#Food Processing & Handling Equipment Market

Explore tagged Tumblr posts

Text

#Food Processing & Handling Equipment Market Share#Food Processing & Handling Equipment Market Analysis#Food Processing & Handling Equipment Market Report

0 notes

Text

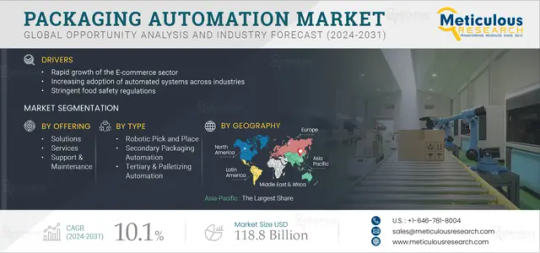

Packaging Automation Market Size, Share, Forecast, & Trends Analysis

Meticulous Research®—a leading global market research company, published a research report titled, ‘Packaging Automation Market by Offering (Solution, Services), Type, End-use Industry (Healthcare & Pharmaceuticals, E-commerce & Logistics, Food & Beverage, Chemical & Refinery, Aerospace & Defense), and Geography - Global Forecast to 2031.’

According to this latest publication from Meticulous Research®, the global packaging automation market is projected to reach $118.8 billion by 2031, at a CAGR of 10.1% during the forecast period. The growth of the packaging automation market is mainly attributed to the rapid growth of the E-commerce sector, the increasing adoption of automated systems across industries, and stringent food safety regulations. However, the high initial costs of installing automated systems restrain the market’s growth.

The high demand for packaging automation in the logistics industry and the increasing demand for sustainable and eco-friendly packaging are expected to create market growth opportunities. However, the shortage of skilled operators is a major challenge for the players in this market. Integration of advanced technologies and smart packaging are major trends in the packaging automation market.

The global packaging automation market is segmented by offering (solutions [case sealers & erectors, sleevers & cartoners, palletizers & depalletizers, strappers, markers & labelers, automated mailer systems, case packers, and other solutions], services [consulting, installation & training, and support & maintenance]), type (robotic pick & place, secondary packaging, and tertiary & palletizing), end-use industry (healthcare & pharmaceuticals [healthcare & pharmaceuticals manufacturing companies and contract manufacturing organizations], e-commerce & logistics [E-commerce, contract packaging, and logistics companies], food & beverage, automotive, chemical & refineries, aerospace & defense, and other end-use industries), and geography (Asia-Pacific, Europe, North America, Latin America, and the Middle East & Africa). The study also evaluates industry competitors and analyses the market at the country and regional levels.

Based on offering, the packaging automation market is segmented into solutions and services. Furthermore, the solutions segment is subsegmented into case sealers & erectors, sleevers & cartoners, palletizers & depalletizers, strappers, markers & labelers, automated mailer systems, case packers, and other solutions. The services segment is subsegmented into consulting, installation & training, and support & maintenance. In 2024, the solutions segment is expected to account for the larger share of the global packaging automation market. The segment’s large market share is mainly attributed to the need for increased manufacturing speed and ensuring products and workers’ safety. However, the services segment is projected to record the highest CAGR during the forecast period. The segment’s growth is driven by the increasing deployment of automation in various industries such as e-commerce, healthcare & pharmaceuticals, food & beverage, automotive, and chemical & refineries and the growing demand for packaging automation to speed up production, optimize warehouse space, and reduce reliance on labor to provide more value-added services to their customers.

Based on type, the packaging automation market is segmented into robotic pick & place, secondary packaging, and tertiary & palletizing. In 2024, the robotic pick & place segment is expected to account for the largest share of the global packaging automation market. The segment’s large market share is mainly attributed to rising demand for pick and place robots in various industries such as manufacturing, food & beverage, automotive, chemical & refineries, aerospace & defense, e-commerce & logistics, healthcare & pharmaceuticals, and the growing demand for automation from manufacturing companies to increase production rates. However, the secondary packaging segment is projected to record the highest CAGR during the forecast period. The segment’s growth is driven by the rising need to safely transport products during shipment and the growing demand for supplementary protection in the e-commerce and pharmaceutical sectors.

Based on end-use industry, the packaging automation market is segmented into healthcare & pharmaceuticals, E-commerce & logistics, food & beverage, automotive, chemical & refineries, aerospace & defense, and other end-use industries. Furthermore, the healthcare & pharmaceuticals segment is subsegmented into healthcare & pharmaceuticals manufacturing companies and contract manufacturing organizations. The E-commerce & logistics segment is subsegmented into E-commerce, contract packaging, and logistics companies. In 2024, the food & beverage segment is expected to account for the largest share of the global packaging automation market. The segment’s large market share is mainly attributed to shifting consumer tastes, high competition in the packaged food market, and a surge in demand for packaged food. However, the e-commerce & logistics segment is projected to record the highest CAGR during the forecast period. The segment’s growth is attributed to various factors, including the rise in online sales channels, the increase in online shopping among customers, the increasing adoption of automation in e-commerce & logistics to ensure timely delivery, and the rising consumer demand for convenience shopping.

Based on geography, the global packaging automation market is segmented into North America, Europe, Latin America, and the Middle East & Africa. In 2024, Asia-Pacific is expected to account for the largest share of the packaging automation market, followed by Europe, North America, Latin America, and the Middle East & Africa. Asia-Pacific’s significant market share is attributed to the increasing utilization of sustainable packaging in the food & beverage sector, supportive government initiatives aimed at promoting the adoption of automation and Industry 4.0 technologies to enhance manufacturing capabilities, the growing demand for eco-friendly packaging solutions, and the rapid expansion of the E-commerce sector in countries like China and India. Moreover, Asia-Pacific is also projected to register the highest CAGR over the forecast period.

