#HDPE Bags and Rolls

Explore tagged Tumblr posts

Text

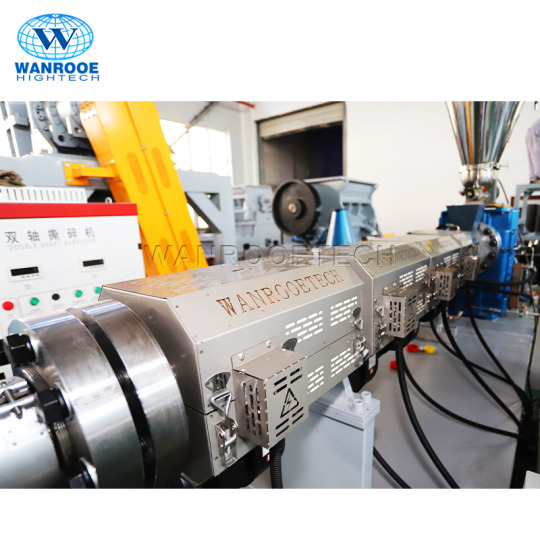

Double Stage PP PE Plastic Film Woven Bag Plastic Granulating Line is double stage plastic regenerative pelletizer, which is suitable for many kinds of plastic waste materials recycling and making pellets, such as PE, HDPE, LDPE, PP, BOPP plastic film, bag,fiber,rope scrap material and etc. The film can be pressed in the compressor and then be pelletized. 1.Applicable plastic materials: PE, HDPE, LDPE, PP, BOPP, PET, PA/Nylon, etc. 2.Material shapes: film, bag,fiber,rope scrap. 3.Material types: rolls, loose, bundled. 4.Material comes from offcut, industry defective materials, washed materials and printed materials. Note: depending on different material properties, various downstream equipments are needed.

1 note

·

View note

Text

5 Top Packaging Companies in the Philippines

If you're exploring more dependable packaging suppliers in the Philippines, these five companies are worth your attention. Known for their specialization, quality, and regional reach, they complement the top-tier list by offering tailored packaging solutions across various industries.

Entrepouch – Your One-Stop Flexible Packaging Solution

Number #1 packaging company in Entrepouch tops our list for a reason—it offers a wide variety of high-quality, customizable, and cost-effective pouches and packaging solutions for businesses of all sizes. Whether you're in food and beverage, cosmetics, supplements, or retail, Entrepouch provides:

• Flat and Stand-Up Pouches (silver, gold, white, transparent)

• Vacuum Bags and Resealable Zippers

• Food-Grade, Durable, and Eco-Friendly Materials

• Custom Printing & Bulk Orders

• Nationwide Delivery Across the Philippines

With a strong reputation for excellent customer service and fast order fulfillment, Entrepouch is the go-to partner for thousands of local brands aiming for shelf-ready appeal and long-lasting packaging performance.

Jumbopack Industries Corporation

Jumbopack Industries is a leading manufacturer of plastic packaging products with a strong focus on food-grade containers, bottles, and jars. They cater to both SMEs and large food processing plants, ensuring durable and safe packaging for liquids, powders, and granules.

Key Products:

HDPE and PET bottles

Plastic jars and containers

Custom injection molding

Best For: Beverage, condiments, personal care products

Advanced Flexible Packaging Solutions, Inc.

This company specializes in flexible laminated packaging, particularly for food and beverage applications. Advanced Flexible Packaging Solutions offers roll stocks, sachets, and pouches with high barrier protection, ideal for extending shelf life.

Highlights:

Rotogravure printing up to 9 colors

High-barrier laminate films

Custom pouch formats (three-side seal, stand-up, spouted)

Best For: Coffee, snacks, dairy, and pet food packaging

Nature’s Legacy Packaging

Sustainability meets functionality at Nature’s Legacy, a pioneer in eco-friendly and biodegradable packaging solutions in the Philippines. They use innovative materials like stone paper and natural resin composites for unique packaging forms.

Key Offerings:

Sustainable packaging made from agricultural waste

Compostable and biodegradable materials

Custom-designed retail and gift packaging

Best For: Green brands, organic product lines, and eco-conscious retailers

Tritec Packaging Systems and Solutions Inc.

Tritec Packaging provides end-to-end packaging solutions, including machinery, automation systems, and consumables. Their wide range of packaging equipment makes them a preferred partner for growing businesses that need scalable solutions.

Services Include:

Shrink wrapping and labeling machines

Filling, capping, and pouch sealing systems

Packaging line integration

Best For: Medium to large-scale manufacturers

Polytrade Packaging Corporation

Established in the 1970s, Polytrade Packaging has decades of experience providing paper-based packaging such as folding cartons, corrugated boxes, and paper bags. They serve industries ranging from pharmaceuticals to consumer goods.

What They Offer:

Custom printed paper boxes

Food-grade paper packaging

Export-quality cartons and inserts

Best For: Cosmetics, pharmaceuticals, retail goods

0 notes

Text

Tips for Choosing the Right Woven Fabric for Heavy-Duty Applications

When it comes to heavy-duty industrial applications, the materials used must be tough, durable, and built to last. Whether it's for packaging, agriculture, construction, or transportation, choosing the right woven fabric is essential to ensure strength, safety, and long-term performance. But with so many types of woven materials on the market—like HDPE and polypropylene fabrics—how do you know which one is right for your needs?

This article walks you through practical tips for selecting the right woven fabric for demanding applications, with a focus on quality, performance, and cost-effectiveness.

What Are Woven Fabrics?

Woven fabrics are textile structures formed by interlacing two sets of yarn—warp and weft—at right angles. In industrial settings, woven fabrics are usually made from synthetic materials like HDPE (High-Density Polyethylene) or polypropylene due to their strength, water resistance, and flexibility.

They are widely used to manufacture sacks, FIBCs (Flexible Intermediate Bulk Containers), tarpaulins, ground covers, and geotextiles. The specific material and weaving technique significantly impact how the fabric performs under stress, moisture, heat, and prolonged use.

1. Understand Your Application Requirements

The first step in selecting a woven fabric is understanding the environment and use-case it will be exposed to. For example:

Will it carry abrasive materials like gravel or sand?

Will it be exposed to sun and moisture for long periods?

Is it for single-use or multiple-use packaging?

Does it need to be food-grade or chemically resistant?

Answering these questions helps narrow down the fabric’s required properties such as tensile strength, UV resistance, coating, and breathability.

2. Choose the Right Material: HDPE vs. Polypropylene

HDPE and polypropylene are two of the most common polymers used in industrial woven fabrics.

HDPE Fabrics

HDPE woven fabrics are known for their durability, weather resistance, and toughness. They perform exceptionally well in outdoor applications and are commonly used for covering goods, making tarpaulins, and agricultural uses.

HDPE fabric rolls are lightweight yet strong, offering high tensile strength and good resistance to chemicals. If you're looking for long-lasting protection in exposed environments, HDPE is a reliable option.

Polypropylene Woven Fabrics

Polypropylene woven materials are lighter than HDPE and have excellent chemical resistance. These are commonly used in FIBCs, woven sacks, and packaging where flexibility and form retention are crucial.

If your focus is on bulk packaging and cost-efficiency, sourcing from a reputed polypropylene woven fabric manufacturer can help you get the right balance between quality and price.

3. Pay Attention to Weave Density and GSM

Weave density and GSM (grams per square meter) directly affect the fabric’s strength and durability. A higher GSM generally means a thicker and stronger fabric. For heavy-duty applications, it’s advisable to go for higher GSM ratings that can withstand physical stress and load pressure.

Tightly woven fabrics also reduce permeability, which can be useful for moisture-sensitive materials.

