#LeanTools

Explore tagged Tumblr posts

Text

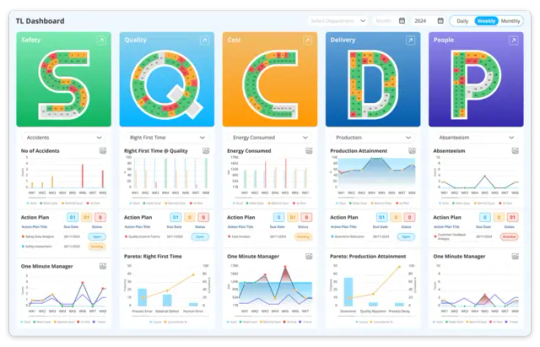

Experience the KPI dashboards operational leaders actually use!

If you want KPIs that live - not hide in spreadsheets , this is where you start. Not sure what to track, when to track it, or how to keep teams accountable? Forget static files and experience a live KPI planning and tracking dashboard built to keep every KPI clear, owned and actionable. With Data Point Balanced Scorecard, your KPIs stay visible and drive daily results.

Fill in the form to get started and see your KPI dashboard in action. Plan and execute with Data Point Today!

#lts#leantools#bsc#balancedscorecard#datapoint#leandatapoint#Datamanagement#digitalbalancedscorecard#balancedscorecardonline#KPIdefining#KPImanagement#DashboardsforKPItracking#kpitrackingmethods#kpitrackingandreporting#kpitrackingformanufacturing#kpitrackingsoftware#kpitrackertool#customKPIdashboards#customkpidashboardsoftware#kpidashboard#projectmanagementkpidashboard#realtimekpidashboard#RemoteKPItracking#huddleboard#huddleboardexamples#huddleboardtemplate#dailyhuddleboardlayout#performancetracking#performancetrackingexamples#trackindividualperformance

0 notes

Text

Lean Manufacturing Training – Boost Operational Efficiency and Minimize Waste

In today’s highly competitive industrial environment, Lean Manufacturing Training is essential for companies looking to optimize operations, eliminate waste, and improve overall productivity. This structured training helps teams at all levels understand and implement lean principles that reduce inefficiencies and create more value for customers.

Lean Manufacturing Training is based on the core principles of the Toyota Production System (TPS), which focuses on continuous improvement, value stream mapping, and waste elimination. Through this training, participants learn how to identify and eliminate the eight types of waste—overproduction, waiting, transport, overprocessing, inventory, motion, defects, and underutilized talent.

By implementing Lean Manufacturing Training, organizations benefit in the following ways:

Reduced production costs

Improved quality control

Increased employee engagement

Streamlined workflows and faster delivery times

Whether you are a manufacturer, service provider, or logistics company, Lean Manufacturing Training can be tailored to fit your specific operational needs. The training includes hands-on tools such as 5S (Sort, Set in order, Shine, Standardize, Sustain), Kaizen (continuous improvement), Kanban (visual workflow management), and Value Stream Mapping.

Lean Manufacturing Training is not just for large corporations; small and medium enterprises (SMEs) also gain tremendous value from lean implementation. By equipping frontline employees, supervisors, and managers with lean knowledge, organizations foster a culture of accountability and operational excellence.

Professionals who undergo Lean Manufacturing Training develop a keen eye for spotting inefficiencies, setting performance metrics, and driving improvement initiatives across departments.

Companies that invest in Lean Manufacturing Training often see long-term benefits such as increased profitability, better resource utilization, and enhanced customer satisfaction.

#LeanManufacturing#LeanManufacturingTraining#OperationalExcellence#LeanTools#WasteReduction#Kaizen#5S#ToyotaProductionSystem#ProcessImprovement#LeanImplementation

0 notes

Text

🌟 Become a Lean Practitioner and Lead the Change! 🌟

Are you ready to drive efficiency, eliminate waste, and improve organizational processes? Join our Live Online Instructor-Led Lean Practitioner Certification Training Program and gain the skills to implement Lean principles in your organization successfully.