Key Players

The key players operating in the global packaging automation market are ABB, Ltd. (Switzerland), Robert Bosch GmbH (Germany), Siemens AG (Germany), Fanuc Corporation(Japan), and Mitsubishi Electric Corporation (Japan), Swisslog Holding AG (Switzerland), Rockwell Automation, Inc. (U.S.), Schneider Electric SE (France), WestRock Company (U.S.), SATO Holdings Corporation (Japan), Krones AG (Germany), Automated Packaging Systems, Inc. (U.S.), Emerson Electric Co. (U.S.), Crawford Packaging (Canada), Fuji Machinery (Japan), Brenton LLC (U.S.), BEUMER Group GmbH & Co. KG(Germany), Barry-Wehmiller Group, Inc. (U.S.), KHS GmbH (Italy), MULTIVAC Sepp Haggenmüller SE & Co. KG (Germany), Omori Machinery Co., Ltd. (Japan), and Syntegon Technology GmbH (Germany).

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5324

Key Questions Answered in the Report:

Which are the high-growth market segments in terms of offering, type, and end-use industry?

What is the historical market for packaging automation across the globe?

What are the market forecasts and estimates for the period of 2024–2031?

What are the major drivers, restraints, opportunities, challenges, and trends in the global packaging automation market?

Who are the major players in the global packaging automation market, and what are their market shares?

What is the competitive landscape like?

What are the recent developments in the global packaging automation market?

What are the different strategies adopted by the major players in the market?

What are the geographic trends and high-growth countries?

Who are the emerging players in the global packaging automation market, and how do they compete with the other players?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Packaging Automation Market#Packaging Automation#Smart Packaging#Automated Packaging Systems#Packaging & Processing Solutions#Portioning#Labeling#Marking#Inspection#Handling#Packaging Machines#Robotic Pick & Place#Secondary Packaging#Tertiary & Palletizing#Automation Solutions#Automated Equipment#Automated Bagging Systems#Transit Packaging#Food Packaging Equipment

0 notes

Text

The food processing and handling equipment market is projected to surge from USD 130.6 billion in 2021 to USD 175.1 billion in 2026, with a CAGR of 6.0% during the forecast period.

#Food Processing and Handling Equipment Market#Food Processing and Handling Equipment#Food Processing and Handling Equipment Market Size#Food Processing and Handling Equipment Market Share#Food Processing and Handling Equipment Market Growth#Food Processing and Handling Equipment Market Trends#Food Processing and Handling Equipment Market Forecast#Food Processing and Handling Equipment Market Analysis#Food Processing and Handling Equipment Market Report

0 notes

Text

Food Processing and Handling Equipment Market Growth by Emerging Trends, Analysis, & Forecast

The food processing and handling equipment market is projected to surge from USD 130.6 billion in 2021 to USD 175.1 billion in 2026, with a CAGR of 6.0% during the forecast period. The food processing and handling equipment market is experiencing tremendous growth due to a combination of factors, including a surging demand for processed and packaged food, a growing need for efficient and hygienic processing methods, and the adoption of cutting-edge technology and automation in the food and beverage industry. This report delves into the key drivers of this growth, as well as the trends, challenges, and growth opportunities present in the market.

The food processing and handling equipment market is witnessing substantial growth as the food industry expands, driven by increasing demand for processed foods such as meat products, baked goods, convenience food, and more. The development of new technologies, like non-thermal processing, is streamlining the production process and reducing waste, time, and costs. Innovations in processing technology, the demand for healthy and functional foods, and the growth of food manufacturing capacities in emerging economies are all contributing factors to the market's growth. The food and beverage industry is being transformed by advancements in food processing, creating opportunities for manufacturers to meet the growing demand for healthy and functional products using cutting-edge equipment.

Food Processing and Handling Equipment Market Drivers: Rising demand for meat, poultry, bakery, dairy, and confectionery products

Meat, dairy, bakery, and confectionery products are some of the major applications of food processing and handling equipment. The growing consumption of protein-based food products, frozen meat, frozen bakery products, and fruits & vegetables; and the growing preference for healthy food products in developed countries drive the demand for higher food production. This growth in demand for various food products will, in turn, drive the demand for food processing and handling equipment. There have been various product launches in snack and bakery product categories, with health claims such as gluten-free and non-GMO in the European market.

Similarly, snacks and bakery products require cutting, coating, slicing, and thermal equipment for manufacturing end products, adding taste and texture, and extending the shelf life. The growth of the bakery & confectionery industry in Europe and other developed countries is also expected to drive the demand for food processing and handling equipment.

Bakery, meat, poultry, and seafood are the major applications of food processing and handling equipment. In the last decade, the changing and busy lifestyles of consumers due to rapid urbanization have led to high demand for processed and convenience meat products. Moreover, processed meat products require less time and effort to cook and have enhanced nutrition and durability. Meat processing involves a wide range of physical and chemical treatment methods, generally combining a variety of methods. Various processing methods that include cutting, blending, stuffing & filling, grinding, drying, slicing, smoking, grinding, and massaging are performed with the help of different equipment.

Similarly, in the dairy industry, the demand for various equipment for a range of applications is driving the food processing & handling equipment market growth. According to the dairy index from Tetra Pak Global consumption of products, such as milk, cheese, and butter, is expected to rise by 36% in the next decade, reaching more than 710 million tons of liquid milk equivalent by 2024. The booming demand for dairy products is majorly witnessed in emerging economies, such as India, China, and Latin American countries. This demand is fueled by population growth, rapid urbanization, increased disposable income, and the emergence & modernization of cold chain facilities such as refrigerated transport & storage.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=145960225

Food processing segment is estimated to dominate the global food processing and handling equipment market

Advancements in the food processing industry, innovation in processing technology, and continuous growth in the demand for processed food are some factors expected to support the growth of the food & beverage processing equipment market. With the growing preference for healthy food and functional foods, manufacturers are expected to adopt new equipment to fulfill the demand for healthy functional foods & beverages. The expansion of food manufacturing capacities and growth of the food processing industry in emerging economies will also support the growth of the food processing & handling equipment market.

