#Precision CNC Machine Shop

Explore tagged Tumblr posts

Text

Top Houston Machine Shop Services – GoSpencerMFG.com

Looking for the top Houston machine shop services? GoSpencerMFG.com delivers precision machining, expert fabrication, and custom solutions tailored to your industrial needs. With cutting-edge equipment and a skilled team, we ensure high-quality results for every project. Discover why we're a trusted name in Houston's manufacturing landscape.

URL: https://gospencermfg.com

#Top Houston Machine Shop Services#Houston CNC machining#precision machining Texas#GoSpencerMFG#Houston manufacturing services

0 notes

Text

0 notes

Text

Advanced CNC Aerospace Machining: Precision & Innovation

JBC Machine specializes in cutting-edge CNC aerospace machining, delivering unparalleled precision for aircraft manufacturing. As a leading aerospace machine shop, they excel in aerospace precision machining, ensuring the highest innovation and quality standards.

0 notes

Text

How to Choose the Best Custom CNC Machining Services for Your Needs?

Custom CNC machining services have become essential in today’s manufacturing landscape. cnc precision machiningWith the need for precision, speed, and high-quality production, choosing the right custom CNC machining services is critical for industries ranging from aerospace to automotive. But how do you find the best service provider that meets your specific needs? In this blog, we’ll explore the factors to consider when selecting the right custom CNC machining services for your projects.

1. What Are Custom CNC Machining Services?

Before diving into how to choose the best provider, it's important to understand what custom CNC machining services offer. CNC machining stands for Computer Numerical Control machining, where pre-programmed computer software dictates the movement of machinery and tools. These services allow for the precise manufacturing of complex parts from various materials like metals, plastics, and composites.

The key benefit of custom CNC machining services is the ability to create highly customized parts that meet the exact specifications of your project, all with a high degree of accuracy and consistency.

2. How to Assess the Capabilities of Custom CNC Machining Services

Not all CNC machining providers offer the same range of services or expertise. When evaluating a company, consider the following factors to ensure they can meet your project's requirements.

a) Range of Materials

When selecting custom CNC machining services, it’s crucial to confirm that the provider has experience working with the materials relevant to your project. Whether you need aluminum, steel, brass, titanium, or plastic components, the company should be able to handle various materials effectively.

At Fuson Precision Machining, we specialize in working with a wide array of materials to ensure that we can meet the specific demands of any industry.

b) Precision and Tolerance Levels

Precision is paramount in CNC machining. The tolerance levels—the degree of variation that is acceptable—can make or break the functionality of your part. Always inquire about a company’s tolerance capabilities and their track record in delivering precision-machined parts.

At Fuson Precision Machining, we pride ourselves on maintaining tight tolerances to deliver parts that meet or exceed our clients’ expectations for precision and accuracy.

c) Turnaround Time

The efficiency of custom CNC machining services plays a major role in your project timeline. Fast turnaround times can be crucial for businesses that rely on just-in-time manufacturing or need to meet tight deadlines. Ask potential suppliers about their production schedules and delivery timelines.

Fuson Precision Machining understands the importance of fast and reliable service. We offer flexible scheduling options to accommodate urgent projects and guarantee on-time deliveries for all orders.

3. How to Evaluate the Technology and Equipment of Custom CNC Machining Services

Advanced technology and state-of-the-art equipment are essential for delivering high-quality parts. Here’s how to assess the capabilities of a custom CNC machining services provider:

a) Machinery and Software

Check if the provider uses up-to-date CNC machines and software. Newer machines offer better accuracy, faster production, and more versatility. Also, ask about the types of software they use for designing and programming the CNC machines, as this can impact the complexity of parts they can produce.

At Fuson Precision Machining, we invest in cutting-edge technology to provide clients with the highest level of service. Our advanced CNC machines and software ensure that we can handle even the most intricate designs and complex projects.

b) 3D Prototyping and Design Capabilities

Many custom CNC machining services now offer 3D prototyping and design assistance. This helps streamline the production process, allowing for quick adjustments and reducing the risk of errors. A provider that offers these capabilities will make it easier for you to visualize the final product and make necessary modifications before full production.

Fuson Precision Machining provides 3D prototyping services to help you visualize your part before it goes into production, allowing for fine-tuning and ensuring that the final product matches your expectations.

4. How to Ensure Quality Control in Custom CNC Machining Services

Quality control is a critical component of custom CNC machining services. You need to be sure that the final products meet your specifications and standards, especially if the parts are used in highly regulated industries like aerospace or medical devices.

a) Certifications and Standards

Ask potential providers if they comply with industry standards and certifications such as ISO 9001, AS9100 (for aerospace), or IATF 16949 (for automotive). These certifications indicate that the company follows strict quality control procedures and is committed to delivering high-quality products.

At Fuson Precision Machining, we adhere to stringent quality control processes and hold certifications that ensure our commitment to delivering reliable, high-precision parts.

b) Inspection and Testing

Find out what kind of inspection and testing processes the provider uses to ensure that each part meets specifications. Advanced inspection techniques such as coordinate measuring machines (CMM) or laser scanners help verify the accuracy of parts.

Fuson Precision Machining uses the latest inspection and testing equipment to guarantee that all parts we manufacture meet the highest standards for accuracy and quality.

5. How to Compare Costs of Custom CNC Machining Services

Finally, consider the cost of custom CNC machining services, but don’t make your decision based solely on price. While it might be tempting to go with the cheapest option, lower prices can sometimes mean cutting corners on quality or service. Instead, look for a balance between cost-effectiveness and the ability to deliver high-quality parts.

At Fuson Precision Machining, we offer competitive pricing without compromising on quality. We provide transparent quotes and work closely with our clients to deliver cost-effective solutions that meet their budget and production needs.

Conclusion

Choosing the best custom CNC machining services is a critical decision that can impact the success of your project. By assessing the provider’s capabilities, technology, quality control, and costs, you can make an informed choice that ensures the highest quality and precision for your parts.

At Fuson Precision Machining, we take pride in offering top-notch custom CNC machining services to meet the diverse needs of our clients. With advanced technology, skilled technicians, and a commitment to quality, we are your trusted partner in delivering precision-machined parts. Contact us today to learn more about our services and how we can help with your next project!

