#PCB Software Market Size

Explore tagged Tumblr posts

Text

Global PCB Design Software Market Is Estimated To Witness High Growth Owing To Increasing Demand for Advanced Electronics

A) Market Overview: PCB design software is a computer-aided design tool used to create layout designs for printed circuit boards (PCBs). These software tools offer numerous advantages such as enhanced efficiency, accuracy, and productivity in the design process. With the rapid advancements in technology and the increasing demand for advanced electronic devices in various industries, the need for PCB design software has become crucial. This software enables engineers and designers to create complex and highly functional PCB designs, ensuring proper connectivity and signal integrity. The global PCB design software market is expected to witness significant growth due to the growing adoption of advanced electronics across various industries such as automotive, aerospace, consumer electronics, healthcare, and telecommunications.

The global PCB Design Software Market Size is estimated to be valued at US$3.56 billion in 2022 and is projected to grow at a CAGR of 12.3% from 2023 to 2030, according to a market research report published by Coherent Market Insights.

B) Market Key Trends: One key trend in the PCB design software market is the adoption of cloud-based solutions. Cloud-based PCB design software offers several advantages over traditional on-premise software. It enables remote collaboration, allowing multiple stakeholders to work on the same design simultaneously. Cloud-based solutions also provide easy access to design files from anywhere and on any device, facilitating seamless workflow and faster decision-making. Moreover, cloud-based software eliminates the need for expensive hardware infrastructure, reducing costs and improving scalability. For example, Altium LLC, a key player in the PCB design software market, offers Altium 365, a cloud-based platform that enables collaborative PCB design. C) PEST Analysis: Political: The political environment plays a significant role in the growth of the PCB design software market. Government regulations and policies regarding intellectual property rights and data security can impact the adoption of PCB design software. Economic: The economic factors such as GDP growth, industrial development, and disposable income influence the demand for PCB design software. The growth of end-user industries such as automotive, aerospace, and consumer electronics drives the market. Social: The social factors such as changing consumer preferences, increased awareness about advanced electronics, and the need for innovative products drive the demand for PCB design software. Technological: Technological advancements in the field of electronics, such as the integration of IoT, AI, and 5G technology, are driving the demand for advanced PCB designs. PCB design software needs to keep up with these technological developments to meet the evolving requirements of the industry. D) Key Takeaways: - The global PCB design software market is expected to witness high growth, exhibiting a CAGR of 12.3% over the forecast period, due to increasing demand for advanced electronics. - North America is expected to dominate the PCB design software market, owing to the presence of key players, technological advancements, and early adoption of advanced electronics. - Cadence Design Systems, Inc., Altium LLC, and WestDev Ltd. are some of the key players operating in the global PCB design software market. In conclusion, the global PCB design software market is poised for significant growth in the coming years. The increasing demand for advanced electronics and the adoption of cloud-based solutions are driving factors for this market. However, political, economic, social, and technological factors will continue to influence the market dynamics. Key players in the market are focusing on innovative solutions to cater to the evolving needs of the industry.

#PCB Design Software Market#PCB Design Software Market Size#Coherent Market Insights#PCB Design Software Market Demand#PCB Design Software Market Trends#PCB Design Software Market Forecast

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

What Are the Advantages of SMT Processing Technology Compared to DIP?

In today's mass-produced electronic hardware, a significant portion utilizes Surface Mount Technology (SMT) processing, which has become an industry trend.

Surface Mount Technology for High-Speed PCBA Processing

From a developmental perspective, the widely adopted SMT soldering process today is essentially a derivative and upgraded version of the DIP (Through-Hole Technology) plug-in process. When using SMT, only the quality of PCB pads needs to be considered, eliminating the need for drilling. This not only significantly improves production speed but also greatly simplifies the process. Although SMT may not offer the same seismic stability as through-hole mounting in certain special environments, its advantages still make it suitable for large-scale application.

Five Key Stages of the SMT Process

PCB Production: This stage focuses on manufacturing the PCB, with emphasis on the quality of solder pads.

Solder Paste Printing: Applying solder paste onto the pads to prepare for the next mounting step.

Component Placement: A pick-and-place machine precisely positions components on the solder paste-printed pads through programming.

Reflow Soldering: Bonding components firmly to the pads via reflow soldering.

PCBA Finishing/Testing/Shipping: Assembling, testing, and delivering the finished PCBA.

Differences Between SMT and DIP Through-Hole Technology

Space Optimization: Through-hole mounting often suffers from space constraints, which SMT addresses effectively. SMT components are smaller and more flexibly arranged, allowing a higher component density per unit area. This enables more powerful functionality in smaller spaces, whereas through-hole mounting has the opposite effect.

Faster Circuit Speed: Reduced component size contributes to higher circuit operation speeds.

Superior Vibration Resistance: SMT has proven more stable in high-vibration or shaking environments.

Cost Efficiency: SMT components typically cost less than their through-hole counterparts.

Shorter Production Cycle: The elimination of drilling significantly shortens SMT production time, accelerating manufacturing and reducing time-to-market. This makes SMT an ideal choice for new product development. Using Design for Manufacturability (DFM) software tools further minimizes rework and redesign needs for complex circuits, enhancing the speed and feasibility of intricate designs. [View the guide on why process control measurements are crucial for preventing defects in SMT PCB assembly.](Link to relevant resource)

If you’re interested in PCB&PCBA products, pls kindly email to Sandy: [email protected]

1 note

·

View note

Text

payroll outsourcing company malaysia

✅ Why More Businesses Choose to Outsource Payroll in Malaysia: Simplifying Success with Expert Payroll Services

Managing payroll is one of the most time-consuming and detail-sensitive tasks for businesses of every size. In Malaysia’s fast-evolving business environment, where compliance rules frequently change and companies strive to remain agile, the trend toward outsourcing payroll services Malaysia is growing rapidly.