Key Highlights:

✅ Instructor-Led Training: Engage in live, interactive sessions with expert Lean practitioners.

✅ Hands-on Learning: Apply Lean tools and techniques to real-world projects and case studies.

✅ Comprehensive Curriculum: Learn about Value Stream Mapping, 5S, Kaizen, Waste Reduction, and more.

✅ Global Certification: Earn an internationally recognized Lean Practitioner certification.

✅ Flexible Schedule: Learn at your own pace, with live online classes that fit your schedule.

💡 Why Choose Our Program?

Learn directly from experienced Lean professionals.

Access to exclusive study materials and resources.

Ongoing support and guidance even after the course ends.

Lifetime access to recorded sessions for review.

#LeanPractitioner#LeanCertification#ProcessImprovement#WasteReduction#Efficiency#LeanTools#5S#Kaizen#ValueStreamMapping#ContinuousImprovement#LeanTraining#BusinessExcellence#LeanThinking

0 notes

Text

Unlock the power of Lean principles and tools to deliver business value efficiently and sustainably! In part 2 of our series, delve into the 7 types of wastes, essential Lean tools like RCA, VSM, and JIT, and learn how to embody a Lean and Agile mindset for success. Don't miss out! Subscribe for more insights on Lean principles, Agile methodologies, and effective project management practices. #LeanPrinciples #LeanTools #AgileMindset

#LeanPrinciples#LeanTools#LeaninSoftwareDevelopment#LeanMethodology#leantoolsmeaning#jogoagilecoaching#jogocoaching#leanagileleadership#leantoolsppt#leantoolspdf#leanagilemeaning#leanagilemanifestoprinciples#leanagilecenterofexcellence#Whatisleanagile?#Leanagilemindset?#AgileandLean#pdcacycle#continuousimprovement#pdcafullform#pdcaisalsoknownas#continuousimprovementprocess#continuousimprovementexamples#pullsysteminmanufacturing#kanban#kanbanmethodology#kanbanpullsystem#kanbanpull#kanbanpullexamples#7typeofwastes#leanmethodology

0 notes

Text

Gemba Walk: An Important Lean Tool

Gemba Walk: An Important Lean Tool #gembawalk #lean #leantool

Gemba Walk: An Important Lean Tool Shubham Anil Jain Aditya Birla Fashion and Retail Limited Bangalore, India Email: [email protected] Introduction: A Gemba walk is a safety management technique that boosts productivity in the manufacturing sector. Gemba walks are the walks made by executives or managers to watch the production process and gather information from workers. The walk’s…

View On WordPress

0 notes

Photo

Learning to improving. Today we learn the factory material handling with lean approach. #leantools #leanmanager #busbar #busduct #continousimprovement #handling https://www.instagram.com/p/CHpFpHWJIwM/?igshid=16vexs682cdgw

0 notes

Photo

Lean Where You Least Expect It – Toilet Paper Origami - https://t.co/AiCdDXrUA3 #5S #LeanHotel #LeanTools #Management #ProcessConfirmation #Standard #Visualization #Management #Standards https://www.youtube.com/c/lifesang

0 notes

Link

5S is about organizing a workspace in order to maintain or – ideally – improve its efficiency. Read the correct way to use a simple Lean tool from creative safety.

0 notes

Text

25-11-2016

Afgelopen week zijn we op woensdag bij Vebego langs geweest om de benodigde informatie voor onder andere leantools als QFD, Spaghetti-diagram, 5S model & opzet van de databases te verzamelen. Uit de QFD waar de meeste aandacht naar uit ging, is duidelijk geworden wat het uiteindelijke beste gekozen alternatief gaat worden. Naast deze productieve werkdag sloten we deze af met elkaar met een A3 Sessie, hierin werd openlijk gesproken over eventuele verbeterpunten qua informatie en diverse duidelijkheden. Zo moeten wij duidelijk de mijlpalen in kaart brengen op de planning voor de opdrachtgever.

Belangrijkste gebeurtenissen afgelopen week (mijlpalen, gereed product)

● Werken aan verbeterpunten

● A3 methode met de facilitair manager en projectmanager.