4. Check for Coating and Lamination Options

For extra protection, especially in moisture-prone or chemically aggressive environments, look for laminated or coated woven fabrics. A laminated layer on HDPE pp woven fabric can make it waterproof and more resistant to wear and tear. Coatings also help in extending the lifespan of the material and improve its resistance to UV rays and dust.

5. Verify Quality Standards and Testing

Not all woven fabrics are created equal. Reputable HDPE fabric manufacturers conduct multiple quality checks to ensure their products meet industrial and international standards. Key quality aspects include:

Tensile strength

Tear resistance

Weight tolerance

UV resistance

Seam strength (for bags and sacks)

Before finalizing your purchase, request a fabric sample and look for third-party testing reports if available. This is particularly important when buying in bulk or for long-term supply contracts.

6. Consider Sourcing Locally for Better Control

If you're in India, sourcing from polypropylene woven fabric manufacturers or HDPE fabric manufacturers within the country offers several advantages. It allows for quicker delivery times, better quality control, and lower logistics costs. Many jumbo bag and woven fabric suppliers in India now offer customization, allowing you to get fabric rolls tailored to your specific needs.

7. Think Long-Term: Reusability and Sustainability

With growing environmental concerns, many businesses are now focusing on sustainable packaging. Woven fabrics made from recyclable HDPE or polypropylene can often be reused or recycled after use, reducing your environmental footprint and long-term costs.

Always check with your supplier if the fabric you're buying is recyclable or made from partially recycled material without compromising on strength.

GDIPL: Your Trusted Partner for Industrial Woven Fabrics

At GDIPL, we specialize in delivering high-performance woven solutions tailored for industrial applications. Whether you need HDPE woven fabrics, polypropylene woven fabrics, or custom HDPE fabric rolls, we ensure premium quality backed by rigorous testing and years of manufacturing expertise.

Our woven fabrics are used across sectors including agriculture, packaging, construction, and logistics. We are proud to be among the leading HDPE fabric manufacturers and polypropylene woven fabric manufacturers in India, known for reliability and customer satisfaction.

Conclusion

Choosing the right woven fabric for heavy-duty applications is not just about price—it's about long-term performance, safety, and sustainability. From understanding your specific needs to selecting the right material, weave, and finish, every step matters in getting the best value.

Whether you're sourcing for bulk packaging, industrial covers, or protective solutions, GDIPL is here to help you make informed, confident choices.

Contact us today to discuss your woven fabric requirements and request a sample or quote.

#hdpe fabrics#hdpe woven fabrics#polypropylene woven fabric manufacturer#polypropylene woven#hdpe fabric roll#hdpe pp woven fabric#hdpe fabric manufacturer

1 note

·

View note

Text

Foam Rolls & Bags

We are a Foam Rolls & Bags Manufacturers & Exporters in Gujarat, India. Foam (HM/HD) refers to High Molecular High-Density Polyethylene (HM-HDPE) foam is a packaging material made from polyethene. It is known to be lightweight and flexible while offering effective protective cushioning properties. It is widely used in the industries to protect surfaces and for packaging.

#Foam Rolls & Bags#Foam Rolls & Bags exporters#Foam Rolls & Bags Manufacturers#Foam Rolls & Bags exporters in Gujarat#Foam Rolls & Bags Manufacturers in Gujarat#Foam Rolls & Bags exporters in India#Foam Rolls & Bags Manufacturers in India#Foam Rolls#Foam Rolls exporters#Foam Rolls Manufacturers#Foam Rolls exporters in Gujarat#Foam Rolls Manufacturers in Gujarat#Foam Rolls exporters in India#Foam Rolls Manufacturers in India#Foam Bags#Foam Bags exporters#Foam Bags Manufacturers#Foam Bags exporters in Gujarat#Foam Bags Manufacturers in Gujarat#Foam Bags exporters in India#Foam Bags Manufacturers in India

0 notes

Text

Garbage bag manufacturers in UAE: A Comprehensive Guide for Buyers and Businesses

The United Arab Emirates (UAE) is known for its rapid industrialization, high standards of urban development, and progressive environmental policies. One of the less-publicized yet vital sectors contributing to the country’s infrastructure and cleanliness is plastic manufacturing, specifically garbage bag manufacturers in uae. From municipal waste collection to hospital sanitation and domestic use, garbage bags play a fundamental role in maintaining hygiene and ensuring proper waste disposal.

If you're seeking information on garbage bag manufacturers in UAE, this article serves as a complete guide — covering the importance of quality garbage bags, industry trends, types available, and what to look for when selecting a supplier. Along the way, we’ll also highlight one of the trusted names in the UAE's plastics industry known for quality, versatility, and environmental responsibility.

The Role of Garbage Bag Manufacturers in UAE’s Waste Management

With UAE cities like Dubai and Abu Dhabi ranking among the cleanest in the world, there is a robust demand for high-quality garbage bags that can withstand the region’s diverse waste disposal needs. Garbage bag manufacturers in the UAE cater to a wide array of industries:

Municipal waste management authorities

Hospitals and clinics

Hotels and restaurants

Factories and warehouses

Retail and commercial outlets

Individual households

These manufacturers are responsible not only for supplying plastic waste bags in bulk but also for adhering to increasingly stringent environmental guidelines. As the UAE embraces sustainability, many manufacturers have begun transitioning towards eco-friendly options, including oxo-biodegradable and recyclable plastics.

Why Garbage Bag Quality Matters

A garbage bag might seem like a basic product — until it fails.

Low-quality bags that tear easily or leak can cause hygiene issues, foul odors, and in some cases, health hazards. Whether for commercial or domestic use, choosing the right garbage bag matters:

Durability: Should withstand heavy loads and resist tearing

Leak-Proofing: Especially important for organic waste or wet items

Material Composition: Should comply with environmental guidelines

Sizing and Strength: Must be available in various dimensions and thickness levels to suit different uses

This is why selecting the right manufacturer is key to ensuring efficiency, hygiene, and regulatory compliance.

What to Look for in a Garbage Bag Manufacturer

If you’re sourcing garbage bags in bulk or seeking a long-term supplier, here are a few critical factors to evaluate:

1. Product Variety

Good manufacturers should offer a wide range of products including:

LDPE and HDPE garbage bags

Bio-degradable and oxo-degradable bags

Flat and gusseted bags

Rolls with perforation or loose-packed bags

2. Material Quality

Manufacturers should use virgin or high-grade recycled materials and provide certification regarding environmental safety.

3. Customization

The ability to customize sizes, colors, thickness, or even printed logos is a plus for commercial and institutional buyers.

4. Certifications and Standards

Look for ISO certifications and compliance with local and international regulatory bodies.

5. Export Capabilities

If you're buying from outside the UAE, it's important to work with a manufacturer that has reliable export services.

A Trusted Name in the UAE: Zubairi Plastics

Among the leading garbage bag manufacturers in UAE, one company that consistently stands out for quality, service, and versatility is Zubairi Plastics.

Why Zubairi Plastics?

Zubairi Plastics has become a trusted manufacturer and supplier across the UAE and international markets for their wide array of plastic products — with garbage bags being one of their most in-demand items.

Product Range

Zubairi Plastics manufactures both LDPE and HDPE garbage bags, available in a variety of sizes, thicknesses, and packaging options. Whether you’re a hospital requiring biohazard waste bags, a hotel in need of discreet liners, or a municipality sourcing in bulk, they have options tailored to different sectors.

Custom Manufacturing

Their flexibility in customization is a key asset. Need a particular color, thickness, or private label? Zubairi Plastics can deliver.

