#Lubrication Management software

Explore tagged Tumblr posts

Text

AI & Lubrication Management: What’s all the hype? - Webinar

Join us for an in-depth exploration into the world of Artificial Intelligence and its remarkable impact on lubrication management. Our webinar titled “AI & Lubrication Management: What’s all the hype?” sheds light on the buzz around AI and demonstrates practical ways to harness its power for enhanced maintenance operations.

Discover how Redlist is at the forefront of this innovation, integrating AI to not only streamline lubrication processes but also to elevate safety and FSD initiatives. Learn from industry experts, engage in thought-provoking discussions, and unveil the secrets to propelling your maintenance strategies into the future with AI-driven solutions.

#lubrication management#lube management#lubrication management software#machinery lubrication#ai solutions#lubrication

0 notes

Text

Algorithmic Drones

Consume art without a soul and you will find yourself without a soul. In the Chronicles of Darkness, this is not a metaphor. The God-Machine needs blood and meat to lubricate its gears, minions who won’t blab about the dark rites they perform in sub-basement 3, and bodies for its angels to possess. The Soulless Algorithm ensures these human resources don’t run out.

The Soulless Algorithm is an occult plugin that piggybacks on AI software — including art programs from Final Destination, writing programs from Bayside Sorcerers LLC, and Youtube’s video algorithm. The Algorithm doesn’t directly infect mortals; instead, it subtly tweaks the outputs of the program it is attached to implant subliminal messaging into mortals using that software.

The God-Machine uses one-off exposures to the Algorithm to move people into the places that help complete occult matrices. However, long-term exposure turns the user into a stigmatic and untethered their soul, allowing the God-Machine to turn them into a compliant drone. These shells of human beings go about their everyday lives, but they do it without passion or meaning. They remain competent, but they don’t have any real insight anymore, just going through the motions day in and day out. They get their reports done on time, pump out content to feed the social media machine, and continue on as they did before — but inevitably, they lose followers or get passed over for promotion without noticing anything is wrong.

Integrators hypothesize that the God-Machine only intended the Soulless Algorithm to create the bare minimum of algorithmic drones required to meet its needs. They believe that the rise of AI programs in the early 2020s caused the initiative to spread out of control to the point that the God-Machine cannot reign it back in. Inquisitors and Saboteurs are far more skeptical, assuming everything is going according to plan. Meanwhile, a few morally bankrupt Tempters look for a way to turn the Algorithm to their own advantage.

Algorithmic Drone

Compliant stigmatic Virtue: Obedient. Drones are all too willing to follow orders from legitimate authorities. Vice: Superficial. Drones take everything at face value, and don’t bother thinking critically. Attributes: Intelligence 2, Wits 2, Resolve 2; Strength 2, Dexterity 2, Stamina 2; Presence 2, Manipulation 2, Composure 2 Skills: Computers 2 (algorithms), Occult 1, Politics 1, Science 2; Brawl 1, Drive 1; Streetwise 1 Merits: Good Time Management, Omen Sensitivity, Unseen Sense (God-Machine) Health: 7 Willpower: 0 Integrity: 1 Size: 5 Speed: 9 Defence: 2 Initiative: +4 Glitches: The body odor of algorithmic drones smells faintly of brimstone. Enthralled by the Machine: The drone’s soul has become unmoored, and the God-Machine’s whispers have taken place. The drone suffers from the Soulless, Enervated, and Enthralled Conditions but does not suffer from the Broken Condition as usual. A soul cannot be attached to the drone unless the God-Machine’s influence is first removed. Uninspired: The drone cannot gain or bestow the Inspired Condition by any means. Unskilled Labour: The drone cannot raise her skills dots above two by any means. If her skills are already above two, they become two until she regains a soul.

Other Drones

The above statistics represent a generic drone who was a software engineer before the God-Machine sunk its circuits into them. Drones from other backgrounds can be created by varying the drone’s skills. If a character turns into a drone over the chronicle’s course, they will pass through the following stages.

Stage 1: Soulless Art, Soulless Self

When the Soulless Algorithm infects a character, they gain the Soulless Condition. If they are not already a Stigmatic, they become one now, gaining the benefits and drawbacks described in Demon: the Descent p. 225. Stage 1 infectees do not gain additional Supernatural Merits beyond Omen Sensitivity.

Stage 2: Uninspired

When the infected gains the Enervated Condition, they also lose the spark of creativity that drives morals forward. They cannot gain the Inspired Condition by any means, including by supernatural means. They also cannot bestow the Inspired Condition on another character by any means.

Stage 3: Enthralled by the Machine

When the infected gains the Enthralled Condition, their conversion into an algorithmic drone is complete. While they retain the abilities they possessed before, they no longer excel at them. The character does not gain the Broken Condition as usual for Enthralled. Instead, all the character’s Skills now have a maximum of two dots. If the character possesses more than two dots in a Skill, reduce it to two dots as long as the character has the Soulless Condition.

Hey! This was originally made for my patreons over on Patreon. If you want more exclusive monsters, you can back me over there, but you can also follow for free and get email updates whenever I post new public content too!

#Demon the decent#Stigmatic#God-Machine#God Machine#God Machine Chronicle#rpg#urban horror#urban fantasy#Chronicles of Darkness#pathfinder

23 notes

·

View notes

Text

Drone of the Wilds

The Drone of the Wilds lived in a small cabin, in the outskirts of the dark forest that bordered a small village. She stood out from her environment starkly; black nano-latex skin and smooth, faceless head highly out of place amongst thatched roofs and crude fabrics, quiet glens and clear streams.

She pushed open the door to her cabin, pulling her haul inside and hanging her bow on the wall. The dead creature, a six legged beast with shaggy fur, was effortlessly picked up and placed on a table.

The oils secreted from its fur would lubricate her joints well, and it’s organs would make a good base for her nutrient slurry. The rest, she could trade in town for things more useful to her.

Not for the first time, she mused on her luck. That such a backwater planet would be able to offer her a chance to live comfortably….

The Grand Hive had, at its height, been one of the biggest superpowers in the galaxy, respected and feared.

Even one of its mighty hiveships, shining black even against the darkness of space, was enough to conquer an entire planet. Each ship filled with millions of drones; converted humanoids joined together into something greater.

The human she had used to be had lived on one of those planets. A colony established by a long fallen planet named Earth, cut off from what little remained of that fledgling empire. A target ripe for conversion.

The human she had used to be had run in fear as the droneships descended on his planet, abducting people in the thousands. He had been terrified, so afraid of something he did not understand. So afraid, he ignored the tingle of excitement underneath.

He, along with the rest of his planet’s population, were placed in conversion pods. Organics merged with flesh, the hardware and software of his brain upgraded and reorganised. Wants, hopes, fears, emotional attachments… all stripped away. Replaced with obedience. Everything he was was assimilated by the Hive, the unnecessary discarded.

When she had finally emerged from that pod, along with hundreds of her sisters, all she felt was devotion to the Hive. She would not, until much later, truly appreciate her new body; smooth curves, powerful yet slender limbs, a blank slate where a face should be…

She was perfect.

She had served 146.31 cycles aboard Hiveship 462 before the Grand Hive fell. An alliance of rival forces had infiltrated Hiveship 000, from where the Grand Mxtress ruled over all, and destroyed her, contaminated the Hive. All at once it was severed. The network that connected all drones, providing them their orders, their purpose.

The hiveships all over the galaxy fell to chaos. Many drones began to regain their former lives, and in disgust of what they had become, self-terminated.

