#HVAC Industrial Projects Development

Explore tagged Tumblr posts

Text

What are the Latest Trends in Building Construction in Dubai?

The construction industry in Dubai has long been a symbol of innovation, luxury, and futuristic design. With its rapid development and architectural marvels, the emirate has consistently set the bar for what is possible in the construction sector. Over the years, the building construction industry in Dubai has evolved significantly, and new trends continue to emerge, reshaping the landscape of urban development. From sustainability to technology integration, Dubai is at the forefront of the latest building construction trends. In this article, we will explore the key trends influencing the building construction sector in Dubai.

1. Sustainable and Green Building Practices

As the global emphasis on sustainability continues to grow, Dubai is also embracing green building practices. This trend is driven by the increasing need for energy-efficient buildings and eco-friendly solutions that minimize the environmental footprint of construction projects. Developers and building construction company in Dubai are now focusing on incorporating sustainable materials, energy-saving technologies, and eco-friendly designs in their projects.

One of the key features of sustainable buildings in Dubai is the use of solar panels. Solar energy is becoming a popular choice for powering buildings, helping to reduce energy consumption and carbon emissions. In addition to this, there is an increased use of recycled materials such as reclaimed wood, steel, and glass, which not only helps to preserve natural resources but also contributes to the reduction of construction waste.

Moreover, Dubai's commitment to sustainability is evident in the numerous green certifications, such as the Dubai Green Building Regulations, which encourage developers to integrate environmentally friendly technologies into their buildings. The use of smart building systems that optimize energy consumption and reduce water usage is also a growing trend. The shift towards green building practices is expected to continue as Dubai aims to reduce its carbon footprint and enhance the quality of life for its residents.

2. Smart and Connected Buildings

The concept of smart buildings has gained significant traction in Dubai over the past few years. With advancements in technology, there is a growing demand for buildings that are equipped with intelligent systems capable of enhancing comfort, convenience, and security. Smart buildings in Dubai are being designed with integrated technologies that allow for real-time monitoring and management of building systems such as lighting, HVAC (heating, ventilation, and air conditioning), security, and energy consumption.

The integration of Internet of Things (IoT) devices into building infrastructure is another trend that is revolutionizing the construction industry in Dubai. These devices can collect data on building performance, detect anomalies, and provide insights into how the building can be optimized for energy efficiency and occupant comfort. For instance, smart thermostats can automatically adjust the temperature based on occupancy, while intelligent lighting systems can dim or brighten according to the time of day or the presence of people.

Building automation systems (BAS) are becoming a crucial part of construction projects, allowing building managers to remotely control and monitor systems, reducing operational costs and improving efficiency. These smart technologies not only enhance the living and working experience but also provide a competitive edge for property developers and investors who are looking to attract tech-savvy tenants.

3. Modular and Prefabricated Construction

Modular and prefabricated construction is gaining popularity in Dubai as a way to speed up the construction process and reduce costs. Prefabricated construction involves assembling parts of a building off-site in a controlled environment before transporting and assembling them at the construction site. This method allows for greater precision and quality control, as the components are built in a factory setting rather than at the construction site.

One of the main benefits of modular and prefabricated construction is the significant reduction in construction time. In Dubai, where there is a constant demand for rapid development, this approach helps to meet deadlines and reduces the overall time required to complete projects. Additionally, it minimizes the disruption to the surrounding environment, as fewer materials are stored and handled on-site.

Another advantage of this construction method is the potential for cost savings. Since much of the work is completed off-site, labor costs are lower, and there is less waste generated. Furthermore, modular and prefabricated construction allows for the creation of more standardized and repeatable designs, which is ideal for large-scale developments such as residential communities or commercial buildings.

4. Use of Advanced Building Materials

Dubai’s construction industry is also witnessing a shift toward the use of advanced building materials that offer improved durability, sustainability, and aesthetic appeal. These materials include high-performance concrete, glass, and steel, as well as newer innovations such as self-healing concrete, transparent aluminum, and carbon fiber.

Self-healing concrete, for example, is a breakthrough material that has the ability to repair its cracks over time. This material can significantly extend the lifespan of buildings and reduce maintenance costs, making it an attractive option for developers in Dubai. Transparent aluminum, on the other hand, offers a unique combination of strength and transparency, making it an ideal material for modern facades and windows.

The use of carbon fiber in construction is also on the rise, particularly in the reinforcement of concrete structures. Carbon fiber is lightweight yet incredibly strong, making it an ideal material for improving the structural integrity of buildings without adding significant weight. As the demand for innovative, high-performance materials continues to grow, building construction companies in Dubai are exploring new ways to incorporate these materials into their projects.

5. Vertical Construction and Skyscrapers

As land space becomes increasingly limited in Dubai, vertical construction continues to be a key trend. Skyscrapers and high-rise buildings are a hallmark of Dubai’s skyline, and this trend is not slowing down. The demand for tall buildings in Dubai is driven by the need to accommodate a growing population and provide commercial and residential spaces in the limited available land area.

Dubai has already set several records in the construction of skyscrapers, including the iconic Burj Khalifa, the tallest building in the world. Vertical construction allows for the development of more compact, space-efficient buildings that maximize the use of available land. In addition, skyscrapers are designed to be multi-purpose, combining residential, commercial, and leisure spaces within the same structure.

In recent years, there has been a push towards even taller and more innovative designs. Architects and developers are constantly pushing the boundaries of what is possible in vertical construction, incorporating advanced technologies and engineering solutions to create more sustainable and energy-efficient high-rise buildings.

6. Luxury and High-End Residential Developments

Dubai has long been known for its luxury real estate market, and this trend shows no signs of slowing down. In recent years, there has been an increasing demand for high-end villas and residential properties that offer exceptional levels of comfort, style, and exclusivity. Developers are focusing on creating luxurious living spaces that cater to the needs and desires of affluent residents.

Villa construction companies in Abu Dhabi and Dubai are capitalizing on this demand by designing and building opulent villas with state-of-the-art amenities, such as private pools, gyms, and expansive gardens. These properties are often located in prime locations, such as beachfront areas or exclusive gated communities, providing residents with the ultimate in privacy and luxury.

The rise of luxury residential developments is also influencing the broader construction market in Dubai. Developers are incorporating cutting-edge designs, high-end finishes, and the latest technologies to ensure that their properties stand out in a competitive market. With a growing number of wealthy investors and residents, the demand for top-tier residential developments is expected to continue.

7. Focus on Mixed-Use Developments

Mixed-use developments are another major trend shaping the construction industry in Dubai. These projects combine residential, commercial, retail, and recreational spaces into a single, integrated development. The goal of mixed-use developments is to create self-sufficient communities where residents can live, work, and play without having to leave the development.

The rise of mixed-use developments in Dubai is driven by the need for more efficient land use and the desire to create vibrant, walkable communities. These developments often feature high-rise buildings, modern amenities, and extensive green spaces, providing a balanced lifestyle for residents and workers alike. Mixed-use developments also offer a sustainable solution to urban growth by reducing the need for long commutes and promoting a more connected, community-oriented way of life.

Conclusion

The construction industry in Dubai is undergoing significant transformations, with new trends and innovations reshaping the way buildings are designed and constructed. From sustainable building practices to the use of cutting-edge technologies, the emirate continues to set the standard for modern construction. As the demand for luxury, smart, and sustainable buildings continues to grow, building construction companies in Dubai will need to adapt and embrace these trends to stay competitive and meet the evolving needs of the market.

With the increasing popularity of modular and prefabricated construction, advanced materials, and vertical construction, Dubai’s skyline will continue to evolve, providing residents and visitors with an ever-changing and dynamic urban landscape. The future of construction in Dubai looks bright, and the trends we are witnessing today are only the beginning of what promises to be an exciting era for the industry.

