#Fiber Fusion Splicer

Explore tagged Tumblr posts

Text

Fusion Splicer FFS-7000 FTTx Splicer

The FFS-7000 is a portable, high-performance fusion splicer for joining optical fibers. It features precise core alignment, a 5-inch LCD touchscreen, and a long-life battery. It's designed for field use in telecommunications and FTTX projects. contact Us: 9319797663

Visit at: https://star-technologies.co.in

#fiberoptic#fttx#fusion splicer#optical fiber#Splicing#splicing machine#fiber fusion splicer#technology#star technologies

0 notes

Text

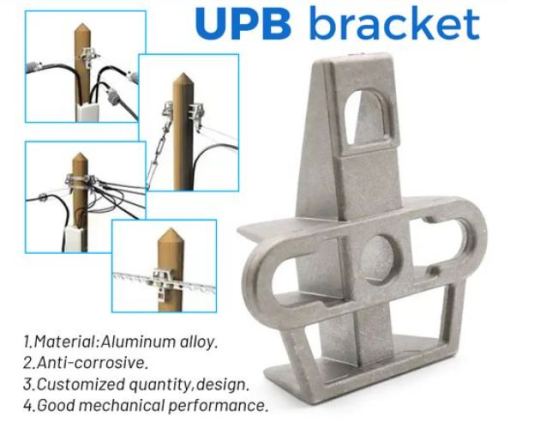

UPB bracket

Product Features:

1.Material:Aluminum alloy

2.Anti-corrosive

3.Good mechanical performance

4.Customized quantity,design

#fiber optics#opticalfiber#opticalfibersa1 fusion splicer#fiberoptic#optician#optical illusion#waterproofing

2 notes

·

View notes

Text

What does a fusion splicer do?

:: What is a Fusion Splicer? As we said above, fusion splicer is the machine used to weld (fuse) two optical fibers together. This process is called fusion splicing. The fiber ends are prepared, cleaved, and placed in alignment fixtures on the fusion splicer.

0 notes

Text

How to Splice Fiber: A Step-by-Step Guide for Clean, Reliable Connections

Introduction

Fiber splicing is at the heart of building and maintaining strong, efficient fiber optic networks. Whether you're deploying a new line or repairing an old one, mastering the splicing process ensures low signal loss and high reliability. In this guide, we’ll walk you through the complete splicing process using advanced equipment such as the Star Ultima Fusion Splicer.

What is Fiber Splicing?

Fiber splicing is the process of joining two optical fibers together to ensure continuous data transmission. The two main types of splicing are:

Fusion Splicing (melting fibers together)

Mechanical Splicing (aligning and holding fibers with a connector)

Fusion splicing is preferred for its low signal loss and strong durability.

Essential Tools for Fiber Splicing

To ensure precise and efficient fiber optic splicing, the following tools are required:

Fusion Splicer – A high-precision device for joining fibers, such as the Star Ultima Fusion Splicer.

Fiber Cleaver – Used to create clean, 90-degree cleaves on optical fibers for optimal fusion results.

Stripping Tool – This removes the protective coating from the fiber without damaging the core.

Cleaning Materials – Includes IPA (isopropyl alcohol) and lint-free wipes to maintain fiber cleanliness.

Fiber Holders – Secure fibers in place during the splicing process.

Heat Shrink Sleeves – Protect the spliced area by reinforcing and insulating the joint.

Protective Gloves – Ensure safety while handling sharp fiber ends and chemicals.

Tips for Better Fiber Splicing

Keep Your Work Area Dust-Free A clean environment is essential for high-quality splicing. Dust particles can interfere with alignment and lead to signal loss or weak splices. Use an anti-static mat, keep the splicing machine closed when not in use, and avoid windy or dusty conditions during outdoor splicing.

Always Use Clean Tools Dirty cleavers, strippers, or fiber holders can contaminate the fiber ends and ruin the splice. Regularly clean your tools using alcohol wipes or lint-free cloths, and replace worn-out blades or pads as needed.

Practice on Scrap Fibers Before Field Use Don’t wait until you're in the field to get comfortable with your tools. Practice splicing on spare or scrap fibers to perfect your cleaving, alignment, and heating techniques. This helps you get consistent low-loss results when it matters.

Proper Cleaving is Crucial The cleave must be as flat and perpendicular as possible. Poor cleaving leads to high splice loss and weak joints. Invest in a good cleaver and handle it with care.

Avoid Bending or Stressing the Fiber Even a well-spliced fiber can fail if it is bent or under tension. Always place splices in a proper protective sleeve and secure the fiber in a splice tray.

