#Inkjet Batch Coder

Explore tagged Tumblr posts

Text

Hidden Costs of Choosing the Wrong Industrial Coding Machine

Understand the many applications of industrial coding with Technopack's inkjet coders. These machines deliver high-speed, accurate printing for batch numbers, expiration dates, and barcodes, supporting diverse production lines across food, pharma, and logistics sectors.

1 note

·

View note

Video

youtube

Auto L sealer machine with Shrink tunnel machine

Royal Inks & Equipments Pvt. Ltd.

Pioneering Excellence in Printing Inks & Industrial Machinery Since 1994.

At Royal Inks & Equipments Pvt. Ltd., we are a trusted manufacturer and supplier of high-quality printing inks and industrial coding & marking solutions. With over 25 years of industry expertise, we have been at the forefront of innovation, precision, and reliability in the printing and packaging industry, catering to both domestic and international markets.

Our Product Range 🔹 Printing Inks: ✔️ Marking Inks – Ensuring long-lasting impressions and superior adhesion. ✔️ Water-Based Flexographic Inks – Ideal for eco-friendly, high-speed printing applications. ✔️ Solvent-Based Poly Inks – Designed for flexible packaging and high-quality prints. ✔️ Lino Inks & Offset Inks – Delivering sharp, vibrant, and consistent color output. 🔹 Industrial Coding & Packaging Machinery: ✔️ Handy Coder Machines – Reliable for batch coding and marking. ✔️ Batch Coding & Inkjet Coding Machines – Enabling seamless product labeling and traceability. ✔️ Auto Coder Machines – Designed for automated, high-speed printing requirements. ✔️ Filler & Packing Machines – Enhancing efficiency in packaging operations.

0 notes

Text

Batch Coding Machine: Revolutionizing Efficiency in Manufacturing

In today’s rapidly evolving manufacturing landscape, batch coding machines have become indispensable tools for businesses striving to maintain accuracy, efficiency, and compliance. These machines ensure that products are labeled with critical information, such as batch numbers, expiration dates, and barcodes, which is essential for both consumers and regulatory agencies. Below, we dive deep into the world of batch coding machines, exploring their types, functionalities, benefits, and how they are transforming industries worldwide.

What is a Batch Coding Machine?

A batch coding machine is a device designed to print or emboss essential information on products or packaging. This information includes manufacturing dates, expiration dates, batch numbers, and other identifiers that help track products throughout the supply chain. These machines are widely used across industries such as pharmaceuticals, food and beverages, cosmetics, and electronics.

With advancements in technology, batch coding machines now incorporate features like high-speed printing, automated adjustments, and error detection, making them more reliable and efficient than ever.

Types of Batch Coding Machines

1. Inkjet Batch Coding Machines

Inkjet printers are among the most common batch coding solutions. They use tiny nozzles to spray ink onto surfaces, creating clear and precise codes. These machines are suitable for high-speed production lines and can print on a variety of surfaces, including paper, plastic, glass, and metal.

Advantages:

High-speed printing

Suitable for various surfaces

Low maintenance requirements

2. Laser Batch Coding Machines

Laser coding machines use focused laser beams to etch information onto surfaces. These machines are ideal for industries requiring permanent and tamper-proof markings.

Advantages:

Permanent markings

No need for consumables like ink

Eco-friendly and cost-effective over time

3. Thermal Transfer Batch Coding Machines

Thermal transfer printers use heat to transfer ink from a ribbon onto the surface of a product or label. These machines are commonly used in industries where high-resolution printing is required.

Advantages:

High-quality prints

Ideal for flexible packaging

Durable codes resistant to smudging

4. Contact Coding Machines

Contact coders use a stamping mechanism to transfer ink onto a product. Though older than other methods, they are still used in industries where simplicity and cost-effectiveness are priorities.

Advantages:

Simple operation

Low initial cost

Reliable for low-volume production

Key Features of Modern Batch Coding Machines

1. Versatility

Modern batch coding machines are designed to handle a wide range of materials, including cardboard, plastic, glass, and metal. This versatility makes them suitable for diverse industries.

