#High Speed Robotic Palletizer

Explore tagged Tumblr posts

Note

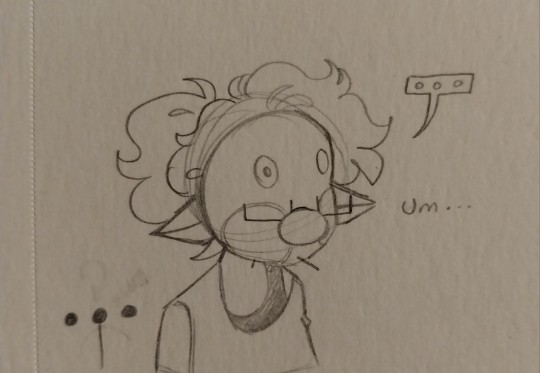

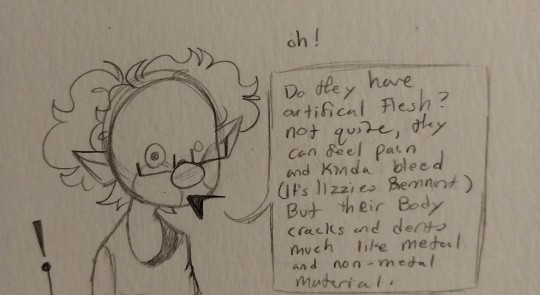

By the way,

Regarding the Trumpet playing from forever ago, do the robots have like... artificial flesh or something? Because to change octaves tightening/loosening the lips is required to change the note/octave. (3 valves, or 'keys' and all.) Tonguing a note by pressing the tip (I think?) Of the tongue to the little place between the hard/soft pallete at the roof of the mouth.

I assume they can change airflow speed, and thus I would also like to recommend a woodwind instrument. I present, the Alto Saxaphone and Bb (B flat) Clarinet. The Saxaphone can get very loud, and change notes with the pressing/release of a key. Now I don't play the saxophone, but I do play the clarinet.

Blow out the cheeks for squeaking and squawking.

If your actually trying to play the clarinet, roll bottom lip under + pull corners of lips back for the 'clarinet mask' as ive heard it be described. Think the 'E' sound, for up the octave. Can get really high notes. But can't play as loud as a saxaphone. Relatively easy to learn how to play. Go up octave with the press of a singular key. Can also go up octave without pressing said key by fast air stream + 'E' syllable with tongue.

However, more keys to accidentally press/cover/uncovering holes. Not covering a hole completely results in a squeak. Reeds can break. But that also results in horrible noise. 👍 also mouth seams bc of faceplates???

Also, recorder. Those are just horrible in general, though.

Im so sorry you had to read all that 😭

👍

Loved the yap session, but no comment.

#damn thats a lot fascinating but I dont have much commentary#aceinacloset art#aceinacloset rambles#my persona#reminder to others: my inbox is closed for now#inbox#au lore

4 notes

·

View notes

Text

Getting Started with Industrial Robotics Programming

Industrial robotics is a field where software engineering meets automation to drive manufacturing, assembly, and inspection processes. With the rise of Industry 4.0, the demand for skilled robotics programmers is rapidly increasing. This post introduces you to the fundamentals of industrial robotics programming and how you can get started in this exciting tech space.

What is Industrial Robotics Programming?

Industrial robotics programming involves creating software instructions for robots to perform tasks such as welding, picking and placing objects, painting, or quality inspection. These robots are typically used in factories and warehouses, and are often programmed using proprietary or standard languages tailored for automation tasks.

Popular Robotics Programming Languages

RAPID – Used for ABB robots.

KRL (KUKA Robot Language) – For KUKA industrial robots.

URScript – Used by Universal Robots.

Fanuc KAREL / Teach Pendant Programming

ROS (Robot Operating System) – Widely used open-source middleware for robotics.

Python and C++ – Common languages for simulation and integration with sensors and AI.

Key Components in Robotics Programming

Motion Control: Programming the path, speed, and precision of robot arms.

Sensor Integration: Use of cameras, force sensors, and proximity detectors for adaptive control.

PLC Communication: Integrating robots with Programmable Logic Controllers for factory automation.

Safety Protocols: Programming emergency stops, limit switches, and safe zones.

Human-Machine Interface (HMI): Designing interfaces for operators to control and monitor robots.

Sample URScript Code (Universal Robots)

# Move to position movej([1.0, -1.57, 1.57, -1.57, -1.57, 0.0], a=1.4, v=1.05) # Gripper control (example function call) set_digital_out(8, True) # Close gripper sleep(1) set_digital_out(8, False) # Open gripper

Software Tools You Can Use

RoboDK – Offline programming and simulation.

ROS + Gazebo – Open-source tools for simulation and robotic control.

ABB RobotStudio

Fanuc ROBOGUIDE

Siemens TIA Portal – For integration with industrial control systems.

Steps to Start Your Journey

Learn the basics of industrial robotics and automation.

Familiarize yourself with at least one brand of industrial robot (ABB, KUKA, UR, Fanuc).

Get comfortable with control systems and communication protocols (EtherCAT, PROFINET).

Practice with simulations before handling real robots.

Study safety standards (ISO 10218, ANSI/RIA R15.06).

Real-World Applications

Automated welding in car manufacturing.

High-speed pick and place in packaging.

Precision assembly of electronics.

Material handling and palletizing in warehouses.

Conclusion

Industrial robotics programming is a specialized yet rewarding field that bridges software with real-world mechanics. Whether you’re interested in working with physical robots or developing smart systems for factories, gaining skills in robotics programming can open up incredible career paths in manufacturing, automation, and AI-driven industries.

2 notes

·

View notes

Text

Why Indian FMCG Lines Should Invest in a High-Speed Robotic Palletizer 🚀

In India’s fast-moving consumer goods (FMCG) industry, every second matters. From the moment a product rolls off the production line to when it’s ready to be shipped, speed, accuracy, and consistency define profitability. And that’s exactly why High-Speed Robotic Palletizers are no longer optional—they’re essential.

🏭 The Demand for Speed in India’s FMCG Industry

With the rise of e-commerce, urban retail expansion, and increasing demand for same-day deliveries, Indian FMCG manufacturers are under pressure to produce more, faster. Manual palletizing just can’t keep up—it’s slow, error-prone, and labor-intensive.

Enter the High-Speed Robotic Palletizer.

These machines, like the ones from Fuji Robotics India, can handle up to 1800 cycles/hour, operating at lightning-fast speeds with zero compromise on stacking accuracy or product safety.

🤖 What Exactly Is a High-Speed Robotic Palletizer?

A High-Speed Robotic Palletizer is an advanced industrial robot designed to pick, place, and stack cartons, bags, buckets, or cases on pallets in precise configurations—at high speeds. Unlike conventional palletizers, they:

Adapt to multiple product types and sizes

Save floor space with compact footprints

Reduce energy consumption (Fuji models need as little as 4.5 kVA)

Operate 24/7 with minimal supervision

🚀 Speed Meets Consistency: The Fuji Edge

Fuji Robotics India offers cutting-edge palletizers like the EC-201—a model engineered for maximum throughput and low power use. With over 140,000+ global installations, Fuji is the trusted name in robotic palletizing.

These robots are perfect for handling:

Carton boxes

Paint buckets

Lube oil containers

Pouches or bags

High-mix, low-volume products (common in India)

💡 Real-World Benefits for FMCG Manufacturers

1. Labour Optimization: High-speed robotic palletizers reduce manual labor requirements by up to 80%, helping manufacturers navigate India’s increasing labor costs and skill shortages.

2. Improved Safety: No more back-breaking lifts or repetitive strain injuries for your workers. Robots take over the heavy lifting, literally.

3. Minimal Downtime: These machines offer seamless integration with existing conveyor lines and quick changeover capabilities—so you spend less time configuring and more time producing.

4. Quality Assurance: Every pallet stack is identical and stable, reducing damage during transit and ensuring your brand's reputation remains intact.

