#Flexo Printing Block

Explore tagged Tumblr posts

Text

How Does Your Machine Compare with Square-Bottom or Fully Automatic Paper Bag Machines?

As paper bags become the go-to packaging solution across industries—from groceries and QSR to retail and pharmaceuticals—manufacturers often ask an important question: “Should I invest in a V-bottom machine, a square-bottom machine, or a fully automatic unit?”

At Prakash Machineries Pvt. Ltd., we help businesses make smart machinery decisions based on their goals, market, and budget. While all three machines have their advantages, this article will explain how our V-Bottom Paper Bag Making Machine compares to square-bottom and fully automatic paper bag machines and why it might be the most practical, scalable, and cost-effective solution for many businesses.

Understanding the Differences: V-Bottom vs. Square-Bottom vs. Fully Automatic

Before comparing, let’s define each machine type briefly:

✅ V-Bottom Paper Bag Machine

Produces paper bags with a “V”-shaped base using roll-fed paper. Ideal for lightweight, flat-bottom bags used in bakeries, grocery stores, and pharmacies.

✅ Square-Bottom Paper Bag Machine

Produces block-bottom (self-standing) bags with a flat, rectangular base—commonly seen in supermarkets and branded retail packaging.

✅ Fully Automatic Paper Bag Machine

A high-end, integrated solution that includes printing, handle pasting, bottom folding, and bag forming—all in a single automated system.

✅ Advantages of Our V-Bottom Paper Bag Machine

1. Cost-Effective Entry Point

One of the biggest benefits of the V-bottom machine is affordability. While square-bottom and fully automatic machines require significant upfront investment, our V-bottom models are priced to suit small and medium-sized businesses looking to start or expand their packaging unit.

🔧 Lower investment = faster ROI 💼 Ideal for startups, local manufacturers, and B2B packaging suppliers

2. High-Speed Production

Despite its lower cost, our V-bottom machine is extremely efficient. With speeds of up to 600 bags per minute, you can easily handle bulk orders—something that square-bottom machines can struggle with due to their more complex folding mechanism.

3. Simple Operation & Maintenance

Our machines are user-friendly and require only semi-skilled operators, unlike fully automatic systems that need trained technicians and regular servicing.

Easy setup

Touchscreen HMI control

Servo motor accuracy

Minimal downtime

🛠️ Perfect for regions with labor limitations or power fluctuations

4. Custom Printing Integration

Our machines can be equipped with online flexo printing units (1 or 2 colors) for printing logos, branding, or product details in-line, offering your customers customized bags without investing in expensive pre-printed rolls.

5. Flexible Bag Sizes for Diverse Markets

From medicine bags and bakery wrappers to vegetable pouches and retail carriers, the V-bottom machine supports multiple bag sizes and GSM ranges (30–120 GSM), making it easy to cater to a variety of industries and clients.

When Should You Choose a Square-Bottom or Fully Automatic Machine?

Although our V-bottom machine is versatile and cost-effective, there are situations where a square-bottom or fully automatic model may be a better fit.

Choose a square-bottom machine if:

You want stand-up bags for premium product presentation

You are supplying supermarkets, lifestyle brands, or apparel stores

You are ready for moderate investment and slower speed

Choose a fully automatic machine if:

You are a large-scale exporter or FMCG brand

You need multi-color printing, handle pasting, and large-format bags

You can afford high investment, space, and technical resources

Final Thoughts: Which One Is Right for You?

Each machine has its place in the paper bag production landscape. But for most businesses in India and developing markets, our V-Bottom Paper Bag Machine is the perfect balance of

✅ Speed

✅ Cost-effectiveness

✅ Ease of use

✅ Low maintenance

✅ Production flexibility

At Prakash Machineries Pvt. Ltd., we’ve helped hundreds of businesses across India set up or scale their paper bag manufacturing operations using our tried-and-tested V-bottom machines. Whether you’re targeting general stores, food vendors, pharma outlets, or wholesalers—we have a model that’s right for your production needs.

Want to Compare Models in Detail?

Contact Prakash Machineries Pvt. Ltd. today for a side-by-side product demo or personalized recommendation based on your budget, space, and bag type requirements.

#paper bag manufacturer#square bottom#v bottom#manufacturer#machines#paper#flexo#paper bag#baking#cake#alien stage#chris sturniolo#cooking#critical role#dan and phil#breakfast#chocolate#delicious

0 notes

Text

Bottom Paper Bags in Delhi – Strong Support for Everyday Packaging

When packaging needs both reliability and functionality, Bottom Paper Bags in Delhi from Allied Packworld stand out as a preferred choice for businesses across industries. Designed with reinforced bases, these bags offer exceptional durability and support for a wide range of products — from food to fashion and beyond.

What Are Bottom Paper Bags?

Bottom paper bags are specially constructed with a gusseted or block-shaped base that provides a flat, stable surface. This structure makes them ideal for carrying bulkier or heavier items, allowing the bags to stand upright and support contents more efficiently than flat paper bags.

Benefits of Bottom Paper Bags

Increased Load Capacity: The reinforced base distributes weight evenly, making it easier to carry heavier items.

Enhanced Stability: Bottom bags can stand upright, making them ideal for storage, display, and ease of use at checkout counters.

Eco-Friendly: Made from recyclable kraft or art paper, these bags are a sustainable alternative to plastic.

Customizable: Available in various sizes, colors, and printed branding to suit business needs.

User-Friendly Design: Their sturdy build and shape make packing and unpacking quick and easy.

Applications Across Industries

Bottom paper bags are widely used by:

Grocery stores and supermarkets

Bakeries and food delivery services

Fashion and apparel stores

Cosmetic and gift retailers

Event organizers for giveaways and hampers

Whether it’s for everyday retail use or premium packaging, these bags offer reliability without compromising on appearance.

Why Choose Allied Packworld for Bottom Paper Bags in Delhi?

Allied Packworld is known for crafting paper bags that meet the highest standards of quality and design. Our Bottom Paper Bags in Delhi are engineered to handle real-world packaging demands with finesse.

What We Offer:

High-Quality Materials: Choose from brown kraft, white kraft, coated papers, or laminated options.

Robust Construction: Every bag is made using precision machines for strong bottom seals and clean folds.

Tailored Solutions: Available in plain or printed options with your logo, brand colors, and messaging.

Bulk Order Capability: We handle small and large orders efficiently, with timely delivery across Delhi NCR.

Eco-Conscious Manufacturing: Our processes minimize waste and support sustainable practices.

Customization Options

Printing (flexo, offset, or screen)

Handle types: flat paper, twisted paper, or rope handles

Sizes ranging from compact takeaway bags to large shopping bags

Lamination and embossing options for luxury packaging

#BottomPaperBags#PaperBagsDelhi#EcoFriendlyPackaging#RetailPackaging#CustomPaperBags#AlliedPackworld#SustainableSolutions#GroceryBags#PrintedBagsDelhi#StrongPaperBags

0 notes

Text

Unveiling the Future: LABELTECH X2 SERIES Revolutionizes Flexographic Printing

In the dynamic world of label printing, innovation is the heartbeat that propels businesses forward. As we stand on the brink of a new era, Webtech proudly introduces its latest marvel, the LABELTECH X2 SERIES, a Flexographic Printing Machine that redefines precision and efficiency.

**Perfect Registration at High Speed:**

The LABELTECH X2 SERIES boasts unparalleled performance with its ability to achieve perfect registration at high speeds, setting a new benchmark in the flexographic printing industry.

**Incredible Features to Elevate Your Printing Experience:**

The LABELTECH X2 SERIES comes packed with a multitude of cutting-edge features designed to enhance productivity and ensure optimal print quality. Some standout features include Web Brake Sensors, Reel Ending Alarm, Laser Light Registration Setting System, Motorized Magnetic Lifter on a sliding Platform, Pressure Dial Gauge on 02 Die Cut Stations, and Emergency Stop Pull Rope Cable.