2. Integration with Production Lines

Advanced models can seamlessly integrate with production lines, ensuring that coding operations do not disrupt workflow.

3. User-Friendly Interfaces

Most machines now come equipped with touchscreen interfaces and intuitive software, allowing operators to easily adjust settings and monitor performance.

4. Compliance with Regulations

Batch coding machines ensure adherence to regulatory standards, such as those set by the FDA, ensuring that products meet legal requirements.

Benefits of Using Batch Coding Machines

1. Improved Traceability

Batch coding ensures that products can be tracked from production to distribution, which is critical for quality control and recall management.

2. Enhanced Brand Reputation

Accurate and professional-looking batch codes enhance the perceived quality of a product, boosting customer confidence and brand loyalty.

3. Cost Savings

By automating the coding process, manufacturers can reduce labor costs and minimize errors, leading to significant cost savings over time.

4. Increased Efficiency

Modern machines operate at high speeds and require minimal supervision, allowing businesses to optimize their production workflows.

Applications of Batch Coding Machines

1. Pharmaceutical Industry

In the pharmaceutical sector, batch coding is crucial for ensuring product safety and compliance. Machines print batch numbers, expiration dates, and barcodes on medicine bottles, blister packs, and cartons.

2. Food and Beverage Industry

Batch coding machines help maintain food safety by providing essential information, such as expiry dates and batch details, on packaging.

3. Electronics Industry

In the electronics industry, batch coding is used to label components with serial numbers and manufacturing details, ensuring proper assembly and quality control.

4. Cosmetics Industry

Batch coding machines play a vital role in labeling cosmetic products with lot numbers and expiration dates, meeting both consumer demands and regulatory requirements.

Choosing the Right Batch Coding Machine

When selecting a batch coding machine, consider the following factors:

Type of Material: Ensure the machine is compatible with the materials used in your products.

Production Speed: Choose a model that matches your production line’s output.

Budget: Factor in both initial costs and long-term operational expenses.

Regulatory Compliance: Opt for machines that meet industry-specific standards.

Ease of Use: Look for user-friendly features like touchscreen interfaces and automated adjustments.

Future Trends in Batch Coding Technology

1. AI Integration

Artificial Intelligence is being integrated into batch coding systems to enhance error detection and predictive maintenance.

2. Sustainability

Manufacturers are focusing on eco-friendly solutions, such as laser coding and biodegradable inks, to reduce their environmental impact.

3. IoT Connectivity

The Internet of Things (IoT) allows machines to be connected to central systems, enabling real-time monitoring and data analysis.

Conclusion

Batch coding machines are essential for modern manufacturing, offering unparalleled efficiency, accuracy, and compliance. By investing in the right batch coding solution, businesses can streamline their operations, enhance product traceability, and build consumer trust.

0 notes

Text

Batch Coding Machine Manufacturer | SH Hitech Solutions

The Complete Guide to Batch Coding Machines: What They Are, How Much They Cost, and Top Manufacturers

By admin / October 18, 2024

In this guide, we’ll break down everything you need to know about batch coding machines, including what they are, how much they cost, and which companies make the best ones. We’ll also highlight SH Hitech Solutions, a leading provider of batch coding machines.

What is a Batch Coding Machine?

A batch coding machine is a device that prints essential information like batch numbers, manufacturing dates, expiry dates, and other details on product packaging. These machines are widely used in industries like food, beverages, pharmaceuticals, cosmetics, and electronics. The main goal of batch coding is to ensure products are easy to track and trace, which helps in quality control and regulatory compliance.

Why Are Batch Coding Machines Important?

Batch coding machines are crucial for several reasons:

Compliance: Many industries are legally required to print batch numbers and expiry dates on their products.

Quality Control: If there is an issue with a product, batch codes help companies trace the faulty product back to its source.

Consumer Trust: Accurate labeling gives customers confidence in the products they buy.

Types of Batch Coding Machines

There are different types of batch coding machines available, each designed for specific uses:

Inkjet Coding Machines: These machines spray ink onto the product’s surface. They can print on various materials like plastic, glass, and metal.

Laser Coding Machines: Instead of ink, laser coders use a laser beam to print information. The print is permanent, making it ideal for high-end or durable products.