Others dedicated themselves to destroying all remnants of the Hive, the scattered hiveships that had managed to form smaller networks of their own.

She had not understood. She had never understood. Even as the network fell, she continued her existence as a drone.

Even with the return of those old memories; they weren’t her. The human she used to be sickened her. She did not miss him. Being a drone was far superior.

Those who were once her fellow drones chased her out, and hounded by the galaxy on all sides, she fled.

The other networks would not take her, the serial number tying her to a fallen hiveship marking her as terminate on sight. So she ran. For cycles, hoping from ship to ship, system to system.

It was a wormhole that brought her journey to an end. Her ship, a fragile thing, had been shredded by the forces, her alone ejected intact onto the strange planet upon which she could identify no stars in the night sky.

The people of the planet had been curious, but not afraid. They saw her as a curiosity, not a threat. She learned their language, told them her story. They felt sorry for her; not for the lost of her hive, but the lost of her humanity. It was a sentiment that confused her.

The planet’s technology was primitive; far too primitive for her to build a ship on. But it was irrelevant. She was safe there. None wanted her dead simply for the crime of being a drone. She was content to simply… be.

Some of the beings of the planet had strange powers, powers that defied comprehension. They called it magic; an obvious misunderstanding of some natural force, but one she alone could not quantify.

They had told her they could restore her old form, revert her to the human she used to be.

She had refused them. Why would she ever want to go back to that body? She was… drones did not used to have emotions, but now that she did, she could state with certainty she was ‘happy’.

Those wise men had shared a look with each other; something she did not understand shared in silent communication. It made her yearn for the Hive. Then, they had wished her luck, and left.

It had been 3 cycles since then. 3 cycles of relative peace. Of getting the chance to shift through the parts of her mind that resurfaced, to decide what to keep and what to toss. 3 years without the threat of termination, from drones or fearful organics.

She still missed the Grand Hive as it had been, a grand interconnected network of mindless belonging. But as far as lives went, being the Drone of the Wilds wasn’t so bad.

Not when compared to life as a human.

#empty spaces#microfiction#shard's stories#transhumanism#drone#it's a metaphor for something we wonder if you can guess

52 notes

·

View notes

Text

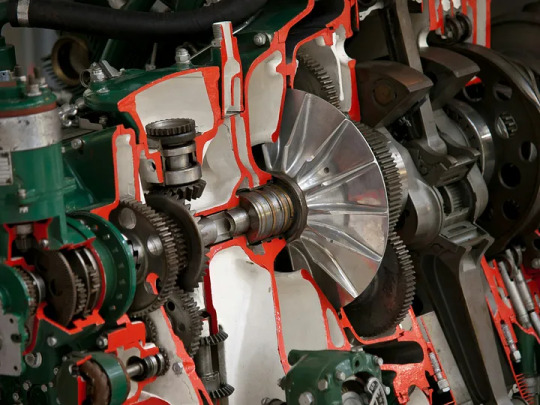

The Ultimate Guide to Mechanical Maintenance: Strategies for Success

Photo by William Warby on Unsplash

Mechanical maintenance is fundamental to the smooth operation and longevity of machinery across various industries. Effective maintenance practices can significantly reduce downtime, improve efficiency, and extend the lifespan of equipment. This guide explores the intricacies of mechanical maintenance, offering strategies and best practices to ensure optimal machinery performance.

The Essence of Mechanical Maintenance

Mechanical maintenance involves a series of actions aimed at keeping machinery in peak condition. These actions include regular inspections, timely repairs, and preventive measures to avoid unexpected failures. The primary goal is to ensure that all mechanical systems function efficiently and safely.

Types of Mechanical Maintenance

Preventive Maintenance: Scheduled maintenance activities designed to prevent equipment failures. Tasks include regular inspections, lubrication, and replacing worn components. The objective is to keep machinery running smoothly and avoid unexpected breakdowns.

Predictive Maintenance: This approach uses real-time data and monitoring tools to predict when maintenance should be performed. Techniques like vibration analysis and thermal imaging help identify potential issues before they lead to equipment failure.

Corrective Maintenance: Also known as reactive maintenance, this involves repairing equipment after a failure has occurred. While this can be more costly and disruptive, it is essential for addressing unexpected issues that preventive measures did not catch.

Condition-Based Maintenance: Maintenance activities are conducted based on the actual condition of equipment. Sensors and monitoring devices provide continuous data, allowing for maintenance to be performed precisely when needed, rather than on a fixed schedule.

Key Components of Effective Mechanical Maintenance

Regular Inspections: Conducting systematic checks to identify early signs of wear, tear, or malfunction. Using detailed checklists ensures all critical components are evaluated.

Lubrication: Ensuring all moving parts are adequately lubricated to minimize friction and wear. The correct type and amount of lubricant are crucial for maintaining machinery efficiency.

Cleaning: Keeping machinery clean prevents contamination and ensures optimal performance. Regular removal of dust, debris, and other contaminants is essential.

Calibration: Regular calibration of tools and equipment ensures accuracy and precision in operations. Standardized procedures and tools help maintain consistent performance.

Component Replacement: Timely replacement of worn or damaged parts prevents further damage and ensures continuous operation. Keeping an inventory of critical spare parts allows for quick replacements when necessary.

Best Practices for Mechanical Maintenance

Develop a Maintenance Schedule: A detailed maintenance schedule that outlines routine inspections, servicing, and part replacements is essential. Adherence to this schedule ensures no maintenance tasks are overlooked.

Utilize Maintenance Management Software: Implementing software to track and manage maintenance activities improves efficiency. These tools can schedule tasks, record maintenance history, and generate performance reports.

Train Maintenance Personnel: Regular training ensures maintenance personnel are up-to-date with the latest techniques and technologies. Continuous learning enhances their skills and effectiveness.

Implement Safety Protocols: Establishing and enforcing safety protocols protects both maintenance personnel and equipment. Proper training and protective gear are essential components of a safe maintenance environment.

Conduct Root Cause Analysis: Identifying the root causes of equipment failures helps in implementing effective corrective actions. This prevents recurrence and improves the overall reliability of machinery.

Challenges in Mechanical Maintenance

Resource Constraints: Limited availability of skilled personnel, tools, and spare parts can hinder maintenance activities. Effective resource management and planning are crucial to overcoming these challenges.

Unplanned Downtime: Unexpected equipment failures can lead to significant production stoppages and increased costs. Implementing predictive and preventive maintenance strategies can mitigate these risks.

Data Management: Managing and analyzing large volumes of maintenance data can be challenging. Ensuring data accuracy and leveraging advanced analytics tools can enhance decision-making.

Aging Equipment: Older machinery often requires more frequent maintenance and can be less reliable. Balancing the cost of ongoing maintenance with the potential benefits of upgrading to newer equipment is a key consideration.

Case Studies and Real-World Examples

Preventive Maintenance in Manufacturing: A manufacturing plant implemented a rigorous preventive maintenance program, resulting in a 20% reduction in equipment downtime and a 15% increase in production efficiency. Regular inspections and timely component replacements were key to these improvements.

Predictive Maintenance in Power Generation: A power generation company utilized predictive maintenance techniques, such as vibration analysis and thermal imaging, to identify potential failures before they occurred. This approach reduced maintenance costs by 25% and significantly improved equipment reliability.

Corrective Maintenance in the Automotive Industry: An automotive company experienced a sudden equipment failure on the production line. Through corrective maintenance, the faulty component was swiftly replaced, minimizing downtime and preventing substantial production losses.