● Planning Trello board aanpassen Aandachtspunten en mogelijke problemen

● Mijlpalen in planning Vebego duidelijk in kaart brengen

● Toevoegen van de projectmanager Niels Reedijk aan het nieuwe Trello board. Vooruitblik naar volgende week

● Verbeterpuntenverslag afronden

● QFD lijst met resultaat van alternatieven overleggen

● BPMN schema’s corrigeren en perfectioneren van alternatieven 1b & 2b

● Begin aan eindverslag

0 notes

Text

Your strategy isn’t failing. Your execution is! Big plans on paper mean nothing if teams can’t see them, own them and act on them every day.

Data Point connects boardroom goals to shop floor reality — combining strategic planning, strategic alignment and daily execution. With Hoshin Kanri for policy deployment, objective flow charts for structured strategic planning, line of sight alignment to link every role to your strategic goals, real-time KPI tracking and daily lean management tools — all in one place. This visibility and alignment turn your strategy into results. Stop hiding goals in slides — put them where action happens.

Make your strategic execution process the best with Data Point Balanced Scorecard.

#lts#leantools#bsc#balancedscorecard#datapoint#leandatapoint#Datamanagement#digitalbalancedscorecard#balancedscorecardonline#howDataPointdrivesstrategymanagement#strategymanagement#datadrivenstrategicplanning#datadrivenstrategyexamples#StrategicPlanning#XMatrixforstrategicclarity#strategicplanningtechniques#Createstrategicobjectives#strategymapping#Multipleinteractivedashboards#Advancedgoalsettingframeworks#Dataintegration#Comprehensiveperformancemanagement#strategicimplementation#Implementplans#KPIdefining#KPImanagement#DashboardsforKPItracking#kpitrackingmethods#kpitrackingandreporting#kpitrackingformanufacturing

0 notes

Text

Lean Strategy Implementation: Transform Your Business with Seicho Consulting

In a rapidly evolving world, operational excellence is no longer a luxury—it’s a necessity. Whether you’re a large manufacturer or a growing enterprise, the need to deliver faster, smarter, and leaner is universal. That’s where Lean Strategy Implementation by Seicho Consulting comes in.

At Seicho, we don’t just help you remove inefficiencies—we help you reshape your business to thrive.

💡 What is Lean Strategy?

Lean is more than a toolbox—it’s a strategic umbrella that shields your business from the constant “rain” of unproductive processes, operational waste, cost overruns, safety risks, and quality issues.

Implementing a Lean strategy transforms your organization into a high-efficiency, value-delivering machine, perfectly aligned with your long-term goals.

🚀 Why Choose Seicho for Lean Strategy Implementation?

At Seicho Consulting, we combine deep industry experience with data-driven strategies to bring Lean to life inside your organization. From the factory floor to the boardroom, we align execution with your Vision, Mission, and Strategic Goals.

🔍 Our Lean Implementation Approach

Every organization is unique—and so is our approach. We tailor each phase to match your needs:

✅ Comprehensive Lean Assessment

Baseline analysis of your current operations to identify value and waste across processes.

✅ Value Stream Mapping (VSM)

Visualizing the entire production or service process to eliminate non-value-adding steps.

✅ Strategic Data Collection & Mining

Using analytics to drive insight-led decision-making.

✅ Intelligent Lean Tool Selection

We don’t throw tools at problems—we prescribe what works best for your business.

✅ Execution for Long-Term Success

Implementation plans focused on skill development, system optimization, and strategic alignment.

🛠️ Lean Tools We Deploy

Our consultants handpick tools that fit your organization’s challenges, industry, and maturity level:

5S – Workplace organization and visual clarity

Kaizen – Continuous small improvements with big impact

Poka-Yoke – Error proofing to ensure first-time quality

Andon Systems – Real-time problem signaling and response

Heijunka – Production leveling for smooth flow

8D Problem Solving – Structured root-cause elimination

TPM & TQM – Asset care and total quality initiatives

Six Sigma – Reducing variation, improving precision

Hoshin Kanri – Strategic policy deployment across teams

Each tool is carefully deployed like a custom prescription—not one-size-fits-all, but strategic and tailored.