📈 Ready for Industry 4.0

Fuji’s palletizers come with IoT compatibility and data feedback systems to monitor output, maintenance schedules, and operational efficiency—making them a perfect fit for smart factories across India.

🌍 Why Now?

India’s FMCG market is growing at a CAGR of over 14%, and supply chain automation is becoming a necessity, not a luxury. Companies that invest in high-speed robotic palletizers today are not just preparing for growth—they’re staying ahead of it.

⚙️ Thinking of Upgrading?

Fuji Robotics India offers a wide range of automatic palletizer machines tailored to Indian manufacturing conditions—dusty environments, varying power supply, and space constraints.

Whether you’re palletizing 20 boxes a minute or 60, Fuji has a solution to match your line speed and budget.

👉 Let’s Talk Robotics.

If you’re in the FMCG space and wondering how to automate palletizing, we’d love to chat. Explore Fuji’s full range of robots: fujiroboticsindia.com

#RoboticPalletizer#FMCGIndia#FactoryAutomation#HighSpeedPalletizer#FujiRobotics#SmartManufacturing#PackagingLineIndia#IndustrialRobots#PalletizerMachineManufacturers#AutomationIndia#RoboticsInIndia

0 notes

Text

Durability and Material Choices for Custom Packaging Boxes

The Critical Role of Material Selection in Packaging Longevity Industrial buyers prioritizing protective packaging solutions must evaluate materials through the lens of supply chain realities. The relationship between substrate composition and container resilience directly impacts product safety during transcontinental shipping, warehouse storage cycles, and last-mile delivery challenges. Corrugated fiberboard remains the cornerstone for balance between structural integrity and weight optimization, with flute configurations (B-flute vs E-flute) offering customizable compression resistance. For electronics or precision instruments, rigid paperboard with laminated coatings provides anti-static protection while maintaining recyclability – a key consideration as global e-waste regulations tighten.

Balancing Cost and Performance in Protective Packaging Procurement teams increasingly demand packaging that withstands ISTA 3A testing protocols without inflating per-unit costs. Advanced kraft paper blends now incorporate hemp fibers to achieve 22% greater tear resistance compared to standard options, enabling thinner material profiles that reduce shipping weight. Injection-molded pulp packaging emerges as a cost-competitive alternative for fragile items, absorbing 34% more impact energy than expanded polystyrene (EPS) according to ASTM D4169 testing. Forward-thinking manufacturers now offer hybrid solutions pairing recycled PET internal cushioning with corrugated exteriors, achieving 18% better damage protection than traditional double-wall boxes at comparable price points.

Packaging Boxes

Environmental Compliance Meets Structural Requirements The convergence of circular economy mandates and packaging performance needs drives innovation in plant-based polymers and cellulose nanocomposites. Water-based barrier coatings now replace traditional polyethylene laminates, enabling 100% curbside-recyclable moisture-resistant boxes – a critical advantage for perishables shipping. Mushroom-based mycelium packaging, while currently niche, demonstrates comparable compressive strength to polypropylene containers in controlled humidity environments. Industrial buyers should prioritize suppliers offering life cycle assessment (LCA) documentation to validate sustainability claims against mechanical performance metrics.

Climate-Specific Material Engineering Strategies Globalized distribution networks require packaging solutions adaptable to diverse climatic conditions. For high-humidity corridors, silica gel-infused paperboard maintains 92% dry strength retention after 72-hour humidity chamber testing (ASTM E104). Arctic shipping routes benefit from ethylene-vinyl acetate (EVA) foam laminates that retain flexibility at -40°C, preventing brittle fracture risks. Pharmaceutical companies now adopt phase-change material (PCM) inserts in corrugated boxes, maintaining 2-8°C temperature ranges for 96+ hours without external refrigeration – a breakthrough validated through WHO PQS certification protocols.

Optimizing Packaging for Automated Logistics Systems The rise of robotic warehouse systems demands packaging materials with consistent friction coefficients and edge crush resistance. Corrugated boxes treated with nano-ceramic coatings demonstrate 40% better conveyor belt compatibility compared to standard finishes, reducing jams in high-speed sorting facilities. Anti-abrasion varnishes now protect offset-printed surfaces from scuffing during automated palletizing, maintaining brand presentation through extended supply chains. Advanced die-cutting technologies enable precise ventilation patterns in storage boxes, preventing condensation buildup during temperature-controlled海运运输 while meeting automated handling system requirements.

Future-Proofing Packaging Investments Strategic material selection now incorporates predictive analytics for evolving regulatory landscapes and consumer trends. Conductive graphene inks embedded in packaging surfaces enable real-time shock monitoring through IoT integration, providing logistics teams with actionable data to improve handling practices. Self-healing polymer coatings under development promise to automatically repair surface abrasions during transit, potentially extending container reuse cycles by 300%. Forward-looking procurement specialists are partnering with material engineers to develop adaptive packaging systems that learn from supply chain stressors, ensuring long-term ROI as market conditions evolve.

0 notes

Text

Automated Sortation System Market Size Powering Precision and Efficiency in Logistics

The Automated Sortation System Market Size is experiencing significant growth as companies seek to improve operational speed, accuracy, and scalability. These systems, comprised of conveyor belts, automated scanners, vision systems, and robotic arms, enable seamless handling of thousands of packages per hour. From e-commerce giants to postal services and industrial manufacturers, sortation technologies are becoming integral to modern supply chains and distribution networks.

Market Size Research Future projects substantial growth in automated sortation, driven by increasing consumer demand for same-day delivery, labor shortages, and the integration of predictive analytics.

Market Size Overview

Automated sortation systems streamline the process of identifying, categorizing, and routing items through distribution centers and warehouses. Equipped with barcode or RFID scanners, weight verification, and vision sensors, these systems can handle diverse products—letters to pallets—with high speed and minimal human intervention. They also interface with Warehouse Management Systems (WMS) and Inventory Control Systems for real-time visibility and optimized throughput.

As logistics networks embrace omnichannel retailing and face rising transaction volumes, investment in scalable automation systems has surged.

Key Drivers

1. E-commerce and Omnichannel Retail Growth

The continued expansion of online retail and consumer expectations for fast delivery are driving warehouse automation investments. Sortation systems can process up to 50,000 pieces per hour—critical for meeting delivery windows and reducing bottlenecks.

2. Rising Labor Constraints

Warehouse operations face increasing labor shortages and wage costs. Automated sorters reduce reliance on manual labor, lowering errors and operational expenses over the long term.

3. Integration of Smart Technologies

The adoption of robotic handling, machine vision, and predictive analytics improves sorting accuracy and uptime. Real-time data allows for capacity planning and dynamic resource allocation.

4. Scalability and Flexibility

Modern sortation systems are modular and reconfigurable to handle peak seasons, SKU variety, and changing network requirements, making them ideal for seasonal demand and client expansion.

Market Size Segmentation

By Sortation Technology:

Belt-Based Systems

Shoe Sorters

Pusher Sorters

Tilt-Tray Systems

Cross-Belt Sorters

Robotic Arm Sorters

By End User:

E-commerce

Parcel & Postal Services

Third-Party Logistics (3PL)

Grocery & Retail

Manufacturing & Pharmaceuticals

By Geography:

North America – Early adopters with high logistics automation penetration

Europe – Significant growth from e-fulfillment and omnichannel retail

Asia-Pacific – Driven by rapid urbanization, manufacturing, and digital retail

Rest of the World – Emerging demand in Middle East and Latin America

Regional Insights

North America

Leading logistics companies and fulfillment centers invest heavily in automated sorters to manage urban demand and maintain competitive speed standards.

Europe

A focus on sustainable warehouse operations and last-mile delivery optimization in Germany, the UK, and France is driving system upgrades.

Asia-Pacific

China, India, and Southeast Asia are witnessing explosive growth in distribution centre infrastructure, elevating adoption rates of sortation technologies.

Competitive Landscape

Key global players are focusing on advanced integration, robotics, and software-driven efficiency. Leading companies include:

Dematic

Daifuku Co., Ltd.