Thermal Transfer Overprinters (TTO): These machines are commonly used for flexible packaging, like plastic wrappers or foils. They offer clear, high-quality printing.

Hot Stamp Coders: These coders use heat and pressure to print codes. They’re often used for simpler printing jobs, like date stamping.

Features to Look for in a Batch Coding Machine

When buying a batch coding machine, here are some important features to consider:

Versatility: The machine should be able to print on various surfaces like paper, plastic, or metal.

Speed: If you have a high production rate, you’ll need a machine that can print quickly without slowing down your operations.

Durability: A sturdy machine will last longer and need fewer repairs.

Ease of Use: Choose a machine that is easy to set up and operate, so your staff doesn’t need extensive training.

Compliance: Make sure the machine meets industry standards and regulations.

How Much Does a Batch Coding Machine Cost?

The batch coding machine price can vary based on the type of machine and its features. Here are some factors that affect the price:

Type of Machine: Inkjet machines are generally cheaper than laser machines. However, inkjet machines require consumables like ink, which adds to the running cost.

Technology: Advanced machines like laser coders or thermal transfer printers cost more but offer better quality and longer-lasting prints.

Speed and Capacity: Machines that print faster and handle higher production volumes tend to be more expensive but are worth the investment for large-scale operations.

Customization: Some machines offer extra features like different fonts, barcodes, or integration with other production systems, which can increase the price.

On average, a basic batch coding machine can cost anywhere from a few hundred to several thousand dollars, depending on these factors.

Leading Batch Coding Machine Manufacturers

If you’re looking to buy a batch coding machine, it’s important to choose a reliable manufacturer. Here are some of the top batch coding machine manufacturers:

SH Hitech Solutions: A leading provider of batch coding machines, SH Hitech Solutions offers a wide range of coding machines suited for various industries like pharmaceuticals, food, and beverages. Their machines are known for their durability, precision, and easy operation.

Videojet Technologies: This company is well-known for offering a variety of industrial coding solutions, including inkjet and laser coders.

Domino Printing: Domino is a global manufacturer of batch coding machines with a reputation for high-quality products.

Linx Printing Technologies: Linx provides a range of inkjet and laser coders, known for their long-lasting performance and user-friendly interfaces.

Markem-Imaje: This manufacturer offers a variety of batch coding solutions, including inkjet, laser, and thermal transfer printers.

Why Choose SH Hitech Solutions?

When selecting a batch coding machine, you want a company that provides not only the right product but also excellent support. SH Hitech Solutions stands out for several reasons:

Tailored Solutions: They offer batch coding machines customized to meet your specific needs.

Industry Expertise: With years of experience, they understand the challenges businesses face and offer solutions that work.

Customer Support: SH Hitech Solutions provides full support, from installation to maintenance, ensuring your machine runs smoothly.

Affordable Options: They offer a range of machines at competitive prices, making them a great choice for businesses of all sizes.

Batch Coding Machine Manufacturers in India

India is home to several manufacturers producing high-quality batch coding machines. Batch coding machine manufacturers in India offer solutions that meet both local and international standards, making them a great option for businesses looking for affordable yet reliable machines. Some of the top batch coding machine manufacturers in India include:

SH Hitech Solutions: Known for their innovative and reliable coding machines, SH Hitech Solutions is a trusted name in India.

