#PowderMetallurgy

Explore tagged Tumblr posts

Text

Discover how the MIM process solves big problems in small part manufacturing!

#MIM#金属注射成型#工业科技#制造业革命#精密加工#Facebook行业标签:#MetalInjectionMolding#AdvancedManufacturing#PowderMetallurgy

2 notes

·

View notes

Text

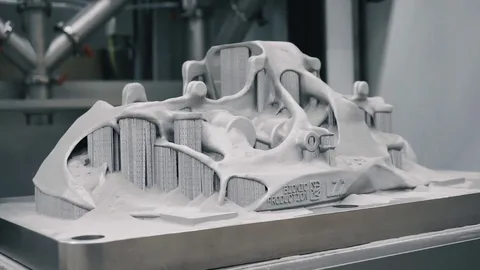

3D Printing Powder Market Growth Fueled By Advanced Material Innovations

The 3D Printing Powder Market is witnessing substantial growth, driven by advancements in powder materials. These innovations are transforming additive manufacturing, enhancing performance, reducing costs, and unlocking new industrial applications.

Evolution of Powder Materials in Additive Manufacturing

Initially limited to a few metals and polymers, the 3D printing powder segment has evolved considerably. Early materials such as stainless steel, titanium, and nylon posed limitations in strength, stability, and compatibility with demanding end-use applications.

Today, advanced powder formulations include high-performance alloys, ceramics, metal-polymer hybrids, and bioresorbable materials. These new powders offer improved heat resistance, strength-to-weight ratios, and the ability to create complex geometries that traditional processes cannot achieve.

Aerospace Sector Driving Demand

Aerospace remains a major adopter of advanced 3D printing powders. Lightweight yet strong materials are essential in aerospace for improving fuel efficiency and structural durability. Aluminum and titanium alloy powders are now widely used to manufacture turbine blades, engine components, and structural frames.

Nickel-based superalloys are gaining traction due to their excellent mechanical properties at high temperatures. These powders enable the production of precision parts that meet strict safety and performance standards, reducing assembly time and part complexity.

Automotive Industry Expands Use Cases

The automotive sector is increasingly utilizing advanced powders to achieve customization, weight reduction, and faster prototyping. While steel and aluminum remain common, magnesium alloys and carbon-reinforced composites are gaining popularity for their lightweight properties.

These materials allow for the production of lighter chassis components, exhaust systems, and structural parts without compromising durability. Copper-based powders are also being explored for EV applications, offering high thermal and electrical conductivity for powertrain components and heat exchangers.

Growth in Medical Applications

Healthcare is another key industry benefiting from material advancements. Titanium and cobalt-chrome powders are used for orthopedic and dental implants due to their strength and biocompatibility. These materials are corrosion-resistant and safe for long-term implantation.

Recent developments include bioresorbable polymers and ceramic-based powders for bone grafting and tissue scaffolding. Customized prosthetics and implants, printed using patient-specific data, enhance comfort, reduce recovery time, and improve surgical outcomes.

Innovation Through R&D

Research and development are central to the progress of advanced materials. Universities and industrial R&D centers are continuously exploring new chemistries, refining powder morphology, and optimizing flowability—critical for consistent printing.

Nanoparticles are a promising area of innovation. Nano-powders with ultra-fine particles provide better surface finish, mechanical strength, and layer adhesion. Although not yet widely commercialized, they represent the next frontier in high-precision applications.

Focus on Sustainability and Recycling

Environmental considerations are shaping material innovation. Manufacturers are developing recyclable and biodegradable powders to reduce waste and emissions. Many use closed-loop systems to recover and reuse unused powders, maintaining quality while minimizing environmental impact.

Recycled metals are also being integrated into powder production, reducing the carbon footprint of additive manufacturing. These efforts align with global sustainability goals and support environmentally responsible manufacturing practices.