#Building Contracting Company In Dubai#Building Construction Company In Dubai#General Contracting Company In Abu Dhabi#Best Construction Companies In Abu Dhabi#Contracting Companies In Al Ain#Construction Companies In Al Ain#Interior Design Fit Out Company Dubai#Interior Fit Out Contracting Company Dubai#Fit Out Contracting Company In Abu Dhabi#Villa Construction Companies In Abu Dhabi

2 notes

·

View notes

Text

SLB Electrical Contracting Inc.

youtube

SLB Electrical Contracting Inc.

SLB Electrical Contracting, with 40 years of experience, is a premier full-service electrical contractor in New Jersey. Established in 2003 and based in Middletown, NJ, we’re a licensed, insured, and bonded company, recognized by the Building Trades Association and certified as a Public Works Contractor, NJ Schools Development Authority, and by the New Jersey Small Business Enterprise. Our team, led by V.P. Steve Burke, has successfully served over 1000 homeowners, delivering top-notch electrical solutions for residential, commercial, and industrial projects. Services include home backup generators, emergency EV charging, 24/7 electrical emergency response, and efficient lighting upgrades. SLB Electrical is renowned for excellent customer service and satisfaction. We pride ourselves on our professional approach, punctuality, and leveraging the latest technology for safe and reliable service. We offer competitive rates and free estimates. For superior electrical services, contact us at (732) 889-7914, Monday-Friday from 9am to 5pm. Trust SLB Electrical for all your electrical needs where safety and quality are guaranteed.

Belford’s Top Electrical Contractor

With 40 years experience and over 1,000 homes and businesses serviced, SLB Electrical is the electrician in Belford Middletown Township, NJ to call for your next electrical project. Our team is dedicated to providing top-notch service that ensures the safety and functionality of your home’s or business’s electrical system. A qualified and licensed electrician will take the time to explain our process and ensure that our work meets the highest standards of safety and compliance.

SLB Electrical serves all of Monmouth County and surrounding areas.

Call now or fill out a form for a free quote on your next project.

Electrical Contractor Middletown NJ

Belford Commercial Electricians

Our team also services commercial and industrial properties to ensure your business electrical system is up to code. Trained in handling larger loads, three-phase power systems, and specialized equipment such as HVAC units, commercial refrigeration systems, and industrial machinery.

Request a free electrical estimate online or call SLB Electrical Contracting, Inc. at (732) 978-9173 today for reliable electrical service in Belford, NJ, and the nearby communities.

Electrician Middletown NJ

contact us

SLB Electrical Contracting Inc. https://slbelectrical.com/areas-served/belford-nj/ ADDRESS: 495 Roxbury Rd Belford, NJ 07718, United States PHONE: (732) 495-5883

Facebook

YouTube

2 notes

·

View notes

Text

Best Commercial Consultants in Delhi NCR

Sanelac Consultants Pvt. Ltd. stands at the forefront of MEP (Mechanical, Electrical, and Plumbing) engineering in India, delivering innovative and sustainable solutions across a diverse range of large-scale projects. With over 39 years of experience, Sanelac has been instrumental in shaping the nation's infrastructure landscape.

Innovative MEP Solutions:

Sanelac's approach to MEP design emphasizes energy efficiency and environmental sustainability. By integrating cutting-edge technologies and adhering to the highest industry standards, they ensure that each project not only meets but exceeds client expectations. Their services encompass HVAC, electrical systems, fire protection, plumbing, and sanitary solutions, all tailored to the unique requirements of each development.

Key Projects:

Bharti Mega Development at Aerocity, New Delhi: A monumental commercial complex covering 10.4 million sq ft, currently in the execution phase.

Omaxe Development of DD Integrated Multi-sports Arena at Sec-19B, Dwarka, New Delhi: This 2.59 million sq ft facility includes indoor and outdoor stadiums, clubhouses, and retail spaces, presently in the tender stage.

Shahi IT Park, Bangalore: An expansive 3.5 million sq ft office complex, currently under design, set to become a significant IT hub.

World Trade Centre at Mohali near Chandigarh, Punjab: A mixed-use development spanning 1.7 million sq ft, in the schematic design phase, aimed at boosting regional economic growth.

IREO Mixed Use Development, Sector-58, Gurgaon: A comprehensive 4.5 million sq ft project comprising offices, retail spaces, hotels, and residential units, with all services successfully completed.

DLF Two Horizon Centre, Gurgaon: A 1.25 million sq ft office complex, fully operational, serving as a hub for various corporate entities.

Select City Walk at Saket, New Delhi: A premier 1.35 million sq ft shopping mall and multiplex, including a 100-room hotel, with all services completed, offering a blend of retail and hospitality.

Sanelac's commitment to excellence is evident in their meticulous planning, innovative design, and efficient execution. Their expertise ensures that each project is not only functional and aesthetically pleasing but also sustainable and compliant with local regulations. By prioritizing client satisfaction and environmental responsibility, Sanelac Consultants Pvt. Ltd. continues to set benchmarks in the MEP consulting industry.

#hvac#air conditioner repair#hvac installation#hvac contractor#mep shop drawings#electrical#artists on tumblr#mep consultants#hvac services#commercial#branding#business#mep coordination#mep#ahmedabad#delhincr#delhi#delhi news#gurgaon#gurugram#realestate#moderndesign

2 notes

·

View notes

Text

Enhancing Urban Development in Saudi Arabia with DSP Consultants' Acoustic Expertise

As Saudi Arabia experiences a surge in urban and infrastructural development, effective noise control and sound design have become integral to creating sustainable and livable spaces. Acoustic consultants play a vital role in shaping environments that prioritize comfort, productivity, and compliance with regulatory standards. At DSP Consultants, we specialize in offering tailored acoustic solutions for a variety of projects across Saudi Arabia.

The Role of Acoustic Consultants in Saudi Arabia

Acoustic consultants provide services that go beyond basic noise control, addressing the growing need to mitigate urban noise from traffic, construction, and industrial activities. They utilize cutting-edge technology to ensure projects meet both local and international regulations while enhancing the acoustic quality of indoor and outdoor spaces.

Key Acoustic Services Offered by DSP Consultants

Acoustic Testing and Noise AssessmentDSP Consultants leverages advanced equipment, such as decibel meters and noise modeling software, to assess existing noise levels at project sites. Noise maps and predictive models are developed to evaluate the potential impacts of new developments, ensuring compliance with environmental standards.

Noise Mitigation StrategiesWe design effective solutions to minimize noise pollution, such as:

Installing sound barriers to shield sensitive areas from urban noise.

Incorporating green zones to act as natural buffers.

Optimizing building orientations and material selection for maximum noise reduction.

Building AcousticsOur services include room acoustic design, soundproofing, and HVAC noise control to create quieter indoor environments in residential, commercial, and industrial spaces. Whether it's enhancing speech clarity in meeting rooms or designing home entertainment systems, we deliver customized solutions for optimal acoustics.

Sustainable Acoustic DesignBy aligning with green building initiatives, DSP Consultants promotes the use of eco-friendly materials for sound insulation and vibration control. This approach not only supports environmental sustainability but also ensures long-lasting acoustic efficiency.

The Growing Demand for Acoustic Consulting in Saudi Arabia

As cities like Riyadh, Jeddah, and Dammam expand, the need for comprehensive acoustic consulting is rising. Major projects, including mixed-use developments, high-rise buildings, and transportation hubs, require expert noise management to enhance livability and meet regulatory standards. DSP Consultants has extensive experience working on complex urban developments, ensuring seamless integration of acoustic solutions with architectural and engineering designs.

Why Choose DSP Consultants?