Vanderlande Industries

BEUMER Group

Murata Machinery

Honeywell Intelligrated

TGW Logistics Group

SSI Schaefer

KION Group

Fives Group

These companies deliver turnkey sortation lines, robotic integration, and AI-driven controls to create powerful, flexible distribution systems.

Opportunities and Challenges

Opportunities:

Integration of autonomous mobile robots for dynamic sorting

Adoption of vision-based weight and dimension scanning

Implementation of edge-computing for real-time analytics

Increase in micro fulfillment centers close to consumers

Challenges:

High CAPEX for advanced systems

Integration complexity with legacy IT systems

Need for ongoing maintenance and software updates

Cybersecurity concerns of connected systems

Environmental and Sustainability Impact

Energy-efficient sortation systems and predictive maintenance help reduce power consumption and waste. Circular design and recyclable materials are being incorporated by leading integrators to meet ESG criteria.

Future Outlook

As warehouses and distribution centers shift to dynamic, tech-driven operations, automated sortation systems will remain vital. Advances in AI, robotics, and real-time analytics will reduce manual interventions, minimize errors, and improve throughput. The next generation of sorters will be autonomous, self-optimizing, and seamlessly integrated into digital ecosystems.

Trending Report Highlights

Explore other pivotal automation and sensing technologies reshaping industry:

Carbon Monoxide Gas Sensors Market Size

Wire To Board Connector Market Size

Wireless Occupancy Sensors Market Size

Outdoor Solar LED Market Size

Sensors and Actuators Market Size

Street Lighting Market Size

Additive Manufacturing In Semiconductor Market Size Market Size

GPS Antenna Market Size

Machine Vision Camera Market Size

Semiconductor Device For Processing Application Market Size

Sensor Fusion In Autonomous Vehicle Market Size

Handheld Thermal Imaging Equipment Market Size

Hazardous Waste Handling Automation Market Size

0 notes

Text

Plastic Pallets Near Me: The Smart Choice for Modern Logistics

Plastic pallets have rapidly become a staple in logistics, warehousing, and manufacturing across a wide range of industries. As the global economy emphasizes speed, safety, and sustainability, the demand for more efficient transport and storage solutions continues to grow. One phrase that frequently enters the minds of logistics managers, warehouse owners, and manufacturers is: plastic pallets near me. Whether driven by convenience, cost-effectiveness, or immediate supply chain needs, proximity and availability matter.

From food and pharmaceuticals to automotive and retail, plastic pallets play a crucial role in moving goods safely and efficiently. Understanding why they’re preferred, how they compare to other pallet types, and where they’re used can help businesses make informed decisions that support both productivity and sustainability goals.

Why Plastic Pallets Are Gaining Ground

Traditionally, wood pallets dominated the shipping and warehousing industry due to their availability and low upfront costs. However, as companies began factoring in hygiene, longevity, and environmental considerations, plastic pallets started to take the lead in many sectors.

Durability and Longevity

Plastic pallets are known for their strength and resistance to wear and tear. Unlike wooden pallets, they don’t splinter, warp, or suffer from moisture damage. Many plastic pallets can last for years without needing repairs, even under heavy use. This durability makes them an ideal long-term investment for companies looking to reduce operational costs and improve supply chain efficiency.

Hygiene and Safety

Industries like food and pharmaceuticals require high levels of hygiene. Plastic pallets are easy to clean, non-porous, and resistant to bacteria, making them compliant with various safety standards. They’re often preferred in closed-loop systems or clean environments where cross-contamination could be an issue.

Uniformity and Performance

Unlike wooden pallets that can vary in size and construction, plastic pallets are molded to exact specifications. This uniformity ensures consistency in automated systems like conveyor belts, forklifts, and robotic handling. It reduces jams, increases efficiency, and supports precision in shipping operations.

Environmental and Sustainability Considerations

As environmental consciousness grows, companies are looking for logistics solutions that align with their sustainability goals. Plastic pallets provide a compelling advantage in this area.

Reusability

One of the most important benefits of plastic pallets is their reusability. Many can be used hundreds of times before they need to be recycled, which drastically reduces waste compared to single-use alternatives.

Recyclability

When a plastic pallet reaches the end of its lifecycle, it can be recycled into new pallets or other useful plastic products. This closed-loop recycling system helps reduce the environmental footprint of businesses that rely on heavy shipping and logistics.

Reduced Carbon Footprint

Because plastic pallets are lighter than wood, they can help reduce fuel consumption during transport. Lighter shipping loads mean lower emissions, contributing to a smaller carbon footprint over time.

Applications Across Industries

The question of plastic pallets near me arises across various industries for good reason. Their versatility and dependability make them a valuable asset in multiple sectors.

Food and Beverage

Strict hygiene regulations make plastic pallets the preferred choice for food manufacturers and distributors. They don’t absorb moisture, are resistant to mold and mildew, and are easy to sanitize between uses.

Pharmaceuticals

Plastic pallets are frequently used in pharmaceutical environments due to their cleanability and non-reactive surfaces. They are often used in climate-controlled or sterile environments where product purity is essential.

Retail and Grocery

Retailers often use plastic pallets for in-store displays and bulk transportation. Their neat appearance, ease of cleaning, and lightweight nature make them ideal for moving merchandise through stores and warehouses.

Automotive and Manufacturing

In manufacturing and industrial settings, plastic pallets support heavy loads and offer the durability needed for repeated use. They’re also used for storing sensitive electronic components since they can be made anti-static and resistant to chemicals.

Economic Impact of Choosing Plastic Pallets

Although the upfront cost of plastic pallets can be higher than that of wood pallets, the long-term savings are often substantial. Businesses looking up plastic pallets near me are usually considering more than convenience—they’re evaluating ROI, safety, and waste reduction.

Lower Maintenance Costs

Because plastic pallets don’t splinter or break easily, they require minimal maintenance. This leads to lower repair costs and fewer disruptions in daily operations.

Fewer Injuries and Damages

Plastic pallets help reduce injuries caused by splinters, nails, and broken boards—common issues with wood pallets. In turn, this improves worker safety and reduces liability for warehouse operations.

Inventory and System Efficiency

The uniform size and weight of plastic pallets simplify storage, loading, and automation. They stack more consistently, fit better in storage racking, and work seamlessly with automated systems.

Local Availability and On-Demand Fulfillment

The growing popularity of the search term plastic pallets near me reflects the increasing need for just-in-time delivery models. Businesses today want materials close by to minimize delays, shipping costs, and supply chain risks.

Being able to quickly obtain high-quality plastic pallets allows companies to stay agile and responsive in changing market conditions. Local access often leads to shorter lead times, better customer service, and the ability to maintain consistent quality.

Considerations When Choosing Plastic Pallets

While the advantages are clear, businesses should keep certain factors in mind when sourcing plastic pallets:

Load Requirements

Not all plastic pallets are created equal. Some are designed for light-duty loads, while others are built to handle the weight of industrial machinery or multiple layers of packaged goods.

Design and Functionality

Pallets come in various configurations—rackable, stackable, nestable, and custom-molded options. The right type depends on the handling and storage systems used in your operation.

Compliance

Ensure that any plastic pallet used for food or pharmaceutical applications meets the necessary compliance standards such as FDA or ISPM 15 exemption, depending on the industry.

Environmental Impact

For businesses with sustainability goals, choosing recycled or recyclable plastic pallets supports green initiatives and corporate responsibility.

The Rise of Returnable Transit Packaging (RTP)

Plastic pallets are a major component of the broader movement toward Returnable Transit Packaging (RTP). This refers to systems that rely on durable, reusable materials rather than single-use alternatives. RTP systems reduce waste, improve logistics efficiency, and deliver long-term savings—making plastic pallets a natural fit.

Companies implementing RTP strategies often rely on returnable plastic pallets to create closed-loop systems where the same pallets are cycled through warehouses, distribution centers, and retail locations multiple times before retirement.

