#IBM Sterling Warehouse Management System enables you to:

Explore tagged Tumblr posts

Text

What is Supply Chain Execution (SCE) System? (Definition, List of Top Vendors)

The supply chain is an important term in business. However, executing it is a more challenging thing. This post discusses the software tools and lists the best Supply Chain Execution software that helps to automate tasks and run the supply chain. Also, you get to know about the benefits of supply chain execution and warehouse management system(WMS). It includes manufacturing, warehouse, transportation execution systems, and systems that provide visibility across the supply chain.

Definition of Supply Chain Execution

It is the process of effectively managing the supply chain. In other words, we can say supply chain execution is the process of providing the supply chain items where they are required most.

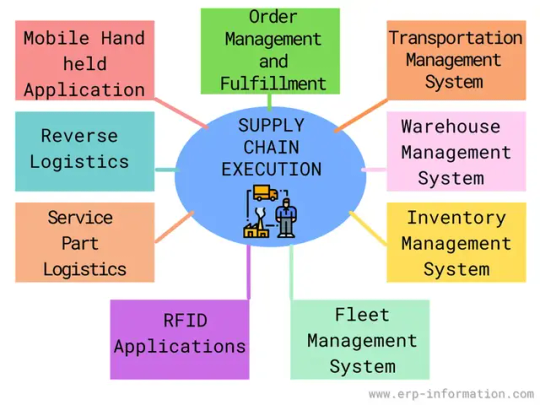

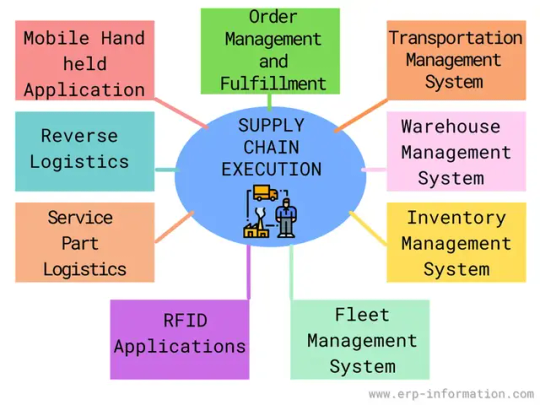

In this digital and technological era, numerous Enterprise Resource Planning Software and Enterprise Application software are available with an in-built Supply Chain Execution System. Many large organizations and small businesses are already leveraging these in-built systems to effectively manage their supply chain logistics. There are numerous tasks that an automated system for supply chain execution can do. Some well-known software for supply chain execution is transportation management software, warehouse management software, order fulfillment software, and global trade management software. All of this software, as mentioned above, is geared towards managing the supply chain execution process more conveniently. For instance, global trade management software allows business owners to manage the transportation and carriage of their products. Fleet management software enables corporate governors to control the shipment of their finishing goods locally. Inventory control tools allow a company to save money by achieving a leaner inventory model. These core technologies and many more may help the company automate the tasks related to Supply Chain Execution. The components that make up a typical SCE system The main components of an SCE system are order management, inventory management, transportation management, warehouse management, and production planning. Each component is designed to optimize the flow of materials through the supply chain and improve efficiency.