With a proven track record in the Middle East, DSP Consultants is a trusted partner for delivering innovative acoustic solutions tailored to Saudi Arabia’s unique needs. Our experienced team provides:

Detailed Noise Assessments: From environmental impact studies to real-time monitoring.

Specialized Acoustic Modeling: Utilizing tools like CadnaA to visualize and optimize sound management strategies.

Compliance Expertise: Ensuring projects align with Saudi Arabia’s environmental noise regulations.

Creating Sound Solutions for a Better Tomorrow

At DSP Consultants, we believe that sound design is more than just noise reduction—it’s about creating spaces that foster productivity, well-being, and community harmony. From residential areas and commercial hubs to industrial zones, our acoustic expertise enhances the quality of life across Saudi Arabia.

For tailored acoustic consulting services, contact DSP Consultants at [email protected].

2 notes

·

View notes

Text

Copper Alloys Market Disruption: How New Tech Is Changing Everything

Rising Demand and Transformative Growth in the Global Copper Alloys Market

The global copper alloys market is experiencing an era of substantial expansion, projected to grow at a CAGR of 11.2% between 2024 and 2031. As the demand for high-performance, corrosion-resistant, and electrically conductive materials surges across sectors—particularly in electronics, construction, automotive, marine, aerospace, and renewable energy—copper alloys have emerged as indispensable components of modern industrial ecosystems.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40473-global-copper-alloys-market

Copper Alloys Market Dynamics Driving Growth:

Surging Electrical and Electronics Applications

The electronics and electrical segment remains the largest end-user of copper alloys, leveraging their exceptional conductivity, durability, and thermal management properties. Copper alloy wires, connectors, and terminals are vital in:

Smart grids and renewable energy systems

High-performance computing devices

Consumer electronics and telecom infrastructure

As the global transition to electric vehicles (EVs) and green power accelerates, the demand for copper alloys in EV batteries, charging systems, and powertrain architectures is poised for exponential growth.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40473-global-copper-alloys-market

Infrastructure Modernization and Construction Boom

Modern construction projects emphasize aesthetic appeal, longevity, and sustainability. Copper alloys—used in roofing, cladding, plumbing, and ornamental components—are at the core of smart infrastructure development across North America, Europe, and Asia-Pacific. Their low maintenance costs and resistance to weathering make them ideal for both residential and commercial applications.

Automotive and Marine Sector Momentum

In automotive manufacturing, copper alloys serve in radiators, bushings, connectors, and sensor housings, enhancing both performance and safety. Meanwhile, marine applications increasingly depend on copper-nickel and aluminum bronze for their superior seawater corrosion resistance, significantly reducing maintenance in ships, offshore structures, and desalination plants.

Strategic Copper Alloys Market Segmentation

By Alloy Type

Brass (Copper + Zinc)

Preferred for its machinability, strength, and aesthetic finish, brass finds extensive use in:

Plumbing fixtures

Musical instruments

Decorative hardware

Bronze (Copper + Tin)

A legacy alloy with exceptional wear resistance and strength, bronze is key to:

Sculptures

Bearings

Marine components

Copper-Nickel Alloys (Cu-Ni)

Known for superior corrosion resistance, especially in saltwater, Cu-Ni alloys are indispensable in:

Shipbuilding

Coinage

Heat exchangers

Nickel-Silver

This silver-like alloy offers high strength and visual appeal in:

Cutlery

Jewelry

Optical frames

Phosphor Bronze

Valued for elasticity and fatigue resistance, it's used in:

Electrical contacts

Fasteners

Precision springs

Aluminum Bronze

With superior tensile strength and oxidation resistance, it serves in:

Oil & gas valves

Aerospace fasteners

High-load bushings

Beryllium Copper (BeCu)

A high-performance alloy offering spark resistance and thermal stability for:

Explosive environments

Instrumentation tools

Aerospace connectors

By Product Form

Sheets & Plates: Construction and machinery

Bars & Rods: Automotive and electrical applications

Wires: Critical in power transmission and electronics

Tubes & Pipes: Plumbing, HVAC, industrial systems

Strips & Foils: Electrical connectors, precision electronics

Fittings: Used extensively in HVAC, plumbing, and electrical systems

Regional Copper Alloys Market Analysis

Asia-Pacific

China, India, Japan, and South Korea lead in both consumption and production.

Infrastructure growth, EV proliferation, and industrialization are major growth catalysts.

Dominant manufacturing hub for electronics and heavy machinery.

North America

The United States remains a technological innovator, particularly in aerospace, defense, and healthcare.

Emphasis on sustainable infrastructure and electric mobility is boosting demand.

Europe

Nations like Germany, France, and the UK drive demand through green energy adoption and precision engineering.

Strong focus on recyclability and eco-friendly materials.

Middle East and Africa

Rising construction activity and energy sector investments, especially in UAE and Saudi Arabia.

Marine and oilfield applications fueling growth in copper-nickel alloys.

South America

Brazil is a dominant player with strong construction and mining sectors.

Expanding urbanization fosters copper alloy usage in utilities and infrastructure.

Competitive Landscape

The copper alloys market is moderately consolidated with a blend of global giants and regional specialists. Key players are driving innovation through advanced metallurgy, sustainability initiatives, and expansion into high-growth regions.

Major Companies Include:

KME Germany GmbH

Wieland

Aurubis AG

Mueller Industries

Poongsan Corporation

NGK Insulators, Ltd.

Mitsubishi Materials Corporation

Hitachi High-Tech Analytical Science

Cadi Company, Inc.

Hussey Copper

Chase Brass and Copper Company, LLC

Metalminotti

Shri Manak Copper

Aviva Metals

Diehl Stiftung & Co. KG

Their strategies revolve around:

Geographic Expansion

Sustainable Recycling Techniques

Strategic Mergers and Acquisitions

R&D in High-Performance Alloys

Future Copper Alloys Market Outlook (2024–2031)

The trajectory of the copper alloy market is unequivocally upward. With clean energy adoption, urbanization, and industrial automation on the rise, demand for durable, conductive, and recyclable materials will only intensify. Copper alloys are perfectly positioned to meet these multi-industry needs, underscoring their role in the future of sustainable industrial materials.

Key Copper Alloys Market Growth Forecasts:

Widening use in EVs and renewable energy infrastructure

Surge in demand from healthcare and defense sectors

Expanded R&D investments in next-generation alloys

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40473-global-copper-alloys-market

Conclusion

The global copper alloys market is undergoing transformative growth, anchored in its unmatched versatility and performance across critical sectors. As industrial demands evolve toward sustainability, precision, and efficiency, copper alloys will remain central to powering tomorrow's innovations.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Text

Exploring the Growth Potential of the Construction Adhesive Tapes Industry: Key Trends and Innovations Driving the Market

The construction adhesive tapes industry has been gaining significant momentum in recent years, becoming an essential component in modern construction projects. From residential buildings to large-scale infrastructure, adhesive tapes are revolutionizing how structures are assembled, sealed, and protected. In this blog, we’ll explore the factors driving the industry's growth, the latest innovations, and the benefits that construction adhesive tapes offer over traditional bonding methods.

1. Market Growth and Demand Drivers

The global construction adhesive tapes market is expanding rapidly, driven by rising demand for more efficient, cost-effective, and sustainable construction materials. Factors contributing to the market's growth include:

Increased construction activities in developing regions

A growing emphasis on sustainable and green building practices

The need for faster, labor-saving solutions on construction sites

Technological advancements in adhesive formulation, ensuring stronger and more durable bonds

2. Types of Construction Adhesive Tapes

Adhesive tapes in the construction industry come in a variety of forms, each designed for specific applications. Some of the most popular types include:

Duct tapes: Known for their versatility and strength in temporary bonding.