Conclusion: Why "Plastic Pallets Near Me" Matters

Whether you run a bustling warehouse, a food processing plant, or a retail distribution center, plastic pallets offer the durability, hygiene, and performance needed to keep operations running smoothly. Their eco-friendly properties, long lifespan, and compatibility with modern logistics make them an increasingly valuable tool in today’s supply chains.

Searching for plastic pallets near me isn’t just about convenience—it’s about finding a smart, sustainable, and dependable solution to meet the demands of modern business. From reducing waste to increasing efficiency and ensuring compliance, plastic pallets check all the boxes for companies ready to move forward with confidence.

0 notes

Text

Packaging Automation Market Future Growth Analysis

Meticulous Research®—a leading global market research company, published a research report titled, ‘Packaging Automation Market by Offering (Solution, Services), Type, End-use Industry (Healthcare & Pharmaceuticals, E-commerce & Logistics, Food & Beverage, Chemical & Refinery, Aerospace & Defense), and Geography - Global Forecast to 2031.’

According to this latest publication from Meticulous Research®, the global packaging automation market is projected to reach $118.8 billion by 2031, at a CAGR of 10.1% during the forecast period. The growth of the packaging automation market is mainly attributed to the rapid growth of the E-commerce sector, the increasing adoption of automated systems across industries, and stringent food safety regulations. However, the high initial costs of installing automated systems restrain the market’s growth.

The high demand for packaging automation in the logistics industry and the increasing demand for sustainable and eco-friendly packaging are expected to create market growth opportunities. However, the shortage of skilled operators is a major challenge for the players in this market. Integration of advanced technologies and smart packaging are major trends in the packaging automation market.

The global packaging automation market is segmented by offering (solutions [case sealers & erectors, sleevers & cartoners, palletizers & depalletizers, strappers, markers & labelers, automated mailer systems, case packers, and other solutions], services [consulting, installation & training, and support & maintenance]), type (robotic pick & place, secondary packaging, and tertiary & palletizing), end-use industry (healthcare & pharmaceuticals [healthcare & pharmaceuticals manufacturing companies and contract manufacturing organizations], e-commerce & logistics [E-commerce, contract packaging, and logistics companies], food & beverage, automotive, chemical & refineries, aerospace & defense, and other end-use industries), and geography (Asia-Pacific, Europe, North America, Latin America, and the Middle East & Africa). The study also evaluates industry competitors and analyses the market at the country and regional levels.

Based on offering, the packaging automation market is segmented into solutions and services. Furthermore, the solutions segment is subsegmented into case sealers & erectors, sleevers & cartoners, palletizers & depalletizers, strappers, markers & labelers, automated mailer systems, case packers, and other solutions. The services segment is subsegmented into consulting, installation & training, and support & maintenance. In 2024, the solutions segment is expected to account for the larger share of the global packaging automation market. The segment’s large market share is mainly attributed to the need for increased manufacturing speed and ensuring products and workers’ safety. However, the services segment is projected to record the highest CAGR during the forecast period. The segment’s growth is driven by the increasing deployment of automation in various industries such as e-commerce, healthcare & pharmaceuticals, food & beverage, automotive, and chemical & refineries and the growing demand for packaging automation to speed up production, optimize warehouse space, and reduce reliance on labor to provide more value-added services to their customers.

Based on type, the packaging automation market is segmented into robotic pick & place, secondary packaging, and tertiary & palletizing. In 2024, the robotic pick & place segment is expected to account for the largest share of the global packaging automation market. The segment’s large market share is mainly attributed to rising demand for pick and place robots in various industries such as manufacturing, food & beverage, automotive, chemical & refineries, aerospace & defense, e-commerce & logistics, healthcare & pharmaceuticals, and the growing demand for automation from manufacturing companies to increase production rates. However, the secondary packaging segment is projected to record the highest CAGR during the forecast period. The segment’s growth is driven by the rising need to safely transport products during shipment and the growing demand for supplementary protection in the e-commerce and pharmaceutical sectors.

Based on end-use industry, the packaging automation market is segmented into healthcare & pharmaceuticals, E-commerce & logistics, food & beverage, automotive, chemical & refineries, aerospace & defense, and other end-use industries. Furthermore, the healthcare & pharmaceuticals segment is subsegmented into healthcare & pharmaceuticals manufacturing companies and contract manufacturing organizations. The E-commerce & logistics segment is subsegmented into E-commerce, contract packaging, and logistics companies. In 2024, the food & beverage segment is expected to account for the largest share of the global packaging automation market. The segment’s large market share is mainly attributed to shifting consumer tastes, high competition in the packaged food market, and a surge in demand for packaged food. However, the e-commerce & logistics segment is projected to record the highest CAGR during the forecast period. The segment’s growth is attributed to various factors, including the rise in online sales channels, the increase in online shopping among customers, the increasing adoption of automation in e-commerce & logistics to ensure timely delivery, and the rising consumer demand for convenience shopping.

Based on geography, the global packaging automation market is segmented into North America, Europe, Latin America, and the Middle East & Africa. In 2024, Asia-Pacific is expected to account for the largest share of the packaging automation market, followed by Europe, North America, Latin America, and the Middle East & Africa. Asia-Pacific’s significant market share is attributed to the increasing utilization of sustainable packaging in the food & beverage sector, supportive government initiatives aimed at promoting the adoption of automation and Industry 4.0 technologies to enhance manufacturing capabilities, the growing demand for eco-friendly packaging solutions, and the rapid expansion of the E-commerce sector in countries like China and India. Moreover, Asia-Pacific is also projected to register the highest CAGR over the forecast period.

Key Players

The key players operating in the global packaging automation market are ABB, Ltd. (Switzerland), Robert Bosch GmbH (Germany), Siemens AG (Germany), Fanuc Corporation(Japan), and Mitsubishi Electric Corporation (Japan), Swisslog Holding AG (Switzerland), Rockwell Automation, Inc. (U.S.), Schneider Electric SE (France), WestRock Company (U.S.), SATO Holdings Corporation (Japan), Krones AG (Germany), Automated Packaging Systems, Inc. (U.S.), Emerson Electric Co. (U.S.), Crawford Packaging (Canada), Fuji Machinery (Japan), Brenton LLC (U.S.), BEUMER Group GmbH & Co. KG(Germany), Barry-Wehmiller Group, Inc. (U.S.), KHS GmbH (Italy), MULTIVAC Sepp Haggenmüller SE & Co. KG (Germany), Omori Machinery Co., Ltd. (Japan), and Syntegon Technology GmbH (Germany).

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5324

Key Questions Answered in the Report:

Which are the high-growth market segments in terms of offering, type, and end-use industry?

What is the historical market for packaging automation across the globe?

What are the market forecasts and estimates for the period of 2024–2031?

What are the major drivers, restraints, opportunities, challenges, and trends in the global packaging automation market?

Who are the major players in the global packaging automation market, and what are their market shares?

What is the competitive landscape like?

What are the recent developments in the global packaging automation market?

What are the different strategies adopted by the major players in the market?

What are the geographic trends and high-growth countries?

Who are the emerging players in the global packaging automation market, and how do they compete with the other players?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

0 notes

Text

Packaging Automation Market Future Growth Analysis

Meticulous Research®—a leading global market research company, published a research report titled, ‘Packaging Automation Market by Offering (Solution, Services), Type, End-use Industry (Healthcare & Pharmaceuticals, E-commerce & Logistics, Food & Beverage, Chemical & Refinery, Aerospace & Defense), and Geography - Global Forecast to 2031.’

According to this latest publication from Meticulous Research®, the global packaging automation market is projected to reach $118.8 billion by 2031, at a CAGR of 10.1% during the forecast period. The growth of the packaging automation market is mainly attributed to the rapid growth of the E-commerce sector, the increasing adoption of automated systems across industries, and stringent food safety regulations. However, the high initial costs of installing automated systems restrain the market’s growth.

The high demand for packaging automation in the logistics industry and the increasing demand for sustainable and eco-friendly packaging are expected to create market growth opportunities. However, the shortage of skilled operators is a major challenge for the players in this market. Integration of advanced technologies and smart packaging are major trends in the packaging automation market.

