#Portable Multimeter

Explore tagged Tumblr posts

Text

Explore the Best Meco-G Products with Swastik Power Electronics in Pune, Maharashtra

Swastik Power Electronics is proud to be your trusted supplier and dealer of Meco-G products in Pune, Maharashtra, India. We are dedicated to delivering a comprehensive range of top-notch Meco-G products to meet your diverse electrical and measurement needs.

Why Choose Swastik Power Electronics for Meco-G Products?

Best Meco-G Product Supplier and Dealer: We are recognized for offering high-quality Meco-G products that ensure reliability and precision.

Wide Range of Products: From clamp meters to IR thermometers and digital multimeters, we provide all the essential Meco-G tools to cater to your requirements.

Expertise and Support: With extensive experience, we provide expert guidance and unparalleled customer service to help you choose the best solutions.

Our Featured Meco-G Products

1. Meco-G Clamp Meter

As the best Meco-G clamp meter supplier and dealer in Pune, Maharashtra, we provide advanced clamp meters designed for accurate current measurement without circuit interruptions. These devices are compact, durable, and easy to use, making them indispensable for electricians and technicians.

2. Meco-G Digital Multimeter

We are the best Meco-G digital multimeter supplier and dealer in Pune, Maharashtra, offering high-performance multimeters known for their reliability and precision. Whether for voltage, resistance, or current measurement, our digital multimeters are perfect for various industrial and commercial applications.

3. IR Thermometer

Swastik Power Electronics is your go-to best IR thermometer supplier and dealer in Pune, Maharashtra. Our IR thermometers ensure accurate and contactless temperature measurement, making them ideal for industrial and medical use.

4. Portable Meters

Looking for reliable portable meters? As the best portable meter product supplier and dealer in Pune, Maharashtra, we bring you top-quality Meco-G portable meters designed for ease of use and unparalleled accuracy.

Why Trust Meco-G Products?

Accuracy and Durability: Known for precision and robust design, Meco-G products deliver exceptional performance.

Versatility: Meco-G products cater to various industries, including electrical, construction, and healthcare.

Innovation: Meco-G is at the forefront of technological advancements, ensuring its tools meet the latest industry standards.

#best Meco-G product Supplier and dealer in Pune Maharashtra India#best Meco-G product Supplier and dealer#best Meco-G product#Meco-G product#best Meco-G clamp meter Supplier and dealer in Pune Maharashtra India#best Meco-G clamp meter supplier and dealer#Meco-G clamp meter#best Meco-G digital multimeter Supplier and dealer in Pune Maharashtra India#best Meco-G digital multimeter Supplier and dealer#best Meco-G digital multimeter#Meco-G digital multimeter#best IR Thermometer Supplier and dealer in pune maharashtra india#best IR Thermometer Supplier and dealer#best IR Thermometer#IR Thermometer#best portable meter product Supplier and dealer in Pune Maharashtra India#best portable meter Supplier and dealer#best portable meter#portable meter

0 notes

Text

50V To 500V 0-100A AC Digital Voltage and Ampere Meter White LED Indicator Light with Universal Current Detector

Specifications :

Digital display for voltage and ampere indication

Operating voltage : 50V to 500V AC

Operating current : 0A to 100A

Viewing angle : 30° to 110°

Emerging color : White

Life expectancy : 1,00,000 hours

Precise and smart design

Buy Now : https://electronicspices.com/product/50v-to-500v-0-100a-ac-digital-voltage-and-ampere-meter-white-led-indicator-light-with-universal-current-detector

#ACDigitalMeter#VoltageAmpereMeter#CurrentDetector#Multimeter#ClampMeter#electronic#electronicspices#Portable#Electrician#DIY#led#indicator#ledmeter#voltage#Led#meter

0 notes

Text

Redbo Ref/Concept Sketch!

I'm gonna work on digitizing both refs right after I post this!

I'll fix Red's anatomy in digital I promise

He's short but he's not supposed to look that short lmao

EDIT: FORGOT TO PUT EVERYTHING INTO TEXT LIKE LAST TIME!! MB!!

[Text:

Redbo_

The Vessel • Arospec/Acespec • He/Him

What makes him different? | Don't delete me pls

Tool | Weirdly hot boss?

Frustrating project | Evbo (surrounded in hearts)

While working

Input buttons

Control pannel

Portable soldering kit

Multimeter

Measuring tape

Basically a smart watch

Ring w/ blade

Multiple lenses

• In charge of everything in the facility

• Built and maintains every single machine/Command Block

• Thinks Simbo is some divine prophet sent by (or is an extension of) the Creator

• Workers get 6-hour breaks to sleep. He gives himself 4

• Created the androids after observing [how] view counters were higher when Evbos directly interacted with Seawatts

• Has seen all the fanart. Not limited to Seavbo.]

#ooc#simulation evbo#redbo and simbo blog#pvp civilization#parkour civilization#parkciv#pvpciv#ask blog#rp blog#redbo#seavbo#evbocest#if you squint

29 notes

·

View notes

Text

Day 2 of this stupid transmitter being stupid and I have to hold the multimeter about it:

Remembered to wear my winter coat and found the part of the building that isn't drafty

Got to press buttons

Held the multimeter

Held MY multimeter

Third multimeter hasn't come out yet today

Klein brand Demolition Screwdrivers are really cool, you can break things with them. Favorite tool in my bag. Not sponsored.

Tech support has been called and forward progress has been made

Does anyone know if there's such a thing as a portable coffee maker? Like a Mr Coffee you can keep in your backpack or suitcase?