Double-sided tapes: Ideal for permanent bonding in installations like flooring or wall paneling.

Foil tapes: Used in HVAC applications, offering excellent resistance to temperature and moisture.

Masking tapes: Perfect for precise painting and surface protection.

Each type serves a critical function, whether it's sealing, joining, or protecting surfaces.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=222451392

3. Key Innovations in the Industry

Recent developments in the construction adhesive tapes industry have focused on improving adhesion strength, environmental resistance, and ease of application. Some innovations include:

Heat-resistant and waterproof tapes for extreme conditions

Low-VOC (volatile organic compound) adhesives that contribute to healthier building environments

Eco-friendly options using recyclable materials and biodegradable adhesives

Smart tapes that change color to indicate correct application or curing

These advancements ensure that adhesive tapes not only perform better but also contribute to more sustainable building practices.

4. Benefits Over Traditional Bonding Methods

Compared to conventional fastening systems like nails, screws, or liquid adhesives, construction adhesive tapes offer several advantages:

Quick application: Tapes require minimal equipment and can be applied faster than traditional methods.

Clean worksite: Adhesive tapes eliminate the need for liquid adhesives, reducing mess and cleanup time.

Strong and flexible bonding: Tapes provide long-lasting bonds that can withstand the stresses of construction environments.

Minimal damage to materials: Tapes cause less structural damage compared to drilling or nailing into surfaces.

These benefits are making adhesive tapes the go-to choice for many contractors and builders.

5. Future Outlook for the Industry

As construction projects continue to evolve with advancements in building materials and methods, the construction adhesive tapes industry is poised for continued growth. Innovations like smart adhesives, sustainable materials, and more specialized tapes tailored for unique construction needs will play a vital role in the industry's future. Moreover, as green building regulations become stricter, the demand for eco-friendly adhesive solutions will continue to rise.

#construction additives tapes industry#construction additives tapes#construction additives tapes market#construction#construction additives#construction additives industry#construction industry#business#news

2 notes

·

View notes

Text

Precision Core Drilling Services in Dubai | Cosmic Technical Services LLC

At Cosmic Technical Services LLC, we specialize in core drilling services in Dubai that exceed industry standards. With our cutting-edge equipment and expert technicians, we deliver precise results tailored to your needs.

Core drilling is a crucial process in construction, renovation, and infrastructure projects. Whether you require precise holes for plumbing, electrical, HVAC, or structural purposes, our team has the expertise to deliver. We understand the importance of accuracy and efficiency, which is why we employ advanced techniques and machinery for every project.

Our core drilling services in Dubai are comprehensive, covering a wide range of materials including concrete, asphalt, masonry, and more. No matter the complexity or scale of your project, we have the capabilities to meet and exceed your expectations. From small residential projects to large-scale commercial developments, Cosmic Technical Services LLC is your trusted partner for all core drilling needs.

Why Choose Cosmic Technical Services LLC for Core Drilling Services in Dubai?

Expertise: Our team consists of highly skilled technicians with years of experience in core drilling. We understand the nuances of each project and strive for perfection in every job we undertake.

State-of-the-Art Equipment: We invest in the latest core drilling technology to ensure precision and efficiency. Our equipment undergoes regular maintenance to guarantee optimal performance and safety.

Tailored Solutions: We recognize that every project is unique, which is why we offer customized core drilling solutions to suit your specific requirements. Whether you need standard-sized holes or custom dimensions, we can accommodate your needs.

Safety First: Safety is our top priority on every job site. Our technicians adhere to strict safety protocols to minimize risks and ensure a safe working environment for everyone involved.

Timely Completion: We understand the importance of deadlines in construction projects. With our efficient workflows and skilled team, we ensure timely completion without compromising on quality.

Customer Satisfaction: At Cosmic Technical Services LLC, customer satisfaction is paramount. We prioritize clear communication, transparency, and responsiveness to ensure a positive experience from start to finish.

Experience the Difference with Cosmic Technical Services LLC

When you choose Cosmic Technical Services LLC for core drilling services in Dubai, you're partnering with a trusted industry leader committed to excellence. Whether you're a contractor, developer, or homeowner, you can rely on us for superior quality, precision, and professionalism.

Contact us today to discuss your core drilling needs and discover how we can help bring your project to fruition. With Cosmic Technical Services LLC, your satisfaction is guaranteed.

2 notes

·

View notes

Text

In my novel "Season of Fools" there are two general types of machinery that could be considered mecha. The 4-6 meter tall Alfar and the 9-12 meter tall Einherjar. Both types of frame most commonly use a generally humanoid body plan, are powered by eitr and house their pilots within their torsos.

Alfar frames as a class still bear the name of the original line of industrial labor frames produced by Blivet Heavy Industries (BHI) for the purposes of increasing worksite efficiency and operation within hostile environments. Their systems generally lack any onboard AI other than a basic steward for adjustments during traversal and HVAC within the cockpit. Alfar are rarely controlled through neural synchronization as analog controls are sufficient for most tasks they are deployed for, the exception being some of those designed for security or military use.

Einherjar fulfill a much different role than their smaller counterparts, being primarily military materiel. The frames were initially developed in a joint project by The Penrose Foundation and Necker Group. Necker worked primarily on the neural interface and the surgeries required to install an adapter to a pilot; using their previously developed Augmented Reality Chip (ARC) as a springboard. Penrose developed the miniaturized eitr reactor which would become the heart of an Einherjar as well as the modular body of the machine. Mobius SciTech, a late arrival to the project, would provide their own version of AI stewards with a vastly increased capacity to aid a pilot.

In the modern day Einherjar are on their second generation which includes general power output improvement, more sophisticated articulation and the addition of a comprehensive thruster system. Despite the numerous improvements, Synchronization Syndrome persists as a risk for pilots, albeit at lower rates. It is a degenerative neurological condition that advances with continued usage of an Einherjar or any other neural sync device and has proven resistant to attempts to reverse the damage.

4 notes

·

View notes

Text

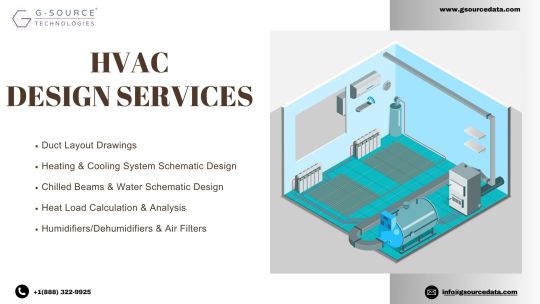

Gsource Technologies is your trusted partner for top-notch HVAC design services that ensure optimal comfort, energy efficiency, and air quality for your residential, commercial, or industrial spaces. Our HVAC design solutions encompass a comprehensive range of services, meticulously crafted to meet your unique requirements.

One of our key offerings is Duct Layout Drawings, where our experts create detailed plans to optimize air distribution, taking into account factors like space constraints and airflow dynamics. This ensures efficient heating and cooling throughout your premises.

Our Heating & Cooling System Schematic Design is another standout service. We develop customized schematics tailored to your specific needs, guaranteeing the right balance between temperature control and energy conservation.

For projects that demand sophisticated climate control, our expertise extends to Chilled Beams & Water Schematic Design, ensuring the seamless integration of advanced technologies for precise temperature management.

To accurately size and design your HVAC system, we perform Heat Load Calculation & Analysis, accounting for variables like insulation, occupancy, and outdoor climate conditions.

Moreover, we offer solutions to enhance air quality, including Humidifiers/Dehumidifiers & Air Filters, promoting a healthy and productive environment for your occupants.

At Gsource Technologies, we prioritize sustainability, cost-efficiency, and functionality in every HVAC design project we undertake. With our expertise, you can trust that your HVAC system will be optimized to meet your specific needs while adhering to the highest industry standards. Partner with us for HVAC design services that deliver comfort and efficiency, every time.