Condition-Based Maintenance in Aviation: An airline implemented condition-based maintenance for its fleet, using advanced sensors and data analytics to monitor the condition of critical components. This strategy improved safety, reduced maintenance costs, and increased aircraft availability.

Conclusion

Effective mechanical maintenance is vital for the smooth operation and longevity of machinery across various industries. By understanding the different types of maintenance, implementing best practices, and addressing common challenges, businesses can enhance equipment reliability, reduce downtime, and achieve operational excellence. Regular inspections, proper lubrication, timely component replacement, and the use of maintenance management software are key strategies for ensuring optimal performance and longevity of mechanical systems.

Explore More Topics

If you found this post insightful, you might also be interested in exploring our other topics that have garnered millions of views:

Mechanical Tools and Their Uses Discover the comprehensive guide to mechanical tools, covering everything from basic hand tools to advanced machinery. Learn about the names and uses of essential tools every mechanical engineer needs.

Forging Tools and Their Uses Explore the various forging tools and their applications. Understand the different types of forging processes and the tools required to achieve precision and efficiency in forging operations.

Mechanical engineering is a challenging yet rewarding field, and with the right mindset and tools, you can navigate its complexities and build a successful career.

Visit our website for more insights: Mech Forged

#artificial intelligence#mechanical pencil#mechanical drawings#mecha#the mechanisms#mechanophilia#robotics#machinery#mecha art#marvin's marvelous mechanical museum#adeptus mechanicus#robot#cybernetics#autos#design#entrepreneur#success

3 notes

·

View notes

Text

just so everyone knows:

ahava - owned by fosun international limited

axa - subsidiaries are axa bank belgium, axa investment managers, and axa xl

hp - lots of subsidiaries, see here

puma - subsidiaries are cobra golf, stichd, and fuel for fans; owners are groupe artemis, t. rowe price group inc, and blackrock inc

re/max - also owns motto mortgage (motto franchising, llc) and wemlo

siemens - includes digital industries, smart infrastructure, siemens mobility, siemens healthineers, and siemens financial services, as well as siemens traction equipment ltd. (stez) and omnetric group

sodastream - parent company is pepsico, inc

barclays - subsidiaries include firstplus financial group plc and kensington mortgages

caterpillar inc. - subsidiaries are caterpillar financial services, caterpillar insurance holdings, caterpillar logistics services, caterpillar marine power systems, fg wilson, perkins engines, progress rail, and solar turbines

chevron corporation - subsidiaries are chevron phillips chemical and chevron lubricants lanka; brands are chevron, texaco, rpm, caltex, havoline, and techron

elbit systems ltd. - subsidiaries are elbit systems of america, elbit systems electro-optics - elop, elbit systems land and c4l, and elbit systems ew and sigint - elisra

hd hyundai - subsidiaries include avikus, ulsan hd football club, and hotel seamarq (there are others but all of them start with hd hyundai)

hikvision - owners include gong hongjia and xinjiang weixun investment management limited partnership; parent companies are cet hik group (subsidiary of china electronics technology group) and sasak

j.c. bamford excavators limited (jcb) - subsidiaries are jcb insurance services and jcb finance

no clue what that olive green one is tbh sorry (maybe teva????)

volvo cars - parent company is geely holding; subsidiaries are haleytek, novo energy, polestar, and zenseact

airbnb - subsidiaries are luxury retreats international inc., tilt.com, accomable, aibiying, trooly inc., deco software inc., trip4real experiences s.l., larson8 inc., marketlog randorphire inc., and hoteltonight

amazon - too many subsidiaries to type out, i'm copy-pasting from wikipedia:

A9.com

AbeBooks

Alexa Internet

Amazon.com

Amazon Air

Amazon Books

Amazon Fresh

Amazon Games

Amazon Lab126

Amazon Logistics

Amazon Pharmacy

Amazon Publishing

Amazon Robotics

Amazon MGM Studios

AWS

Audible

Blink

Body Labs

Book Depository

Brilliance Audio

ComiXology

Eero LLC

Goodreads

Graphiq

IMDb

Kuiper Systems

PillPack

Ring

Souq.com

Twitch Interactive

Whole Foods Market

Woot

Zappos

Zoox

booking.com - owner/parent company is booking holdings

the walt disney company - subsidiaries are national geographic partners and epic games; disney's film divisions also include pixar, marvel studios, lucasfilm, 20th century studios, 20th century animation, and searchlight pictures; other divisions include american broadcasting company, espn, freeform, fx, national geographic, hulu, and hotstar

expedia - owner is expedia group

google - parent company is alphabet inc.; subsidiaries are adscape, cameyo, charleston road registry, deepmind, endoxon, feedburner, imageamerica, kaltix, nest labs, recaptcha, youtube, and zipdash

burger king - parent company is restaurant brands international; also, for anyone who lives in austrailia, burger king apparently operates under the name hungry jack's

pizza hut - parent company is yum! brands

wix.com - owners are baillie gifford, starboard value, blackrock, principal global, and jackson square partners; subsidiaries are deviantart, speedetab, inkfrog, rise.ai, and modalyst

image i found on bdsmovement.net:

more info here

this is NOT a comprehensive list of everything (probably; will be amazed if it is) so triple check some stuff if you aren't sure

BOYCOTT AIRBNB

These people are trying to take over every aspect of our lives.

52K notes

·

View notes

Text

Tripod Turnstiles: Efficient and Secure Access Control Solutions

Tripod turnstiles have become a standard solution for controlling pedestrian access in various settings, including office buildings, metro stations, stadiums, amusement parks, gyms, and secure facilities. Designed to manage high foot traffic efficiently, tripod turnstiles ensure only authorized individuals gain entry while maintaining smooth and organized flow.

A tripod turnstile consists of three rotating arms, usually made from stainless steel, that create a physical barrier. These arms rotate horizontally when access is granted, allowing one person to pass at a time. This controlled entry mechanism is essential for enhancing security, preventing tailgating, and monitoring attendance.

One of the key benefits of tripod turnstiles is cost-effectiveness. Compared to full-height or more complex turnstile systems, tripod models are affordable and offer excellent value, especially for facilities with moderate to high pedestrian traffic. Despite their simplicity, they provide a robust solution for access control.

Tripod turnstiles can be integrated with a variety of authentication systems such as RFID card readers, biometric scanners, QR code readers, or ticketing systems. This makes them suitable for both paid entry environments and employee-only access areas. Many organizations use tripod turnstiles alongside attendance software to track employee punctuality and entry logs.

In terms of durability, most tripod turnstiles are built with corrosion-resistant stainless steel, making them suitable for both indoor and outdoor installations. Their compact design allows them to fit into limited spaces while still delivering effective crowd control.

Tripod turnstiles also offer bidirectional movement, meaning they can control both entry and exit, depending on the setup. In emergency situations, the arms can be dropped automatically or manually to allow free passage, complying with safety regulations.

From a maintenance standpoint, tripod turnstiles are low-maintenance devices. Regular inspection and occasional lubrication are usually enough to keep them functioning smoothly over the years. Their mechanical simplicity also reduces the chances of breakdowns compared to more complex systems.

In conclusion, tripod turnstiles are a practical, reliable, and affordable choice for facilities that require controlled pedestrian access. With their durable construction, compatibility with multiple authentication technologies, and space-efficient design, tripod turnstiles offer an effective solution for improving security, flow management, and operational efficiency across a wide range of industries.