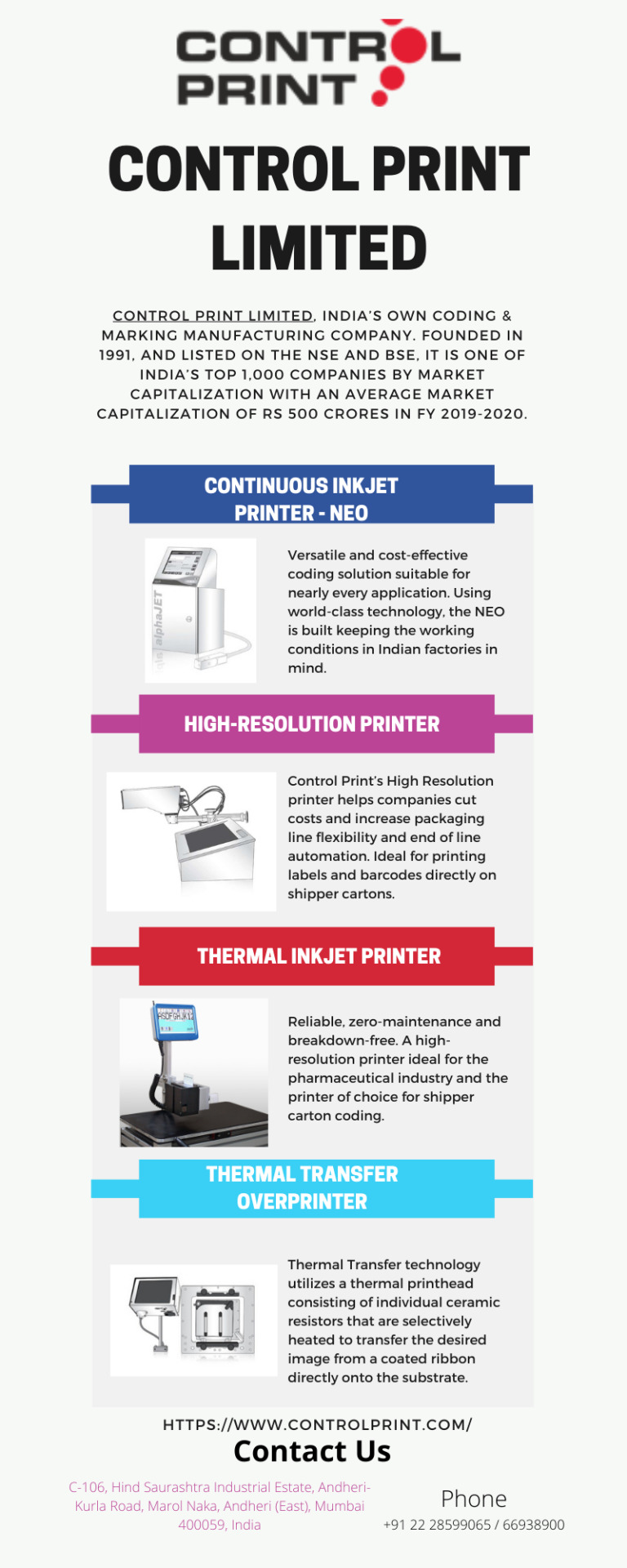

Control Print: Another major player, Control Print offers a range of industrial coding machines designed for the Indian market.

Conclusion

A batch coding machine is an essential tool for any business that needs to print batch numbers, manufacturing dates, or other key information on their products. These machines ensure compliance with legal standards, improve product traceability and boost customer trust.

By choosing the right machine, such as those offered by SH Hitech Solutions, you can streamline your production process while ensuring that your products are properly labeled. Whether you’re a small business or a large enterprise, investing in a high-quality batch coding machine is crucial for long-term success.

If you’re looking for reliable and affordable batch coding machines, consider SH Hitech Solutions, one of the leading batch coding machine manufacturers in India.

#batch coding machine#batch coding machine manufacturer#batch coding machine supplier#batch coding machine in india

1 note

·

View note

Link

We are leading exporter, and supplier of Industrial Inkjet Printer from last 25 years. Industrial Inkjet Printer gives you high-quality prints. Offline Batch Coding is an important part in packaging design process. Our Batch Printing Machine, Batch Coding Machine Inkjet Printers are working on sophisticated date codes and traceability codes. It can apply on pouches, rigid plastic pots, cartons, plastic inserts, leaflets, labeling and much more. An automatic system with unique 15 digital serial number, 2D barcode, batch, expiry detail and many more.