The global packaging automation market is segmented by offering (solutions [case sealers & erectors, sleevers & cartoners, palletizers & depalletizers, strappers, markers & labelers, automated mailer systems, case packers, and other solutions], services [consulting, installation & training, and support & maintenance]), type (robotic pick & place, secondary packaging, and tertiary & palletizing), end-use industry (healthcare & pharmaceuticals [healthcare & pharmaceuticals manufacturing companies and contract manufacturing organizations], e-commerce & logistics [E-commerce, contract packaging, and logistics companies], food & beverage, automotive, chemical & refineries, aerospace & defense, and other end-use industries), and geography (Asia-Pacific, Europe, North America, Latin America, and the Middle East & Africa). The study also evaluates industry competitors and analyses the market at the country and regional levels.

Based on offering, the packaging automation market is segmented into solutions and services. Furthermore, the solutions segment is subsegmented into case sealers & erectors, sleevers & cartoners, palletizers & depalletizers, strappers, markers & labelers, automated mailer systems, case packers, and other solutions. The services segment is subsegmented into consulting, installation & training, and support & maintenance. In 2024, the solutions segment is expected to account for the larger share of the global packaging automation market. The segment’s large market share is mainly attributed to the need for increased manufacturing speed and ensuring products and workers’ safety. However, the services segment is projected to record the highest CAGR during the forecast period. The segment’s growth is driven by the increasing deployment of automation in various industries such as e-commerce, healthcare & pharmaceuticals, food & beverage, automotive, and chemical & refineries and the growing demand for packaging automation to speed up production, optimize warehouse space, and reduce reliance on labor to provide more value-added services to their customers.

Based on type, the packaging automation market is segmented into robotic pick & place, secondary packaging, and tertiary & palletizing. In 2024, the robotic pick & place segment is expected to account for the largest share of the global packaging automation market. The segment’s large market share is mainly attributed to rising demand for pick and place robots in various industries such as manufacturing, food & beverage, automotive, chemical & refineries, aerospace & defense, e-commerce & logistics, healthcare & pharmaceuticals, and the growing demand for automation from manufacturing companies to increase production rates. However, the secondary packaging segment is projected to record the highest CAGR during the forecast period. The segment’s growth is driven by the rising need to safely transport products during shipment and the growing demand for supplementary protection in the e-commerce and pharmaceutical sectors.

Based on end-use industry, the packaging automation market is segmented into healthcare & pharmaceuticals, E-commerce & logistics, food & beverage, automotive, chemical & refineries, aerospace & defense, and other end-use industries. Furthermore, the healthcare & pharmaceuticals segment is subsegmented into healthcare & pharmaceuticals manufacturing companies and contract manufacturing organizations. The E-commerce & logistics segment is subsegmented into E-commerce, contract packaging, and logistics companies. In 2024, the food & beverage segment is expected to account for the largest share of the global packaging automation market. The segment’s large market share is mainly attributed to shifting consumer tastes, high competition in the packaged food market, and a surge in demand for packaged food. However, the e-commerce & logistics segment is projected to record the highest CAGR during the forecast period. The segment’s growth is attributed to various factors, including the rise in online sales channels, the increase in online shopping among customers, the increasing adoption of automation in e-commerce & logistics to ensure timely delivery, and the rising consumer demand for convenience shopping.

Based on geography, the global packaging automation market is segmented into North America, Europe, Latin America, and the Middle East & Africa. In 2024, Asia-Pacific is expected to account for the largest share of the packaging automation market, followed by Europe, North America, Latin America, and the Middle East & Africa. Asia-Pacific’s significant market share is attributed to the increasing utilization of sustainable packaging in the food & beverage sector, supportive government initiatives aimed at promoting the adoption of automation and Industry 4.0 technologies to enhance manufacturing capabilities, the growing demand for eco-friendly packaging solutions, and the rapid expansion of the E-commerce sector in countries like China and India. Moreover, Asia-Pacific is also projected to register the highest CAGR over the forecast period.

Key Players

The key players operating in the global packaging automation market are ABB, Ltd. (Switzerland), Robert Bosch GmbH (Germany), Siemens AG (Germany), Fanuc Corporation(Japan), and Mitsubishi Electric Corporation (Japan), Swisslog Holding AG (Switzerland), Rockwell Automation, Inc. (U.S.), Schneider Electric SE (France), WestRock Company (U.S.), SATO Holdings Corporation (Japan), Krones AG (Germany), Automated Packaging Systems, Inc. (U.S.), Emerson Electric Co. (U.S.), Crawford Packaging (Canada), Fuji Machinery (Japan), Brenton LLC (U.S.), BEUMER Group GmbH & Co. KG(Germany), Barry-Wehmiller Group, Inc. (U.S.), KHS GmbH (Italy), MULTIVAC Sepp Haggenmüller SE & Co. KG (Germany), Omori Machinery Co., Ltd. (Japan), and Syntegon Technology GmbH (Germany).

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5324

Key Questions Answered in the Report:

Which are the high-growth market segments in terms of offering, type, and end-use industry?

What is the historical market for packaging automation across the globe?

What are the market forecasts and estimates for the period of 2024–2031?

What are the major drivers, restraints, opportunities, challenges, and trends in the global packaging automation market?

Who are the major players in the global packaging automation market, and what are their market shares?

What is the competitive landscape like?

What are the recent developments in the global packaging automation market?

What are the different strategies adopted by the major players in the market?

What are the geographic trends and high-growth countries?

Who are the emerging players in the global packaging automation market, and how do they compete with the other players?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#PackagingAutomation#AutomationTechnology#SmartPackaging#IndustrialAutomation#ManufacturingSolutions#PackagingMachinery#EcommerceGrowth#SupplyChainInnovation#MarketForecast#PackagingIndustry

0 notes

Text

How Palletizer Machines Are Transforming Modern Manufacturing

Speed, accuracy, and efficiency are not merely desirable qualities in the dynamic fields of manufacturing and logistics; they are necessary. One unsung hero stands tall (literally) when it comes to simplifying the end-of-line process: the palletizer machine.

The last packing step frequently entails stacking boxes or bags onto pallets, regardless of whether you're making consumer items, packaged meals, beverages, or medications. Doing this by hand? It takes a lot of time, is physically demanding, and is prone to human mistake. The palletizing machine is a technological marvel that has revolutionized the industry by automating a labor-intensive manual process.

What is a Palletizer Machine?

Fundamentally, a palletizer machine is a device that automatically arranges goods on pallets in a predetermined pattern for secure and effective storage or transportation. However, that's only the tip of the iceberg. Palletizers of today are intelligent, nimble, and incredibly configurable. There is a palletizing machine that can perform the task with robotic accuracy, whether it is for shrink-wrapped cartons, cases of soda, or bags of cement.

Palletizers come in a variety of forms, including hybrid, robotic, and conventional models. While robotic palletizers employ articulated robot arms with grippers or suction pads to pick and put things, conventional palletizer uses mechanical arms and conveyors to align products. Hybrid systems offer speed and versatility in one convenient package, combining the best features of both systems.

Why a Palletizer matter more than ever

Manufacturers are under pressure to transport items more quickly and precisely as supply chains get more complicated and demand increases. Palletizers are ideal in this situation. These machines eliminate heavy lifting-related workplace injuries and labor expenses by taking over repetitive stacking operations.

They also make the packaging process more consistent. A palletizing machine never gets bored, fatigued, or distracted. It consistently positions every item just where it should be. This translates into greater utilization of storage space, fewer damaged goods, and more effective warehouse operations.

The Rise of Smart Palletizing

The palletizers of today are not only robust, but also intelligent. These days, a lot of systems have sensors, vision systems, and AI-powered software that enables them to instantly adjust to various product sizes, shapes, and configurations. Because of this, they are quite helpful in businesses whose product lines are constantly changing.

Real-time performance, uptime, and output data can be obtained by integrating smart palletizing machines with enterprise resource planning (ERP) platforms and warehouse management systems (WMS). Better decision-making and more effective resource planning are made possible by this digital connectivity.