#custom CNC machining services#cnc precision machining#cnc machine tools#precision cnc machining#cnc machine shop#chinese machine shop#precision machining

0 notes

Text

#cnc-machined-components-manufacturers#CNC-machining-parts-manufacturer#CNC-precision-machining-company#precision-CNC-machining#precision-CNC-machining-shops

0 notes

Text

Custom CNC Machining Services at JBC Machine

Experience the peak of precision with custom cnc machining services at JBC Machine. Our dedicated team ensures excellence in crafting tailored solutions, delivering unmatched quality for all your machining needs.

#Custom Machine Shop#CNC machining manufacturers#CNC machining parts manufacturer#Precision cnc machining parts

0 notes

Video

youtube

New Detection Method Of Wheel Let Your Wheel CNC Machine More Precise #wheelcnclathe #wheelrepair

Introduction to Tai'an Haishu's Wheel Repair Machine Tai'an Haishu is a leading manufacturer specializing in wheel repair machines that deliver efficient and precise solutions for restoring deformed wheel rims.

Our wheel repair machines are designed with advanced technology to effectively restore the integrity of your wheels, ensuring the safety and performance of vehicles.

Key Features of Our Wheel Repair Machines

High-Precision Detection

Our wheel repair machines are equipped with the latest wheel detection systems. This technology enables quick and accurate identification of wheel deformation, ensuring precise repairs.

The enhanced detection capabilities improve the overall effectiveness of the wheel CNC machine, allowing for a streamlined repair process.

Multi-Functionality

The versatility of our wheel repair lathe allows it to accommodate various types of wheels. Whether you are dealing with aluminum alloy wheels or steel rims, our machines are engineered to handle diverse materials, catering to the needs of different customers. This adaptability makes our wheel repair machines an essential tool for any automotive repair shop.

User-Friendly Operation

We prioritize ease of use in our wheel CNC machines. The user interface is designed to be intuitive, minimizing the learning curve for operators. This means that even those new to wheel repair can quickly become proficient in using the machine, enhancing productivity in workshops.

Robust Stability

Built with high-quality materials and advanced manufacturing processes, our wheel repair machines are designed for long-term stability and durability. This robust construction ensures that the machines perform consistently, even under heavy usage, making them a reliable choice for busy repair shops. Energy Efficiency Our wheel repair machines are engineered to be energy-efficient, reducing operational costs while maintaining high performance. By utilizing eco-friendly technologies, our machines support sustainable practices in the automotive repair industry.

Applications of Tai'an Haishu Wheel Repair Machines Tai'an Haishu's wheel repair machines find extensive application in various fields, including:

Automotive Repair Shops: Essential for any shop looking to offer comprehensive wheel repair services.

The precision and efficiency of our wheel CNC machines help enhance service offerings and customer satisfaction.

Specialized Wheel Repair Companies: Businesses that focus solely on wheel restoration benefit greatly from our advanced wheel repair lathes, which can quickly and effectively restore wheels to their original specifications.

Automotive Manufacturing: Our machines are also suitable for manufacturers looking to maintain quality control in their production processes, ensuring that every wheel meets safety and performance standards.

Why Choose Tai'an Haishu?

When it comes to wheel repair machines, Tai'an Haishu stands out as a trusted partner. Our commitment to quality and customer satisfaction is unmatched. We offer not only high-performance machines but also comprehensive after-sales support. Our team is dedicated to ensuring that you get the most out of your investment in our wheel repair lathe technology.

Conclusion Investing in a wheel repair machine from Tai'an Haishu means choosing reliability, precision, and efficiency.

Our advanced wheel CNC machines and wheel repair lathes are designed to meet the rigorous demands of the automotive repair industry. With features that enhance usability and performance, our machines help you provide top-notch services to your customers.

In summary, Tai'an Haishu’s wheel repair machines are essential tools for anyone involved in wheel restoration. With our focus on innovation and quality, we ensure that our customers receive the best equipment available. Whether you are a small repair shop or a large automotive manufacturer, our wheel repair machines will help you achieve your business goals while maintaining the highest standards of safety and performance. Choose Tai'an Haishu for your wheel repair needs and experience the difference in quality and service.

2 notes

·

View notes

Text

Manual vs Automatic CNC Machines: Which One Saves You Money Long-Term?

Are you planning to invest in CNC machines but unsure whether to go for a manual or automatic setup? This is a common dilemma for manufacturers, job shops, and fabricators looking to expand or upgrade their operations. While manual CNC machines offer control and cost-efficiency upfront, automatic CNC machines bring precision, productivity, and long-term financial benefits.

In this in-depth guide, we explore the real-world cost savings and value each type offers. By the end, you’ll have a clear understanding of which CNC machine gives you better returns over time and how Rajesh Machine Tools Pvt. Ltd. helps you make a smart investment.

Understanding the Basics

Before jumping into a cost comparison, let’s break down the core differences between manual and automatic CNC machines.

What is a Manual CNC Machine?

A manual CNC machine (also known as semi-automatic CNC) requires the operator to manually control certain functions like tool changes, material positioning, or data input. The machine follows pre-set programs, but it depends on human intervention for many steps.

What is an Automatic CNC Machine?

An automatic CNC machine is a fully integrated system where operations such as material loading, tool shifting, job scheduling, and even real-time adjustments are computer-controlled. Once programmed, the machine works with minimal operator input.

Cost Comparison: Manual vs Automatic CNC Machines

Let’s look at the long-term cost-saving potential from multiple angles:

1. Initial Investment Cost

Manual CNC machines generally have a lower upfront cost. This makes them attractive to startups and small workshops. You can expect to save 20–40% on the initial machine price when compared to an automatic system.

However, this is just one piece of the puzzle.

2. Labor Cost

Manual machines require a dedicated skilled operator for every shift. Operators must monitor the machine, adjust settings, and sometimes redo steps in case of errors.

In contrast, automatic CNC machines reduce labor dependency by up to 60%. A single operator can supervise multiple machines simultaneously. This leads to substantial savings in salaries, training, and recruitment over the years.