Supply Chain Execution Software

To correctly manage the task related to supply chain execution, we strongly recommend you to use the appropriate software. Top 10 SCE Software Solutions 1. Oracle Transportation Management Oracle TMS is a cloud-based supply chain management software that offers users a complete view of their transportation operations. It allows users to plan and execute shipments, track shipments in real-time, and optimize routes. 2. Manhattan Associates Warehouse Management Manhattan WMS is a warehouse management system that helps users to increase, - Productivity - Accuracy - Customer satisfaction - Revenue growth - Reduce operational costs 3. JDA Manufacturing Planning JDA Manufacturing Planning is a software application that allows users to plan and optimize production processes. It helps users increase production efficiency, reduce inventory levels, and improve customer satisfaction. 4. Infor LN Distribution Infor LN Distribution software application is designed to help users manage the distribution process. It allows users to track inventory levels, manage customer orders, and optimize route planning. 5. Kinaxis RapidResponse Kinaxis RapidResponse is a cloud-based software application that helps users manage the production process. It allows users to plan components that make up a typical SCE system order management component designed to manage customer orders, track inventory levels, and optimize production processes. 6. IBM Sterling Order Management IBM Sterling Order Management software application is designed to help users manage customer orders. It allows users to track inventory levels, manage customer accounts, and create sales reports. 7. Epicor Prophet 21 Epicor Prophet 21 software application is designed to help users manage the production process. It provides users with the ability to, schedule production Auto-generate purchase orders Optimize inventory levels Improve customer satisfaction 8. Microsoft Dynamics AX Trade & Logistics Microsoft Dynamics AX Trade & Logistics software application is designed to help users manage the production process. It allows users to track inventory levels, manage customer accounts, and generate sales reports. 9. NetSuite SuiteLedger NetSuite's SuiteLedger is an accounting software application that allows users to track their financial transactions. It helps users manage their cash flow, create financial reports, and track their spending. 10. Infor CloudSuite It is a cloud-based software application that offers users a complete view of their transportation operations. It allows users to plan and execute shipments, track shipments in real-time, and optimize routes. In addition, it allows users to manage their financial transactions, create financial reports, and track their spending. This is a list of some of the most popular SCM software applications today. Each software application offers users different features and benefits. Numerous automated software for the supply chain execution can govern the overall manufacturing operations and supervise distribution processes like receiving and fulfilling orders and order shipment. Application software for supply chain execution works in synergy to create harmony between manufacturing operations required to design a product usable by the customer. Let's look more in-depth at the software applications used to manage the product-related information within the operations.

Automated System for Warehouse Management

Smartly managing the inventories required by the business has a long-term impact on business operations. Well-Known corporate leaders emphasize the importance of effective inventory management in these words, Keeping too much inventory reduces the liquidity of money. But, on the other hand, too few products mean stocks, which leads to the loss of too much capital investment. An automated tool for Warehouse Management can benefit the proper management of finishing goods inventory. The automated warehouse management system ensures the right amount of stock available in the right place. The right place may vary from situation to situation. For example, the right place may be the manufacturing facility, distribution center, warehouse, or anywhere. The most basic warehouse management system lays the foundation for the day-to-day business activities that are crucial to warehousing, including - Receiving of order - Framing a strategy for the practical completion of the order - Transporting finishing goods from the manufacturing facility to an appropriate place - Picking, procurement, and shipping of the order The below image shows the supply chain execution application focused on by industry.

Feature list An advanced, fully automated warehouse management system may include, Consistent Upgradation of Inventory The automated warehouse management system continually upgrades the inventory and calls for the transportation of the finishing well from the manufacturing facility to the pickup area. It keeps transporting the inventory so pickers won't run out of stock. Capable of Handling Large Quantities of Returns For the last few years, there has been a drastic increase in online shopping; and there is an increase in customers returning items for various reasons. The automated warehouse management systems have an in-built feature to deal with many returns. Cyclic Inventory Counting Automated WMS generally comes with support for the usual inventory accounting process. However, this pre-defined process involved the most accurate inventory counting systematically. Coordination with the Production Team The warehouse management system consistently engages with the production team via a handheld RF device and voice technology.

Improvement in the Pre-Existing Warehouse Management System

The warehouse management system is vital in effectively managing the business cycle. As the need for a more robust and dynamic WMS comes into play, more automated systems were developed in the past to address the flaws of the pre-existing WMS system. Various applications were developed and deployed to reduce the shortcomings of the pre-existing WMS. These well-known applications are slotting, yard management systems, and labor management systems. Slotting Software The autonomous slotting software algorithm is delicately designed to precisely calculate the fast-moving items by mapping the warehouse, velocity of orders, and order mixes. The information gleaned through this automated system is then leveraged to determine where each product should be placed to frame the most effective and prominent picking operation. For instance, fast movers should be placed at a very optimum distance from the shipping area, and slow movers can be recognized at long distances from the storage place. Companies should place similar items at an appropriate site to minimize pickup errors. Yard Management System Richard Kirker, SAP's solution owner for warehouse management, expressed the importance of a yard management system in these words, "Yard management system solely relies on the concept of WMS, and Visibility is the greatest issue." The yard management system is a valuable and prominent tool to bridge the warehouse management system and transportation gap. Business owners can easily leverage information the yard management system revealed to analyze the carrier's delivery performance. Labor Management Tool The warehouse management system governs all manufacturing activities and is an automated tool for labor management to manage workers' requirements efficiently. Labor management automated tools precisely monitor the performance of warehouse personnel. Aside from all these peculiar features, the labor-management tool provides real-time feedback to the management tool.