The solid segment is estimated to account for the largest share in the food processing and handling equipment market

The solid segment dominated the global food processing & handling equipment market due to the rising consumption of solid food products, such as bread, processed meat, and processed vegetables, in regular diets. Changing consumer preferences and the adoption of upgraded technologies to enhance the shelf life of products are also driving the growth of the solid segment. Customizations and innovations in the bakery and dessert industries, along with the rising demand for processed fruit and vegetable products, provide huge opportunities for the manufacturers to grow in the food processing & handling equipment market.

The Asia Pacific market dominated the food processing and handling equipment market during the forecast period.

The food industry in Asia Pacific is gigantic. In the region, product innovations and technological advances have put increasing pressures on the quality standards at all levels, with a growing emphasis on food safety, integrity, quality, and nutritional and health impacts. Growth in the demand for processed foods, the rapid rise in supermarkets, and retail outlets are some of the positive factors shaping the growth of the food and beverages industry in the region. With the rising urban incomes and higher consumption proportions of animal products, there is a demand for a more varied range of foodstuffs. Changing demand for processed food and gradual liberalization of the international food trade has resulted in the rise of multinational food retailers.

Top Companies in the Food Processing & Handling Equipment Market:

The key players in this market include GEA Group (Germany), ALFA LAVAL (Sweden), Bühler Holding AG (Switzerland), JBT Corporation (US), SPX Flow (US), Robert Bosch (Germany), IMA Group (Italy), Multivac (Germany), Krones Group (Germany), Tetra Laval International S.A. (Switzerland), Middleby Corporation (US), Dover Corporation (US), Ali Group S.r.l (Italy), Electrolux (Sweden), and Hoshizaki (Japan). Manufacturers are adopting strategies such as new product launches, expansion & investments, mergers & acquisitions, agreements, and partnerships to strengthen their position in the market.

#Food Processing and Handling Equipment Market#Food Processing and Handling Equipment#Food Processing and Handling Equipment Market Size#Food Processing and Handling Equipment Market Share#Food Processing and Handling Equipment Market Growth#Food Processing and Handling Equipment Market Trends#Food Processing and Handling Equipment Market Forecast#Food Processing and Handling Equipment Market Analysis#Food Processing and Handling Equipment Market Report#Food Processing and Handling Equipment Market Scope#Food Processing and Handling Equipment Market Overview#Food Processing and Handling Equipment Market Outlook#Food Processing and Handling Equipment Market Drivers#Food Processing and Handling Equipment Industry#Food Processing and Handling Equipment Companies

0 notes

Text

Middle East and Africa Food Processing and Food Material Handling Equipment Market, Middle East and Africa Food Processing and Food Material Handling Equipment Market Share, Middle East and Africa Food Processing and Food Material Handling Equipment Market Size, Middle East and Africa Food Processing and Food Material Handling Equipment Market Growth.

#Middle East and Africa Food Processing and Food Material Handling Equipment Market#Middle East and Africa Food Processing and Food Material Handling Equipment Market Share#Middle East and Africa Food Processing and Food Material Handling Equipment Market Size#Middle East and Africa Food Processing and Food Material Handling Equipment Market Growth.

0 notes

Text

Udaan by InAmigos Foundation: Elevating Women, Empowering Futures

In the rapidly evolving socio-economic landscape of India, millions of women remain underserved by mainstream development efforts—not due to a lack of talent, but a lack of access. In response, Project Udaan, a flagship initiative by the InAmigos Foundation, emerges not merely as a program, but as a model of scalable women's empowerment.

Udaan—meaning “flight” in Hindi—represents the aspirations of rural and semi-urban women striving to break free from intergenerational limitations. By engineering opportunity and integrating sustainable socio-technical models, Udaan transforms potential into productivity and promise into progress.

Mission: Creating the Blueprint for Women’s Self-Reliance

At its core, Project Udaan seeks to:

Empower women with industry-aligned, income-generating skills

Foster micro-entrepreneurship rooted in local demand and resources

Facilitate financial and digital inclusion

Strengthen leadership, health, and rights-based awareness

Embed resilience through holistic community engagement

Each intervention is data-informed, impact-monitored, and custom-built for long-term sustainability—a hallmark of InAmigos Foundation’s field-tested grassroots methodology.

A Multi-Layered Model for Empowerment

Project Udaan is built upon a structured architecture that integrates training, enterprise, and technology to ensure sustainable outcomes. This model moves beyond skill development into livelihood generation and measurable socio-economic change.

1. Skill Development Infrastructure

The first layer of Udaan is a robust skill development framework that delivers localized, employment-focused education. Training modules are modular, scalable, and aligned with the socio-economic profiles of the target communities.

Core domains include:

Digital Literacy: Basic computing, mobile internet use, app navigation, and digital payment systems

Tailoring and Textile Production: Pattern making, machine stitching, finishing techniques, and indigenous craft techniques

Food Processing and Packaging: Pickle-making, spice grinding, home-based snack units, sustainable packaging

Salon and Beauty Skills: Basic grooming, hygiene standards, customer interaction, and hygiene protocols

Financial Literacy and Budgeting: Saving schemes, credit access, banking interfaces, micro-investments

Communication and Self-Presentation: Workplace confidence, customer handling, local language fluency

2. Microenterprise Enablement and Livelihood Incubation

To ensure that learning transitions into economic self-reliance, Udaan incorporates a post-training enterprise enablement process. It identifies local market demand and builds backward linkages to equip women to launch sustainable businesses.