Estimated Labor Savings Over 5 Years:

Manual CNC: ₹25–40 lakhs (2 operators per machine)

Automatic CNC: ₹10–18 lakhs (1 operator per 3 machines)

3. Production Speed

Time is money. Automatic CNC machines offer faster turnaround time, better throughput, and 24x7 operation capabilities.

Manual machines, on the other hand, suffer from:

Longer setup times

Slower tool changes

Downtime between shifts

Over time, the cumulative production loss with manual systems becomes financially significant, especially if you're in high-demand markets.

4. Material Waste & Rework

Manual operation introduces higher chances of human error, resulting in:

Misaligned cuts

Improper finishes

Rework and scrap

Automatic CNC machines operate with consistent precision, maintaining tolerance levels as tight as ±0.01 mm. This leads to:

Less material wastage

Fewer rejected parts

More profit per unit

5. Maintenance Costs

Manual machines might seem easier to maintain, but they also:

Wear out faster due to frequent human adjustments

Depend on operator habits

Lack predictive maintenance capabilities

Automatic CNC machines from trusted manufacturers like Rajesh CNC are equipped with:

Diagnostics software

Auto-lubrication systems

Real-time alerts

These features reduce breakdowns and unplanned service costs in the long run.

6. Energy Consumption

Automatic CNC machines are generally more energy-efficient, as newer models are optimized for load balancing and energy-saving modes.

Manual machines, while simpler, tend to consume more power during idle and transition periods.

Which One Is Right For You? Key Considerations

1. Type of Job

If your work is low-volume, highly customized, or involves frequent prototyping, a manual CNC might be more flexible.

For batch production, repetitive tasks, or large-scale manufacturing, automatic CNC delivers better cost efficiency.

2. Workforce Skills

Manual machines need skilled machinists. Training costs and employee turnover can impact long-term ROI. Automatic machines reduce dependency on highly skilled operators and increase process standardization.

3. Growth Plans

Planning to scale operations? Go automatic. As your business grows, the ability to increase output without increasing labor or machine count becomes vital.

Long-Term ROI: Real Value of Automation

Here’s a simplified 5-Year Cost Breakdown based on industry averages: ParameterManual CNC MachineAutomatic CNC MachineInitial Machine Cost₹10–15 lakhs₹18–25 lakhsOperator Cost (5 yrs)₹25–40 lakhs₹10–18 lakhsDowntime Losses₹8–12 lakhs₹3–5 lakhsRework/Waste Loss₹6–10 lakhs₹2–4 lakhsMaintenance₹4–6 lakhs₹2–3 lakhsTotal 5-Year Cost₹53–83 lakhs₹35–55 lakhs

Despite the higher initial cost, automatic CNC machines save ₹15–30 lakhs over 5 years, depending on usage and efficiency.

How Rajesh Machine Tools Pvt. Ltd. Helps You Save More

At Rajesh CNC, we help you make data-driven decisions by offering:

1. Tailored Machine Recommendations

We evaluate your:

Production volume

Material types

Workforce availability

Future growth goals

Then we suggest the right balance of automation and cost. Whether it’s a semi-automatic CNC press brake or a fully automatic shearing system, our machines are engineered for long-term value.

2. Made in India. Built to Last.

All Rajesh machines are manufactured in our advanced facility in Rajkot, Gujarat. This allows us to:

Control build quality

Offer quicker deliveries

Provide cost-effective customization

3. Automation with Simplicity

Our automatic CNC machines come with:

User-friendly HMI panels

Remote diagnostics

Offline programming support

You get all the benefits of automation, without needing a full team of software engineers.

4. Training & Onboarding

We offer comprehensive operator training with every machine—manual or automatic. This ensures your team knows how to maximize output and reduce downtime from Day 1.

5. Exceptional After-Sales Service

Our pan-India service network ensures:

Quick part availability

Annual maintenance contracts

On-call tech support

You focus on production—we take care of performance.

The Rajesh CNC Advantage

Here’s why thousands of manufacturers across India trust Rajesh CNC for their machine needs:

30+ Years of Experience in metalworking solutions

In-house R&D Team driving innovation

Custom CNC Systems tailored to your requirements

Affordable Automation that scales with your business

Fast ROI Machines designed for Indian market conditions

Whether you're starting a fabrication unit or expanding an established factory, we help you invest smartly—maximizing uptime, quality, and profitability.

Final Verdict: Manual vs Automatic – Who Wins?

While manual CNC machines may seem economical at first, they often end up costing more in terms of labor, downtime, and efficiency losses.

Automatic CNC machines offer:

Faster production

Higher accuracy

Less dependency on skilled labor

Lower long-term operating cost

Over 3 to 5 years, the financial gap becomes undeniable. For companies serious about growth, productivity, and profit, automation is no longer a luxury—it’s a necessity.

Let Rajesh CNC Guide Your Investment

Choosing the right CNC machine isn’t just a technical decision—it’s a business strategy. At Rajesh Machine Tools Pvt. Ltd., we combine engineering expertise, industry insight, and customer focus to help you make the right choice.

Whether you’re leaning toward manual CNC for flexibility or automatic CNC for high-volume performance, we have a machine that fits your goals—and your budget.

1 note

·

View note

Text

Empowering Sustainable Packaging: Why Prakash Machineries Pvt. Ltd Paper Bag Making Machines Stand Out

As businesses worldwide shift toward eco-friendly solutions, paper bags have emerged as a cornerstone of sustainable packaging. Prakash Machinery Private Limited, based in Faridabad, Haryana, is leading this revolution with its state-of-the-art paper bag making machines. Since its inception in 2002, Prakash Machineries Pvt. Ltd has built a reputation for delivering innovative, high-performance machinery that empowers businesses to meet the growing demand for environmentally responsible packaging. This article delves into why Prakash Machineries Pvt. Ltd machines are the preferred choice for manufacturers and how they are transforming the packaging industry.