Whether you run a local SME or a multinational branch, outsourcing payroll isn’t just about saving time; it’s about accuracy, compliance, and letting your team focus on what truly matters: growing the business.

In this article, let’s explore why outsourcing payroll makes sense, how to choose the right partner, and what benefits you can expect when you rely on experienced professionals.

📊 What Do Payroll Services Really Cover?

Before diving deeper, let’s clarify what payroll services typically include.

Professional payroll service providers in Malaysia handle:

Monthly salary calculation and processing

Statutory deductions (EPF, SOCSO, EIS, PCB)

Payslip generation (digital or printed)

End-of-year tax forms (EA, CP8D, etc.)

Leave and allowance calculations

Payroll reporting for HR and finance teams

Some advanced providers also offer integration with HR software, automated banking instructions, and real-time dashboards to track costs and trends.

🧾 The Top Benefits of Working with a Payroll Outsourcing Company in Malaysia

So why are so many companies choosing a payroll outsourcing company Malaysia instead of handling payroll in-house? Here are the main reasons:

✅ Expertise: Payroll professionals stay updated with the latest regulations, so you remain fully compliant.

✅ Efficiency: Eliminate hours of manual calculation and repetitive tasks each month.

✅ Cost savings: Avoid hiring additional full-time payroll staff, paying for training, or investing in complex payroll software.

✅ Reduced risk: Minimise costly errors that can lead to fines or employee dissatisfaction.

✅ Confidentiality: Reliable payroll providers ensure secure handling of sensitive salary data.

These benefits free up your HR and finance teams, letting them concentrate on strategy and employee engagement rather than paperwork.

🏢 Why Businesses Outsource Payroll in Malaysia

Choosing to outsource payroll Malaysia makes sense in today’s competitive market. Let’s look at the most common business scenarios:

Growing companies: When your team expands quickly, payroll complexity multiplies. Outsourcing keeps everything consistent.

Startups and SMEs: Small businesses can’t always justify hiring a dedicated payroll officer. Outsourcing offers professional support at a predictable monthly fee.

Multinational corporations: MNCs need to comply with local laws and require local payroll experts who understand Malaysian tax and statutory contributions.

Seasonal businesses: Companies with fluctuating headcounts benefit from scalable payroll solutions.

In all these cases, outsourcing reduces stress and supports smoother operations.

🔍 How to Choose the Right Outsourced Payroll Provider in Malaysia

Selecting the right outsourced payroll provider Malaysia is key to unlocking these benefits. Here’s what to look for:

✅ Proven track record: Choose a provider with clients in your industry and positive testimonials.

✅ Local expertise: Malaysian payroll has unique statutory requirements; ensure your provider knows them well.

✅ Data security: Confirm that strict data protection measures (encryption, secure servers) are in place.

✅ Transparent pricing: Avoid hidden charges; ask for clear monthly or annual fees.

✅ Customer support: Look for responsive service with dedicated account managers.

✅ Technology: Modern providers should offer digital payslips, self-service portals, and easy integration with HR or accounting software.

Meeting these criteria ensures you work with a partner who adds real value rather than becoming another process to manage.

📈 The Impact of Outsourcing Payroll on Business Growth

Outsourcing payroll isn’t just about cutting costs — it can actively drive growth.

Better compliance reduces risk: Avoiding fines or penalties keeps resources focused on growth.

Improved employee satisfaction: Timely, error-free salaries and digital payslips enhance trust and morale.

Strategic HR: HR teams can use time saved to focus on talent development, training, and culture.

Data insights: Professional providers often deliver analytics and reports, helping you track costs and plan budgets more accurately.

🌟 Real-World Example: Why Companies in Malaysia Are Adopting Outsourced Payroll

Consider a mid-sized retail business operating in several Malaysian cities. Each month, HR staff had to:

Manually gather attendance data

Calculate overtime and allowances

Prepare bank files

File monthly statutory submissions

Errors occasionally led to employee dissatisfaction and compliance worries.

After switching to a trusted payroll outsourcing provider: ✅ Processing time dropped by 70% ✅ Errors were nearly eliminated ✅ HR could spend more time on training and engagement

The result? A happier team, lower costs, and more energy focused on customer service and sales.

🔄 Is It Time to Move to Outsourced Payroll?

If your team is overwhelmed, errors are creeping in, or you’re worried about compliance, it might be the perfect moment to consider outsourcing.

Many businesses start by outsourcing just part of payroll (like calculations or statutory filings). Over time, they often expand to full payroll management once they see the benefits.

✅ Final Thoughts: Simplify, Comply & Grow with Payroll Outsourcing

Payroll is a critical part of business success, but it doesn’t have to be a daily challenge. By choosing professional outsourcing payroll services Malaysia, your business can enjoy accurate processing, lower risk, and happier employees — all while freeing your team to focus on strategic goals.

Whether you’re a fast-growing startup, a stable SME, or part of a multinational, outsourcing payroll brings peace of mind and a competitive edge.

Ready to simplify your payroll? Discover how the right partner can transform your operations and help your business thrive.

0 notes

Text

Video Measuring System Market Drivers Include Automation Demand and Precision Measurement Requirements

As industries around the world advance toward smarter manufacturing, the demand for automation and high-precision measurement technologies has surged. This shift is one of the major forces propelling the Video Measuring System Market. These systems are essential for ensuring dimensional accuracy and consistency, especially in sectors like automotive, electronics, and aerospace where micrometer-level tolerances are critical. With quality assurance at the core of every modern production line, video measuring systems provide non-contact, fast, and repeatable solutions that align with the broader goals of efficiency, error minimization, and digital integration.

