#Metal stud partitions

Explore tagged Tumblr posts

Text

Benefits of Metal Stud Partitioning | Ultimate Chippy

Metal stud partitioning has become a popular choice for both commercial and residential spaces. This modern construction method offers a range of benefits that make it a superior option compared to traditional wooden studs. Here are the key advantages of using Metal Stud Partitioning:

1. Durability and Strength

Metal studs are known for their exceptional durability and strength. Unlike wood, metal does not warp, twist, or split over time. This makes metal stud partitioning a long-lasting solution that can withstand the wear and tear of daily use. It's especially beneficial in high-traffic areas where robustness is crucial.

2. Fire Resistance

Safety is a top priority in any building, and metal studs provide an added layer of protection. Metal is inherently fire-resistant, reducing the risk of fire spreading through the walls. This quality makes metal stud partitioning an ideal choice for buildings that require stringent fire safety measures.

3. Pest Resistance

Unlike wood, metal studs are impervious to pests such as termites and rodents. This pest resistance helps maintain the structural integrity of the walls and reduces the need for costly repairs and pest control treatments over time.

4. Lightweight and Easy to Install

Metal studs are lighter than their wooden counterparts, making them easier to handle and install. This can significantly reduce labor costs and installation time. Additionally, metal studs come with pre-punched holes for running electrical and plumbing lines, further simplifying the construction process.

5. Versatility

Metal stud partitioning is incredibly versatile and can be used in a variety of applications. Whether you're creating office cubicles, dividing a large room, or building a new wall in a residential space, metal studs can adapt to any design requirements.

6. Sustainability

Sustainability is increasingly important in construction. Metal studs are often made from recycled materials and are themselves recyclable, making them an eco-friendly choice. Their long lifespan also means less frequent replacements, contributing to a reduction in overall material waste.

In conclusion, metal stud partitioning offers numerous benefits that make it a practical and efficient choice for modern construction. Its durability, fire resistance, pest resistance, ease of installation, versatility, and sustainability are compelling reasons to consider metal studs for your next building project.Benefits of Metal Stud Partitioning

For More:

Ph: 03 9504 4036

Mail id: [email protected]

Working Time: Monday to Friday 9:00am – 5:00pm

Website: https://www.ultimatechippy.com.au/

0 notes

Text

Birthday Week Vignettes

*

As a little gift for my bestie and worstie, for her birthday week, I’ve written a selection of fun little vignettes (stretching the terms fun, little and vignette to mean several thousand words of something gory or fucked up).

It has been the greatest and most treasured experience I’ve had on here getting to know you. From the hilarious shit talking, to expanding my horizons in terms of what I read and write, and giving each other constant new ideas and support, I am so grateful for all the downsides of existing in an online space as it’s meant making a wonderful, cherished friend. Happy birthday and may we enjoy your presence in our lives and this garbage fire for a long, long time to come! 😍😍❤️❤️😈😈 @safarigirlsp

*

Day 1; assassin!Mills x RC

*

Summary: The Museum needs two operatives to pose as a married couple and go into a chateau full of depraved people letting loose and acting out their fantasies in an Eyes wide shut-type party. That old chestnut.

A/N: I’m a sucker for going undercover as a couple, in every iteration of that trope, and undercover at a sex party is an especially fun variation. This little episode didn’t fit into my main assassin!Mills story, but it was too interesting to throw out completely, so this seems like the best way to share it. If you like the premise, I’m happy to write a conclusion for it.

CW: mentions of wlw, mlm, group sex, fetishes, voyeurism, dubcon, murder, drugs, alcohol, sex work

WC: ~5.5k

*

Cipher and Gage picked up their small leather bags soon after they landed, exiting the airport hand in hand. Cipher’s steel toe boots thumped loudly on the tiles, his long leather coat rustling with every casual move of his tall, broad frame. Gage sized him up out of the corner of her black-rimmed eye, appreciating the sexy, disheveled swoop of his sandy hair, the frosty glint of his blue eyes, his sharp jawline dusted with a few days’ growth of beard. Her eyes wandered lower, to the tight black tank top that peeked out from his unbuttoned white shirt, the studded belt drawn tight around his narrow hips, and the tightly coiled muscles of his legs working under his equally tight pants. She couldn’t wait to get her hands on him in the car. Their quick encounter in the airplane toilet was too short for her appetite.

She walked briskly in her six inch shiny leather boots, barely reaching his shoulder despite the added height, feeling the chill in the airport as a gust blew under her scandalously short skirt. A man walking past them balked at what the blown up material revealed and she giggled to herself. Cipher squeezed her hand tighter and walked even faster in retaliation, leaving her to practically run to catch up with him. They barely jumped into the stretch limousine parked and waiting to take them to the rendezvous point that Rostov decided on when Cipher pulled her roughly onto his lap and glared, squeezing his large hand painfully around her thigh until she squirmed and pouted, removing her round Windsor sunglasses and giving him a plaintive look, all innocence and invitation. She had often remarked that it didn’t serve him any good to get all worked up over other men ogling her like that; if he wanted an attractive and flirty wife like her, then there were consequences to deal with.

They had enough time to redress and clean up as well as could be managed on a backseat when the limousine pulled up on Museum property. The partition rolled down and an Acquisitions operative pointed the barrel of a gun at the pair.

*

The heavy metal door creaked and moaned as it was pushed open for Adriane. She entered the small circular cell, windowless and bleached by harsh white halogen lights, where Cipher and Gage sat bound and gagged.

Without gracing either with eye contact, Adriane walked briskly, sweeping an elegant circle around the small cell, her heels clacking an ominous rhythm on the concrete floor. “In a moment, you will be separated. You will never see each other again,” she spoke the chilling words quietly and emotionlessly, as though to herself, as she circled the young pair like a crow awaiting carrion to feast on. “Whoever talks first will go free. The other will not leave this place alive.” She tossed the last words over her shoulder as she slipped like a shadow out the door and it closed heavily behind her.

She was not negotiating. She was not trying to entice them with anything only to pull the rug out from under them, as other people they had dealt with in the past had. The pair understood the danger they were in as they locked eyes, determined to leave this place together, and alive.

*

30 minutes, my office. A, the letters scrolled across the beeper in your hand.

When you arrived, with a minute to spare, you were feeling pretty smug about yourself that you managed not to be late, to say nothing of the fact you were chosen as the operative to be entrusted with this last minute, highly sensitive task.

Adriane’s office looked like the wardrobe department of some grungy photo shoot, with distressed denim, faux leather, fishnets and studs galore. Racks and racks of clothing were hurriedly rolled in, no doubt for the purpose of outfitting for this impromptu exhibition you were going on.

“Our guests have a meeting with their prospective employer this evening. We intercepted the coordinates Rostov provided and took Cipher and Gage on a detour here,” Adriane informed as Mills strode out from behind a rack with an armful of clothes. You looked from him to Adriane, wondering if this was some test and her omitting he would be there was supposed to catch you by surprise. Satisfied you did not betray your heart jumping into your throat, you diverted your attention to the racks of female clothing surrounding you.

“Won’t he know we’re not them? You know, when he looks at us?” you asked too snarkily for someone who knew Adriane wouldn’t waste anyone’s time if this was a real concern.

“Rostov doesn’t know what they look like. Both he and our guests are too discreet in their dealings to allow something like that. And the private party you are attending is designed to ensure privacy. At least where your faces are concerned.”

You felt a nervous knot tie in your gut, thinking ahead at what the night would more than likely demand of you. “And their stupid nicknames?” you asked, forcibly casual, as you pressed a red plaid skirt to your hips, wondering if it would even cover half your ass.

“For the same reason. They are decently intelligent, cautious people in their business dealings, even if their behavior otherwise is questionable. Under different circumstances, they might have been potential operatives for the Museum. As it stands, their use is limited to a single outing.”