Barriers to Market Expansion

Despite progress, several challenges hinder widespread adoption. Advanced powders are often expensive to produce, which can be a barrier in price-sensitive sectors. Scaling production while maintaining quality requires significant investment in manufacturing infrastructure and quality control.

Certification is another challenge. Industries like aerospace and healthcare demand rigorous validation processes, and the lack of standardized protocols for new materials slows down approvals and market entry.

Future Market Outlook

The future of the 3D printing powder market is promising. Continued innovation in materials will expand possibilities across industries. Strategic collaborations between material scientists, equipment developers, and manufacturers will be vital for commercial success.

Artificial intelligence is expected to play a larger role in optimizing powder formulations for specific applications. By integrating data-driven insights, manufacturers can fine-tune material properties, improve efficiency, and reduce trial-and-error cycles.

As additive manufacturing becomes more embedded in production workflows, demand for high-performance, cost-effective, and sustainable powders will grow. Advanced materials will continue to be the backbone of this evolving market, enabling faster, lighter, and more precise manufacturing solutions.

#3DPrinting#AdditiveManufacturing#AdvancedMaterials#3DPrintingPowders#AerospaceInnovation#Medical3DPrinting#SustainableManufacturing#SmartMaterials#DigitalManufacturing#Industry40#PowderMetallurgy#PrototypingSolutions#ManufacturingInnovation#CustomManufacturing#TechTrends2025

0 notes

Text

#IronPowder#MetalPowders#PowderMetallurgy#IronBasedMaterials#AdditiveManufacturing#SinteredComponents#IndustrialPowders#MagneticMaterials#AutomotiveComponents#Metal3DPrinting#IronAlloys#ManufacturingMaterials#IronPowderMarket

0 notes

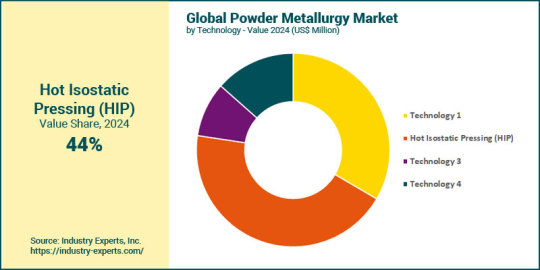

Photo

(via Powder Metallurgy Market Size, Trends, Outlook 2024-2030)

Global market for Powder Metallurgy is expected to maintain a CAGR of 8.5% between 2024 and 2030 and reach a projected US$37.2 billion by 2030 from an estimated US$22.8 billion in 2024. Some of the factors include increasing vehicle production.

0 notes

Text

Applications of Molybdenum Crucibles:

Materials Processing: Molybdenum crucibles are widely used in high-temperature applications such as melting and casting metals, alloys, and other materials. They are suitable for processes involving the production of superalloys, exotic metals, and high-purity materials.

Single Crystal Growth: Molybdenum crucibles are used in various crystal growth methods, including the Czochralski (CZ) and float-zone (FZ) techniques. They provide a clean and stable environment for growing high-purity single crystals of materials like silicon, sapphire, and other semiconductors.

Vacuum and High-Temperature Furnaces: Molybdenum crucibles are used in vacuum furnaces and high-temperature furnaces for applications such as sintering, heat treatment, and brazing of materials that require elevated temperatures in controlled atmospheres.

Chemical Analysis: Molybdenum crucibles are used in analytical chemistry and spectroscopy for sample preparation and chemical analysis. They are suitable for the heating and digestion of samples for analysis.

Powder Metallurgy: Molybdenum crucibles are used in the sintering and consolidation of metal powders and ceramics in the powder metallurgy process.

Aerospace and Defense: Molybdenum crucibles are employed in specialized aerospace and defense applications, particularly for the production of high-performance alloys and materials used in aerospace and defense systems.

Laboratory Research: Molybdenum crucibles are used in various laboratory applications, including metallurgical research, material testing, and high-temperature experiments.