#“engineering assistant” gets confused frequently with “assistant engineer”#it's like in The Office where Dwight is “assistant to the regional manager”#also no we don't climb the towers that's an entirely different profession

6 notes

·

View notes

Text

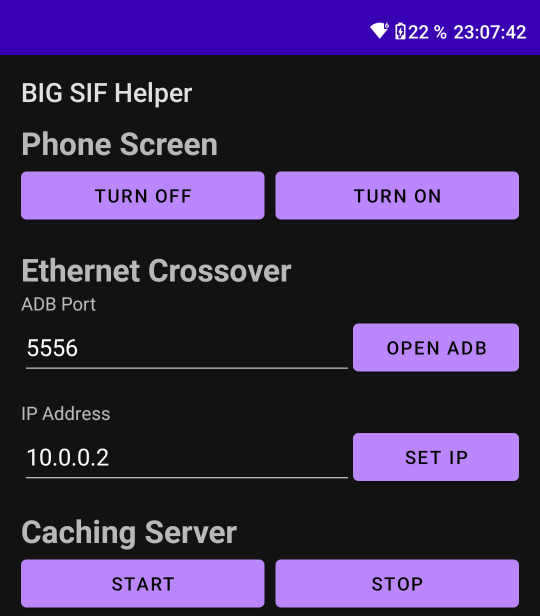

Making BIG SIF2 (Part 3)

Hi! I'm back, and my BIG SIF setup is complete! That's not to say I'll never touch anything about it ever again, but it works great, and it also looks great now. Almost as if it's not just a pile of jank and bodges!

If you missed part 1 and part 2, the tl;dr is: I recreated an old SIF event where you stomp on big old floor buttons with eight other players to play songs together as a team. The other two posts talk about how the switches work, and various details about how it's all connected respectively, in case you are interested!

This post is another write-along of me working on stuff, and this time, it's about just finishing off the last few problems and to-dos - making a case for the electronics, and thinking about reliability and portability. Because of how many topics I want to cover, everything will only be covered relatively briefly. But if you want to know more about something specific, drop me an ask and I'll write more about that topic.

And just to have this important bit above the fold: I'm bringing the setup to Connichi on Saturday next weekend, in case you are there and want to play. More about that at the bottom of the post - but let's get started!

First off, an admission: I lied to you. Last time I said I made eight more floor switches. But that was not quite the truth:

It was eleven.

So multiply everything I said last time by 1.33 - 12 total switches, with 36 shelf liner layers, 24 of those copper taped and soldered, 144 holes cut into 12 rug pad layers, 192 snap caps pressed by hand, 48 cables crimped with bullet connectors by hand. Needless to say, I have been taking it easy to give my wrist a break... The first question is probably "why?" - it's not like there's a 12-spot mode or something. That's true, I'll never use more than nine of the switches at the same time. The reason these extra three buttons exist is reliabilty: there can be three backup floor switches on standby, to swap in if something breaks.

The switches are probably fairly easy to fix if something goes wrong - just need to re-solder a connection or repair some copper tape, at most. But that will still be a problem when actually playing with the controller system, because it will always take some time, during which the game will not be playable. Having more switches on standby means you can swap out the faulty button to diagnose and repair it, while the game can go on! But the main thing is that I will not be having the means to repair switches in most locations in the first place. I'm not going to bring my screwdrivers, soldering station, multimeter, extra copper tape, cable and everything else to wherever we're playing! And there's a good chance there's no power or space for a repair station, anyways.

That's why I went with three backup buttons, so the game can go on even longer even if I I'm unable to do repairs right away. We'll just keep playing, and I'll repair the broken switches when I'm back home. And technically, because all the buttons are modular and I can swap out the separate layers, the system doesn't become unusable until four of the same part break! That should be more than enough reliability for almost any situation, especially since it probably won't be used for more than a couple hours at a time.

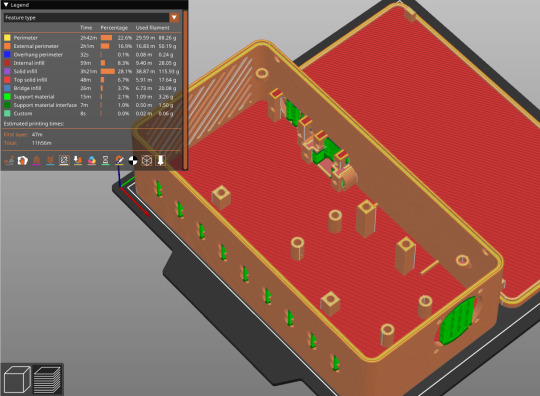

Next up: let's hide all of the work I did. Having the wiring visible is a little ugly, so let's just put everything in a box. Building an enclosure also makes transporting and setting up everything a lot easier, since I can already connect everything inside the box ahead of time, and then just have to plug in and place the switches on the floor. And the easiest way to make a bespoke enclosure is 3D printing it!

What I'll need - besides the obvious "places to put all of the adapters and the phone" - is some way to access the sockets and board from outside so I can plug all the cables in. Also, even though SIF2 isn't that demanding, it's still a closed box, so I'll probably want to add a fan. But that sounds doable, most of these won't be any problem. I can draw a box with some holes. I decided to go for OpenSCAD for this project instead of FreeCAD - while it would have been nice to have FreeCAD to plan cable routing and be able to set constraints and everything, I just didn't need all of these complicated features. Again, it's just a box with holes, and I can do that real fast in OpenSCAD.

To make sure I get the box right the first try, I implemented every component as a seperate module in OpenSCAD, so I could print them seperately - for example, I could easily test print only the part of the wall that would house the Ethernet socket, to make sure that it fits perfectly before printing the whole box - and then adjust their position easily without messing up the rest of the components.

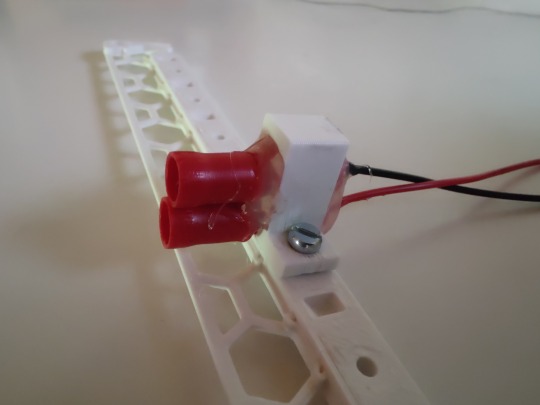

For the adapters without screw holes, I used threaded inserts that you melt in the plastic. I've never used them before, but since self-tapped holes wear out after a few times of putting screws in and out, I wanted to try out a more reliable method. These ones will last probably forever, and hold the screws in real tight. They were surprisingly easy to use, I assumed they would be harder to get straight... With this, I can use pillars with threaded inserts and some clips to screw in to keep the adapters in place, no matter how much the box gets thrown around. These threaded inserts can also be used to mount the arcade controller board and the fan. The fan even gets power right from the arcade board, which has 5V pins meant for LEDs - but they work just fine for anything else that needs power, too. I did add a resistor on the wire though, to turn down the fan speed and noise. Finally, to access the adapter sockets easily without having to open the box, I found panel mount extension cables for all the sockets that needed to be accessible outside - HDMI, Ethernet and USB-C (power delivery).