Growing Demand for Automation in Manufacturing

Automation has become a cornerstone of competitive manufacturing. The need for speed, repeatability, and cost-effective operations is pushing industries to integrate automated metrology solutions. Video measuring systems meet this need by offering quick inspections without compromising accuracy. Unlike manual measurement tools, they minimize human error and can be seamlessly integrated into automated workflows.

Furthermore, the growing adoption of robotics and automated quality control lines is reinforcing the relevance of video measuring systems. These systems can function in tandem with robotic arms and conveyor-based inspection setups, enabling real-time measurements and adjustments that streamline production.

Precision Measurement as a Competitive Advantage

Precision in measurement is no longer a luxury—it's a necessity. Especially in high-tech industries like aerospace and medical devices, even minute deviations can lead to functional failures or regulatory non-compliance. Video measuring systems are preferred for their ability to inspect complex geometries and fragile materials without physical contact, ensuring product integrity while maintaining throughput.

These systems are particularly advantageous when dealing with miniaturized components, such as microchips and implants, where traditional contact measurement tools are ineffective. Their high resolution and sub-micron accuracy capabilities make them indispensable in quality assurance workflows.

Industry-Specific Adoption Driving Market Expansion

Different industries have specific requirements that are perfectly aligned with the capabilities of video measuring systems. For instance:

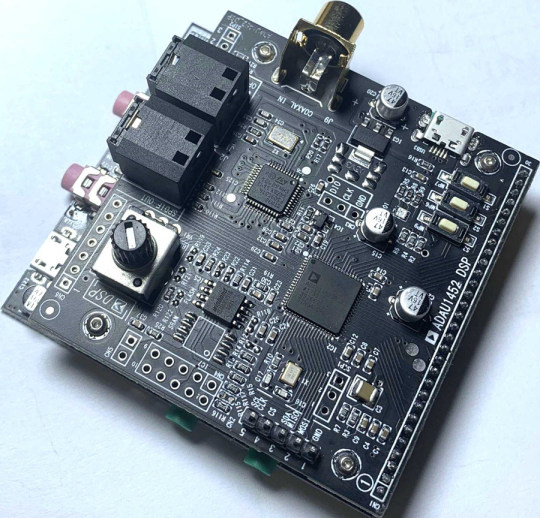

Electronics and Semiconductors: The need to inspect densely packed PCBs and micro-sized components has made video measurement an essential tool in this sector.

Automotive: The increasing complexity of vehicle components, along with stringent safety and performance standards, necessitates reliable dimensional verification.

Aerospace: High-value parts require rigorous quality checks, and video measuring systems allow manufacturers to maintain compliance with strict international standards.

As these industries continue to scale and adopt next-gen technologies, the use of video measuring systems will only become more entrenched.

Advancements in System Capabilities

One of the reasons video measuring systems are becoming more widespread is their technological evolution. Today’s systems are equipped with advanced features such as:

Multi-sensor integration: Combining optical, laser, and touch probes enhances flexibility.

3D measurement capabilities: More advanced systems provide depth measurements, critical for complex parts.

AI-enhanced software: Algorithms can now detect anomalies and optimize measurement routines, reducing setup times.

These improvements make the systems easier to operate, more versatile, and capable of handling complex inspection tasks, thereby increasing their appeal across verticals.

Geographical Expansion and Global Demand

The Video Measuring System Market is experiencing growth not only in developed economies but also in emerging manufacturing hubs such as India, Brazil, and Southeast Asia. As these regions aim to elevate their manufacturing standards, investment in precision measurement tools is becoming a strategic priority. This geographical diversification is further boosting overall market momentum.

Additionally, government initiatives such as “Make in India” or “Industry 4.0” policies in Europe and North America are encouraging the adoption of automated and high-precision systems, creating a supportive environment for market growth.

Challenges in Implementation

While the market is thriving, there are challenges to overcome. High initial costs and the requirement for skilled operators can act as barriers, especially for small and medium-sized enterprises. However, as system usability improves and training resources expand, these hurdles are becoming less formidable over time.

The availability of scalable models also allows businesses to start small and upgrade as their operations grow, making the adoption curve more flexible and accommodating.

Concluding Thoughts

The drive toward automation and demand for precise measurement are creating a strong foundation for the Video Measuring System Market’s expansion. These systems offer tangible ROI through improved quality control, reduced scrap, and compliance assurance—key priorities for modern manufacturers.

#VideoMeasuringSystems#PrecisionMeasurement#IndustrialAutomation#QualityControl#ManufacturingInnovation#SmartFactories#NonContactInspection#MetrologySolutions#IndustrialEquipment#AutomatedInspection#3DMeasurement

0 notes

Text

Solar Combiner Boxes Market 2025 Size, Recent Scope and SWOT Analysis Report

Global “Solar Combiner Boxes Market” research report is a comprehensive analysis of the current status of the Solar Combiner Boxes industry worldwide. The report categorizes the global Solar Combiner Boxes market by top players/brands, region, type, and end-user. It also examines the competition landscape, market share, growth rate, future trends, market drivers, opportunities, and challenges in the global Solar Combiner Boxes market. The report provides a professional and in-depth study of the industry to help understand its current state and future prospects. What Are The Prominent Key Player Of the Solar Combiner Boxes Market?

ABB

Pentair

KACO new energy GmbH

Weidmüller Interface GmbH & Co. KG

Delta Electronics, Inc

Texas Instruments

China Suntree Electric

SolarBOS, Inc.

