building industrial systems such as medical monitors, factory HMI panels, or transportation dashboards, choosing the right display matters. Two of the most widely used technologies are IPS (In-Plane Switching) and OLED (Organic Light Emitting Diode). But which one is better for embedded and industrial applications?

Key Differences Between IPS and OLED Displays

IPS displays offer excellent color accuracy, wide viewing angles, and long lifespans.

OLED displays provide deeper blacks and higher contrast but may suffer from screen burn-in and shorter lifespans.

For long-term industrial use, IPS panels are generally more durable and stable.

Why IPS Displays Are Preferred in Industrial Applications

IPS technology is ideal for applications where reliability and visibility are essential—like medical diagnostic tools, energy monitoring systems, and factory automation. These displays handle prolonged usage, wide operating temperatures, and high-brightness environments better than OLEDs.

OLED is popular in consumer electronics for its vibrant colors, but in industrial settings, it often fails to match IPS in terms of stability and durability.

Read the Full Comparison

If you want a detailed breakdown of IPS vs OLED from an industrial design perspective—including performance, longevity, and real-world application insights—check out the full article here:

IPS vs OLED Display: The Best Technology for Industrial Applications

About Rocktech

Rocktech is a trusted manufacturer of custom industrial TFT displays and embedded display solutions. We support a wide range of display sizes and technologies, including high-brightness IPS panels ideal for medical, automotive, and HMI use cases.

0 notes

Text

GEIMS Vietnam 2025 – A Strategic Bridge Between Supply and Demand in Vietnam’s Electronics and Smart Manufacturing Industry

Global Electronic Intelligent Manufacturing Show ‒ Vietnam (GEIMS Vietnam) will officially return from November 20–22, 2025, at the I.C.E Hanoi International Exhibition Center (91 Tran Hung Dao / 4 Tran Binh Trong, Cua Nam Ward, Hanoi). This marks the second edition of the exhibition organized by Global Sources, a leading international trade show organizer with over 20 years of industry experience. GEIMS Vietnam 2025 is expected to become a key destination for global buyers in the electronics and smart manufacturing sectors.

The show will feature over 200 international suppliers across 250+ booths, coming from Asia’s major electronics manufacturing hubs including Vietnam, Mainland China, Hong Kong, Taiwan, South Korea, and Japan. GEIMS Vietnam will showcase thousands of breakthrough products and technologies, spanning six core categories:

· Electronic Components/Wire Harnesses: ICs, active and passive components, optoelectronic devices, electroacoustic components, motor fans, sensors, switches, connectors, relays, potentiometers, fuses, filter elements, display components, microwave components, wire harnesses, and wiring accessories.

· Surface Mount Equipment and Testing & Measurement Devices: Placement machines, AOI inspection machines, 2D/3D inspection systems, bare board testing devices, visual inspection equipment for electronic components, packaging machines, wave soldering, reflow soldering, drag soldering, dispensing and spraying machines, solder paste, adhesive for surface mounting, and solder wire.

· PCB/PCBA: PCBs, FPCs, multilayer circuit boards, conformal coatings, and PCBA assembly services.

· Factory Support Equipment and Related Materials: Packaging materials, production support materials, dust-free clothing, anti-static shoes and gloves, temperature testing equipment, factory environmental protection and cleaning equipment, logistics and warehousing systems, and factory information management systems.

· Precision Processing Parts and Automation Equipment: Metal components/non-standard parts, hardware components/stamped parts, injection molding machines and molds, laser processing machines, mold subcontracting services, post-assembly intelligent testing equipment, custom automation equipment, industrial robots, machine vision and related components

· VIOE & Optoelectronics: Optoelectronic components, precision optical materials, laser devices and equipment, optoelectronic display, machine vision.

GEIMS Vietnam 2025: Practical Solutions to Save Time and Optimize Supply Chain Costs

For electronics manufacturers, GEIMS Vietnam 2025 is the ideal platform to explore cutting-edge technologies in the field—from components, SMT equipment, measurement systems, and factory management software to cleanroom materials, robotics, machine vision, and automation. Amid the global supply chain shift toward Southeast Asia, Vietnam is rising as a new electronics manufacturing hub with rapid growth. Today’s electronics factories need more than just components—they need reliable, cost-effective, and flexible local suppliers to build a responsive supply chain. GEIMS Vietnam 2025 gives buyers the opportunity to evaluate suppliers in person, test real products on-site, book 1-on-1 meetings for deeper discussions, and attend technical seminars to stay updated on the latest innovations and procurement strategies.

For suppliers, GEIMS Vietnam 2025 is a golden opportunity to connect with the right buyers—at the right time, with the right demand. With thousands of qualified purchasing professionals from the electronics, automotive, industrial, healthcare, and IoT sectors, plus a tailored 1-on-1 B2B matching program, suppliers can shorten the sales cycle, increase order conversion rates, and elevate brand visibility in both local and international markets. Unlike traditional trade shows, GEIMS Vietnam is built as a focused, high-impact platform—prioritizing quality connections and real business results. It’s where top-tier companies don’t just exhibit—they form lasting, strategic partnerships.

GEIMS Vietnam 2025 – Global Electronics Intelligent Manufacturing Show

Date: November 20–22, 2025 (Thursday to Saturday) | Visitor Hours: 9:00 AM – 5:00 PM

Venue: I.C.E Hanoi International Exhibition Center, 91 Tran Hung Dao (4 Tran Binh Trong), Cua Nam Ward, Hanoi

Website: https://www.globalsources.com/trade-fair/geims/

Hotline: +84 28 7101 2828

Visitor Registration: https://byvn.net/3g

Booth Registration Contact

· Email:

Vietnam: [email protected] (Mr. Hoai)

China: [email protected] (Mr. Ben)

1 note

·

View note