#PLC architecture

Explore tagged Tumblr posts

Text

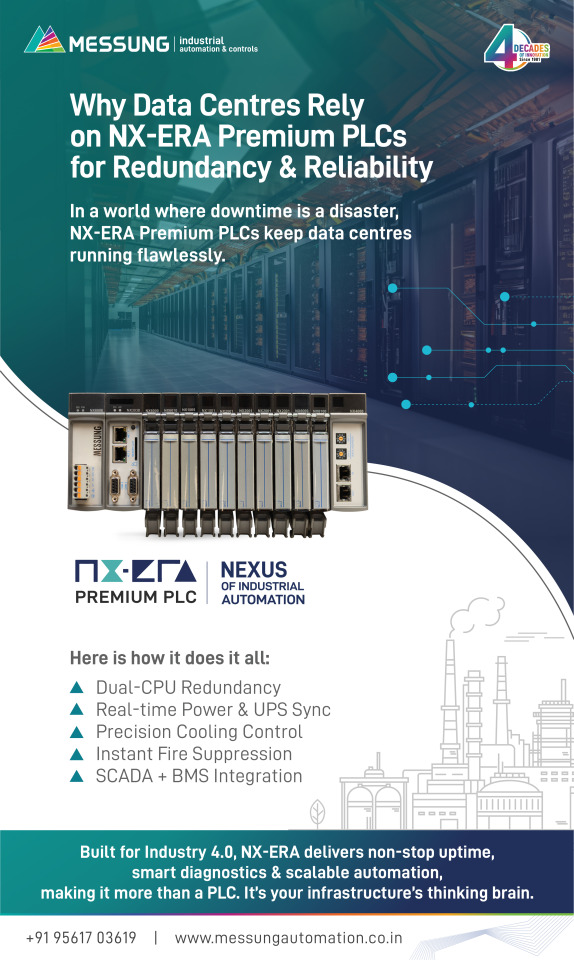

Why Data Centres Rely On NX-ERA Premium PLCs For Redundancy & Reliability

Data centres are the online headquarters of businesses today. Every click, transaction, login, or query is responded to via a data centre. In this hyper-connected world, downtime is more than a slowdown; it's a disaster.

Whether it is hosting cloud applications, running finance systems, or managing mission-critical enterprise data, data centres simply can't afford failure of control. That's why businesses often spend money on layers of redundancy, not merely power or cooling, but even on the thinking brain of their infrastructure: the Programmable Logic Controller (PLC).This is where Messung Industrial Automation's NX-ERA Premium PLCs come in as a strategic benefit, designed to provide unparalleled modular scalability, PLC redundancy, and seamless SCADA integration for control that's future-proof. For more information about NX-ERA Premium Plc visit us https://www.messungautomation.co.in/why-data-centres-rely-on-nx-era-premium-plcs-for-redundancy-reliability/

#data centres#Programmable Logic Controller (PLC)#PLC redundancy#SCADA integration#mini PLCs#Premium PLC#PLC controller#data centre automation#redundant PLC#high-speed PLC#modular PLC design#MODBUS TCP/IP#NX-ERA Premium PLCs#PLC architecture#PLC systems#Industry 4.0 PLC#AI-based decision systems

0 notes

Text

Common Applications of Multi-Core Fiber Coupling Connectors

Multi-core fiber coupling connectors let you bundle dozens of individual fibers into a single, compact module. Forget about messy, sprawling fiber panels—these connectors keep everything neat and scalable.

Top Use Cases:

Data Centers & Enterprise Networks • Spine-leaf architectures (100G, 400G) • High-density patch panels that reduce cable runs

Telco & 5G Deployments • Fiber to the Antenna (FTTA) for multiple RRUs in one shot • DAS systems inside stadiums and large venues

HPC & Research • Supercomputers, university clusters, and scientific labs • Parallel I/O links for storage arrays and compute nodes

Industrial & Automation • Smart factories—linking sensors, PLCs, and robots • Rugged, EMI-resistant assemblies for extreme conditions

Broadcast & Media • Live production rigs and OB vans carrying multiple SDI/HDMI signals • Reducing bulk when transmitting multi-camera feeds

Medical Devices • Diagnostic imaging (OCT, endoscopes) needing multi-wavelength fibers • Minimizing footprint inside medical carts

Military & Aerospace • Avionics fiber buses with tight space constraints • Ruggedized battlefield communications requiring secure, strain-relieved connections

Multi-core fiber coupling connectors aren’t just about saving space—they also simplify maintenance, cut installation time, and future-proof your network as speeds and densities increase.

2 notes

·

View notes

Text

Automotive Cockpit Electronics Market Size, Share & Trends Analysis Report By Forecasts 2034

As per a recent report by Fact.MR, the size of the global automotive cockpit electronics market has been estimated to be worth US$ 56.1 billion in 2024 and is likely to move forward at a 5% CAGR (2024-2034) to reach a valuation of US$ 91.2 billion towards the end of 2034.

A major trend within the automotive cockpit electronics market is the pace of technology developments, ranging from advanced driver-assistance systems (ADAS) to electric vehicle incorporation and in-car connectivity. Global demand for autonomous vehicles and electric vehicles is also increasing gradually, which will propel growth of this market. Automotive innovation within cockpit electronics will be one of the top concerns of automakers.

For More Insights into the Market, Request a Sample of this Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=9985

What are the Drivers of Global Automotive Electronics Market Growth?

"Strict Safety and Compliance Standards in Automotive Electronics"

Traditional cockpit components like steering, music systems, HVAC, brakes, and navigation systems are covered under it. These components are controlled manually. These distract drivers many times and increase the accident possibility.

Electronic cockpits have evolved several screens providing all the pertinent details. This amiable human machine interface (HMI) provides simple communication and vehicle control for the driver, enhancing vehicle safety and lowering the chances of accidents.

Country-wise Insights

China in the East Asia region is expected to maintain a dominant market share of 58.7% in 2024 with a market value of US$ 8.14 billion.