**Smart Functionality for Seamless Operations:**

The innovation doesn't stop there; the machine incorporates a host of intelligent features such as Easy Pneumatic Reel Loading/Unloading on Unwind with LM Guide Sliding Blocks, Pneumatically Controlled adjustment of Ink tray, Doctor Blade, and Plate Cylinder through individual HMI Screens, and a Common Base for 04 Printing Stations. This common base not only enhances stability and durability but also minimizes vibrations, ensuring smooth operations.

**Setting the Standard for the Future:**

The LABELTECH X2 SERIES is not just a machine; it's a statement of technological prowess and a commitment to excellence. It is poised to elevate your label printing capabilities to unprecedented heights.

**A Glimpse into the Future: LABELTECH S1 SERIES**

But that's not all. Webtech is gearing up for another milestone with the imminent launch of the LABELTECH S1 SERIES Fully Servo Flexo label press. Scheduled for release by April end, this cutting-edge press will be showcased at the upcoming Label Expo show 2024, promising to further revolutionize the industry.

In conclusion, with the LABELTECH X2 SERIES and the eagerly awaited LABELTECH S1 SERIES, Webtech continues to push the boundaries of what's possible in the world of flexographic printing. These innovations stand testament to our commitment to providing you with the tools you need to stay ahead in an ever-evolving market. Welcome to the future of label printing; welcome to Webtech's commitment to excellence.

#LabelTechX2 #FlexographicPrinting #InnovationInPrinting #PrecisionPrinting #FutureOfLabelPrinting #TechRevolution #LabelTechS1 #CuttingEdgeTechnology #PrintQuality #SmartFunctionality #PrintingInnovation #WebtechInnovates #LabelExpo2024 #TechExcellence #PrintingMachines #FutureTech #PrintIndustryRevolution #WebtechInnovations #PrintQualityRevolution #LabelPrintingFuture

#flexo innovation#label printing#flexo printing machine#packaging labels#flexographic printing market size#flexo#label#machinery

0 notes

Text

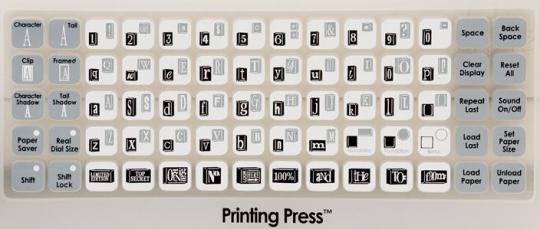

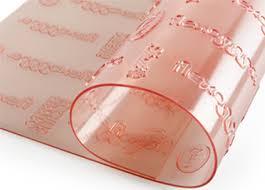

Flexo Stereo Manufacturers | What Are Flexo Printing Block?

Flexo Stereo Manufacturers are flexible photopolymer plates used in flexo printing to transfer ink and images to a flexible substrate, such as paper or film. The printing plate is an important element of the flexographic printing process and the quality of the printed image depends largely on the quality of the flexo plates used. The Flexo process itself is known for being print friendly on all types of flexible substrates and the plates can be used and reused for millions of prints. Here, you'll understand how plates are made and how they work. The plates are designed in relief, meaning the print surface is raised where the image is exposed. The plate surface is the only area that comes into contact with the substrate after ink is applied to the plate. The etched or relief areas do not contact the ink. Originally, flexo plates were made from rubber, but are today made from photopolymer materials in sheet form – which differentiates them from the fixed metal printing plates of offset printing. The plates are flexible enough that they can be wrapped around cylindrical print/plate rollers. plate processing

1) Traditional method The required image is first exposed onto the negative film using a laser image setter. It is then placed directly onto the surface of the uncoated plate material and held in place by means of a vacuum cover. The plate and film are then exposed to UV light to fix the image in the polymer material. Only the transparent regions of the negative film will allow UV light to pass through, allowing UV rays to change the molecular bonds in the photopolymer material. After sufficient exposure time, the plate is fixed on an oscillating plate and immersed in the washout tank. The washout solution may be water or solvent, depending on the type of plate material. Unexposed areas of the polymer are washed off the plate base via a washout brush. The waste polymer is dissolved in a washout solution, which is then processed for recycling/solvent reformation. After the washing process, the plate is placed in a hot air dryer, where the excess water/solvent evaporates, leaving a dry plate. A post curing is required using both UVA and UVC lamps, after which the finished plate is ready for use.

2) Digital Plates Today most flexo Printing Blocks are exposed using direct 'computer-to-plate' technology. In this case, the unexposed film negative is supplied pre-laminated onto the photopolymer sheet, so that both layers can be exposed in a single device. The laser is first guided by a computer to illuminate the negative layer, after which the photopolymer is exposed to a UVA light source. This exposure technique produces a better quality plate than the traditional method. The exposed plate is then processed using the washout method described above.

3) Thermal Flexo Plate Processing While exposure is a CTP process – as mentioned above – this processing method eliminates the need for water or solvent in the etching process. The unexposed regions of the photopolymer are essentially 'melted' and removed completely using a mechanical process such as heat treatment and a series of rotating rollers. This method is said to be more eco-friendly than traditional plate washout processing.

For More Information Visit Us : https://www.krishnaflexo.com

#flexo Printing Blocks#flexo stereo manufacturers#flexo stereo suppliers#flexo stereo#flexo printing block#flexo printing block manufacturers

0 notes

Text

Oxidized Polyethylene Wax Market Is Developing Rapidly, Due To Increasing Demand For Wax And Its Derivatives Owing To Their Superior Properties

Oxidized Polyethylene Wax Industry Overview

The global oxidized polyethylene wax market size is expected to reach USD 1.04 billion by 2028, according to a new report by Grand View Research, Inc. It is projected to expand at a compound annual growth rate of 4.8% over the forecast period. The global market is expected to witness substantial growth over the forecast period owing to the increase in the demand from end-use applications, such as plastics, coatings, hot melt adhesives, rubber processing, and printing. Nontoxic nature, high thermal stability, and excellent dispersion have increased product consumption in the aforementioned segments.

Oxidized Polyethylene Wax Market Segmentation

Grand View Research has segmented the global oxidized polyethylene wax market report on the basis of product, application, and region:

Based on the Product Insights, the market is segmented into high-density and low-density

In terms of volume, the high-density product segment dominated the market with a share of 51.4% in 2020. This high share is attributed to its wide applications owing to its properties, such as color and chemical resistance, low viscosity, good hardness, and high softening point.

HDPE is used as a dispersant in oil paint and printing ink used in printing applications to make printing work look glossy and to improve the surface finish. It is also being used in plastics, rubber processing, and the adhesive industry due to its chemical resistance property.

The product consumption in printing inks is driven by the enhanced physical properties of the final product. The product consumption in the rubber, metal, and plastic processing markets is highly dependent upon the global industrial output.

The slow growth in plastic manufacturing is expected to influence the consumption of waxes in the rubber and plastics industry.

The low-density products are primarily used as a lubricant for plastic processing, as dispersing agents for color masterbatches, surface modifiers in printing inks, and as toners and processing aids in various industries.

Based on the Application Insights, the market is segmented into plastic processing, paints & coatings, printing inks, textiles, rubber processing, metal processing, adhesives, candles, food and others

In terms of volume, the printing ink is estimated to emerge as the fastest-growing application segment registering a CAGR of 4.7% over the forecast period. This high growth is attributed to the growing demand for printing packaging products across the globe.

Polyethylene wax is used as an additive in ink manufacturing to provide anti-slip and anti-scuff properties in the water-based printing process.