Flexibility for Every Industry

The adaptability of contemporary palletizers is one of their main advantages. There is a solution for almost every industry, ranging from high-speed systems for mass production lines to small robotic units made for confined places.

Food and Beverage: In bottling and packaging facilities where efficiency and hygienic conditions are crucial, palletizer machines are an essential component.

Pharmaceuticals: Palletizer is essential for securely stacking delicate medical goods because of the requirement for accuracy and traceability.

FMCG and Retail: Palletizers make it easier to handle the range of shapes and sizes that are frequently used in retail-ready packaging.

Chemicals and Agro-products: Sturdy, dust-resistant palletizing systems are advantageous for bagged items such as fertilizers or powders.

A Green Advantage Too

You might be surprised to learn that palletizing devices can also help achieve sustainability objectives. They contribute to minimizing packaging waste and increasing transportation efficiency by guaranteeing optimal stacking patterns. More goods on a pallet means fewer shipping, which means less fuel and carbon emissions.

Some devices are even made with energy efficiency in mind, reducing the amount of electricity they use by utilizing servo motors and regenerative drives.e.

Choosing the Right Palletizer Machine

Here are some things to think about if you're thinking about purchasing a palletizing equipment for your company:

Type of Product and Packaging: Are you stacking trays, drums, cartons, or bags?

Speed Requirements: How many units must be palletized every minute, hour, or day?

Space Available: Do you require a small robotic device or do you have space for a huge mechanical system?

Budget & ROI: Although initial expenditures may be substantial, they are justified over time by labor savings and less damage.

Integration Capabilities: Is it possible to connect the machine to your current control systems and conveyor lines?

The Future Is Automated

The palletizer will continue to be a vital component of contemporary logistics as automation boosts productivity across many industries. In addition to increasing accuracy and efficiency, these devices empower human workers by relieving them of physically taxing and repetitive jobs.

Palletizer machines are undoubtedly a need for businesses hoping to maintain their competitiveness in the fast-paced world of today, rather than only a choice.

Your packaging line cannot afford to fall behind in a world that is changing at an accelerating rate. You get speed, accuracy, and peace of mind when you have a palletizer machine. Therefore, whether you're opening a new facility or renovating an old one, think about boosting your operations by stacking smarter, not harder.

0 notes

Text

Reducing Labor Costs Through Packaging Robotics

The global packaging automation market is undergoing significant transformation, fueled by demand for speed, precision, and sustainability in industrial operations. Valued at US$ 37.5 Bn in 2023, the market is projected to grow at a CAGR of 3.7% from 2024 to 2032, reaching US$ 52.2 Bn by 2032. Key sectors such as ecommerce, food & beverage, healthcare, and logistics are increasingly investing in automated systems to boost productivity and reduce operational costs.

Why Packaging Automation Matters

Packaging automation refers to the use of advanced technologies—such as robotics, software, and vision systems—to automate tasks like labeling, filling, sealing, palletizing, and more. The adoption of these systems helps eliminate manual errors, improve output speed, and reduce material waste. Automation not only enhances manufacturing consistency but also helps businesses remain competitive in a fast-paced environment.

Semi-automated systems—often the entry point for smaller enterprises—offer a balance between human intervention and automation, making them cost-effective yet efficient. Fully automated systems, on the other hand, provide end-to-end control, managing everything from picking to palletizing with little to no manual oversight.

Growth Drivers: Efficiency & Ecommerce

The two primary catalysts driving market growth are:

Efficiency Through Advanced Technology: Packaging automation systems have transformed traditional methods. In sectors like food and pharmaceuticals, filling machines now offer volumetric or weight-based accuracy. Automated labeling, wrapping, and sealing reduce human error and allow for high throughput operations with minimal supervision. These systems not only reduce labor expenses but also support compliance with quality standards.

Ecommerce Expansion: The rise of online retail has escalated the demand for efficient packaging systems. Retailers require packaging that ensures safe product delivery while optimizing costs. Automated packaging enables real-time adjustments for various package sizes and materials, improving mail order fulfillment and reducing carbon footprint. Companies like Amazon are testing made-to-measure paper bag automation to minimize excess packaging and streamline shipping logistics.

Technology Spotlight: Filling Machines and Smart Packaging

Filling machines, widely used across multiple industries, exemplify the sophistication of packaging automation today. They offer rapid, consistent output and seamlessly integrate with other systems such as cappers, sealers, and conveyors. This level of synchronization not only increases efficiency but also ensures product integrity, which is critical in sensitive sectors like healthcare and cosmetics.

Smart packaging technologies go a step further by integrating traceability features. For example, sensors embedded in packages can help track ingredients from source to shelf. This helps prevent issues like the 2022 Kinder Egg recall by detecting contaminated products early and isolating affected batches efficiently.

Regional Outlook: Europe at the Forefront

Europe dominated the global packaging automation market in 2023 and is expected to maintain its lead through 2032. Factors such as increased concern for worker safety, sustainability regulations, and rapid adoption of digital manufacturing technologies are driving growth in the region.

In November 2023, SEE (formerly Sealed Air) launched the CRYOVAC Brand 308A CE Vertical Form-Fill-Seal System for liquids, showcasing Europe’s commitment to automation in complex packaging tasks. Additionally, Amazon's investment in automated, sustainable packaging systems across Europe highlights the region’s role as an innovation hub.

Competitive Landscape: Key Players and Developments

Top companies are prioritizing product innovation and strategic collaborations to maintain their competitive edge. Noteworthy developments include:

Swisslog Holding AG was chosen to develop an automated high-bay warehouse for Bartels-Langness in Germany, a €13.9 Mn project.

Rockwell Automation Inc. partnered with Comau to simplify robot deployment for industrial packaging operations.

EndFlex Packaging Machinery introduced a turnkey solution for bottle packing and sealing in July 2023.

Prominent vendors include ABB Ltd., Siemens AG, Mitsubishi Electric Corporation, Schneider Electric SE, Swisslog Holding AG, and Automated Packaging Systems Inc. These companies are investing in AI-driven vision systems, modular packaging solutions, and flexible automation software to address diverse industry needs.

Future Outlook

As companies look to enhance their operational capabilities and reduce carbon emissions, packaging automation will play a central role in next-generation manufacturing and logistics. Customizable, data-driven solutions will likely dominate the landscape, helping businesses adapt to changing consumer expectations and regulatory environments.

With strong growth anticipated across sectors and geographies, stakeholders investing in automation today are poised to reap long-term benefits in productivity, safety, and profitability.

0 notes

Text

Top Automotive Conveyor System Manufacturers in the UK: Driving Innovation in Industrial Automation

The automotive industry thrives on speed, efficiency, and precision. At the heart of these capabilities lies a robust material handling system – and nothing plays a more crucial role than automotive conveyor systems. In the UK, several manufacturers are leading the charge, offering state-of-the-art conveyor solutions tailored to the demands of automotive assembly lines.

Whether it's for transporting engines, chassis, or assembled components, automotive conveyor systems help streamline production, reduce human error, and improve overall safety. This blog highlights some of the top automotive conveyor system manufacturers in the UK and what sets them apart in the market.

1. L.B. Foster Automation

L.B. Foster stands out for its advanced material handling systems and turnkey solutions for automotive manufacturing. They offer everything from belt conveyors to robotic integration systems, ensuring smooth production flow.

Key Features:

Custom-built systems for specific automotive applications

Integration with robotics and IoT sensors

In-house engineering and support

2. Conveyor Units Ltd

As one of the UK’s leading conveyor manufacturers, Conveyor Units Ltd supplies a wide variety of roller conveyors and chain conveyors ideal for automotive plants. Their robust systems are designed to handle high-load components with precision.

Why Choose Them:

Proven track record in automotive installations

Modular and scalable designs

UK-wide service and support

3. Amber Industries

Amber Industries specialises in overhead and floor conveyor systems, perfect for complex automotive assembly environments. Their Autotrack™ systems are widely used in paint shops and final assembly lines.