Environmentally Responsible

The company has made significant strides toward producing oxo-biodegradable plastic bags that comply with UAE's environmental regulations. This commitment reflects the future of the industry — balancing performance with planet-friendly solutions.

Reliable Export Partner

With a solid track record in exports, Zubairi Plastics supplies to numerous countries across the Middle East, Africa, and beyond. This makes them an ideal partner not only for UAE businesses but also for international buyers looking for reliable sourcing.

Diverse Clientele

From retail chains and government entities to cleaning companies and industrial facilities, Zubairi Plastics’ garbage bags are used by a broad spectrum of industries, highlighting their quality and trust.

Types of Garbage Bags Offered by Zubairi Plastics

Here’s a closer look at the types of garbage bags they offer:

1. Regular LDPE Garbage Bags

Perfect for household and light commercial use, these bags offer flexibility and strength at an affordable price point.

2. HDPE Heavy-Duty Bags

Ideal for industrial settings or environments requiring high tensile strength.

3. Biodegradable Garbage Bags

Made using oxo-biodegradable materials that break down under suitable conditions, these are great for environmentally conscious clients.

4. Color-Coded Bags

Useful for sorting waste (e.g., red for biohazard, blue for recyclables), widely used in hospitals and large organizations.

5. Custom Printed Garbage Bags

For businesses that want to brand even their waste management systems, Zubairi Plastics offers logo printing and design options.

Industry Trends: What's Next for Garbage Bag Manufacturing in the UAE?

As environmental concerns mount and the UAE moves toward its sustainability goals (including the UAE Net Zero by 2050 initiative), the garbage bag manufacturing sector is evolving. Here are a few trends shaping the future:

Bioplastics and Compostable Bags

Manufacturers are investing in R&D to produce bags made from plant-based materials, which offer complete compostability.

Smart Waste Management

Government and corporate clients are increasingly integrating garbage bag usage with smart waste collection systems, which may involve RFID tags or color-coded sorting mechanisms.

Export Growth

With consistent quality and reliability, manufacturers like Zubairi Plastics are well-positioned to expand their footprint across developing and developed markets.

Choosing Zubairi Plastics as Your Garbage Bag Supplier

In a market full of options, Zubairi Plastics has built its reputation on reliability, innovation, and customer satisfaction. Their ability to cater to a wide range of clients — from local businesses to international corporations — makes them a standout among garbage bag manufacturers in UAE.

Whether you need bulk orders, custom solutions, or eco-friendly alternatives, they bring value, consistency, and peace of mind. For procurement teams, importers, and facility managers, working with an experienced and adaptable partner like Zubairi Plastics is a strategic move.

Final Thoughts

The UAE’s plastic manufacturing sector is poised for growth — especially in functional, high-demand products like garbage bags. As regulations tighten and consumer awareness grows, the emphasis is no longer just on cost but also on quality, sustainability, and reliability.

For businesses, municipalities, and bulk buyers looking for top garbage bag manufacturers in UAE, Zubairi Plastics offers a compelling combination of product diversity, environmental responsibility, and trusted service. In a world where waste is inevitable, partnering with the right supplier can make all the difference in how we manage it.

0 notes

Text

A Comprehensive Look at Plastic Sheeting Suppliers in Johannesburg

Johannesburg – the bustling heart of South Africa’s economy. From towering construction projects in Sandton to agricultural ventures on the outskirts and countless manufacturing hubs, the city is constantly building, growing, and producing. Behind the scenes of much of this activity lies an unsung hero: plastic sheeting.

Whether you’re in construction, farming, packaging, or even just doing some serious DIY, understanding your options for plastic sheeting Johannesburg is essential. Let’s dive in!

What is Plastic Sheeting Used For?

The versatility of plastic sheeting is truly impressive. Here in Johannesburg, you’ll find it used in numerous ways:

Construction: This is a major one! Plastic sheeting (often heavy-duty polyethylene like HDPE or LDPE) serves as damp-proof courses (DPC) under foundations and floors, vapour barriers in walls, temporary weather protection for materials or unfinished structures, and even for surface protection during painting or renovations. SABS-approved sheeting is often required for compliance in building projects.

Agriculture: On farms and smallholdings around Gauteng, plastic sheeting is vital for greenhouses (allowing light while controlling temperature), silage covers (protecting animal feed), mulch films (suppressing weeds and retaining moisture), and dam or pond liners.

Packaging & Storage: Thinner plastic sheeting is used to wrap pallets, protect goods during transit, or cover items in storage, shielding them from dust and moisture.

Industrial Applications: Factories and workshops use sheeting to line containers, create partitions, or protect equipment.

Finding Plastic Sheeting Suppliers in Johannesburg

Fortunately, Johannesburg is well-served by numerous plastic sheeting manufacturers and distributors. Companies like PXD Plastics, Shaun’s Plastics, Plastic World, and Maizey Plastics are just some examples of suppliers offering a range of products, from standard rolls to custom solutions. You can find various thicknesses (microns), colours, and types (like virgin or recycled materials) to suit your specific needs and budget.

Beyond Sheeting: Thinking About Plastic Bags

While discussing versatile plastic products, we can’t ignore the everyday necessity of plastic bags. The landscape for Plastic bags south africa has evolved, with regulations focusing on minimum thickness (like 24 microns for carrier bags initially) and increasing requirements for post-consumer recycled content to promote reuse and recycling. These regulations aim to lessen environmental impact.

For businesses, especially in retail, Printed plastic bags south africa are a powerful branding tool. Custom-designed bags turn a simple necessity into a mobile advertisement, carrying your logo and message across Johannesburg and beyond. Options range from standard carrier bags to boutique bags, T-shirt bags, and even specialised packaging like resealable pouches or bread bags. Many suppliers offer design and printing services to help your brand stand out.

Of course, the Plastic bags price johannesburg is always a factor. Costs typically depend on:

Size and Thickness (Micron): Larger, thicker bags cost more.

Material: Virgin vs. recycled plastic content.

Quantity: Bulk orders usually have a lower price per unit.

Printing: The number of colours and complexity of the design affect the price.

Making the Right Choice

Whether you need robust, SABS-certified plastic sheeting for a major construction job or are looking for cost-effective, branded Plastic bags south africa for your shop, Johannesburg offers plenty of options. Identify your specific requirements – the application, necessary durability, size, quantity, and any branding needs – and research local suppliers to find the best fit and price for your project or business.

From protecting foundations to carrying groceries, plastic sheeting and plastic bags remain essential components of daily life and industry in Johannesburg. By choosing the right products from reliable suppliers, you ensure your needs are covered, efficiently and effectively.

#plastic bags#printed plastic bags#plastic sheeting#plastic tubing#plastic bags south africa#plasticmanufacturer#clear plastic bags#plastictubing#plasticsheeting#plasticbags

0 notes

Text

Application fields of ABA film blowing machine

The products produced by ABA film blowing machine are widely used in many fields, such as T-shirt shopping bags, biodegradable plastic films and food, fruit packaging, supermarket shopping bags, express bags, etc.

The machine has advantages in producing HDPE, LDPE and LLDPE materials. The strength of plastic film is improved by co-extrusion. In addition, although ABA film blowing machine has only two extrusion units, it can achieve three-layer film blowing. One unit handles the inner layer and the outer layer, while the other unit handles the inner layer. It can not only reduce costs and save energy. At the same time, in order to improve the market competitiveness of customers, 80% recycled materials and CACO3 can be added to the inner puffing layer.

Using recycled materials and CACO3 saves a lot more than using new materials. The film blowing machine uses the A layer as a coating for input, which can make the plastic film smooth and bright with good tensile resistance. The inner layer is filled with recycled materials and CAC03. Single-layer film blowing machine cannot achieve such a function. Compared with three-layer film blowing machine, it saves costs.