Cutting-Edge Features for Maximum Efficiency

Prakash Machineries Pvt. Ltd paper bag making machines are designed to deliver speed, precision, and reliability. Their flagship fully automatic square bottom paper bag making machines, such as the SPBM 360 and SPBM 460, produce high-quality shopping, grocery, and food bags with twisted or flat handles at rates of up to 400 bags per minute. These machines feature advanced automation, including servo motor control and intuitive touch screen interfaces, which simplify operation and minimize errors. The production process—encompassing roll feeding, gluing, tube forming, cutting, and bottom folding—is seamlessly integrated, reducing labor costs and boosting output.

The machines’ versatility is a key advantage. They handle a wide range of paper types, including Kraft, art paper, and coated paper, allowing manufacturers to create customized bags for diverse applications. Features like automatic tension control, laser-cut size plates, and quick size changeovers ensure consistent quality and adaptability to varying bag dimensions. For instance, a retailer can switch from producing small gift bags to larger shopping bags with minimal downtime, catering to dynamic market needs.

Tailored Solutions for Every Industry

Prakash Machineries Pvt. Ltd offers a range of machines to suit different production needs. Their V Bottom Paper Bag Making Machine (PBM2C 1517 and PBM2C 1824) is perfect for high-speed production of economical bags used in food, pharmaceutical, and confectionery industries, with outputs of up to 400 bags per minute. The ability to adjust bag sizes through simple gear changes ensures flexibility for small and large-scale manufacturers. Additionally, their twisted rope handle making machine (RHM-1000) supports semi-automatic systems by producing durable, high-quality handles, enhancing the functionality of premium shopping bags.

For the booming e-commerce sector, Prakash Machineries Pvt. Ltd mailing and shipping paper bag making machines offer robust, eco-friendly solutions tailored to the needs of online retailers. These machines produce sturdy bags that withstand the rigors of shipping while aligning with sustainability goals, making them ideal for businesses aiming to reduce plastic usage.

Driving Sustainability and Cost-Effectiveness

With environmental concerns at the forefront, Prakash Offset’s machines enable the production of biodegradable and recyclable paper bags, helping businesses meet consumer demand for green alternatives. The machines’ energy-efficient designs and waste-minimizing automation further enhance their eco-friendly credentials. For example, precise cutting and gluing processes reduce material wastage, lowering production costs. Features like automatic lubrication and pneumatic reel lifting extend machine lifespan, ensuring long-term reliability and reduced maintenance expenses.

Unmatched Quality and Support

Prakash Offset’s commitment to excellence is evident in its ultra-modern manufacturing facility in Faridabad, where every component is crafted using high-precision CNC machines. This ensures durability and consistent performance, even under heavy workloads. The company’s global reach, with clients in over 20 countries, is backed by robust after-sales support, including installation, training, and maintenance services. This customer-centric approach makes Prakash Offset a trusted partner for businesses of all sizes.

Take the Next Step

Prakash Machineries Pvt. Ltd paper bag making machines combine innovation, efficiency, and sustainability to help businesses thrive in a competitive market. Whether you’re launching a new packaging line or scaling existing operations, their solutions offer unmatched value. Visit Prakash Offset to explore their range of machines, request a quote, or contact their team to discuss your needs. Join the sustainable packaging revolution with Prakash Offset today.

If you’re exploring your options, check out manufacturers like Prakash Machineries Pvt. Ltd, who offer globally competitive machines tailored to both startups and large-scale operations.

#cake#chris sturniolo#chocolate#baking#cooking#alien stage#delicious#breakfast#critical role#dan and phil

1 note

·

View note

Text

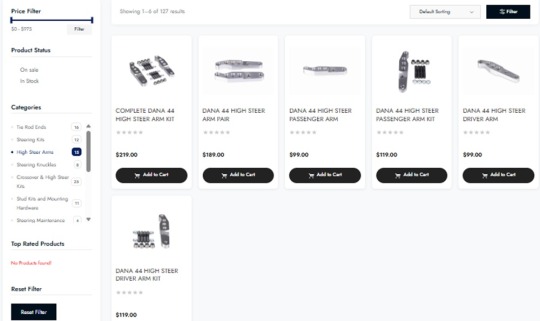

Why a Complete Dana 44 High Steer Arm Kit is Essential for Your Off-Road Build

When it comes to serious off-roading, steering precision and durability are non-negotiable. If you're running a Dana 44 axle, upgrading to a Complete Dana 44 High Steer Arm Kit can transform your rig’s handling, strength, and overall performance. Whether you're tackling rocky trails, deep mud, or high-speed desert runs, a high-quality high steer setup ensures better control and reduces steering component stress.

At East West Offroad (EWO), we specialize in premium off-road components designed for extreme conditions. Our Dana 44 High Steer Arm Kits are built to last, offering superior strength and reliability. In this guide, we’ll break down why upgrading to a high steer system is a game-changer and how EWO’s kits stand out from the competition.

What is a High Steer Arm Kit, and Why Do You Need One?

A high steer arm kit relocates your steering linkage above the leaf springs or axle housing, improving clearance and reducing bump steer. This setup is especially beneficial for lifted trucks and Jeeps, where factory steering geometry can become problematic.

Key Benefits of a Dana 44 High Steer Arm Kit:

✔ Improved Steering Geometry – Reduces bump steer and wandering for better on- and off-road handling. ✔ Increased Ground Clearance – Moves steering components higher, preventing rocks and debris from damaging them. ✔ Stronger Construction – High-quality arms and tie rods handle extreme forces without bending or failing. ✔ Better Approach Angles – Essential for crawling over obstacles without getting hung up. ✔ Compatibility with Larger Tires – Ensures smooth steering even with 37"+ tires.

If you're running oversized tires or frequently off-road, a Dana 44 high steer kit is a must-have upgrade.

Why Choose East West Offroad’s Dana 44 High Steer Kit?

At East West Offroad (EWO), we engineer our Complete Dana 44 High Steer Arm Kits for maximum strength and reliability. Here’s what sets our kits apart:

1. Precision-Machined High Steer Arms

Our arms are CNC-machined from high-grade steel or billet aluminum, ensuring perfect fitment and durability. Unlike cheap cast arms, ours won’t crack under stress.

2. Heavy-Duty Tie Rods & Drag Links

We include 1.25” or 1.5” DOM tubing tie rods with high-strength rod ends, eliminating weak points in your steering system.