You followed Adriane to her laptop computer, as thick as a briefcase, sitting in front of her leather chair, with a video paused. Scattered on the desk were photos of Cipher and Gage, taken over the last few weeks, as evidenced by the changes in the color and style of their hair. They were photographed several times in rather compromising positions, not that they seemed to mind. Gage was always smiling brightly when her hand was shoved possessively in Cipher’s back pocket, and he was not shy about embracing her in a town square and kissing her with what you personally deemed to be an excess of tongue, with both his hands on her ass, peeking out of another too-short skirt. Frenzied moaning and the squeak of leather grabbed your attention and you looked up at the video Adriane played.

“This was just over an hour ago, in the back of the car we sent for them,” she informed, looking unimpressedly at the screen.

The parallels between you and Julian were not lost on you. Two people, outrageously in love, killing for a living. Except the pair rutting wildly in a limo were free to be out in the open, not concealing anything from anyone, while you could only look at Julian askance and steal brief moments when you were sure no one was looking, which was hardly ever.

“The girl has great stamina,” you quipped, averting your eyes discreetly. From their copious, almost defiant public displays of affection, you didn’t imagine either would be bothered to know a few people had watched some blurry, low resolution footage of their intercourse, but the aversion was for your sake, not letting the Museum make a voyeur out of you. It was enough they made you a ghost and a killer.

“You need to become Cipher and Gage for the duration of this Exhibition,” Adriane underscored. “They are ruthless, reckless, and passionate. Their reputation precedes them in Rostov’s inner circle.”

“We understand,” Mills assured, seeming to imply that even if you didn’t quite get it, he did.

Adriane came up to stand next to you and snatched the blue tinged, white rimmed sunglasses off your face, replacing them with a dark, edgy pair more in line with Gage’s confirmed style. “Rostov is a hedonist with wild delusions of grandeur. He will try to flirt with you, and his demands are known to go far,” she informed in a tone that signaled you were to go along with it, as far as necessary.

“I’m cool,” you shrugged, stomach twisting with disgust you were still not entirely able to suppress.

“He will likely flirt with you too, Julian,” Adriane said in the same demanding tone to him.

“Mh,” he grunted vaguely, shucking on a leather biker jacket and ruffling his hair, as he studied his reflection, deciding if it all came together just right for Cipher.

You barely contained a grin, thinking of this scrawny little man, twisted with perversion, trying to entice the architectural marvel that was Julian Mills.

A clink of metal on hard wood rang through the air. “Put these on.”

Julian made his way to Adriane’s desk first, picking up the two rings with discreet tracking devices installed inside. He deftly slipped the smaller one up to the knuckle of his ring finger and let the other one drop. You followed moments behind and picked up the ring off the desk. It gaped around your ring finger, looking too big even for your thumb.

“Doesn’t fit,” you dismissed, setting it down and pushing it towards Adriane.

“Let me,” Julian said lowly, his long, thick fingers wrapping around your wrist. He brought your hand up and twisted the ring off his finger, sliding it carefully over yours and inspecting his work when he was done. He seemed to approve of the way your hand looked adorned with his wedding ring.

He then picked the other ring up and set it in your hand, expecting you to put it on him.

“Do I have to love, honor and obey?” you looked up at him as he offered a waiting hand. His silence filled the air with crackling intensity and you fought with yourself not to look away.

“Just obey,” Adriane answered for him and brought the moment to an end. Without ceremony, you slipped the ring on Julian’s finger and turned away from both of them.

Obey, you scoffed inwardly. Love was easy. Honor, you conceivably could. The only demand they both had of you was the one you struggled with most.

“You leave in 15 minutes,” Adriane informed as dispassionately as ever.

Before you left, curiosity got the better of you. “You got all this information out of them… Which one cracked?”

“They both did, of course,” Adriane gave a serene, composed smile, assured in the Museum’s methods.

“So who got to go free?”

Adriane blinked and for a moment, you had the distinct sense a huge grin would slice across her face. A jeering, hideous one, mocking your naiveté. “You should go get ready,” was all the reply she would give, and all the reply you needed.

*

As you descended in the gold-adorned elevator, on your way to the armory, Julian was quiet, looking at his panel and committing every detail of the plan, of Cipher and Gage’s history and activities, of intelligence on Rostov - all he could - to memory.

“Why was I chosen for this task?” you asked, choosing the opposite approach to Julian’s and clearing your mind before jumping into the task at hand.

He was silent as you descended for several levels and you started to assume he had not even registered your question. “It was an opportunity to improve your field mechanics,” he answered like a politician on the campaign trail.

Silence then followed from you. “Field mechanics,” you repeated, deeply unconvinced.

He turned and looked hard at you, pleading with you to hear what he was not allowed to say. “Adriane is under the impression that we are convincing as two people in love.”

It was not a compliment. The words had the cadence of a slur, and his tone of regret. It was not a good thing at all. He narrowed his eyes, satisfying himself that you took his meaning correctly.

*

The warm sunset, full of purples and oranges, gave way to a fine evening as you drove outside the city. As soon as you exited, you donned your masks as a precaution, wary of how far Rostov’s eyes reached. Yours was a white mask that extended into a crescent moon shape above your forehead and under your chin. Along its edges and around the eyes, the mask was outlined in silver and small stars twinkled along its face. Julian’s mask was white and gold, representing the sun, with five curvy rays creating an inverted pentagram around the smooth white face of the mask, adorned with golden arabesque designs. You looked at each other once the masks were on and the eerie blank canvass they presented, not knowing what face and expression they hid, was chilling.

You joined the scattered trail of other cars, uniformly black and armored, as they traveled noiselessly down a private road that would have been impossible to find without very specific instructions. The road was maintained to perfection, allowing you to glide smoothly down and weave its serpentines as they appeared without the slightest trouble. If not for the heady mix of trepidation and excitement that kept you wired and buzzing awake, you could have been lulled into a dreamlike sleep and sunk into the impenetrable darkness that surrounded you.

After stretching for what felt like an eternity, the road finally ended at a well-fortified gate, where you were ushered in and led up a lavishly landscaped path. A veritable army of masked guards stood sentinel all along the path, the entrance to a grand building and all the way to a sequestered area separated by gold stanchions and a red rope. Neither the host nor the guests wanted the security’s scrutiny while indulging in their hidden pleasures, a mistake that Julian and you were instructed to exploit. Behind unadorned gunmetal gray masks, the guards’ eyes followed every guest as they approached the rope forbidding entrance to the room beyond to all but a select few. There, you were instructed to shed your clothing and don party attire.

Rostov had purchased the magnificent château a few years back and it currently served as the crown jewel of his ostentatious tendencies and debauched proclivities. He restored it to its former glory, and had it outfitted with every modern comfort to boot, ensuring maximum pleasure and safety. It soon became the perfect place to host his monthly bacchanals, a pleasurable distraction from his usual activities of acquiring and testing biological weapons.

Invitations were handed out either to former collaborators who had displayed a keen sadistic and perverted streak, or to prospective talent, like Cipher and Gage, to ascertain if they possessed the requisite depravity of character to join in on Rostov’s activities unflinchingly. Masks and the privacy of the location guaranteed zero risk of discovery and damage to anyone’s reputation that would result from engaging in this sort of activity in a public venue.

With that in mind, you did not hesitate to disrobe. There was little to remove anyway and the mask served another useful purpose in making you bolder by hiding your face and whatever chagrined expression it might reveal. Julian watched, his eyes moving appreciatively behind his white and gold mask, as your skirt hit the floor and you removed your cropped top in one smooth movement. He waited, and at first you wondered why, but quickly surmised he meant to wait and have you undress him. You were proven right when he stepped into you as your last stitch of clothing came off and stood facing you, to shield you from any prying eyes. He did not put it beyond this rabble to be spying on guests as they changed. You slipped his trench coat off and, suddenly aware of your nakedness and his imposing proximity, made quick work of his shirt and pants, unzipping them roughly and making him flinch, before tugging them down just as harshly. Remembering your role, you chuckled, as though you had done it to tease him and crossed your arms over your bare chest, eager for the dress, as revealing as it was. Julian seemed unfazed by being completely naked in a large anteroom and offered the white halter neck satin dress for you to step into. The dress had a large slit in the side and flowed with every step, and the back was left entirely bare. It glided as smoothly as water up your body as he pulled it up and tied it at the base of your neck. He pressed his mask into your neck, in an approximation of a steadying kiss, and you felt the length of his body pressed into you, with the material of the dress dividing you leaving little to the imagination.