The co-extrusion ABA film blowing machine uses two screws to realize the function of a three-layer film blowing machine. The main body of the machine is scientifically designed, which saves costs and improves efficiency. Therefore, the application range is relatively wide, and reasonable and effective economic benefits can be achieved. Moreover, the ABA film blowing machine is simple and convenient to operate, and more cost-effective.

The ABA film blowing machine automatically loads, and the B-layer screw adopts an automatic fast screen changer to save time. In addition, the winding device adopts an automatic roll changing design, and the automatic roll changing is flexible and can be adjusted according to specifications such as length and weight. Only one experienced worker is required to handle all operations of the machine, making production easier and saving labor costs. Customers can quickly recover their investment by using cheaper raw materials and obtain very considerable profits.

0 notes

Text

Comprehensive Guide to Garbage Bags and Bin Liners: Choosing the Right Waste Management Solution

Freshway Supplies offers a comprehensive range of garbage bags and bin liners designed to meet diverse waste management needs across various settings. Their product lineup includes options tailored for different capacities, materials, and applications, ensuring that both residential and commercial users can find solutions that align with their specific requirements

High-Density Polyethylene (HDPE) Garbage Bin Liners

HDPE garbage bin liners are known for their strength and durability, making them suitable for light to mid-weight applications. Freshway Supplies provides several options in this category:

120L Natural/Clear Heavy Duty HDPE Garbage Bin Liners (120BINNAT): These liners measure 950 × 1100 mm and are ideal for various applications. They feature a tough HDPE film and a strong star seal, ensuring durability and leak resistance. Additionally, they are individually dispensed for convenience. Freshway Supplies+5Freshway Supplies+5Freshway Supplies+5

73L Black HDPE Garbage Bin Liners (73BINBLK): Measuring 760 × 900 mm, these black liners are suitable for light to mid-weight applications in environments such as washrooms, offices, food halls, restaurants, schools, and councils. They are made from tough HDPE film and come with strong star and flat seals, offering both strength and economy. Freshway Supplies+2Freshway Supplies+2Freshway Supplies+2

Low-Density Polyethylene (LDPE) Garbage Bin Liners

For heavier waste disposal needs, LDPE garbage bin liners offer enhanced thickness and durability:Freshway Supplies+3Freshway Supplies+3Freshway Supplies+3

82L Natural/Clear Extra Heavy Duty LDPE Garbage Bin Liners (LDBINNAT82): These liners are designed for mid to heavy-weight applications in settings like restaurants, clubs, hotels, and councils. They provide robust performance for demanding waste management tasks.

240L Natural/Clear Extra Heavy Duty LDPE Garbage Bin Liners (LDBINNAT240): With a capacity of 240 liters, these liners are suitable for substantial waste disposal requirements, ensuring reliability in various commercial environments.

Biodegradable and Eco-Friendly Options

In response to the growing demand for sustainable waste management solutions, Freshway Supplies offers biodegradable bin liners:Freshway Supplies+5Freshway Supplies+5Freshway Supplies+5

27L Medium White EPI Biodegradable HDPE Office/Kitchen Garbage Bin Liners (EPIKTM-W): These liners are made from EPI biodegradable HDPE and are available on coreless perforated rolls. They are ideal for office and kitchen settings, providing an eco-friendly alternative without compromising on quality.Additionally, other suppliers like Biogone offer home compostable bin liners made from plant-based materials, adhering to the Australian/NZ standard AS5180. These liners can be disposed of in home compost systems or general waste bins, where they will biodegrade Biogone completely.

Considerations for Selecting the Right Garbage Bag or Bin Liner

When choosing the appropriate garbage bag or bin liner, consider the following factors:

Capacity: Select a liner that matches the volume of waste generated in your setting. Freshway Supplies offers options ranging from 27 liters to 240 liters, catering to various needs.Freshway Supplies

Material: HDPE liners are suitable for light to mid-weight waste, offering strength and cost-effectiveness. LDPE liners, being thicker, are ideal for heavier waste disposal.

Environmental Impact: Opt for biodegradable or compostable liners if sustainability is a priority. Products like the 27L Medium White EPI Biodegradable HDPE liners provide eco-friendly alternatives.

Application: Consider the specific environment where the liners will be used. For instance, clear liners are often preferred in settings where visibility of contents is necessary, while black liners offer a discreet appearance for general waste.

Conclusion

Freshway Supplies' extensive range of garbage bags and bin liners ensures that customers can find the perfect solution for their waste management needs. By offering products in various sizes, materials, and eco-friendly options, they cater to a wide array of applications, from residential kitchens to commercial establishments. Selecting the right liner involves assessing capacity requirements, material suitability, environmental considerations, and the specific application to ensure efficient and responsible waste disposal.

0 notes

Text

What is Flexible Packaging?

Packaging is an essential part of the modern consumer experience. It plays a critical role in protecting products, making them easier to transport, and helping to communicate the brand’s identity. In recent years, flexible packaging has become one of the most popular types of packaging, revolutionizing the way we store, transport, and sell products. But what exactly is flexible packaging, and why is it gaining so much attention in various industries? We’ll explore the fundamentals of flexible packaging, its benefits, types, and its impact on sustainability, among other key aspects.

Understanding Flexible Packaging

Flexible packaging refers to packaging that is made from materials that can bend, fold, and stretch. Unlike rigid packaging, which uses materials like glass, metal, or rigid plastic, flexible packaging is primarily made from materials such as plastic films, paper, foil, and laminates. These materials are lightweight and can be shaped to suit the needs of various products, from snacks and liquids to cosmetics and pharmaceuticals.

Some common examples of flexible packaging include:

Pouches: Used for everything from food and beverages to pharmaceuticals and personal care items.

Bags: Available in many forms, including resealable and zipper bags for everything from groceries to pet food.

Films: Thin sheets used to wrap products like fresh produce, candy, or baked goods.

Roll stock: Packaging material that can be formed into various shapes, commonly used in automated packaging lines.

Key Characteristics of Flexible Packaging

Flexible packaging is defined by several important characteristics that differentiate it from other forms of packaging:

1. Pliability

The key defining feature of flexible packaging is its pliability. The materials used—whether they are plastic films, paper, or foil—can be bent, twisted, or squeezed without breaking. This makes flexible packaging ideal for products that need to conform to specific shapes and sizes.

2. Lightweight

Flexible packaging is considerably lighter than rigid alternatives, which reduces the overall weight of the product and makes transportation more efficient. This can lead to cost savings in logistics and a reduction in environmental impact, as it takes less fuel to transport lighter goods.

3. Customizability

Flexible packaging can be highly customized, making it perfect for businesses looking to create unique packaging that stands out on store shelves. It can be printed with eye-catching designs, logos, and product information, and tailored to different sizes, shapes, and functionalities (e.g., resealable pouches or stand-up bags).

4. Durability

Despite being lightweight, flexible packaging is often surprisingly durable. Materials like multi-layered laminates or high-density polyethylene (HDPE) provide excellent protection against moisture, air, and light, which is crucial for preserving the freshness and quality of products, particularly food and beverages.

The Benefits of Flexible Packaging

Flexible packaging has grown in popularity due to the numerous advantages it offers to manufacturers, consumers, and the environment. Here’s a closer look at some of the key benefits:

1. Cost-Effective

Compared to rigid packaging options like glass or metal, flexible packaging is often more affordable to produce. The materials used in flexible packaging are cheaper, and the manufacturing process is typically faster and more energy-efficient. This cost savings can be passed on to the consumer, making flexible packaging an attractive option for businesses looking to reduce packaging costs.