At the global level, the North American region has a dominant automotive cockpit electronics market share of approximately 27.8%, with the value of the market estimated at US$ 15.6 billion in 2024.

Category-specific Insights

Infotainment & navigation systems are highly sought after at present and have a dominant market share of 28.7% in 2024. The segment is estimated at US$ 16.11 billion in 2024 and is anticipated to grow to US$ 25.28 billion by 2034.

Passenger cars are estimated to capture a market share of 63.7% by 2024. The segment holds a market value of US$ 35.75 billion in the year 2024 and has been estimated to grow at 5.8% CAGR during 2034.

Competition Landscape

Continental AG, DENSO CORPORATION, Visteon Corporation, Harman International Industries Inc., Alpine Electronics Inc., Clarion Company Ltd., Delphi Automotive Plc, Robert Bosch GmbH., Panasonic Corporation, Garmin Ltd., Samsung Electronics, and Magneti Marelli are major players in the international automotive cockpit electronics market.

Industry participants are emphasizing market differentiation with digital offerings and fresh designs. Firms are aligning with technology leaders to access expertise and resources needed for the production of sophisticated electronic cockpits. Inter-industry collaboration with technology giants is enabling market participants to upgrade their products.

In January 2024, Visteon Corporation released SmartCore® Service Oriented Architecture (SOA) platform, AllGo® Connected Services, and SmartZone Zonal Controller concept. These are intended to expand its product line and provide it with a market competitive advantage.

In January 2024, Robert Bosch GmbH and Qualcomm Technologies, Inc. introduced the automotive industry's first-ever central vehicle computer. The platform is capable of running advanced driver assistance system (ADAS) features along with infotainment software on a single platform simultaneously.

In December 2023, Continental AG partnered with Korean semiconductor firm Telechips. Continental took this strategic step for cost minimization. It also introduced a new 'Smart Cockpit High-Performance Computer' for OEMs. This new HPC system is developed for cost-optimization and an efficient and streamlined solution for automakers.

Segmentation of Automotive Cockpit Electronics Market Research

By Product :

Infotainment & Navigation

Information Displays

Head-up Displays

Instrument Clusters

Telemetric

By Vehicle Category :

Passenger Vehicles

Commercial Vehicles

By Region :

North America

Latin America

Western Europe

Eastern Europe

East Asia

South Asia & Pacific

Middle East & Africa

𝐂𝐨𝐧𝐭𝐚𝐜𝐭:

US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

Global Building Information Modeling Market – Trends, Growth and Forecast 2022-2032

The global building information modeling market is expected to reach USD 21.15 Billion by 2032, at a CAGR of 12.4% during the forecast period 2023 to 2032.

Building Information Modeling (BIM) is a digital approach used in the architecture, engineering, and construction industry to create and manage a central, shared model that contains all relevant information about a building project.

This study gives a detailed analysis of drivers, restrains, opportunities and challenges limiting the market expansion of Building Information Modeling market. The survey included a diverse set of players, including a balance of leading and growing manufacturers for business profiling, such as;

Autodesk Inc., Bentley Systems, Inc., Trimble Inc., Nemetschek SE, Dassault Systèmes SE, Hexagon AB, PlanGrid Inc., Procore Technologies Inc., Asite Ltd., AVEVA Group plc, Graphisoft SE, Bluebeam Inc., Newforma LLC, Viewpoint Inc., Archidata Inc., RIB Software SE, Innovaya LLC, Thinkproject AG

Our expert team is consistently working on updated data and information on the key player's related business processes that value the market for future strategies and predictions

Get Access to a Free Copy of Our Latest Sample Report - https://www.sphericalinsights.com/request-sample/1763

Market Segmentation:

By Deployment Type (On-Premises Deployment and Cloud Deployment

By Application (Industrial, Civil Infrastructure, Oil & Gas, Utilities, and Others)

Covered in this Report:

1. Go-to-market Strategy. 2. Neutral perspective on the market performance. 3. Development trends, competitive landscape analysis, supply side analysis, demand side analysis, year-on-year growth, competitive benchmarking, vendor identification, QMI quadrant, and other significant analysis, as well as development status. 4. Customized regional/country reports as per request and country level analysis. 5. Potential & niche segments and regions exhibiting promising growth covered. 6.Analysis of Market Size (historical and forecast), Total Addressable Market (TAM), Serviceable Available Market (SAM), Serviceable Obtainable Market (SOM), Market Growth, Technological Trends, Market Share, Market Dynamics, Competitive Landscape and Major Players (Innovators, Start-ups, Laggard, and Pioneer).

Buy this report now:- https://www.sphericalinsights.com/checkout/1763

Industry Developments:

In November 2022, Bentley has unveiled enhanced capabilities for its iTwin Platform, which greatly broaden the range and interoperability of infrastructure data available for engineering firms and owner-operators to utilize in creating and leveraging digital twins in design, construction, and operations workflows. These new features of the iTwin Platform will serve as the backbone of Bentley Infrastructure Cloud, a comprehensive suite of solutions that encompass the entire infrastructure lifecycle and value chain, including ProjectWise, SYNCHR, and iTwin Platform. This expansion of the iTwin Platform's capabilities empowers users with advanced tools for managing and collaborating on data, enabling more streamlined and efficient workflows throughout the entire infrastructure industry.