3. Complete Bolt-On Design

No guesswork—our kits come with all necessary hardware for a straightforward installation. Whether you’re a DIY enthusiast or a professional, you’ll appreciate the ease of setup.

4. Optimized for Performance & Clearance

Our high steer arms position the tie rod above the leaf springs or axle, preventing interference and improving articulation.

5. Trusted by Off-Roaders Nationwide

EWO is a USA-based brand known for top-tier off-road components. Our customers rely on our parts for everything from weekend trail rides to hardcore rock crawling.

Who Needs a Dana 44 High Steer Kit?

If you answer YES to any of these, it’s time to upgrade:

✅ Running 35” or larger tires✅ Experiencing bump steer or wandering on the trail ✅ Have a lifted suspension (4” or more) ✅ Frequently rock crawl or tackle technical terrain✅ Want stronger steering components than stock

Installation Tips for Your Dana 44 High Steer Kit

While installation varies by vehicle, here are some general tips:

Disassemble Factory Steering – Remove the stock tie rod, drag link, and pitman arm (if necessary).

Mount High Steer Arms – Bolt the new arms to the knuckles using provided hardware.

Install Tie Rod & Drag Link – Adjust length for proper alignment.

Check Clearance – Ensure full suspension travel without binding.

Get an Alignment – A professional alignment ensures optimal steering performance.

For detailed instructions, check out EWO’s installation guides or consult a trusted off-road shop.

FAQs About Dana 44 High Steer Kits

Q: Will a high steer kit work with my lift?

A: Yes! High steer kits are ideal for lifted rigs (4”+), improving steering angles and reducing bump steer.

Q: Do I need to modify my knuckles?

A: Most EWO kits are bolt-on, but some applications may require minor drilling or grinding.

Q: Can I still use my factory pitman arm?

A: Some kits work with stock pitman arms, but a drop pitman arm may be needed for extreme lifts.

Q: Are these kits street-legal?

A: While high steer improves off-road performance, check local regulations for compliance.

Upgrade Your Rig with EWO’s Dana 44 High Steer Kit Today!

If you’re serious about off-roading, a Complete Dana 44 High Steer Arm Kit is one of the best investments you can make. Better steering, increased durability, and improved clearance will take your rig to the next level.

Shop now at East West Offroad and get the ultimate steering solution for your Dana 44 axle!

🔗 Browse EWO’s Dana 44 High Steer Kits Here

Final Thoughts

A Dana 44 High Steer Arm Kit isn’t just an upgrade—it’s a necessity for off-roaders who demand precision and strength. With East West Offroad’s premium components, you can tackle any trail with confidence.Have questions? Contact EWO’s support team—we’re here to help you build the ultimate off-road machine! 🚙💨

#High Steer Arms#Steering Knuckles#Crossover & High Steer Kits#Stud Kits and Mounting Hardware#Dana 44 Components#Dana 60 Components#CrossoverSteering

1 note

·

View note

Text

Mastering Woodworking with the Router Table 4x8: Elevate Your Craft with Precision and Versatility

In the world of woodworking, achieving professional-grade results relies heavily on having the right tools at your disposal. Among these tools, the router table 4x8 stands out as an essential piece of equipment for both novice and experienced woodworkers. This article explores the features, benefits, and applications of a router table while also comparing it to the increasingly popular desktop CNC machine.

What is a Router Table 4x8?

A router table 4x8 is a large woodworking device designed to support a router, enabling it to make precise cuts and shapes in various materials. The "4x8" designation refers to the dimensions of the tabletop, providing ample space for handling large workpieces. This expansive surface allows for increased stability and control, essential for executing detailed woodworking tasks.

Benefits of Using a Router Table 4x8

Enhanced Stability and Control: The larger size of a router table provides a stable working environment, which helps minimize vibrations and errors during the routing process. This stability is particularly beneficial when working with intricate designs or larger boards.

Versatile Applications: Router tables are incredibly versatile and can perform numerous tasks, such as shaping edges, creating grooves, and making joinery cuts. With adjustable speeds and heights, you can tailor your routing operations to suit various woodworking projects.

Improved Safety: Operating a router table significantly reduces the risk of injury compared to using a handheld router. The secure positioning of the workpiece minimizes kickback and enhances user safety, allowing for a more focused and productive work environment.

Compatibility with Different Router Bits: A router table 4x8 is designed to accommodate a wide range of router bits. This flexibility enables woodworkers to explore diverse techniques and styles, facilitating the creation of unique designs and finishes.

Comparing Router Tables and Desktop CNC Machines

Both the router table 4x8 and desktop CNC machines have their merits, and understanding their differences can help you choose the right tool for your needs.

Precision and Automation

Desktop CNC machines excel in precision and automation, making them ideal for detailed and repetitive tasks. These machines use computer-controlled settings to execute intricate designs with high accuracy, which can be especially beneficial for commercial woodworking applications. However, they often require significant upfront investment and time to master the software.

Hands-On Flexibility

In contrast, a router table 4x8 offers a more hands-on approach, allowing for immediate adjustments and manual control over the routing process. This hands-on experience fosters creativity, enabling woodworkers to experiment with different techniques and designs. The tactile nature of routing can enhance the enjoyment of woodworking and lead to innovative results.

Selecting the Right Router Table 4x8

When choosing a router table, keep these considerations in mind:

Build Quality: Select a router table with a sturdy construction that can handle regular use. A solid base will contribute to the table's durability and stability during operations.

Ease of Use: Look for features like adjustable heights, clear measurements, and intuitive controls that simplify your workflow. A user-friendly design is crucial for maximizing efficiency and effectiveness in your woodworking projects.

Included Accessories: Many router tables come with valuable accessories such as fences, dust collection ports, and miter gauges. These tools can enhance your routing capabilities and improve the accuracy of your cuts.

Conclusion

A router table 4x8 is an invaluable addition to any woodworking shop, providing a perfect blend of stability, versatility, and safety. While desktop CNC machine offer advanced precision and automation, the hands-on experience of using a router table can inspire creativity and innovation in your projects. By understanding the benefits and features of a router table, you can elevate your woodworking skills and bring your creative visions to life. Embrace the possibilities that a router table 4x8 offers, and take your woodworking craft to new heights.