Inspect and Clean Before Every Splice Use an inspection microscope to check fiber ends. Even invisible dust or small cracks can cause issues. Clean both the fiber and the V-grooves of your splicing machine.

Professional Fiber Splicing Process

Achieve clean, reliable splices with precision. Follow these 7 critical steps:

1. Strip the Fiber

🔹 Gently remove the outer coating using a precision fiber stripper. ✔️ Ensure the bare glass is undamaged and the stripped length is consistent.

2. Clean the Fiber

🔹 Use a lint-free tissue soaked in 99% IPA (isopropyl alcohol) to wipe the bare fiber. ✔️ Remove all debris, dust, and oils for optimal signal clarity.

3. Cleave the Fiber

🔹 Place the cleaned fiber into a precision cleaver and make a 90° cut. ✔️ A clean cleave is essential for low splice loss and core alignment.

4. Prepare the Fusion Splicer

🔹 Power on the Star Ultima Fusion Splicer, select the correct fiber mode (SM/MM), and load the fibers into the holders. ✔️ Ensure fiber ends are centered and properly aligned.

5. Perform the Splice

🔹 Close the lid and press “Start.” The splicer will align the fibers and fuse them using a calibrated arc. ✔️ Look for a smooth fusion arc and minimal splice loss (typically <0.05 dB).

6. Apply Heat Shrink Protection

🔹 Carefully slide a splice protection sleeve over the joint and place it in the built-in heater. ✔️ Allow the full heat cycle until the sleeve is tight and the joint is sealed.

7. Inspect the Splice

🔹 Use the splicer’s internal inspection mode or an external OTDR to verify splice quality. ✔️ Confirm alignment, loss level, and sleeve integrity.

Conclusion

Fiber splicing is a vital skill for anyone working with fiber optic networks, and mastering it ensures long-term network performance, minimal signal loss, and high reliability. With the right tools—especially advanced equipment like the Star Ultima Fusion Splicer—and a clean, precise technique, you can consistently produce professional-grade splices. Whether you're installing new lines or performing maintenance, following best practices and understanding each step of the process will help you achieve strong, stable connections every time. Keep practicing, stay meticulous, and your splicing results will speak for themselves.

1 note

·

View note

Text

May the spirit of sacrifice guide us on the path of righteousness throughout this holy month and beyond.

Happy Muharram!

#Happy Muharram!#islamic new year#fiber splicing#optical splicing machine#ofc splicing machine#fusion splicer

0 notes

Text

Horizontal Fiber Optic Splice Closure#CH002

Specification:

1.Dimension: 450x175.8x106mm

2.Weight: 3.0kg

3.Cable diameter :Ф7-Ф18mm

4.Cable entry ports :Two cables entry ports on each end

5.Max. Capacity of fiber splice tray:5pcs (12 slots per tray)

6.Max. Capacity :60 fibers / 120 fibers (2 fiber per slot)

7.Sealing structure: Sticky cincture or silicon gum material

#fiber optic#fiber optic patch panel#fiber#fiber optic terminal box#drop cables#optical fiber communication#fusion splicer#fiberoptic#fttx

0 notes

Text

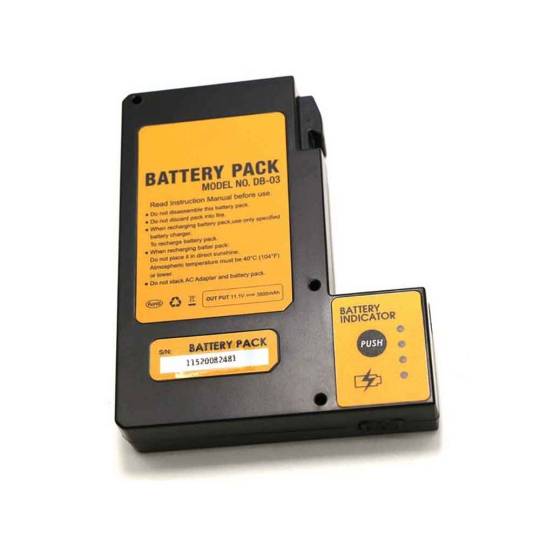

Power Tool Battery DB-03 Replacement Battery for Darkhorse H9 D21 Optical Fiber Fusion Splicer

The DB-03 Battery as a high-performance replacement battery for Darkhorse H9 D21 Optical Fiber Fusion Splicer, guaranteed to meet or exceed the original manufacturer's specifications. Each DB-03 battery is 100 % brand new, rigorously tested, and backed by a 1-year warranty to ensure complete reliability and quality assurance. Designed as a fully compatible equivalent to the original battery, it delivers exceptional power and durability while maintaining 100% quality compliance. Rest assured with our industry-leading quality guarantee and thorough performance testing for optimal Darkhorse H9 D21 Optical Fiber Fusion Splicer.