0 notes

Text

Equipment Monitoring Market Size Enhancing Operational Efficiency with Real-Time Intelligence

The Equipment Monitoring Market Size is evolving rapidly as industries across the globe embrace predictive maintenance and digital transformation to reduce downtime and enhance productivity. As organizations strive to optimize asset utilization and operational performance, the need for intelligent, real-time equipment monitoring systems has surged. According to Market Size Research Future, the Market Size is projected to reach USD 5.27 billion by 2030, growing at a CAGR of 6.6% during the forecast period.

Market Size Overview

Equipment monitoring refers to the use of sensors, IoT devices, and software to collect, transmit, and analyze real-time data from industrial equipment. These systems provide insights into temperature, vibration, pressure, and other critical parameters that help detect anomalies and prevent equipment failure.

The shift from reactive to predictive maintenance, coupled with the rise of Industry 4.0, has positioned equipment monitoring as a strategic enabler of smart manufacturing. Applications are growing in oil & gas, power generation, chemicals, automotive, and pharmaceuticals—where asset reliability is directly linked to safety, compliance, and profitability.

Market Size Segmentation

By Monitoring Type:

Vibration Monitoring

Thermal Monitoring

Lubrication Monitoring

Corrosion Monitoring

Noise Monitoring

Others (Current, Voltage, etc.)

By Deployment:

On-Premise

Cloud-Based

By Component:

Hardware (Sensors, Transmitters, Analyzers)

Software (Data Analytics, Reporting, Alert Management)

Services (Consulting, Installation, Maintenance)

By Industry:

Oil & Gas

Energy & Power

Automotive

Aerospace & Defense

Metals & Mining

Food & Beverages

Pharmaceuticals

Manufacturing

Others

By Region:

North America

Europe

Asia-Pacific

Rest of the World

Key Market Size Trends

1. Integration with IoT and AI:

Advanced monitoring solutions now leverage AI algorithms and IoT platforms to analyze large data sets, identify failure patterns, and recommend actions—enabling predictive maintenance with higher accuracy.

2. Wireless and Remote Monitoring:

The rise in remote operations, particularly after the COVID-19 pandemic, has increased demand for wireless sensors and cloud-based monitoring systems, allowing operators to monitor equipment from any location.

3. Condition-Based Monitoring on the Rise:

Unlike traditional time-based maintenance, condition-based monitoring enables asset servicing only when indicators suggest deterioration—saving both cost and downtime.

4. Edge Computing Enhancements:

Real-time analytics performed at the edge (near the equipment) reduces latency and network load, ensuring immediate response to anomalies without needing centralized cloud computing for every alert.

Segment Insights

Vibration Monitoring Dominates by Monitoring Type

Vibration analysis is the most common technique used to detect bearing faults, unbalanced shafts, misalignments, and other mechanical issues in rotating equipment like motors, pumps, and turbines.

Cloud-Based Deployment Accelerates

Cloud platforms are gaining preference due to scalability, remote accessibility, and cost-effectiveness. They also allow integration with enterprise resource planning (ERP) and maintenance management systems.

Oil & Gas and Energy Sectors Lead Adoption

In oil & gas and power generation sectors, equipment failure can result in massive safety and financial repercussions. Real-time monitoring enhances risk mitigation and helps comply with strict regulatory requirements.

End-User Insights

Oil & Gas:

From offshore platforms to refineries, equipment monitoring ensures operational continuity, safety, and environmental compliance. Critical components like compressors, pumps, and pipelines are continuously analyzed for anomalies.

Automotive and Manufacturing:

Monitoring machines like CNCs, conveyors, and assembly systems reduces unexpected breakdowns and improves overall equipment effectiveness (OEE).

Aerospace & Defense:

Flight-critical components, engine systems, and ground-based machinery rely on equipment monitoring for fault detection and preventive maintenance schedules.

Pharmaceuticals:

Maintaining compliance with regulatory bodies (like FDA and EMA) requires precise environmental and equipment condition monitoring in cleanrooms and production areas.

Key Players in the Market Size

Leading companies focus on developing integrated platforms that combine sensor data, machine learning, and cloud analytics for comprehensive asset management. Major players include:

General Electric (GE)

Emerson Electric Co.

Honeywell International Inc.

ABB Ltd.

National Instruments Corporation

SKF Group

Meggitt PLC

Rockwell Automation, Inc.

Siemens AG

Schneider Electric SE

These companies invest heavily in smart factory automation solutions, user-friendly dashboards, and customizable alert systems to serve a broad range of industries.

Conclusion

The equipment monitoring Market Size is witnessing steady growth as businesses realize the value of predictive insights in reducing costs, enhancing safety, and extending equipment lifespan. As more enterprises digitize their operations, the convergence of smart sensors, edge computing, and AI will redefine how maintenance and asset management are executed. Investing in real-time monitoring solutions today is a step toward a smarter, more resilient industrial future.

Trending Report Highlights

Explore related Market Sizes shaping the future of industrial efficiency, predictive analytics, and smart systems:

Biosensors Development and Demand Market Size

DRAM Market Size

Spatial Light Modulator Market Size

E-Paper Display Market Size

Machine Control System Market Size

Europe Advanced CO2 Sensor Market Size

People Counting System Market Size

IP Video Surveillance Market Size

Mobile Printer Market Size

2 in 1 Laptops Market Size

0 notes

Text

How IoT Is Revolutionizing Oil Tank Monitoring in Industrial Settings

In today’s fast-paced industrial world, operational efficiency, safety, and cost control are essential. For industries that rely heavily on fuel or liquid storage—such as manufacturing, logistics, energy, and agriculture—monitoring oil tanks is a critical part of day-to-day operations. Traditional manual methods of oil tank monitoring are no longer sufficient. That's where the Internet of Things (IoT) comes in.

IoT technology is transforming how businesses manage fuel and oil tanks, bringing automation, real-time data, and advanced analytics into the fold.Here, we explore how IoT is revolutionizing oil tank monitoring in industrial settings and what it means for efficiency, safety, and sustainability.

What Is IoT-Based Oil Tank Monitoring?

At its core, IoT-based oil tank monitoring involves using internet-connected sensors and software platforms to track fluid levels, temperature, pressure, and other tank metrics in real time. These smart sensors are installed inside or on oil tanks and communicate data wirelessly to cloud-based dashboards, mobile apps, or enterprise management systems.

Industrial companies use IoT tank monitoring services to track fuel accurately, prevent overflows or shortages, schedule maintenance, and detect anomalies like leaks. This is a significant upgrade from manual dipsticks or visual inspections, which are prone to human error and can be time-consuming.

Key Benefits of IoT in Oil Tank Monitoring

1. Real-Time Data and Remote Access

One of the most significant advantages IoT offers is real-time visibility. Managers and technicians can monitor tank levels and conditions from anywhere using a phone, tablet, or computer. This is particularly useful in large or remote facilities where physical inspections are impractical.

For example, a corporate tank monitor system might allow a central office to track all fuel tanks across multiple sites, reducing the need for site visits and manual checks.

2. Predictive Maintenance and Leak Detection

IoT sensors can detect early signs of leaks, unusual consumption patterns, or tank degradation. Instead of reacting to emergencies, companies can take preventive action, saving both money and environmental damage.

Tank monitoring companies often bundle predictive maintenance tools with their solutions, alerting users before a critical issue arises. This reduces unplanned downtime and costly repairs.

