#Genset Electronic Controller & Sensors

Explore tagged Tumblr posts

Text

Genset Electronic Controller and Sensors provider

UNI-TECH Automation Pvt. Ltd specializes in providing high-quality Genset Electronic Controller & Sensors, ensuring reliable performance and efficiency for your power generation needs.

#UL & CSA approved Cables India#Control Panel Suppliers Pune#Wiring harness manufacturer Pune#Sheet metal fabrication & Powder coating#Genset Electronic Controller & Sensors#Capacitive Fuel level sensors

0 notes

Text

Unitech: Genset Electronic Controller & Sensors provider

UNI-TECH Automation Pvt. Ltd specializes in providing high-quality Genset Electronic Controller & Sensors, ensuring reliable performance and efficiency for your power generation needs.

#UL & CSA approved Cables India#Control Panel Suppliers Pune#Wiring harness manufacturer Pune#Sheet metal fabrication & Powder coating#Genset Electronic Controller & Sensors#Capacitive Fuel level sensors

0 notes

Text

Selection of Diesel Generator Sets in the Data Center Industry

The energy consumption of data centers originates from IT equipment, lighting, cooling systems, and power distribution systems. Power supply reliability is critical for data centers. Diesel generator sets, as essential backup power equipment, can take over power supply during grid power failures, thereby preventing significant losses caused by server downtime or data loss. Below is an overview of diesel generator selection in the data center industry.

Generator power ratings selection

As key standards for diesel generator sets, ISO 8528-1 and GB/T 2820-1 define four types of generator power ratings:

Continuous Operating Power (COP)

Prime Rated Power (PRP)

Limited-Time Prime (LTP)

Emergency Standby Rating (ESP)

The generator power rating selected should be based on actual operating conditions. Choosing the right generator significantly impacts both the investment and power supply reliability of a data center. Different clients may select generator power ratings flexibly based on their specific requirements.

Cummins Power Generation pioneered the DCC (Data Center Continuous) power rating in the industry, tailored to the continuous power supply needs of data centers. This rating provides significant value for data center investment and operational management. The DCC power rating is recognized by Uptime Institute and can be used for Tier III and Tier IV certifications.

Key considerations for data center generator sets

The engine, which provides the necessary power for the generator set, is the most critical component in the selection process.

Primary consideration: Sufficient power output and dynamic response to load changes.

Due to the complexity of designing and manufacturing large-capacity diesel engines, engines from different manufacturers may vary significantly. Ensuring sufficient power output is a primary consideration, followed by the engine’s dynamic response to load fluctuations.

Trends: Small displacement with high power output.

Advances in technology have driven diesel engines toward smaller displacements and higher power outputs. Manufacturers are enhancing engine power density through innovations such as turbocharging and high-pressure clean combustion technologies. Traditional naturally aspirated engines, whose power output was proportional to displacement, are now obsolete. Key methods to improve power density include increasing air intake, optimizing mechanical efficiency, and improving combustion efficiency.

Four key factors when selecting a diesel generator for data center:

Adequate power output for requirements.

Superior dynamic performance—ability to handle single-step full load application.

Electronic fuel injection (EFI)—better load-handling characteristics.

Generator manufacturers with proven application experience and extensive case studies.

In addition to the considerations above, other factors such as harmonic loads, capacitive loads, rapid parallel system capability of genset, high-voltage generator neutral grounding, and ventilation systems should also be taken into account.

Fuel tanks and supply systems

Fuel tank capacity and design of generator sets comply with technical specifications and fire safety codes. Key requirements include:

Underground tanks: High-quality steel with anti-corrosion treatment, continuous magnetic float level sensors (4–20mA output to PLC).

Day tanks: Access covers, inlet/return/drain/overflow pipes, magnetic level gauges with local/remote (4–20mA) signals.

Fuel transfer pumps: Dual pumps with filters, check valves, and explosion-proof motors (3-phase, 50Hz, overload protection).

Control systems: Monitor tank levels, control valves/pumps, provide alarms, and integrate via Modbus-RS485.