Power Tool Battery DB-03 Replacement Battery for Darkhorse H9 D21 Optical Fiber Fusion Splicer

Replaces these part numbers: DB-03

Compatible with the following models: Darkhorse H9 D21 Optical Fiber Fusion Splicer

Features of Our DB-03 Replacement Battery:

1. Constructed with premium Li-ion cells for extended lifespan and reliable performance. 2. Fully compliant with original specifications for seamless compatibility. 3. Certified for safety and quality (CE, UL, RoHS, ISO9001/9002). 4. Features durable interface metals and insulated components ensuring stable current transmission. 5. Optimized protection circuitry for enhanced charge cycle durability.

How to Choose the Correct DB-03 Power Tool Battery

Visual Match: Ensure the battery’s appearance matches your original DB-03 by comparing it with the images listed on this page. Genuine Quality: Authentic DB-03 batteries feature original battery cells and a certified protection board, ensuring extended charge cycles and full compatibility with your device. Replacement Option: A cost-effective alternative is available! Replacement batteries for the DB-03 require minimal maintenance, are consistently in stock, and can be purchased at a lower cost whenever needed. Need Help? If uncertain about compatibility, please contact us for confirmation before purchasing.

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

Fusion Splicer Market Size, Share, Trends, Demand, Growth, Challenges and Competitive Analysis

"Global Fusion Splicer Market - Size, Share, Demand, Industry Trends and Opportunities

Global Fusion Splicer Market, By Offering (Hardware, Software and Services), Product (Single Fiber Fusion Splicer, Ribbon Fiber Fusion Splicer, Special Fiber Fusion Splicer), Type (Field Splicing, Laboratory Splicing, Factory Splicing), Alignment Type (Core Alignment, Cladding Alignment), End User (Telecommunication, Enterprise, Healthcare, Automotive, Cable TV, Aerospace, Defense, Specialty), Application (Communication, Safety and Security, Surveillance), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa) Industry Trends.

Access Full 350 Pages PDF Report @

**Segments**

- By Type: Core Alignment, Cladding Alignment - By Alignment Type: Single Fiber, Ribbon - By Application: Telecommunications, Enterprise, Cable TV, Aerospace & Defense, Others

The fusion splicer market can be segmented based on various factors. Firstly, by type, the market can be categorized into core alignment and cladding alignment fusion splicers. Core alignment splicers provide the highest level of precision and are often preferred for specialized applications. On the other hand, cladding alignment splicers are more cost-effective and easier to use for simpler projects. Secondly, by alignment type, fusion splicers can be classified into single fiber and ribbon splicers. Single fiber splicers are commonly used for individual fiber connections, while ribbon splicers are ideal for applications requiring multiple fiber connections. Finally, by application, the market can be segmented into telecommunications, enterprise, cable TV, aerospace & defense, and others. Telecommunications segment is anticipated to dominate the market due to the increasing demand for high-speed internet and network connectivity.

**Market Players**

- Fujikura Ltd. - Furukawa Electric Co., Ltd. - Sumitomo Electric Industries, Ltd. - INNO Instrument - Ilsintech Co., Ltd. - Fiber Fox - Darkhorsechina - Signal Fire Technology Co., Ltd. - Shenzhen Ruiyan Communication Equipment Co., Ltd. - Eloik Communication Equipment Technology Co., Ltd.

The fusion splicer market is highly competitive with several key players leading the industry. Fujikura Ltd., Furukawa Electric Co., Ltd., and Sumitomo Electric Industries, Ltd. are among the top companies known for their advanced fusion splicing technology. Other notable market players include INNO Instrument, Ilsintech Co., Ltd., Fiber Fox, Darkhorsechina, Signal Fire Technology Co., Ltd., Shenzhen Ruiyan Communication Equipment Co., Ltd., and Eloik Communication Equipment Technology Co., Ltd. These companies are actively engaged in research and development activities to enhance their product offerings and maintain a competitive edge in the market.

https://www.databridgemarketresearch.com/reports/global-fusion-splicer-marketThe global fusion splicer market is witnessing significant growth driven by various factors such as the increasing demand for high-speed internet and network connectivity, expansion of telecommunication networks, and growing adoption of optical fiber technology in various industries. The market is expected to continue its upward trajectory as advancements in fusion splicing technology lead to more efficient and reliable connections. Additionally, the rise in data traffic and the need for enhanced data transfer capabilities are further fueling the demand for fusion splicers in the telecommunications sector.