2 notes

·

View notes

Text

What Are the Most Common Bending Techniques Used in Press Work?

A sheet metal bending press is a machine used to bend, fold, or shape flat metal sheets into specific angles or forms. It does this by applying pressure through special tools, often called punches and dies. These tools press down on the metal to create a precise bend, giving it the shape needed for construction, manufacturing, or custom parts.

This type of press is widely used in industries like automotive, construction, and furniture. It's perfect for making brackets, panels, frames, or any part that needs a clean, accurate fold. Because it uses force and precision, it helps workers and businesses get repeatable results with minimal effort.

Why It’s a Key Tool in Modern Workshops

Today’s sheet metal bending press machines are much more advanced than older manual versions. Many are now automated or use digital controls to follow detailed instructions. This means less guesswork, less waste, and a faster process overall.

With the right setup, a press can handle different materials—like steel, aluminium, and stainless steel—and bend them at various angles without cracking or damaging the metal. Thanks to their reliability and efficiency, bending presses have become essential in almost every metalworking shop.

How Does a Sheet Metal Press Brake Work in Fabrication?

Bending Angles with Power and Precision

A sheet metal press brake is the most common tool used in metal bending. It works by using a top tool (the punch) and a bottom tool (the die). The sheet metal is placed between them. When the punch is pressed down into the die, it bends the sheet to the required angle.

This method is popular in fabrication because it gives great control over the bend. Whether you need a small fold or a wide curve, a sheet metal press brake can be adjusted to do the job right. It also allows for clean edges, which is important in high-quality manufacturing.

Tools That Make Bending More Accurate

For accurate results, these machines also use a part called a back gauge. This helps position the metal at the exact spot needed for each bend. It acts like a stop guide and ensures that every part is bent in the same place, over and over again.

When combined with trained operators or digital programming, a press brake becomes a powerful tool for shaping metal parts. It’s a key part of the engineering manufacturing and fabrication capabilities used by professionals today.

What Is Air Bending and Why Is It So Common?

Forming Metal Without Full Contact

Air bending is the most widely used method on a sheet metal bending press. In this technique, the punch doesn’t press the metal all the way into the bottom of the die. Instead, the punch pushes the metal partway, and the angle is formed by the position of the punch and the space between the die walls.

This method doesn’t need full contact with the bottom surface, which makes it more flexible. You can make different angles with the same set of tools, simply by adjusting how far the punch moves down.

Why Air Bending Is a Popular Choice

There are many reasons why shops and manufacturers use air bending. It requires less force, so it reduces wear on tools. It also allows faster bending and makes it easier to adjust for different jobs. Plus, it works well with different metal types and thicknesses.

Air bending is especially useful in cnc sheet metal fabrication, where precision and efficiency are critical. Thanks to digital programming, the bending depth can be controlled perfectly, helping you create accurate parts with minimal setup.

How Does Bottom Bending Differ from Air Bending?

Using More Force for Better Contact

Bottom bending is another method used on a sheet metal bending press, but it works a bit differently from air bending. In this process, the punch pushes the metal all the way into the die. This creates full contact between the metal and the tooling.

Because of that full contact, bottom bending usually needs more force than air bending. The benefit is that the final angle tends to be more consistent, especially when you're working with thicker or harder metal.

When to Use Bottom Bending for Better Accuracy

While air bending is faster, bottom bending offers more stability. It’s a better option when high repeatability is needed and there’s no room for variation. This technique is also great for parts that will go into precise assemblies or frames.

In many engineering manufacturing and fabrication capabilities, bottom bending is used when the final product needs tight control over dimensions. It's a little slower, but the accuracy and strength of the bend can be worth it.

What Is Coining and When Should It Be Used?

Coining for Sharp, Accurate Bends

Coining is the most forceful bending method used in a sheet metal bending press. It uses extreme pressure to press the metal tightly between the punch and die, which changes the structure of the metal slightly. This results in a sharp, clean bend that stays exactly as designed.

Unlike air or bottom bending, coining doesn’t spring back. That’s because the metal has been compressed at the bend line. This makes it ideal for very precise parts where angle variation is not allowed.

Trusted in High-Precision Manufacturing

Coining is a common practice in advanced engineering manufacturing and fabrication capabilities, especially when small parts or electronic enclosures are involved.

If you're looking for a provider that offers a full range of services—including coining, laser cutting, cnc punching, turret punching services, Metal punching services, as well as Shelving Units and Storage Cabinets and Machining—you can turn to Premier Engineering & Storage Solutions. They combine expert tools and experienced staff to help you get reliable results every time.

How CNC Sheet Metal Fabrication Enhances Bending Precision

Digital Control Means More Consistency

Cnc sheet metal fabrication is all about accuracy and speed. With CNC (computer numerical control), machines follow digital instructions. This removes the need for manual adjustments and cuts down on errors.

When a press brake is CNC-controlled, each bend can be programmed for exact depth, position, and angle. That means parts come out nearly identical, even in large production runs.

Less Setup Time, More Productivity

Another benefit of cnc sheet metal fabrication is how easy it is to switch between jobs. Instead of changing tools or settings manually, you just upload a new program. This saves time and increases output, especially for businesses with custom orders or short lead times.

Whether you're making a few brackets or hundreds of panels, CNC control keeps every bend sharp and in line with your design.

Can Laser Cutting Be Used with Bending for Better Results?

Pre-Cut Parts Improve the Bending Process

Laser cutting is often used before bending to shape metal sheets to the right size. When done properly, it prepares the metal for bending with smooth edges and perfect dimensions. This helps the press brake perform better and reduces chances of misalignment.

For parts with cut-outs, slots, or tabs, laser cutting is especially helpful. It ensures everything is in the right place before the sheet ever touches a sheet metal press brake.

Combining Techniques for a Smoother Workflow

By combining laser cutting with bending on a sheet metal bending press, manufacturers get the best of both worlds—speed and precision. It’s a smart way to streamline production and reduce the number of machines or manual steps needed.

Many modern workshops rely on this combo to handle complex parts and meet tight deadlines. It’s a popular approach in industries that require quality and speed in every job.