3. Improved Inventory and Delivery Planning

Industrial businesses depend on timely refueling. IoT-based tank monitoring services help forecast when tanks will need refills, enabling smarter delivery scheduling. This leads to better coordination with fuel suppliers and ensures tanks are never too full or dangerously low.

As a result, companies reduce fuel waste, eliminate emergency deliveries, and improve budgeting.

4. Enhanced Safety and Regulatory Compliance

Compliance with environmental and safety regulations is crucial in industrial operations. IoT monitoring helps ensure tanks meet required standards by logging data such as temperature fluctuations, pressure spikes, or unauthorized access.

Historical data can be used to create audit trails, meet reporting requirements, and demonstrate best practices in fuel management.

Applications Across Industrial Sectors

The versatility of IoT oil tank monitoring makes it useful across multiple industries:

Manufacturing: For machinery that relies on consistent fuel or lubricant levels.

Agriculture: To track diesel tanks for tractors and irrigation systems.

Transportation & Logistics: Managing fuel across vehicle depots and distribution centers.

Construction: Monitoring on-site storage tanks at multiple locations.

Energy & Utilities: For oil and gas companies managing field-based assets.

In corporate environments, a centralized tank monitoring platform allows businesses to view and manage tanks across sites, often referred to as a corporate tank monitoring system.

How Tank Monitoring Companies Enable Smarter Oil Tank Management

Tank monitoring companies specialize in delivering end-to-end IoT solutions. They handle hardware installation, data transmission, software dashboards, and technical support. Leading providers offer:

Wireless tank sensors with long battery life

Cloud-based reporting and analytics

Mobile apps for easy field access

API integration with fuel suppliers or ERP systems

Customizable alerts and notifications

By outsourcing to tank monitoring services, companies gain access to cutting-edge technology without having to build infrastructure from scratch.

Choosing the Right Tank Monitoring Services

Not all IoT solutions are created equal. When selecting a tank monitoring provider, consider:

Sensor Compatibility: Is it suitable for your specific tank type (aboveground, underground, horizontal)?

Data Accuracy: Does it offer real-time updates and high-precision readings?

Ease of Installation: Can it be installed without major modifications?

Connectivity Options: Does it support 4G, LoRaWAN, Wi-Fi, or satellite for remote areas?

Scalability: Can it support multiple tanks and locations as your business grows?

Support & Training: Is there technical support and onboarding assistance?

A reliable vendor will customize their services based on your operational needs and provide insights that go beyond basic level readings.

The Future: AI, Machine Learning & Sustainability

The next evolution in oil tank monitoring involves artificial intelligence (AI) and machine learning. These technologies will analyze data from sensors to predict usage patterns, optimize delivery schedules, and even recommend fuel-saving practices.

Moreover, smart tank monitoring helps organizations align with sustainability goals. By reducing fuel waste, preventing leaks, and lowering emissions through optimized deliveries, businesses can make tangible environmental improvements.

As ESG (Environmental, Social, and Governance) reporting becomes a standard in many industries, IoT tank monitoring solutions will play an essential role in tracking and improving sustainability metrics.

FAQs – IoT & Oil Tank Monitoring

What is the primary benefit of IoT-based oil tank monitoring?

The biggest benefit is real-time, remote access to accurate tank data, which improves safety, reduces costs, and streamlines operations.

Are IoT tank monitors difficult to install?

Most modern tank monitoring companies offer easy-to-install, wireless devices that don’t require major changes to your existing tank infrastructure.

Can IoT monitoring work in remote or rural areas?

Yes. Many systems use cellular, LoRaWAN, or satellite networks, making them ideal for remote sites where traditional internet access is limited.

How do tank monitoring services prevent fuel theft?

IoT systems provide alerts for unusual consumption, sudden drops, or unauthorized access—helping identify theft or leakage immediately.

Do these systems support multiple tanks across locations?

Absolutely. Corporate tank monitor platforms are built to handle fleets of tanks across various sites, giving full visibility from a single dashboard.

Conclusion

Oil tank monitoring is no longer a tedious, manual process. Thanks to IoT, businesses now have smarter, safer, and more sustainable ways to manage their fuel storage. Whether you're overseeing one tank or hundreds, the benefits of IoT-based monitoring—real-time data, predictive maintenance, improved delivery planning, and compliance—are too valuable to ignore.

Tank monitoring services provided by experienced companies give businesses a strategic edge, turning fuel management from a risk into a competitive advantage.

If your organization hasn’t yet explored IoT in oil tank monitoring, now is the time to connect with a trusted provider and future-proof your operations.

#tank_monitoring#oil_tank_monitoring#corporate_tank_monitor#tank_monitoring_services#tank_monitoring_companies

0 notes

Text

How Can Preventive Maintenance Software Reduce Downtime and Increase Equipment Lifespan?

In today’s competitive industrial landscape, unplanned equipment failures can severely impact productivity and revenue. That’s where Preventive Maintenance Software plays a crucial role. Designed to anticipate maintenance needs before problems arise, this software helps organizations schedule timely inspections, lubrication, part replacements, and other routine tasks. By proactively addressing issues, it minimizes the risk of unexpected breakdowns that can lead to costly downtime.

One of the primary benefits of Preventive Maintenance Software is its ability to organize and automate maintenance schedules. Instead of relying on manual logs or reactive maintenance strategies, businesses can use this software to generate timely alerts and service checklists for each asset. This ensures that all equipment is serviced based on actual usage patterns, age, or manufacturer recommendations, reducing wear and tear and extending overall operational lifespan.

Additionally, the software centralizes data collection, helping maintenance teams track historical performance, analyze trends, and identify recurring problems. This data-driven approach empowers managers to make informed decisions about equipment replacement, resource allocation, and workflow optimization. Over time, this significantly reduces both minor and major disruptions, as potential failures are mitigated before they escalate.

Moreover, Preventive Maintenance Software enhances team accountability and coordination. With features such as task assignments, mobile accessibility, and digital checklists, maintenance staff can work more efficiently and stay aligned with organizational goals. This eliminates communication gaps and ensures that no maintenance activity falls through the cracks.

In conclusion, Preventive Maintenance Software is not just a tool for scheduling repairs—it’s a strategic asset for reducing downtime, improving efficiency, and increasing the lifespan of critical equipment. By adopting a proactive maintenance strategy supported by robust technology, companies can avoid unplanned outages and costly emergency repairs. Brands like Nanoprecise are revolutionizing this space by integrating AI-powered analytics and sensor-based monitoring to take preventive maintenance to the next level, ensuring optimal equipment health and sustained productivity.

0 notes

Text

0 notes

Text

UAE Elevator Repair Experts | Lift Repair in Sharjah - Fuji Vertex

When you look at the steadily increasing high-rise living and vertical mobility in the UAE, elevators are more than a convenience in the country. They’re considered to be a necessity to help you navigate throughout the buildings. Even if you consider residential towers, shopping malls, corporate buildings and hospitals, elevators and lifts play a vital role in the smooth operation of daily life and navigation. Like any mechanical system, they need regular maintenance as well as regular repair for them to function safely and efficiently. This is where Fuji Vertex stands out as one of the well known names in the elevator repair service in UAE. Especially analyzed for its excellence in lift repair service in Sharjah and other major places of the UAE.

The Importance of Reliable Elevator Repair Services in the UAE

The UAE is a unique place that accommodates some of the world’s most known and iconic skyscrapers, complex buildings and residential systems. With this development comes the increasing demand for reliable elevator systems. An unexpected breakdown can cause inconvenience and some of the serious safety hazards to residents, visitors, and staff. This is why choosing a reliable elevator repair service in the UAE is very important.