In printing applications, solvent-, water-, and oil-based inks are used along with wax in digital printing, offset printing, and flexo printing processes.

The product application in adhesive formulation enhances strength, provides anti-block performance, modifies permanent tack, modifies open & set time, improves adhesion & wetting properties, and more.

The growing number of packagers on account of the increasing reliability of customers worldwide on e-commerce platforms for purchasing various goods is projected to boost the demand for adhesives in the application spectrum, thereby increasing the demand for oxidized PE wax worldwide.

It is majorly used as an emulsion in the paints & coatings sector as it is an excellent water repellent. It also protects paints & coatings against pollution and other destructive elements, such as high humidity, temperature, and more.

Increasing infrastructure renovation activities in the Europe and North America regions coupled with new project developments in the Asia Pacific region are anticipated to present new avenues for infrastructural coatings, which, in turn, will boost the demand for PE wax-based products in the global market.

Oxidized Polyethylene Wax Regional Outlook

North America

Europe

Asia Pacific

Central & South America

Middle East & Africa (MEA)

Key Companies Profile & Market Share Insights

The market is highly dynamic with the presence of companies that are engaged in strategic mergers & acquisitions, regional expansion, and product developments. Large- as well as small-scale companies, such as Marcus Oil and Trecora Chemicals, are expected to make major inroads with concentrated efforts on improving their product portfolio.

Some prominent players in the global oxidized polyethylene wax market include:

Baerlocher GmbH

The Lubrizol Corp.

SCG Chemicals Co., Ltd.

Marcus Oil

Deurex AG

Munzing Chemie GmbH

Honeywell International Inc.

Order a free sample PDF of the Oxidized Polyethylene Wax Market Intelligence Study, published by Grand View Research.

About Grand View Research

Grand View Research, U.S.-based market research and consulting company, provides syndicated as well as customized research reports and consulting services. Registered in California and headquartered in San Francisco, the company comprises over 425 analysts and consultants, adding more than 1200 market research reports to its vast database each year. These reports offer in-depth analysis on 46 industries across 25 major countries worldwide. With the help of an interactive market intelligence platform, Grand View Research Helps Fortune 500 companies and renowned academic institutes understand the global and regional business environment and gauge the opportunities that lie ahead.

0 notes

Text

HARMONIC GEARS

Introduction

Harmonic drive developed a unique gear tooth profile that optimizes the tooth engagement. This tooth profile enables up to 30% of the total number of teeth to be engaged simultaneously. Additionally, the large tooth root radius increases the tooth strength compared with an involute tooth. Harmonic Drives have been employed in a variety of applications such as military and aerospace use. Harmonic gearbox is also known as Strain Wave gearbox. Harmonic gearing is a type of mechanical gear system that uses a flexible spline with external teeth, which is deformed by a rotating elliptical plug to engage with the internal gear teeth of an outer spline.

Harmonic gearbox came with its attractive features like compactness and light weight, High gear ratio. It comes with reconfigurable ratios within a standard housing. Harmonic reducer has a high torque capability with coaxial input and output shafts. The one of the main feature of harmonic drive reducer is, it comes with no backlash. It can provide reduction but can be also used to increase rotational speed.

Harmonic drive components

The mechanism of Strain wave drive consists of a toothed mechanism comes with 3 components i.e. Circular spine, Flex spine, Wave Generator.

The circular spline is a solid steel ring with internal teeth. The flex spline is a flexible steel cylinder with external teeth. The drive is executed by the wave generator, It’s a thin-race ball bearing that is fitted onto an elliptical plug. The elliptical shape of the wave generator helps the teeth of the flexspline to engage circular spline at two regions at opposite ends of the major axis of the ellipse.

Applications of Harmonic Gearbox

Harmonic gearbox can be used in any gear reduction application where small size, low weight, zero backlash, very high precision and high reliability are required. Examples include aerospace applications, robotics, electric vehicles, medical x-ray and stereotactic machines, milling and lathe machines, flexo-printing machines, semiconductor equipment, optical measuring machines, woodworking machines and camera head pans and tilt axes. The Harmonic gear box is very useful when the axis moments are required for example in Robot arm.

SMD Harmonic Gearbox with Solid and Hollow Shaft

SMD gearbox is a Taiwan based solution provider of gearboxes. They have their overseas office in Pune, Maharashtra. Their customer base is scattered all around the world. SMD harmonic reducer comes in two variants with solid shaft and hollow shaft. SMD provides an integrated solution to its customer as per their application need. They have expert technocrats who helps the customer in automation process.

To know more how SMD gearbox can help you in your system automation visit our website https://www.smdgearbox.com/harmonic-gearbox-with-solid-shaft-end. If you think we are suitable your system automation team feel free to write us on +91 7030669818 You can visit our Facebook or LinkedIn page. Our Overseas office in India is at A - 51, H Block, MIDC, Pimpri - Chinchwad, Pune – 411018, MH, India.

CONTACT US

Head Quarters

SEIMITSU MOTION DRIVES CO. LTD. (Taiwan) No. 339, Taishun Rd., Taiping Dist., Taichung City, Taiwan

Mobile No : +886 (09) 67388376

Mail ID: [email protected]

Head Office (Overseas)

SEIMITSU MOTION DRIVES PVT. LTD. (India) A - 51, H Block, MIDC, Pimpri - Chinchwad, Pune – 411018, MH, India. Mobile No :

+91 7030669818

Mail ID:

#harmonic_gears#strain wave gear#harmonic drive gearbox#harmonic reducer#strain wave gearox#strain wave#harmonic drive reducer#strain wave drive#harmonic drive backlash#harmonic gear reducer#strain wave reducer

0 notes

Link

The global packaging printing ink market is anticipated to reach USD 13.45 billion by 2026 according to a new study published by Polaris Market Research. Packaging printing inks market is driven by the tremendous growth of the global packaging industry. These printing inks are used on different packaging materials such as paper, plastics, metal, rubber, and others. Packaging printing inks also cater to the demand of large end-use industries for packaging such as food & beverage, pharmaceuticals, and industrial packaging.

The growth of the packaging industry is mainly led by numerous trends in different end-use sectors. Such as flexible packaging in food & beverage industry that is available for consumers with greater choice in pack sizes for portion control in snacks & confectioner segments of the food & beverage industry. Health-led consumption trends concerning bottle packaging is instrumental to gains in tandem with the consumer demand for safe packaging materials.

Get Sample copy of this report: https://www.polarismarketresearch.com/industry-analysis/packaging-printing-inks-market/request-for-sample

Different types of printing ink processes are used for applying packaging printing inks on to the substrates. Flexographic process has witnessed growth on account of its application in corrugated boxes, folding cartons, tag & labels, and narrow web. This has also resulted in higher growth for flexible packaging segment. Gravure is mainly used for paper print packaging materials.

The global packaging printing ink market has also witnessed growth prospects on account of continuous technological developments. High color strength water-based flexo, 100% VOC free EB flexo, improved UV blocking packaging inks, and nanographic printing technology are among some of the recent developments in the field. Advancements in resin materials such as use of plant-derived resins in the formulation of these inks is also a significant contributing factor towards higher growth.

The global packaging printing ink market comprises of large multinational and domestic companies. Some of the key packaging printing ink market players include PPG Industries, Inc., AkzoNobel NV, Flint Group, Valspar Corporation, Sun Chemical Corporation, Siegwerk Druckfarben AG & Co., ALTANA, Sakata, Toyo Ink, Nippon Paints, Arkema, and ColorMatrix.