Regional Analysis for Building Information Modeling Market:

✫ North America: (U.S., Canada, Mexico) ✫ Europe: (U.K., Italy, Germany, Russia, France, Spain, The Netherlands and Rest of Europe) ✫ Asia-Pacific: (India, Japan, China, South Korea, Australia, Indonesia Rest of Asia Pacific) ✫ South America: (Colombia, Brazil, Argentina, Rest of South America) ✫ Middle East & Africa: (Saudi Arabia, U.A.E., South Africa, Rest of Middle East & Africa)

Benefits of the Report:

⏩ A descriptive analysis of demand-supply gap, market size estimation, SWOT analysis, PESTEL Analysis and forecast in the global market. ⏩ Top-down and bottom-up approach for regional analysis ⏩ Porter’s five forces model gives an in-depth analysis of buyers and suppliers, threats of new entrants & substitutes and competition amongst the key market players. ⏩ By understanding the value chain analysis, the stakeholders can get a clear and detailed picture of this Market

Insightful inquiry before buying:- https://www.sphericalinsights.com/inquiry-before-buying/1763

Frequently asked questions:

➥ What is the market size of the Building Information Modeling market? ➥ What is the market growth rate of the Building Information Modeling market? ➥ What are the Building Information Modeling market opportunities and threats faced by the vendors in the global Building Information Modeling Industry? ➥ Which application/end-user or product type may seek incremental growth prospects? What is the market share of each type and application? ➥ What focused approach and constraints are holding the Building Information Modeling market? ➥ What are the different sales, marketing, and distribution channels in the global industry?

Unlock the full report now! @ https://www.sphericalinsights.com/reports/building-information-modeling-market

About the Spherical Insights

Spherical Insights is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

Contact Us:

Company Name: Spherical Insights

Email: [email protected]

Phone: +1 303 800 4326 (US)

Follow Us: LinkedIn | Facebook | Twitter

#Building Information Modeling Market#Global Building Information Modeling Market#Building Information Modeling Market Size#Building Information Modeling Market Share#Building Information Modeling Market Analysis#Building Information Modeling Market Growth#Building Information Modeling Market Trends#US Building Information Modeling Market#Europe Building Information Modeling Market#Global Building Information Modeling Market Trends

0 notes

Link

#automation#automation(industry)#automationconcept#automationportfolio#automationtask#automationtasks#automationtiatotallyintegratedautomation#futureofautomation#industrialautomation#industryautomation#integratedautomation#integratedengineering#misterautomation#mr.automation#safetyintegrated#siemensautomation#totallyintegratedautomation#totallyintegratedautomationportal#totallyintegratedautomationportalv13

0 notes

Text

Latest thermal power tenders

A large pithead thermal power station has floated a fresh thermal power tender for automating its stacker reclaimer systems. The tender involves a PLC retrofit for a 4000+ MW super thermal complex, targeting the replacement of aging control systems with advanced automation. This latest thermal power tender signals a focused shift toward digital modernization of India's older coal handling plants (CHPs), where traditional relay-based systems are reaching obsolescence. At the core of this upgrade is the integration of Siemens S7-1500 PLC hardware, which is fast becoming the standard across retrofits in India’s thermal generation sector. The latest thermal power tenders increasingly specify PLC systems that support real-time data exchange, remote diagnostics, and predictive maintenance—features absent in legacy installations. The new control architecture allows stacker reclaimers to operate with higher precision, reducing coal yard bottlenecks and enhancing overall plant efficiency. This development aligns with a broader national trend where latest thermal power tenders now emphasize automation, O&M optimization, and life extension of balance-of-plant systems. While much of the attention in recent years has focused on FGD, ESP, and boiler retrofits, CHP upgrades are emerging as the next critical frontier for efficiency improvements in thermal plants. Bidders participating in this latest thermal power tender\ will need to demonstrate expertise in integrating advanced PLC systems within live operating environments. The tender also underscores the growing role of digital twins, virtual commissioning, and OT cybersecurity in India’s thermal sector EPC projects. As the competition heats up, both OEMs and specialized system integrators are positioning for a slice of this evolving market, Thermal Power Tenders, India Power Tenders, Thermal Energy India, Power Projects India, EnergylineIndia.

0 notes

Text

Why Data Centres Rely on NX-ERA Premium PLCs for Redundancy & Reliability

Data centres are the online headquarters of businesses today. Every click, transaction, login, or query is responded to via a data centre. In this hyper-connected world, downtime is more than a slowdown; it's a disaster.

Whether it is hosting cloud applications, running finance systems, or managing mission-critical enterprise data, data centres simply can't afford failure of control. That's why businesses often spend money on layers of redundancy, not merely power or cooling, but even on the thinking brain of their infrastructure: the Programmable Logic Controller (PLC).This is where Messung Industrial Automation's NX-ERA Premium PLCs come in as a strategic benefit, designed to provide unparalleled modular scalability, PLC redundancy, and seamless SCADA integration for control that's future-proof.

The Challenge: When Control Systems Become the Weak Link

Power? Backed up. Cooling? Redundant. However, what about the control systems controlling these vital components?

Standard or mini PLCs lack the sophistication needed to handle the mission-critical data centres' demand. One logic mistake or hardware malfunction can take down numerous systems, usually with SLA fines, reputation damage, and monetary loss.

What is required is a Premium PLC solution that guarantees:

High-speed, deterministic control

Hardware and logic level redundancy

Modern SCADA and BMS integration

Scalability as the data centre grows

The Solution: NX-ERA Premium PLCs, Control that Never Sleeps

Built to provide dependable, high-availability automation, our NX-ERA provides much more than your average PLC controller. Let's break down what makes NX-ERA the top choice for data centre automation:

Built with Redundancy: Always On, Always Watching

Designed with a redundant PLC, NX-ERA runs on two CPUs - one primary and one hot-standby. They are mirroring each other in real time. If the main unit fails because of power problems, software glitches, or hardware malfunction, the standby takes over immediately, with no downtime. This degree of PLC redundancy is mission-critical to sustain:

Continuous HVAC and precision cooling

Real-time UPS and power distribution management

Live fire detection and suppression procedures

Integrated High-Speed PLC Performance

NX-ERA is a high-speed PLC with processing power for complex, distributed systems. With event sequencing, real-time I/O update, and determinism support, it ensures that each action is done with precision and accuracy. It's like having a control system that can anticipate trouble before it occurs.

Modular PLC architecture for changing infrastructure

In contrast to fixed systems, our NX-ERA boasts a modular PLC design wherein you can introduce new elements, such as I/O racks, processors, or server room sensors, without having to reconfigure or replace the original configuration. This is necessary in contemporary data centres where growth is ongoing.