#laser#cnc machining#cnc punching#engineering#welding#metal fabrication#metal press#metal punching#sheet metal fabrication#metal bending press#bending press australia

0 notes

Text

CNC Router

Transform Your Production Capabilities with Cutting-Edge Printing and Engraving Technology

In today’s competitive market, businesses are constantly looking for innovative solutions to enhance product quality, increase production speed, and expand customization options. Technologies such as Direct-to-Garment printing, advanced ink formulations, laser engraving, and CNC machining have revolutionized manufacturing and creative industries. If you’re seeking to upgrade your production workflow or start a new venture, investing in state-of-the-art equipment like a DTF t shirt Printer, UV Curable Ink, dtg printer, Fiber laser machine, and CNC Router can unlock new possibilities and revenue streams.

This article explores the benefits and applications of these technologies and how they can elevate your business operations.

DTF T Shirt Printer: The Future of Custom Apparel Printing

Personalized apparel continues to be a lucrative market, driven by demand for unique designs, small-batch production, and rapid turnaround times. A DTF t shirt Printer offers an efficient and cost-effective method to produce high-quality prints on garments with vibrant colors and excellent durability.

Unlike traditional screen printing, DTF (Direct-to-Film) printing transfers the design onto a special film before heat-pressing it onto the fabric. This process enables printing on a wide range of materials including cotton, polyester, blends, and even nylon, making it highly versatile. Businesses benefit from the ability to print complex, multi-color designs without setup delays, while customers enjoy customized apparel with soft, comfortable prints.

With the latest DTF printers, manufacturers can scale production effortlessly—from personalized one-offs to bulk orders—making this technology a game-changer for print shops and fashion brands alike.

UV Curable Ink: Enhancing Print Quality and Durability

The choice of ink is critical to achieving professional-grade prints with longevity and vibrancy. UV Curable Ink has become increasingly popular due to its unique curing process and environmental benefits.

Unlike solvent or water-based inks, UV curable inks dry instantly when exposed to ultraviolet light. This immediate curing reduces smudging and allows printing on a broad array of materials, including plastics, glass, metal, and wood. The result is sharp, vivid images with excellent adhesion and resistance to scratching, fading, and moisture.

Moreover, UV inks are more eco-friendly as they emit fewer volatile organic compounds (VOCs), supporting sustainable production practices. This ink technology is ideal for commercial printing applications like signage, packaging, product labeling, and decorative printing.

DTG Printer: Direct Printing for Superior Garment Customization

For textile businesses focused on fine detail and soft prints, a dtg printer is an indispensable tool. Direct-to-Garment printing applies ink directly to fabric, enabling photo-quality designs with smooth gradients and rich colors.

DTG printers are perfect for on-demand and small-batch production, allowing brands to respond quickly to market trends without the need for large inventory. The printers handle complex designs with ease, including photographic images, logos, and intricate artwork.

By incorporating DTG technology, businesses can offer customers highly personalized products while minimizing waste and inventory costs. Additionally, modern DTG printers support various fabric types and ink formulations for maximum versatility.

Fiber Laser Machine: Precision Engraving and Marking for Industrial Use

Engraving, marking, and cutting tasks in industries like automotive, electronics, and manufacturing require machines that combine speed, precision, and reliability. The Fiber laser machine is a state-of-the-art solution that meets these demands effectively.

Fiber lasers use a highly focused beam of light to engrave or mark materials such as metals, plastics, ceramics, and composites with permanent, high-contrast results. They are ideal for serial number marking, branding, QR codes, and decorative engraving.

Advantages of fiber laser systems include low maintenance, fast processing speeds, and the ability to work on small or complex parts. Additionally, fiber lasers are energy-efficient and provide consistent output quality, helping manufacturers maintain high standards while reducing operational costs.

CNC Router: Versatile Precision Cutting and Shaping

For businesses requiring detailed cutting, carving, or shaping of materials like wood, plastic, metal, or composites, a CNC Router offers unmatched versatility and precision. CNC (Computer Numerical Control) routers automate complex cutting operations, enabling the production of intricate designs with high repeatability.

CNC routers are widely used in cabinetry, signage, prototyping, furniture making, and custom manufacturing. Their computer-driven operation allows for quick design changes and efficient use of materials, reducing waste and production time.

Integrating CNC routers into your workflow can expand your product range while improving accuracy and finish quality. Whether you need fine engravings or large-scale cutting, these machines provide the flexibility necessary for modern fabrication demands.

Why Upgrading to Advanced Printing and Engraving Equipment Makes Sense

Investing in innovative production machinery enables businesses to:

Expand Product Offerings: Print on diverse materials and customize products to meet niche markets

Increase Efficiency: Faster printing and engraving reduce turnaround times and improve throughput

Enhance Quality: Advanced technology delivers vibrant, durable prints and precise engravings

Reduce Costs: Less waste, fewer errors, and lower maintenance costs improve profitability

Stay Competitive: Meeting customer demand for customization and high-quality output keeps you ahead

Choosing the right equipment—whether it’s a DTF t shirt printer for apparel, a fiber laser for marking, or a CNC router for shaping—can transform your production capabilities and business growth.

Conclusion

The convergence of digital printing and laser technology offers exciting opportunities for manufacturers, designers, and entrepreneurs. By leveraging innovations like the DTF t shirt Printer, UV Curable Ink, dtg printer, Fiber laser machine, and CNC Router, businesses can enhance efficiency, product quality, and customization options.

IEHK provides cutting-edge solutions tailored to meet these evolving industry needs. Whether you’re entering the custom apparel market, upgrading your signage capabilities, or streamlining industrial marking processes, these technologies empower you to deliver excellence and meet customer expectations with confidence.

0 notes

Text

Buy Now Arlen Ness 10 Gauge Black Exhaust Online in the Uk

Buy Now Arlen Ness 10 Gauge Black Exhaust Online in the Uk

Are you a British motorbike enthusiast looking for ways to improve the appearance and sound of your vehicle? For anyone looking to give their motorbike a little flair and luxury, the Arlen Ness 10 Gauge Black Exhaust is a great choice. This exhaust tip is designed for Vance & Hines slip-on mufflers and is popular among motorbike riders all over Britain, UK.