Highlights:

Overhead chain conveyors for body shops

Floor-mounted solutions for heavy loads

Custom control systems

4. Automotion Components

Known for their high-precision solutions, Automotion Components delivers modular conveyor systems designed to be easily integrated into any automotive production line. They also provide extensive spare parts and upgrade options.

Notable Offerings:

Modular belt and slat conveyors

Compact, space-saving designs

Comprehensive parts catalogue

5. Monk Conveyors

With decades of experience in the UK automation sector, Monk Conveyors provides tailored solutions for the automotive industry. Their systems improve production efficiency while maintaining strict safety standards.

Features Include:

Pallet conveyor systems

Transfer units and robot interfacing

Advanced control systems

Why Automotive Conveyor Systems Matter

Automotive conveyor systems are more than just a means of transport — they are central to lean manufacturing strategies. From just-in-time delivery to synchronized workflows, these systems reduce downtime, improve productivity, and support the complex logistical needs of modern automotive plants.

Conclusion

When choosing an automotive conveyor system manufacturer in the UK, it’s crucial to consider experience, scalability, and the ability to customize solutions to your production line. The companies listed above are leading the way in innovation and reliability, helping UK-based automotive manufacturers stay competitive in a fast-paced global market.

0 notes

Text

Secondary Packaging Solutions for Frozen Food

The frozen food industry in India is gaining momentum every passing day. It is a sector where convenience meets culinary delight. In such a scenario, frozen food packaging solutions have become a prominent part of the supply chain, ensuring your favourite frozen treats travel safely from warehouse to kitchen.

For businesses, secondary frozen food packaging isn’t just about applying one more layer of the package; it’s about intelligently packing products in bulk to streamline logistics, protect quality, and enhance efficiency. Unlike traditional secondary packaging that adds a protective outer layer, this method aims at grouping primary packaged items like pouches of frozen veggies or meals into larger units for transport or storage.

Packaging solutions for food are critical in a country as varied as India, comprising spicy curries, frozen snacks, and ready-to-eat meals sold on e-commerce sites. Alligator Automations is one of the industry leaders with innovative secondary packaging solutions that ensure your frozen food business grows in the competitive market.

Let’s discuss why secondary packaging for frozen food is vital and how it is revolutionising the food industry.

What is secondary food packaging for frozen food?:

The secondary food packaging for frozen food items can incorporate boxes or trays that include individual bags, like ready-to-eat meals or vegetables. These single packaged items need a specialised interface, like cartons, to facilitate handling and storage, especially for transportation that requires maintaining the cold chain.

Importance of Secondary Food Packaging for Frozen Foods:

For frozen food companies, secondary food packaging for frozen foods is like a lifeline, supporting the cold chain, managing expenses, and dealing with high consumer expectations.

Here are some of the key benefits of frozen food packaging solutions:

Preserves Freshness: Keeps frozen products at optimal temperatures, preventing freezer burn or spoilage.

Improves Efficiency: Automates bulk packing, speeding up warehouse-to-delivery processes.

Less Damage: Securely groups items to withstand rough handling or long transits.

Boosts Scalability: Supports high-volume orders, crucial during festive seasons like Diwali.

Integrating robotics and conveyors, Alligator Automations’ secondary packaging solutions helps by automating delays previously caused by manual packing.

Benefits of Secondary Packaging in Frozen Food Logistics:

Benefit

Description

Enhanced Protection

Shields products from physical damage and temperature fluctuations during transit.

Efficient Handling

Simplifies loading, unloading, and storage processes, reducing manual labour and time.

Optimized Storage

Enables better space utilization in warehouses and retail freezers by allowing for uniform stacking.

Improved Traceability

Facilitates easier tracking of product batches through barcodes and labelling on secondary packaging.

Regulatory Compliance

Helps meet food safety standards by providing necessary information and maintaining product integrity.

Sustainability

Use of recyclable or biodegradable materials in secondary packaging supports environmental initiatives.

Alligator Automations: Leading the Way in Secondary Packaging Solutions

Alligator Automations is leading the way in developing automated secondary packaging solutions for the frozen food industry. Our systems are designed to accommodate product handling at low temperatures to avoid the breakage of the cold chain. Our packaging solutions include:

High-Speed Case Packing: Groups and packs frozen products into cartons efficiently.

Robust Palletizing Systems: Provides automation to stack packaged goods on pallets for storage or shipment.

Customizable Configurations: Preset tailored solutions for various product sizes and packaging needs.

Installing these automated systems enables businesses to attain higher throughput, consistent packaging standards, and lower labour expenditure.

Conclusion:

Alligator Automations’ secondary packaging solutions transform the frozen food industry by ensuring that your food items are delivered on time, fresh, and intact. In the competitive e-commerce food delivery space, frozen food packaging solutions by Alligator Automations assist businesses by optimizing bulk packing, reducing costs, and elevating trust from customers, which helps them strategically market their products. With local know-how and advanced technology, these solutions stand out for various frozen food brands. Contact us today and learn how to integrate secondary packaging for frozen food into your systems effortlessly.

FAQs

Why is secondary packaging important for frozen food? It protects products during transit, supports cold chain, and helps in bulk handling.

What types of secondary packaging are used for frozen food? Cartons, trays, shrink wraps, and corrugated boxes.

Is secondary packaging customizable? Yes, it can be tailored to product size, weight, and handling needs.

Is sustainable secondary packaging available for frozen food? Yes, recyclable and eco-friendly materials are widely used.

#secondary packaging#secondary packaging important#Secondary Packaging Solution#Packaging Solutions for Frozen Food#Solutions for Frozen Food

0 notes

Text

Emerging Trends in Logistics Automation: Market Dynamics and Forecast

The global logistics automation market was valued at USD 34.56 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 15.0% from 2024 to 2030. Logistics automation encompasses a broad range of hardware and software solutions designed to streamline and enhance key logistics operations, including transportation, storage, retrieval, and data management. By automating these functions, businesses can significantly improve operational efficiency, reduce manual errors, and decrease turnaround times. The adoption of automation enables companies to scale operations effectively, as larger volumes of goods can be managed more efficiently with the aid of autonomous mobile robots (AMRs), conveyor systems, automated guided vehicles (AGVs), and automated storage and retrieval systems (AS/RS).

One of the primary drivers behind the rapid expansion of this market is the growing consumer preference for online shopping, which is accompanied by increasing expectations for faster and more efficient delivery services. This shift in consumer behavior has led to a significant rise in the number of fulfillment centers, particularly those catering to last-mile delivery and on-demand or quick-delivery services. These centers are increasingly turning to advanced automation technologies, evolving from basic mechanized solutions to fully autonomous, operator-free systems. As robotics and automated vehicle technologies continue to advance and mature, their applications in logistics and warehousing are expected to expand further, opening up substantial growth opportunities for the market throughout the forecast period.

However, the logistics automation industry also faces a number of challenges and barriers to adoption. Key among these is the intensifying competition among market players, which exerts pressure on pricing and innovation cycles. Another significant hurdle is the lack of standardization within the industry. The absence of universal standards across platforms and processes complicates integration and interoperability, making it difficult to implement uniform, scalable supply chain solutions. As a result, companies often incur high development and customization costs to create tailored systems for specific operational needs.

Moreover, the sector is affected by a shortage of skilled labor, particularly in developing economies such as India and China. The sophisticated nature of automation equipment and related software systems requires specialized training and expertise, which is not always readily available. This gap in technical workforce availability can slow down the implementation of automation projects and limit their effectiveness.

Despite these challenges, the overall outlook for the logistics automation market remains highly positive. With technological advancements, increasing investments in smart warehouses, and growing pressure on businesses to improve speed, accuracy, and efficiency, automation is set to play a central role in the transformation of logistics and supply chain operations worldwide.

Detailed Segmentation:

Component Insights

Based on components, the hardware segment dominated the market with the largest revenue share of 66.6% in 2023. Based on the hardware, the market is further segmented into automated sorting systems, autonomous robots, conveyor systems, de-palletizing/palletizing systems, automated storage and retrieval systems, automatic identification and data collection.