The support ecosystem includes:

Access to seed capital via self-help group (SHG) networks, microfinance partners, and NGO grants

Distribution of startup kits such as sewing machines, kitchen equipment, or salon tools

Digital onboarding support for online marketplaces such as Amazon Saheli, Flipkart Samarth, and Meesho

Offline retail support through tie-ups with local haats, trade exhibitions, and cooperative stores

Licensing and certification where applicable for food safety or textile quality standards

3. Tech-Driven Monitoring and Impact Tracking

Transparency and precision are fundamental to Udaan’s growth. InAmigos Foundation employs its in-house Tech4Change platform to manage operations, monitor performance, and scale the intervention scientifically.

The platform allows:

Real-time monitoring of attendance, skill mastery, and certification via QR codes and mobile tracking

Impact evaluation using household income change, asset ownership, and healthcare uptake metrics

GIS-based mapping of intervention zones and visualization of under-reached areas

Predictive modeling through AI to identify at-risk participants and suggest personalized intervention strategies

Human-Centered, Community-Rooted

Empowerment is not merely a process of economic inclusion—it is a cultural and psychological shift. Project Udaan incorporates gender-sensitive design and community-first outreach to create lasting change.

Key interventions include:

Strengthening of SHG structures and women-led federations to serve as peer mentors

Family sensitization programs targeting male allies—fathers, husbands, brothers—to reduce resistance and build trust

Legal and rights-based awareness campaigns focused on menstrual hygiene, reproductive health, domestic violence laws, and maternal care

Measured Impact and Proven Scalability

Project Udaan has consistently delivered quantifiable outcomes at the grassroots level. As of the latest cycle:

Over 900 women have completed intensive training programs across 60 villages and 4 districts

Nearly 70 percent of participating women reported an average income increase of 30 to 60 percent within 9 months of program completion

420+ micro-enterprises have been launched, 180 of which are now self-sustaining and generating employment for others

More than 5,000 indirect beneficiaries—including children, elderly dependents, and second-generation SHG members—have experienced improved access to nutrition, education, and mobility

Over 20 institutional partnerships and corporate CSR collaborations have supported infrastructure, curriculum design, and digital enablement.

Partnership Opportunities: Driving Collective Impact

The InAmigos Foundation invites corporations, philanthropic institutions, and ecosystem enablers to co-create impact through structured partnerships.

Opportunities include:

Funding the establishment of skill hubs in high-need regions

Supporting enterprise starter kits and training batches through CSR allocations

Mentoring women entrepreneurs via employee volunteering and capacity-building workshops

Co-hosting exhibitions, market linkages, and rural entrepreneurship fairs

Enabling long-term research and impact analytics for policy influence

These partnerships offer direct ESG alignment, brand elevation, and access to inclusive value chains while contributing to a model that demonstrably works.

What Makes Project Udaan Unique?

Unlike one-size-fits-all skilling programs, Project Udaan is rooted in real-world constraints and community aspirations. It succeeds because it combines:

Skill training aligned with current and emerging market demand

Income-first design that integrates microenterprise creation and financial access

Localized community ownership that ensures sustainability and adoption

Tech-enabled operations that ensure transparency and iterative learning

Holistic empowerment encompassing economic, social, and psychological dimensions

By balancing professional training with emotional transformation and economic opportunity, Udaan represents a new blueprint for inclusive growth.

From Promise to Power

Project Udaan, driven by the InAmigos Foundation, proves that when equipped with tools, trust, and training, rural and semi-urban women are capable of becoming not just contributors, but catalysts for socio-economic renewal.

They don’t merely escape poverty—they design their own systems of progress. They don’t just participate—they lead.

Each sewing machine, digital training module, or microloan is not a transaction—it is a declaration of possibility.

This is not charity. This is infrastructure. This is equity, by design.

Udaan is not just a program. It is a platform for a new India.

For partnership inquiries, CSR collaborations, and donation pathways, contact: www.inamigosfoundation.org/Udaan Email: [email protected]

3 notes

·

View notes

Text

Expert Welding and Fabrication Project Management with KJW Welding & Fabrication

In the dynamic world of industrial and construction projects, effective project management is crucial for success. KJW Welding & Fabrication, a leading name in Auckland, New Zealand, excels in delivering specialized project management services for welding, welding and fabrication project management, plant installation and commissioning services, and stainless steel fabrication Auckland. With a commitment to quality, precision, and efficiency, KJW Welding & Fabrication ensures every project is completed on time, within budget, and to the highest industry standards.

Comprehensive Project Management Services for Welding

Welding projects, whether small custom jobs or large-scale industrial endeavors, require meticulous planning and execution. KJW Welding & Fabrication offers tailored project management services for welding to streamline operations. Their experienced project managers oversee every phase, from initial planning to final delivery, ensuring seamless coordination of resources, schedules, and budgets. By leveraging advanced project management tools and techniques, KJW minimizes risks, optimizes material usage, and ensures compliance with safety and quality standards.

These services are ideal for industries such as dairy, food and beverage, wastewater, and construction, where precision welding is critical. KJW’s ability to manage complex welding projects, including structural welding and custom metalwork, makes them a trusted partner for clients across Auckland and beyond.

Welding and Fabrication Project Management Expertise

Welding and fabrication project management is at the core of KJW Welding & Fabrication’s offerings. Their team understands the technical intricacies of metalwork, enabling them to deliver cost-effective and high-quality solutions. Whether it’s fabricating steel structures for commercial buildings, custom components for machinery, or decorative metalwork for residential projects, KJW ensures every project is executed with precision.

The process begins with a detailed assessment of client requirements, followed by the creation of a comprehensive project roadmap. KJW’s project managers assign skilled welders and fabricators, utilize state-of-the-art equipment, and implement rigorous quality control measures. This approach guarantees durable, high-strength fabrications that meet client expectations and industry standards. Their expertise in managing projects of varying scales, from bespoke designs to large industrial fabrications, sets them apart in the Auckland market.