Centralised Command SCADA Integration

NX-ERA enables smooth SCADA integration via MODBUS TCP/IP and lets you:

Monitor system health through central dashboards

BMS and environmental management system integration

Allow predictive maintenance and compliance monitoring

Custom logic event-based fire alarms

This turns your PLC controller into the eyes and ears of your operation, reporting, responding, and recording in real time.

NX-ERA in Action: Where It Delivers Inside a Data Centre

Contemporary data centres are precision ecosystems. Every subsystem, power, cooling, and fire protection, has to work in a very sophisticated unison. And NX-ERA Premium PLCs are the invisible heroes, directing all the elements to work together in precision, in complete synchrony and faultlessly.

Let's observe how NX-ERA extends operational excellence to the most critical automation domains:

Precision Environmental & Cooling Management

Maintaining the right temperature and humidity is not just about extending equipment life; it's about performance reliability and data integrity. Any slight discrepancy can cause server throttling, random shutdown, or damage due to condensation. NX-ERA exercises close control over:

CRAC units and air handlers: Thermal hotspots are averted by continuous feedback loops and high-speed actuation.

Chilled water distribution and airflow systems: Adaptive logic keeps cooling in phase with current server loads.

Humidity control: Essential in helping prevent electrostatic discharge and hardware long-term health.

What is special about NX-ERA in this regard is that it can perform environmental control logic with microsecond accuracy, supplemented with real-time data monitoring and logging for auditing, regulatory compliance, and AI-driven optimisation.

UPS Control & Power Synchronisation

Uninterruptible Power Supply (UPS) systems are only as good as the logic behind them. Our NX-ERA functions as a moderator, synchronising among multiple PDUs, UPS systems, and switchgear units. It ensures:

Seamless power source transitions during outages or load fluctuations

Real-time load balancing to avoid overloads and maintain energy efficiency

Phase synchronisation for harmonised energy supply between server halls

Where basic PLCs can lag or lose a beat during transitions, NX-ERA's high-speed PLC architecture anticipates power shifts and actively synchronises systems to absorb the impact, critical in Tier III and Tier IV data centres where downtime is not an option.

Fire Detection & Suppression Integration

When safety is not negotiable, response time is paramount. NX-ERA has real-time fire detection integration with intelligent logic chains that coordinate:

Smoke, temperature, and gas detector sensor integration

Alarm signalling through audio-visual signals

Release logic for chemical or inert gas extinguishing agents

But here's the surprise: NX-ERA performs these life-safety functions without affecting other automation tasks. Fire suppression systems may initiate in one area, yet cooling, power, and access control systems continue uninterrupted in other zones.

Shutdown-Free Maintenance: Redundancy in Action

All PLC systems will eventually need maintenance, but taking down operations to make it happen? That's a luxury no contemporary data centre can afford. NX-ERA avoids this inconvenience with live-switching redundancy:

You can upgrade firmware, replace I/O modules, or perform diagnostics on the main PLC.

In the meantime, the secondary PLC continues the automation uninterrupted.

After maintenance is finished, the jobs reverse, without any effect on operations.

This is redundancy in practice, not on paper, but in everyday ops. It's the way Redundant PLC logic makes scheduled downtime a non-event.

Business Benefits Over Engineering Specs

NX-ERA is more than just an upgrade to technology; it is an enabler for business. Here is how it immediately impacts operational and financial KPIs:

Uptime Confidence: Meets even the strictest SLAs with real-world dependability, minimising risk of penalties and guaranteeing service continuity.

Cost Efficiency: Avoids the enormous cost of downtime—lost business, manual intervention, and recovery of the system—and optimises energy usage with intelligent logic.

Compliance-Ready: With NX-ERA's thorough logging, audit trails, and snapshots of environmental data, ISO, ASHRAE, and Tier certifications are simple to comply with.

Future-Proofing: Built with Industry 4.0 PLC capabilities, such as remote access PLC capabilities, analytics, and diagnostics that become increasingly smarter with your infrastructure.

This is intelligent automation systems delivering tangible return on investment, not in years, but in months

The Road Ahead: Industry 4.0 Compliant, Future-Ready

NX-ERA is designed for the future by predicting the needs of tomorrow's data centre architecture today.

Designed for Edge computing applications where distributed processing is paramount

Smart analytics tools that are AI-enabled, performance optimisation compliant

Remote diagnostics and control, allowing for predictive maintenance anywhere

Integrates perfectly with AI-based decision systems, positioning your business for the next decade

As the business shifts towards smart control systems, NX-ERA is leading the way—not just prepared but already ahead.

Conclusion: Trust NX-ERA for Control that Never Compromises

Trust drives data centres. Trust that each byte is secure. Trust that there's uninterrupted uptime. Trust that operations persist, no matter what. NX-ERA Premium PLCs are designed for this trust.

Where time matters, every control logic matters. And that's where NX-ERA sets the pace: redundant PLCs, real-time SCADA integration, and modular PLC architecture for the intricacies of the future. We don't merely create control systems at Messung Industrial Automation. We create trust.

FAQs

In what way is NX-ERA different from standard PLC controllers?

NX-ERA is a High-availability Premium PLC that is suitable for high-availability environments. It accommodates redundant configurations, modular scalability, and advanced SCADA integration, as opposed to basic or micro-PLCs.

What is the method of NX-ERA's PLC redundancy?

NX-ERA has dual CPUs (main and standby). If the main fails, the standby takes over at once, with zero downtime or loss of data.

Is NX-ERA compatible with the current data centre infrastructure?

Yes. With MODBUS TCP/IP and SCADA-ready capabilities, NX-ERA is easily compatible with all control systems and BMS.

Is NX-ERA able to support small and large-scale data centres?

In fact. Its modular PLC design allows for effortless scaling, from small server rooms to multi-hall Tier IV data centres.

Does NX-ERA support Industry 4.0 PLC features?