🏗️ Greenfield & Brownfield Project Expertise

No matter where you are in your operational lifecycle, Seicho helps optimize your infrastructure:

🟢 Greenfield Projects

Design efficient layouts from scratch

Ensure scalable, waste-free foundations

Embed Lean at the core of your systems

🟤 Brownfield Projects

Restructure existing operations

Identify bottlenecks and hidden inefficiencies

Retrofit Lean thinking into legacy systems

Layout is the backbone of Lean—and we ensure yours is built to support long-term success.

📈 The Impact of Lean Strategy Implementation

🔄 Reduced operational costs

📉 Elimination of waste and non-value activities

🚀 Improved throughput and productivity

📊 Data-backed decision-making

🤝 Cross-functional alignment and accountability

Whether you’re starting your Lean journey or scaling it organization-wide, Seicho Consulting helps you embed Lean into your DNA.

👣 Ready to Lead the Change?

Lean isn’t a trend—it’s a transformation journey. When implemented with strategic precision, it becomes a catalyst for growth, culture, and competitive advantage.

📞 Let’s build your Lean roadmap together. Contact Seicho Consulting today.

#LeanStrategy#LeanManufacturing#LeanConsulting#BusinessTransformation#OperationalExcellence#ContinuousImprovement#Kaizen#ValueStreamMapping#BusinessConsulting#SeichoConsulting#ProcessImprovement#LeanThinking#5S#SixSigma#EfficiencyMatters#LeadershipDevelopment#ProductivityHacks#BusinessGrowth#LeanTools#BusinessStrategy

0 notes

Text

“Our monthly performance review now finishes two hours sooner. With Data Point’s FCIL scorecard, our branch costs, loan turnaround times, and NPS scores are all clear and live in one place. We’re saving over £120k a year in meeting costs alone — and making quicker, sharper decisions for our customers.”

— Feels this like a far-off dream? It’s not. Choose Data Point Balanced Scorecard and track every FCIL metric where it matters

From cost-to-income ratio to customer experience, Data Point keeps banking KPIs live, visible, and actionable. That’s how service leaders protect time, budget, and performance. Book a demo and see it live.

#lts#leantools#bsc#balancedscorecard#datapoint#leandatapoint#Datamanagement#FCIL#FCILBalancedScorecard#frameworkforoperationalexcellence#fourperspectivesofbalancedscorecard#finance#customer#internalprocess#learningandgrowth#balancedscorecard4perspectives#BalancedScorecardDefinition#balancedscorecard4perspectivesexplained#4perspectivesofbalancedscorecard#balancedscorecardperspectivesexamples#balancedscorecardcustomerperspective#balancedscorecardmeasuresthatdriveperformance#strategicperformancemanagementtool#fourKeyPerformanceIndicators#Optimisedbusinessperformance#CustomerCentricapproach#Continuousimprovement#FCILmetrics#VisualManagementFrameworks#FourPerspectivesofBSC

0 notes

Text

Leaders, how fast can your teams spot a problem? Daily targets slipping through Excel sheets and whiteboards cost time, money — and trust. Your KPIs deserve better. The Data Point SQDCP Board puts live KPIs in front of every team, shift, and plant — so problems stand out today, not next week. Faster decisions. Real accountability. Zero blind spots. Run operations that can see, react, and win. Upgrade to real-time SQDCP now.

#lts#leantools#bsc#balancedscorecard#datapoint#leandatapoint#Datamanagement#SQCDPBoard#visualmanagementsoftware#SQCDPBoardvisualmanagementsoftware#sqcdpboardmeaning#sqcdpboardexamples#sqcdpboarddefinition#sqcdpboardmanufacturing#whyissqcdpimportant#sqcdpperformancedashboard#bestvisualprojectmanagementsoftware#bestvisualprojectmanagementtools#projectmanagementvisualizationtools#visualmanagementexamples#visualprojectmanagementtools#WhatisSQCDP#digitalvisualmanagementsystem#Leanmanufacturingvisualmanagement#RealTimeproductiontracking#Continuousimprovementmetrics#managekeyperformancemetrics#Visualisekeyperformancemetrics#SQDCPdashboardexplained#Safety

0 notes

Text

The spreadsheet era is over; Welcome to Data Point, the real-time system for your strategy and KPI management. We are trusted by manufacturers (SQDCP), service leaders (FCIL), and global enterprises to turn strategy into action, live.