Julian’s attire was similarly revealing. A similar white material folded and tucked in around his hips, like the bottom half of a toga, and draped over his torso, cinched over one shoulder with a gold hoop and cascading down like a cape. He looked like an ancient marble statue, its perfection exaggerated by an impassioned artist in ardent love with his model, was brought to life.

The low thump of the music pulsed through the closed door as you neared it, and Julian brushed the bare skin of your lower back with his clever fingers as he claimed your waist, holding you close to his side as you ascended the steps and entered the party.

The renovated château was a blend of showy rococo and sleek modern styles. The dichotomy made for a luxurious experience, striking a balance between the lavish furnishings of the past and the present-day creature comforts, such as telephones, cameras, air conditioning, and modern mechanics. You followed a servant, distinguished by her plain gunmetal gray mask, into a spacious ballroom where the main activities were taking place. Heavy velvet curtains were drawn over the tall windows that lined the walls, keeping the lighting in the room low and atmospheric with only the dimmed chandeliers and scattered candelabras to set the mood. Dry ice created a mist swirling around the floor and ghosting around your steps. Erotic house music filtered in from the speakers embedded high above, and its thumping bass rattled in your bones as it provided a steady rhythm to rut to.

You passed sections of the ballroom, some divided by pillars and more heavy drapery, others raised on a dais, and each offered different activities. In some, more accessible areas, guests mingled and leaned masked faces close to exchange conversation and toasts, lifting only the bottoms of their masks to take quick sips. On a chaise longue, red and trimmed in gold, lay a man with his toga hiked up around his waist, straddled and vigorously ridden by a woman with nipple piercings connected by a series of chains and pendants, and her dark skin extensively tattooed. A small group of people, in various stages of undress gathered around them and commented on the participants and their activity.

You passed onto a higher level, leaving the couple behind you, and noticed that this area had raised platforms around one central viewing point. Each platform had two red leather sofas, one lower and one higher, permitting more positions and participants, surrounded by several waist-high columns. Each column held an object for members to use, either for pleasure or pain. You took in a few, including phallus-shaped implements, ball gags, riding crops, and pliers. In the viewing area, more of those comfortable chaise longues were laid out for those wishing to observe. Several platforms were currently occupied, but one drew your attention. A masked woman had her long legs wrapped around two men, one inside of her, the other inside of the man between them, and the three were being observed by a masked man in a black robe. He was one of Rostov’s inner circle, designated by his robe as untouchable – unless he asked to be – and irrefusable. His build was wrong; he was too young and too fit to be Rostov, so you moved on.

Sooner rather than later, you remembered as the stench of too many bodies fucking in an enclosed space hit your nostrils, you would have to engage in some activity yourself, lest your restraint draw unwanted attention. Even now, you felt appraising eyes land on you and Julian as you passed. You could not blame them. For all the young and attractive participants present, paid or drugged, who walked around and offered themselves like hors d’oeuvres to be sampled, they smacked of sex workers who were only doing a job. Some had the shaky, twitchy physique of junkies, while others had the used up bodies of veteran sex workers. You and Julian, by contrast, were trained by the Museum to be lethal, and having looks to kill was not a mere phrase where you came from. All those lessons in walking runways, learning classical dances, gymnastics, yoga, and the subtle art of erotica over the two years of your training made you both stand out in the most noteworthy way. Every step showed off your bodies, effortless grace and proud bearing; every brush of your fingers against Julian’s sculpted arm promised something more between you, and you felt eager eyes follow you, hoping to witness the moment you decided to take it farther.

The sounds of leather cracking and moans, quickly drowned out by delighted praise or mockery, led you into a large chamber, lined with ornate columns. A red carpet painted the floor red and several servants walked unobtrusively around with smoking censers, diffusing aphrodisiac scents around the cavernous chamber and perfuming the aroma of sex before it grew stale. In its center sat a long table, with a smorgasbord of men and women on top. From your vantage point, you could see two women with their heads between the other’s legs, one on her back, the other over her on her knees, both writhing and exaggerating their pleasure as their surgically enhanced breasts jiggled in one unmoving spot. Next to them were two handsome men on their sides, performing the same act and moaning deeply around the other’s shaft. In the middle was a piano bench with three women of widely varying ages in an embrace, busily alternating positions and acts. Around the table sat the more important attendees, watching, some stroking themselves or others under the table. The first woman you’d seen dressed in a black robe sat on the lap of a bony old man, his skin hanging like wet paper over his frame. She wriggled on his lap from his touch under her robes and pulled up a sleeve to offer her arm. He produced a syringe and injected her with a cloudy substance before resuming his ministrations. Julian walked by and caught the woman’s attention. She reached out for him and he extended her a hand, letting her pull him in close as she arched her back and spread herself across the table for him to sample. Julian loomed over her until she couldn’t wait anymore and tugged on his arm, splaying his large hand over her comparatively small breast, instructing him to knead at her chest. He did so, leaning closer over her so he could swipe the empty syringe from the floor and tuck it into the folds of his clothing. When he accomplished his task, he disengaged from the woman and you could see her roaming hand had found his way in between the folds of his toga and was trying to get in another one or two strokes as he retreated. As his partner, his wife, for the evening, you felt no need to disguise either your proprietary sense or your jealousy. Grabbing for his elbow, you jerked him towards you and spun him out of the way, positioning yourself between the woman in black and the object of both your desires. Too late it occurred to you that it could be huge mistake to challenge a high-ranking member. Your body spoke for itself, like a cat bristling and hissing, ready to claw out any eye that rested too long on Julian. You looked at her hand, suspended in midair as she considered demanding Julian back. With what relish you would break each and every finger, enjoying the snap of each knuckle. The flash in your eyes seemed to communicate this rather eloquently to the women and she turned back to the decrepit old man she was sitting on and threw her head back, her deranged laughter muffled behind her mask. The scene drew many masked faces to turn towards you and examine you with uncanny glittering eyes from behind impassive disguises. They had the eerie curiosity of carrion birds, waiting for their prey to become carcasses.

Julian drew you close, acting possessively, as if the fighting and territorial behavior was part of your foreplay. Grinding his hips into your backside, you felt him stiffen reflexively. His hands squeezed your hips and you threw your head back against his broad shoulder, letting him play out the scene and get you safely away. His hands roved up your body, following the contours of your waist and ribs. One hand slipped inside your dress and drew a lazy circle around the nipple, drawing it into a stiff peak and rolling it between his rough fingers. You let a shudder roll visibly through you and pressed your thighs theatrically together for the benefit of those savoring your reaction, creating some friction and relief. Julian’s other hand snaked up and coiled around your throat as he bent to whisper in your ear. “Fuck,” you heard a guttural grunt as he panted behind his mask, and his strained voice sent a jolt of pleasure through your body. You arched your back into him before you could think not to and his hips responded with a deep thrust as his stiffening cock sought some relief against the curve of your ass. “We should get out of here, he’s--” words failed him and he had to swallow hard before resuming, “he’s not here.”