Molybdenum crucibles also have excellent temperature and atmosphere resistance capacities, although they have slightly lower melting points compared to pure tungsten. Here’s an overview of the temperature and atmosphere resistance of molybdenum crucibles:

Temperature Resistance:

Molybdenum has a melting point of approximately 2,623 degrees Celsius (4,753 degrees Fahrenheit), which is significantly higher than most other common materials.

Molybdenum crucibles can withstand very high temperatures and are often used in applications that require extreme heat, such as the melting and casting of various metals and alloys.

Atmosphere Resistance:

Molybdenum exhibits good resistance to chemical reactions and corrosion in many atmospheric conditions, including inert and reducing gas environments. It is particularly well-suited for use in a vacuum or inert gas.

However, like tungsten, molybdenum can react with oxygen at elevated temperatures. When exposed to oxygen or oxidizing atmospheres, molybdenum can form molybdenum oxide, which can lead to embrittlement and degradation of the crucible. Therefore, it’s important to limit its use in oxygen-rich environments.

Molybdenum crucibles are commonly used in various high-temperature applications, including the production of sapphire crystals, melting and casting of metals, and thermal evaporation processes. Their combination of high-temperature resistance and resistance to many atmospheres makes them a popular choice for these applications.

As with any material, the specific temperature and atmosphere resistance of molybdenum crucibles can be influenced by factors like crucible size, design, and the presence of impurities. Manufacturers typically provide recommendations for the safe usage of molybdenum crucibles in different environments, so it’s advisable to consult with the manufacturer or supplier to ensure you are using the crucible within its specified resistance limits for your particular application.

Molybdenum crucibles are valued for their ability to withstand extreme temperatures and harsh chemical environments, making them essential tools in a range of industries where high-temperature materials processing and materials research are critical.M-Kube Enterprise is an Australian company catering customized laboratory products, laboratory consumables and laboratory solutions in Australia, New Zealand, Singapore, Malaysia, South Korea, India, Dubai, Philippines, Indonesia and Vietnam.

#MolybdenumCrucibles#HighTemperatureApplications#MaterialsProcessing#SingleCrystalGrowth#CzochralskiMethod#FloatZoneTechnique#VacuumFurnaces#HighTemperatureFurnaces#Sintering#HeatTreatment#Brazing#ChemicalAnalysis#Spectroscopy#PowderMetallurgy#AerospaceApplications#DefenseMaterials#TemperatureResistance#AtmosphereResistance#Superalloys#ExoticMetals#HighPurityMaterials#SemiconductorManufacturing#SapphireProduction#ThermalEvaporation#CorrosionResistance#MolybdenumProperties#IndustrialApplications#MKubeEnterprise#LaboratorySolutions

0 notes

Text

Powder Metallurgy Market - Forecast(2024 - 2030)

Powder Metallurgy Market Overview

Request Sample Report :

COVID-19 Impact

The onset of Covid-19 in the entire nation had a negative impact on the automotive industry. There was an overall revenue impact across the automotive industry. The pandemic also impacted all the stakeholders present in the value chain for the short as well as medium term. Shortage of raw material, shifting of production to other countries, liquidity crunch to delays in availability of models, deferred launches, and shrinkage in consumer demand were some of the main issues faced by the automotive stakeholders, owing to which the production and demand of automobiles had significantly fallen. For instance, according to the China Passenger Car Association (CPCA), China’s passenger car sales in June fell 6.5% year on year to 1.68 million units. The unstable automotive production and demand have significantly impacted the market of powder metallurgy as the demand for powder metal was also uncertain during the period. A prolonged truncation of consumer demand due to the lockdown has significantly affected auto manufacturers’ revenues and cash flows. Even after the restriction is eased in 2021, with discretionary spending taking a backseat, further declines in the market for passenger vehicles are expected.

Powder Metallurgy Market Report Coverage

The report: “Powder Metallurgy Market — Forecast (2021–2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the powder metallurgy Industry.