#Industrial Inkjet Printer#Inkjet Coder#Industrial Printer#Batch Printing Machine#Batch Coding Machine#Winder Rewinder for Inkjet Printer Thermal Printer#Winding Rewinding Machine#Doctoring Rewinding Machine

1 note

·

View note

Link

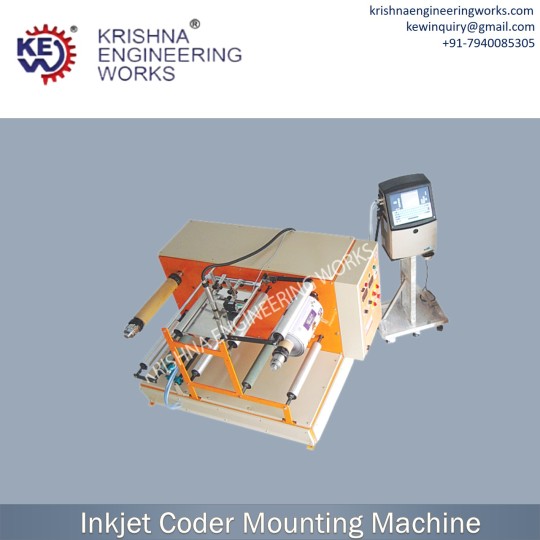

Inkjet Coder Mounting Machine manufacturers, suppliers, and exporters in Inkjet Coder Mounting Machine, in any paper, film, and foil conversing industries, the Winder/Rewinder (Doctor Machine) is used widely for online printing of Mfg. Dt., Exp. Dt. B. No. etc. using Inkjet printer or other contact coding machines from Roll to Roll at high speeds & then these printed roll are used in various packaging machines. For more information:

Website: krishnaengineeringworks.com

Email: [email protected]

Contact Us: +91-7940085305

#Inkjet Coder Mounting Machine#inkjet batch code printer#batch coder mini printer#batch printing machine#batch coding machine#manual batch coding machine#automatic batch coding machine#batch printer machine#batch coding printing machine

1 note

·

View note

Link

Inkjet Coder Mounting Machine manufacturer India, high-speed Inkjet Coder Mounting Machine for paper, film, foil converting industries. The Winder/Rewinder (Doctor Machine) is used widely for online printing of Mfg. Dt., Exp. Dt. B. No. etc. using Inkjet printer or other contact coding machines from Roll to Roll at high speeds & then these printed roll are used in various packaging machines. Also, we are a manufacturer of Bow Roll for flexible packaging, textile machinery industries.

#Inkjet Coder Mounting Machine#Batch Coding Machine#Batch Coding Machines#Batch Coding Machine Manufacturer#Batch Coder#Batch Printing Machine#Batch Printing Machines#Batch Printing Machine Manufacturer#Batch Printing#automatic batch coding machine#batch printing machine price#batch coding machine price#inkjet printer for batch coding#inkjet printer for batch coding s

0 notes

Photo

Control Print’s Thermal Transfer Overprinter is one of the easiest printers to set up, and it also integrates into almost any production line. When it comes to printing codes on fresh and frozen food packaging, not all printers can meet requirements like harsh conditions, sub-zero temperature, condensation, and varying product weights, while also maintaining strict hygiene standards.

The FMCG and Food Industries are known to have a large number of product variations. Therefore, generic-coding solutions can help frozen food units cut down costs while also reducing the need to stock different pre-printed packages. The Thermal Transfer Overprinter offers high-resolution coders that can print barcodes and product identity information directly onto generic packages.

0 notes

Text

Batch Coding Machine in Jaipur

Choosing the appropriate batch coding machine is the crucial factor for keeping products moving seamlessly through a supply chain. There are so many options available that it can be hard to decide which one you need.

Which Coding Machine is best suitable for your product?

Different industries require different kinds of batch coding machines in Jaipur that are capable of applying codes and print data to a variety of products and packaging. Other factors, like production line speeds and factory environment, also play a major role in determining which coding machine is best suitable for your product.

Major Industries And The Best Suitable Coding Machine

Different industries have different requirements. Regulatory requirements, traceability needs, and the ability to effortlessly find out more about products are just some of the major reasons why batch coding is becoming increasingly important.

Manufacturing Industries

In this industrial sector, batch coding machines in Jaipur are being used for different products. This sector includes cables, wires, automotive parts, aerospace, and electronic components.

This industry requires the application of codes and information on curved or irregular surfaces, which can be achieved using non-contact batch printing machines. Non-contact batch coding machines include continuous inkjet (CIJ), thermal inkjet (TIJ) printers, and laser coders.