Load bank testing

Load testing is vital for verifying generator performance during project acceptance. It validates full-load output, ventilation, exhaust, fuel supply, and electrical system design. Regular generator load bank testing during maintenance prevents issues like carbon buildup from light-load operation, ensuring long-term reliability of diesel generators.

This structured approach ensures diesel generator sets meet the stringent demands of modern data centers, balancing power reliability, efficiency, and operational safety.

Looking for a reliable power generator? Contact us today to order the right generator for your needs.

0 notes

Photo

SmartGen | Common Fault & Solution of Genset Control System

Fault Symptom 1: Controller no water temperature/oil pressure/level, showing “####”. Solution: Check controller temperature/oil pressure/level sensor and whether its “G” and “WK” is connected correctly.

Fault Symptom 2: Controller displayed water temperature/oil pressure/level data is inaccurate. Solution: Check controller temperature/oil pressure/level curve type and whether it is matched with selected sensor.

Fault Symptom 3: Controller displayed temperature/oil pressure/level data is unstable. Solution: 1. Ground the common end of sensor on the controller to genset ground pile. 2. Check whether genset starter negative pole’s wire diameter is too thin causing voltage change in starting.

Fault Symptom 4: Controller start output port is always burnt out. Solution: Controller inner starting relay is small, its bearing current is limited; but genset starting current may be 2~3 times the relay bearing current. It can bear for a short time, but relay contact will be bonded if start repeatedly for a long time. So another relay should be added in starting.

Fault Symptom 5: No start speed, no display or “0 rpm” display. Solution: Check speed sensor and whether its screw-in position is too far from fly wheel; check wire connection and controller setting crank disconnect conditions.

Fault Symptom 6: Genset no idle speed or over speed directly, controller issues “Over Speed Shutdown”. Solution: 1.Check whether controller’s auxiliary output ports are configured; 2.Confirm genset using electronic speed adjusting or mechanical wire speed adjusting; 3.Check whether external connected electronic GOV has fault and its wire; 4.Check whether controller’s idle timing is “0s”; 5.Adjust electronic GOV’s rated speed, anticlockwise adjust it to drop speed.

Fault Symptom 7: Genset cannot enter high speed, controller issues “Under Speed Shutdown”. Solution: 1.Check whether controller’s idle control output port is disconnected in idle timing; 2.Check whether electronic GOV has fault and its wire; 3.Check whether electronic GOV’s rated speed is too low; 4.Check whether the speed raise time adjusting of electronic GOV is too large.

www.smartgen.cn

0 notes

Text

Electronic Products at UNI-TECH Automation

UNI-TECH Automation manufacture various types of Electronic Products for Diesel Genset Applications

Esmart APU-601

Esmart AMF-387

Esmart AMF-111

Esmart Fire Controller

Esmart SMC-111-2C

Esmart ESU-SHD

Esmart Capacitive Level Sensor

Esmart Tachometer

Esmart APU-601

APU-601 controller is a versatile, low-cost high-speed processor, high technology controller meant for maintaining the critical parameters of Diesel Loco engine system

Unit’s features are Automatic and manual start stop sequencing of APU Engine and safety monitoring Read more.

Esmart AMF-387

Auto Start & Auto Mains Failure (AMF) 387 Controller Module is a perfect suit for a wide variety of single diesel-based Generator Set applications

The unit finds application in single/three phase Genset automation panels of all complexities Read More.

Esmart AMF-111

AMF-111 is a versatile high technology electronic Genset controller meant for automating single phase diesel gensets

The unit automates the starting and stopping sequences, thus allowing completely unattended Genset Operation Read More.

Esmart Fire Controller

Fire controller is a versatile high Technology electronic controller meant for monitoring the critical parameters of the fire pump controller.

Unit helps in restarting the engine, maintaining the oil pressure, engine temperature, battery voltage and other critical parameters. Read More.