By Material: Ferrous (Iron, Steel, and Stainless Steel), Non-Ferrous (Copper, Aluminium, Cobalt, Tin, Nickel, Magnesium, Zinc, Titanium, Molybdenum, and Others By Process: Conventional Process, Metal Injection Moulding, Hot Isostatic Pressing, and Metal Additive Manufacturing By Application: Porous Products, Bearing and Bushes, Filters (Ceramic Filter, Fiber Metal Filter, and Others), Refractory Metal Composites, Electric Motors, Cemented Carbides, Machinery Parts (Gears, Sprockets, Rotors, and Others), Tungsten Wires, Medical Implants, Magnetic Materials, Cutting Tools and Dies, and Others By End-Use Industry: Medical & Healthcare, Automobile (Transmission, Engine Parts, and others), Oil & Gas, Electrical and Electronics (Refrigerators, Vacuum Cleaners, Circuit Breakers, Electric Motors, Sewing Machines, and Others), Industrial (Hydraulics, Motors/Controls, and Others), Aerospace (Aero-engine, Land-based Gas Turbine, Airframes, and Others), Household Appliances, Recreation and Leisure, and Others By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East, and Africa)

Inquiry Before Buying :

Key Takeaways

Asia-Pacific dominates the powder metallurgy market, owing to the increasing demand and production of lightweight vehicles in the region. For instance, according to OICA, the production of passenger cars has increased by 2.6 % in Malaysia in 2019.

There are many cases in which powder metallurgy over casting has a strong benefit. The benefits of the powder metallurgy process are particularly apparent when dealing with high-value and high-melting-point materials, owing to which there is increasing adoption of powder metallurgy over die casting, which will propel the market growth.

There are growing interests in producing customized medical implants using additive manufacturing and in producing porous implant structures (to match bone stiffness and to aid osteointegration) by powder metallurgy processing, which may boost the market growth.

For More Details on This Report — Request for Sample

Powder Metallurgy Market Segment Analysis — By Material

The ferrous segment held the largest share in the powder metallurgy market in 2020. Ferrous powdered metals such as iron, steel, and more offer the highest level of mechanical properties. Ferrous metal powders are also known for their extensive characteristics such as durability, hardness, tensile strength, lower costs, broad flexibility, and more. The ferrous powdered metal is largely employed in the automotive industry for designing bearings, gears, or other auto parts, owing to its good strength and flexibility. Furthermore, ferrous metals are also widely utilized in various other end-use industries such as construction, piping, aerospace, electronics, and more. Thus, it is anticipated that these extensive characteristics and wide applications of ferrous powder metallurgy are the major factors driving its demand during the forecast period.

Powder Metallurgy Market Segment Analysis — By Application

The bearings segment held the largest share in the powder metallurgy market in 2020 and is growing at a CAGR of 7.4% during 2021–2026, owing to its self-lubricating property. Bearings that are made from powder metallurgy are known as self bearings of sintered metal. They are economical, suitable for high production rates, and precision tolerances can be produced. The majorities of porous-metal bearings consist of either bronze or iron with pores that are interconnected. These voids take up 10 percent of the total volume to 35 percent. In operation, lubricating oil is deposited in these voids and feeds to the bearing surface through the interconnected pores. Sintered-metal self-lubricating bearings are widely used in home appliances, small motors, machine tools, aircraft, and automotive accessories, business machines, instruments, and farm and construction equipment, owing to which it holds a prominent share in the powder metallurgy application segment.