Food And Beverage Sector

Batch Codes are vital for manufacturers and sellers of food and drink products. Batch Codes will vary depending on the product being sold, but, it typically consists of numbers or letters that represent information about the product, such as expiration date, manufacturing date, origin location, lot number, etc.

Pharmaceutical

Batch code printers hold a critical place in the pharmaceutical industry. Manufacturers need them to create labels with manufacturing dates, best before dates, anti-counterfeit Data Matrix codes, and regional legislative serialization codes. Adding codes to pharmaceutical products is crucial because it prevents drug abuse, misuse by the public, and over-prescription.

Final Thoughts

Industries rely on batch coding machines for efficient tracking of products. Batch Numbers are also capable of tracking products throughout production and distribution.

These particular machines give each unit a unique code so the consumers can trace back to the original manufacturer and even identify where the product came from if there has to be an incident that requires the recall of products.

Batch Numbers are also capable of tracking products throughout production and distribution.

Not only does this make tracking of faulty goods easier but, also makes withdrawal of the products simpler.

0 notes

Link

Linx Continuous Industrial Inkjet Printers

IJPN Technologies is an awarded Distributor, Supplier of Linx Printing Technology, Offer wide range of Printing, Coding & Laser Marking Technologies Solutions as per the industrial requirement, The Inkjet Printing offer by IJPN Technologies India(http://www.ijpntechnologies.com) include - Continuous Inkjet printers - Linx 5900 series continuous Inkjet Printer, Linx 7900 series continuous Inkjet Printer, Linx 8900 series continuous Inkjet Printer.

Inkjet laser Coder machine- inkjet batch coding machine, LINX SL 501, 50-WATT LASER CODER, LINX SL301 INDUSTRIAL LASER CODER, LINX SL1 COMPACT LASER CODER, LINX SL101 INDUSTRIAL LASER CODER, Linx FSL20 & FSL50.

Continuous ink & fluids supplier in New Delhi, India.

1 note

·

View note

Link

#Winder Rewinder Machine#Winding Rewinding Machine#Winding Rewinding Machine Manufacturer#Packaging Rewinding Machine Manufacture

0 notes

Text

What is a Batch Coding Machine? | Creature Industry

In the world of manufacturing and packaging, keeping track of product information is crucial. One essential tool that helps with this is the batch coding machine. But what exactly is a batch coding machine, and how can it benefit your business? Let's find out.

What is a Batch Coding Machine?

A batch coding machine is a device used to print important information, like manufacturing dates, expiry dates, batch numbers, and other data on products and packaging. This information helps with tracking products, ensuring quality, and meeting regulations.

Key Features of Batch Coding Machines

High Precision: Accurate and clear printing on various surfaces.

Versatility: Can print on plastic, metal, glass, paper, and more.

Ease of Use: Simple to operate.

Speed and Efficiency: Works quickly without sacrificing print quality.

Benefits of Using a Batch Coding Machine

Adding a batch coding machine from Creature Industry to your business can bring several benefits:

Regulatory Compliance: Easily meet industry standards and legal requirements.

Enhanced Traceability: Track products through every stage of the supply chain.

Improved Quality Control: Quickly identify and address production issues.

Brand Protection: Deter counterfeiting by adding unique batch codes.

Types of Batch Coding Machines

At Creature Industry, we offer different types of batch coding machines to meet various needs:

Inkjet Printers: Ideal for non-contact printing on uneven surfaces.

Thermal Transfer Overprinters: Perfect for high-quality prints on flexible packaging.

Laser Coders: Provide permanent marking solutions without the need for consumables.

Special Offers from Creature Industry

Take advantage of our exclusive offers on batch coding machines:

Free Consultation: Get expert advice on the best batch coding solution for your business.

Extended Warranty: Enjoy peace of mind with our extended warranty options.

Bulk Discounts: Save more when you purchase multiple units.

Why Choose Creature Industry?

Quality Products: We provide reliable and durable batch coding machines.

Exceptional Support: Our dedicated support team is always ready to assist you.

Competitive Pricing: Get the best value for your investment.

Contact Us Today!