Sinetech

ZJBENY

Micno

Shenzhen City ROHOX Technology Co.,Ltd

The Primary Objectives in This Report Are:

To determine the size of the total market opportunity of global and key countries

To assess the growth potential for Solar Combiner Boxes

To forecast future growth in each product and end-use market

To assess competitive factors affecting the marketplace

This report also provides key insights about market drivers, restraints, opportunities, new product launches or approvals.

Regional Segment of Solar Combiner Boxes Market:

Geographically, the report includes research on production, consumption, revenue, market share, and growth rate of the following regions:

United States

Europe (Germany, UK, France, Italy, Spain, Russia, Poland)

China

Japan

India

Southeast Asia (Malaysia, Singapore, Philippines, Indonesia, Thailand, Vietnam)

Latin America (Brazil, Mexico, Colombia)

Middle East and Africa (Saudi Arabia, United Arab Emirates, Turkey, Egypt, South Africa, Nigeria)

The global Solar Combiner Boxes Market report answers the following questions:

What are the main drivers of the global Solar Combiner Boxes market? How big will the Solar Combiner Boxes market and growth rate in upcoming years?

What are the major market trends that affecting the growth of the global Solar Combiner Boxes market?

Key trend factors affect market share in the world's top regions?

Who are the most important market participants and what strategies being they pursuing in the global Solar Combiner Boxes market?

What are the market opportunities and threats to which players are exposed in the global Solar Combiner Boxes market?

Which industry trends, drivers and challenges are driving that growth?

Browse More Details On This Report at - https://www.businessresearchinsights.com/market-reports/solar-combiner-boxes-market-104441

Contact Us:

Business Research Insights

Phone:

US: (+1) 424 253 0807

UK: (+44) 203 239 8187

Email: [email protected]

Web: https://www.businessresearchinsights.com

Other Reports Here:

Anti Spyware Software Market

Luxury Ski Clothing Market

Impregnating Autoclaves Market

Mixed Drink Blender Market

Running Belts and Armbands Market

Sorting Equipment Market

PV Metallization Silver Paste Market

Ulinastatin Market

Fog Computing Market

Hexafluorozirconic Acid Solution Market

Other Reports Here:

Luxury Makeup Market

MarTech market

Process Manufacturing Software Market

Kids Makeup Market

Liquid Coating Sprayers Market

PCB Drills Market

User Generated Content (UGC) Software Market

Infrared Imaging and Wide Area Surveillance Infrared Imaging Market

Offshore AUV and ROV Market

LTCC RF Filter Market

0 notes

Text

Global Polyurethane Foam Mattress Market Forecast (2025–2031): Growth, Trends & Strategic Insights

"

The Global Polyurethane Foam Mattress Market is projected to grow steadily from 2025 through 2031. This report offers critical insights into market dynamics, regional trends, competitive strategies, and upcoming opportunities. It's designed to guide companies, investors, and industry stakeholders in making smart, strategic decisions based on data and trend analysis.

Report Highlights:

Breakthroughs in Polyurethane Foam Mattress product innovation

The role of synthetic sourcing in transforming production models

Emphasis on cost-reduction techniques and new product applications

Market Developments:

Advancing R&D and new product pipelines in the Polyurethane Foam Mattress sector

Transition toward synthetic material use across production lines

Success stories from top players adopting cost-effective manufacturing

Featured Companies:

Tempur Sealy International

Serta Simmons Bedding

Sinomax

Sleemon

Recticel

Corsicana

MLILY

Sleep Number

Hilding Anders

Ashley

Pikolin

Derucci

King Koil

Get detailed profiles of major industry players, including their growth strategies, product updates, and competitive positioning. This section helps you stay informed on key market leaders and their direction.

Download the Full Report Today https://marketsglob.com/report/polyurethane-foam-mattress-market/1007/

Coverage by Segment:

Product Types Covered:

King Size

Queen Size

Single Size

Applications Covered:

Private Households

Hotels

Hospitals

Others

Sales Channels Covered:

Direct Channel

Distribution Channel

Regional Breakdown:

North America (United States, Canada, Mexico)

Europe (Germany, United Kingdom, France, Italy, Russia, Spain, Benelux, Poland, Austria, Portugal, Rest of Europe)

Asia-Pacific (China, Japan, Korea, India, Southeast Asia, Australia, Taiwan, Rest of Asia Pacific)

South America (Brazil, Argentina, Colombia, Chile, Peru, Venezuela, Rest of South America)

Middle East & Africa (UAE, Saudi Arabia, South Africa, Egypt, Nigeria, Rest of Middle East & Africa)

Key Insights:

Forecasts for market size, CAGR, and share through 2031

Analysis of growth potential in emerging and developed regions

Demand trends for generic vs. premium product offerings

Pricing models, company revenues, and financial outlook

Licensing deals, co-development initiatives, and strategic partnerships

This Global Polyurethane Foam Mattress Market report is a complete guide to understanding where the industry stands and how it's expected to evolve. Whether you're launching a new product or expanding into new regions, this report will support your planning with actionable insights.

" Exclusion Chromatography (SEC) HPLC Columns Cell-Site Simulators Ship Dismantling CAD/CAM Software for Sheet Metal Ship Management and Crew Management Rebar Coupler Modular Office Furniture Consumer Goods (CPG)ing Software and Platforms Energy-as-a-Service (EaaS) Glass-Melting Furnaces Vacuum Plasma Machine for Bare PCB Manufacturing Direct to Garment Printers Under Eye Gel

0 notes

Text

How Does Circuit Card Assembly Impact Electronics Production?