One of the key trends shaping the fusion splicer market is the shift towards core alignment fusion splicers due to their superior precision and performance. Core alignment splicers are capable of aligning the fiber cores with high accuracy, resulting in lower splice loss and improved signal quality. This trend is especially prominent in sectors such as aerospace & defense and enterprise where reliability and performance are crucial. On the other hand, cladding alignment fusion splicers are finding increased adoption in applications where cost-effectiveness and ease of use are prioritized.

Another important aspect of the market is the emergence of ribbon fusion splicers, which are designed to splice multiple fibers simultaneously. This technology is gaining traction in cable TV and telecommunications applications where the demand for high-density fiber connections is on the rise. Ribbon splicers offer efficiency and time savings by enabling the splicing of fiber ribbons with minimal manual intervention. As the need for faster data transmission speeds increases, the demand for ribbon fusion splicers is expected to grow further.

In terms of market players, companies like Fujikura Ltd., Furukawa Electric Co., Ltd., and Sumitomo Electric Industries, Ltd. are at the forefront of innovation in fusion splicing technology. These industry leaders are focusing on R&D efforts to develop cutting-edge solutions that meet the evolving needs of customers. Moreover, the competitive landscape of the market is characterized by partnerships, collaborations, and strategic acquisitions aimed at expanding product portfolios and strengthening market presence.

Overall, the fusion splicer market is poised for substantial growth in the coming years, driven by technological advancements, increasing investments in telecommunications infrastructure, and the growing demand for high-speed data transmission. As industry players continue to innovate and diversify their offerings, the market is expected to witness further expansion across various application segments, creating lucrative opportunities for key stakeholders in the global fusion splicer market.**Segments**

- Global Fusion Splicer Market, By Offering (Hardware, Software, and Services) - Product (Single Fiber Fusion Splicer, Ribbon Fiber Fusion Splicer, Special Fiber Fusion Splicer) - Type (Field Splicing, Laboratory Splicing, Factory Splicing) - Alignment Type (Core Alignment, Cladding Alignment) - End User (Telecommunication, Enterprise, Healthcare, Automotive, Cable TV, Aerospace, Defense, Specialty) - Application (Communication, Safety and Security, Surveillance) - Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, Italy, U.K., France, Spain, Netherlands, Belgium, Switzerland, Turkey, Russia, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028.

The fusion splicer market is witnessing significant growth and opportunities across different segments. The offering segment, including hardware, software, and services, plays a crucial role in catering to the diverse needs of customers. Hardware components are fundamental for the functioning of fusion splicers, while software solutions enhance operational efficiency and provide advanced features. Additionally, services such as maintenance, training, and support contribute to the overall customer experience and market expansion. The product segment, comprising single fiber, ribbon fiber, and special fiber fusion splicers, reflects the market's focus on versatility and customization to meet specific requirements. Single fiber splicers remain popular for individual connections, while ribbon and special fiber splicers address the demands of high-density and special applications.

In terms of alignment type, core alignment and cladding alignment splicers offer distinct advantages based on precision and ease of use, catering to different market needs. Core alignment splicers are known for their high accuracy in aligning fiber cores, leading to superior performance, particularly in critical sectors like aerospace, defense, and enterprise. On the other hand, cladding alignment splicers provide cost-effective solutions suitable for simpler projects and applications where precision alignment is not as critical. The divergence in alignment types highlights the market's ability to provide tailored solutions across various industries.

The fusion splicer market's end-user segmentation showcases the diverse range of industries benefiting from advanced splicing technology. Telecommunications, being a key end-user, drives market growth with the expansion of high-speed internet services and network infrastructure. Enterprises leverage fusion splicers for internal communication networks, while healthcare and automotive sectors use them for specific applications requiring reliable data transmission. Additionally, cable TV, aerospace, defense, and specialty industries rely on fusion splicers for enhanced connectivity and performance in their respective operations.

Moreover, the application segment emphasizes the pivotal role fusion splicers play in communication, safety, security, and surveillance systems. The seamless integration of fusion splicing technology in these applications enhances connectivity, data transmission efficiency, and overall system reliability. As industries increasingly prioritize data integrity and network security, fusion splicers become essential tools for ensuring robust communication networks and surveillance systems.

Overall, the fusion splicer market's comprehensive segmentation underscores its adaptability to diverse industry needs and technological advancements. The market's growth trajectory is supported by continuous innovation, evolving end-user requirements, and expanding application areas across different regions globally. As market players focus on developing cutting-edge solutions and strengthening their market presence through strategic collaborations, the fusion splicer market is poised for sustained growth and innovation in the forecast period.