Yes, it also has remote access, diagnosis, data logging, and intelligent analytics capabilities, and therefore is fully Industry 4.0-compatible.

#data centres#Programmable Logic Controller (PLC)#PLC redundancy#SCADA integration#mini PLCs#Premium PLC#PLC controller#data centre automation#redundant PLC#high-speed PLC#modular PLC design#MODBUS TCP/IP#NX-ERA Premium PLCs#PLC architecture#PLC systems#Industry 4.0 PLC#AI-based decision systems

0 notes

Text

Cosel 3L014-2 Power Supply Circuit Board | Industrial Automation Power Module | Ram Automations

Ensure reliable power delivery with the Cosel 3L014–2 Power Supply Circuit Board, engineered for performance and stability in high-demand industrial environments. Available now at Ram Automations, this Cosel board is the ideal choice for professionals needing a high-quality power supply solution for PLC panels, OEM cabinets, industrial control systems, and marine automation units.

Designed to deliver uninterrupted, clean, and regulated power, the Cosel 3L014–2 board is compatible with various automation architectures. Whether you’re restoring legacy systems, upgrading cabinet electronics, or expanding industrial racks, this board is a trusted solution to maintain operational consistency and power integrity.

🛒 Buy Now: https://ramautomations.com/products/cosel-3l014-2-power-supply-circuit-board

🌐 Explore More Automation Products: https://ramautomations.com

🔧 Product Specifications: • 📦 Model: 3L014–2 • 🏢 Brand: Cosel • ⚡ Type: Power Supply Circuit Board • 🛠️ Application: Industrial automation, PLC cabinets, marine systems, control panels • ⚙️ Function: Power regulation and electrical signal management

✅ Key Features: ✔️ Delivers consistent, clean power to sensitive components ✔️ High-efficiency conversion and voltage regulation ✔️ Compatible with multiple automation platforms ✔️ Easy integration in panel and rack systems ✔️ Manufactured by trusted brand Cosel

🏭 Perfect For: ✔ Factory Automation Systems ✔ OEM Control Panels ✔ Marine Control Consoles ✔ Industrial PLC Cabinets ✔ SCADA Systems ✔ I/O Expansion Modules

🛠️ Why Choose Ram Automations? At Ram Automations, we specialize in providing genuine and premium automation components across 1000+ trusted global brands. Our inventory supports automation engineers, electrical integrators, and industry professionals worldwide with fast delivery and friendly support.

✔ Genuine, Tested Industrial Components ✔ Support for Bulk Orders & OEMs ✔ Global Shipping with Prompt Service ✔ Tech-Friendly Customer Assistance

🎬 What You’ll See in This Video 🔍 Close-up of the Cosel 3L014–2 board 📦 Integration tips for automation systems ⚙️ Real-world use case examples 💡 Benefits of reliable power supply boards 🌐 Why Cosel power modules stand out

📣 Subscribe & Connect With Ram Automations 🔔 Subscribe for weekly updates on industrial automation components 💬 Drop your questions or suggestions in the comments 👍 Like the video if it helps

🎯 Ram Automations — Keeping Industry in Motion

#Cosel 3L014-2#Power Supply Board#Industrial Power Module#Automation Circuit Board#PLC Power#Cosel Automation#Ram Automations#Power Supply Cosel#OEM Power Board#Panel Power Module#Voltage Regulator Circuit#Marine Automation#PLC Cabinet Power#Electrical Board Cosel#Automation Spare Parts#Cosel Power Card#Industrial Control#Panel Integration#Automation Equipment#Electrical Components#Global Automation Parts#Genuine Automation Board#Control Panel Module

1 note

·

View note

Text

Additive Manufacturing Market Size, Anticipating Growth Prospects from 2034

The world additive manufacturing market stands at US$ 26.79 billion in 2024 according to a fresh study released by Fact.MR, a market research and competitive intelligence firm. Global sales of additive manufacturing solutions are anticipated to grow ahead at 21.6% CAGR during 2024-2034.

More companies these days are likely to sustainable production practices because of their positive impacts on the environment. Compared to conventional production, additive manufacturing offers a number of environmental benefits. Energy and waste reduction are two significant benefits of additive manufacturing technologies over conventional production processes. Additive manufacturing eliminates the use of extra materials required for production with greater efficiency.

3D printing is chosen as the most advanced and latest manufacturing method. This technology is gaining popularity and capable of replacing conventional manufacturing methods in a number of end-use sectors. Medical, electronics, aerospace, defense, and other sectors are willing to embrace these additive manufacturing methods. Advances in electronics manufacturing are expected to result in more automation, and, in turn, additive manufacturing technologies.

Get Free Sample Copy of This Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=9254

Key Takeaway from Market Study

The international additive manufacturing industry is valued at US$ 26.79 billion in the year 2024.

Global additive manufacturing technologies demand is to value at US$ 189.34 billion as of the year 2034.

The market is estimated to grow with a productive CAGR of 21.6% during 2024 to 2034.

North America will dominate with a share of 29.1% in the world's additive manufacturing industry as of the year 2034.

China's demand for additive manufacturing technologies is expected to grow at 22.4% CAGR between 2024 and 2034.

Canada's market is expected to be US$ 9.26 billion by the end of 2034.

The medical sector is expected to have 22.1% of the total market revenue worldwide by 2034.

"Growing usage of additive manufacturing methods across various industries, such as aerospace and defense, to create intricate parts and light-weight components is anticipated to be one of the major growth drivers," provides a Fact.MR analyst.

Browse Full Report: https://www.factmr.com/report/additive-manufacturing-market

Key Market Players

Renishaw Plc.,

Wipro Limited,

Materialise,

ANSYS, Inc.,

Evonik,

Siemens Industry Software Inc.,

Stratasys Ltd.,

General Electric,

Xerox Corporation,

AMFG,

Mazak Corporation,

American Additive Manufacturing LLC,

Optomec are leading additive manufacturing solution providers.