Esmart SMC-111-2C

The controller provides a simple operator interface to the engine in the manual mode with remote START/STOP, fault indication by LED and LCD display for displaying parameters

In the event of parameters going outside the set limits, the controller displays it on LCD Read More.

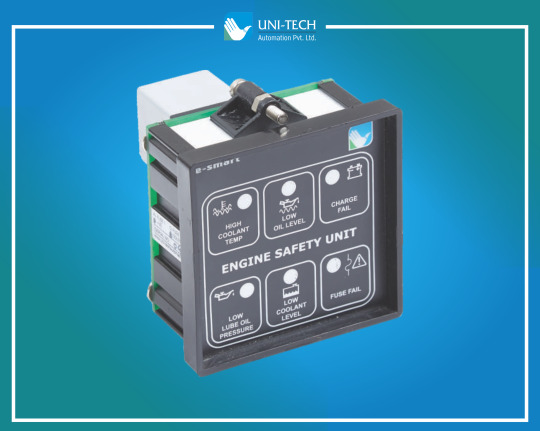

Esmart ESU-SHD

ESU is Microcontroller based engine safety unit(ESU). The controller provides a simple operator interface to the engine with EMG/Aux Stop control Shutdown fault indication by LED and Buzzer.

The unit provides protection in a single integrated package which minimizes the control panel size while reducing the wiring, discrete parts & assembly costs Read More.

Esmart Capacitive Level Sensor

LVL-160 level transmitter is capacitive liquid level measuring instrument. The capacitance is measured with respect to liquid in liters

Unit is designed for liquid level measurement with good stability & processing electric circuit of high accuracy. Read More.

Esmart Tachometer

A Tachometer is a sensor device for measuring the rotation speed of an object such as the engine shaft in the car. This device indicates revolutions per minute(RPM) performed by the object

The UNI-TECH Esmart Tachometer comes with LCD Display and over speed fault indication LED. Read More.

0 notes

Text

250kva Perkins diesel generator set

As we know that Perkins is the world famous engine manufacturer and set up more than 3500 service outlets worldwide. Perkins is committed to product quality, environment and economy. By strictly enforcing the ISO9001 and ISO14001 standard, the products have high emission standard, high efficiency, high stability and high reliability and so on. In addition, Perkins engine also meets international standard of ISO 8528, ISO 3046 and BS 5514 for generator set.

In this article, Starlight Power mainly shares 250KVA Perkins 1506A-E88TAG2 standby generator features and main parameters.

Building upon Perkins proven reputation within the power generation industry the Perkins® 1500 Series Electropak engines now fit even closer to customer’s needs.

The 1506A-E88TAG2 ElectropaK is a 6 cylinder, fully electronic, turbocharged, air-to-air charge cooled diesel engine. It is economical, quiet and reliable and provides the high performance that is demanded by customers for their power generation needs.

Focusing on the Perkins common platform theme, changes to engine envelope dimensions and connection points have been kept to a minimum, making for easy installation across the ratings.

Function

Automatic start/stop, data measurement, alarm protection and three “remote” (remote control, remote measure and remote communication)

Can measure and display 3 phase voltage, 3 phase current, frequency, power parameters of mains/genset

Optional language interface

Chinese, English, Spanish, Russian, Portuguese, Turkey, Polish and French

Communication port

RS485

Features and benefits of Perkins 1506A-E88TAG2 Engine

Dependable power

1. The 1506A-E88TAG2 delivers greater productivity through an improved power to weight ratio.

2. The world-class power density has been achieved from an 8.8 litre turbocharged engine using a hydraulic actuated unit injection (HEUI) fuel system; making this engine robust for all markets due to its ability to cope with the variation of fuel quality around the world

3. In its class, the 1506A-E88TAG2 has been designed to provide dependable power even in extreme ambient climates.

Low operating costs

1. Oil change service intervals are set at 500 hours as standard.

2. Designed to provide low cost of ownerhsip, simple maintenance and reduced downtime.

3. 12 months unlimited warranty with 24 months on Major items. For low use applications <500 hours per year warranty is extended by a further 12 months. See Perkins Warranty Policy for further details.