Plant Installation and Commissioning Services

Beyond welding and fabrication, KJW Welding & Fabrication provides expert plant installation and commissioning services. These services are essential for industries requiring the setup of complex systems, such as water treatment plants, dairy processing facilities, or manufacturing units. KJW’s team collaborates closely with clients to ensure smooth installation and commissioning, minimizing downtime and ensuring operational efficiency.

From mechanical installation to stainless steel pipe fitting, KJW handles every aspect of plant setup with precision. Their experience in working with diverse metals, including mild steel, aluminum, and stainless steel, ensures compatibility with industry-specific requirements. By adhering to strict safety protocols and quality standards, KJW delivers reliable and efficient plant installations that support long-term operational success.

Stainless Steel Fabrication Auckland

KJW Welding & Fabrication is renowned for its stainless steel fabrication Auckland services, catering to both residential and commercial clients. Stainless steel’s durability, corrosion resistance, and aesthetic appeal make it a popular choice for applications ranging from architectural features to industrial components. KJW’s skilled fabricators use advanced machinery for cutting, welding, and finishing, ensuring precision and high-quality results.

Whether it’s custom railings, staircases, or specialized components for the dairy and beverage industries, KJW delivers tailored solutions that meet unique client needs. Their expertise in stainless steel pipe fitting and welding, led by owner Kory Whitaker, ensures clean, uncontaminated welds that comply with stringent industry standards. This dedication to craftsmanship has earned KJW a reputation as a leading stainless steel fabricator in Auckland.

Why Choose KJW Welding & Fabrication?

KJW Welding & Fabrication stands out for its commitment to excellence, driven by a team of highly skilled tradesmen and advanced project management practices. Here’s why clients choose KJW:

Expertise Across Industries: Specializing in dairy, food and beverage, wastewater, and construction, KJW delivers industry-specific solutions.

Advanced Technology: Utilization of cutting-edge welding and fabrication equipment ensures precision and efficiency.

Tailored Solutions: From custom designs to large-scale projects, KJW adapts to meet unique client requirements.

Quality Assurance: Strict adherence to quality control and safety standards guarantees durable and reliable results.

On-Time, On-Budget Delivery: Effective project management ensures projects are completed within deadlines and budgets.

Contact KJW Welding & Fabrication Today

For businesses and homeowners seeking reliable project management services for welding, welding and fabrication project management, plant installation and commissioning services, or stainless steel fabrication Auckland, KJW Welding & Fabrication is the go-to choice. With a proven track record of delivering high-quality results, KJW is ready to bring your vision to life.

To discuss your project requirements or request a quote, contact KJW Welding & Fabrication today. Visit their website at kjwwelding.co.nz or reach out directly to experience their exceptional service firsthand.

1 note

·

View note

Text

Can an automatic paper bag machine be customized for different bag sizes and shapes?

In today’s packaging industry, flexibility is power. Whether you're supplying grocery stores, fashion retailers, food delivery services, or pharmacies, each client may require paper bags of different sizes, styles, and shapes. To stay competitive and meet diverse customer needs, manufacturers need a machine that does more than just produce paper bags—it must adapt, scale, and deliver variety.

This leads to a common question we hear at Prakash Machineries Pvt. Ltd: Can an automatic paper bag machine be customized for different bag sizes and shapes? The short answer is—absolutely yes.

Modern paper bag machines are built with flexibility in mind. In this article, we’ll explore how our advanced automatic paper bag machines can be customized to produce a wide range of bag dimensions and formats, and how this capability benefits your business.

Why Customization Matters in Paper Bag Production

As the demand for eco-friendly alternatives to plastic continues to rise, different industries are looking for tailored paper bag solutions. For example:

A restaurant may need medium-sized square bottom bags with handles for food deliveries.

A retail outlet might want printed shopping bags in multiple sizes.

A pharmacy may prefer flat, compact bags for lightweight items.

A grocery store might need heavy-duty flat bottom bags in bulk.

Without customization, you’d need separate machines or manual setups for each size—which reduces efficiency and increases cost. This is where a customizable automatic paper bag machine offers a major competitive edge.

How Automatic Paper Bag Machines Offer Customization

Modern automatic paper bag machines, especially those from Prakash Machineries Pvt. Ltd, are engineered for flexibility. Here’s how they enable quick and easy customization:

1. Adjustable Forming Plates and Tubes

The forming unit is the heart of the bag-making process. By changing or adjusting the forming plate and tube, you can produce bags of different widths and gusset sizes. This allows you to create small, medium, and large paper bags using the same machine.

Adjustable Parameters Include:

Bag width

Bag length

Bottom width (flat or square)

Side gusset width (for volume capacity)

With tool-less adjustments or quick-change mechanisms, switching between bag sizes becomes a matter of minutes—not hours.

2. PLC-Controlled Settings for Size Variability

Our machines are equipped with PLC-based touchscreen interfaces that allow operators to input desired bag dimensions with ease. You can set the length, bottom width, and cutting parameters electronically, ensuring precise output every time.

This not only enhances accuracy but also reduces the chances of human error during changeovers.

3. Multi-Format Bag Production

Advanced machines are capable of producing various types of paper bags from a single setup. These include:

Flat bottom bags for groceries and medicine

Square bottom bags for retail and takeaway

V-bottom/satchel bags for bakery and pharmacy use

Handle bags (twisted rope or flat handle)

Printed bags with custom branding

The ability to switch between formats on the same machine gives your business a huge advantage in catering to different market segments.

4. Compatible with Various Paper Grades and Roll Widths

To accommodate different bag shapes and weights, our machines can process multiple paper types such as:

Kraft paper

White or brown recycled paper

Coated/laminated paper for moisture resistance

With adjustable roll holders and web aligners, you can easily switch between different paper rolls and thicknesses, ensuring compatibility with diverse applications.