Get Started Today!

#lts#leantools#bsc#balancedscorecard#datapoint#balancedscorecardtools#bestbalancedscorecardsoftware#balancedscorecardsoftware#leandatapoint#digitalbalancedscorecard#balancedscorecardexamples#whatisabalancedscorecardinbusiness#balancedscorecardfeatures#strategyplanning#Strategyexecution#LeanDailyManagementSystem#Digitalvisualmanagementboard#KPImanagement#Gembawalk#balancedscorecardCustomisation#strategyplanningframeworks#strategyplanningmeaning#strategyplanningtools#dailyvisualmanagementboard#visualmanagementboardexamples#visualperformanceboards#leanvisualmanagementboard#howtoimprovekpiperformance#bestwaytotrackkpis#howtomanagekpis

0 notes

Text

Still using Excel for KPIs? You're wasting time and money.

You’re not alone. 73% of leaders admit Excel-based KPIs delay critical decisions by days or weeks. Manual errors, version chaos, and stale data are bleeding revenue and agility.

But what if your KPIs could live?

Data Point Balanced Scorecard Software transforms raw data into real-time momentum. Whether you’re in manufacturing, healthcare, logistics, or retail, we deliver custom solutions built for your operational DNA:

Industry-Specific Frameworks: SQDCP/SQDCM for ops excellence, FCIL for compliance, or tailor your own.

Strategic Tools: Cascade goals from boardroom to shop floor.

Operational Capabilities: Live dashboards, predictive alerts, and drill-down analytics.

See performance pulse in real-time. Spot risks before they explode. Turn insights into impact.

68% of companies using real-time KPIs outpace competitors in decision speed.

Stop reporting history. Start building your future.

Custom frameworks

Battle-tested tools

No more one-size-fits-all

Get Started With Your KPI management Now

#Still using Excel for KPIs? You're wasting time and money.#lts#leantools#bsc#balancedscorecard#datapoint#balancedscorecardtools#bestbalancedscorecardsoftware#balancedscorecardsoftware#leandatapoint#digitalbalancedscorecard#balancedscorecardexamples#whatisabalancedscorecardinbusiness#balancedscorecardfeatures#strategyplanning#Strategyexecution#LeanDailyManagementSystem#Digitalvisualmanagementboard#KPImanagement#Gembawalk#balancedscorecardCustomisation#strategyplanningframeworks#strategyplanningmeaning#strategyplanningtools#dailyvisualmanagementboard#visualmanagementboardexamples#visualperformanceboards#leanvisualmanagementboard#howtoimprovekpiperformance#bestwaytotrackkpis

0 notes

Text

Why Digital TCard Systems are Key to Effective Layered Process Audits in Manufacturing?

For more insights read our Article

#lts#leansolution#leantools#tcard#tcardsoftware#tcards#digitaltcard#tcardonline#LayeredProcessAudits#LayeredProcessAuditsinManufacturing#ProcessAudits#layeredprocessauditsexamples#layeredprocessauditchecklist#layeredauditchecklist#layerprocessauditplan#layeredprocessauditsteps#processauditsexamples#typesofprocessaudits#LayeredProcessAuditingfortheShopFloorManagement#LayeredprocessauditimplementationwithdigitalTCard#DigitalWorkflowforScheduling#DigitalWorkflowforTracking#CustomisableDigitalChecklists#RealTimeDataCollection#RealTimeDataAnalysis#LPAAudits#LPAImplementation#ProcessEfficiency#DigitalAuditTools#LeanProcessAudit

0 notes