Flexibility

1. The 1506-E88TAG2 has been designed to hit the power node requirements of customers.

2. Switchability functionality from 50 Hz/1500 rpm to 60 Hz/1800 rpm and vice versa is available to provide greater flexibility for frequency selection.

World class product support

1. Experienced global network of distributors and dealers, fully trained engine experts deliver total service support around the clock, 365 days a year. They have a comprehensive suite of web based tools at their disposal, covering technical information, parts identification and ordering systems, all dedicated to maximising the productivity of your engine.

2. Perkins actively pursues product support excellence by insisting our distribution network invest in their territory to provide customers with a consistent quality of support across the globe

3. Throughout the entire life of a Perkins engine, we provide access to genuine OE specification parts giving 100% reassurance that you receive the very best in terms of quality for lowest possible cost, wherever your Perkins powered machine is operating in the world.

Technical information

Air inlet system - Mounted air filter and turbocharger

Fuel system

1. HEUI fuel system with full authority electronic control

2. Electronic governing to ISO 8528-5 with stand-alone isochronous and load-sharing capabilities

3. Fuel filter, fuel transfer pump, fuel priming pump

4. Spin on primary, secondary and water filter separator

Lubrication system

1. Wet full aluminium sump with filler and dipstick

2. Full-flow spin-on filters

3. Oil pump, gear driven

Cooling system

1. Thermostatically controlled with belt driven, circulating pump and belt-drive fan

2. Mounted belt driven pusher fan

3. Radiator supplied loose with all guards and pipes

4. Air-to-air charge cooler incorporated in radiator

Electrical equipment

1. 24V starter motor and 24V, 45 amp alternator with DC output

2. Electronic Control Module (ECM) mounted on engine with wiring looms and sensors

Flywheel and housing

1. High inertia flywheel to SAE 1 J620 Size 355.6 mm (14 in)

2. Aluminium SAE 1 flywheel housing

Mountings - Front engine mounting bracket

Perkins Diesel Generator Maintenance

1. Perkins diesel generator needs to change oil, clean diesel filter and air filters after 60 hours of operation.

2. The electrolyte of the battery should be checked frequently and replenished in case of shortage.

3. Should always check the tightness of the belt, adjust the tensioning mechanism to maintain the tensioning state.

4. In the cold season, the water heating and oil heating switches should be turned on to keep the genset at a certain temperature to ensure the normal use of the diesel generator set.

0 notes

Text

LPG and CNG variants as an alternative to DG sets during the recent years.

Seasonal power outage, shortage of power, deficit of power and irregular power supply can be attributed to this very reason of shortage of power supply. These aspects explain the reason behind the growth in the generator sales. Coupled by a boost in infrastructure and automobile sector, sales of generators have taken off in a big way. While the diesel gensets has long been preferred by customers owing to the fuel efficiency, ease of operation and easy availability of diesel. However, there has been a focus on the use of natural gas-powered generators in their LPG and CNG variants as an alternative to DG sets during the recent years. Generators of

any category has been a sure shot solution to address the power shortage issues and has become an almost indispensable feature during the recent years for both commercial and domestic purposes. When it comes to powering homes or commercial establishments, Cooper Corporation is among one of the most well-known generator manufacturing companies in India. With a manufacturing history of over 50 years, the company, which initially began its expertise in the manufacturing of engine components has now diversified into generators and engines.

Cooper Corporation generators are known to be an efficient power-back up as much as they are known to be cost-effective and fuel-efficiency. The addition of ECOPACK range of Cooper generators redefines performance efficiency and provides a most cost-effective solution for efficient power back-up management.