#gsourcetechnolgies#architecturedesigns#engineeringdesigns#hvac services#HVACdesigns#heating and cooling#hvac

2 notes

·

View notes

Text

Why Is Self Drilling Screw in India High Demand?

One product stands out for its efficiency, versatility, and ease of use — the self drilling screw. As the country moves toward faster, safer, and more efficient assembly methods, demand for self drilling screws in India is surging across industries. Raj Industries, a reputed name in fasteners, has witnessed firsthand how this innovation is reshaping both large-scale industrial applications and small DIY projects.

No Pre-Drilling Needed with Self Drilling Screw in India

One of the biggest advantages of using Self drilling screw in India is the elimination of the pre-drilling step. These screws come with a drill-like flute at the tip, allowing them to cut through metal, wood, and composite surfaces directly. For contractors and technicians, this means reduced labor time, fewer tools, and higher productivity. Raj Industries manufactures self drilling screws that are engineered for maximum precision and minimal surface damage.

Preferred for Fast-Paced Construction in Urban Areas

India's rapid urban development has pushed timelines and budgets tighter than ever. In such a fast-moving environment, speed and accuracy are crucial. The growing popularity of self drilling screws in India stems from its ability to perform both drilling and fastening in a single action, making it the preferred choice in high-rise construction, commercial fit-outs, and prefab building work.

Strong Grip Makes It Ideal for Metal Applications

A key reason behind the increased use of self drilling screws in India is its strong grip on metal surfaces. These screws are widely used in fabricating steel frames, metal roofs, and HVAC units where a secure, vibration-resistant fit is essential. The thread design and self-piercing tip ensure deep embedding and tight fastening. Raj Industries offers a variety of sizes and coatings that prevent rust and enhance durability, especially in outdoor and industrial settings.

Self Drilling Screw in India Aids Modular Furniture

The modular furniture industry in India has expanded exponentially with the rise of smart homes and space-saving interiors. In this space, self drilling screws in India plays a crucial role. These screws are perfect for MDF, particle board, and laminated plywood, which require delicate yet firm fastening. Raj Industries provides low-profile, countersunk self drilling screws that blend seamlessly into furniture joints, ensuring both functionality and aesthetics.

Durable Coatings for India’s Climate Conditions

India’s diverse climate — from humid coasts to dry interiors — demands hardware that can withstand environmental challenges. A major reason why self drilling screw in India is in such high demand is because many are now made with advanced coatings such as zinc plating, black oxide, or ceramic finishes. Raj Industries produces weather-resistant variants that prevent corrosion and maintain their structural integrity even in aggressive conditions.

Trusted in Electrical and Light Mechanical Installations

Electricians and light mechanical installers are increasingly turning to self drilling screw in India for securing brackets, switchboards, electrical trays, and conduits. The main advantage is secure and efficient mounting on both wood and metal surfaces without cracking or slipping. Raj Industries understands the needs of these professionals and supplies screws designed for minimal electric conductivity and safe installation.

Cost-Effective Choice for High-Volume Industrial Use

Beyond speed and strength, self drilling screw in India is also winning due to its cost-effectiveness. In high-volume applications like assembly lines, ducting, and frame fabrication, using a two-step process (drilling + screwing) is labor-intensive and more expensive. Raj Industries provides bulk solutions for manufacturers looking to cut down on operational costs without sacrificing quality.

Conclusion

The rising demand for self drilling screw in India is a clear reflection of the country’s transition toward smarter, faster, and more durable construction and manufacturing methods. From urban infrastructure to modular furniture and from HVAC to light engineering, these screws are redefining how India builds. Raj Industries continues to supply high-quality self drilling screws to meet the unique challenges of Indian industries.

0 notes

Text

Construction Company In Hyderabad | Urban Build

Hyderabad, the City of Pearls, has emerged as one of India's most rapidly growing urban hubs. From IT parks to luxurious high-rises, the skyline of Hyderabad is changing faster than ever before. In this evolving cityscape, choosing the right construction partner is critical—one that combines vision, reliability, quality, and innovation. If you’re searching for a construction company in Hyderabad that ticks all these boxes, look no further than Urban Build.

In this blog, we’ll explore the growing demand for construction services in Hyderabad, what makes Urban Build stand out, and how we redefine quality and commitment in every project we undertake.

The Booming Construction Landscape of Hyderabad

The demand for residential, commercial, and industrial infrastructure in Hyderabad has soared in the last decade. With the rise of the IT sector and expanding business districts like HITEC City, Gachibowli, and Madhapur, the need for well-planned construction projects is at an all-time high.

Urban sprawl is pushing developers and homeowners alike to seek innovative and sustainable building solutions. Whether it’s a gated community, a standalone villa, or a multi-floor commercial space, clients are prioritizing construction companies in Hyderabad that bring experience, trust, and modern practices to the table.

This is where Urban Build plays a transformative role.

Why Urban Build is Your Ideal Construction Partner

1. Experience Meets Innovation

Urban Build brings years of hands-on experience in diverse construction domains—residential, commercial, and industrial. Our team comprises engineers, architects, designers, and project managers who are well-versed in the latest construction methodologies and technologies. We don't just build structures; we create landmarks that reflect your vision and our precision.

Whether it’s a 3BHK duplex in Jubilee Hills or a commercial tower in Banjara Hills, Urban Build ensures that every project stands as a testament to modern design and construction excellence.

2. End-to-End Construction Services

As a full-service construction company in Hyderabad, we offer comprehensive services from concept to completion:

Architectural Planning & Design

Structural Engineering

Turnkey Construction

Interior Designing

MEP Services (Mechanical, Electrical, Plumbing)

Project Management and Execution

Clients love the convenience of dealing with a single trusted brand throughout the entire construction process. We understand the value of time and communication, ensuring clear project timelines, cost estimates, and regular progress updates.

Tailored Solutions for Every Need

Every client is unique, and so is every project. At Urban Build, we begin every engagement with in-depth consultations. We take time to understand your requirements, preferences, and budget before offering customized solutions.

Residential Projects

We have successfully delivered luxury villas, independent homes, and apartment complexes across Hyderabad. Our focus is always on livability, sustainability, and elegance.

Commercial Projects

From office spaces to shopping complexes, Urban Build designs structures that maximize utility and aesthetics. We pay attention to layout optimization, ventilation, safety, and legal compliances.

Renovation & Remodeling

Our expertise also extends to remodeling and upgrading existing structures. Whether you need a modern kitchen revamp or a complete commercial makeover, we breathe new life into your spaces.

Sustainability is Our Commitment

As an eco-conscious construction company in Hyderabad, Urban Build incorporates green building techniques and sustainable materials into every project. We promote:

Energy-efficient lighting and HVAC systems

Rainwater harvesting

Solar panel installations

Low-VOC paints and eco-friendly construction materials

Waste reduction during construction

Hyderabad’s future deserves development that doesn’t come at the cost of the environment, and Urban Build is committed to responsible growth.

Unmatched Transparency & Pricing

One of the most stressful parts of any construction project is budgeting. Urban Build simplifies this with:

Transparent cost estimations

Itemized quotations

No hidden charges

We also help clients understand the house construction cost in Hyderabad, which can vary depending on land size, materials, location, and design complexity. We provide accurate pricing based on prevailing market rates and offer cost-optimization suggestions without compromising quality.

Our Process: Step-by-Step Execution

Here’s how we typically approach any construction project:

1. Consultation & Requirement Analysis

We gather your ideas, budget, and expectations and analyze the site conditions.

2. Design & Planning

Our architects and designers create a 3D model, layout plan, and project timeline for your approval.