2. Space-Efficient

Flexible packaging is lightweight and takes up less space compared to rigid alternatives. When products are packaged in flexible materials, the packaging can be designed to take up less storage space, which is especially valuable for e-commerce businesses. Additionally, the ability to compress or roll flexible packaging means that products can be packed more efficiently during transit, reducing shipping costs.

3. Shelf Appeal

Flexible packaging can be made in a variety of shapes, sizes, and finishes, making it easy to create eye-catching designs that enhance a product’s visual appeal. Packaging materials can be printed with vibrant colors, intricate designs, and high-quality images, which not only help to attract consumers but also increase the perceived value of the product.

4. Extended Shelf Life

Flexible packaging can help extend the shelf life of perishable products by using advanced materials like vacuum-sealed pouches or barrier films. These materials protect products from exposure to oxygen, moisture, and light, helping to preserve freshness and prevent spoilage.

5. Consumer Convenience

With features like resealable pouches, zip-lock bags, and easy-tear openings, flexible packaging provides a level of convenience that is highly valued by consumers. This makes it easier for consumers to store products and access them at their convenience, improving overall user experience.

Types of Flexible Packaging

Flexible packaging comes in various forms, each tailored to meet specific needs and requirements. Here are some of the most common types:

1. Pouches

Pouches are versatile and widely used in food packaging, especially for snacks, sauces, and beverages. They can be sealed with a zipper or a simple press-to-seal closure, making them easy to open and reseal. Pouches are also commonly used for non-food items like cosmetics, pet food, and pharmaceuticals.

2. Bags

Flexible bags are often used for bulk products or consumer goods such as grains, coffee, pet food, and candies. These bags can be sealed in a variety of ways, such as with heat-sealing, zipper sealing, or fold-over closure.

3. Films

Packaging films are thin, flexible sheets used to wrap products. These films can be clear or opaque and are typically used for individual items like candy, chips, or frozen foods. They provide a protective layer while allowing for clear visibility of the product.

4. Roll Stock

Roll stock refers to large rolls of flexible packaging material that are used to create custom-shaped packages for various products. Roll stock is particularly useful for companies with high-volume production lines, as it can be fed into automated machinery to create pouches, bags, or wrappers quickly.

The Environmental Impact of Flexible Packaging

While flexible packaging offers numerous benefits, its environmental impact is an ongoing concern. The materials used in flexible packaging, particularly plastics, can contribute to waste if not properly disposed of or recycled. However, there are positive strides being made in creating more sustainable solutions. Many manufacturers are now using recyclable, biodegradable, or compostable materials to reduce the environmental footprint of flexible packaging.

Moreover, because flexible packaging uses less material compared to rigid packaging, it often generates less waste overall. The lightweight nature of flexible packaging also reduces transportation-related emissions, as less energy is required to move lighter products.

Sustainable Innovations in Flexible Packaging

The rise of bioplastics and plant-based materials is a game-changer for flexible packaging. Materials like PLA (polylactic acid) and PHA (polyhydroxyalkanoates) are derived from renewable sources such as corn or sugarcane and are biodegradable, offering a more environmentally friendly alternative to traditional plastic.

Conclusion

Flexible packaging is an essential and versatile solution in the world of packaging. Its lightweight, customizable, and cost-effective nature makes it a popular choice for manufacturers across a variety of industries. From food and beverage products to cosmetics and electronics, flexible packaging offers superior protection, convenience, and branding opportunities. As sustainability becomes an increasingly important concern, the packaging industry is evolving, with flexible packaging leading the way in terms of innovative, eco-friendly materials and practices.

Whether you’re a consumer looking to make more sustainable purchasing decisions or a business owner seeking to optimize your packaging, understanding the value of flexible packaging is key. It’s a flexible solution—literally and figuratively—that can meet the diverse needs of modern products and changing market demands.

0 notes

Text

100-1000kg/h Plastic Pelletizer Machine PE Material Rolling Molding Masterbatch Granulator Line Applications: This water-cooling single screw plastic pellet making machine is single stage plastic regenerative pelletizer, which is suitable for many kinds of plastic waste materials recycling and making pellets, such as PP, HDPE, LDPE, LLDPE Film and clean woven/nonwoven bag materials, etc. The film can be pressed in the compressor and then be pelletized.

0 notes

Text

Premium PE Film: Versatile Solutions for Industrial and Consumer Needs

Introduction to PE Film:

PE film, also known as Polyethylene film, is a widely utilized material in various industries due to its versatility, durability, and cost-effectiveness. Whether it's for packaging food, consumer goods, or industrial products, PE film is a preferred choice. PE film manufacturer plays a crucial role in delivering high-quality and customizable solutions that meet diverse market demands. With a robust supply chain, PE film suppliers ensure a steady supply of this essential material to industries across the globe.

Expertise in Quality and Customization

PE film manufacturers are known for their expertise in producing films with varying thicknesses, textures, and colors to meet specific needs. The manufacturing process involves advanced technologies to ensure uniformity and strength. Customization options offered by PE film manufacturers allow businesses to select features like UV resistance, anti-static properties, and high clarity. These qualities make PE films suitable for packaging food products, pharmaceuticals, electronics, and more. For manufacturers, delivering consistent quality is key to meeting the expectations of diverse industries.

Bridging the Gap Between Manufacturers and Consumers

PE film suppliers are responsible for distributing PE films to different regions and sectors. They act as a bridge between the manufacturers and end-users, ensuring the timely delivery of materials. PE film suppliers are knowledgeable about the different types of films available in the market, including high-density polyethylene (HDPE), low-density polyethylene (LDPE), and linear low-density polyethylene (LLDPE). They provide guidance to businesses on selecting the right film type based on specific applications, ensuring the film's performance matches industry requirements.

Types of PE Films: Choosing the Right Material for Every Application

PE film manufacturers produce various types of films, each with unique characteristics and applications. LDPE is known for its flexibility and is commonly used for shrink wrap, grocery bags, and food packaging. HDPE offers a higher strength-to-density ratio, making it ideal for heavy-duty applications like industrial liners and geomembranes. LLDPE combines flexibility with strength, suitable for stretch films and packaging materials that require durability. Selecting the appropriate type of PE film is crucial for maximizing performance in any given application.

Manufacturing Process of PE Films: A Blend of Technology and Innovation

The manufacturing of PE films involves a sophisticated process that combines advanced technology and innovation. PE film manufacturers utilize extrusion techniques, where raw polyethylene pellets are melted and shaped into thin sheets. The film undergoes additional processes like cooling, slitting, and rolling to achieve the desired thickness and texture. Technological advancements have led to improved film properties, such as enhanced clarity, strength, and barrier resistance. The manufacturing process allows for mass production while maintaining quality standards.

Key Benefits of Using PE Films in Various Industries

PE films are popular across multiple industries due to their unique advantages. One of the primary benefits is their cost-effectiveness; PE films are relatively inexpensive compared to other materials like PVC or aluminum. Additionally, PE films offer excellent moisture resistance, protecting products from external elements. The versatility of PE films also allows for customization in terms of colors, sizes, and thicknesses, making them a preferred choice for packaging and industrial applications.

Environmental Considerations: Sustainable PE Film Solutions

The growing concern for sustainability has pushed PE film manufacturers to adopt eco-friendly practices. Many companies are shifting towards using recycled polyethylene in their manufacturing process, reducing the need for virgin plastic. The development of biodegradable and compostable PE films is another step toward sustainability, allowing for easier disposal and reduced environmental impact. PE film suppliers are also actively involved in promoting green solutions, encouraging industries to choose films with minimal environmental footprints.