They are fitted with the indigenously-built Cooper-make, four-stroke liquid cooled gas engines and are equipped with the Common Rail Direct Injection (CRDi) technology developed in partnership with Ricardo, UK. Some of the most notable features of the

Cooper generators include:

-Cost effectiveness and fuel-efficiency

-low maintenance and efficient power-back up supply

-dynamic designs

-environment-friendly design and technology

With over five decades of manufacturing expertise, Cooper is among the renowned

generator manufacturing companies in India that is instrumental for providing

efficient power back up for homes, retail spaces, commercial outlets, hospitality

sector, industries and infrastructure projects. The DG sets are integrated with

modern technology and other design aspects that makes it stand out among its

peers. Some of the features here include:

-these generators are 40% lighter as compared to the others

-occupy 25% lesser space

-has high fuel efficiency where the lube oil consumption is only 0.01%

-maintenance interval of five hundred hours and a running life of 7,000 hours.

-lower noise levels in the range between 75-57 dbA at one meter under free field

conditions.

Cooper Generators-both diesel- and gas-powered generators make for a greener and eco-friendly options for its users. This is indeed a welcome change from the high decibel sounds caused by other commercial diesel generators. In their efforts to provide clean energy solutions, the company has attained Euro IV, US Tier IV (Interim) and CPCB 2 compliance certificates for their make of generators.

Cooper generators and DG sets are fitted with ECU and ECU modules which control all the critical engine functions and mechanisms. Talking about clean energy generators, there is a growing need for people to control emission of harmful pollutants into the atmosphere. In their efforts to do so, Cooper’s gas-powered generators are super-silent generators that are available in the power ranging from 10KVA-140 KVA with the fuel capacity ranging from 1.2L to 7.8L. These generators are fitted with a 2, 3, 4 and 6 cylinder, in-line, 4 strokes LPG gas engine that makes them efficient and powerful. The indigenously fitted Electronic Engine Management System, safety switches and sensors help regulate temperature and oil pressure.

The double overhead camshaft add up for the key features of the gas powered generators variant. While choosing the right generator for your living space or workspace can be a daunting task, finding the right buy is crucial to save energy and costs.

Step one-find the choices available,

Two- Scale down your choice depending on the company, make etc. Three-make the right choice based on efficiency, cost effectiveness.Finally, understand whether the company offers a good after sales service, has a good dealer and sales network

0 notes

Text

New engines for the Royal Navy’s Type 23 Frigates

Originally designed with a service life of around 18 years, the RN’s Type 23 Frigates will now have to serve for around 30 years. All 13 frigates are undergoing life extension (LIFEX) refits and an important component of these upgrades is the Power Generation Machinery Upgrade (PGMU) to replace the ships’ four diesel generator sets.

The Type 23 LIFEX programme is being run by the Surface Ship Support Alliance (a partnership between the MoD, Babcock and BAE Systems) and began in June 2015 when HMS Argyll was taken in hand at Devonport. At the time of writing HMS Argyll, Westminster, Montrose, Northumberland and Kent have all completed LIFEX refits. The most obvious external change is the fitting of the CAAM Sea Ceptor missile system to replace the ageing GWS-26 Sea Wolf but the refits also include major changes to equipment, the combat system, chilled water arrangements and work to extend the life of the hull and superstructure. Unfortunately, the first ships to undergo LIFEX have not received new engines and will have to wait until their next major refit. HMS Richmond will be the first ship to receive the machinery upgrade and is currently mid-way through her refit in Devonport. Work has also started on the LIFEX of HMS Portland and HMS Lancaster at Devonport. The LIFEX refit of each Type 23 is costing at least £35M per ship, not including the PGMU. Totalling around £600M for this work across the frigate fleet, this is a very necessary and worthwhile investment but could have been much reduced if the Type 26 frigates had been ordered earlier.

The oldest Type 23s HMS Argyll and HMS Lancaster will never receive the PGMU. Assuming they survive future defence cuts, they will have to soldier on with their Paxman diesels until they go out of service in 2023 and 2024 respectively. The project is set to be completed by 2024 when last of the other 11 ships receives its new engines.