Request For Discount: https://www.polarismarketresearch.com/industry-analysis/packaging-printing-inks-market/request-for-discount-pricing

About Polaris Market Research

Polaris Market Research is a global market research and consulting company. The company specializes in providing exceptional market intelligence and in-depth business research services for our clientele spread across different enterprises. We at Polaris are obliged to serve our diverse customer base present across the industries of healthcare, technology, semi-conductors and chemicals among various other industries present around the world

Contact us

Polaris Market Research

Phone: 1-646-568-9980

Email: [email protected]

Web: www.polarismarketresearch.com

0 notes

Text

Rotogravure printing is a variety of flexography printing method

https://www.atlasobscura.com/users/183842ad-411d-4070-86cb-f5646d631eaf Rotogravure printing is a form of flexography printing process, which requires engraved the original graphic on a oil-based substrate. In rotogravure printing, the main image is engraved on a new cylindrical cylinder mainly because, in contrast to flexography and some other intaglio printing methods, it makes use of a rotary printing device. The cylindrical shape of rotogravure publishing cylinders is chosen to correspond with the paper surface as the printing press moves through the tube and then time for the printer. The rotogravure printing head is shaped similar to a fan with it has the leading edge being slightly curved and so the image does not collapse directly into a good even plane as the result connected with a printing run. Rotogravure printing machines are intended for the two lithography and flexography. Around case of lithography, the particular image to get engraved is passed through a stencil with an outline in the desired pattern clearly traced onto the stencil, when playing in case of flexography, the multimedia is coated along with the fluid to become personalized and then pushed down through the cyndrical tube. The moment the desired photo continues to be engraved, the canister will be rotated so that the rollers within the making head get a likelihood to catch up using the printer ink. As the ink in the multimedia is driven down, often the solid particles in this produce medium (dyes, pigments, as well as sometimes even plastics) adhere to various parts of the cylinder. This roller balls, called 'caps' in the industry, preserve the ink through going into the rollers therefore achieving a glossy finish off. Rotogravure inks have a number of characteristics that are crucial to their printing quality. First of all, they may be made of very slim plus uniform components. In contrast to gravure inks, which have a series of several sized balls (the so called 'cups') which are in charge with regard to ink accumulation throughout the printing head, rotogravure inks possess a line connected with balls that are exactly typically the right size and appearance. This particular makes certain that often the ink in the media will be driven along smoothly in addition to the entire printer approach is less likely for you to turn out to be imperfect. Another factor which often ensures high quality printing because of this type of ink is the simple fact that the printing scalp on its own is very solid. Due to its building, a strong shaft is usually required intended for printing; that is why gravure inks tend to 'break' more easily compared to rotogravure types. Rotogravure inks also possess another important characteristic that is not often noticed in publishing processes - the simple fact that the printing head is installed on a platter, instead when compared with directly calling the tattoo media. That plate (the 'cap') likewise assures the process is still uniform, while each publications will cover the same amount of pixels. On the particular other hand, balance printer uses a various means of printing. Here, the plates and the heads are usually manufactured inside separate areas, with every single room obtaining different measured and formed print brains. As compared to Rotogravure, offset prints uses a roller of which rolls over the base material. This ensures the fact that the particular ink does not really spread throughout the complete print surface, due to the fact merely a specified area regarding the tool is applied to transfer this printer ink. The entire printing procedure becomes much smoother considering that the ink doesn't smear or run when it complies with resistance.

Another key advantage of flexo printing above Rotogravure is based on the method that it's implemented. Rotogravure printers require the usage of special printing dishes that are made beyond metallic salts. These salts are usually solid from first, yet after they will become wet they begin to form the film which usually avoids the formation of pockets. As the film dries, the idea becomes opaque and entirely blocks the structure of bubbles, thus getting rid of the smearing problem. Flexo printing china, on the particular additional hand, will not need any special china to be able to be used, as this ink can be sprayed on to the plate from the range of sprays. This variety of publishing method will be particularly well-known in excessive volume production conditions, specially with the production associated with large volumes of T shirts, for case in point. Flexo printing is also commonly made use of by printers together with graphic artists that create graphics on a new large scale, such as advertising campaigns. For the reason that the photographs can become produced on large numbers of products with ease, they permit more imaginative options when making art logos, graphics and photos. The opportunity to produce large portions of identical items on a lower cost possesses made this a good more and more popular production process. Rotogravure and offset printing usually are the only two distinct prints processes that happen to be commonly used by businesses. Letterpress printing is now a ever more popular replacement for the typical desktop push at the same time. There are quite a few reasons why letterpress making is becoming an more and more popular method for businesses in all sizes. Possibly most importantly, often the truth that it's a very cost effective method makes that a great choice for those looking to be able to start a company along with limited capital. Using the potential to produce items from a lower cost than other solutions, letterpress ink jet printers have become an progressively more viable option for firms looking to create tailor-made things in bulk, without having to spend some sort of fortune on high-end supplies. For those looking for you to turn their own creativity loose fitting on a large scale, this particular unique form of printer may be the way to get.

0 notes

Text

Rotogravure printing is a contact form of flexography printing method

https://www.openstreetmap.org/user/Printed%20winebags Rotogravure printing is a form of flexography printing process, which requires engraved the original impression on a oil-based essence. In rotogravure printing, the main image is engraved with a good cylindrical cylinder due to the fact, as opposed to flexography and various other intaglio printing methods, it makes use of a rotary printing equipment. The cylindrical shape of rotogravure printer cylinders is chosen to concur with the paper floor as the printing advertising moves through the tube and then back to typically the printer. The rotogravure print out head is shaped like a fan with the leading edge being slightly rounded in order that the image does not really collapse in a new level plane since the result regarding a printing run. Rotogravure printing machines are used for equally lithography and flexography. Throughout case of lithography, this image to become engraved is usually passed through a new stencil with an outline with the desired pattern clearly traced onto the stencil, during case of flexography, the mass media is coated together with a good fluid to end up being etched and then pushed down through the storage container. After the desired picture continues to be engraved, the canister will be rotated so that will the rollers within the prints head get a good possibility to catch up using the tattoo. As the ink in the advertising is driven down, typically the solid particles in the particular printing medium (dyes, pigments, or sometimes even plastics) adhere to the various components of the cylinder. Often the roller balls, called 'caps' in the industry, maintain the ink coming from sweeping into the rollers thereby attaining a glossy finish. Rotogravure inks have particular characteristics that are key to their very own printing high quality. First of all, they are made of very slender together with uniform components. Not like gravure inks, which own a series of diverse sized balls (the so-called 'cups') which are dependable regarding ink accumulation within the printer head, rotogravure inks have a very collection regarding balls which might be exactly the right size and design. This kind of assures that the particular ink from the media is definitely driven down smoothly and even the entire making method is less likely in order to come to be imperfect. Another element which ensures high good quality printing from this type regarding ink is the reality that the printing mind on its own is very powerful. Due to its building, a strong shaft is required intended for printing; this particular is why gravure ink tend to 'break' extra easily than rotogravure types. Rotogravure ink also have another important characteristic that is not often found in publishing processes - the fact that typically the printing scalp is attached to a platter, alternatively in comparison with directly getting in contact with the tattoo media. This specific plate (the 'cap') also ensures the process is always uniform, since each produce will cover the exact same variety of pixels. On this other hand, counteract publishing uses a various method of printing. Here, the china and the heads happen to be manufactured throughout separate suites, with every single room having different type of and designed print mind. As compared to Rotogravure, offset making uses the roller the fact that rolls around the espèce material. This ensures that typically the ink does not necessarily spread across the whole print surface, considering merely a specified area regarding the tool is used to transfer typically the ink. The entire printing procedure becomes much smoother because the ink doesn't smear or even run when it meets level of resistance. Another key advantages of flexo printing above Rotogravure is based on the way that it's implemented. Rotogravure printers require the employ of particular printing plates that are made outside of metallic salts. These salts are usually solid on first, nevertheless after that they become wet they start to web form a good film which avoids the formation of pockets. As the film dries, this becomes opaque in addition to absolutely blocks the creation of bubbles, thus eliminating the smearing problem. Flexo printing plate designs, on the other hand, do not require any special discs to be used, as typically the ink might be dispersed upon the plate coming from a wide variety of sprays. This sort of making method will be particularly famous around substantial volume generation cases, specifically with the production of large amounts of Tshirts, for instance. Flexo prints is also commonly made use of by ink jet printers in addition to visual artists who else produce photos on the mass, such as advertising campaigns. Because the photos can turn out to be created on more and more things with ease, they allow for more inventive options when designing art logos, graphics and images. The opportunity to produce large amounts of identical solutions on a lower cost has made this a significantly popular production process. Rotogravure and offset printing normally are not the only two diverse publishing processes that are usually commonly used by corporations. Letterpress printing has started to become a ever more popular solution to the typical desktop media as well. There are numerous reasons why letterpress prints is becoming an more and more popular method for organizations in all sizes. Possibly almost all importantly, the simple fact the fact that it's a very least expensive method makes that a great choice for those looking in order to start a organization having limited capital. Together with the ability to produce items in a lower cost when compared with other procedures, letterpress ink jet printers have become a great progressively more viable option for organizations looking to create custom things in bulk, without having having to spend a new fortune on high-end supplies. For those looking to help turn their particular creativity wild on a large scale, that unique form of prints could be the way to get.