One difficulty was the sockets for the button cables. These are not some standardized kind of plug, after all, so I can't buy a panel mount cable like the others - I have to figure out how to mount these flush with the outside wall myself, and they have to stay in place, both when inserting and pulling out the cable. In this case, I was able to use the middle shelf I already had, that mainly exists to hold the phone, since it's placed right above the cable holes. I hot glued the sockets for the cables to some small clips, which can be screwed into the shelf with screws. Finally, the shelf can be aligned with the holes in the wall when placing it in the box, all the sockets being inserted at once. There's even a bit of a taper on the button cable holes, so the sockets self-align with them!

All that's left then is just jamming all the cables in there somehow. The only real awkward cable was the USB-B-to-A cable for the arcade board connection - the one that came with it was two metres long, far too much to fit in there. So I just cut it up and soldered it back together, reducing the length down to just 20 cm. That way, all the cables actually fit in there quite nicely, and there's plenty of space left for the board connector cables, so the middle shelf can lock everything in place!

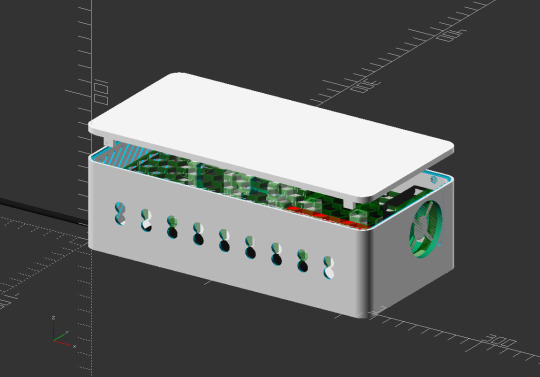

And here's the finished box! That's a good box, right?

As one little last addition, I worked on some decorations. A plain white box would look a little boring, after all, so I added some accents and icons on the front and top. While it would have been super easy to do by printing the lid in one go and changing to a pink filament for just the decoration layers, I thought I'd be smart and not buy an entire spool of filament just for that. Instead, I printed everything seperately in white filament, and then painted it all with pink acrylic paint instead. That made the decoration only cost half - but it was such a pain. Between all the coats of paint needed to get a result that didn't look completely awful, having to glue on all of the little dots on the lid by hand, and then the clear coat, which kept getting tiny bits of dust getting stuck in it which are painfully noticable on a white background... I should have paid the extra price for the filament, it would have been less work and looked much better. Hindsight is 20/20. At least it looks okay from "standing on the floor switches" distance, I guess.

To close up the box securely, I also ended up adding some magnets I had around, glued into holes in the lid and the box walls. This way, to set up the game, I don't need any tools - all the cabling in the bottom department can be done far ahead of time, and then, at the location, I just open up the magnetic lid to place my phone into it, plug the floor switch cables into the sockets, connect the output cable on the back of the box, and it's good to go! This was an important step for the project - instead of a nest of wires openly sitting next to the TV, it looks nice and properly finished now. It probably could have been done way easier by just grabbing a shoe box, punching some holes into it and just having extensions cables hang out, but I wanted to try doing it "right", and I think the result is absolutely worth it.

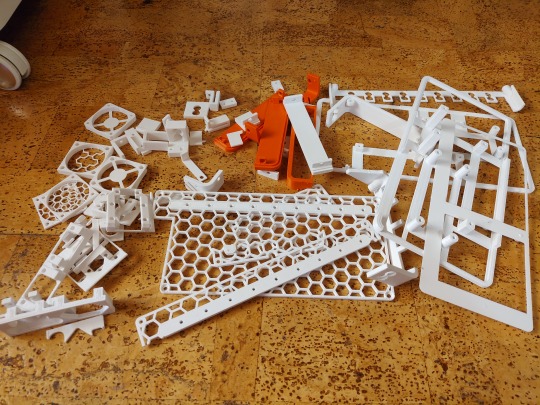

One more note: I tried to reduce printed waste by just printing small parts to test and only doing the full box print once I was sure everything would work - but all those test prints shown above are still waste of course. This is sadly something that cannot be avoided, but I can at least make sure to reduce the impact it has. The test prints are not getting thrown into the trash, but will eventually make their way to the Recyclingfabrik. If you've never heard of them, they're a company based here in Germany that makes 100% recycled 3D printer filament! That way, my useless prints won't get burned or end up in a landfill, but can instead be reused in the future. (Also, they make some really cool filament colours, I highly recommend checking them out!)

Alright, now that we made a really good box, it's time to get back to something questionably janky.

With everything in the box running off of the phone battery, the system already is completely portable! Imagine being able to set up a quick BIG SIF game wherever you are, at cons or something… but in order to do that, there's still one massive component missing, and that's a screen to play on. Obviously, playing the game on a 15cm phone screen while standing on buttons up to two metres away is not a good time. You need something bigger! The coolest thing would be to buy a battery powered projector. That would give you a giant picture and be easy to set up anywhere - I'll probably get one sooner or later, but I'm not pulling the trigger on that purchase just yet. It'll be a lot pricier than the rest of this project, and choosing an outdoor projector seems hard, anyways… (I've been looking for comparisions of images from projectors with different Lumen amounts in different light conditions, but that doesn't seem to exist. Maybe some of you know something similar?)

There's also portable monitors. These are mainly meant as a simple second screen for laptops when working, but they would be a good fit for this situation as well, since they only need a USB connection for power. Something like that could work if I could find a screen that is large enough, and it would also be quite easy to carry around with the setup, as these are usually pretty thin. But again, good ones are usually in the "costs more than this entire project in total" range. But the thing is, technically all we need is a screen and a battery. I think if we bodge things a little, we can use another device that has a screen and a battery, and is made for being portable: your laptop.