Growing Adoption of Additive Manufacturing in Automotive Sector

Demand for additive manufacturing solutions in the automotive industry is forecasted to grow at 23% CAGR and reach a market value of US$ 27.64 billion by the end of 2034. Increased adoption of additive manufacturing methods is responsible for the simplification of the supply chain, speeding up prototyping, making customization easier, and allowing the manufacture of lightweight parts.

More Valuable Insights on Offer

Fact.MR, in its new offering, presents an unbiased analysis of the additive manufacturing market, presenting historical demand data for 2018 to 2023 and forecast statistics for 2024 to 2034.

The study divulges essential insights into the market based on product type (hardware, material, software), technology (power bed fusion, direct energy deposition, material jetting, material extrusion, photopolymerization), and application (medical, automotive, aerospace & defense, consumer electronics, architecture, industrial equipment, education & research institutions), across six major regions of the world (North America, Europe, East Asia, Latin America, South Asia & Oceania, and MEA).

𝐂𝐨𝐧𝐭𝐚𝐜𝐭:

US Sales Office 11140 Rockville Pike Suite 400 Rockville, MD 20852 United States Tel: +1 (628) 251-1583, +353-1-4434-232 Email: [email protected]

1 note

·

View note

Text

Efficient Optical Signal Distribution with PLC Splitters

PLC Splitters by FiberLife are compact, low-loss components that distribute optical signals evenly across multiple outputs. Designed for EPON/GPON networks, they come in multiple packaging types (bare fiber, ABS box, rack mount, etc.) and are ideal for FTTH rollouts, CATV networks, and centralized telecom architectures.

0 notes

Text

Channel Coil Actuator Market: Revenue Forecast and Competitive Landscape 2025–2032

Channel Coil Actuator Market, Trends, Business Strategies 2025-2032

Channel Coil Actuator Market was valued at 1685 million in 2024 and is projected to reach US$ 3508 million by 2032, at a CAGR of 11.3% during the forecast period.

Our comprehensive Market report is ready with the latest trends, growth opportunities, and strategic analysis https://semiconductorinsight.com/download-sample-report/?product_id=103459

MARKET INSIGHTS

The global Channel Coil Actuator Market was valued at 1685 million in 2024 and is projected to reach US$ 3508 million by 2032, at a CAGR of 11.3% during the forecast period.

Channel coil actuators are electromagnetic devices consisting of four bi-directional voltage-controlled current sources designed to drive inductive loads. These precision components feature balanced differential inputs that isolate coil drivers from control electronics, making them ideal for applications requiring high accuracy motion control in 3-axis assemblies. The system architecture typically supports MOT (magneto-optical trap) configurations with bias field integration.

The market growth is driven by expanding automation across manufacturing and robotics sectors, where these actuators deliver superior positioning repeatability below 1µm. While industrial applications dominate demand, emerging opportunities in medical technology (particularly surgical robots) and electric vehicle powertrains are creating new growth avenues. Recent supply chain challenges have highlighted the importance of localized production, prompting key players like Parker Hannifin and Moog to expand their regional manufacturing footprints. Technological advancements in rare-earth magnet materials are further enhancing actuator efficiency, with modern designs achieving energy savings of 15-20% compared to previous generations.

List of Major Channel Coil Actuator Manufacturers

Johnson Electric (Hong Kong)

Honeywell International Inc. (U.S.)

Rotork plc (U.K.)

Parker Hannifin Corp (U.S.)

Moog Inc. (U.S.)

BEI Sensors (U.S.)

Kendrion N.V. (Netherlands)

Thomson Industries (U.S.)

Dexter Magnetic Technologies (U.S.)

Steinmeyer Mechatronik (Germany)

Celera Motion (U.S.)

EAE Technology (China)

EELECTRON SPA (Italy)

ELKO EP (Czech Republic)

H2W Technologies (U.S.)

PI (Physik Instrumente) (Germany)

SMAC Moving Coil Actuators (U.S.)

Texas Instruments (U.S.)

Thorlabs, Inc. (U.S.)

Toshiba Corporation (Japan)

Hangzhou Zhongke Microelectronics Co. (China)

Segment Analysis:

By Type

Closed-Loop Segment Dominates Due to Precision Control in Industrial Automation

The market is segmented based on type into:

Open Loop

Closed Loop

By Application

Automotive Industry Leads Market Demand Driven by Electrification Trends

The market is segmented based on application into:

Mechanical Engineering

Automotive Industry

Aerospace

Medical Technology

Electrical Industry

By Technology

IoT-Enabled Actuators Gain Traction with Industry 4.0 Adoption

The market is segmented based on technology into:

Standard Electromagnetic

Smart/IoT Enabled

High-Precision

By End User

Industrial Automation Sector Accounts for Major Market Share

The market is segmented based on end user into:

Industrial Automation

Manufacturing

Healthcare

Energy & Utilities

Regional Analysis: Channel Coil Actuator Market

North America The North American market, led by the U.S., is driven by advanced automation adoption across manufacturing, aerospace, and medical technology sectors. With major players like Moog and Parker Hannifin headquartered in the region, technological innovation focuses on precision and IoT integration. Stringent safety regulations in industries such as aerospace (FAA compliance) and healthcare (FDA standards) create demand for high-performance actuators. Recent infrastructure investments, including the $1.2 trillion Bipartisan Infrastructure Law, are accelerating demand in industrial automation. However, supply chain complexities and labor shortages pose challenges to market expansion.

Europe Europe’s market thrives on strict industrial standards and growing emphasis on energy-efficient actuation systems. Germany and France dominate with robust automotive (accounting for 28% of regional demand) and industrial robotics sectors. EU directives on machinery safety (2006/42/EC) and the push for Industry 4.0 adoption are key growth drivers. Local manufacturers like Kendrion and Rotork emphasize customization for niche applications, particularly in renewable energy systems. While Brexit has introduced supply chain complexities, the region’s focus on sustainable manufacturing continues to fuel demand for advanced coil actuators.