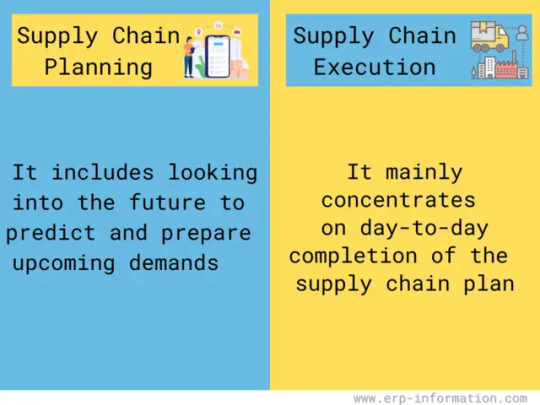

What is Supply Chain Planning?

Supply chain planning helps map the manufacturing process, logistics, and inventory required to meet future demand. It balances product supply and customer demand by combining pricing strategy, forecasting, and inventory management. Supply chain planning v/s supply chain execution

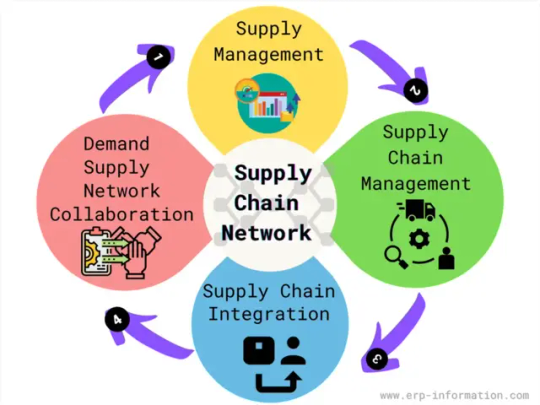

How do you build a good supply chain network?

Before executing any work, it is crucial to build the network. Following are the few stages of evaluating a supply chain network.

- The first stage is supply management. It contains tier-one vendors. Interaction with vendors is through documentation like purchase orders and releases. - The second one is supply chain management. It contains tier-two vendors. Interaction with vendors is through documentation with some data sharing. - The third one is supply chain integration. It boosts the members in supply to collaborative involvement. At this level, communication will be transactional with the exchange of data and information. - The last one is demand-supply network collaboration. In this stage, critical information flows through the entire supply chain simultaneously. Designing of the supply chain network Here are a few tips for building and designing a supply chain network. - Have a clear idea about your goals: Clearly define the following things. - The demand for customer service level in the market - Mode of transportation that should balance cost and performance - Number of warehouses that you must have - Amount of inventories that you must have for each product - Assign a particular warehouse to supply products for a specific customer - Collect the supporting data: Collect essential data like product demand in the market, transportation cost, inventory and warehouse cost, lead times during transportation, etc., for a better decision. - Choose a good tool: It is crucial to have a good supply chain network optimization tool. Choose the tool carefully so that it should address all the decisions you are required to make and reflect your business. - Inspect the supply chain network: Keep on analyzing your supply chain network. - Keep on implementing: It is a never-ending process. So keep on revising and implementing the supply chain network.

Benefits of Supply Chain Execution

In this today's revolutionary era, supply chain execution has become crucial for companies to remain competitive in an excessively saturated market. Savvy consumers further intensify the situation as he expects an elegant product from the manufacturers, fast delivery, and a maximum level of accuracy. An organization can benefit from an advanced supply chain execution system. Enhance Productivity Automated tool for supply chain execution generally comes with Radio Frequency picking and voice-activated commands. The time consumed on manual processes is reduced by one-half through these automated tools. Productivity is further enhanced by the in-built features of automated supply chain execution explicitly designed to address an organization's specific needs, such as retail, manufacturing, CPG (example of CPG), and distribution planning. Optimize Cost and Consolidates Assets An advanced supply chain execution system appreciates the net worth of an organization's assets and reduces the production cost across every aspect of the supply chain logistics lifecycle. With the most potent and elegant tool designed explicitly for streamlining operations, you can efficiently enhance labor productivity, leverage equipment, and improve production capacity. Sophisticated transportation equipment reduces transportation time and operating expenses. On the other hand, an inventory management system reduces reliance on excess inventory. Improve the Quality of Manufactured Goods Small and large-scale organizations and manufacturing firms can enhance the - Overall order accuracy - Reduce the cost incurred on an error correction by the proper implementation of an advanced automated supply chain execution system that includes a computerized system for - Warehousing - Transportation - Billing.