In the rapidly evolving field of electronics, Circuit Card Assembly (CCA) plays a crucial role in determining the performance, reliability, and scalability of electronic devices. Circuit Card Assembly, also known as Printed Circuit Board Assembly (PCBA), involves mounting electronic components onto a pre-designed circuit board, forming the foundation of all modern electronic products.

Enhancing Product Efficiency

Circuit Card Assembly significantly improves the efficiency and functionality of electronics. By automating the process using Surface Mount Technology (SMT) and Through-Hole Technology, manufacturers can ensure consistent and high-speed assembly with minimal human error. This streamlined process allows for mass production of devices ranging from consumer gadgets to industrial control systems, while maintaining performance integrity.

Supporting Innovation in Design

The evolution of electronics design is deeply connected to advancements in CCA. High-density assemblies allow more complex circuits to be placed in smaller form factors. This has enabled innovations in smartphones, medical devices, and IoT products. With technologies like multi-layer boards and flexible PCBs, companies can now meet unique design challenges with customized, compact solutions.

Reducing Production Costs

Efficiency in Circuit Card Assembly directly translates to cost savings. Automated machines reduce labor costs, and precise component placement minimizes material waste. Moreover, the early detection of defects through automated optical inspection (AOI) and X-ray testing helps avoid costly recalls or field failures, improving overall quality assurance.

Improving Reliability and Lifespan

One of the key impacts of CCA is enhanced product reliability. A professionally assembled circuit card undergoes rigorous testing to ensure long-term durability, even under demanding conditions. This is especially critical in industries like aerospace, automotive, and telecommunications, where component failure can have significant consequences.

Role of Guangzhou Wangerbao Software Development Co., Ltd.

Guangzhou Wangerbao Software Development Co., Ltd. is at the forefront of providing software solutions that optimize Circuit Card Assembly processes. Their intelligent software platforms integrate with production lines to manage real-time monitoring, defect tracking, and process control. By using data analytics and automation tools, Wangerbao helps manufacturers ensure precision and efficiency across the assembly lifecycle.

Wangerbao’s solutions are particularly valuable for small to medium-sized enterprises (SMEs) seeking to adopt smart manufacturing practices. Their platforms support traceability, resource planning, and predictive maintenance, which are critical to maintaining competitiveness in global electronics production.

Enabling Scalable Manufacturing

With growing demand for custom electronics and rapid prototyping, scalable CCA processes are essential. Modular assembly lines, supported by smart software from companies like Wangerbao, allow manufacturers to shift quickly from prototyping to full-scale production. This flexibility enables businesses to meet market demands faster while maintaining quality.

Conclusion

Circuit Card Assembly is a foundational element of modern electronics manufacturing, influencing everything from design innovation to production cost and product reliability. With the support of advanced software systems developed by Guangzhou Wangerbao Software Development Co., Ltd., manufacturers can optimize their processes and stay ahead in a competitive, technology-driven market. As electronics continue to evolve, so too will the role and impact of intelligent, efficient circuit card assembly.

0 notes

Text

PCB Calculator: Simplifying Your PCB Design and Cost Estimation Process

In the world of electronics, printed circuit boards (PCBs) are the heart of every functional device. From mobile phones and consumer electronics to industrial control systems and medical instruments, PCBs provide the foundational platform for mounting and interconnecting components.

Designing a reliable PCB requires a strong understanding of not just circuit logic, but also physical parameters like trace width, copper thickness, and impedance. While professionals can handle this manually, it often leads to errors or delays, especially when time or budget constraints are involved.

That’s where a PCB Calculator becomes essential. This article explains what a PCB Calculator is, how it helps with PCB design and cost estimation, and why it’s becoming an integral part of the electronics development process — especially for engineers, startups, students, and manufacturers in regions like India.

What Is a PCB Calculator?

A PCB Calculator is a web-based or software-based tool that performs essential calculations needed during the PCB design and planning phase. It simplifies complex engineering formulas and allows designers to determine specifications like:

Required trace width based on current

Via size and spacing

Impedance for high-speed signals

Copper thickness

Power dissipation

Thermal performance

Estimated manufacturing cost

Instead of spending time manually solving equations or consulting multiple data sheets, the calculator does all the work in seconds. It’s a powerful utility that improves design accuracy, saves time, and reduces the risk of manufacturing defects.

Why Is a PCB Calculator Useful?

1. Accurate Design Calculations

One of the main purposes of a PCB calculator is to eliminate guesswork. Trace width, via size, and copper thickness all play critical roles in how well a board performs — especially under higher loads. An undersized trace might overheat or fail, while excess copper could unnecessarily increase costs. With a calculator, you get precise results based on standardized formulas and real-world inputs.

2. Faster Prototyping

During the early stages of product development, engineers often work against tight timelines. A PCB calculator helps shorten the design cycle by providing quick answers to common design questions. This means fewer revisions, faster prototyping, and quicker time-to-market.

3. Improved Cost Control

Knowing your potential production cost early in the design process can help you make smarter decisions. A PCB calculator that includes a cost estimation module gives you an overview of your PCB price in India or globally, based on parameters like layer count, board size, surface finish, and quantity.

Key Functions of a Modern PCB Calculator

Most online PCB calculators now offer a wide range of functions that go beyond simple trace width calculations. Let’s explore some of the most commonly used features:

1. Trace Width Calculator

Determines the minimum width needed for a PCB trace to safely carry a specific current. This is especially useful in power supply designs or boards with high-current paths.

Input parameters include:

Current (in Amps)

Copper weight (in oz/ft²)

Temperature rise (°C)

The calculator returns the recommended trace width in millimeters or mils.