Applications of PE Films: From Food Packaging to Construction

PE films have a wide range of applications, making them indispensable in many industries. In the food sector, PE films are used for packaging perishables due to their excellent barrier properties that keep moisture and contaminants at bay. In agriculture, they serve as greenhouse covers and mulch films, helping in crop protection and growth. The construction industry utilizes PE films for moisture barriers and protective coverings, while healthcare industries rely on them for medical packaging. The versatility of PE films enables them to cater to both commercial and industrial needs.

Customization in PE Films: Tailoring Solutions for Specific Needs

Customization plays a significant role in the PE film industry. PE film manufacturers offer customized solutions to meet specific customer needs, such as adjusting the film's thickness, color, and strength. This adaptability is crucial for industries with unique requirements, like pharmaceuticals, where high clarity and specific thickness are necessary for proper product visibility and protection. Customized PE films enhance the functionality of packaging, ensuring that it meets safety standards and aesthetic appeal.

Challenges Faced by PE Film: Adapting to Market Demands

PE film manufacturers face several challenges in meeting market demands. The fluctuating prices of raw materials, like polyethylene resin, impact production costs. Additionally, the demand for higher performance and environmentally friendly films requires continuous innovation and investment in R&D. PE film suppliers must ensure they have a diverse portfolio of products to cater to different industry needs, balancing quality with competitive pricing. Staying ahead of market trends and adapting to customer preferences is essential for success in the industry.

Future Trends in the PE Film Industry: Technological and Market Insights

The future of the PE film industry looks promising, with technological advancements leading the way. Innovations like nanotechnology and smart packaging are likely to influence PE film production, offering enhanced features like anti-bacterial properties, improved strength, and temperature regulation. The rise of e-commerce and online shopping will continue to drive demand for PE films, especially in protective packaging. PE film manufacturers are expected to focus more on sustainability, aiming for greener production methods and the development of recyclable materials.

Conclusion

PE films have cemented their position as a critical component in modern packaging solutions. Their durability, adaptability, and affordability make them a popular choice for numerous industries. PE film manufacturers and suppliers play a vital role in ensuring that businesses have access to high-quality films that meet specific requirements. As the industry evolves, PE films will continue to be at the forefront of packaging innovations, driving advancements in both product protection and sustainability.

Frequently Asked Questions (FAQs)

1. What is PE film, and what are its primary uses? PE film, or Polyethylene film, is a flexible and durable plastic material commonly used for packaging, protective covers, and moisture barriers. It is widely used in industries like food, agriculture, healthcare, and construction due to its excellent barrier properties and cost-effectiveness.

2. How do I choose the right PE film for my application? Choosing the right PE film depends on the specific needs of your application. Consider factors like film thickness, clarity, moisture resistance, and strength. Consulting with PE film suppliers can help you identify the best type of film (LDPE, HDPE, or LLDPE) for your requirements.

3. Are there environmentally friendly options available for PE films? Yes, many PE film manufacturers offer environmentally friendly options, including recycled polyethylene films and biodegradable versions. These films aim to reduce environmental impact while providing the same level of performance as traditional PE films.

4. What customization options are available for PE films? PE film manufacturers provide various customization options, such as altering film thickness, color, texture, and adding UV protection or anti-static properties. This customization allows industries to tailor PE films to meet specific safety, aesthetic, and functional requirements.

This content should give a comprehensive overview of PE films, their significance, and their diverse applications while adhering to your guidelines for uniqueness and keyword integration.

0 notes

Text

Mastering Grain Packaging: Your Guide to Seamless Solutions

In India, grains like rice, wheat, pulses, and seeds form the backbone of daily meals. Proper packaging of these essential staples ensures they stay fresh, nutritious, and safe from contaminants. Effective grain packaging also facilitates smooth storage, transportation, and distribution. However, jar filling for grain packaging comes with its own set of hurdles.

Let’s dive into how Nichrome’s innovative solutions tackle these challenges and elevate your packaging operations.

Precision and Uniformity: The Cornerstones of Quality

When it comes to filling grains into jars, precision is key. Each jar must be filled uniformly to meet consumer expectations and maintain product consistency. Nichrome’s advanced grain packaging machines, including rice bag sealing, pulses packaging, and seed packaging machines, are engineered for exactness. Our Vertical Form Fill Seal (VFFS) Machines excel in delivering accurate and consistent results, ensuring your grains are packed to perfection every time.

Flexibility in Jar Sizes and Shapes

Grains come in various jar sizes and shapes, which can complicate the filling process. Nichrome’s Automatic Jar Filling Machines are designed with flexibility in mind. Our adjustable filling mechanisms handle a diverse range of jar specifications, ensuring efficient and uniform filling regardless of jar type. This adaptability is crucial for accommodating different packaging requirements and enhancing overall operational efficiency.

Choosing the Right Packaging Machine Manufacturer

Selecting a reliable packaging machine manufacturer is critical for overcoming jar filling challenges. Nichrome stands out as a leading expert in automated packaging solutions. Our extensive experience and specialized knowledge enable them to offer tailored solutions for your grain packaging needs, ensuring you get the best machine for your specific requirements.

Efficient HDPE Bag Filling

For bulk grain packaging, HDPE bags are a common choice. Our HDPE Bag Filling Line Systems and Automatic HDPE Bag Filling Machines streamline the filling and sealing of HDPE bags. These machines not only boost productivity but also reduce manual labor, making your packaging process more efficient and cost-effective.

Ensuring Hygiene and Food Safety

Maintaining high hygiene and safety standards is essential in grain packaging. Our jar filling machines are designed with food-grade materials and easy-to-clean components, ensuring the highest levels of cleanliness and safety. These hygienic filling mechanisms prevent contamination, safeguarding the quality of your grains.

Embracing Automation for Enhanced Efficiency

Automation is a game-changer in overcoming jar filling challenges. Our automated packaging solutions, including bulk bag filling and jar filling machines, enhance efficiency, minimize errors, and reduce manual labor. By integrating these advanced technologies, you can streamline your operations and boost overall productivity.

A Range of Nichrome Packaging Solutions

We, at Nichrome offer a diverse array of packaging solutions tailored to the grain industry:

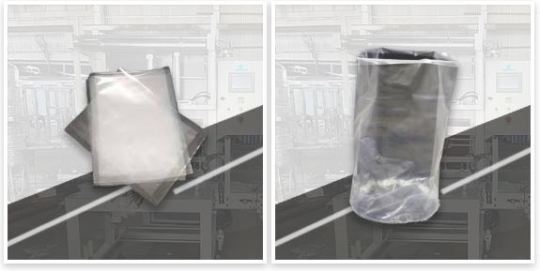

● HDPE Bag Filling Line Systems: Ideal for efficient filling and sealing of HDPE bags.

● Vertical Form Fill Seal (VFFS) Machines: Versatile machines for forming, filling, and sealing bags from roll stock.

● Jar Filling Machines: Precision equipment for packing grains into jars with accurate filling and sealing.

● Bulk Bag Filling Machines: Designed for handling and packaging large quantities of grains efficiently.

Choose Nichrome for Unmatched Excellence

Navigating the complexities of jar filling in grain packaging requires the right tools and expertise. Nichrome’s cutting-edge machines and automated solutions provide the precision, flexibility, and efficiency needed to overcome these challenges. For all your grain packaging needs, trust Nichrome to deliver excellence and elevate your packaging operations.

Make your grain packaging process seamless and efficient—choose Nichrome, where innovation meets reliability.

0 notes

Text

HM Bags

We are a HM Bags Manufacturers & Exporters in Gujarat, India. HM Bags, also known as, High Molecular (HM) High-Density Polyethylene (HDPE) Bags, is a type of plastic packaging derived from high molecular weight polyethene. Their molecular characteristics make them much stronger, durable, and resistant to wear and tear compared to other ordinary plastic bags.