As you straightened up, trying to find the closest exit point and make for it, one of the marauding sex workers, emboldened by whatever chemical cocktail she was on, made her way to you and placed one hand over the breast Julian wasn’t cupping, and the other around his neck, inviting herself into your company. Not worried about causing trouble due to her rank, you unceremoniously slapped her hand away from Julian, to delighted comments and encouragements from the throng watching on. She tottered like a toddler and you knew a single push could knock her down, and in her state, she likely wouldn’t even feel it. Still, she did not take the hint and tried to touch Julian again. His hand fell away from you and you caught her wrist, twisting only a little before she crumpled into the ground.

As you turned to leave, you nearly bumped into a woman, stripped to her waist, holding a young man’s wrists over an antique letter writing desk. Another woman, with sagging breasts that suggested breast feeding several children, bound in a leather harness, was whipping the youth across the back while an old man in black robes held his hips and frantically pumped. His legs were wiry and crooked and his gut was visibly round as he worked around the protruding flesh to stick his small member into the young man. You squeezed Julian’s thigh in question, as the gesture could be viewed as announcing your eagerness to join in. He wrapped his hand around yours and stilled you, signaling no. Rostov was scrawnier than this round-bellied man. But you were likely getting close.

Julian raised his masked head towards the upper levels of the chamber. All along the top floor were small viewing chambers, like opera boxes, and most of them held a member dressed in black, with a select guest, or guests, keeping them company. It was there he spied him.

Rostov, ever the attention seeker, was the only attendee with a mask made entirely of gold. Noticeably shorter than the naked woman accompanying him, he seemed to be watching Julian too. Without flinching or looking away, Julian stood and waited for a few beats. Finally, Rostov seemed to make up his mind and with a quick summoning gesture, a servant materialized next to you and asked you to join the host on the uppermost level.

As you were led along the balustrade to Rostov, you saw peep show-like personal rooms with acts going on in glass cages. These seemed to be one per box and, anticipating that you were brought here to perform rather than talk, you were grateful you wouldn’t be ogled by a multitude of criminals. Just one.

In one box, there was a woman in thigh-high boots and a collar around her neck, with a leash leading to some unseen master, bound to a velvet-cushioned chair. The viewer was issuing commands on what was to be done to her and you tried not to listen as you passed that box and approached another. In the glass box, a throuple was enjoying hot wax and blindfolds. At Rostov’s box, you saw a naked man wipe himself down as he exited and a pair of servants untied the woman and helped her out of a harness. The truncated scene confirmed what Julian had shared about Rostov and his penchant for more dominant men and submissive women. Gage’s impish and dominant behavior was a departure from that, so you made sure to remember not to play a meek, passive role.

The small man, hardly larger than a child, wore a golden mask that was reminiscent of hannya masks from Japanese theater, with large eyes, and a twisted grimace with a gaping mouth, revealing sharp teeth. Rostov examined Julian first, holding his large hand in his two small ones, looking at the golden band on his ring finger. He gave yours a glance to confirm he had it right, and let Julian’s hand go. As if examining a thoroughbred, he ran his hands over Julian’s thickly muscled chest, the marvelously sculpted ridges and valleys of his arms.

“You hold Gage so close, so very close,” Rostov said in a thick accent and sighed. “I can see why.” He ran a finger over your mask, down its smooth, cool cheek, and lower still, dragging his small hand flat down your chest, down the valley between your breasts. Julian shifted his weight and his chest involuntarily puffed up, making Rostov huff a small laugh.

He walked a few small steps away, into his box, and Julian surmised he should follow. When Rostov lounged on the divan, Julian did the same, and they were at last on the same plane.

“From the moment you two walked in, I had one single thought.” He waited until Julian leaned in closer, tacitly asking for an answer. “I want to fuck your wife,” he stage-whispered, loud enough for both of you to hear. “This is a family, Cipher,” Rostov placed a proprietary hand on the back of his neck, pulling him intimately in. Without the masks, they would have been a hair away from kissing. Julian heard Rostov’s labored breath behind his mask and was sure the man was hard to bursting, though his proportions were such that robes successfully hid on his body what they could never hope to hide on Julian. The man’s eyes devoured him, taking in his body greedily, lust shining in his beady eyes. “We do everything as a unit,” he coaxed.

Julian did not blink. He was playing the role of a man who did not share the woman he loved, and it came naturally to him. Both he and Cipher were the sort to risk powerful people’s displeasure for what they truly wanted. He observed his host, aware of his own intensely masculine appeal and let the man’s desire win out, breaking his determination and making him willing to negotiate.

“Bah,” the little man waved a frustrated hand, “I can see that your wife is not the sharing sort – for a moment there, I was worried she would break my wife’s arm when she was playing with you. And you can imagine the sort of pain in the ass she would be then,” Rostov laughed and phlegm rattled in his lungs. “I’m saddened to see you have the same sick notions of fidelity.” He sighed again and shook his head. “I’ll satisfy myself with watching you this first time, then.” With the matter decided in his mind, Rostov rolled away from him, and servants came in to escort you and Julian inside the glass box, while the pair that was in it before you came back and fell into an embrace with their host.

*

@thegrislady @lumberjack00fantasies @queeniebee @vedavan @mythrielofsolitude @house-of-cadwyn

97 notes

·

View notes

Text

youtube

How To Get Lathing and Plastering Contractors License C35

In this video, we'll show you how to get a lathing and plastering contractors license C35 in California. This is a required license if you want to do work in the Lathing and Plastering industry in California.

The lathing & plastering contractors license will allow you to coat surfaces with a mixture of sand, gypsum plaster, quick-lime or hydrated lime and water, or sand and cement and water, or a combination of such other materials that create a permanent surface coating, including coatings for the purpose of soundproofing and fireproofing. These coatings are applied with a plasterer's trowel or sprayed over any surface which offers a mechanical means for the support of such coating and will adhere by suction. This contractor also installs lath (including metal studs) or any other material prepared or manufactured to provide a base or bond for such coating.

A lathing & plastering contractor also applies and affixes wood and metal lath, or any other material prepared or manufactured to provide key or suction bases for the support of plaster coatings. This classification includes the channel work and metal studs for the support of metal or any other lathing material and for solid plaster partitions.

Before you can apply for your lathing & plastering contractors license, you must meet the following experience requirements:

4 years of experience performing/supervising lathing & plastering (C-35) work.

Social Security number or ITIN

Be at least 18 years old

#how to get c35 lathing and plastering contractors license#how to get lathing and plastering license#how to get lathing and plastering contractors license#how to get c35 license#how to get c35 contractors license#lathing and plastering license requirements#obtaining lathing and plastering license#how to become c35 contractor#c35 license#c35 contractors license#lathing and plastering license#Youtube

1 note

·

View note

Text

Top Applications of Drywall Screw in India’s Interior Work

India’s interior design and construction industry is evolving rapidly, with increasing focus on precision, durability, and modern aesthetics. One small yet crucial component in this process is the drywall screw. These screws are designed specifically for fastening drywall sheets to metal or wooden studs, and they play a key role in creating sleek, strong, and seamless interiors. Raj Industries, as a trusted name in fastener manufacturing, understands the significance of quality hardware.

Securing Gypsum Boards with Drywall Screw in India

Gypsum board installation is one of the most common applications of drywall screw in India. Whether used in ceilings or walls, these screws help secure the board firmly to the framework without cracking or damaging the material. Drywall screws are designed with a sharp point and fine or coarse threads to penetrate gypsum efficiently and hold it tightly in place.

Installing False Ceilings Using Drywall Screw in India

False ceilings, or drop ceilings, are a major trend in modern Indian interiors, especially in offices, hotels, and urban homes. The use of drywall screws in India for this application ensures a safe and sturdy ceiling frame. These screws are ideal for attaching metal framing channels and ceiling boards. Raj Industries offers corrosion-resistant variants that are especially valuable in moisture-prone areas such as bathrooms and kitchens.

Drywall Screw in India for Partition Wall Construction

Drywall partitions are widely used in commercial spaces to create flexible layouts. Drywall screw in India plays a vital role in ensuring these non-load-bearing walls are stable and soundproof. The strength and precision offered by Raj Industries’ drywall screws make them ideal for joining drywall sheets to metal or wood studs in partition systems. These screws minimize the need for adhesives or nails, offering a cleaner, faster, and more durable solution.