2. Via and Drill Size Calculator

Helps you determine appropriate via sizes and drill diameters based on board thickness and plating requirements. Proper via sizing ensures electrical reliability and manufacturability.

3. Impedance Calculator

High-speed digital designs or RF circuits require impedance-controlled traces. The calculator can estimate impedance based on:

Dielectric material

Trace width and thickness

Dielectric height

Trace configuration (microstrip or stripline)

4. Copper Thickness and Resistance Calculator

Estimates resistance and voltage drop for traces based on copper thickness and length. Useful in managing heat and power loss in power electronics.

5. Layer Stack-Up Planner

Allows designers to plan the layout and spacing of multiple PCB layers. It helps with signal integrity and EMI performance.

6. Thermal Calculator

Analyzes how much heat a particular design might generate and suggests appropriate copper thickness or thermal relief patterns.

7. Cost Estimation Module

One of the most sought-after features is the cost calculator, which estimates your PCB manufacturing cost in India or other regions based on selected parameters:

Board dimensions

Number of layers

Surface finish (HASL, ENIG, OSP, etc.)

Quantity (prototype vs. production run)

Lead time

This helps businesses plan budgets and compare vendors more effectively.

How the PCB Calculator Works — A Simple Guide

Using a PCB calculator is usually straightforward. Here’s how a typical tool functions:

Select Board Type — Choose between single, double, or multi-layer boards.

Enter Design Parameters — Input board dimensions, copper weight, and current load.

Set Material Preferences — Choose between FR4, aluminum, Rogers, or other materials.

Add Surface Finish & Color — These options impact final pricing and appearance.

Submit Design Values — The calculator instantly returns results for trace widths, via sizes, impedance, and cost.

Download Report (Optional) — Save the results for further analysis or sharing.

This type of real-time calculation gives users a comprehensive view of design and production feasibility.

Benefits of Using a PCB Calculator in India

1. Localized Cost Estimation

With a growing number of PCB manufacturers operating in Ahmedabad, Bangalore, Pune, Noida, and other industrial hubs, the calculator can help you get accurate price ranges for PCB cost in India.

2. Better Vendor Negotiation

If you understand how pricing is structured — by layer count, size, or finish — you’re in a stronger position to negotiate with your manufacturer.

3. Budget-Friendly Prototyping

Startups and entrepreneurs can estimate costs and plan low-volume prototyping without surprise expenses. This encourages experimentation and innovation.

4. Educational Applications

Many engineering institutions in India now use online PCB calculators to teach students about trace resistance, signal integrity, and circuit behavior — without needing advanced simulation tools.

Real-Life Applications of a PCB Calculator

Example 1: Startups Building IoT Devices

A startup working on an IoT-based agricultural sensor used a PCB calculator to estimate design parameters and production costs for a batch of 200 units. By analyzing the trace width and copper thickness in the early stages, they reduced redesign efforts and managed to get a working prototype manufactured on budget.

Example 2: University Projects

Students at an Indian engineering college used the calculator to plan a 4-layer PCB for a drone control system. They optimized trace impedance and via size to ensure minimal signal loss and thermal buildup.

Example 3: Professional PCB Designers

Freelance PCB designers often use these calculators to validate client requirements. With instant access to trace and cost data, they can quote projects with better accuracy.

Common Mistakes the Calculator Helps Avoid

Using undersized traces for high currents

Choosing inappropriate via sizes for signal layers

Overdesigning boards with excessive copper thickness

Underestimating manufacturing cost due to finish or drill complexity

Designing multilayer boards without impedance control

These issues can lead to failed prototypes, delays, or unnecessary expenses. A PCB calculator keeps these risks under control.

How to Choose the Right PCB Calculator

Not all calculators offer the same depth. Here’s what to look for:

Free to use with no registration

Supports metric and imperial units

Includes cost estimation for India

Allows Gerber file input

Mobile-friendly interface

Accurate and verified formulas

Tools like the one offered by Megabytes Circuit System include all these features and are regularly updated to match industry trends.

Final Thoughts

The PCB Calculator has become a critical tool for anyone involved in electronics design and manufacturing. Whether you’re a student, engineer, entrepreneur, or hobbyist, this tool can save time, improve accuracy, and offer valuable cost insights.

In fast-paced industries where even a small design error can lead to big losses, having a calculator by your side is a smart move. If you’re working on a project and need to estimate design parameters or PCB prices in India, don’t rely on guesswork. Let the numbers guide you.

Try a PCB calculator today and experience the difference in your workflow.

0 notes

Text

[IOTE&IOTSWC Exhibition] BAT Wireless: Pioneering Customized Wireless Solutions

Preface

With the acceleration of the global digital transformation wave, IoT technology is becoming a key force in promoting changes in all walks of life. With their advantages in technology research and development, cost control and industrial chain improvement, Chinese IoT companies have turned their attention to overseas markets to seek broader development space.

IOTE and IOSWC have joined hands to provide domestic companies with opportunities to conduct in-depth exchanges and cooperation with global software vendors to achieve resource sharing and market expansion!

IOTSWC Exhibition

Shenzhen Bat Wireless Technology Co.,Ltd

Booth No.: B46-3

Fira Gran Via, Barcelona, Spain

May 13-15, 2025

Meet you at the Barcelona Global Event

Company Profile

BAT Wireless Technology Co., Ltd. is a high-tech company specializing in the research, development, design, manufacturing, and sales of wireless communication products. Our experienced R&D team and advanced testing equipment allow us to offer customized R&D and comprehensive OTA testing for products such as GNSS, Wi-Fi, Bluetooth, LoRa, 2G, 3G, 4G, 5G, and NB-IoT devices, covering a frequency range of 100 kHz to 53 GHz. Additionally, our quality-certified manufacturing facility provides ODM/OEM production services for communication antennas, RF devices, and RF cables.