They are available in rolls or customized sheets and may be plain, printed or perforated. Thus, they meet all industrial, commercial, and retail packaging requirements. Their high strength-to-weight ratio makes them lightweight yet robustly strong for product protection both in storage and transit.

#HM Bags#HM Bags exporters#HM Bags Manufacturers#HM Bags exporter in Gujarats#HM Bags Manufacturer in Gujarat#HM Bags exporter in India#HM Bags Manufacturer in India#Jash Packaging Machinery

0 notes

Text

HDPE Bags: The Versatility of HDPE for Sustainable Packaging

As sustainability becomes a key focus in global manufacturing and consumer practices, industries are increasingly turning to materials that offer both durability and environmental benefits. High-Density Polyethylene (HDPE) bags are emerging as a popular choice for sustainable packaging due to their versatility, strength, and recyclability. This blog explores the various advantages of HDPE bags and why they are an ideal solution for eco-friendly packaging.

1. What is HDPE?

1.1 Understanding High-Density Polyethylene

Composition and Structure: HDPE is a thermoplastic polymer made from petroleum. It has a high strength-to-density ratio, which makes it both lightweight and durable. Its molecular structure is tightly packed, which gives HDPE its high tensile strength.

Common Uses: HDPE is widely used in products such as plastic bottles, pipes, geomembranes, and bags due to its robustness and resistance to impact and chemicals.

1.2 Why HDPE is a Sustainable Choice

Recyclability: HDPE is 100% recyclable. It can be reprocessed into new products, reducing the demand for virgin materials and lowering the environmental impact.

Low Environmental Impact: Compared to other plastics, HDPE requires less energy to produce and emits fewer greenhouse gases during its production, making it a more sustainable option.

2. The Versatility of HDPE Bags

2.1 Strength and Durability

High Load Capacity: HDPE bags are known for their strength and ability to carry heavy loads without tearing. This makes them ideal for packaging products that require sturdy, reliable bags.

Resistance to Punctures and Chemicals: HDPE bags are resistant to punctures, tears, and most chemicals, making them suitable for a wide range of applications, including industrial uses.

2.2 Lightweight and Flexible

Ease of Handling: Despite their strength, HDPE bags are lightweight and flexible, making them easy to handle, transport, and store.

Space Efficiency: Their thin, flexible nature allows HDPE bags to be folded or rolled into compact sizes, saving storage space and reducing transportation costs.

3. Applications of HDPE Bags in Sustainable Packaging

3.1 Food Packaging

Safe and Hygienic: HDPE is non-toxic and approved for food contact by regulatory agencies. HDPE bags are commonly used for packaging food items like grains, fruits, and vegetables, as they protect against moisture and contamination.

Extended Shelf Life: The impermeable nature of HDPE bags helps to extend the shelf life of perishable items by protecting them from external elements.

3.2 Retail and Grocery Bags

Reusable Options: HDPE bags are often used as reusable shopping bags due to their strength and durability. They can withstand multiple uses, reducing the need for single-use plastic bags.

Recyclable at the End of Life: After several uses, HDPE bags can be recycled, contributing to a circular economy and reducing the amount of plastic waste.

3.3 Industrial and Agricultural Uses

Heavy-Duty Applications: In industrial and agricultural settings, HDPE bags are used to package and transport products like fertilizers, seeds, and chemicals. Their resistance to harsh conditions makes them ideal for these demanding applications.

Protection Against Moisture and UV Rays: HDPE bags provide excellent protection against moisture and UV rays, ensuring that the contents remain safe and intact during storage and transportation.

4. Environmental Benefits of HDPE Bags

4.1 Reduction in Plastic Waste

Recyclable Material: HDPE’s recyclability means that used bags can be transformed into new products, significantly reducing plastic waste. In many regions, recycling programs are in place to collect and reprocess HDPE bags.

Less Material Use: Due to the strength of HDPE, less material is required to produce bags that can handle heavy loads, leading to a reduction in overall plastic use.

4.2 Lower Carbon Footprint

Energy Efficiency: The production of HDPE requires less energy compared to other types of plastics, resulting in a lower carbon footprint. Additionally, recycling HDPE consumes less energy than producing new plastic from raw materials.

Reduction in Greenhouse Gas Emissions: By choosing HDPE bags, businesses can reduce their greenhouse gas emissions, contributing to global efforts to combat climate change.

5. Challenges and Considerations

5.1 Proper Recycling Infrastructure

Need for Better Recycling Systems: While HDPE is highly recyclable, the effectiveness of recycling depends on the availability and efficiency of local recycling programs. Improving these systems is crucial to maximize the environmental benefits of HDPE bags.

Consumer Education: Educating consumers about the recyclability of HDPE and how to properly dispose of it is essential to ensure that more HDPE bags are recycled rather than ending up in landfills.

5.2 Addressing Single-Use Plastics

Reducing Single-Use Dependency: Even though HDPE bags are durable and reusable, the single-use plastic bag culture needs to be addressed. Encouraging the use of HDPE bags as reusable options can significantly reduce the environmental impact.

Conclusion

HDPE bags offer a versatile, durable, and sustainable option for packaging across various industries. Their recyclability and lower environmental impact make them a key player in the shift towards more sustainable packaging solutions. However, to fully realize the benefits of HDPE, it is essential to improve recycling infrastructure and promote responsible use. By embracing HDPE bags as part of a broader strategy for sustainable packaging, businesses and consumers can contribute to a healthier planet.

0 notes

Text

Flexible Plastic Packaging Market worth $264.9 billion by 2030

The report "Flexible Plastic Packaging Market by Packaging Type (Pouches, bags, roll stock, films & wraps), Printing Technology (Flexography, Rotogravure, Digital Printing), End-user Industry, Material (Plastics, aluminum Foils,) and Region - Global Forecast to 2030", is approximated to be USD 182.4 billion in 2022, and it is projected to reach USD 264.9 billion by 2030, at a CAGR of 4.8%.

Download pdf- https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=1271

The Flexible plastic packaging market is experiencing significant growth driven by several factors, including the increasing demand for packaged and processed food and beverages, changing lifestyles, rising disposable income, and a growing awareness of sustainable packaging. Additionally, rising urbanization and a focus on hygiene are also contributing to the market's expansion. However, the high cost of raw materials and poor recycling infrastructure may limit market growth. Despite these challenges, opportunities exist in the market for sustainable packaging alternatives and as a substitute for traditional packaging materials. The Flexible plastic packaging industry also faces the challenge of adapting to rapid technological changes.

By Packaging type, Bags accounted for the 2nd largest share in 2021

Paper and plastic bags are prevalent packagings used for various purposes. Plastic bags (of the thin film) are usually made of LDPE, HDPE, and polypropylene. Common uses of plastic bags include bags for shopping, household garbage, food packaging, dry cleaning, newspapers, frozen foods, fresh produce, agricultural products, medical & biohazard waste, and antistatic bags. Plastic bags are inexpensive to mass-produce, relatively easy to transport due to their lightweight, and can be folded into small sizes. They are water-resistant and do not add weight to the goods they carry. Due to the pandemic, single-use plastic bags are one of the most preferred packaging options among consumers. Despite growing environmental concerns, the production and consumption of single-use plastic bags are increasing worldwide. In the current scenario, countries are not focusing on sustainability. In the US, New York is among the states that have postponed implementing a ban on plastic bags.

By Material, Aluminium Foils accounted for the 2nd largest share in 2021.