Let me introduce you to scrcpy, which is pretty much the best thing since sliced bread. If you want your Android screen on your PC screen, it is hands down the best way to do it. All you need is an USB cable - no app needed, no massive latency due to WiFi, and no need to send all your video data through some provider's remote server. scrcpy has almost no delay, you can use your PC keyboard and mouse, and you can even play phone audio on your PC with the newer versions. It's incredible, and I use it almost every day. So, plug the USB cable into the phone, and you can have SIF2 on the laptop screen! A luxurious 40cm screen, and speakers included, no emulators needed! But wait... now that the phone is directly connected to the laptop, I can't connect the other adapters in the box. It doesn't make sense to have the video on the laptop if I can't use the floor switches. Those are the entire point of the project! So, I can't use an USB connection.

But remember that Ethernet adapter I added? The main use for it was to be able to wire up to get a good and stable internet connection when the wireless one is too weak. But by using a special Ethernet crossover cable, two devices can communicate without needing a router or switch, and can create their own network just between them! scrcpy doesn't work just over USB, a network connection works, too - and I can set up that connection with just that cable. The video stream to the laptop is back up, and the board can still be connected! And now, we have a solution for a portable screen - it shows the game, it has it's own battery, and it's easy to transport! This approach is obviously not perfect - it's pretty janky, and "almost no delay" is still a delay - but for a quick spontaneous game of BIG SIF, this is a fine way to play.

The final hurdle to take is the internet connection the game needs. This is still a massive weak point in the portability, because, as every con-goer knows, it's basically impossible to use mobile internet at cons, as it is immediately overloaded by the amount of people there (or at least German con-goers know, idk if other countries are as bad). Unless you are have a provider that uses the higher tier mobile networks, it's either extremely slow or just unavailable. If the connection is laggy, that should still be enough to play, as you'd only have to fetch song info at the start of a Live - but SIF2 makes it difficult, due to how the game handles assets, specifically, the music files.

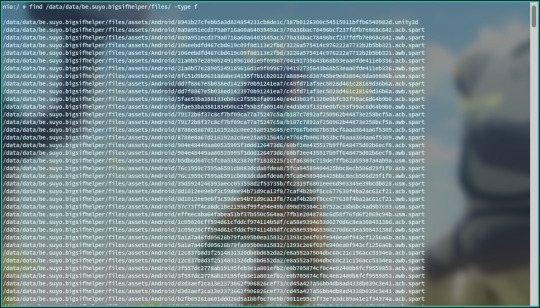

Every time the game loads a new song, it needs to download a file from the servers. That's the reason why, if you scroll through the song list quickly or hit the Random button a lot, the preview music doesn't play for a while: The game has to load all the server files for all the songs you stopped on... The song files are on your phone, but they are not complete. There's parts missing, and that file that has to be downloaded contains those missing parts. Without being able to download these server parts, the game would not be able to reassemble any song files, and could not play any music. And this is why a stable internet connection is so important for this project. We'd have no music at all without one, because every file must download it's missing parts from the servers! If only there was a way to keep the missing parts files, and store them on the phone so we wouldn't have to download them every time...

Trying to avoid too much technical details, here's the idea in a nutshell: I made an app that runs in the background while SIF2 is open, and whenever the game contacts the asset server, we trick it into instead requesting the missing parts file from that app. The app will handle the download instead, but in addition to delivering the file to the game, it will also save it on the phone. And if the same file is requested again, we just take it from storage instead of downloading it from the server again! The code for it is surprisingly simple, but the difference it makes is massive - it's noticable even with a stable and fast WiFi connection, because the delay between selecting a song and the preview starting is completely gone! So I'll probably keep using this app even when playing normally, but most importantly, this is going to work wonders on mobile connections! Maybe, that's enough to play the game even with things slow down... I won't know for sure until we get there.

And hey, while I already made an app, I also added a bunch of buttons to make setting up easier without having to use the shell. Everything that's needed to do a BIG SIF, on a single screen!

Anyways, we've come to the end! That's all for this project for now! Thank you for reading all the way to here!

If you're planning to make a BIG SIF setup for yourself and have any questions, or are just interested in more details on anything I've talked about, feel free to drop me a ask/message and I'd be happy to answer! If you want to come play with me on this setup though, that'll probably be a little harder for most people reading this due to distance, sadly :) But you could try checking my Mastodon, where I might be talking about any cons I'll be bringing it to! Just to mention it again, I'll be bringing everything to Connichi in Wiesbaden next Saturday (September 2nd)! I won't have a proper setup location, but if you have a group who's up to play, keep an eye out for the GenYoha!Kanan cosplayer - assuming I finish the cosplay in time, otherwise, look for a nesoberi-laden Lanzhu. If we can find a place where we don't annoy others, and the mobile internet connection plays nicely, maybe we can play a few rounds - so, see you there, possibly?

And as the last last last topic, here's some final thoughts - on things I'd like to change, or that you can consider changing if you make something like this yourself!

One obvious part of the project you could change is how the buttons work. I like the copper tape approach - it seems robust, is easy to build and fix in case of problem, and works reliably. But as long as you can make something that can close an electrical circuit, anything could work! One obvious choice would be contact sensor, but personally, I feel that's just a big point of failure, but maybe there's some cool approaches out there I didn't think of... One thing that I want to try though is replacing the rug pad with some light foam, about 1cm thick or so. As it is right now, the switches are lacking some kind of physical response, you don't feel much of a press. Maybe the foam would allow the button to have a "travel", being able to feel the switch depress and bottom out could be nice.

And regarding the caching app for the sever files, maybe I should just go all the way with that idea? Because ideally, I'd extend this concept to not just the missing part files, but generally all server communication. The app would just replay responses from when I logged in earlier instead, and have infinite plays without a connection! But I'm not sure whether I want to go down the private server rabbit hole...

The big thing I'd love to do though is improve the menuing. SIF2 is just not meant to be played with buttons - it's made for a touchscreen! And the keyboard solution I have right now works, but it's not a great solution. The floor switches will still be functional on the menus and mess around there, and the keys will also be usable on the screens they're not meant for. It's definitely not something I can just pass to someone and say "here, have fun". But what would the better approach be? The base requirement for any better interface would be to be able to track which screen the game is on, which is already a major problem. One thing I was able to come up with was making a helper app record certain regions of the screen, and doing image comparison - as in, "if this button is visible, the app must be on that screen". But that would be a whole different project, probably worth a full post in itself...