Product Introduction

Cellular Antenna: In mobile communication systems, various types of antennas can be designed and produced to meet different scenarios and requirements, such as omnidirectional, directional, and sector antennas.Cellular antennas feature high gain, wide coverage, and good signal quality, ensuring the efficient operation and reliable communication of cellular networks. These antennas include macro base stations, small cell base stations, mobile communication terminals, IoT products, and vehicular communication devices, which are widely used in 2G, 3G, 4G, and 5G networks.

LoRa Antenna: LoRa antennas are key components of Long Range wireless communication technology, specifically designed for long-distance, low-power IoT applications. They transmit data using low-frequency bands (such as 433MHz, 866MHz, and 915MHz), providing extensive coverage and good penetration capabilities. LoRa antennas are widely used in various fields, including smart cities, agricultural monitoring, industrial automation, and asset tracking. Common types include omnidirectional antennas, directional antennas, and PCB antennas. The appropriate type of antenna can be selected and customized based on specific application needs to optimize coverage and signal quality.

GNSS/RTK Antenna: BAT Wireless provides a variety of positioning antenna modules with multi-band support, high gain, strong anti-interference capability, and a compact, lightweight design. These components include ceramic patch, multi-layer ceramic chip, active ceramics, fiberglass, quad helix antennas, choke ring antennas, multi-constellation, and rubber duck antennas.

They are widely used in applications such as automotive navigation, smartphones, drones, surveying and GIS, wearable devices, precision agriculture, and marine and aviation sectors. You can select the appropriate model or develop a customized solution based on key parameters such as frequency band, gain, size, and anti-interference capability.

Application Areas

Smart City

Smart Agriculture

Logistics & Asset Tracking

Energy Management

Smart Home

Communication Device

IOT

0 notes

Text

PCB Design Software Market Size, Share, Trends, Forecast & Growth Analysis 2034

PCB Design Software Market is undergoing a dynamic transformation, projected to grow from $2.5 billion in 2024 to a remarkable $5.2 billion by 2034, at a CAGR of approximately 7.6%. This growth is largely fueled by the rising complexity of electronic devices and the demand for compact, high-performance circuit boards. Printed Circuit Boards (PCBs) are the backbone of all electronics, and design software is the critical tool used to conceptualize, simulate, and validate these intricate systems. As industries ranging from consumer electronics to automotive and telecommunications advance, the need for smarter, more efficient PCB design solutions is accelerating.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS23910

Market Dynamics

This market is driven by continuous innovations in electronics and the global push for miniaturization. With shrinking device sizes and increasing functionality, design complexity has surged, prompting the adoption of advanced PCB design software. The rise of IoT devices, AI-powered systems, and autonomous vehicles is also fueling this demand, requiring robust, high-speed, and flexible board designs.

One major trend reshaping the industry is the transition toward cloud-based solutions, enabling real-time collaboration, seamless updates, and scalable design environments. Simultaneously, AI and machine learning integration is streamlining workflows — automating error detection, optimizing layouts, and speeding up time-to-market. These smart capabilities are now a top priority for designers and engineers seeking competitive advantages.

Additionally, the demand for simulation and verification tools is increasing, allowing designers to virtually test and validate PCBs before manufacturing. This not only reduces development costs but also minimizes design errors, which is especially crucial in sectors like automotive and aerospace where safety and precision are paramount.

Key Players Analysis

Several industry leaders dominate the PCB design software landscape, including Altium, Cadence Design Systems, Mentor Graphics, and Zuken. These companies offer comprehensive solutions for schematic capture, layout, simulation, and manufacturing output. Their success lies in continuous R&D investment, intuitive interfaces, and integration with hardware systems.

Emerging players like KiCad, EasyEDA, and DipTrace are gaining traction among hobbyists and small-scale manufacturers due to their open-source models and cost-effective solutions. Meanwhile, companies like Upverter Labs and Altium Nexus are exploring cloud-based and collaborative design approaches, meeting the evolving needs of distributed teams and agile product development cycles.

Regional Analysis

Asia-Pacific leads the global PCB design software market, driven by the booming electronics manufacturing hubs in China, India, and South Korea. These countries are investing heavily in semiconductors, consumer electronics, and automotive electronics, creating strong demand for design software.

North America follows closely, with the United States at the forefront due to its strong technology sector, early adoption of innovative solutions, and a thriving IoT ecosystem. The region’s emphasis on R&D, paired with the presence of major design software developers, continues to reinforce its leadership.

Europe plays a significant role as well, with Germany and the United Kingdom investing in renewable energy technologies, automotive innovation, and industrial automation. The focus on high-precision engineering in the region enhances the need for sophisticated PCB design platforms to maintain competitive manufacturing quality.

Recent News & Developments

The market is witnessing a surge in AI-driven PCB tools, enabling auto-routing, predictive layout optimization, and real-time error checking. This has significantly shortened product development cycles, a critical benefit in today’s fast-paced electronics market.

Pricing models are evolving, with subscription-based and cloud-accessible platforms becoming the norm. These flexible models — ranging from $500 to $5000 — are attracting SMEs who previously found entry costs prohibitive.

Collaborations between software providers and hardware manufacturers are also intensifying, aiming to streamline the entire design-to-manufacture pipeline. Additionally, industry compliance with IPC and ISO standards is becoming a key software feature, ensuring global compatibility and manufacturing readiness.