Key points covered in the report: -

The pivotal aspect considered in the global Fusion Splicer Market report consists of the major competitors functioning in the global market.

The report includes profiles of companies with prominent positions in the global market.

The sales, corporate strategies and technical capabilities of key manufacturers are also mentioned in the report.

The driving factors for the growth of the global Fusion Splicer Market are thoroughly explained along with in-depth descriptions of the industry end users.

The report also elucidates important application segments of the global market to readers/users.

This report performs a SWOT analysis of the market. In the final section, the report recalls the sentiments and perspectives of industry-prepared and trained experts.

The experts also evaluate the export/import policies that might propel the growth of the Global Fusion Splicer Market.

The Global Fusion Splicer Market report provides valuable information for policymakers, investors, stakeholders, service providers, producers, suppliers, and organizations operating in the industry and looking to purchase this research document.

Table of Content:

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Global Fusion Splicer Market Landscape

Part 04: Global Fusion Splicer Market Sizing

Part 05: Global Fusion Splicer Market Segmentation by Product

Part 06: Five Forces Analysis

Part 07: Customer Landscape

Part 08: Geographic Landscape

Part 09: Decision Framework

Part 10: Drivers and Challenges

Part 11: Market Trends

Part 12: Vendor Landscape

Part 13: Vendor Analysis

Reasons to Buy:

Review the scope of the Fusion Splicer Market with recent trends and SWOT analysis.

Outline of market dynamics coupled with market growth effects in coming years.

Fusion Splicer Market segmentation analysis includes qualitative and quantitative research, including the impact of economic and non-economic aspects.

Regional and country level analysis combining Fusion Splicer Market and supply forces that are affecting the growth of the market.

Market value data (millions of US dollars) and volume (millions of units) for each segment and sub-segment.

and strategies adopted by the players in the last five years.

Browse Trending Reports:

Digital Dose Inhaler Market Farber's Disease Drug Market Epidermolytic Ichthyosis Market Engine and Transmission Thermal Systems Market Capacitive Sensor Market Nano GPS (Positioning System) Chip Market Diameter Interworking Function (IWF) Market Automotive Energy Absorption (EA) Pads Market D-Malic Acid Market Blood Processing Devices and Consumables Market Bio preservation Market Acrylic Adhesives Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

#fiberoptic#fusion splicer#splicing machine#mass fusion splicer#fttx#Splicer#ffs-9000#fiber optical splicer

0 notes

Text

Fiber optic terminal box

#fiber optics#opticalfiber#opticalfibersa1 fusion splicer#optician#fiberoptic#optical illusion#waterproofing

2 notes

·

View notes

Text

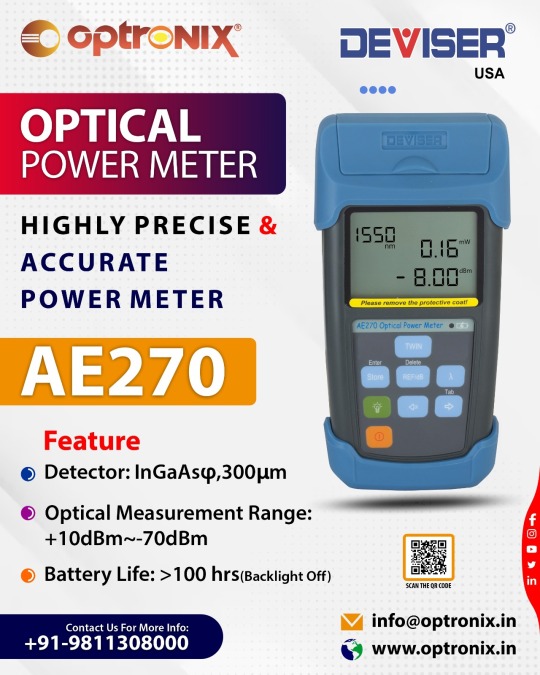

Deviser Power Meter Ae270 for FTTx

The Deviser AE270 Power Meter is the perfect solution for FTTx deployments, providing precise measurements essential for fiber optic networks.

With its intuitive interface and high accuracy, it simplifies power monitoring tasks, ensuring optimal performance and reliability. Trust the Fiber Optic fiber tester AE270 for accurate measurements and seamless FTTx operations.

#fusion splicing machine#optical splicing machine#fusion splicer#otdr machine#fiber joint machine#sumitomo splicing machine

1 note

·

View note

Text

OTB-C04-F and OTB-C04-A comparison chart

#fttx#fiber optic#optical fiber communication#drop cables#fibreoptique#fusion splicer#fiber#fiberoptic

0 notes