Conclusion

For manufacturers to corporate governors looking for a way to achieve operational excellence, it is strongly recommended to leverage the game-changing capabilities of advanced supply chain execution. The advanced supply chain execution system generally comes with the in-built feature to reduce complexity, reduce operating expenses, and boost overall revenue and profitability. Read the full article

0 notes

Text

INTERVIEW Alex Alexander of Yoox Net-A-Porter on innovation

It is only two years since the merger of Yoox and Net-a-Porter but since then much has been done to integrate these two fashion retailers, which sell luxury in-season fashion and out-of-season discounted goods as well as developing flagship ecommerce sites for luxury brands. Listed on the Milan stock exchange, the Yoox Net-a-Porter Group has headquarters in Bologna, Italy – where Yoox is based – as well as in London, where Net-a-Porter has its roots. Commercial and tech teams are based in both locations. The Group has a turnover of almost £2bn and set its sights on double-digit growth through to 2020. As well as boosting sales through its multi-brand in-season Net-a-Porter and Mr Porter sites the Group aims to increase sales of multi-brand off-season luxury fashion from its original Italy-run Yoox.com and the Net-a-Porter launched site, The Outnet. Its expertise in luxury content and customer service will further be brought to the fore through partnerships with luxury brands for which it designs and operates flagship ecommerce stores. It currently operates 40 flagship stores for brands including Armani and Chloe using technology from the Yoox arm of the business. It plans to deepen the digital opportunity for these brands through development of omnichannel capabilities, native apps services, editorial content, tailored customer service, and further creative and digital projects.

Core platform

Since the merger, the group has been reorganising its operations around three distinct parts of the business – in season, off season and flagship stores. A core cloud-based platform has been developed with IBM using Yoox’s proprietary software and IBM WebSphere Commerce. This will provide a robust and scalable foundation for the different ecommerce sites within the business as well helping to ease post-merger systems integration. Running all of the businesses on one platform also provides a single focal point for in-house technology development. In addition, working with IBM gives YNAP access to the IBM Innovation Lab and the Fashion & Luxury Innovation Committee. The core commerce platform is underpinned by product information management, IBM Sterling Order Management and back-end systems including ERP and warehouse management systems. “Decoupling the front end from the platform means we can create the differentiators and maintain the DNA of the brands while we focus on the platform to just expose the services, so if you look at Net-a-Porter or Moncler they are pixel perfect but they are all different, but that is all experience, UI and UX,” says Alex Alexander, CIO, Yoox Net-a-Porter Group. He adds: “They all use the same sort of capability but not all brands want the same features, certain payment methods or checkout features.” Aspects such as these are determined at the brand level, based on the features they want to enable for customers, along with regional aspects such as payment methods. UI and UX can further localise the experience. The idea is to build only once with a set of APIs enabling the core functionality and features to be used many times in different ways across the various brands. This enables brands to differentiate and provide the desired experience for their own customer base, whether it is via a mobile app, m-web, smart watch or in-car device. In addition, the front-end customer experience can be differentiated by country or even by customer. One core global platform also means that the tech teams can develop solutions for specific brands with functionality added into the core platform and then made available to all. Funding this five-year growth plan is an investment of more than £462m (€500m) in technology and logistics across the group, including a new Tech Hub in London which opened at the end of June.