Browse Full Report : https://www.globalinsightservices.com/reports/pcb-design-software-market/

Scope of the Report

As the electronics ecosystem expands across emerging technologies like 5G, EVs, wearables, and medical devices, the PCB Design Software Market will be a cornerstone in enabling innovation. The report covers detailed insights across segments including schematic capture, simulation, design verification, and deployment models such as cloud, hybrid, and on-premise.

The future of this market lies in intelligent, cloud-native, and modular platforms that support real-time design collaboration, ensure compliance, and reduce prototyping costs. As digital transformation continues, PCB design software will become indispensable in every stage of electronic product development.

#pcbdesign #electronicsdesign #iottech #automotiveelectronics #smartdevices #cadtools #cloudpcb #embeddeddesign #techinnovation #hardwaredevelopment

Discover Additional Market Insights from Global Insight Services:

Cyber Insurance Market : https://www.globalinsightservices.com/reports/cyber-insurance-market

Commercial Drone Market : https://www.globalinsightservices.com/reports/commercial-drone-market/

Push To Talk Market : https://www.globalinsightservices.com/reports/push-to-talk-market/

Invoice Market : https://www.globalinsightservices.com/reports/workflow-automation-market/

Procurement Software Market : https://www.globalinsightservices.com/reports/procurement-as-a-service-market/

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

Boundary Scan Hardware Market: Ensuring Testability in an Increasingly Complex Electronics Landscape

The relentless march of technological advancement in the electronics industry is characterized by miniaturization, increasing component density, and the proliferation of complex integrated circuits (ICs). This evolution, while delivering unprecedented performance and functionality, presents significant challenges in terms of testing and validation. Enter Boundary Scan, a standardized on-chip testability feature that has become indispensable for ensuring the quality and reliability of modern electronic assemblies. This blog delves into the Boundary Scan Hardware Market, analyzing its key drivers, segmentation, emerging trends, and promising growth opportunities.

CAGR of 7.6% from 2025 to 2031, with a market size expanding from US$ XX million in 2024 to US$ XX Million by 2031.

One of the primary drivers is the increasing complexity of printed circuit boards (PCBs). Higher layer counts, finer pitches, and the widespread adoption of Ball Grid Array (BGA) and other surface-mount packages make traditional in-circuit testing (ICT) methods increasingly difficult and, in many cases, impossible. Boundary Scan provides a non-physical access testing mechanism, allowing engineers to control and observe the I/O pins of compliant ICs, effectively bypassing the limitations of physical probes.

Furthermore, the growing demand for high-reliability electronics across industries like aerospace, automotive, and medical devices is a significant catalyst. In these sectors, even minor defects can have critical consequences. Boundary Scan offers a robust and comprehensive testing approach that can detect a wide range of manufacturing defects, including shorts, opens, and incorrect component placement, thereby ensuring the functional integrity and safety of the final product.

The market is segmented based on several criteria. By product type, the market includes:

Boundary Scan Controllers: These are the core hardware units that provide the interface between the test system and the target UUT (Unit Under Test). They generate the test vectors and analyze the responses.

TAP (Test Access Port) Interfaces: These are physical adapters and cables that connect the controller to the JTAG (Joint Test Action Group) connector on the UUT.

Software Integration Tools: While not strictly hardware, these tools are crucial for developing test programs and often bundled with hardware solutions.

By application, the market caters to diverse industries, including:

Telecommunications: Testing complex network equipment and mobile devices.

Aerospace and Defense: Ensuring the reliability of mission-critical avionics and military systems.

Automotive: Validating the intricate electronics within modern vehicles, including ADAS (Advanced Driver-Assistance Systems).

Industrial Automation: Testing control systems and embedded devices used in manufacturing processes.

Consumer Electronics: Ensuring the quality of high-volume electronic goods.

Several emerging trends are shaping the future of the Boundary Scan Hardware Market. Technological advancements are leading to the development of faster controllers with higher channel counts, enabling more efficient testing of increasingly complex boards. The integration of AI and machine learning into test software is also gaining traction, promising intelligent test vector generation and fault diagnosis.

Changing consumer preferences in this market primarily revolve around the demand for more integrated and user-friendly solutions. Engineers are looking for hardware and software combinations that simplify test development, execution, and analysis. There's also a growing emphasis on portability and flexibility, with a demand for compact and adaptable test equipment that can be used in various environments.

Regulatory changes, particularly in high-reliability sectors, are also impacting the market. Stringent quality standards and compliance requirements often mandate the use of comprehensive testing methodologies like Boundary Scan. For instance, aerospace and automotive industries adhere to rigorous testing protocols to ensure product safety and reliability, directly driving the adoption of Boundary Scan hardware.

The growth opportunities within the Boundary Scan Hardware Market are substantial. The continuous increase in electronic content across all industries will necessitate robust testing solutions. The rise of 5G and future communication technologies, with their complex hardware architectures, will further drive demand. Moreover, the increasing focus on functional safety and cybersecurity in connected devices will underscore the importance of thorough testing throughout the product lifecycle.

Furthermore, the integration of Boundary Scan with other test methodologies, such as functional testing and embedded software testing, presents opportunities for more holistic validation strategies. The development of more affordable and accessible Boundary Scan solutions for small and medium-sized enterprises (SMEs) can also unlock new market segments.

In conclusion, the Boundary Scan Hardware Market is a vital and growing segment within the electronics testing landscape. Driven by the increasing complexity of electronics, the demand for high reliability, and continuous technological advancements, Boundary Scan remains a cornerstone for ensuring the quality and functionality of modern electronic assemblies. As technology continues its rapid evolution, the importance and market value of Boundary Scan hardware will only continue to rise, offering significant opportunities for innovation and growth.

0 notes

Text

0 notes