5. Optional Add-Ons for Advanced Features

At Prakash Machineries Pvt. Ltd, we offer machines with optional modules that can be integrated based on your product line:

Handle pasting units for retail carry bags

Inline flexographic printing units for branded bags

Window patching units for bakery or gift bags

Lamination compatibility for water-resistant bags

These upgrades can be added at the time of purchase or later as your business grows.

Benefits of Customization for Your Business

Having a customizable paper bag machine opens up numerous advantages:

✅ Serve Multiple Industries

Adapt your product offering to cater to retail, food service, healthcare, and more.

✅ Improve Profit Margins

Produce premium, value-added bags like printed or handled bags that command higher prices.

✅ Stay Competitive

Offer a wide variety of bag sizes to meet changing customer demands and stand out from competitors with limited options.

✅ Scale Seamlessly

Start with basic production and expand your capabilities without replacing your machine.

✅ Faster Order Fulfillment

Switch between sizes and designs quickly to fulfill small or bulk orders efficiently.

Why Choose Prakash Machineries Pvt. Ltd?

At Prakash Machineries Pvt. Ltd, we specialize in delivering machines that are not only durable and high-speed, but also highly customizable. Our paper bag machines are designed to adapt to your production requirements, offering:

Precision-engineered forming systems

Easy-to-use control panels

Servo-driven mechanisms for accuracy

Modular designs for future upgrades

We also provide complete training, technical support, and after-sales service to ensure your team can operate the machine to its full potential.

Conclusion: One Machine, Endless Possibilities

In a dynamic and growing market, versatility is key. A customizable automatic paper bag machine allows you to stay ahead of trends, expand your customer base, and increase your profits—all without investing in multiple machines.

Whether you're launching a new production line or upgrading your current setup, the ability to produce different bag sizes and shapes on one machine is a smart, future-proof investment.

Ready to make your paper bag production more flexible and profitable? Contact Prakash Machineries Pvt. Ltd today to explore our range of customizable automatic paper bag machines—engineered for performance, precision, and scalability.

#manufacturer#paper bag manufacturer#square bottom#machines#paper bag#flexo#v bottom#bags#paper#dan and phil#cake#chris sturniolo#cooking#critical role#baking#alien stage#chocolate#delicious#breakfast

1 note

·

View note

Text

#Food Processing & Handling Equipment Market Share#Food Processing & Handling Equipment Market Analysis#Food Processing & Handling Equipment Market Report

0 notes

Text

Packaging Automation Market to be Worth $118.8 Billion by 2031

Meticulous Research®—a leading global market research company, published a research report titled, ‘Packaging Automation Market by Offering (Solution, Services), Type, End-use Industry (Healthcare & Pharmaceuticals, E-commerce & Logistics, Food & Beverage, Chemical & Refinery, Aerospace & Defense), and Geography - Global Forecast to 2031.’

According to this latest publication from Meticulous Research®, the global packaging automation market is projected to reach $118.8 billion by 2031, at a CAGR of 10.1% during the forecast period. The growth of the packaging automation market is mainly attributed to the rapid growth of the E-commerce sector, the increasing adoption of automated systems across industries, and stringent food safety regulations. However, the high initial costs of installing automated systems restrain the market’s growth.

The high demand for packaging automation in the logistics industry and the increasing demand for sustainable and eco-friendly packaging are expected to create market growth opportunities. However, the shortage of skilled operators is a major challenge for the players in this market. Integration of advanced technologies and smart packaging are major trends in the packaging automation market.

The global packaging automation market is segmented by offering (solutions [case sealers & erectors, sleevers & cartoners, palletizers & depalletizers, strappers, markers & labelers, automated mailer systems, case packers, and other solutions], services [consulting, installation & training, and support & maintenance]), type (robotic pick & place, secondary packaging, and tertiary & palletizing), end-use industry (healthcare & pharmaceuticals [healthcare & pharmaceuticals manufacturing companies and contract manufacturing organizations], e-commerce & logistics [E-commerce, contract packaging, and logistics companies], food & beverage, automotive, chemical & refineries, aerospace & defense, and other end-use industries), and geography (Asia-Pacific, Europe, North America, Latin America, and the Middle East & Africa). The study also evaluates industry competitors and analyses the market at the country and regional levels.

Based on offering, the packaging automation market is segmented into solutions and services. Furthermore, the solutions segment is subsegmented into case sealers & erectors, sleevers & cartoners, palletizers & depalletizers, strappers, markers & labelers, automated mailer systems, case packers, and other solutions. The services segment is subsegmented into consulting, installation & training, and support & maintenance. In 2024, the solutions segment is expected to account for the larger share of the global packaging automation market. The segment’s large market share is mainly attributed to the need for increased manufacturing speed and ensuring products and workers’ safety. However, the services segment is projected to record the highest CAGR during the forecast period. The segment’s growth is driven by the increasing deployment of automation in various industries such as e-commerce, healthcare & pharmaceuticals, food & beverage, automotive, and chemical & refineries and the growing demand for packaging automation to speed up production, optimize warehouse space, and reduce reliance on labor to provide more value-added services to their customers.

Based on type, the packaging automation market is segmented into robotic pick & place, secondary packaging, and tertiary & palletizing. In 2024, the robotic pick & place segment is expected to account for the largest share of the global packaging automation market. The segment’s large market share is mainly attributed to rising demand for pick and place robots in various industries such as manufacturing, food & beverage, automotive, chemical & refineries, aerospace & defense, e-commerce & logistics, healthcare & pharmaceuticals, and the growing demand for automation from manufacturing companies to increase production rates. However, the secondary packaging segment is projected to record the highest CAGR during the forecast period. The segment’s growth is driven by the rising need to safely transport products during shipment and the growing demand for supplementary protection in the e-commerce and pharmaceutical sectors.