Asia-Pacific As the fastest-growing region, APAC benefits from China’s massive electronics manufacturing base and Japan’s leadership in precision robotics (contributing 35% of global actuator shipments). Government initiatives like “Made in China 2025” are accelerating smart factory adoption, while India’s automotive sector expansion creates demand for cost-effective actuation solutions. Price sensitivity drives local manufacturing, though international players like Toshiba and SMC Corporation maintain strong positions in high-end applications. Infrastructure limitations and inconsistent regulatory environments in emerging economies remain growth barriers, offset by rapid urbanization and industrial digitization trends.

South America The region shows gradual market maturation, with Brazil’s oil & gas and mining sectors driving most demand. Economic volatility limits capital investments in automation, favoring basic actuator models over advanced channel coil variants. Local manufacturers focus on servicing industrial maintenance needs rather than new installations. Recent trade agreements are improving access to components, but political instability in key markets continues to deter large-scale automation projects. The renewable energy sector, particularly in Chile and Argentina, presents untapped opportunities for specialized actuator solutions.

Middle East & Africa MEA’s growth stems from oilfield automation and infrastructure megaprojects in GCC countries, where actuators are critical for pipeline and refinery operations. The UAE’s diversification into aerospace manufacturing is creating demand for precision actuation systems, while South Africa’s mining sector requires robust industrial components. Limited local manufacturing capability results in heavy import reliance, though partnerships with global players like Honeywell are developing regional expertise. Economic constraints in African markets restrict adoption, but smart city initiatives in Saudi Arabia (NEOM project) indicate long-term potential for advanced actuator technologies.

MARKET DYNAMICS

While channel coil actuators offer superior performance characteristics, their manufacturing involves complex winding techniques and precision assembly methods that require specialized equipment. Production costs for high-quality channel coil actuators remain approximately 30-35% higher than conventional alternatives, creating a significant barrier to widespread adoption in price-sensitive markets. The specialized nature of these components also leads to longer lead times compared to standard actuators, particularly for custom-engineered solutions.

Supply Chain Vulnerabilities The industry faces ongoing challenges in securing rare earth materials essential for high-performance magnetic components, with supply constraints periodically causing price volatility. Recent geopolitical tensions have further complicated the procurement of these critical materials.

Technical Complexity Designing channel coil actuators for extreme environments requires substantial engineering expertise, and the industry-wide shortage of skilled electromagnetic engineers has slowed innovation cycles. End-users frequently report difficulties in properly integrating these actuators with existing control systems.

The actuator market continues to see intense competition from alternative technologies including piezoelectric, pneumatic, and traditional solenoid-based systems. While channel coil actuators offer superior performance in specific applications, their adoption is restricted in general-purpose applications where cost considerations dominate. Emerging technologies like shape-memory alloys and electroactive polymers are beginning to address similar application spaces with potentially lower production costs, creating pricing pressure across the market.

Additionally, the industry faces challenges in educating potential customers about the long-term cost benefits of channel coil actuators, as many procurement decisions continue to prioritize initial purchase price over total cost of ownership. This is particularly evident in emerging markets, where price sensitivity remains a significant barrier to adoption despite the technology’s performance advantages.

The global medical robotics market, projected to reach $20 billion by 2030, represents a significant growth opportunity for high-precision channel coil actuators. These components are ideally suited for surgical robots requiring precise force control and miniaturized dimensions, with current adoption rates growing at approximately 18% annually. Manufacturers developing medical-grade actuators with biocompatible materials and sterilization capabilities are particularly well-positioned to capitalize on this expanding market segment.

Furthermore, the integration of AI-assisted positioning systems with channel coil actuators opens new possibilities in robotic-assisted surgery, where sub-millimeter accuracy and rapid response times can significantly improve surgical outcomes. Several leading medical device manufacturers have recently announced partnerships with actuator specialists to develop next-generation surgical instruments, signaling strong market momentum in this specialized application area.

Emerging applications in renewable energy systems, particularly in solar tracking and wind turbine control mechanisms, also present substantial growth opportunities. These sectors require robust actuation solutions capable of withstanding harsh environmental conditions while maintaining precision over extended operational lifetimes.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies https://semiconductorinsight.com/download-sample-report/?product_id=103459

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global Channel Coil Actuator Market?

Which key companies operate in Global Channel Coil Actuator Market?

What are the key growth drivers?

Which region dominates the market?

What are the emerging trends?

Related Reports:

CONTACT US: City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014 [+91 8087992013] [email protected]

0 notes

Text

Advanced Programmable Logic Controllers (PLCs) for Scalable Automation Solutions

WAGO’s Programmable Logic Controllers (PLCs) deliver flexible, high-performance automation for a wide range of industrial applications. Designed to support modular architectures, these controllers integrate seamlessly with field devices, networks, and the cloud, enabling precise control and efficient data processing. Whether for factory automation, process control, or building systems, WAGO’s PLCs offer a reliable platform for scalable and future-ready operations.

0 notes

Text

Euchner Safety Relays & Safety Controllers Manufacturers in India

Euchner Safety Relays & Safety Controllers Manufacturers in India – Sanocs

In the industrial automation landscape, ensuring worker safety and machine protection is a top priority. Sanocs, a leading name in the industry, is recognized as one of the most trusted manufacturers of Euchner safety relays and safety controllers in India. We specialize in developing high-performance safety PLCs, machine safety relays, and safety controllers that cater to a wide variety of industries including automotive, manufacturing, robotics, packaging, and material handling.

Why Safety Controllers Are Essential in Industrial Environments

A safety controller is an essential component in any industrial setup where hazardous machinery and automated systems operate. It ensures that safety devices such as emergency stop switches, light curtains, interlocks, and two-hand controls are working efficiently to prevent accidents. With growing automation and complex machinery, using reliable and programmable safety controllers in India has become increasingly important for compliance, safety, and operational efficiency.

At Sanocs, we understand the critical need for dependable and intelligent safety solutions. That’s why we offer a wide range of safety controllers designed for integration with a variety of safety sensors and actuators.