3. Approvals & Documentation

We assist you in obtaining building permits, municipal approvals, and legal paperwork.

4. Construction Phase

Our execution team ensures seamless workflow, safety compliance, and quality control during every construction stage.

5. Final Handover

We deliver your project on time, ready to move in or operate. Post-construction support is part of our commitment to client satisfaction.

Urban Build’s Competitive Edge

With many construction companies in Hyderabad, you might wonder what sets us apart. Here’s why hundreds of clients trust Urban Build:

✔ Timely Delivery

We understand the importance of timelines in construction. Delays are costly, which is why we adhere to strict project schedules.

✔ Quality Materials

Only branded and certified materials go into our projects. Our vendor relationships ensure the best pricing without compromising durability.

✔ Skilled Workforce

Our team consists of experienced civil engineers, laborers, site supervisors, and technicians who work with integrity and professionalism.

✔ Tech-Driven Construction

We use modern construction management software and tools like BIM (Building Information Modeling) for real-time tracking and efficient resource utilization.

✔ Exceptional After-Service

Our relationship doesn’t end with handover. We offer post-project maintenance assistance and are always a call away for any help you might need.

Future-Ready Construction with Urban Build

As Hyderabad continues to expand into new suburbs and tech corridors, the demand for smart, sustainable, and scalable construction solutions will only grow. Urban Build is prepared for that future. We’re constantly upgrading our knowledge, investing in new technologies, and training our teams to handle complex architectural challenges.

Whether you are a homeowner, entrepreneur, builder, or investor, Urban Build is the name you can trust when looking for a construction company in Hyderabad that delivers excellence.

Get in Touch

Are you planning to start your dream project in Hyderabad?

Let’s build it together.

CONTACT US;

+91 7095992159

EMAIL ID;

Address;

Plot no 74,75, Akshitha Residency, Sai Balaji enclave, Mallampet, Bachupally, Telangana, 502303.

Conclusion

Choosing the right construction company in Hyderabad can be the difference between a project that meets your expectations and one that falls short. At Urban Build, we go beyond just laying bricks and mortar—we build trust, relationships, and legacies.

From luxurious villas to high-rise marvels, our work speaks volumes. Let Urban Build be your partner in progress as you shape your next project into a masterpiece. After all, we don’t just construct buildings—we craft your dreams into reality.

#building construction company in hyderabad#construction company in hyderabad#home construction companies in hyderabad

0 notes

Text

Best Commercial Interior Construction Delhi NCR – DLH Infra

When it involves constructing high-appearing, aesthetically alluring, and emblem-centric commercial spaces, DLH Infra stands at the forefront because the issuer of the Best Commercial Interior Construction in Delhi NCR. Our recognition is to create environments that enhance productiveness, enhance client revel in, and mirror your brand's identification. With years of know-how in commercial layout and turnkey execution, DLH Infra has come to be the go-to name for agencies trying to transform their interiors into impactful, purposeful areas.

Comprehensive Commercial Interior Construction Services DLH Infra gives a entire suite of industrial interior construction services to meet the dynamic requirements of shops, company places of work, hospitality chains, establishments, and co-running spaces. Our paintings is pushed through a deep understanding of design traits, industrial structure, and operational functionality.

Our industrial solutions include:

Space making plans and layout optimization

Structural remodeling and partitioning

HVAC, electric, and plumbing (MEP) systems

False ceiling and lighting fixtures answers

Flooring and wall finishes

Modular and custom furniture

Acoustic treatment and hearth protection compliance

Branding integration into design

By presenting quit-to-cease offerings under one roof, we ensure seamless execution, cost manage, and regular first-class at every step.

Expertise Across Commercial Sectors DLH Infra has effectively achieved commercial interior production projects for a numerous range of organizations. Whether you very own a retail showroom, a eating place, a company head workplace, or a healthcare hospital, our group grants region-specific layout and construction solutions tailor-made to your business dreams.

We cater to:

Retail shops and showrooms

Restaurants and cafes

Corporate workplaces and business facilities

Clinics, labs, and healthcare spaces

Educational and education institutes

Co-operating and shared workplace environments

Each mission reflects no longer just brilliant layout however additionally operational glide, compliance, and branding — making the space paintings for both personnel and customers.

Tailored Design & Construction Approach At DLH Infra, we understand that no two organizations are the equal. Our business indoors creation method is notably personalised to align together with your emblem identification, target audience, and finances. From the primary consultation to final handover, we involve the customer at each critical level.

Our manner includes:

Detailed Site Evaluation – Understanding the place’s physical obstacles and ability

Concept Development – Layout design, material choice, temper boards

Cost Estimation – Transparent pricing with options for value engineering

Approvals and Compliance – Adhering to building codes, fireplace protection, and nearby guidelines

Execution and Quality Control – Timely transport with professional craftsmanship

Final Finishes and Handover – Move-in-prepared business space

This transparent and structured technique guarantees no longer handiest pleasant results however also a strain-free revel in for the patron.

Modern Technology Meets Functionality DLH Infra combines aesthetic design with cutting-edge generation to ensure business interiors serve their purposeful purpose while staying ahead of enterprise developments. Our commercial interiors combine:

Smart lighting and automation systems

Energy-efficient HVAC systems

Visitor control and access manage solutions

Digital signage and branding walls

Ergonomic and flexible furnishings

Sustainable building substances

This fusion of tech and design now not handiest makes the distance visually appealing however additionally improves capability and power performance.

On-Time Project Delivery & Budget Control Time is money, mainly in business commercial enterprise. DLH Infra’s project management structures are designed to make certain that each one commercial indoors construction projects are finished on time and inside price range. Our team follows a strict schedule, presents weekly development reviews, and makes contingency plans to avoid surprising delays or costs.

Clients benefit from:

Fast-tune execution models

Strict milestone monitoring

Transparent pricing

Cost-saving value engineering

Real-time web page reporting

We take delight in being reliable companions who understand the urgency of industrial timelines.

Quality Materials & Sustainable Construction DLH Infra uses most effective certified and top class-grade materials that offer durability, overall performance, and visual attraction. We also integrate inexperienced production principles wherever relevant to help power efficiency and environmental responsibility.

Materials include:

Commercial-grade laminates and woodwork

Anti-skid and heavy-traffic flooring

Fire-retardant panels and fabric

Low-VOC paints and sustainable wall finishes

Energy-saving lighting systems

Our material choice and execution quality stand the check of time, assisting clients avoid frequent preservation and highly-priced upkeep.

Why DLH Infra is Trusted for Commercial Interiors End-to-End Execution – Design, production, MEP, and finishing below one umbrella

Cross-Sector Experience – Versatility across retail, hospitality, healthcare, and training

High Attention to Branding – Integration of company identification into indoors aesthetics

Fast Turnaround Time – Rapid execution without compromising on first-class

Post-Handover Support – Continued help even after mission final touch

With a confirmed song document throughout Delhi NCR, DLH Infra has emerged as a favored indoors construction associate for startups, SMEs, and huge organisations alike.

Testimonials from Commercial Clients “DLH Infra converted our café right into a vibrant and inviting space that helped us entice extra footfall. The detailing and execution have been faultless.” — Restaurant Owner, Connaught Place

“Our workplace interiors have been completed on time with complete transparency. The consequences speak for themselves. Highly recommended.” — IT Firm, Gurgaon

“They understood our emblem vision and created a retail space that displays our merchandise perfectly. Sales progressed visibly post-renovation.” — Apparel Showroom Owner, South Delhi

Conclusion For companies searching out the Best Commercial Interior Construction in Delhi NCR, DLH Infra provides unequalled carrier, modern design, and perfect execution. Whether you are launching a new industrial venture or upgrading an existing one, our team ensures your interior creation journey is clean, green, and transformative.