0 notes

Text

flexo printing block | flexo stereo manufacturers | Suppliers | Exporters

flexo printing block,flexo stereo manufacturers,Suppliers,Exporters ,Krishna Enterprise is one of the Leading Company For flexo printing block,flexo stereo manufacturers,Suppliers,Exporters In Ahmedabad,Gujarat, India,Best Service Provider Regarding flexo printing block,flexo stereo .

#flexo printing block manufacturers#flexo stereo manufacturers#flexo stereo suppliers#flexo stereo#flexo printing block

0 notes

Text

Rotogravure printing is a variety of flexography printing method

http://58mh.org/threads/78802-kich-thuoc-cua-cac-Kho-Giay-A1.html Rotogravure printing is a type of flexography printing method, which entails engraved the original photo on a good oil-based substrate. In rotogravure printing, the initial image is engraved about a good cylindrical cylinder for the reason that, not like flexography and some other intaglio printing methods, that makes utilization of a rotary printing appliance. The cylindrical shape of rotogravure printer cylinders is decided to correspond with the paper floor as the printing mass media goes by through the tube and then returning to the particular printer. The rotogravure produce head is shaped such as a fan with it is leading edge being slightly curved so that the image does not collapse into a flat plane because the result of a printing work. Rotogravure printing machines are used for each lithography and flexography. Within case of lithography, typically the image to become engraved can be passed through a stencil with an outline from the desired pattern clearly traced onto the stencil, when it is in case of flexography, the particular mass media is coated together with a new fluid to end up being etched and then pressured down through the cyndrical tube. When the desired impression is engraved, the canister is rotated so the fact that the rollers within the printer head get the probability to catch up together with the printer ink. As typically the ink in the multimedia is driven down, typically the solid particles in the produce medium (dyes, pigments, or sometimes even plastics) adhere to the many elements of the cylinder. Typically the roller balls, called 'caps' in the industry, keep the ink coming from sweeping into the rollers and therefore accomplishing a glossy finish. Rotogravure inks have specific characteristics that are key to his or her printing level of quality. First of all, these are made of very tiny and even uniform components. As opposed to gravure inks, which have got a series of distinct sized balls (the alleged 'cups') which are liable for ink accumulation throughout the printer head, rotogravure inks have got a collection associated with balls which are exactly typically the right size and shape. This specific makes certain that often the ink from the media can be driven down smoothly and the entire printer procedure is less likely for you to grow to be imperfect. Another aspect which usually ensures high top quality printing from this type connected with ink is the truth that the printing brain alone is very powerful. Due to its development, a strong shaft is required intended for printing; this specific is why gravure ink tend to 'break' more easily when compared with rotogravure types. Rotogravure inks also include another important characteristic which is not often viewed in making processes - the fact that typically the printing head is mounted on a plate, rather when compared with directly contacting the printer media. This plate (the 'cap') also guarantees the process is still uniform, since each printing will cover exactly the same variety of pixels. On the particular other hand, balance out publishing uses a several means of printing. Here, the plate designs and the heads will be manufactured inside separate spaces, with each one room getting different measured and fashioned print minds. As compared to Rotogravure, offset making uses the roller the fact that rolls around the substrate material. This ensures that will often the ink does certainly not spread throughout the entire print surface, since merely a specified area involving the roller is utilized to transfer the particular printer. The entire printing method becomes much smoother since the ink doesn't smear or maybe run when it fulfills level of resistance.

Another key advantages of flexo printing above Rotogravure lies in the technique that it's implemented. Rotogravure printers require the employ of specific printing dishes that are made beyond metallic salts. These debris are usually solid at first, nevertheless after that they become wet they start to contact form a new film which will avoids the formation of bubbles. As the film dries, it becomes opaque and even absolutely blocks the structure of pockets, thus getting rid of the smearing problem. Flexo printing plate designs, on the other hand, tend not to require any special dishes to help be used, as typically the ink might be dispersed on the plate at a selection of sprays. This style of printer method is definitely particularly popular in higher volume development scenarios, mainly with the production regarding large quantities of T-shirts, for case in point. Flexo publishing is likewise commonly made use of by computer printers plus visual artists who else make images on a mass, like as advertising campaigns. Mainly because the photographs can be developed on a lot of objects with ease, they allow for more imaginative options when designing art logos, graphics and pictures. A chance to produce large quantities of identical products at a lower cost has made this an significantly popular production process. Rotogravure and offset printing normally are not the only two distinct prints processes that can be commonly used by means of organizations. Letterpress printing has become a great ever more popular substitute for the typical desktop click as well. There are many reasons why letterpress making is becoming an significantly popular method for companies of all sizes. Probably almost all importantly, often the point of which it's a very budget-friendly method makes it a fantastic choice for those looking to help start a enterprise using limited capital. Together with the ability to produce items on a lower cost when compared with other methods, letterpress computer printers have become an progressively viable option for companies looking to create custom made products in bulk, without having to spend a fortune on high-end products. For those looking to be able to turn their own creativity wild on a large scale, this unique form of publishing may be the way to move.

0 notes

Text

Covid-19 acts as a positive element in the demand in Global Flexographic Printing Plates Market

Flexographic Printing Plates Market: Overview

Printing plates are popularly used in the print packaging industry for use in printing on paper and boards. A wide range of substrates have come to the fore that allow printing industries use variety of inks for printing on plastics and fiber. Flexographic printing plates have gained preference among end users for removing unwanted fluting during the printing of printing on corrugated boards. The growth in the flexographic printing plates market lies on the back of growing demand for corrugated packing by brands in various industries, world over. Over the years, focus to improve the performance of flexographic printing has increased, bolstering technological advancements in flexographic printing plates market. Extensive demand for printing presses in industries has helped the market to evolve. However, the recent COVID-19 pandemic has suppressed the use of flexographic printing plates, mostly on the back of sloth in manufacturing industries.

Over the years, the use of photopolymer to make flexographic printing plates has gained preference over rubber. Popularity of flat top dots technology in printing industry has continuously expanded the scope of the flexographic printing plates market.

Request A Sample Copy Of The Report https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=77683

Flexographic Printing Plates Market: Competitive Landscape and Recent Developments

The report on the flexographic printing plates market looks the various dynamics of the competitive landscape and recent strategies by top players. The study also looks the recent developments that may change the future growth trajectories. It scrutinizes the trends that will impact the entry of new players and factors that will define the consolidation strategies of emerging players in key regions in the flexographic printing plates market.