The MTU 20V-4000 M53B Diesel Engine (Photo: Rolls Royce)

The first of the new MTU 12V 4000 M53B diesel generator sets were delivered to Devonport Naval Base in late 2016 for fitting to HMS Richmond. The new gensets are manufactured in Germany by MTU (A subsidiary of the Land & Sea division of Rolls-Royce) and provide 1.65MW each. This will provide the ship with approximately 20% increase in available power for onboard weapons, sensors and electronics as well as for cruising propulsion. The old Paxman Valenta 12 RP2000CZ diesel design dates from the 1960s and are becoming increasingly maintenance-intensive. They are rated at 1.3MW but and have reduced power output as low as 1MW in hot climates. The new diesels perform better in hot conditions and will drastically reduce maintenance time and running cost. The MTU 4000 gensets include sophisticated noise reduction and shock resistance measures and are exceptionally reliable. The PGMU project presented a considerable engineering challenge as new equipment had to fit within the existing structural and compartment constraints and integrate with the ship’s services and systems.

The PGMU project comprises 5 separate components (which the DE&S tendered for in ‘lots’); diesel generators, power conversion equipment, electrical switchboards, the machinery control and surveillance system (MCAS) and the integration work. A £68M contract was signed by the DE&S with MTU to supply the 48 generator sets in April 2015. The contract includes a complete logistics package, spare parts and initial training. The RN’s mechanical engineering training establishment, HMS Sultan will receive equipment and electronic manuals so it can provide relevant training for MEs serving on the upgraded Type 23s.

Hitzinger UK won a £12M contract for the voltage converters and Rolls-Royce signed a £18M contract in January 2016 to deliver the updated MCAS. Babcock Marine and Technology is responsible for the integration of the new systems aboard the ships and was awarded a £3.6M for this task. The project includes installing 600m of new pipework in each ship together with over 8km of new cable. The Upper Auxiliary Machinery Room (UAMR) and the Forward Auxiliary Machinery Rooms (FAMR) have to be almost entirely stripped out and new machinery foundations and uptakes and downtakes fitted.

The MTU 4000 gensets have specialist mounting and are surrounded by an acoustic enclosure, ensuring low radiated noise levels, critical to anti-submarine warfare. (Photo: Rolls Royce)

The new propulsion package fitted to the Type 23s will not only improve ship availability, fuel efficiency and available power but will provide useful experience for the RN as similar MTU gensets are being fitted the future Type 26 frigates. Although the Type 26 is an evolution of the Type 23’s propulsion system there are significant differences. Type 23 utilised a CODLAG arrangement – Combined Diesel Electrical AND Gas Turbine. Both the gensets driving the motors and both Spey Gas Turbines are required to be online to achieve full speed. The Type 26 is CODELOG Combined Diesel-Electric OR Gas Turbine. The single MT-30 gas turbine alone is sufficient to drive the ship at full speed without the need for the motors, and in that mode the gensets can provide power purely for the ships electrical needs.

Although the Type 23’s legacy Spey gas turbines do not, the new MTU propulsion system meets the requirements of the International Maritime Organization (IMO) III emissions directive. Meeting civilian emissions standards is challenging for the unique requirements of naval vessels but it is obviously desirable to maximise fuel efficiency and reduce emissions. The RN has utilised various new hydrodynamic features to minimise drag on its ship hulls. These have been incorporated at the design stage of the modern vessels Type 45, the aircraft carriers and the Type 26 but the older Type 23s have undergone some modifications in service including self-polishing anti-fouling coatings on the hull and propeller blades, stern wedges, and improved propeller designs. The intention is that the Type 26 frigates will be fully compliant with IMO’s MARPOL (Nitrogen oxides) NOx regulations and will be fitted with a Selective Catalytic Reduction (SCR) system together with the efficient MTU4000 20V diesel generators and MT-30 Gas Turbines.

HMS Montrose in the final stages of her LIFEX (May 2017) in Devonport. Babcock’s Frigate Refit Complex comprises 3 covered dry docks and is being heavily utilised for the LIFEX programme. The future Type 26 frigates will not fit inside this facility, although the Type 31 designs probably can be accommodated.

from Save the Royal Navy https://www.savetheroyalnavy.org/new-engines-for-the-royal-navys-type-23-frigates/

0 notes

Text

Leading Automation Company in Pune | Expert Solutions

Top Automation Company in Pune, offering control panel suppliers, UL & CSA approved cables India, and capacitive fuel level sensors. Contact us today!