Schedule A Call :

Powder Metallurgy Market Segment Analysis — By End-Use Industry

The automotive segment held the largest share in the powder metallurgy market in 2020 and is growing at a CAGR of 8.6% during 2021–2026. Powder metal parts display excellent controlled porosity and self-lubricating properties that allow gases and liquids to be filtered. Powder metallurgy is also a strongly recommended method in the manufacture of components involving complex bends, depressions, and projections. Flexibility in the development of mechanical parts of different compositions, such as metal-non-metal and metal-metal hybrids, allows high dimensional precision in the production of automobile parts and ensures consistent properties and measurements with very little scrap and waste of material. The most popular vehicle parts that are manufactured through the method of powder metallurgy are the bearings and gears. A variety of metals, including ferrous, and non-ferrous are used in automotive components including chassis, steering, exhaust, transmission, shock absorber parts, engine, battery, seats, air cleaners, brake disc, and more. The powder metallurgy is often used in these components as it improves the net shape, utilizes heat treatment, enhances surface treatment, and improves the precision of these components. Thus, the demand for powder metallurgy in the automotive sector is growing due to such factors.

Powder Metallurgy Market Segment Analysis — By Geography

Asia-Pacific region held the largest share in the powder metallurgy market in 2020 up to 45%, owing to the increasing automotive manufacturing coupled with population growth in the region. China is the world’s largest vehicle market, according to the International Trade Administration (ITA), and the Chinese government expects automobile production to reach 35 million by 2025. In 2019, according to OICA, the automotive production in Malaysia and Vietnam has increased up to 571632, and 250000, i.e., 1.2%, and 5.5%. India’s annual production in 2019 was 30.91 million vehicles, according to Invest India, compared to 29.08 million in 2018, recording a healthy 6.26 percent growth. Also, by 2026, the US$118 billion Indian car industry is projected to cross US$300 billion. The increasing automation production in the Asia Pacific will eventually boost the demand for powder metallurgy to manufacture various automobile components, which will likely influence the growth of the powder metallurgy market in the APAC region.

Powder Metallurgy Market Drivers

Flourishing Aerospace Industry

Powder metallurgy is used extensively in aerospace, because of its advantages of high strength/weight ratio, high heat capacity, and high modulus of elasticity. Within aerospace, powder metallurgy finds its most significant application in turbine engines, compressors, fan sections, discs, airframes, fasteners, and landing gear. Tungsten metallurgy based tungsten carbide has received considerable attention in the aerospace industry because of its high strength at very high temperatures. Tungsten carbide is sintered through a selective laser sintering process based on the additive manufacturing process. In 2019, China was the second-largest civil aerospace and aviation services market in the world and one of the fastest-growing markets, according to the International Trade Administration (ITA). China will need 7,690 new aircraft over the next 20 years, valued at US$1.2 trillion, according to Boeing (Commercial Market Outlook 2018–2037). China also currently accounts for 15 percent of the world’s commercial aircraft fleet, and it will be almost 20 percent by 2037. According to Boeing, the demand for 2,300 airplanes worth US$320 billion is projected in India over the coming 20 years. Boeing’s current market outlook (BMO) forecasts demand for 2,520 new aircraft in the Middle East by 2030. With the flourishing aerospace industry, the demand for aircraft components will also gradually increase, which will drive the market growth.

Buy Now :

Expanding Electrical and Electronics Sector

The powder metallurgy method offers the opportunity to cost-effectively produce net form components from a variety of materials. A market segment that has exhibited the ability to take advantage of powder metallurgy’s flexibility has been in electromagnetic applications such as household appliances, industrial applications, and more. Magnetic materials are essential elements in the electronic industry in recent times. From the motors and turbines that provide the power for the industry to the high-frequency transformers that power computers, magnetic materials are becoming increasingly important for consumers. The electronic sector is booming in various regions, which will further drive the market growth as there is an increasing demand for powder metallurgy from the electrical and electronics sector. For instance, the consumer electronics and appliances sector in India is expected to become the fifth-largest in the world by 2025, according to Invest India. India could create an US$800 billion to US$1 trillion digital economy by 2025, and India’s digital economy could fuel 18–23 percent of overall economic activity by 2025. According to the Government of Canada, revenues in the ICT sector reached an estimated US$210 billion in 2019. ICT sector revenues grew from US$158 billion to US$200 billion from 2013 to 2018, a 26.9 percent increase.