The Tech Hub

The Tech Hub, in London’s White City, brings together 500 developers from two separate offices in the capital, with space for a further 100 recruits, Alexander explains. It works closely with the group’s other tech hub in Bologna, which also has 500 developers. They work on projects across the business but each has its own areas of expertise: Bologna is a centre of excellence for fulfilment optimisation, warehouse management tools and techniques, and omnichannel, order management and ERP, while London focuses on mobile, content, visual merchandising and artificial intelligence (AI). Each area of functionality has a lead, such as the owner of payments functionality, but the team working on it may be spread across both locations. Data is a global team effort, for example, but some of the niche smart data elements are being worked on in London. AI’s initial base was in the capital, but Alexander believes that within 2 years it will be applied across every part of the business as niche technology uses are matured in one centre and then migrated to the rest of the organisation. For the past two years, the two Tech Hubs have been working closely together on a number of projects and co-locating project teams between Bologna and London. Alexander explains: “We tried to encourage face-to-face working in the early days of 2015/16. It was essential to building a global team you have to know people and interact with them.” He adds that some projects were deliberately chosen in 2016 to ensure people from both locations had to work together. A mobile initiative, for example, was set up in a similar way to a start-up so the team had to work out their own co-location arrangements and complete the product development at the earliest possible time. The group has invested heavily in video and conferencing tools at the London hub, as well as in collaboration apps and unified communications tools, to enable continued close working across project teams wherever they are located. “We tried to encourage face-to-face in the early days but now the teams are effectively working as a global team so we can use collaboration tools and video tools to maintain that collaboration,” says Alexander “The notion of one team is so important to me,” he adds. “Because as a global team, unless we think and act as one team, we won’t be effective to support a global business, and that is one of my key priorities, to continue to reinforce this one team mindset.” Alexander aims to put YNAP at the forefront of technology innovation in luxury retailing and to create a team that’s able to develop in a sustainable way wherever particular project teams are based – and that may extend to further tech hubs in different locations in the future. He comments: “I want to have more technology hubs because of the diversity of the talent and the speciality we can get from different locations is key. We have cracked the notion of creating a global technology team and the next focus is execution.

Innovating with AI

“AI is one of the technologies which will transform our business. Every decade there is a game-changing technology which comes to the landscape and I see AI as one of those game changers which will help us give our customers a personalised experience and not look at customers as a segment but as an individual,” says Alexander. YNAP plans to use AI in areas such as returns optimisation, pricing optimisation and targeted marketing enhancement and its focus this year is natural language search.

Three pillars

The tech hubs are concentrating on three pillars for the business growth: personalisation, omnichannel and mobile. Underlying much of this is machine learning and AI. “Personalisation is key to creating inspiration for the customer,” says Alexander explaining how the Group plans to enable one-to-one personalisation of every aspect of customer interaction, be it on web, mobile, apps or other touchpoints. He believes that true personalisation means understanding each customer, their location and their mission. His stated goal is to enable one-to-one personalisation in terms of assortment, outfit curation, experience, content and pricing. “The way we are trying to achieve our personalisation objective is through AI and machine learning and key to that is smart data,” he adds. The Group has view of lots of data on customers from its own sites, in the form of how they behave and their searches, as well as from external sources, including the images they viewed on Instagram. However, as Alexander points out: “Only AI and machine learning can actually process all kinds of data because that data is partly structured. But the majority of it is unstructured data and putting all of that together is what our AI and personalisation strategy is all about. That is the key game changer for us in being able to create the personalised experience for our customers.” Further external data, such as the weather, the customer’s current location and the location of the occasion for which they are buying attire can be combined with this data to give a fully personalised outfit recommendation experience. He comments that there is no point sending someone an offer for a fur coat when they are spending Christmas in Australia. YNAP is using IBM Watson to build, train and test a natural language engine which will allow customers to speak or type into a mobile app without having to adhere to specific rules. Alexander gives examples of a customer wanting to buy a skiing outfit from a specific brand or someone saying they want to buy a gift for their husband. “We’re building the engine and testing it and this can then be exposed to the front end,” he says. How the different sites utilise the technology will be up to them. Another feature being developed with AI is an outfit builder which uses personalisation data held by the company, such as the customer’s clothes size and preferred brands. The outfit builder can be triggered by a retailer, personal shopper or by the customer themselves with different forms of interaction added at the front end. Visual search is also being investigated. This enables a shopper to upload an image of someone and say that they want to purchase a similar outfit. The engine will then build them an outfit based on that photograph offering garments sold by the retailer or the brand.