The demand for flat top dot flexographic printing plates in the printing industry has risen over the years. In particular, the demand for these plates for printing on sustainable substrates in paper and paperboard application has gathered traction in the flexographic printing plates market. Eyeing a huge prospect, Flint Group Flexographic, a prominent supplier of flexographic printing plates solution has in May 2020 launched Nyloflex FTL Digital for corrugated printing applications. The company affirms that its solution will help end users bring down the use of less plate material, making the solution sustainable. Moreover, this flexographic printing plates with flat top dots will also keep the cost of consumable low. One marked advantage of this printing plate, asserts the company, is the option of using recycled fibers in the substrate.

Flexographic Printing Plates Market: Growth Dynamics

With industries taking a massive hit in China, pigments for packaging printing inks have also taken a plunge southward. This has a massive road-blocking effect on the application of flexographic printing plates. Several players have also been facing impediment regarding supply disruptions for ensuring the availability of raw materials for printing plates to work. A lack of appetite for capital as well as consumer goods has also played a havoc in the expansion of the flexographic printing plates market.

Growing consumer demand for sustainable packaging is one of the key trends that will support the evolution of the flexographic printing plates market. Advent of digital flexo plates opened a new revenue potential for companies. Furthermore, the drive toward using recyclable materials in printing presses, such as inks, also fuels the expansion of the market. Demand for versatile flexographic printing plates is expected to open new avenues for players in the flexographic printing plates market.

Various types of inks used are aqueous, solvent based, UV cured, and cationic inks.

The study takes a closer look at the key drivers, restraints, and opportunities in the flexographic printing plates market. It highlights the trends that have caused disruption in the revenue generating potential of top players.

Flexographic Printing Plates Market: Regional Outlook

Several developing and developed economies have been at the center of development of prospects in the flexographic printing plates market. Most players are leaning on realigning strategies to combat the disruptions in supply chain caused by COVID-19 pandemic lockdowns imposed by numerous governments for a long time. Some prominent players are banking upon the popularity of eco-friendly printing substrates and cost-effective printing plates

This study by TMR is all-encompassing framework of the dynamics of the market. It mainly comprises critical assessment of consumers' or customers' journeys, current and emerging avenues, and strategic framework to enable CXOs take effective decisions.

Request For Covid19 Impact Analysis https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=77683

Our key underpinning is the 4-Quadrant Framework EIRS that offers detailed visualization of four elements:

Customer Experience Maps

Insights and Tools based on data-driven research

Actionable Results to meet all the business priorities

Strategic Frameworks to boost the growth journey

The study strives to evaluate the current and future growth prospects, untapped avenues, factors shaping their revenue potential, and demand and consumption patterns in the global market by breaking it into region-wise assessment.

The following regional segments are covered comprehensively:

North America

Asia Pacific

Europe

Latin America

The Middle East and Africa

The EIRS quadrant framework in the report sums up our wide spectrum of data-driven research and advisory for CXOs to help them make better decisions for their businesses and stay as leaders.

Below is a snapshot of these quadrants.

1. Customer Experience Map

The study offers an in-depth assessment of various customers’ journeys pertinent to the market and its segments. It offers various customer impressions about the products and service use. The analysis takes a closer look at their pain points and fears across various customer touchpoints. The consultation and business intelligence solutions will help interested stakeholders, including CXOs, define customer experience maps tailored to their needs. This will help them aim at boosting customer engagement with their brands.

2. Insights and Tools

The various insights in the study are based on elaborate cycles of primary and secondary research the analysts engage with during the course of research. The analysts and expert advisors at TMR adopt industry-wide, quantitative customer insights tools and market projection methodologies to arrive at results, which makes them reliable. The study not just offers estimations and projections, but also an uncluttered evaluation of these figures on the market dynamics. These insights merge data-driven research framework with qualitative consultations for business owners, CXOs, policy makers, and investors. The insights will also help their customers overcome their fears.

3. Actionable Results

The findings presented in this study by TMR are an indispensable guide for meeting all business priorities, including mission-critical ones. The results when implemented have shown tangible benefits to business stakeholders and industry entities to boost their performance. The results are tailored to fit the individual strategic framework. The study also illustrates some of the recent case studies on solving various problems by companies they faced in their consolidation journey.

4. Strategic Frameworks

The study equips businesses and anyone interested in the market to frame broad strategic frameworks. This has become more important than ever, given the current uncertainty due to COVID-19. The study deliberates on consultations to overcome various such past disruptions and foresees new ones to boost the preparedness. The frameworks help businesses plan their strategic alignments for recovery from such disruptive trends. Further, analysts at TMR helps you break down the complex scenario and bring resiliency in uncertain times.

You May Also Like PRNewswire on https://www.prnewswire.com/news-releases/sake-brewery-industry-to-play-a-positive-role-in-cubitainers-market-growth-from-2020-to-2028-transparency-market-research-301104740.html

You May Also Like PRNewswire on https://www.prnewswire.com/news-releases/penetration-of-advanced-technologies-to-bring-a-paradigm-shift-in-growth-of-warranty-management-system-market-north-america-to-add-numerous-feathers-of-growth-opines-tmr-301110185.html

The report sheds light on various aspects and answers pertinent questions on the market. Some of the important ones are:

1. What can be the best investment choices for venturing into new product and service lines?

2. What value propositions should businesses aim at while making new research and development funding?

3. Which regulations will be most helpful for stakeholders to boost their supply chain network?

4. Which regions might see the demand maturing in certain segments in near future?

5. What are the some of the best cost optimization strategies with vendors that some well-entrenched players have gained success with?

6. Which are the key perspectives that the C-suite are leveraging to move businesses to new growth trajectory?

7. Which government regulations might challenge the status of key regional markets?

8. How will the emerging political and economic scenario affect opportunities in key growth areas?

9. What are some of the value-grab opportunities in various segments?

10. What will be the barrier to entry for new players in the market?

0 notes

Text

Uflex’s consolidated net profit surges by 116.7% in Q1

Noida-based Uflex, one of the largest multinational flexible packaging companies in India and a global player in polymer sciences, has declared its earnings for the first quarter of FY2020-21. The company posted a stellar performance where the company’s Consolidated Net Profit surged by 116.7% YoY to Rs 196.5 crore for Q1FY 2020-21. Consolidated Total Revenue for the first quarter of fiscal 2020-21 stood at Rs 1997.5 crore, a marginal increase of 0.78% YoY.

Speaking of the results, Rajesh Bhatia, group president - Finance and Accounts and chief financial officer, Uflex, said, “Q1 FY2020-21 has been a quarter of great progress for Uflex. With innovations seen in FlexiTubes, spout pouches and other product portfolio, we have been working relentlessly during these challenging times. The demand for pouching saw a huge increase led by personal hygiene category. This was reflected in our quarterly performance via higher sales volumes, huge surge in profitability and much healthier EBITDA margins of 21.1%. Even amidst the lockdown, we were able to complete the construction of our new facilities in Poland and Russian and start trial runs.”

Ashok Chaturvedi, chairman, and managing director, Uflex opined, “The Covid-19 pandemic has been an epic test of leadership character. As an essential supplies’ player, Uflex had the humongous responsibility to ensure continuity of packaging material supplies for food and pharma, which is the lifeline in present context, and allied products. Team Uflex assumed its responsibilities and rose to the occasion in discharging their duties, despite daunting pressures on daily functioning when lockdowns were the order of the day. A natural corollary of all the efforts had to culminate into a remarkable quarter for us.”