0 notes

Text

Green Building Materials Market Forecast: The Eco-Friendly Shift Disrupting Traditional Building

Green Building Materials Market Overview: A Transformational Shift Toward Sustainable Construction

The global green building materials market is undergoing a seismic transformation. With a projected surge from USD 422.27 billion in 2023 to approximately USD 1,199.52 billion by 2031, the sector is advancing at a CAGR of 12.3%. This remarkable growth is a direct response to the construction industry’s pivot towards sustainability, energy efficiency, and environmental responsibility.

As we navigate a climate-conscious era, the demand for eco-friendly construction materials—ranging from recycled steel and bamboo to non-toxic adhesives and solar-integrated systems—is becoming increasingly paramount. This dynamic market evolution is not only driven by environmental regulations but also by a widespread global commitment to reduce carbon footprints, enhance building longevity, and optimize resource use.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40527-global-green-building-materials-market

Driving Forces Behind the Growth of Green Building Materials

1. Regulatory Support and Policy Integration

Across continents, government mandates and green building codes are catalyzing the adoption of sustainable materials. LEED, BREEAM, and other certification frameworks are now pivotal in driving demand across both residential and commercial sectors.

2. Urbanization and Infrastructure Development

Rapid urban expansion, particularly in Asia-Pacific, the Middle East, and Africa, necessitates infrastructure that is both scalable and environmentally conscious. Smart city initiatives and net-zero energy building goals are further amplifying green material deployment.

3. Technological Innovation

Advanced research has yielded next-generation materials—such as aerogel insulation, transparent solar panels, hempcrete, and bio-based concrete alternatives—that outperform traditional solutions while minimizing ecological impact.

4. Rising Energy Costs

As energy prices continue to escalate globally, builders and developers are shifting focus toward materials that reduce energy consumption, such as cool roofs, triple-glazed windows, and low-E coatings.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40527-global-green-building-materials-market

Green Building Materials Market Segmentation Analysis

Product Type Landscape: Diversifying Material Innovation

Structural Materials Includes recycled concrete aggregates, bamboo composites, hempcrete, and steel with high recycled content. These materials offer durability and reduced embodied carbon.

Interior Materials Emphasizes low-VOC paints, recycled carpets, cork flooring, and sustainable cabinetry that contribute to healthy indoor environments.

Exterior Materials Comprises green facades, fiber cement cladding, and permeable pavers, all engineered for weather resistance and reduced heat absorption.

Solar Products Encompasses BIPV (building-integrated photovoltaics), solar shingles, and facade-embedded panels, providing dual utility as both building envelope and energy source.

Others Covers innovative entries like mycelium insulation, algae-based wall systems, and CO₂-sequestering tiles.

Application Breakdown: Functional Integration Across Building Elements

Structural Components Green load-bearing solutions that align strength with sustainability.

Interior Finishes Eco-friendly paints, plasters, and finishes enhancing indoor air quality and aesthetic.

Exterior Finishes Designed for weather endurance and thermal regulation.

Building Systems Systems such as smart HVAC, rainwater harvesting setups, and energy-recovery ventilation (ERV) systems embedded with sustainable material use.

End-Use Spectrum: Adoption Across Sectors

Residential Buildings Driven by consumer demand for energy-efficient homes, cost savings, and green mortgages.

Commercial Buildings Developers adopt green materials to improve ROI via lower operational costs and higher tenant attraction.

Institutional Buildings Schools, hospitals, and public buildings increasingly leverage sustainable construction for health benefits and operational resilience.

Industrial Buildings Integration of green roofing systems, daylighting technologies, and low-emission flooring into warehouses and production facilities.

Public Infrastructure Utilization of green concrete, recycled asphalt, and modular prefabrication in government-funded projects.

Regional Insights: Green Building Materials Market Trends by Geography

North America

The United States and Canada remain pioneers, with state-sponsored green mandates, corporate ESG strategies, and smart home adoption driving demand.

Europe

Buoyed by the European Green Deal, the region leads in energy-positive buildings and circular construction economies.

Asia-Pacific

Urban megaprojects and environmental initiatives in China, India, and Southeast Asia are fueling unprecedented demand for green materials.

Middle East and Africa

Desert urbanism and water-smart materials gain traction, particularly in UAE, Saudi Arabia, and South Africa.

South America

Countries like Brazil and Chile are fostering green construction through renewable energy integration and sustainable housing initiatives.

Key Green Building Materials Market Players

Saint-Gobain – Innovator in high-performance building envelopes and low-carbon glazing.

Interface Inc. – Pioneer in modular, sustainable carpet tile and flooring systems.

Kingspan Group – Industry leader in insulated panels and building envelope solutions.

Hempitecture – Specializes in hemp-based insulation and prefabricated panels.

BASF – Provides eco-efficient polyurethane foams and concrete admixtures.

Nucor Corporation – Key supplier of recycled steel solutions for green buildings.

Ecovative Design – Known for mycelium-based construction and insulation.

Sika AG – Offers sustainable roofing membranes and adhesives.

Mohawk Industries – Develops recycled and biodegradable flooring solutions.

Greenbuild International – Focuses on global green building advocacy and product deployment.

Green Building Materials Market Challenges and Opportunities

Challenges

Initial Capital Costs: Premium pricing of green materials can deter small-scale developers.

Supply Chain Gaps: Availability varies regionally, especially in developing economies.

Technical Expertise: Implementation requires skilled labor trained in green practices.

Green Building Materials Market Opportunities

Prefabrication and modular green construction streamline costs and reduce waste.

Carbon-neutral and net-positive building designs open new market avenues.

Green financing and tax incentives are fueling adoption among mainstream builders.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40527-global-green-building-materials-market

Conclusion

The green building materials market stands at the nexus of environmental necessity and economic opportunity. With the continued fusion of policy enforcement, technological innovation, and sustainability awareness, the sector is poised for exponential evolution.

By leveraging regional growth trends, application-based innovation, and diversified material portfolios, stakeholders—from architects and developers to governments and manufacturers—can spearhead a new era of resilient, regenerative construction.

We foresee a future where every new building contributes positively to the planet, and green materials are not an exception—but the standard.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Text

HVAC Relay Market Outlook 2031: Smart Automation, Energy Efficiency, and Green Building Demand Driving Industry Growth

The global HVAC relay market is experiencing a remarkable evolution driven by the rising adoption of smart automation, integration of Internet of Things (IoT) technologies, and increasing demand for sustainable infrastructure. Valued at US$ 3.7 billion in 2022, the industry is forecast to expand at a compound annual growth rate (CAGR) of 7.4% from 2023 to 2031, reaching approximately US$ 7.1 billion by the end of 2031. The market’s growth is underpinned by innovations in smart HVAC systems, rising energy management needs, and environmental considerations in commercial and industrial projects.

Understanding the Role of HVAC Relays in Modern Systems

An HVAC relay, short for Heat, Ventilation, and Air Conditioning relay, is a crucial component in HVAC systems. It acts as an electrical switch that controls the operation of components such as compressors, fans, and motors. These relays help streamline the system’s performance by automating and coordinating electrical circuits for consistent climate control and energy management.

Modern HVAC relays have evolved beyond their traditional switching functions. Integration with IoT platforms and real-time monitoring solutions has enabled them to deliver superior control, predictive maintenance, and adaptability to diverse operating environments.

Rise in Automation and IoT: A Core Growth Driver

One of the most transformative trends fueling HVAC relay market growth is the integration of automation and IoT platforms. These technologies allow for real-time control of HVAC systems, remote monitoring, and data-driven decision-making. Such connectivity enhances operational efficiency, reduces manual intervention, and supports predictive maintenance strategies.