Fitting Electrical Boxes Behind Drywall Panels

Another essential application of drywall screw in India is in the installation of electrical boxes, panels, and wiring conduits within drywall-covered walls. In this case, the screw not only secures the drywall itself but also helps fasten hidden boxes and fixtures. Raj Industries supplies screws with the perfect thread length and head size to ensure a flush surface while still maintaining grip and support behind the panels.

Mounting Lightweight Fixtures with Drywall Screw in India

From wall-mounted shelves to decorative panels, many fixtures rely on drywall screw in India for a solid and secure hold. These screws are designed to bear moderate loads, making them perfect for items like photo frames, wall art, or light shelving. Raj Industries’ screws provide precise threading that anchors firmly into drywall without requiring wall plugs or additional fittings. This makes installation quick, simple, and damage-free.

Repair and Remodeling Projects in Urban Homes

Urban homes often undergo regular upgrades and remodeling. Drywall screw in India is a preferred fastener for minor repairs, like fixing cracks or replacing damaged panels. Unlike nails or adhesive, drywall screws offer easy removal and reinstallation, allowing homeowners to make changes without professional help. Raj Industries offers a range of screws suitable for different thicknesses of drywall and support material, giving DIYers the confidence to tackle repairs with ease.

Enhancing Fire-Resistance and Soundproofing Measures

Drywall screws are not just about holding boards—they also support advanced interior solutions like fire-rated walls and soundproof panels. The demand for sound insulation and fire resistance has grown in India’s residential and commercial buildings. By using certified drywall screws in India from Raj Industries, builders can ensure that these special boards are fastened according to code and retain their performance properties.

Conclusion

The use of drywall screw in India has expanded far beyond basic wall installation. With applications in partitions, ceilings, fixture mounting, and specialized safety features, these fasteners are essential tools in modern interior construction. Raj Industries continues to support India’s growing need for durable, efficient, and application-specific fasteners by offering a wide range of drywall screws that combine strength with convenience.

0 notes

Text

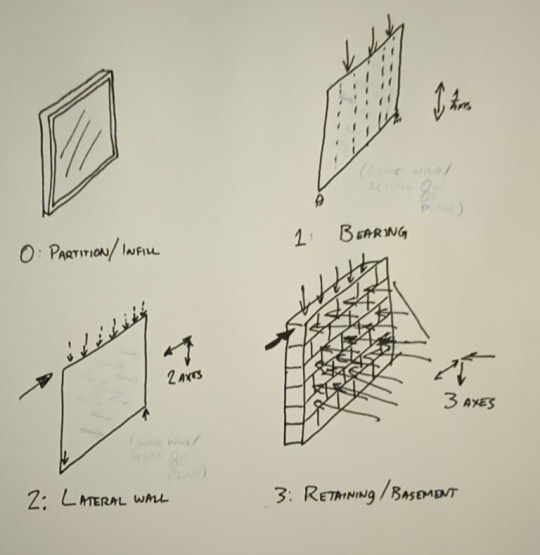

What's that wall doing? A helpful categorization of walls by structural functions (inspired by the sandwich cladistics):

The question boils down to: How many of the walls axes are ready to be heavily loaded?

0. Partition wall/infill wall: maybe suitable for hanging a picture or leaning against, but mostly here to divide space visually and acoustically.

1. Bearing wall: permanently carries the "dead" weight of one or more floors or roofs, plus live (people, furniture) and environmental (snow, rain, ice) gravity loads. Should also stand up to temporary wind or earthquake loading "out-of-plane" if exterior-facing or decorated with heavy brick/stone.

2. Lateral wall (shear wall, strap wall): keeps the building from falling over by carrying the sideways loads along the wall. Often wood, masonry, or concrete. If wood studs, then covered with plywood, drywall, or maybe metal straps. Don't forget to tie down the corners to keep it from rolling away. Usually also a bearing wall unless weird circumstances tell it not to be.

3. Retaining wall (foundation/basement wall): Keeps dirt and/or water on one side of the wall. Does this by carrying permanent soil and fluid loads "out-of-plane" (against the face), sometimes braced at the top by a floor, sometimes not. Almost exclusively concrete or masonry (very occasionally stone rubble). Almost always also a bearing wall, often a lateral wall if it needs to be, but exceptions happen once in a while.

(caveat: specific terms may vary outside of the US, but these should get the point across if you're ever trying to Talk About A Wall.)

#the carpenter is a licensed structural engineer in co and nm#and the much more risky post#would be categorizing these walls by#how screwed you are if you remove one and how quickly you find that out#because if the number is above 0 there is some degree of hazard no matter what#3 will let you know instantly (caving in)#1 will let you know pretty quickly (sagging floor/roof prior to collapse)#and 2 will wait until the next windstorm to surprise you#in any of the above cases if you're lucky you might get some impressive cracks in the drywall/plaster finishes before the catastrophic fail

1 note

·

View note

Text

Drywall Screw in India A Complete Guide for Builders and Contractors

Drywall screws have become an essential component in India’s modern construction landscape, offering strength, efficiency, and ease of installation. Designed specifically for securing drywall sheets to wooden or metal studs, these screws provide a firm grip and reduce the risk of wall damage over time.With the rise in residential and commercial construction across India, the demand for high-quality drywall screws has surged. Builders and contractors now rely on these fasteners for their precision, corrosion resistance, and compatibility with power tools. This guide explores everything you need to know about drywall screws in India from types and sizes to sourcing and applications.

Understanding the Role of Drywall Screws in Construction

Drywall screw in india are specially designed to fasten drywall sheets to wooden or metal framing, offering superior holding power and ease of installation. Their sharp tips and fine or coarse threading allow them to penetrate materials quickly and securely. In Indian construction, drywall screws are now preferred over traditional nails due to their reduced risk of wall cracking and enhanced long-term durability. Builders and contractors favor these screws for both residential and commercial applications. Their ability to be used with power tools increases efficiency, making drywall installation faster, cleaner, and more reliable across varied project scales.

Types of Drywall Screws Available in India

Indian markets offer a wide variety of drywall screws to suit different materials and applications. Coarse-thread screws are ideal for securing drywall to wood, while fine-thread screws are used for metal studs. Bugle head screws help distribute pressure evenly, preventing paper tears on drywall surfaces. Some variants come with phosphate coating for added corrosion resistance, especially in humid or coastal regions. Self-drilling drywall screws are also gaining popularity for their convenience and speed. Knowing the right type to use can significantly improve project outcomes and reduce long-term maintenance costs for builders and contractors across India.

Benefits of Using Drywall Screws Over Traditional Fasteners

Drywall screws offer several advantages over traditional nails and generic screws. Their specialized design ensures tighter fastening, minimal surface damage, and improved alignment of drywall panels. For Indian builders working on time-sensitive projects, the efficiency of power-tool compatibility means faster installation with fewer labor hours. Drywall screws also reduce the chances of loosening over time, which is common with nails. Their corrosion-resistant coatings add to durability, especially in varying Indian climates. These benefits make drywall screws a smart investment for anyone looking to improve build quality and reduce post-construction repairs or readjustments.

Common Applications of Drywall Screws in Indian Projects

Drywall screws are used extensively in various construction segments across India, from urban apartment buildings to commercial complexes and interior renovations. Contractors rely on them for installing gypsum boards, ceiling panels, and partition walls. In modular and prefabricated structures, drywall screws provide the speed and flexibility required for modern construction methods. They are also used in custom interior projects like false ceilings, acoustic panels, and drywall framing systems. Whether the requirement is structural or aesthetic, drywall screws play a crucial role in providing reliable fastening solutions, contributing to the strength and finish of the final installation.