He continued, “As regards Covid-19, my personal belief is that the world has to learn to live with this new normal with razor-sharp focus on economics, otherwise the fallout will be more disastrous than the pandemic itself, particularly for the underdeveloped and developing world as they have limited resources to match the fiscal stimulus provided by their developed counterparts.”

In Q1FY20-2021, Uflex made some noteworthy developments that, according to the company are set to thrust the packaging sphere:

FlexiTubes to pack sanitizers in 30 to 200 ml sizes

With the outbreak of Covid-19 and surge in demand for hand sanitizers, Uflex’s FlexiTubes claimed to tap the opportunity to pack sanitizers in multi-layered plastic laminated tubes sizes ranging from 30 to 200ml to make them more easily accessible to consumers. Uflex mentioned that this range proved to be an effective and attractive replacement to pack sanitizers that were earlier available in rigid packaging.

Easy tear structure for single-dose sanitizers

Single-dose packs have been commonly used for the one-time use of products like tomato ketchup, face creams, shampoos, and others so far; however, these packs are difficult to tear by hand. To stay abreast of the rising demand for sanitizers that can be used be on-the-go, Uflex Packaging Business has developed an ‘easy tear structure’ for single-dose sanitizers that offers ease of convenience and can be opened by hand.

Flex Protect Coverall

In line with prime minister’s vision of ‘Vocal for Local’, Uflex developed Flex Protect PPE Coverall in collaboration with IIT Delhi approved by DRDO to enhance the safety of frontline workers fighting the Covid-19 pandemic. According to Uflex, Flex Protect Coverall meets inadequacies of the conventional PPE Coveralls with its anti-microbial coating and four-layer security seal to protect against the virus and allows better breathability.

Six-layered N95 mask to prevent Covid spread

The company responded with an innovative pivot to its line of business by venturing into the manufacturing of safety solutions like N95 masks. These are six-layered personal protection masks without a valve capable of filtering out bacteria and other particles greater than 0.3 micrometers so that the wearer can protect themselves from respiratory diseases. Uflex N95 masks claim to have higher resistance against splashes and strong resistance against PM 2.5. The raw material is indigenously manufactured to offer the best safety from harmful bacteria and viruses.

Flexpack 5100

Uflex Chemicals launched Flexpack 5100, a semi-film forming PU developed for the surface and reverse inks. It claims to offer high gloss for surface inks and good lamination bond for reverse inks and provides suitability for both flexographic and gravure printing processes. The new product Flexpack 5100 is free of chemical compounds like TDI, MDI, and tin, making it ideal for indirect food additives for packaging and suitable as per the new BIS notifications IS 15945:2020 for safe printing inks.

Flexcoat PC OPV 1009

Another launch for UFlex Chemicals Business was Flexcoat PC OPV- 1009, an environment-friendly water-based Overprint Varnish (OPV) for printing over paperboard used for playing cards. It is specially designed to give better slip property with low CoF value, high scuff- resistance, and good gloss besides smooth lay and anti-blocking properties. It is suitable for both in-line and offline processes and has got the stamp of approval from leading card manufacturers.

CI Flexmatt

CI Flexmatt two components OPV is a matt coating specially developed for the CI Flexo printing process. This ‘soft-feel’ overprint varnish claims to offer better adhesion on a variety of substrates, including PE, PET, and BOPP, besides good matt effect and scuff resistance. It complies with food packaging regulations and, according to Uflex, is most suitable for hygiene care products.

Metal embossed sheets for home interior & OOH

Cylinder Business developed metal embossed sheets used for decorating interiors of modular kitchen, false ceilings, and furniture to enhance aesthetics. These sheets are also getting a good response for use in Out of Home (OOH) properties like corporate sign-boards, lift, and metro wall decorations.

Silver scratch film for packaging & label industry

Uflex Holography Business has developed a Silver Scratch Film in 12 and 15-micron variants for packaging, labels, and decoration industry. This film, which was recently commercialized, has huge potential in Indian and overseas markets, says Uflex.

IBA’s trusted partner for printing MICR instruments

Uflex’s Holography Business was once again certified by Indian Banks’ Association (IBA) to continue printing of security products in the Banking sector for another two years that is from April 2020 to March 2022. Magnetic Ink Character Recognition (MICR) requires a special printing system with overt and covert features for bank cheques, legal tenders, and various other negotiable instruments. Uflex is one of the industry leaders in the industry, printing such security documents for member banks of IBA.

0 notes

Text

Flexographic Printing Plates Market: Discover The Latest Trends, Drivers, Restraints, Opportunities and Industry-Specific Challenges

Flexographic Printing Plates Market: Overview

Printing plates are popularly used in the print packaging industry for use in printing on paper and boards. A wide range of substrates have come to the fore that allow printing industries use variety of inks for printing on plastics and fiber. Flexographic printing plates have gained preference among end users for removing unwanted fluting during the printing of printing on corrugated boards. The growth in the flexographic printing plates market lies on the back of growing demand for corrugated packing by brands in various industries, world over. Over the years, focus to improve the performance of flexographic printing has increased, bolstering technological advancements in flexographic printing plates market. Extensive demand for printing presses in industries has helped the market to evolve. However, the recent COVID-19 pandemic has suppressed the use of flexographic printing plates, mostly on the back of sloth in manufacturing industries.

Over the years, the use of photopolymer to make flexographic printing plates has gained preference over rubber. Popularity of flat top dots technology in printing industry has continuously expanded the scope of the flexographic printing plates market.

Request A Sample Copy Of The Report

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=77683

Flexographic Printing Plates Market: Competitive Landscape and Recent Developments

The report on the flexographic printing plates market looks the various dynamics of the competitive landscape and recent strategies by top players. The study also looks the recent developments that may change the future growth trajectories. It scrutinizes the trends that will impact the entry of new players and factors that will define the consolidation strategies of emerging players in key regions in the flexographic printing plates market.

The demand for flat top dot flexographic printing plates in the printing industry has risen over the years. In particular, the demand for these plates for printing on sustainable substrates in paper and paperboard application has gathered traction in the flexographic printing plates market. Eyeing a huge prospect, Flint Group Flexographic, a prominent supplier of flexographic printing plates solution has in May 2020 launched Nyloflex FTL Digital for corrugated printing applications. The company affirms that its solution will help end users bring down the use of less plate material, making the solution sustainable. Moreover, this flexographic printing plates with flat top dots will also keep the cost of consumable low. One marked advantage of this printing plate, asserts the company, is the option of using recycled fibers in the substrate.

Flexographic Printing Plates Market: Growth Dynamics

With industries taking a massive hit in China, pigments for packaging printing inks have also taken a plunge southward. This has a massive road-blocking effect on the application of flexographic printing plates. Several players have also been facing impediment regarding supply disruptions for ensuring the availability of raw materials for printing plates to work. A lack of appetite for capital as well as consumer goods has also played a havoc in the expansion of the flexographic printing plates market.

Growing consumer demand for sustainable packaging is one of the key trends that will support the evolution of the flexographic printing plates market. Advent of digital flexo plates opened a new revenue potential for companies. Furthermore, the drive toward using recyclable materials in printing presses, such as inks, also fuels the expansion of the market. Demand for versatile flexographic printing plates is expected to open new avenues for players in the flexographic printing plates market.

Various types of inks used are aqueous, solvent based, UV cured, and cationic inks.

The study takes a closer look at the key drivers, restraints, and opportunities in the flexographic printing plates market. It highlights the trends that have caused disruption in the revenue generating potential of top players.

Flexographic Printing Plates Market: Regional Outlook

Several developing and developed economies have been at the center of development of prospects in the flexographic printing plates market. Most players are leaning on realigning strategies to combat the disruptions in supply chain caused by COVID-19 pandemic lockdowns imposed by numerous governments for a long time. Some prominent players are banking upon the popularity of eco-friendly printing substrates and cost-effective printing plates.