Powder Metallurgy Market Challenges

Various Drawbacks Associated with Powder Metallurgy

The cost of metal powders compared to the cost of raw material used for casting or forging a component is relatively higher. At the time the cost of tooling and equipment is also higher. When production volumes are limited, this is especially a limitation. Also, low melting point metal powders such as zinc, tin, and cadmium give thermal difficulties during sintering operation, as most oxides of these metals cannot be reduced at temperatures below the melting point. Furthermore, large or complex-shaped parts, and uniformly high — density products are difficult to produce by the powder metallurgy process. Without any degradation, a few powders are also difficult to store. All these drawbacks associated with the powder metallurgy may hinder the market growth during the forecast period.

Powder Metallurgy Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the powder metallurgy market. Major players in the powder metallurgy market are Arcam AB, Carpenter Technology Corp., ExOne GmbH, GKN Plc, Höganäs AB, Materialize NV, Melrose Industries PLC, Sumitomo Electric Industries, Ltd., and Hitachi Chemical Co., Ltd.

Acquisitions/Technology Launches

In May 2019, Epson Atmix Corp. installed a new production line at its Kita-Inter Plant in Japan for producing amorphous alloy powder. The company invested around ¥800 million (USD 7.43 million) for the installation of a new line and it plans to further increase its production capacity in stages and reach 6,000 tons per year by 2023.

In October 2019, GKN Powder Metallurgy a leading metal powder and parts manufacturers acquired specialist polymer 3D printing service provider Forecast 3D. The acquisition presents a significant expansion of GKN powder metallurgy’s additive capabilities.

Relevant Reports

Powder Coatings Market — Forecast (2021–2026)

Report Code: CMR 0113

Ferromanganese Market — Forecast (2021–2026)

Report Code: CMR 0382

For more Chemicals and Materials Market reports, please click here

#PowderMetallurgy#Metalworking#AdvancedManufacturing#PowderMetals#AdditiveManufacturing#MetalPowder#IndustrialMaterials

1 note

·

View note

Text

Additive Manufacturing In Powder Metallurgy Global Market research report 2022-2027

Additive Manufacturing In Powder Metallurgy: Global Markets

Report Scope:

This report analyzes the global and regional markets in powder metallurgy. We have included individual processes with in-depth applications for metal powder and parts. The report also includes major driving trends and challenges that affect the market and the vendor landscape. Apart from the dynamics, it also provides information about industry standards, government and industry support, regulations, and other factors that will shape the market’s demand in the coming years.

This report has been prepared in a simple, easy-to-understand format; tables and figures are included to illustrate historical, current, and future market scenarios. The report also covers leading companies with information on product types, business footprint, revenue, employee strength, etc. We have also included a list of global and local players with their product-related information.

For this report, we have considered the impact of COVID-19 on the global and regional markets. 2021 is regarded as a historic/base year, while 2022 is considered an estimated year, and the market values are forecast for five years from 2022 to 2027. All market values are in U.S. dollars ($).

Request Sample of Report- https://www.jsbmarketresearch.com/market-report/Additive-Manufacturing-in-Powder-Metallurgy-Global-Markets

Report Includes:

· 27 data tables and 31 additional tables

· An overview of the global market for additive manufacturing in powder metallurgy

· Estimation of the market size and analyses of global market trends, with data from 2020, 2021, estimates for 2022 and 2023 with projections of compound annual growth rates (CAGRs) through 2028

· Characterization and quantification of market potential for additive manufacturing in powder metallurgy by product, type, and region

· Identification of market drivers, restraints and other forces impacting the global market and evaluation of current market trends, market size, and market forecast

· Market share analysis of the key companies of the industry and coverage of events like mergers & acquisitions, joint ventures, collaborations or partnerships, and other key market strategies and a relevant patent analysis