Based on end-use industry, the packaging automation market is segmented into healthcare & pharmaceuticals, E-commerce & logistics, food & beverage, automotive, chemical & refineries, aerospace & defense, and other end-use industries. Furthermore, the healthcare & pharmaceuticals segment is subsegmented into healthcare & pharmaceuticals manufacturing companies and contract manufacturing organizations. The E-commerce & logistics segment is subsegmented into E-commerce, contract packaging, and logistics companies. In 2024, the food & beverage segment is expected to account for the largest share of the global packaging automation market. The segment’s large market share is mainly attributed to shifting consumer tastes, high competition in the packaged food market, and a surge in demand for packaged food. However, the e-commerce & logistics segment is projected to record the highest CAGR during the forecast period. The segment’s growth is attributed to various factors, including the rise in online sales channels, the increase in online shopping among customers, the increasing adoption of automation in e-commerce & logistics to ensure timely delivery, and the rising consumer demand for convenience shopping.

Based on geography, the global packaging automation market is segmented into North America, Europe, Latin America, and the Middle East & Africa. In 2024, Asia-Pacific is expected to account for the largest share of the packaging automation market, followed by Europe, North America, Latin America, and the Middle East & Africa. Asia-Pacific’s significant market share is attributed to the increasing utilization of sustainable packaging in the food & beverage sector, supportive government initiatives aimed at promoting the adoption of automation and Industry 4.0 technologies to enhance manufacturing capabilities, the growing demand for eco-friendly packaging solutions, and the rapid expansion of the E-commerce sector in countries like China and India. Moreover, Asia-Pacific is also projected to register the highest CAGR over the forecast period.

Key Players

The key players operating in the global packaging automation market are ABB, Ltd. (Switzerland), Robert Bosch GmbH (Germany), Siemens AG (Germany), Fanuc Corporation(Japan), and Mitsubishi Electric Corporation (Japan), Swisslog Holding AG (Switzerland), Rockwell Automation, Inc. (U.S.), Schneider Electric SE (France), WestRock Company (U.S.), SATO Holdings Corporation (Japan), Krones AG (Germany), Automated Packaging Systems, Inc. (U.S.), Emerson Electric Co. (U.S.), Crawford Packaging (Canada), Fuji Machinery (Japan), Brenton LLC (U.S.), BEUMER Group GmbH & Co. KG(Germany), Barry-Wehmiller Group, Inc. (U.S.), KHS GmbH (Italy), MULTIVAC Sepp Haggenmüller SE & Co. KG (Germany), Omori Machinery Co., Ltd. (Japan), and Syntegon Technology GmbH (Germany).

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5324

Key Questions Answered in the Report:

Which are the high-growth market segments in terms of offering, type, and end-use industry?

What is the historical market for packaging automation across the globe?

What are the market forecasts and estimates for the period of 2024–2031?

What are the major drivers, restraints, opportunities, challenges, and trends in the global packaging automation market?

Who are the major players in the global packaging automation market, and what are their market shares?

What is the competitive landscape like?

What are the recent developments in the global packaging automation market?

What are the different strategies adopted by the major players in the market?

What are the geographic trends and high-growth countries?

Who are the emerging players in the global packaging automation market, and how do they compete with the other players?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Packaging Automation Market#Packaging Automation#Smart Packaging#Automated Packaging Systems#Packaging & Processing Solutions#Portioning#Labeling#Marking#Inspection#Handling#Packaging Machines#Robotic Pick & Place#Secondary Packaging#Tertiary & Palletizing#Automation Solutions#Automated Equipment#Automated Bagging Systems#Transit Packaging#Food Packaging Equipment

0 notes

Text

The food processing and handling equipment market size is projected to surge from USD 130.6 billion in 2021 to USD 175.1 billion in 2026, with a CAGR of 6.0% during the forecast period.

#Food Processing and Handling Equipment Market#Food Processing and Handling Equipment#Food Processing and Handling Equipment Market Size#Food Processing and Handling Equipment Market Share#Food Processing and Handling Equipment Market Growth#Food Processing and Handling Equipment Market Trends#Food Processing and Handling Equipment Market Forecast#Food Processing and Handling Equipment Market Analysis#Food Processing and Handling Equipment Market Report#Food Processing and Handling Equipment Market Scope#Food Processing and Handling Equipment Market Overview

0 notes

Text

Large Bore Vacuum Insulated Pipe Market Size, Share, Revenue, Trends And Drivers For -2034

The global large bore vacuum insulated pipes market is projected to grow from US$ 81.4 million in 2024 to US$ 169.3 million by the end of 2034, reflecting a compound annual growth rate (CAGR) of 7.6% during the forecast period.

There is increasing demand for large bore vacuum insulated pipes in sectors including energy, aerospace, healthcare, and manufacturing. These industries depend on specialized piping systems to safely and efficiently transport cryogenic fluids such as liquefied natural gas (LNG) and liquid nitrogen.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐚 𝐒𝐚𝐦𝐩𝐥𝐞 𝐂𝐨𝐩𝐲 𝐨𝐟 𝐓𝐡𝐢𝐬 𝐑𝐞𝐩𝐨𝐫𝐭: https://www.factmr.com/connectus/sample?flag=S&rep_id=9900

Country-specific Insights

In the United States, the demand for large bore vacuum insulated pipes is steadily increasing, driven by robust industrial growth. As of 2024, the United States is expected to command a significant 77.6% share of the large bore vacuum insulated pipe market in North America.

The industrial sector in the United States relies heavily on vacuum-insulated pipes for the safe and efficient transport of cryogenic fluids. These pipes are integral to various industries including healthcare, food processing, and aerospace, ensuring the secure handling of liquefied natural gas (LNG) and other cryogenic materials.