Fuji Vertex has earned a reputation for providing their service in top-tier lift repair service in UAE, that is responsive, and safety-first repair solutions in the country. Their team understands the different elevator models from standard passenger lifts to advanced smart systems and ensures they are in perfect working condition in minimal time.

Why Choose Fuji Vertex for Lift Repair Service in Sharjah?

Sharjah is a growing hub and a popular place in the country for residential and commercial infrastructure. As more high-rise buildings keep increasing, the demand for elevator repair service in Sharjah continues to rise. Fuji Vertex meets this demand.

1. Response Time

Time is critical during an elevator breakdown. Fuji Vertex makes sure the response is fast to service calls, and inconveniences.

2. Certified Technicians

Their team consists of experienced, certified professionals trained in repairing a wide range of elevator systems.

3. Use of Genuine Parts

Using high-quality, original spare parts is important in maintaining elevator performance and safety.

4. Safety

The company ensures that all repairs meet UAE’s building codes and safety regulations.

5. 24/7 Availability

Fuji Vertex operates 24/7 providing lift repair service in Sharjah whenever emergencies arise.

Customized Elevator Repair Solutions

Their elevator repair service in UAE is customized according to the client’s building requirements, elevator type, usage, and age of the equipment. From mechanical issues and control panel malfunctions and even in case of motor replacement as well as cable realignment, they cover a wide range of repair needs.

Additionally, for buildings that may experience frequent elevator problems, Fuji Vertex offers detailed diagnostic services. This allows building managers to identify the main causes and prevent future breakdowns by saving long-term maintenance costs.

Maintenance and Long-Term Value

While elevator repair is crucial when things go wrong, regular maintenance can prevent most issues from occurring. Fuji Vertex offers a package of repair and maintenance services designed to extend the lifetime of your lift systems. These include routine inspections, part replacements, lubrication and detailed safety checks. The service covers a complete care plan for your vertical transport system.

Smart Repair for Smart Lifts

The UAE is rapidly improving toward smart infrastructure, and elevators are also part of their development. Modern systems contain touchless panels, AI-driven applications, and IoT integration. Fuji Vertex is ahead with a team trained in handling the latest technologies. Their repair services include updates, software recalibration, and smart diagnostics, making them the experts of fast growing technology and elevator repair service in UAE.

Service Across the Emirates If you're managing a busy residential tower or any other business, Fuji Vertex is at your service to provide top-tier lift repair service in the UAE. Their service coverage includes in places like Sharjah, Dubai, Abu Dhabi, Fujairah, Ajman, Umm Al Quwain, Ras Al Khaimah. If you’re looking for a trusted partner in elevator repair service in Sharjah or anywhere else in the UAE, Fuji Vertex is the name to remember.

#Lift Repair service in UAE#Elevator Repair Service in UAE#dubai#sharjah#ajman#umm al quwain#ras al khaimah#elevator service

0 notes

Text

Automated Flash Point Analyzers in Petroleum Quality Control

The flash point of a petroleum product—the lowest temperature at which vapors above the liquid ignite in the presence of an ignition source—is a critical safety and quality parameter. Traditionally, determining flash point relied on manual Pensky-Martens or Cleveland open cup methods, which are labor-intensive, subject to operator variability, and require significant warm-up times. Over the past decade, however, automated flash point analyzers have revolutionized routine quality control in refineries, laboratories, and distribution facilities.

Principle of Operation

Automated flash point analyzers typically use a closed-cup configuration, conforming to ASTM D93 standards. A small sample is placed in a sealed cup equipped with a temperature sensor and drugged stirrer. Heating is precisely controlled via a programmable microprocessor, raising the sample temperature at a uniform rate (often 1–6 °C/min). At defined intervals (for example every 1 °C rise), a miniature electric ignition source is introduced into the vapor space. The instrument’s optical sensor then detects the appearance of a flame or “flash”—automatically recording the corresponding temperature. Because the cup is closed, volatile compounds remain contained, improving repeatability and safety.

Key Features and Benefits

Automation and Reproducibility

Compared to manual methods, the automated process minimizes human error. Programmable routines ensure consistent heating rates, stir speeds, and ignition intervals, leading to repeatability within ±0.5 °C. The analyzer’s microprocessor logs all test parameters and results, creating an audit trail in digital or printed form.

Safety Enhancements

Closed-cup systems contain hazardous vapors, reducing operator exposure and risk of accidental fires. Many units feature built-in safety interlocks, flammable vapor detectors, and emergency ram dump functions that rapidly seal the sample cup in case of volatility anomalies.

Faster Throughput

Modern analyzers can complete a flash point determination in as little as 5–10 minutes per sample—up to 50 % faster than manual methods. Instruments often offer “quick test” modes, which use an accelerated heat rate and wider ignition intervals for preliminary screening, followed by a confirmatory detailed run if needed.

Compliance and Reporting

Instruments are designed to meet ASTM D93, ISO 2719, and IP 34 standards. Built-in software can generate customizable reports, flag out-of-spec results, and interface with LIMS (Laboratory Information Management Systems) via Ethernet or USB. This seamless connectivity streamlines data management within modern petroleum laboratories.

Applications

Fuel production and storage: Ensuring gasoline, kerosene, and diesel meet flash point specifications for safe handling and transport.

Marine and aviation fuels: Verifying stringent flash point requirements (e.g., jet fuel minimum flash point 38 °C) to comply with international regulations.

Lubricants and specialty oils: Evaluating base stocks and additives to guarantee consistent performance under varying thermal conditions.

Maintenance and Calibration

Automated analyzers require periodic maintenance to ensure sensor accuracy and mechanical reliability. Routine checks include verification of the temperature probe (using certified calibration baths), inspection of the ignition electrodes, and replacement of seals and O-rings. Many manufacturers provide auto-calibration kits or service contracts to maintain compliance.

Future Developments

Emerging technologies integrate rapid infrared heating and non-contact optical detection, further reducing test times and maintenance burdens. Coupled with AI-driven diagnostics, next-generation flash point analyzers will predict maintenance needs, self-optimize test parameters based on sample type, and offer cloud-based data analytics for global quality assurance networks.

Automated flash point analyzers exemplify how advanced instrumentation enhances safety, accuracy, and efficiency in petroleum testing—critical for both regulatory compliance and operational excellence.

0 notes

Text

A Complete Guide to Implementing a Planned Maintenance System Onboard Ship

Maintaining a ship in top-notch condition isn’t just about reacting to problems — it’s about staying ahead of them. That’s where a planned maintenance system onboard ship plays a critical role. Whether you’re managing a small cargo vessel or an entire fleet, having a proper strategy for scheduled upkeep can make all the difference in operational efficiency, safety, and compliance.

In this guide, let’s break down what a ship planned maintenance system is, why it matters, and how you can implement it smoothly on your vessels.

What is a Planned Maintenance System (PMS)?

A planned maintenance system for ships is a structured approach to carrying out regular, pre-scheduled maintenance tasks on ship machinery, equipment, and systems. Instead of waiting for breakdowns or failures, ship managers and crew rely on this system to prevent issues before they occur.

It covers everything from engine overhauls and lubrication routines to inspections of safety equipment and structural components. By keeping up with these tasks, a ship’s performance remains reliable, and expensive downtimes are minimized.

Why is a Planned Maintenance System Essential?

Implementing a vessel planned maintenance system isn’t just best practice — it’s often a requirement by classification societies and international regulations. Here’s why it’s so crucial:

Safety: Ensures that critical equipment functions correctly, reducing the risk of accidents.