Choosing the Right Size and Specification for Your Project

Selecting the correct size and specification of drywall screws is vital for ensuring structural stability and long-term performance. Screw lengths typically range from 19mm to 76mm, depending on the thickness of the drywall and the material of the studs. Indian manufacturers offer screws with different shank diameters, threading styles, and coatings to match various environmental conditions. Builders should also consider whether the project requires coarse or fine threads, and whether to opt for self-drilling options. By choosing the right screw for the job, contractors can avoid issues like panel sagging, surface damage, or premature failure.

Top Indian Manufacturers and Brands to Consider

India is home to several reputed manufacturers producing high-quality drywall screws that meet global standards. Brands like Patta, Revlon, LPS Bossard, and Kapson Fasteners are known for their precision engineering, corrosion resistance, and competitive pricing. These companies use automated production lines and undergo strict quality control checks to ensure reliability. Many Indian manufacturers also export globally, underscoring their credibility. Builders and contractors should look for suppliers who offer a wide product range, timely delivery, and customization options. Partnering with a trusted brand ensures consistency in performance and helps streamline the procurement process for construction professionals.

Tips for Effective Drywall Screw Installation

Proper installation of drywall screws ensures a smooth finish and prevents structural issues. Always use a power drill or drywall screw gun for consistent depth and speed. Avoid over tightening, as it can break the drywall surface or strip the screw threads. For ceiling installations, ensure that screws are evenly spaced and fully embedded to support the panel weight. It’s also important to use the correct screw length for different wall or ceiling assemblies. In Indian conditions, where humidity can vary, using coated screws helps prevent rust. Adhering to best practices during installation enhances the overall quality and longevity of the build.

Conclusion

Drywall screws have become a cornerstone of modern construction in India, offering strength, efficiency, and reliability for a wide range of applications. Their specialized design ensures secure fastening, minimal surface damage, and long-term durability key factors for builders and contractors aiming for high-quality results. With a variety of types, sizes, and coatings available, Indian manufacturers are meeting the evolving needs of both local and global markets. By understanding the right selection and installation techniques, professionals can significantly enhance project outcomes. As demand for smarter building solutions grows, drywall screws will continue to play a vital role in India’s construction landscape.

0 notes

Text

Metal Frame Stud Partitions | Triad Machines

The metal stud dividers made by Triad Machines are sturdy and durable. Perfect for any kind of construction job. Make your purchase now!

Metal Frame Stud Partitions

0 notes

Text

Affordable Drywall Screw Options for Indian Construction Projects

Looking for cost-effective drywall screw in India for your next construction project? Raj Industries offers a wide range of affordable drywall screw options designed to meet the diverse needs of Indian builders and contractors. Our screw are made from high-quality materials to ensure durability, rust resistance, and easy installation, making them ideal for both residential and commercial projects. Whether you're working on ceilings, partitions, or interior walls, Raj Industries provides reliable fastening solutions that don't compromise on quality. With competitive pricing and nationwide delivery, we make it easy to access the right products without exceeding your budget. Choose Raj Industries for dependable drywall screw in India and experience the perfect balance of affordability and performance.

Importance of Using the Right Screw in Drywall Projects

Choosing the correct screw for drywall installation is crucial to ensure long-lasting structural integrity. In India’s diverse climate and building environments, not all fasteners perform equally. A well-manufactured drywall screw reduces the risk of wall damage, increases safety, and ensures better grip on different surfaces. Raj Industries understands the technical demands of Indian construction and offers optimized fasteners for varied conditions. Whether used in large infrastructure or small home renovations, selecting the right drywall screw in India is a step that should not be compromised if durability and performance are priorities.

Key Features to Look for in Drywall Screw

When selecting drywall screw, professionals and DIY enthusiasts should pay close attention to certain features. These include corrosion resistance, thread sharpness, and compatibility with various boards. screw from Raj Industries are designed to meet these specifications, ensuring superior performance. Drywall screw in India should also offer smooth penetration and minimize material damage. It’s essential to choose screw with a phosphated or zinc coating to prevent rusting, especially in humid regions. Raj Industries’ precision manufacturing guarantees reliable fastening, which makes construction safer and more efficient for Indian builders.

Why Indian Construction Projects Prefer Affordable Screw?

Budget is always a key concern for builders and contractors, especially in large-scale Indian construction projects. Affordable options do not necessarily mean compromised quality. Raj Industries delivers competitively priced solutions that meet international quality standards. Builders across India prefer drywall screw in India that offer both cost-effectiveness and performance. Raj Industries has built a reputation for delivering value-driven products without sacrificing quality. By balancing price with reliability, Raj Industries enables construction firms to reduce overall project costs without impacting safety or structural integrity.

Raj Industries as a Trusted Name in Fastener Manufacturing

Raj Industries has been serving the construction hardware market in India for years, offering an extensive range of fasteners, including nuts, bolts, and drywall screw. The company is recognized for its commitment to precision, quality, and customer satisfaction. When it comes to sourcing drywall screw in India, many contractors and hardware suppliers turn to Raj Industries for consistency and excellence. With advanced manufacturing facilities and rigorous quality control systems, Raj Industries ensures that every screw is crafted to meet demanding industry standards, making them a reliable partner in construction.

Exploring Screw Sizes Suitable for Indian Drywall Needs

The thickness of drywall panels and the type of metal or wooden studs dictate the right screw size. For Indian projects, common screw sizes range from 25mm to 50mm. Raj Industries offers a wide selection to match these needs. Using the right length ensures strong fastening without damaging the board. Builders often struggle to find consistent sizing in the market, which is why Raj Industries provides clearly categorized options for drywall screw in India. Their products come with detailed specifications, making selection easier and project outcomes more predictable.

Where to Buy Quality Drywall Screw at the Best Price?

Finding a reliable supplier for drywall screw can be a challenge in India's vast market. Local vendors may not always carry consistent quality or offer bulk options. Raj Industries addresses this by supplying directly to contractors, distributors, and e-commerce channels across the country. Customers looking for affordable and high-performance drywall screw in India can count on timely deliveries and bulk pricing. Whether you’re purchasing for personal use or large-scale projects, Raj Industries ensures every client receives superior service and dependable fasteners.

Supporting Indian Infrastructure with Reliable Fastening Solutions

India's rapid infrastructure growth requires robust and long-lasting building materials, including fasteners that can withstand pressure, weight, and environmental conditions. Raj Industries supports this growth by continuously innovating its product line to cater to both traditional and modern construction techniques. The company’s drywall screw in India contributes to projects ranging from residential flats to commercial spaces. Their fasteners are trusted in demanding settings and known for holding strong even under stress. By using high-grade raw materials and efficient design, Raj Industries plays a crucial role in shaping the built environment of India.

Conclusion

For construction professionals and DIY builders alike, choosing the right drywall screw is essential. Raj Industries provides the perfect combination of affordability, quality, and accessibility for drywall screw in India. With a reputation built on trust and precision, they continue to be the go-to manufacturer for high-performance fasteners across the nation. As construction standards rise, working with a dependable manufacturer like Raj Industries ensures your projects are supported by hardware that performs when it matters most.

0 notes

Text

The Growing Popularity of Steel Stud Framing in Construction

Steel stud framing has become an increasingly popular choice in modern construction due to its durability, efficiency, and eco-friendly qualities. This method uses light gauge metal studs, typically made from galvanized steel, to form the framework for walls, ceilings, and partitions in residential, commercial, and industrial buildings. As construction practices continue to evolve, the benefits of steel stud framing make it a top contender in building projects worldwide.

Durability and Strength

One of the most significant advantages of steel stud framing is its durability. Unlike traditional wood framing, steel does not warp, crack, or rot over time. It’s also resistant to moisture, pests, and mold, which can weaken wooden structures. This resilience ensures that steel-framed buildings remain structurally sound for many years, even in harsh environments.