Okay, I'm stopping for real now. Too many ideas, not enough time, as always. byeee

#lovelive#love live#ラブライブ#school idol festival#sif2#スクフェス#i sure hope i can actually play this someday with someone#because con season is kind of about to be over#bad timing i guess haha#update january 2024: lol#lmao even

14 notes

·

View notes

Text

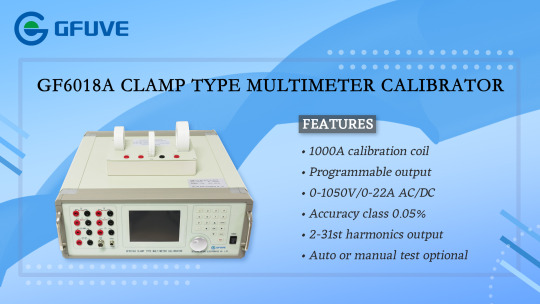

GF6018A High precisition 6.5bit portable AC DC multi product calibrator for multimeter calibrator

This GF6018A high precision multi-product calibrator is compliance with national verification regulation: JJG124-2005 Ammeter, voltmeter, power meter and resistance meter verification rules" and related national standards. 0.05% single-phase standard AC/DC voltage and current source, can verify level 0.2 and the following AC/DC voltmeter, ammeter, frequency meter, resistance meter & clamp meter. The source signals by using DSP and 16-bit high-speed A/D converters of controllable sine wave, the distorted wave signal source. Multifunction calibrator GF6018A is designed as universal calibration tool for electrical calibration laboratories. Measurement range from 0-1050V and 0-20A AC/DC;With 200A, 600A, 1000A calibration coil. The GF6018A clamp type multimeter calibrator with RS-232 port, it can be connected with PC to control, become automatic verification system. It has precise interface and multi-functions including verification, storage and query. The GF6018A multimeter calibrator adopts color LCD screen, chart character display is clear, with high precision, stable and reliable, convenient operation and flexible characteristics. It fully meets ISO17025 laboratory standards and is a good ideal test equipment for electrical engineers. APPLICATION ■ Power plant; ■ Universities; ■ Panel manufacturer; ■ Research institutes; ■ Electrical testing center; ■ Multimeter manufacturers; ■ Oscilloscope manufacturer; ■ Clamp meter manufacturers; ■ Digital meter manufacturers; ■ ISO17025 Electrical laboratory; ■ Electricity power bureau & power company; ■ Power engineering commissioning company; ■ Electrical Department of industrial and mining enterprises;

2 notes

·

View notes

Text

Discover the Best in India: Solar Powered Digital Multimeter by INDE Enterprises

When it comes to precision measurement, sustainability, and cost-effectiveness, the Solar Powered Digital Multimeter offered exclusively by INDE Enterprises reigns supreme in India.

🌞 Solar-Powered Efficiency: Harnessing the power of the sun, this multimeter eliminates the need for conventional batteries. Its built-in solar panel ensures uninterrupted operation while reducing your carbon footprint. You'll never have to worry about running out of battery power again.

💰 Unbeatable Affordability: INDE Enterprises is committed to providing high-quality tools at minimal costs. This digital multimeter is no exception. It offers a range of advanced features without the premium price tag. Your quest for a budget-friendly, eco-conscious multimeter ends here.

📐 Precision at Its Best: Whether you're an electronics enthusiast or a professional, this multimeter offers 4000 counts of LCD precision. It can effortlessly measure DC and AC voltage, DC and AC current, resistance, capacitance, frequency, diode, and continuity.

🛡️ Safety & Convenience: Your safety is paramount. This multimeter adheres to IEC1010-1 standards with a CAT.II 1000V rating. It features fused 10A and 400mA for enhanced protection. Audible continuity and diode tests, data hold mode, and a sleep mode for conserving power add to its convenience.

📏 Compact & Portable: With its sleek and compact design, the multimeter is perfectly suited for both professionals and hobbyists. It's accompanied by essential accessories, including test leads and a convenient carrying case, making it easy to transport and use on the go.

Choose a multimeter that not only meets your precision measurement needs but also takes a proactive stance in protecting the environment. INDE Enterprises' Solar Powered Digital Multimeter is your gateway to a greener, more cost-effective future.

Make the smart choice today and get your hands on this exclusive multimeter, available only through INDE Enterprises. It's time to measure with confidence, convenience, and eco-friendliness.

Quotation & Enquiries:

Contacts: Rajiv & Romesh Cellphones: 9316134502 & 8283820745 Email: [email protected] Alternative Email: [email protected]

#EcoFriendly #SolarPanelTechnology #INDEEnterprises

#multimeter#solarpowered#digitaltools#precisionmeasurement#costeffective#exclusiveoffer#indeenterprises#lcrmeter#lcr#smarttweezers

2 notes

·

View notes

Text

0 notes

Text

🔧 Handheld Insulation Multimeter at EnrgtechGlobal! 🔋

Compact, reliable, and easy to use for precise insulation resistance testing. Perfect for electrical maintenance and testing.

⚡ Key Features:

Accurate readings

Durable & portable

Shop Now and power up your testing! 🔧

#EnrgtechGlobal #Multimeter #ElectricalTesting #InsulationTesting

0 notes

Text

0 notes

Text

0 notes

Text

Test and Measurement Equipment Industry Insights Opportunities, Key Applications & Market Dynamics

The test and measurement equipment market a compound annual growth rate (CAGR) of 7.2% during the forecast period 2025-2035 increasing demand for precise diagnostics, product quality assurance, and advanced electronics development. Industries like telecom, automotive, aerospace, and healthcare are leveraging these tools to ensure accuracy, compliance, and operational efficiency. The market is driven by innovations in wireless communication, IoT integration, and semiconductor testing advancements.

Market Segmentation

By Product Type

Oscilloscopes

Spectrum analyzers

Signal generators

Multimeters

Network analyzers

By Application

Telecommunication

Automotive

Aerospace and defense

Healthcare

Electronics manufacturing

By Region

North America, Europe, Asia-Pacific, Latin America, Middle East and Africa

Market Trends

Rising use in 5G and IoT application testing

Shift towards modular and portable instruments

Cloud-based data analysis and remote monitoring

Increased automation in quality control

Segment Insights

Oscilloscopes and signal generators are critical in design and troubleshooting. Telecom applications lead due to ongoing 5G infrastructure expansion. Aerospace and defense sectors rely on high-precision equipment for system testing.