In sectors such as automotive, HVAC relays play a significant role in managing internal climate conditions based on sensor-driven inputs. Vehicles now utilize relays to ensure seamless cabin temperature adjustments, contributing to passenger comfort while minimizing energy consumption.

According to research by Smart Car, more than 30 million connected vehicles were sold in 2020, with the U.S. accounting for over 91% of global sales. This shift toward smart, connected ecosystems directly benefits the HVAC relay industry as demand for energy-efficient, remote-controlled systems continues to rise. By 2030, it is projected that 91% of vehicles produced will incorporate smart connectivity, indicating immense potential for relay integration.

Green Infrastructure and Sustainability Pave the Way Forward

As environmental sustainability becomes a cornerstone of infrastructure development, the role of HVAC systems in reducing energy consumption and carbon footprints has gained prominence. HVAC relays, by optimizing system performance, directly contribute to green building initiatives. They allow precise energy management and temperature regulation that align with eco-conscious building standards.

Institutions such as airports, colleges, and hospitals are increasingly deploying advanced HVAC technologies to meet green certification requirements. The U.S. Energy Information Administration (EIA) reports that nearly 48% of the energy consumption in a typical U.S. home is attributed to heating and cooling. Implementing energy-efficient HVAC relays can result in 20% to 30% savings in household energy bills, as per the U.S. Department of Energy.

Global infrastructure projects are echoing these concerns. A 2020 CDP report noted that 97 U.S. cities were undertaking 304 sustainable infrastructure projects valued at US$ 25.6 billion, highlighting the growing demand for smart HVAC technologies.

Regional Outlook: Asia Pacific Leads, North America Follows

In 2022, Asia Pacific emerged as the dominant region in the global HVAC relay market. The region’s strong manufacturing base, expansion in the automotive industry, and rapid urban development are driving significant demand. Countries like India and China are witnessing substantial investments in public infrastructure, including airport modernization and smart city initiatives.

For instance, India’s airport expansion plan aims to invest US$ 338 million by 2025 to upgrade existing facilities and construct new ones—an initiative that will likely boost HVAC relay installations.

Meanwhile, North America is poised for consistent growth throughout the forecast period. The rise in green buildings, educational facilities, and energy-efficient housing is contributing to market development. Additionally, strong government backing for sustainability and clean energy solutions supports the integration of HVAC relays across multiple sectors.

Competitive Landscape: Innovation at the Forefront

Leading players in the HVAC relay market are focusing on innovation to improve energy efficiency, user experience, and environmental compatibility. Key players include:

These companies are increasingly launching smart relays, climate control switches, and wireless integration modules tailored to emerging customer needs.

Recent Developments:

Market Segmentation and Future Outlook

The HVAC relay market is segmented by type (Electromagnetic, Solid State, Thermal, Hybrid, Others) and application (Automotive, Industrial, Commercial, Residential). Commercial and industrial applications continue to lead, driven by infrastructural investments, while the residential segment shows rising demand for smart home systems.

With a projected CAGR of 7.4%, the HVAC relay industry is on a robust growth path. The convergence of sustainability goals, smart infrastructure demand, and IoT proliferation is expected to keep the momentum strong through 2031.

Conclusion

The HVAC relay market is evolving in response to the global push for automation, energy efficiency, and environmentally responsible infrastructure. As smart cities rise and connected ecosystems become the norm, HVAC relays will play a pivotal role in managing energy use, maintaining comfort, and reducing environmental impact. Strategic investments by industry leaders and public policy support for green initiatives are expected to accelerate the market’s growth, paving the way for a smarter, cleaner, and more efficient future.

0 notes

Text

Porta Cabins Supplier in Qatar

In the dynamic world of infrastructure and urban development, the need for flexible, reliable, and mobile space solutions has grown substantially. Whether it's a construction site office, a temporary accommodation unit, or a portable security cabin, the demand for high-quality porta cabins is on the rise in Qatar. As a fast-developing nation with numerous commercial and infrastructure projects underway, Qatar relies heavily on portable building solutions to support its growth. This is where a trusted Porta Cabins Supplier in Qatar plays a pivotal role.

What Are Porta Cabins?

Porta cabins, also known as portable cabins or modular cabins, are prefabricated structures designed for temporary or semi-permanent use. These structures are manufactured off-site and transported to the desired location, making them ideal for projects that require swift setup and relocation.

Typically made from high-grade steel or insulated panels, porta cabins are not just convenient — they are durable, cost-effective, and environmentally friendly. From small storage units to multi-room office spaces, porta cabins can be customized to fit any requirement.

Why Porta Cabins Are in High Demand in Qatar

Qatar’s booming economy, driven by real estate, oil, gas, and the construction industry, makes it a prime location for temporary site-based infrastructure. As new roads, stadiums, towers, and housing projects emerge, the demand for quick setup facilities has skyrocketed.

Some common uses of porta cabins in Qatar include:

Construction site offices

Labor accommodations

Security guard cabins

Portable classrooms

Disaster relief shelters

Temporary retail kiosks

Medical clinics

Due to their mobility and ease of installation, porta cabins have become the go-to solution for companies seeking efficiency and adaptability.

Key Benefits of Choosing a Reliable Porta Cabins Supplier in Qatar

1. Customization and Flexibility

Top suppliers in Qatar offer fully customizable porta cabin designs to suit specific needs. Whether you require HVAC systems, electrical fittings, plumbing, or furniture — everything can be built-in according to your preferences.

2. Durability and Weather Resistance

Given Qatar's harsh weather conditions, it is crucial to have structures that can withstand heat, humidity, and sandstorms. Reputable suppliers ensure that their cabins are constructed using high-quality, insulated materials that promise long-term usage and structural integrity.

3. Fast Delivery and Installation

Time-sensitive projects benefit significantly from the quick turnaround times offered by professional porta cabin manufacturers. These portable units are pre-built and simply assembled or installed on-site within hours.

4. Cost-Effective Solutions

Compared to traditional brick-and-mortar buildings, porta cabins are more affordable in both material and labor. Plus, they can be relocated or repurposed, offering better ROI over time.

5. Eco-Friendly Construction

As environmental concerns grow, suppliers in Qatar are focusing on eco-conscious practices. Many porta cabins are built using sustainable materials, reducing construction waste and energy consumption.

Features to Look for in a Porta Cabins Supplier in Qatar

When selecting a porta cabin supplier, consider the following factors:

Proven industry experience and local market knowledge

Wide variety of cabin models and configurations

In-house design and customization team

On-time delivery and after-sales support

Use of quality-certified materials

Options for rental as well as purchase

Leading the Future of Mobile Infrastructure

Qatar’s vision for 2030 involves extensive infrastructure expansion, and portable modular solutions are expected to play a key role in supporting this vision. Porta cabins are no longer just a temporary solution; they are a sustainable, adaptable, and smart alternative to conventional construction. As more industries recognize the value of mobility and fast deployment, the demand for reliable Porta Cabins Suppliers in Qatar will only continue to grow.

Whether you’re a construction manager, project engineer, event organizer, or business owner — choosing the right porta cabin partner can make a significant difference in how efficiently your operations run.

Conclusion

Porta cabins represent the perfect blend of utility, economy, and innovation. For businesses and projects in Qatar, partnering with a dependable porta cabins supplier means gaining access to cutting-edge modular structures that meet your exact needs — quickly and affordably. Embrace the future of smart, mobile infrastructure with high-quality porta cabins tailored to your project’s success.

0 notes

Text

AC Capacitors Market: Regulatory Landscape and Policy Impact 2025-2032

MARKET INSIGHTS

The global AC Capacitors Market size was valued at US$ 2,840 million in 2024 and is projected to reach US$ 4,310 million by 2032, at a CAGR of 6.1% during the forecast period 2025-2032.