Fire Safety

Steel stud framing provides enhanced fire resistance. Unlike wood, which can catch fire and contribute to the spread of flames, steel does not burn. This makes it an ideal choice for buildings that require stringent fire safety measures. It helps prevent the rapid spread of fire, offering increased safety for occupants and reducing the risk of catastrophic damage.

Eco-Friendly and Sustainable

Another important benefit of steel stud framing is its sustainability. Steel is 100% recyclable, which means it can be repurposed without losing strength or integrity. Using recycled steel in construction reduces waste and minimizes the environmental impact of building materials. Additionally, the long lifespan of steel-framed buildings means fewer repairs and replacements, contributing to less overall waste.

Flexibility and Cost Efficiency

Steel stud framing is also highly flexible. Builders can easily modify the framework on-site to accommodate changes in design. Its lightweight nature makes transportation and installation quicker and more cost-effective, reducing labor and material costs. For these reasons, steel stud framing is a smart investment that supports both design flexibility and long-term savings.

Explore more insights on this topic in our blog - https://steelnetwork99.blogspot.com/2025/01/why-steel-stud-framing-is-essential-in.html

0 notes

Text

youtube

How To Get Lathing and Plastering Contractors License C35 In California

In this video, we'll show you how to get a lathing and plastering contractors license C35 in California. This is a required license if you want to do work in the Lathing and Plastering industry in California.

The lathing & plastering contractors license will allow you to coat surfaces with a mixture of sand, gypsum plaster, quick-lime or hydrated lime and water, or sand and cement and water, or a combination of such other materials that create a permanent surface coating, including coatings for the purpose of soundproofing and fireproofing. These coatings are applied with a plasterer's trowel or sprayed over any surface which offers a mechanical means for the support of such coating and will adhere by suction. This contractor also installs lath (including metal studs) or any other material prepared or manufactured to provide a base or bond for such coating.

A lathing & plastering contractor also applies and affixes wood and metal lath, or any other material prepared or manufactured to provide key or suction bases for the support of plaster coatings. This classification includes the channel work and metal studs for the support of metal or any other lathing material and for solid plaster partitions.

Before you can apply for your lathing & plastering contractors license, you must meet the following experience requirements:

4 years of experience performing/supervising lathing & plastering (C-35) work.

Social Security number or ITIN

Be at least 18 years old

If you're looking to get into the Lathing and Plastering industry in California, then this is the video for you! We'll show you how to get your license and how to get started in this exciting field. By watching this video, you'll learn everything you need to get your Lathing and Plastering Contractors License.

#lathing and plastering contractors license c35#contractor license school#california contractor license#how to get a california contractor license#general contractor license#california contractor license requirements#contractor license#california contractor#online contractor license school#contractor school#contractor licensing#contractors license school#general contractor#how to get lathing and plastering contractors license c35 in california#Youtube

1 note

·

View note

Text

Exploring the Market for Drywall Screw in India: Trends and Insights

The market for drywall screw in India has been growing steadily, driven by the increasing demand for construction and renovation projects across the country. As the real estate sector expands, especially in urban areas, drywall systems are becoming more popular due to their cost-effectiveness and ease of installation. Key trends include a shift towards high-quality, corrosion-resistant Screw that ensure durability and long-term performance in diverse environmental conditions. The rise of modular and prefabricated construction methods has further boosted the demand. Additionally, with the growing influence of online retail platforms, access to drywall Screw in India has become more convenient for both professionals and DIY enthusiasts. Manufacturers are also focusing on sustainable production methods to align with global environmental standards.

Introduction to the Growing Demand for Drywall Screw in India

The construction industry in India has experienced remarkable growth in recent years, fueled by urbanization, infrastructure development, and the rise of commercial and residential projects. As a result, the demand for construction materials and tools, including drywall Screw, has seen a significant rise. Drywall Screw are essential fasteners used in the installation of drywall sheets, which are commonly used in modern construction due to their lightweight and cost-effective nature. The increasing trend of dry construction, which involves using materials like drywall, has directly contributed to the demand for drywall Screw in India.

Understanding the Role of Drywall Screw in the Indian Construction Industry

Drywall Screw are specifically designed to attach drywall sheets to wooden or metal studs, ensuring a secure and durable installation. They have a sharp, self-drilling point that helps them penetrate the drywall without causing damage, along with a threaded shaft that ensures a tight grip. In the Indian market, drywall Screw are gaining popularity due to their efficiency and cost-effectiveness in comparison to traditional fastening methods. The increasing use of drywall in partitioning, ceilings, and other interior applications is driving the market for drywall Screw in India.

Key Market Drivers for Drywall Screw in India

Several factors are contributing to the growth of the drywall screw market in India. One of the primary drivers is the rapid growth of the real estate sector, particularly in urban areas. The demand for residential, commercial, and industrial buildings has led to a surge in the use of drywall systems, which in turn drives the demand for drywall Screw. Furthermore, the government's focus on affordable housing and infrastructure development projects has created opportunities for the drywall screw market to expand. The ease of installation and the relatively low cost of drywall systems compared to traditional brick-and-mortar construction methods are also boosting the demand for drywall Screw.

Technological Advancements in Drywall Screw Manufacturing

Advancements in manufacturing technology have played a significant role in the evolution of drywall Screw in India. Modern production techniques have led to the development of Screw that are stronger, more durable, and resistant to rust and corrosion. This is particularly important in India's diverse climate conditions, where high humidity and temperature fluctuations can affect the quality of construction materials. Manufacturers are also introducing Screw with specialized coatings, such as zinc plating or black phosphate, to enhance their longevity and performance in different environments. These innovations are driving the market for high-quality drywall Screw in India.

Regional Variations in the Demand for Drywall Screw in India

The demand for drywall Screw in India varies across regions, influenced by factors such as construction activity, climate, and regional preferences. Urban centers like Mumbai, Delhi, Bangalore, and Hyderabad, where large-scale residential and commercial projects are being developed, are seeing a higher demand for drywall Screw. Additionally, southern and western states, where modern construction practices have gained significant traction, are leading the adoption of drywall systems. In contrast, northern and eastern regions are still transitioning towards dry construction techniques, with slower adoption rates for drywall systems and Screw. However, with the increasing awareness of the benefits of drywall, the demand for drywall Screw is expected to rise across all regions.

Challenges in the Drywall Screw Market in India

Despite the growing demand, the drywall screw market in India faces several challenges. One of the key issues is the lack of awareness about drywall systems and their benefits, especially in rural areas where traditional construction methods dominate. Moreover, the market is also plagued by the availability of low-quality, counterfeit drywall Screw, which can negatively impact the overall quality and safety of drywall installations. To address these challenges, manufacturers and suppliers must focus on educating the market about the advantages of using high-quality drywall Screw and the importance of selecting the right fasteners for drywall installation.

The Future Outlook for the Drywall Screw Market in India

The future of the drywall screw market in India looks promising, driven by the continued growth of the real estate sector, government infrastructure initiatives, and the increasing popularity of drywall construction. As more builders and contractors embrace the benefits of drywall systems, the demand for drywall Screw is expected to rise steadily. Additionally, with ongoing advancements in manufacturing technology and the introduction of new products with enhanced features, the market for drywall Screw in India is poised for further expansion. The growing trend of sustainability in construction practices and the preference for lightweight materials will further fuel the market for drywall Screw.

Conclusion

The market for drywall Screw in India is experiencing a significant transformation, fueled by the rapid growth of the construction industry and the increasing adoption of drywall systems. As more builders and contractors turn to dry construction methods for their efficiency and cost-effectiveness, the demand for drywall Screw is expected to continue growing. Technological advancements, coupled with the government's focus on infrastructure development, are contributing to the expansion of this market. While challenges such as lack of awareness and counterfeit products remain, the future outlook for the drywall screw market in India is optimistic, with ample opportunities for growth and innovation in the coming years.