Omnichannel

Omnichannel development is providing opportunities for the flagship stores to fulfil customers’ need for speedy omnichannel solutions and enabling them to pick up items from anywhere in the world and return them either to the same store or to another one in a different country. Customers will also be able to order certain brands from Net-a-Porter and pick up their purchase from the brands’ own shops. This ‘omni-stock programme’ uses IBM Sterling Order Management to provide the Group with a single, global view of stock across the distribution centres of Yoox, Net-a-Porter and the brands’ own stores. Distribution centres across the Group are being repurposed in line with the in-season and off-season businesses, and a hub and spoke model implemented so stock efficiencies can be increased as well as growing the level of full-price sell-through. The model also future proofs the movement of goods against possible post-Brexit customs duties. The omnichannel functionality will in addition enable more flexible fulfilment options and services, including same-day delivery in New York, London, Milan, Dubai, Shanghai and Tokyo. It will also enable the flagship stores to have a better view of customers and link their online and offline behaviour. Yoox and the flagship stores have already migrated to IBM Sterling Order Management with Valentino becoming the first brand to go live with the first phase of omnichannel functionality in September. Net-a-Porter and Mr Porter have moved across to the Yoox Group’s ERP and will migrate to the new OMS in 2018, when they also move to the full commerce platform. The Outnet will migrate to the full platform at the end of this year. Italian brand Moncler was the first of the flagship stores to run on the commerce and content part of the platform when it went live this July.

Mobile

Mobile apps are becoming increasingly important for YNAP. The number of brands selling via apps is growing every financial quarter and now accounts for 50% of all sales, compared with last year’s 40%. The company is investing in iOS and Android apps to meet the varying demands of customers in all the countries in which it does business. “We can really deliver an inspirational experience through mobile,” says Alexander. The company has recently added messaging via mobile apps and screen sharing, whereby a personal shopper can share information with a customer. YNAP has ambitious plans for the future as it moves towards becoming a mobile-only company, investing in mobile frameworks – to enable speedier deployment and faster apps as well as new services for existing apps – and developing AI and natural language capabilities. For example, customers when travelling will be able to ask what’s trending and what the weather is like at their destination and then collect their order from the closest store. The Group’s Tech Hubs need to balance innovation and the core platform with the needs of each individual company as well as having an understanding of the end customers. If a number of sites are experiencing similar issues, a single functionality can be developed for the core platform but deployed in different ways to match customer behaviour on the individual sites. The level of cart abandonment, for example, was lowered through subtle messaging which showed the shopper the items that had been left in the basket the next time they visited the app. “The tone of the message was such that it was not seen as a random message,” Alexander says. An R&D team is looking further ahead to explore technologies which have yet to be commercially proven, such as augmented reality and shopping from physical shop windows when the store is closed. It is also investigating new use cases for proven technology such as visual recognition in warehouses. “It’s a fail-fast approach,” Alexander comments. As new technologies and business uses are developed, refined, tested and proven, they are added to the core platform and so made available to all of the retailers and brands. Integration plans and cross-group working certainly seem to be working for the business. In the first half of its financial year its net revenues hit £923m (€1bn) for the first time, an increase of 19.5% on an organic basis compared with £828m (€897m) in the first half of 2016. YNAP has successfully launched Moncler as the first online flagship store on the new front-end platform as well as signing a multi-year global agreement for the new Ferrari online flagship store. Over the same period it recorded 400 million site visits, compared with 342.7 million in the first half of 2016, and 4.5 million orders (3.9 million) with the average order value increasing by €10. Active customers are on the rise, too, hitting the 3 million mark in the first half of 2017 (2.6 million). With more parts of the business migrating onto the new platform and the synergies that brings, along with optimisation, innovation and engagement, the Group is set to further establish itself in the minds of its customers worldwide, while new markets and the rise of personalised experience on mobile devices ensure its sites remain close at hand.

A longer version of this interview first appeared in InternetRetailing Magazine in September. Click here to explore the series of magazines.

Image author: Gabriel de la Chapelle

Image courtesy of Yoox Net-A-Porter

from Themes https://ift.tt/2LCbPIn via IFTTT

0 notes