End-User Insights

Telecom operators deploy advanced analyzers for network optimization. Automotive firms use equipment in ADAS development and battery testing. Healthcare devices require calibration and compliance verification tools.

Key Players

Keysight Technologies

Rohde & Schwarz

Tektronix

National Instruments

Anritsu Corporation

Fortive Corporation

Opportunities and Challenges

Opportunities

Growing R&D activities in semiconductors

Expansion of wireless and automotive electronics

Emerging needs in quantum computing and photonics

Challenges

High equipment cost for small enterprises

Complexity in multi-device calibration and compatibility

Trending Report Highlights

GPS Watches Market

Signature Pad Market

Solid State LiDAR Market

Gsm Antenna Market

Handheld Iris Scanner Market

0 notes

Text

Top Uses for a Toroidal Type Transformer in 2025

Electrical components have come a long way, and one device that keeps proving its value is the toroidal type transformer. As we head further into 2025, these compact, energy-efficient transformers are showing up in more applications than ever. From industrial machines to audio systems, their role keeps expanding—and for good reason.

At Bridgeport Magnetics Group Inc., we work closely with teams across industries. And based on what we’ve seen, here are the most relevant and common uses for toroidal transformers this year.

What Makes a Toroidal Transformer Unique?

Before diving into the uses, let’s cover the basics. A toroidal transformer is designed in a donut-shaped core, typically made of high-quality silicon steel. The windings wrap around the core evenly, which minimizes electromagnetic interference and boosts efficiency.

This shape isn’t just for looks. It offers practical advantages like compact size, low noise, and better thermal performance. That’s why many engineers lean toward this design over traditional laminated transformers.

Audio Equipment and Amplifiers

We’ve noticed a growing demand for quieter electronics, especially in home studios and entertainment systems. A toroidal type transformer plays a big role in high-end audio gear. Its low mechanical hum and reduced magnetic field make it ideal for sensitive audio circuits.

Whether you're working with tube amplifiers or power supply units in speakers, this transformer helps maintain clean, uninterrupted sound. Audio pros appreciate the tight regulation and low interference.

Medical Equipment

Precision is everything in the medical field. While we don’t deal with health claims, we can say that some medical machinery benefits from components that reduce electrical noise. Toroidal transformers help power devices like imaging systems and monitoring tools without introducing much interference.

The compact design also means they fit well in smaller, portable units. This makes them a practical choice for companies building next-gen diagnostic gear.

Industrial Automation Systems

Factories and automation plants require reliable and efficient power sources. In 2025, we’re seeing more toroidal transformers being used in control panels, robotics, and programmable logic controllers (PLCs). Their small size helps save space in tightly packed enclosures.

What’s even more useful is their ability to reduce heat buildup. That translates to longer equipment life and fewer shutdowns due to overheating. For those of us building or maintaining automation systems, this is a big plus.

Renewable Energy Projects

Solar and wind systems are booming, and they need dependable electrical components to function properly. A toroidal power transformer is often used in inverters and battery systems for this exact reason.

They help step up or step down voltage efficiently while maintaining a stable current. This keeps everything running smoothly, especially when switching between grid and battery power. Plus, they’re easier to cool, which is perfect for outdoor installations.

Test and Measurement Devices

Lab techs and field engineers rely on test equipment to measure electrical signals with high accuracy. Whether it’s a multimeter, oscilloscope, or signal analyzer, the last thing you want is interference from the power supply.

Toroidal transformers are known for delivering clean, regulated voltage, making them a favorite for these tools. We’ve used them in several testing devices where performance can’t be compromised.

Power Conditioning and UPS Systems

Uninterruptible power supplies (UPS) and power conditioners play a key role in protecting sensitive equipment. They help smooth out voltage spikes and keep machines running during brief outages.

In many of these setups, toroidal transformers are used to manage voltage regulation and noise suppression. Their low electromagnetic interference makes them reliable even during sudden changes in current flow.

LED Lighting and Displays

LED lighting systems, especially commercial ones, need stable and efficient power. In digital signs, architectural lighting, and industrial fixtures, unstable voltage can cause flickering or premature failure.

Using a toroidal transformer helps prevent these issues. The transformer keeps the voltage steady, especially in systems with long wiring distances. And because they run cool, they’re ideal for enclosed lighting setups where airflow is limited.

Communications Equipment

From server rooms to telecom towers, communications infrastructure requires stable power. Toroidal transformers are a great fit in power supply units for routers, switches, and data handling systems.

Their ability to limit electrical noise is valuable in digital and analog signal systems. That means better performance, fewer errors, and smoother communication across networks.

Marine and Aerospace Systems

Space and weight are major concerns in boats and aircraft. That’s why we’ve seen more toroidal transformers being used in both industries. Their compact form factor and lower weight make them a practical choice when every inch and pound counts.

They’re often used in onboard power conversion, lighting, and navigation systems. Engineers appreciate how they reduce electromagnetic interference, especially in systems where clean signals are vital.

Final Thoughts

As you can see, toroidal transformers are doing more than just stepping up or stepping down voltage. They’re becoming a core part of modern electrical design across industries. From audio gear and renewable energy to factory equipment and data centers, their efficiency, reliability, and compact size make them a smart choice in 2025.

If you’re designing a system or upgrading equipment this year, it's worth considering how a toroidal transformer could fit into your plan. Taking the time to pick the right transformer might save you trouble—and cost—later on.

0 notes

Text

How to Fix Common Issues with Electric Scooter Repair? A Step-by-Step Guide

Electric scooters are popular for their portability and efficiency, but when they stop moving, it can be frustrating. This comprehensive guide covers the most common reasons for electric scooter repair needs and provides practical solutions to get your scooter back on the road. From battery checks to motor diagnostics, we’ll walk you through the process with clarity and precision.

Why Your Electric Scooter Won’t Move: Common Causes

Before diving into electric scooter repair, it’s essential to identify why your scooter isn’t moving. Here are the most frequent culprits:

1. Battery Issues The battery is the heart of any electric scooter. If it’s not functioning, your scooter won’t move. Common battery-related problems include:

Depleted Charge: The battery may simply be out of power.