#UL & CSA approved Cables India#Control Panel Suppliers Pune#Wiring harness manufacturer Pune#Sheet metal fabrication & Powder coating#Genset Electronic Controller & Sensors#Capacitive Fuel level sensors

0 notes

Text

UNI-TECH Automation: Precision Sheet Metal & Coating Experts

UNI-TECH Automation specializes in high-quality Sheet metal fabrication & Powder coating services. With precision and expertise, we deliver durable and customized solutions.

#UL & CSA approved Cables India#Control Panel Suppliers Pune#Wiring harness manufacturer Pune#Sheet metal fabrication & Powder coating#Genset Electronic Controller & Sensors#Capacitive Fuel level sensors

0 notes

Text

UNI-TECH Automation Pvt. Ltd.: Top Control Panel Suppliers Pune

UNI-TECH Automation excels in Capacitive Fuel Level Sensors, control panel suppliers, and UL & CSA approved cables in India, ensuring precision, reliability, and innovation.

#UL & CSA approved Cables India#Control Panel Suppliers Pune#Wiring harness manufacturer Pune#Sheet metal fabrication & Powder coating#Genset Electronic Controller & Sensors#Capacitive Fuel level sensors

0 notes

Text

Unitech Automation: Sheet metal fabrication & Powder coating

UNI-TECH Automation Pvt. Ltd. specializes in Sheet metal fabrication & Powder coating, offering precision-engineered solutions for industrial needs with high-quality, durable finishes.

#UL & CSA approved Cables India#Control Panel Suppliers Pune#Wiring harness manufacturer Pune#Sheet metal fabrication & Powder coating#Genset Electronic Controller & Sensors#Capacitive Fuel level sensors

0 notes

Text

Empowering Innovation at Unitech Automation Company in Pune

Unitech Automation Company in Pune delivers cutting-edge automation solutions, driving efficiency and innovation for businesses across industries.

#UL & CSA approved Cables India#Control Panel Suppliers Pune#Wiring harness manufacturer Pune#Sheet metal fabrication & Powder coating#Genset Electronic Controller & Sensors#Capacitive Fuel level sensors

0 notes

Text

UNI-TECH Automation: Leading Automation Company in Pune

UNI-TECH Automation excels in Capacitive Fuel Level Sensors, control panel suppliers, and UL & CSA approved cables in India, ensuring precision, reliability, and innovation. Uni Technology offers advanced automation solutions for industries. Discover innovative products and services from one of the best automation companies near me.

#UL & CSA approved Cables India#Control Panel Suppliers Pune#Wiring harness manufacturer Pune#Sheet metal fabrication & Powder coating#Genset Electronic Controller & Sensors#Capacitive Fuel level sensors

0 notes

Text

UNI-Tech Automation Pvt Ltd: Trusted control panel suppliers.

UNI-Tech Automation Pvt Ltd: Leading electrical panel manufacturers and reliable control panel manufacturers near me, providing high-quality, customized solutions for your needs.

#UL & CSA approved Cables India#Control Panel Suppliers Pune#Wiring harness manufacturer Pune#Sheet metal fabrication & Powder coating#Genset Electronic Controller & Sensors#Capacitive Fuel level sensors

0 notes

Text

Unraveling the Success of Top Cable and Harness Manufacturers

Unitech Automation: Leading automation company in Pune, specializing in high-quality wiring harnesses. Trust us for innovative solutions and reliable products tailored to your needs. Get ready to dive into the world of top cable and harness manufacturers and discover the keys to their unrivaled success.

#UL & CSA approved Cables India#Control Panel Suppliers Pune#Wiring harness manufacturer Pune#Sheet metal fabrication & Powder coating#Genset Electronic Controller & Sensors#Capacitive Fuel level sensors

0 notes