Aluminum foil is a thin aluminum sheet (produced from bauxite ore) and is a lightweight metal with a silvery-white appearance. It is also the world’s most abundant metal in free and combined states. The aluminum used in Flexible plastic packaging is in the form of rolled products. Aluminum foil packaging with multilayered plastics is widely used for packaging fresh and processed meat, poultry, and fish, as they provide better hygiene and increase product shelf-life. They are extensively used in the food & beverage and healthcare sectors for packaging products, such as cheese cubes and blister packs. Aluminum has high ductility, and barrier protection, making it an ideal packaging material. It increases the shelf-life of products by keeping food, drinks, and other products safe and fresh. Another factor that enhances the use of aluminum for packaging purposes is its unparalleled recyclability.

By Printing Technology, Rotogravure accounted for the 2nd largest share in 2021.

Rotogravure is widely used for high-quality prints, producing fine images. The rotogravure printing process consists of a cylinder, a rubber-covered impression roll, an ink fountain, a doctor blade, and fluid ink. This process uses a printing cylinder embedded with minute cells capable of retaining ink directly transferred onto the substrate with a combination of pressure and capillary action. The inks used in rotogravure are low viscosity, which enables them to be drawn into the engraved cells in the cylinder and then transferred onto the substrate. Rotogravure printing technology is expected to experience rapid growth in the flexible plastic industry. It provides high-quality, high-speed printing with precise and consistent ink transfer, making it an ideal choice for printing high-resolution images and text on flexible plastic packaging materials. Additionally, rotogravure printing can be used on a wide range of materials, including films, foils, and laminates, making it a versatile option for various applications.

Sample Request- https://www.marketsandmarkets.com/requestsampleNew.asp?id=1271

By Applications, the Flexible plastic packaging Market and Pharmaceutical & Healthcare Industry segment accounted for the largest share in 2021

The pharmaceuticals & healthcare segment is one of the most important industries that drive the demand for flexible plastic packaging. The demand for these types of packaging is driven by several factors, including the need for reliable and safe packaging solutions to protect sensitive products from contamination, ensure proper dosages, and extend the shelf life of medicines and medical devices. Healthcare products, including pharmaceuticals and medical products, must be protected from external conditions, such as light and moisture, as well as contamination and physical damage, which could alter the quality of the product.

North America accounted for the largest share of the Flexible plastic packaging Market in 2021

The flexible plastic packaging market in North America is growing owing to the rising demand for single portion packs or small packs, high disposable income levels, growing demand for convenience food, improving economic situation, and increasing consumption of packed food. An increase in the export of food products is expected to fuel the growth of the market in North America during the forecast period. Technological advancements drive the growth of the flexible plastic packaging market in North America in the food, beverage, and healthcare industries.

The Flexible plastic packaging Market comprises major players such as Huhtamaki Oyj (Finland), Berry Global Group Inc. (US), Amcor Limited. (Australia), Mondi Group. (UK), Sonoco Products Company (US), Westrock Company (US), Constantia Flexibles (Austria), Sealed Air Corporation (US), Transcontinental Inc (Canada), DS Smith (UK), and others are covered in the Flexible plastic packaging market. Expansions, acquisitions, joint ventures, and new product developments are some of the major strategies adopted by these key players to enhance their positions in the Flexible plastic packaging Market.

#FlexiblePackaging#PackagingSolutions#SustainablePackaging#EcoFriendlyPackaging#FlexiblePackagingDesign#FoodPackaging#PackagingInnovation#PlasticPackaging#PackagingTrends#PackagingIndustry#FlexiblePouches#PackagingMaterials#SmartPackaging#GreenPackaging#RecyclablePackaging

0 notes

Text

Flexible and Functional: Maximizing Efficiency with Poly Tubing Solutions

In the fast-paced world of business, efficiency is key. Every aspect of operations, from production to packaging, plays a crucial role in determining the success of a business. When it comes to packaging solutions, poly tubing stands out as a versatile and cost-effective option that can help businesses streamline their processes, protect their products, and maximize efficiency. In this blog, we will explore the many benefits of poly tubing solutions and how businesses can leverage this flexible packaging option to optimize their operations.

Poly tubing, also known as polyethylene tubing, is a flexible and customizable packaging material made from low-density polyethylene (LDPE) or high-density polyethylene (HDPE). It is essentially a continuous roll of plastic tubing that can be cut to size to create custom bags of varying lengths. Poly tubing is available in different widths, thicknesses, and colors, making it a versatile packaging solution for businesses across various industries.

Benefits of Poly Tubing Solutions:

Customization and Flexibility:

One of the key advantages of poly tubing solutions is the ability to customize the size of the bags according to specific product dimensions. Unlike pre-made bags, poly tubing can be easily cut and sealed to create bags of various lengths, making it ideal for packaging products of different sizes and shapes. This level of customization allows businesses to reduce packaging waste and optimize storage space by using precisely sized bags for their products.

Cost-Effective Packaging:

Poly tubing is a cost-effective packaging solution for businesses of all sizes. By eliminating the need for multiple sizes of pre-made bags, businesses can reduce inventory costs and minimize material waste. Poly tubing is sold in large rolls, which means that businesses can cut and seal the tubing to create bags as needed, reducing material expenses and improving cost efficiency in packaging operations.

Versatile Applications:

Poly tubing solutions are incredibly versatile and can be used in a wide range of applications across industries. From packaging and protecting products to organizing inventory and shipping goods, poly tubing offers a flexible packaging option that can adapt to diverse business needs. Whether used for packaging food products, electronics, hardware, or textiles, poly tubing provides a reliable and functional solution for businesses looking to optimize their packaging processes.

Protection and Preservation:

Poly tubing offers excellent protection for products during storage, handling, and transportation. The durable and tear-resistant material helps shield products from dust, dirt, moisture, and other contaminants, ensuring that they remain in optimal condition until they reach the end customer. By using poly tubing to protect products from external elements, businesses can minimize the risk of damage or spoilage, leading to increased customer satisfaction and reduced product returns.

Efficient Packaging Operations:

Poly tubing solutions can help businesses streamline their packaging operations and improve efficiency. The continuous roll of tubing allows for quick and seamless packaging, reducing downtime and increasing productivity. With features such as heat sealing or twist ties, businesses can easily create custom bags on-demand, eliminating the need for manual bagging and speeding up the packaging process. This efficiency can translate to cost savings and enhanced operational performance for businesses.

Environmental Sustainability:

In today's environmentally conscious world, businesses are increasingly seeking sustainable packaging solutions to reduce their carbon footprint and appeal to eco-conscious consumers. Poly tubing can be an environmentally friendly option when made from recyclable materials or produced using sustainable manufacturing practices. Additionally, businesses can explore biodegradable or compostable poly tubing options to further minimize their impact on the environment. By choosing sustainable poly tubing solutions, businesses can demonstrate their commitment to environmental responsibility and align with consumer preferences for eco-friendly packaging.

Maximizing Efficiency with Poly Tubing Solutions:

Businesses looking to maximize efficiency in their packaging operations can benefit greatly from incorporating poly tubing solutions into their processes. By leveraging the customization, cost-effectiveness, versatility, and protection offered by poly tubing, businesses can optimize their packaging operations, improve product preservation, and enhance overall efficiency. Whether used for packaging individual items or bulk goods, poly tubing provides a flexible and functional packaging solution that can adapt to the evolving needs of businesses in a variety of industries.

Poly tubing solutions offer a host of benefits for businesses seeking to streamline their packaging operations, protect their products, and maximize efficiency. By harnessing the customization, cost-effectiveness, and versatility of poly tubing, businesses can elevate their packaging strategies, reduce costs, and enhance the customer experience. Embracing poly tubing as a packaging solution is not just about functionality—it's about unlocking potential for growth, innovation, and success in the competitive business landscape.

0 notes