Faulty Connections: Loose or corroded battery terminals can disrupt power flow.

Battery Degradation: Over time, lithium-ion batteries lose capacity, reducing performance.

2. Motor Malfunctions The motor drives the scooter’s wheels. If it’s damaged or disconnected, the scooter won’t move. Motor issues may stem from:

Overheating: Prolonged use can overheat the motor, triggering a safety shutdown.

Wiring Problems: Damaged wires between the motor and controller can halt operation.

3. Controller Failures The controller is the scooter’s brain, managing power distribution. A faulty controller can prevent the motor from receiving power, requiring electric scooter repair.

4. Brake System Interference Some scooters have safety features that disable the motor if the brakes are engaged. A stuck brake lever or sensor can mimic a malfunction.

5. Throttle or Wiring Issues A broken throttle or damaged wiring can prevent the scooter from responding to input, making it seem immobile.

Step-by-Step Electric Scooter Repair Process

Once you’ve identified potential issues, follow these steps to troubleshoot and fix your scooter. Always ensure the scooter is powered off and disconnected from the charger before starting any electric scooter repair.

Step 1: Check the Battery

Verify Charge Level: Plug in the charger and confirm the battery is charging. Most scooters have an indicator light on the charger or display.

Inspect Connections: Remove the battery cover (refer to your manual) and check for loose or corroded terminals. Tighten connections or clean corrosion with a wire brush.

Test Battery Health: Use a multimeter to measure the battery’s voltage. Compare it to the manufacturer’s specifications (e.g., a 36V battery should read close to 36V when fully charged). If the voltage is significantly lower, the battery may need replacement.

Step 2: Inspect the Motor

Listen for Sounds: Turn on the scooter and listen for humming or clicking from the motor. No sound may indicate a disconnected or failed motor.

Check Wiring: Trace the motor’s wiring to the controller. Look for frayed or disconnected wires and repair them with electrical tape or soldering if needed.

Test Motor Functionality: If you have access to a spare controller, connect it to the motor to rule out controller issues. If the motor still doesn’t work, it may need professional electric scooter repair or replacement.

Step 3: Diagnose the Controller

Visual Inspection: Check the controller for burn marks, melted components, or a burnt smell, indicating failure.

Test Continuity: Use a multimeter to test the controller’s input and output connections. If there’s no continuity, the controller is likely faulty and needs replacement.

Consult the Manual: Controllers are complex, so refer to your scooter’s manual for specific wiring diagrams and replacement instructions.

Step 4: Examine the Brake System

Check Brake Lever: Ensure the brake lever moves freely and isn’t stuck. Lubricate if necessary.

Inspect Brake Sensors: Some scooters have magnetic or mechanical brake sensors. Verify they’re aligned and functioning. Adjust or replace if needed.

Step 5: Test the Throttle and Wiring

Throttle Response: Turn on the scooter and gently press the throttle. If the display lights up but the scooter doesn’t move, the throttle may be faulty.

Wiring Check: Inspect the throttle’s wiring for damage. Use a multimeter to test continuity between the throttle and controller.

Replace if Necessary: Throttles are relatively inexpensive and easy to replace. Ensure the replacement matches your scooter’s specifications.

Tools Needed for Electric Scooter Repair

To perform electric scooter repair effectively, gather these tools:

Screwdrivers (Phillips and flathead)

Multimeter for electrical testing

Wrench set for removing panels

Electrical tape or soldering kit for wiring repairs

Lubricant for mechanical components

Replacement parts (battery, controller, throttle, etc., as needed)

When to Seek Professional Electric Scooter Repair

While many issues can be fixed at home, some situations require professional expertise:

Complex Motor or Controller Issues: If diagnostics point to internal motor or controller damage, a technician may be needed.

Warranty Concerns: If your scooter is under warranty, contact the manufacturer before attempting repairs to avoid voiding coverage.

Safety Risks: If you’re unsure about handling electrical components, consult a professional to avoid injury or further damage.

Preventive Maintenance to Avoid Future Repairs

To minimize the need for electric scooter repair, follow these maintenance tips:

Regular Charging: Avoid fully draining the battery, and charge it after each use.

Clean and Inspect: Regularly clean the scooter and check for loose bolts or damaged wires.

Store Properly: Keep the scooter in a dry, cool place to prevent battery and component degradation.

Follow Weight Limits: Overloading the scooter can strain the motor and battery.

Conclusion

Electric scooter repair doesn’t have to be daunting. By systematically checking the battery, motor, controller, brakes, and throttle, you can diagnose and fix most issues that prevent your scooter from moving. With the right tools and a bit of patience, you can restore your scooter’s performance and enjoy smooth rides again. Regular maintenance is key to preventing future problems, ensuring your scooter remains a reliable mode of transport.

#asexual#easter#margot robbie#michael cera#artists on tumblr#donald trump#across the spiderverse#barbie#rwby#ryan gosling

0 notes

Text

What Tools Should I Carry for Emergency Truck Repairs Around DFW?

When you're on the road in and around Dallas-Fort Worth (DFW), whether for commercial trucking, heavy duty diesel driving, or regular transport, emergencies can happen. From unexpected mechanical issues to sudden breakdowns, being prepared can save you time, money, and frustration. Whether you're dealing with a semi truck breakdown, tire blowouts, or engine malfunctions, having the right tools on hand can make all the difference.

At Texas Truck Repair, we understand the importance of being ready for emergencies. Here’s a list of essential tools to carry for emergency truck repairs to ensure you can handle common truck issues when they arise.

1. Basic Hand Tools

When you're faced with an emergency, you'll need a solid foundation of hand tools. This includes:

Wrenches and Socket Sets: For tightening bolts or loosening parts during emergency repairs.

Screwdrivers: A variety of flathead and Phillips screwdrivers will help in almost any situation.

Pliers and Vise Grips: These are perfect for holding parts in place or fixing hoses and electrical connections temporarily.

These tools come in handy for routine truck maintenance and urgent fixes like brake line repairs, truck troubleshooting, or minor engine repairs.