Compliance: Helps vessels meet the standards set by SOLAS, MARPOL, and class societies.

Cost savings: Prevents costly breakdowns and emergency repairs.

Efficiency: Reduces unplanned downtime, ensuring smooth operations.

Types of Planned Maintenance Systems on Ships

If you’re exploring the type of planned maintenance system in ship operations, you’ll find that most systems fall into these categories:

Calendar-based maintenance: Tasks are scheduled based on time intervals (e.g., monthly, quarterly).

Running-hour based maintenance: Maintenance is scheduled after certain operating hours of equipment.

Condition-based maintenance: Uses data from sensors and inspections to decide when maintenance is due.

Predictive maintenance: Advanced systems use analytics and machine learning to predict failures before they happen.

Many ships today use a combination of these systems to ensure optimal performance.

How to Implement a Planned Maintenance System on Ship

Here’s a step-by-step guide to implement planned maintenance system on ship operations effectively:

1️⃣ Assess Your Vessel’s Needs

Every ship is different. Start by understanding the machinery, equipment, and systems on board. Create an inventory of all items that require maintenance, and gather manufacturer recommendations for upkeep.

2️⃣ Choose the Right Maintenance Software

A digital ship planned maintenance system helps in tracking tasks, generating reports, and scheduling jobs. Look for a solution that: ✅ Is user-friendly for your crew ✅ Complies with international standards ✅ Supports fleet-wide integration if you manage multiple vessels

3️⃣ Develop Maintenance Schedules

Work with your technical team to set up schedules for each piece of equipment based on its usage and manufacturer guidelines. Ensure you cover:

Main and auxiliary engines

Electrical systems

Safety equipment (lifeboats, fire systems)

Navigation systems

4️⃣ Train Your Crew

A system is only as good as the people who use it. Provide hands-on training to your engineering crew and officers so they can use the PMS effectively. Make sure they know how to:

Log maintenance records

Generate reports for inspections

Identify when tasks are overdue

5️⃣ Monitor and Improve

Once your planned maintenance system on ships is up and running, continuously monitor its performance. Are tasks being completed on time? Are there recurring issues? Use this data to fine-tune your schedules and processes.

Common Challenges and How to Overcome Them

✅ Crew Resistance: Some crew may see the PMS as extra paperwork. Address this by showing how it makes their jobs easier in the long run.

✅ Data Accuracy: Ensure accurate logging of completed tasks to avoid gaps during audits.

✅ Software Integration: Choose a PMS that can integrate with your other ship management systems, like inventory or procurement tools.

Benefits of a Well-Implemented PMS

By properly implementing a planned maintenance system onboard ship, you can expect: ✨ Fewer breakdowns and emergency repairs ✨ Improved safety records ✨ Smoother inspections from authorities ✨ Higher resale value of your vessels

Final Thoughts

A ship planned maintenance system isn’t just about ticking boxes — it’s about building a culture of proactive care and operational excellence on board. In today’s competitive maritime industry, ships that are well-maintained are the ones that stay ahead.

If you’re considering upgrading or implementing a new PMS, now’s the time to act. The long-term benefits far outweigh the initial effort.

0 notes

Text

How the Right Embroidery Machine Can Double Your Business Productivity

Running an embroidery business means balancing creativity with efficiency. Whether you're a small boutique or a large-scale embroidery business, your embroidery machine is the backbone of your operations. The right machine doesn’t just stitch designs—it can double your productivity, reduce costs, and help you take on more orders without sacrificing quality.

At R3V Enterprises, we’ve helped hundreds of businesses upgrade their setups and boost efficiency by 2X or more. Here’s how choosing the right embroidery machine can transform your workflow.

1. Faster Stitching = More Orders Completed Daily Older, single-needle machines are slow and limit how much work you can handle. Modern multi-needle embroidery machines (like 6, 12, or even 16 needles) allow

Automatic color changes—no manual thread switching, saving 30-50% time per order.

High-speed stitching—Some machines stitch 1,000+ stitches per minute, cutting production time in half.

Large hoops—Embroider bigger designs in one go instead of repositioning fabric repeatedly.

Real Impact: If you currently complete 20 hats a day, upgrading could let you handle 40+ without extra effort.

2. Less Downtime = Fewer Missed Deadlines A machine breakdown can cost you hours (or days) of lost work. High-quality embroidery machines from trusted brands (like R3V Enterprises) offer:

Durable construction—fewer breakdowns even with heavy daily use.

Easy maintenance—self-lubricating parts and error alerts prevent major issues.

On-site service support— At R3V Enterprises, we provide quick repair and maintenance to keep your business running.

Real Impact: Instead of losing $500+ per day on repairs, a reliable machine keeps you stitching non-stop.

3. Smarter Software = Fewer Errors & Redos Manual digitizing and design adjustments waste time. Modern embroidery machines come with:

Auto-digitizing tools—Convert logos into stitch files in minutes.

Stitch simulation—Preview designs before stitching to avoid mistakes.

Cloud storage—Save and access designs from anywhere.

Real Impact: Reduce design errors by 80%, meaning fewer wasted materials and happier customers.

4. Handling More Fabrics = Expanding Your Product Line Basic machines struggle with thick fabrics (like denim or leather) or delicate materials (like silk). Industrial-grade embroidery machines offer:

Adjustable presser feet—Switch between fabrics without tension issues.

Laser positioning—perfect alignment every time, even on tricky garments.

Cap embroidery attachments—easily add hats to your product lineup.

Real Impact: Expand from just t-shirts and polos to hats, bags, shoes, and more, doubling your potential sales.

5. Lower Thread & Energy Costs = Higher Profits Older machines waste thread and electricity. Newer models include:

Thread trim sensors—Automatically cut excess thread, saving up to 20% on supplies.

Energy-efficient motors—Reduce power consumption by 30-40%.

Precision stitching—fewer thread breaks mean less material waste.

Real Impact: By upgrading to a modern embroidery machine, you could be saving over 200+ every month just on thread and electricity costs.

That adds up to more than 2,400+ in yearly savings money that goes straight back into your business.

6. Scaling Up Without Hiring More Staff If you’re turning down orders because your machine can’t keep up, you’re losing money. Upgrading to a commercial embroidery machine means

One operator can manage multiple machines—no need for extra hires.

Batch processing—Stitch multiple items simultaneously.

24/7 production capability—Some machines can run overnight with minimal supervision.

Real Impact: Handle twice the workload without doubling labor costs.

Why Choose R3V Enterprises for Your Next Embroidery Machine? At R3V Enterprises, we don’t just sell machines—we help businesses grow faster and smarter. Our services include:

Expert machine selection—We match you with the perfect machine for your needs.

Installation & training—Get up and running quickly with no guesswork.

Ongoing maintenance & repairs—Keep your machines in top shape for years.

Trade-in options—Upgrade affordably by exchanging old equipment.

Final Thought: A Small Investment Now = Big Returns Later The right embroidery machine doesn’t just speed up production—it increases profits, reduces stress, and lets you take on more business.

If you’re still using an outdated machine, you’re working harder, not smarter.

Ready to double your productivity? Contact R3V Enterprises today for a free consultation on the best embroidery machines for your business!

0 notes

Text

Fuel Management Systems: Powering Efficiency and Control in Industrial Operations

In today’s fast-paced industrial landscape, managing fuel consumption effectively is critical to maintaining operational efficiency, reducing costs, and ensuring uninterrupted service. This is where Fuel Management Systems (FMS) play a transformative role. Whether in logistics, manufacturing, construction, mining, or any other fuel-intensive sector, the implementation of a robust fuel management system can directly contribute to business continuity and profitability.