Euchner Safety Relays – High-Quality Safety Relays You Can Trust

Euchner safety relays are designed to provide reliable performance and maximum protection. These safety relays monitor the signals from safety devices and control actuators to ensure safe shutdown of machinery during hazardous conditions. Sanocs offers machine safety relays that are compatible with multiple input devices, providing flexibility and enhanced safety functionality.

Our Euchner safety relays are known for:

Compact design and easy installation

Fast response time and precision

Durable components for long operational life

Compliance with international safety standards

Whether it’s for emergency stop circuits, safety gates, or light curtains, our safety relays offer reliable operation in the most demanding environments.

Sanocs – Leading Manufacturer of Safety Controllers in India

Sanocs is a pioneer in designing and manufacturing safety controllers in India that are robust, programmable, and highly adaptable to different safety applications. Our range of safety controllers includes both modular and compact models, suited for small to large-scale machinery and industrial automation systems.

We design our safety controllers keeping in mind:

Ease of integration with existing safety systems

Compatibility with various safety input devices

Real-time diagnostics and error reporting

Scalable architecture for future upgrades

We also provide safety PLCs that allow for complex logic programming, enabling users to configure custom safety responses based on the specific requirements of their facility.

Applications of Our Safety Relays and Controllers

Sanocs’ safety controllers and Euchner safety relays are widely used in:

CNC machines and robotic arms

Conveyor systems and material handling units

Packaging and bottling machines

Automotive assembly lines

Presses, cutters, and other high-risk machinery

These devices ensure operational safety, reduce downtime, and help companies comply with regulatory standards such as ISO 13849 and IEC 62061.

Why Choose Sanocs for Your Machine Safety Needs?

Trusted Brand – With years of expertise, Sanocs has built a reputation as a dependable manufacturer of safety controllers in India and Euchner safety relays.

Quality Assurance – All our products undergo strict quality checks and conform to global safety norms.

Competitive Pricing – Get the best value with high-performance products at industry-leading prices.

Technical Support – Our team of engineers provides end-to-end assistance, from product selection to implementation and troubleshooting.

Customization Available – We offer tailored safety solutions to suit specific industrial needs.

Safety First with Sanocs

When it comes to industrial safety, compromise is not an option. Sanocs is committed to delivering top-tier safety solutions that safeguard human lives and protect machinery. Our machine safety relays, Euchner safety relays, and programmable safety controllers are trusted across India by manufacturers who prioritize safety, performance, and reliability.

If you are looking for innovative, cost-effective, and certified safety solutions, Sanocs is the ideal choice for all your safety automation requirements.

For More Information

9879242755

Plot 21, Panchratna Green - Industrial Park, Nr. Pirana Village, Ahmedabad 382425

#Safety controller#safety controllers in india#euchner safety relays#safety relays#machine safety relays

0 notes

Text

Acrylic Polymer Emulsion Market

Acrylic Polymer Emulsion Market is witnessing significant growth globally, driven by rising demand for sustainable, high-performance, and cost-effective materials in industries such as paints and coatings, adhesives and sealants, textiles, construction, and packaging. In 2024, the global market for acrylic polymer emulsions is valued at $9.8 billion and is projected to grow at a CAGR of 6.2% during 2024–2031.

What Are Acrylic Polymer Emulsions?

Acrylic polymer emulsions are water-based dispersions of acrylic or methacrylic polymers. They are widely known for their low volatile organic compound (VOC) content, superior adhesion, weatherability, UV resistance, and film-forming capabilities. These features make them highly attractive in formulating environmentally friendly coatings, adhesives, and construction materials.

Market Growth Drivers

Surge in Construction and Infrastructure Projects The increasing number of residential and commercial construction projects, especially in Asia-Pacific, is a major driver. Acrylic emulsions are used in architectural coatings, waterproofing systems, and concrete modifiers to improve durability and environmental performance.

Rising Demand for Water-Based Coatings With growing environmental concerns and stricter regulations on VOC emissions, there is a rapid shift from solvent-based to water-based coatings. Acrylic emulsions offer excellent performance while aligning with sustainability goals.

Expanding Adhesives and Sealants Market The demand for pressure-sensitive adhesives and sealants in packaging, automotive, and electronics sectors further boosts the use of acrylic emulsions as binders due to their flexibility and weather resistance.

Growth in Textile and Nonwoven Applications In textiles, acrylic emulsions are used to enhance fabric stiffness, water repellency, and printability. The increasing popularity of nonwoven fabrics in hygiene and filtration products also supports market growth.

🔗 𝐆𝐞𝐭 𝐑𝐎𝐈-𝐟𝐨𝐜𝐮𝐬𝐞𝐝 𝐢𝐧𝐬𝐢𝐠𝐡𝐭𝐬 𝐟𝐨𝐫 𝟐𝟎𝟐𝟓-𝟐𝟎𝟑𝟏 → 𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐍𝐨𝐰

Market Segmentation

By Type:

Pure Acrylic Emulsions

Styrene Acrylic Emulsions

Vinyl Acrylic Emulsions

Others

By Application:

Paints & Coatings

Construction Additives

Adhesives & Sealants

Textiles

Paper & Packaging

Others

By End-Use Industry:

Building & Construction

Automotive

Consumer Goods

Industrial

Textiles

Regional Insights

Asia-Pacific holds the largest market share, with China and India leading in consumption due to industrialization, urbanization, and infrastructure development.

North America and Europe follow, driven by regulatory pressure to adopt eco-friendly coatings and advanced material technologies.

Latin America and Middle East & Africa are emerging as promising regions due to increasing investments in construction and industrial sectors.

Key Players

Major companies operating in the global acrylic polymer emulsion market include:

BASF S

Dow Inc.

Arkema Group

Celanese Corporation

Synthomer plc

Asian Paints Ltd

DIC Corporation

Ashland Global

These players are focusing on R&D investments, product innovation, and strategic collaborations to develop low-VOC, high-performance emulsions tailored for diverse applications.

Outlook

0 notes