Ready to improve your production process with a batch coding machine? Visit Creature Industry or contact us at:

Email: [email protected]

Phone: +123-456-7890

Address: 123 Industrial Area, City, Country

Investing in a batch coding machine is a smart move for any business looking to improve product identification and traceability. With Creature Industry, you get top-notch machines, exceptional support, and unbeatable value. Don’t miss out on our special offers—contact us today to find the perfect batch coding solution for your needs!

0 notes

Link

Semi & Fully Automatic Machine, Grouping Machine with heavy duty processing equipment and parts. This machine is Auto Seal & Shrink Machine after that to push button. Also, we are specializing in Batch Coder Machine with Industrial Inkjet Printer. Grouping Machine, Batch Coder Machine, Industrial Inkjet Printer, Packing Machine, Multi Packing Machine, Packing Machine Price, Automatic Packing Machine, Group Packing Machine, Krishna Engineering Works, Equipment and Parts, Bottle Packing Machine.

#Grouping Machine#Batch Coder Machine#Industrial Inkjet Printer#Packing Machine#Multi Packing Machine#Packing Machine Price

0 notes

Video

tumblr

India’s No 1 Round Bottle Labeling Machine Manufacturer

The Automatic Vertical Self Adhesive Sticker Labelling Machine Model NKSAL-120, is used for Full / Partial Wrap around Labelling on different size of round and other shape of containers. The Machine incorporates newest refined Servo controlled Label Dispensing system with outstanding sensing system for Label & container. For Container Sensing, it uses special background Suppression Sensor. The distinctive feature of this machine is “No change parts” required for different diameter of containers & adding up; tool less adjustment in order to adjust various size containers therefore down time is very less. It’s capable of Labeling up to 120 units per minute depending on Container diameter and label size.

The Automatic Vertical Self Adhesive Sticker Labeling Machine Model NKSAL-120 has elite single point synchronized speed control system. The Inbuilt Automated Label Length detection systems eradicate need for physically feeding & storing of Label Length data in memory & retrieving same every time for change of Label Size & re-starting machine. Thus result in reducing downtime as well as improving production.

Salient Feature of Machines

Quite a compact design as well as cGMP model.

Machine frame made using AISI 304.

Meticulously designed Superior Slider Label Applicator for better label alignment in both vertical and horizontal direction.

Specially designed reel mechanism to place the roll.

Breaking assembly to avoid variation during releasing of roll.

No Change Parts Required.

Tool Less Guide Rails for Easy Adjustment.

Wrap around mechanism to wrap the label on container.

Delrin Belt for Conveyor.

Auto Label Length Detection.

Accurate label dispensing.

100% Non-Proprietary Electronics & all electronics CE Certified.

Practically a maintenance free machine.

Provision for all type of online batch coding like Ink Coder, Cassette Coder, Hot Foil Coder, SS Metal Stereo Box for printing, thermal inkjet printer.

Contact NK Industries at following:

N.K industries Plot no 1521, Phase -3, GIDC Industrial estate, Vatva Ahmedabad , INDIA-Pin No: 382445 Instant online Quotation on whatsapp : +917940083141 E-mail: [email protected]

#labeling machine#sticker labeling machine#manufacturer#bottle labeling machine#Self-Adhesive Sticker Labeling Machine

0 notes

Photo

The Ultimate Range of Control Print’s Machines that Can Be Used for the Cable and Wiring Industry

Whether it is a plug, cable, or wire, accurate printing and reliable coding solutions are necessary to meet the Cable and Wiring Industry’s compliance standards. Whether they are Ethernet or electric cables, Control Print ensures a complete solution to provide identifiable, precise, and clear coding.

The most important and visible indicator of product quality in cables and wires is the legibility of a brand’s logo and text information, which thereby determines how a product is perceived. The Cable and Wiring Industry demands fast, consistent, and reliable coding. Read on to understand which printer is an ideal solution for printing and coding in the Cable and Wiring Industry.

0 notes

Photo

Batch Coding Machine - Automatic Batch Ink Coder

Industrial laser & inkjet batch coding for traceability & product identification. Rapid & cost effective lot and batch number printing for production lines.

0 notes