Vertical Insights

Based on vertical, the retail and e-commerce segment dominated the market with the largest revenue share in 2023. The sector uses logistics automation solutions in order to meet the increasing volumes of orders and shipments. Logistics automation solutions improve reliability and ensure timely delivery, which aligns with the retail and e-commerce industry's interest.

Function Insights

Based on functions, the market is segmented into inventory & storage management and transportation management. The transportation management segment dominated the market with the largest revenue share in 2023. Autonomous robots, conveyor systems, and de-palletizing/palletizing systems are used for transportation management.

Logistics Type Insights

Based on logistics type, sales logistics dominated the market with the largest revenue share in 2023. Sales logistics is the most critical aspect of the supply chain as it involves moving or delivering the goods to the end consumer. Sales logistics include order management, inventory management, shipping management, and vendor management. Automation solutions such as autonomous robots and automated storage and retrieval systems improve efficient

Organization Size Insights

Based on organization size, large enterprises dominated the market with the largest revenue share in 2023. Large enterprises handle huge volumes of products through the entire supply chain processes, which include raw materials, inventory, and final products.

Software Application Insights

Based on software applications, the market is segmented into inventory management, yard management, order management, labor management, vendor management, shipping management, customer support, and others. Among these, the order management segment dominated the market with the largest revenue share in 2023.

Regional Insights

North America led the logistics automation market in 2023, with a revenue share of 35.5%. The region's growth can be attributed to the presence of several logistics automation solution providers and several logistics companies, such as DHL, UPS, and FedEx Corporation, among others, in North America.

Curious about the Logistics Automation Market? Get a FREE sample copy of the full report and gain valuable insights.

Key Logistics Automation Company Insights

Some of the key companies operating in the logistics automation market include SAP., Jungheinrich AG, and Daifuku Co., Ltd., among others.

Jungheinrich AG is a supplier of warehousing technology and material handling equipment, offering extensive products and services. Its diverse product portfolio encompasses a wide range of equipment, including reach trucks, tow tractors, counterbalanced forklift trucks, shuttle and pallet carriers, order pickers, driverless transport systems, high rack stackers, rack servicing cranes, automatic high-rack silo conveyors, and materials handling systems. In addition, Jungheinrich AG provides various electric pedestrian trucks, explosion-proof forklifts, electric pedestrian stackers, batteries, and associated accessories. The company specializes in internal logistics services and delivers innovative solutions in warehousing technology.

Daifuku Co., Ltd. is an engineering, designing, manufacturing, installation, consultation, and after-sales service company for logistics systems and material handling equipment. The company caters to various industries, including automobile, transportation & warehousing, and commerce & retail. It has operations in 26 countries across Asia Pacific, Europe, and North America.

Key Logistics Automation Companies:

The following are the leading companies in the logistics automation market. These companies collectively hold the largest market share and dictate industry trends.

Dematic (Kion Group AG)

Daifuku Co., Ltd.

Swisslog Holding AG (KUKA AG)

Honeywell International Inc.

Murata Machinery, Ltd.

Jungheinrich AG

KNAPP AG

TGW Logistics Group

Kardex

Mecalux, S.A.

BEUMER GROUP

SSI SCHÄFER AG

Vanderlande Industries B.V.

WITRON Logistik

Oracle

One Network Enterprises

SAP

Recent Developments

In February 2024, Dematic announced a partnership with Canadian logistics company Groupe Robert and opened Quebec's first fully automated cold storage facility for third-party logistics. The facility features a high-capacity Automated Storage and Retrieval System (AS/RS) with 130-foot-tall cranes for managing fresh and frozen products. It also prioritizes sustainability and advanced fire safety measures and aims to enhance supply chain efficiency and serve as a central hub for manufacturers distributing products across North America.

In May 2023, Swisslog Holding AG announced a partnership with Northern Tool + Equipment to implement a Swisslog Automation Solution within the latter’s facility in Fort Mill in the U.S. state of South Carolina. The collaboration was aimed at addressing the omnichannel distribution requirements of Northern Tool + Equipment. The solution designed by Swisslog Holding AG’s experts features the AutoStore system optimized using Swisslog Holding AG’s SynQ software. Anticipated to be fully operational by October 2023, the solution would significantly enhance the efficiency and effectiveness of Northern Tool + Equipment's operations.

Order a free sample PDF of the Market Intelligence Study, published by Grand View Research.

0 notes

Text

Plastic Pallets Near Me: The Smart Choice for Modern Logistics

Plastic pallets have rapidly become a staple in logistics, warehousing, and manufacturing across a wide range of industries. As the global economy emphasizes speed, safety, and sustainability, the demand for more efficient transport and storage solutions continues to grow. One phrase that frequently enters the minds of logistics managers, warehouse owners, and manufacturers is: plastic pallets near me. Whether driven by convenience, cost-effectiveness, or immediate supply chain needs, proximity and availability matter.

From food and pharmaceuticals to automotive and retail, plastic pallets play a crucial role in moving goods safely and efficiently. Understanding why they’re preferred, how they compare to other pallet types, and where they’re used can help businesses make informed decisions that support both productivity and sustainability goals.

Why Plastic Pallets Are Gaining Ground

Traditionally, wood pallets dominated the shipping and warehousing industry due to their availability and low upfront costs. However, as companies began factoring in hygiene, longevity, and environmental considerations, plastic pallets started to take the lead in many sectors.

Durability and Longevity

Plastic pallets are known for their strength and resistance to wear and tear. Unlike wooden pallets, they don’t splinter, warp, or suffer from moisture damage. Many plastic pallets can last for years without needing repairs, even under heavy use. This durability makes them an ideal long-term investment for companies looking to reduce operational costs and improve supply chain efficiency.

Hygiene and Safety

Industries like food and pharmaceuticals require high levels of hygiene. Plastic pallets are easy to clean, non-porous, and resistant to bacteria, making them compliant with various safety standards. They’re often preferred in closed-loop systems or clean environments where cross-contamination could be an issue.

Uniformity and Performance

Unlike wooden pallets that can vary in size and construction, plastic pallets are molded to exact specifications. This uniformity ensures consistency in automated systems like conveyor belts, forklifts, and robotic handling. It reduces jams, increases efficiency, and supports precision in shipping operations.

Environmental and Sustainability Considerations

As environmental consciousness grows, companies are looking for logistics solutions that align with their sustainability goals. Plastic pallets provide a compelling advantage in this area.

Reusability

One of the most important benefits of plastic pallets is their reusability. Many can be used hundreds of times before they need to be recycled, which drastically reduces waste compared to single-use alternatives.

Recyclability

When a plastic pallet reaches the end of its lifecycle, it can be recycled into new pallets or other useful plastic products. This closed-loop recycling system helps reduce the environmental footprint of businesses that rely on heavy shipping and logistics.

Reduced Carbon Footprint

Because plastic pallets are lighter than wood, they can help reduce fuel consumption during transport. Lighter shipping loads mean lower emissions, contributing to a smaller carbon footprint over time.

Applications Across Industries

The question of plastic pallets near me arises across various industries for good reason. Their versatility and dependability make them a valuable asset in multiple sectors.

Food and Beverage

Strict hygiene regulations make plastic pallets the preferred choice for food manufacturers and distributors. They don’t absorb moisture, are resistant to mold and mildew, and are easy to sanitize between uses.

Pharmaceuticals

Plastic pallets are frequently used in pharmaceutical environments due to their cleanability and non-reactive surfaces. They are often used in climate-controlled or sterile environments where product purity is essential.

Retail and Grocery

Retailers often use plastic pallets for in-store displays and bulk transportation. Their neat appearance, ease of cleaning, and lightweight nature make them ideal for moving merchandise through stores and warehouses.

Automotive and Manufacturing

In manufacturing and industrial settings, plastic pallets support heavy loads and offer the durability needed for repeated use. They’re also used for storing sensitive electronic components since they can be made anti-static and resistant to chemicals.

Economic Impact of Choosing Plastic Pallets