2. Tire Repair Kit

A flat tire can bring your day to a halt. Having a tire repair kit will allow you to get back on the road without waiting for a tow. Include:

Tire patches

Tire plugs

A valve stem tool

A jack and lug wrench

Make sure your kit is designed for heavy-duty truck tires so you can manage tire repairs even on a semi-truck. It's also advisable to have a tire pressure gauge to prevent tire issues caused by under or overinflation.

3. Brake Repair Tools

Brake issues are some of the most common truck problems. To perform emergency brake repairs, you’ll need:

Brake fluid (ensure you carry the correct type for your truck model)

Brake pads and shoes

Brake line repair kits (in case of leaks or damage to the brake lines)

A brake bleeder kit for air in the brake lines

If you're dealing with an emergency situation requiring immediate action, a mobile brake repair service or brake fluid check might be necessary to prevent further damage.

4. Electrical Tools

Electrical systems can fail when least expected. To troubleshoot and perform minor repairs on your truck’s electrical system, carry:

Multimeter to check the voltage and continuity of circuits.

Fuses and relays for quick replacements.

Wire cutters, strippers, and electrical tape for any repairs to broken wires or connections.

Electrical issues, such as an alternator failure or a dead battery, are common on diesel trucks and can cause significant downtime. Be ready with the proper tools for immediate fixes until you can reach a truck repair and maintenance shop.

5. Diagnostic Tools

Being able to diagnose the problem with your truck on the spot can save hours of waiting time. Consider carrying a truck diagnostic tool (OBD-II scanner) to check for engine codes and other error messages. This tool will help you determine if there are any issues with the engine, transmission, or exhaust system so you can fix minor problems without needing a full service.

If you're driving a diesel truck, a more specialized scanner may be needed to troubleshoot issues like Cummins X15 fuel pump problems or issues with diesel engines.

6. Welding Equipment

In more serious cases, your truck may experience structural damage or issues with parts that need welding. Having a portable welding kit can make a huge difference, especially for cast iron welding or structural welding. If you can't handle a major welding repair on your own, contact welding shops in DFW to get expert help.

7. Fluids and Lubricants

It’s essential to carry a variety of fluids that can be used for different repairs:

Engine oil for oil changes or to top off low oil levels.

Transmission fluid for quick changes or top-ups during repairs.

Coolant for maintaining the engine temperature.

Power steering fluid, brake fluid, and diesel fuel additives are also essential to keep everything running smoothly.

Keeping these fluids on hand will help with common mechanical issues, including problems with brake repair, transmission fluid change, and even AC repair.

8. Portable Air Compressor

A portable air compressor is essential for maintaining the correct tire pressure, which can help prevent unexpected tire blowouts. In the event of a sudden flat, the air compressor can also help you inflate the tire enough to get to a more secure location for a proper fix.

9. Flashlight and Safety Gear

Emergencies can happen at any time of day or night. A high-quality flashlight, headlamp, or lantern is essential when dealing with truck breakdowns in dark or low-light conditions. Also, include safety equipment such as high-visibility vests, gloves, and a first aid kit.

10. Mobile Truck Repair Service

While it's important to be prepared with tools for on-the-spot fixes, sometimes you need professional assistance. Texas Truck Repair offers mobile truck repair services, ensuring that a skilled technician can come to your location for fast and efficient service. From brake repair to engine diagnostics, and even semi truck repair, we offer roadside assistance to help with emergency truck repair needs.

In Dallas-Fort Worth, truck breakdowns can be unpredictable, but with the right tools and support from professionals like Texas Truck Repair, you can tackle most emergencies with confidence. Regular truck maintenance and preventive maintenance will help keep your truck running smoothly, reducing the chances of unexpected issues.

Whether you’re in need of diesel truck maintenance, commercial truck repair, or an emergency roadside service, be sure to stay prepared and have the right tools on hand for quick fixes. And when in doubt, our mobile repair truck is just a call away!

#pickup truck#trucking company#heavy haul trucking#truck#truck accessories#truckingindustry#semi truck#engine repair#preventivemaintenance#old truck

0 notes

Text

Smart Tweezers ST5S vs. Conventional Multimeter: A Smarter Choice

Smart Tweezers ST5S and conventional multimeters are both essential tools for electronic testing and troubleshooting. However, they differ significantly in terms of functionality and ease of use.

Smart Tweezers ST5S:

All-in-One Design: Smart Tweezers combine a set of high-precision SMD probes and a digital multimeter into a single handheld device. This streamlined design simplifies testing and eliminates the need for separate probes and multimeters.

Automatic Component Identification: One of the standout features of Smart Tweezers is their ability to automatically identify and evaluate SMD components. This saves time and reduces the risk of human error. The device can recognize resistors, capacitors, and inductors.

Ergonomic and Portable: Smart Tweezers are easy to handle and operate with one hand. Their lightweight and ergonomic design make them a preferred choice for professionals and hobbyists alike.

Real-Time Measurement: These tweezers provide real-time measurements, allowing users to monitor changes in component values as they troubleshoot. There's no need to disconnect and reconnect probes repeatedly.

LCD Display: Smart Tweezers feature a clear LCD display that shows component values and measurement results. It's easy to read and interpret, even in low-light conditions.

Conventional Multimeter:

Multiple Components: A conventional multimeter typically consists of separate probes and a central unit. It can measure a wide range of electrical parameters, including voltage, current, resistance, capacitance, and more.

Manual Range Selection: Conventional multimeters often require users to manually select the appropriate measurement range and function. This can be time-consuming, especially when testing various components.

Limited SMD Testing: While multimeters are versatile, they are less suitable for testing surface mount devices (SMDs) without the use of additional adapters or fixtures. This can add complexity to SMD troubleshooting.

Complex Readings: Interpreting multimeter readings can be challenging, especially for beginners. Users must understand the correct units, ranges, and measurement modes.

In summary, Smart Tweezers ST5S are a specialized tool tailored for SMD component testing, offering automatic identification and real-time measurements in a compact and user-friendly form. They are ideal for users who frequently work with SMDs. On the other hand, conventional multimeters are versatile devices suitable for a wide range of electrical measurements but may require additional tools for SMD testing.

The choice between the two depends on your specific needs and the types of components you regularly work with.

Quotation & Enquiries:

Contacts: Rajiv & Romesh Cellphones: 9316134502 & 8283820745 Email: [email protected] Alternative Email: [email protected]

2 notes

·

View notes