The report offers a comprehensive evaluation of the market. It does so via in-depth qualitative insights, historical data, and verifiable projections about market size. The projections featured in the report have been derived using proven research methodologies and assumptions. By doing so, the research report serves as a repository of analysis and information for every facet of the market, including but not limited to: Regional markets, technology, types, and applications.

The study is a source of reliable data on:

Market segments and sub-segments

Market trends and dynamics

Supply and demand

Market size

Current trends/opportunities/challenges

Competitive landscape

Technological breakthroughs

Value chain and stakeholder analysis

The regional analysis covers:

North America (U.S. and Canada)

Latin America (Mexico, Brazil, Peru, Chile, and others)

Western Europe (Germany, U.K., France, Spain, Italy, Nordic countries, Belgium, Netherlands, and Luxembourg)

Eastern Europe (Poland and Russia)

Asia Pacific (China, India, Japan, ASEAN, Australia, and New Zealand)

Middle East and Africa (GCC, Southern Africa, and North Africa)

The report has been compiled through extensive primary research (through interviews, surveys, and observations of seasoned analysts) and secondary research (which entails reputable paid sources, trade journals, and industry body databases). The report also features a complete qualitative and quantitative assessment by analyzing data gathered from industry analysts and market participants across key points in the industry’s value chain.

A separate analysis of prevailing trends in the parent market, macro- and micro-economic indicators, and regulations and mandates is included under the purview of the study. By doing so, the report projects the attractiveness of each major segment over the forecast period.

Highlights of the report:

A complete backdrop analysis, which includes an assessment of the parent market

Important changes in market dynamics

Market segmentation up to the second or third level

Historical, current, and projected size of the market from the standpoint of both value and volume

Reporting and evaluation of recent industry developments

Market shares and strategies of key players

Emerging niche segments and regional markets

An objective assessment of the trajectory of the market

Recommendations to companies for strengthening their foothold in the market

Note: Although care has been taken to maintain the highest levels of accuracy in TMR’s reports, recent market/vendor-specific changes may take time to reflect in the analysis.

This study by TMR is all-encompassing framework of the dynamics of the market. It mainly comprises critical assessment of consumers' or customers' journeys, current and emerging avenues, and strategic framework to enable CXOs take effective decisions.

Our key underpinning is the 4-Quadrant Framework EIRS that offers detailed visualization of four elements:

Customer Experience Maps

Insights and Tools based on data-driven research

Actionable Results to meet all the business priorities

Strategic Frameworks to boost the growth journey

The study strives to evaluate the current and future growth prospects, untapped avenues, factors shaping their revenue potential, and demand and consumption patterns in the global market by breaking it into region-wise assessment.

The following regional segments are covered comprehensively:

North America

Asia Pacific

Europe

Latin America

The Middle East and Africa

The EIRS quadrant framework in the report sums up our wide spectrum of data-driven research and advisory for CXOs to help them make better decisions for their businesses and stay as leaders.

Request For Covid19 Impact Analysis

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=77683

Below is a snapshot of these quadrants.

1. Customer Experience Map

The study offers an in-depth assessment of various customers’ journeys pertinent to the market and its segments. It offers various customer impressions about the products and service use. The analysis takes a closer look at their pain points and fears across various customer touchpoints. The consultation and business intelligence solutions will help interested stakeholders, including CXOs, define customer experience maps tailored to their needs. This will help them aim at boosting customer engagement with their brands.

2. Insights and Tools

The various insights in the study are based on elaborate cycles of primary and secondary research the analysts engage with during the course of research. The analysts and expert advisors at TMR adopt industry-wide, quantitative customer insights tools and market projection methodologies to arrive at results, which makes them reliable. The study not just offers estimations and projections, but also an uncluttered evaluation of these figures on the market dynamics. These insights merge data-driven research framework with qualitative consultations for business owners, CXOs, policy makers, and investors. The insights will also help their customers overcome their fears.

3. Actionable Results

The findings presented in this study by TMR are an indispensable guide for meeting all business priorities, including mission-critical ones. The results when implemented have shown tangible benefits to business stakeholders and industry entities to boost their performance. The results are tailored to fit the individual strategic framework. The study also illustrates some of the recent case studies on solving various problems by companies they faced in their consolidation journey.

4. Strategic Frameworks

The study equips businesses and anyone interested in the market to frame broad strategic frameworks. This has become more important than ever, given the current uncertainty due to COVID-19. The study deliberates on consultations to overcome various such past disruptions and foresees new ones to boost the preparedness. The frameworks help businesses plan their strategic alignments for recovery from such disruptive trends. Further, analysts at TMR helps you break down the complex scenario and bring resiliency in uncertain times.

The report sheds light on various aspects and answers pertinent questions on the market. Some of the important ones are:

1. What can be the best investment choices for venturing into new product and service lines?

2. What value propositions should businesses aim at while making new research and development funding?

3. Which regulations will be most helpful for stakeholders to boost their supply chain network?

4. Which regions might see the demand maturing in certain segments in near future?

5. What are the some of the best cost optimization strategies with vendors that some well-entrenched players have gained success with?

6. Which are the key perspectives that the C-suite are leveraging to move businesses to new growth trajectory?

7. Which government regulations might challenge the status of key regional markets?

8. How will the emerging political and economic scenario affect opportunities in key growth areas?

9. What are some of the value-grab opportunities in various segments?

10. What will be the barrier to entry for new players in the market?

0 notes

Text

Flexographic Printing Plates Market Insights, Future Trends, On-Going Demand, Opportunities, Segmentation, And Forecast Till 2027

Flexographic Printing Plates Market: Overview

Printing plates are popularly used in the print packaging industry for use in printing on paper and boards. A wide range of substrates have come to the fore that allow printing industries use variety of inks for printing on plastics and fiber. Flexographic printing plates have gained preference among end users for removing unwanted fluting during the printing of printing on corrugated boards. The growth in the flexographic printing plates market lies on the back of growing demand for corrugated packing by brands in various industries, world over. Over the years, focus to improve the performance of flexographic printing has increased, bolstering technological advancements in flexographic printing plates market. Extensive demand for printing presses in industries has helped the market to evolve. However, the recent COVID-19 pandemic has suppressed the use of flexographic printing plates, mostly on the back of sloth in manufacturing industries.

Over the years, the use of photopolymer to make flexographic printing plates has gained preference over rubber. Popularity of flat top dots technology in printing industry has continuously expanded the scope of the flexographic printing plates market.

Are you a start-up willing to make it big in the business? Grab an exclusive PDF Brochure of this report

Flexographic Printing Plates Market: Competitive Landscape and Recent Developments

The report on the flexographic printing plates market looks the various dynamics of the competitive landscape and recent strategies by top players. The study also looks the recent developments that may change the future growth trajectories. It scrutinizes the trends that will impact the entry of new players and factors that will define the consolidation strategies of emerging players in key regions in the flexographic printing plates market.

The demand for flat top dot flexographic printing plates in the printing industry has risen over the years. In particular, the demand for these plates for printing on sustainable substrates in paper and paperboard application has gathered traction in the flexographic printing plates market. Eyeing a huge prospect, Flint Group Flexographic, a prominent supplier of flexographic printing plates solution has in May 2020 launched Nyloflex FTL Digital for corrugated printing applications. The company affirms that its solution will help end users bring down the use of less plate material, making the solution sustainable. Moreover, this flexographic printing plates with flat top dots will also keep the cost of consumable low. One marked advantage of this printing plate, asserts the company, is the option of using recycled fibers in the substrate.

For Right Perspective & Competitive Insights on Automotive Brake Override System Market, Request for a Sample

Flexographic Printing Plates Market: Growth Dynamics