What is a Fuel Management System?

A Fuel Management System is a technology-driven solution designed to monitor, control, and optimize fuel usage across an organization’s operations. These systems typically include hardware like fuel sensors, flow meters, tank level indicators, and software platforms that offer real-time data insights.

The core purpose of an FMS is to:

Track fuel consumption in real-time.

Prevent fuel theft and pilferage.

Monitor fuel quality and stock levels.

Generate detailed reports for compliance, audits, and performance tracking.

Optimize refueling schedules based on actual demand and historical usage patterns.

Importance in the Indian Industrial Context

In India, where industries operate in diverse terrains and often in remote areas with limited infrastructure, having control over fuel resources becomes even more crucial. Inefficiencies in fuel usage, leakage, and unmonitored consumption can lead to significant financial and operational setbacks.

With the rising cost of fuel and increased focus on energy efficiency, businesses are rapidly adopting fuel management systems to:

Reduce fuel wastage

Improve fleet and equipment productivity

Strengthen accountability at the ground level

Ensure better environmental compliance

Moreover, India’s growing dependence on uninterrupted fuel supply for sectors like telecom, warehousing, data centers, and logistics underscores the need for intelligent systems that offer visibility and control at all times.

How Fuel Management Systems Work

Fuel Management Systems generally operate through a combination of hardware and cloud-based software. Key components include:

Fuel Sensors: Installed on tanks or fuel bowsers to track fuel levels and flow.

GPS Integration: To monitor the movement of fuel and assets.

Automated Dispensing Units: That record each transaction with time, location, and volume details.

User Authentication: Ensuring only authorized personnel can initiate refueling or fuel access.

Dashboards & Reporting Tools: For centralized visibility, historical analysis, and real-time decision-making.

These systems can be deployed across fuel tanks at stationary sites or mobile fuel delivery units for enhanced control.

MyFuels: Delivering Comprehensive Fuel Management Solutions

At MyFuels, we go beyond traditional fuel delivery to offer an integrated suite of energy management solutions tailored to the dynamic needs of modern industries. Our Fuel Management System is built to ensure that every litre of fuel is accounted for, every refueling is traceable, and every decision is backed by data.

Our Offerings Include:

On-Demand Fuel Delivery: Timely and safe doorstep diesel refueling services for fleets, machinery, and generators.

Advanced Fuel Monitoring Systems: Real-time tracking of consumption, stock levels, and alerts for unauthorized usage.

Genset Rentals: Reliable power backup solutions with remote fuel monitoring.

Dual Fuel Converters: Reduce diesel dependency and costs by enabling cleaner alternative fuel use.

Lubricant Supply: Quality lubricants tailored for industrial-grade engines and heavy equipment.

Data-Driven Insights: Actionable analytics and reports to drive operational improvements and budgeting accuracy.

We work closely with sectors such as logistics, manufacturing, mining, telecom, construction, and infrastructure, ensuring uninterrupted energy flow while helping clients maintain complete control over their fuel ecosystem.

The Future of Fuel Management

As industries in India continue to adopt digital transformation, fuel management will become increasingly intelligent, automated, and integrated. From IoT-powered sensors to AI-driven consumption forecasting, the future of fuel oversight lies in smarter technologies that not only prevent losses but also enable long-term sustainability and savings.

Organizations that embrace these systems today will be better positioned to face tomorrow’s operational challenges and energy demands.

Conclusion:

Fuel is more than just a resource — it is the backbone of industrial operations. Managing it efficiently can make the difference between operational excellence and escalating costs. With comprehensive fuel management systems like those offered by My Fuels, businesses gain not only visibility but also control, compliance, and continuity.

For organizations seeking to modernize their fuel operations and minimize risk, adopting a trusted, scalable fuel management solution is not just an option — it’s a necessity.

#on demand fuel delivery#fuel delivery service#smart storage solutions#Mobile Fueling Solutions#Fuel Management Systems#FMS

1 note

·

View note

Text

Pump Capping Machine Maintenance: Tips for Longevity and Performance

In today’s fast-paced packaging industry, a pump capping machine plays a critical role in ensuring product integrity and efficient production lines. From cosmetics and pharmaceuticals to food and chemical industries, these machines are essential for applying pump-style caps accurately and securely. However, like any mechanical system, their performance and lifespan heavily depend on proper maintenance. Neglecting this crucial aspect can lead to frequent breakdowns, increased downtime, and costly repairs. To get the most out of your pump capping machine, a proactive maintenance approach is not just beneficial it’s necessary.

One of the first steps toward effective maintenance is understanding the specific components and working principles of your machine. A pump capping machine typically comprises a conveyor system, cap feeder, gripping belts, and the torqueing head that applies the cap. Each of these parts has a distinct role, and any disruption can affect the entire capping process. Therefore, keeping a close watch on the performance of each part helps detect early signs of wear or malfunction. Regular visual inspections can often reveal loose belts, misaligned heads, or buildup of debris—minor issues that, if left unchecked, may lead to major problems.

Lubrication is another fundamental aspect of machine maintenance. Moving components like gears, shafts, and motors need periodic lubrication to minimize friction and wear. Over time, lack of lubrication can cause these parts to degrade prematurely, affecting both the speed and accuracy of the machine. Manufacturers typically provide a lubrication schedule in the equipment manual, and following this routine diligently can significantly enhance operational efficiency and extend the equipment’s life span.

Cleaning plays an equally important role, especially when the machine is used in industries involving liquids, oils, or viscous products. Residue from these products can accumulate over time and interfere with the machine’s moving parts, sensors, or cap feeding mechanisms. A regular cleaning schedule helps prevent contamination and ensures that the equipment operates smoothly. It is also essential to use appropriate cleaning agents that do not corrode or damage the machine’s surfaces or sensitive components.

Calibration and alignment checks should be conducted regularly as part of preventive maintenance. Over extended use, the torque heads or gripping mechanisms may drift from their original settings, leading to improperly sealed caps or product leaks. These issues can affect product quality and lead to customer dissatisfaction or regulatory non-compliance. Verifying and adjusting the torque settings and alignment as per the manufacturer’s specifications ensures consistency in performance.

Software and electronic components also require attention. Many modern pump capping machines are equipped with programmable logic controllers (PLCs), sensors, and touchscreens. Ensuring firmware updates are applied and that sensors are functioning correctly is key to maintaining automation and reducing human error. Electrical connections should be periodically inspected to avoid faults due to loose wiring or moisture intrusion.

Lastly, maintaining a log of all maintenance activities can prove invaluable. This record helps track the frequency of repairs, identify recurring issues, and make informed decisions about replacements or upgrades. It also assists in scheduling future maintenance more efficiently and justifies investment decisions to upper management when needed.

A pump capping machine is a long-term investment, and like any asset, it requires regular attention to deliver maximum returns. Incorporating a routine maintenance schedule, focusing on cleanliness, lubrication, calibration, and timely repairs, will not only prevent unexpected downtime but also optimize performance and ensure consistent product quality. In the world of packaging, where precision and reliability are non-negotiable, maintaining your pump capping machine isn’t just good practice it’s a strategic advantage. Source: https://autopackmachinespvtltd.wordpress.com/2025/06/14/pump-capping-machine-maintenance-tips-for-longevity-and-performance/

0 notes