· Company profiles of major players, Carpenter Technology, General Electric, Kennametal Inc., Sandvik, VDM Metals

Get the Complete Report & TOC @ https://www.jsbmarketresearch.com/market-report/Additive-Manufacturing-in-Powder-Metallurgy-Global-Markets

Summary:

Additive manufacturing is a highly advanced process used in powder metallurgy. It is capable of producing a complex geometry of parts directly from a CAD design. Additive manufacturing is used in aerospace and the medical and dental industry to fabric parts that can work robustly in extremely harsh environments. Oil & gas and energy & power end-use industries are emerging in additive manufacturing in the powder metallurgy market. Currently, the automotive industry is likely to be less opportunistic for the 3D printing powders covered in this report since the sector is highly cost-sensitive.

According to BCC Research’s estimations, by the end of 2027, the global value of additive manufacturing in powder metallurgy is expected to reach $REDACTED. It is projected to grow at a compound annual growth rate (CAGR) of REDACTED% during the forecast period. Titanium, nickel, and aluminum-based powders are expected to account for more than REDACTED% of the market by the end of 2022.

For More Research Insights on Leading Industries, Visit our YouTube channel – https://www.youtube.com/channel/UC5QVk_QghCJL7ByrAPwkkUg

Reasons for Doing This Study:

The powder metallurgy (P/M) industry has seen steady growth since the 1980s. Much of this growth was derived from metal powder-based parts replacing castings, forgings, and machined parts. Also, the P/M industry has consistently demonstrated that it can meet manufacturer demand at a lower cost relative to technologies such as drilling, milling, finishing, and others. P/M technology is still evolving, and the industry has adopted particulates (i.e., powders, materials not made solely of metals). Additive manufacturing or 3D printing is a revolutionary parts fabrication process that can produce parts for OEMs (original equipment manufacturers) and parts on demand. Furthermore, this process takes much less time for parts fabrication than the other powder metallurgy process, such as metal injection molding. Powders used in additive manufacturing are spherical and provide strength to the particles and enable the production of a part layer-by-layer. Customization is creating enormous opportunities for the additive manufacturing process. Therefore, BCC research staff decided to analyze the market opportunity for additive manufacturing in the powder metallurgy industry.

Reasons to Purchase Our Research Report:

· Analyzing the outlook of the market with the recent trends and SWOT analysis

· Market dynamics scenario, along with growth opportunities of the market in the years to come

· Market segmentation analysis including qualitative and quantitative research incorporating the impact of economic and non-economic aspects

· Regional and country-level analysis integrating the demand and supply forces that are influencing the growth of the market.

· Market value (USD Million) and volume (Units Million) data for each segment and sub-segment

More Trending Reports by JSB Market Research –

Coal Market- https://www.jsbmarketresearch.com/market-report/Coal-Global-Markets

VERBIO Vereinigte BioEnergie AG- https://www.jsbmarketresearch.com/market-report/verbio-vereinigte-bioenergie-ag

Advanced Materials For 3D Printing- https://www.jsbmarketresearch.com/market-report/advanced-materials-for-3d-printing-technologies-and-global-markets

flexible green packaging market- https://www.jsbmarketresearch.com/market-report/flexible-green-packaging