Category-specific Analysis

Cryogenic pipes are purpose-built for the transportation of extremely cold fluids such as LNG, liquid hydrogen, and liquid nitrogen. Their insulation properties are optimized to maintain these fluids at ultra-low temperatures, minimizing heat transfer and preventing vaporization during transit.

Global demand for cryogenic fluids, particularly LNG, continues to rise across sectors such as energy, manufacturing, and transportation. This trend contributes significantly to the overall growth trajectory of the large bore vacuum insulated pipe market, fueling increased demand for cryogenic pipes to facilitate the safe and efficient transportation of these fluids.

Read More: https://www.factmr.com/report/large-bore-vacuum-insulated-pipe-market

Industry Competition

Key players in the large bore vacuum insulated pipe market, including Ability Engineering Technology, Inc., CRYOSPAIN, INTECH GmbH, Demaco, Schwanner GmbH, Empower, Cryogas Equipment Pvt. Ltd., PERMA-PIPE International Holdings, Inc., Cryoworld, Maxcon Industries Pty. Ltd., and TMK, are actively expanding their market presence and enhancing their competitive positions.

These companies are strategically pursuing acquisitions and partnerships to broaden their product portfolios and capitalize on emerging market opportunities. Each player brings unique capabilities to the table, contributing to the evolving trends in the large bore vacuum insulated pipe market.

In March 2022, PERMA-PIPE secured a significant contract worth US$ 15.5 million in Egypt and Saudi Arabia, supplying insulated piping solutions including the innovative XTRU-THERM insulation system and PermAlert leak detection system.

Similarly, in March 2022, Empower secured a major US$ 52.5 million contract to construct a state-of-the-art district cooling plant in the DLRC area, enhancing eco-friendly cooling solutions. Upon completion, the expanded plant capacity is expected to reach approximately 47,000 RT, supporting sustainable development goals in the region.

Key Segments of Large Bore Vacuum Insulated Pipe Market Research

By Installation Type :

Above Ground

Underground

Under Sea

By End Use :

Cryogenic

Aerospace

Chemicals

By Region :

North America

Latin America

Europe

East Asia

South Asia & Oceania

Middle East & Africa

𝐂𝐨𝐧𝐭𝐚𝐜𝐭:

US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

Asia-Pacific food processing & food material handling equipment is expected to gain market growth in the forecast period of 2021 to 2028. Data Bridge Market Research analyses that the market is growing at a CAGR of 7.7% in the forecast period of 2021 to 2028 and expected to reach USD 97,759,849.88 Million by 2028.

#Asia-Pacific Food Processing and Food Material Handling Equipment Market#Asia-Pacific Food Processing and Food Material Handling Equipment Market Share#Asia-Pacific Food Processing and Food Material Handling Equipment Market Size.

0 notes

Text

What makes Indian rice manufacturers the top choice for global importers?

Indian rice manufacturers have built a strong global reputation for their quality, variety, and consistent supply. As one of the largest rice exporting countries, India supplies premium and affordable rice varieties to over 150 countries. But what makes them the preferred choice for international buyers? Let’s look at the factors that make Indian rice exporters stand out in the global market.

Introduction to Indian Rice Manufacturing

India has long been a global leader in rice production, exporting over 40% of the world’s total rice supply (Source: FAO). The country’s manufacturing capacity is supported by its vast paddy fields, skilled workforce, and advanced milling facilities. Indian rice manufacturers cater to the market’s diverse needs, offering everything from high-quality Basmati to cost-effective bulk options.

This adaptability and focus on quality ensures that Indian rice continues to dominate the global market.

Quality Standards and Certifications

Quality assurance is the cornerstone for rice suppliers in India. They follow international guidelines to ensure that rice meets the expectations of global importers. Some of the key certifications include:

ISO 22000 and HACCP: highlighting their commitment to food safety.

Organic certifications: ensuring compliance with USDA and EU standards.

Fair trade and sustainability practices: signifying ethical production.

Many manufacturers use state-of-the-art milling techniques and conduct strict quality checks. These efforts make Indian rice a reliable choice for consumers around the world.

Wide variety of rice types

India offers an unmatched variety of rice, enabling manufacturers to meet the diverse preferences of global markets. Popular choices include:

Basmati rice: Famous for its aroma and long-grained texture, it is widely in demand in Europe and the Middle East.

Non-Basmati Rice: Varieties such as IR64 and Sona Masuri are staples in Africa and Asia.

Specialty and Organic Rice: Catering to niche markets focused on health and sustainability.

This broad portfolio allows Indian exporters to meet the needs of a variety of customers, from gourmet chefs to wholesale distributors.

Cost-effectiveness and supply reliability

Indian rice manufacturers maintain a balance between quality and affordability. This is achieved through:

High production efficiency: Leveraging large-scale operations and advanced machinery.

Government policies: Subsidies for farm equipment and fertilizers reduce production costs.

Geographical advantage: Fertile land and favorable weather ensure consistent yields.

Their ability to handle bulk orders while adhering to strict timelines makes Indian rice exporters reliable partners for global importers.

Commitment to sustainability and innovation

Sustainability has become a priority for Indian rice manufacturers. Many companies are adopting environmentally friendly practices such as:

Water conservation: Using innovative irrigation techniques to reduce water consumption.

Renewable energy: Integrating solar and bioenergy into milling processes.

Waste utilization: Converting rice husk into biofuels and fertilizers.

Such practices align with the values of environmentally conscious consumers, strengthening India’s position in the global market.

Additionally, advances in traceability and quality control, including digital systems, enhance transparency and trust between manufacturers and importers.

India’s global prominence in rice exports is supported by its strong manufacturing base, diverse offerings, and commitment to quality. By choosing Indian rice manufacturers, importers benefit from reliable, high-quality rice that meets a variety of market demands. Whether it’s aromatic basmati for fine eating or affordable bulk varieties for everyday use, Indian exporters continue to set benchmarks in the global rice trade.

2 notes

·

View notes