0 notes

Text

Metal Stud Framing: The Future of Modern Construction

In the world of construction, building materials and techniques are constantly evolving to meet the demands for faster, more durable, and cost-effective solutions. One such innovation that has significantly impacted the industry is metal stud framing. As an alternative to traditional wood framing, metal stud framing has gained popularity in commercial and residential construction projects due to its numerous benefits. In this blog, we’ll explore what metal stud framing is, its advantages, applications, and why it’s becoming the go-to choice for builders and contractors.

What is Metal Stud Framing? Metal stud framing refers to the use of steel studs and tracks to create the framework for walls, ceilings, and partitions in a building. Just as wood framing involves using wooden beams and studs to create the skeleton of a structure, metal stud framing employs cold-formed steel studs and tracks, which are lightweight, strong, and durable. The metal studs are connected to form a structural framework, which is then covered with drywall, plasterboard, or other materials to complete the wall or ceiling.

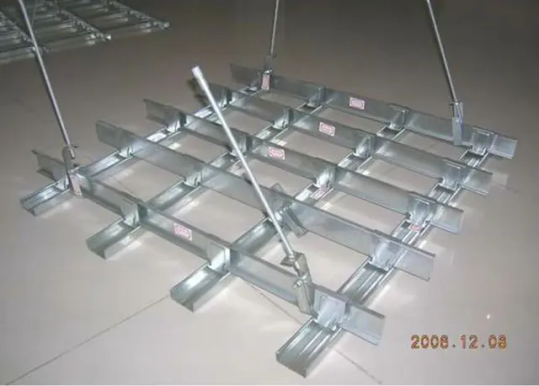

The components involved in metal stud framing typically include:

Metal Studs: Vertical pieces of steel that form the skeleton of the wall or partition. Track: Horizontal pieces that provide stability and are used at the top and bottom of the wall to hold the studs in place. Fasteners: Screws or nails that are used to attach the studs to the track and other components. Metal stud framing is primarily used in the construction of non-load-bearing walls, partition walls, ceilings, and other interior systems. It has found widespread use in both commercial buildings, such as offices and hospitals, and residential construction projects.

How Does Metal Stud Framing Work? The process of metal stud framing begins with the selection of steel studs and tracks, which come in a range of sizes and thicknesses to accommodate the specific needs of the project. Steel studs are made through a cold-rolling process, which involves forming steel sheets into various shapes and sizes without the use of heat. This process results in a lightweight yet sturdy framing material that is resistant to corrosion and provides superior strength compared to traditional wood framing.

The studs are positioned vertically and attached to the track, which runs along the floor and ceiling. The studs are spaced according to the specifications of the project, typically 16 or 24 inches apart, and are secured in place using screws or other fasteners. Once the frame is assembled, drywall or other finishing materials are installed, completing the construction of the walls or partitions.

Metal stud framing systems can be designed to accommodate various types of construction, from simple partition walls to complex systems with insulation, soundproofing, and fire-rated materials.

Advantages of Metal Stud Framing

Durability and Strength One of the primary benefits of metal stud framing is its strength. Steel studs are highly resistant to warping, twisting, or rotting, unlike wood studs that can shrink, bend, or deteriorate over time due to moisture exposure. This makes metal stud framing a more durable and long-lasting option for both residential and commercial construction projects.

Fire Resistance Steel is non-combustible, which makes metal stud framing an excellent choice for improving the fire resistance of a building. It can help slow down the spread of fire, making it a safer option in areas where fire safety is a primary concern. In fact, buildings with metal stud framing often achieve higher fire ratings compared to those using wood framing, which is susceptible to burning.

Resistance to Pests and Mold Unlike wood, metal studs are immune to infestations from termites, carpenter ants, or other pests that can compromise the structural integrity of a building. Additionally, metal framing is resistant to mold and mildew, which can be a problem in areas with high humidity or water exposure. This makes metal stud framing ideal for environments such as basements, kitchens, and bathrooms.

Lightweight and Easy to Handle Despite being incredibly strong, metal studs are much lighter than their wooden counterparts. This makes them easier to handle and transport during construction, which can help reduce labor costs and speed up the building process. Lightweight materials also reduce the overall weight of the structure, which can be beneficial in certain construction scenarios, such as when building on unstable or soft ground.

Eco-Friendly Steel is a highly recyclable material, making metal stud framing an environmentally friendly option. Unlike wood, which may come from non-sustainable sources, steel can be recycled repeatedly without losing its strength or integrity. By using metal stud framing, builders can reduce the environmental impact of their projects and contribute to more sustainable construction practices.

Precision and Consistency Metal stud framing is manufactured in factories with precise specifications, which ensures that each stud is uniform in size and shape. This level of consistency leads to faster installation times and a more accurate final product. With wood framing, natural inconsistencies in the material can make installation more challenging and time-consuming.

Cost-Effectiveness While the initial cost of metal stud framing may be slightly higher than wood framing, the long-term savings often make it more cost-effective. Metal stud framing is less likely to require repairs due to warping, rotting, or pest infestations, and it generally requires less maintenance over time. The ability to use recycled steel also reduces costs, and the faster construction timeline contributes to overall cost savings.

Applications of Metal Stud Framing Metal stud framing is used in a wide range of applications across both residential and commercial construction projects. Here are some of the most common uses:

Interior Partitions and Walls One of the most common applications for metal stud framing is creating interior partition walls in commercial and residential buildings. Metal stud framing allows for the creation of non-load-bearing walls that can be easily customized for office spaces, meeting rooms, and even residential areas. The framing can accommodate electrical wiring, insulation, and other systems, making it a versatile solution for building interiors.

Ceilings Metal stud framing is also used in ceiling systems, particularly in commercial buildings where suspended ceilings are required. The metal studs provide a strong yet lightweight structure for supporting ceiling tiles, light fixtures, and HVAC systems.

Curtain Walls and Facades In some commercial buildings, metal stud framing is used for the construction of curtain walls or facades. These exterior walls are typically made with glass or metal panels and supported by a metal stud frame. This application is common in high-rise buildings and skyscrapers where the building’s outer appearance plays an important role in design.

Fire-Rated Walls Metal stud framing systems can be designed to meet stringent fire safety codes. By adding fire-resistant materials such as gypsum board, these walls can provide enhanced fire resistance, making them ideal for use in fire-rated systems in commercial buildings, hospitals, and schools.

Soundproofing Walls Metal stud framing can be combined with soundproofing materials such as insulation and acoustic panels to create walls that reduce noise transmission. This is especially useful in environments like hotels, apartments, and offices, where privacy and noise control are important.

Exposed Metal Frame Systems In modern architectural design, exposed metal framing is becoming more popular for creating an industrial or minimalist aesthetic. The sleek, metallic appearance of the framing itself can be incorporated into the design, offering both structural benefits and an attractive visual element.

Metal stud framing has emerged as a modern solution for construction projects, offering a range of advantages over traditional wood framing. From increased durability and fire resistance to eco-friendly materials and cost-effectiveness, metal stud framing is quickly becoming the preferred choice for builders and contractors alike. As construction technology continues to evolve, metal stud framing is likely to remain at the forefront, providing a reliable and sustainable method for building the structures of tomorrow.

Whether you’re building a commercial office, a residential home, or a large industrial facility, metal stud framing provides a versatile, cost-efficient, and durable solution that stands the test of time. It is clear that this innovative framing system is shaping the future of construction and will continue to play an integral role in modern building practices. roll forming machines z purlin making machine steel door frame forming machine

0 notes

Text

Gypsum Partition Installation Guide: What You Need to Know

Gypsum partitions have become increasingly more popular in each residential and industrial areas. Known for their flexibility, affordability, and sound insulation properties, those walls are a awesome preference for growing separate rooms or workspaces quickly and efficaciously. If you’re considering including gypsum walls for your area, right here’s a step-via-step manual on the whole thing you need to recognise approximately installation.

1. What Is a Gypsum Partition?