Table of content

Chapter 1 Introduction

· Overview

· Study Goals and Objectives

· Reasons for Doing This Study

· Scope of Report

· Information Sources

· Intended Audience

· Research Methodology

· Regional Breakdown

· Analyst’s Credentials

· BCC Custom Research

· Related BCC Research Reports

Chapter 2 Summary and Highlights

Chapter 3 Technology and Market Background

· Current Market Overview

· History of Additive Manufacturing

· Advantages of Additive Manufacturing in Powder Metallurgy

· AM Offers Freedom to Fabricate Complex Parts

· Design Advantage of Additive Manufacturing

· 3D Printing Takes 10X Less Time to Fabricate Identical Parts

· Weight Reduction

· Influx of 3D Printing Metal Powders

· Secondary Operations After AM Parts Production

· Chemistry of Additive Metal Powders

· Applications of Additive Manufacturing in Powder Metallurgy

· Powder Metallurgy Processes Used in Additive Manufacturing

· Metal Powders Production Process

· Comparison of Metal Powder Production Processes

About JSB Market Research

JSB Market Research is a company that offers comprehensive and insightful market research reports helping you to get a closer view of the market. Started in 2013, JSB Market Research aims at establishing a strong foundation for crucial business decisions of global and regional marketers around the world.

Contact info

JSB Market Research

Online Support: +91 771006748

Email: [email protected]

https://www.jsbmarketresearch.com

#powdermetallurgy#additivemanufacturing#AdditiveManufacturinginPowderMetallurgy#Powdermetallurgyprocess#additivemanufacturingprocess#additivemanufacturingmaterials#manufacturing#Chemicals#metallurgy#marketreport#marketresearch

0 notes

Text

Reduced Iron Powder Market: Market Scope and Growing Demands 2019 | Key Players: Hoganas, Rio Tinto, AK Steel Holding, KOBELCO, etc.

The research study, titled “Global Reduced Iron Powder market Research Report 2019,” evaluates the historical performance and the current status of this market for a detailed understanding, emphasizing especially on the dynamics of the demand and supply of Reduced Iron Powder in 2025. This report presents a detailed study of the global market for Reduced Iron Powder by evaluating the growth drivers, restraining factors, and opportunities at length. The examination of the prominent trends, driving forces, and the challenges assist the market participants and stakeholders to understand the issues they will have to face while operating in the worldwide market for Reduced Iron Powder in the long run. Request for Sample Report Here @ https://www.acquiremarketresearch.com/sample-request/75966/ The research study further offers a study of the existing status of the key regional markets for Reduced Iron Powder, namely, China, North America, Eastern Europe, Western Europe, Japan, the Middle East and Africa, and the Rest of Asia, on the basis of a number of significant Reduced Iron Powder market parameters, such as, the production volume, pricing of the product, production capacity, sales, demand and supply dynamics, revenue, and the rate of growth of this Reduced Iron Powder market in each of the regions. Several segments of the worldwide Reduced Iron Powder market have also been discussed in this research report with thorough information, considering their historical and existing performance in the global arena. It further maps the competitive landscape of this Reduced Iron Powder market by evaluating the company profiles of the leading market players, such as Hoganas, Rio Tinto, AK Steel Holding, KOBELCO, Metal Powder Products, Bohler-Uddeholm, Sandvik, Pellets, Daido Steel, AMETEK On the basis of the product, the market has been classified into: Primary Reduced Iron Powder, Two Reduced Iron Powder, Others Based on the application, the market has been categorized into: PowderMetallurgy, Welding, Chemical, Others For More Information On This Report, Please Visit @ https://www.acquiremarketresearch.com/industry-reports/reduced-iron-powder-market/75966/ The report covers the market study and projection of "Reduced Iron Powder Market" on a territorial along with worldwide point . The report establishes subjective and quantitative valuation by industry examiners, direct information, help from industry specialists alongside their latest verbatim and every industry producers through the market value chain. The examination specialists have also evaluated the by and large sales and income creation of this specific market. Moreover, this report additionally conveys broad examination of basic market drift, many key essentials while overseeing macro-economic indicators, combined with market enhancements according to each section. The growth trajectory of each of the segments has been provided in this study, in global terms and in each of the regional markets, creating a descriptive analysis of the overall Reduced Iron Powder market. This research study has also discussed the current and the upcoming ventures in the worldwide market for Reduced Iron Powder at length, making it of special value for companies, consultants, and other stakeholders functioning in this Reduced Iron Powder market.

0 notes