What Makes the Arlen Ness 10 Gauge Black Exhaust Special?

The Arlen Ness 10 Gauge Black Exhaust stands out for its bold look and top-notch build. Because CNC machining is used in its creation, every component is cut with utmost precision. In addition to being svelte, the black anodized treatment helps shield the exhaust from rust and scratches which is essential for motorbike riders in the UK's sometimes rainy and erratic climate.

This exhaust tip is 4.5 inches in diameter making it a noticeable addition to your motorbike. The unique 10-Gauge styling gives your motorbike a rugged and modern appearance that’s sure to catch eyes wherever you ride in the UK.

Why Should You Choose This Exhaust in Britain UK?

For several reasons motorbike owners in the UK should consider the Arlen Ness 10 Gauge Black Exhaust. Here are some of the primary benefits:

Easy to Install: This exhaust tip is made to properly fit Vance & Hines slip-on mufflers so you don't have to worry about a challenging installation. You can quickly attach it to your motorbike and get back on the road.

Built to Last: Thanks to its high-quality materials and black anodized finish this exhaust tip can handle the changing weather and road conditions found throughout Britain UK.

Stylish Design: The aggressive and bold 10-gauge design gives your motorbike a distinctive edge that makes it stand out from other motorbike riders in the UK.

Increased Exhaust Flow: Although the design's primary focus is on beauty, it also facilitates a smoother exhaust flow, which can enhance performance.

Customizable: The exhaust tip is sold individually, so you can choose exactly how many you need for your motorbike.

Where to Buy in Britain, UK

Finding the Arlen Ness 10 Gauge Black Exhaust online in the UK is easy. Many trusted motorbike accessory shops and online retailers in Britain, UK, offer this product. You can browse different options, compare prices, and read reviews from other motorbike riders, in the UK before making your decision. Most sellers deliver quickly across Britain so you won’t have to wait long to start enjoying your new exhaust tip.

When buying online in the UK it’s important to choose a reputable dealer. This ensures you get a genuine Arlen Ness product and any warranty or support that comes with it. Many shops in Britain UK, offer excellent customer service and can help you with any questions about fitting or maintaining your new exhaust tip.

Arlen Ness 10 Gauge Black Exhaust's salient features

This is a brief overview of what this exhaust tip entails:

4.5-inch in diameter for a striking appearance

Anodized black finish to reduce rust and scuffs

CNC-machined for an accurate and long-lasting fit

Compatible with slip-on mufflers made by Vance & Hines

Individually sold for simple personalization

The Reasons British Motorbike Riders Adore It

British motorbike owners value the Arlen Ness 10 Gauge Black Exhaust, because it combines longevity style and ease of use. Whether you’re riding through busy city streets or enjoying the open countryside, this exhaust tip adds a touch of class and toughness to your motorbike. The black finish matches well with many different motorbike colors and styles, making it a versatile choice for riders all over the UK.

Conclusion

If you want to give your motorbike a fresh, stylish look and enjoy reliable performance the Arlen Ness 10 Gauge Black Exhaust is an excellent choice for riders in Britain UK. It’s easy to buy online, simple to install and built to last through all kinds of weather and road conditions in the UK. With its unique design and strong build this exhaust tip is a favorite among motorbike enthusiasts in Britain. Don’t wait—check out the Arlen Ness 10 Gauge Black Exhaust online in the UK today and see why so many riders in Britain UK are choosing this top-quality exhaust tip for their motorbikes!

Get in touch at [care@motride]

#10gaugeexhaust#motorbike#ukbikers#bikemodsuk#motorbikestyle#exhausttip#britishbikers#custommotorbike#parts#motorbikeaccessories#cncexhausttip#chromeorblack#arlennessuk#rideinstyleuk

0 notes

Text

Low-Budget CNC Machine Options That Don’t Compromise on Performance

In today’s competitive manufacturing industry, the need for precision, automation, and scalability is higher than ever. However, for small workshops, job shops, and startups, investing in CNC (Computer Numerical Control) machinery can be intimidating due to the high initial costs. The common perception is that CNC machines require a hefty investment, and budget options often mean sacrificing performance, durability, or reliability.

But what if you could get high-quality CNC machines that fit within a modest budget without compromising on performance?

At Rajesh Machine Tools Pvt. Ltd., we break this myth by offering low-budget CNC solutions that deliver industrial-grade performance, reliability, and ROI.

This blog explores cost-effective CNC machine options, features to consider, how budget machines can still offer precision and durability, and how Rajesh CNC supports businesses in scaling affordably.

Why CNC Machines Are a Game-Changer?

CNC machines have redefined how parts are cut, milled, shaped, and finished. They bring:

Automation and repeatability

Reduced labor costs

Unmatched precision and finish

Faster turnaround times

High scalability for production

From sheet metal fabrication to automotive components and custom engineering jobs, CNC machines eliminate manual errors and help businesses deliver consistent quality.

The challenge? Many small manufacturers assume CNC machines are beyond their budget.

The Truth About “Budget” CNC Machines

Not all low-cost CNC machines are built alike. Some may offer poor build quality, outdated technology, and substandard support. But with the right manufacturer and configuration, budget-friendly CNC machines can offer:

Rigid construction

Advanced software compatibility

Reliable servo and drive systems

Easy maintenance

High-precision performance

The key is to select a trusted Indian manufacturer like Rajesh CNC that understands the local manufacturing challenges and delivers machines that balance cost, quality, and productivity.

Low-Budget CNC Machines Offered by Rajesh Machine Tools

Rajesh CNC offers a versatile range of affordable CNC solutions that cater to entry-level as well as mid-sized industrial setups. Let’s explore the most popular options:

1. CNC Press Brake (Economy Series)

Ideal For: Sheet metal bending, fabrication workshops, auto parts manufacturing.

Features:

Accurate bend angles with programmable backgauge

NC/CNC controller for easy operation

Robust welded frame structure

Less power consumption

Compact footprint for small shops

Why It’s Affordable Yet Powerful: This CNC press brake combines a lower initial cost with precision tooling and intelligent automation. It is suitable for workshops that want to shift from manual press brakes to automated operations without investing in a high-end model.

2. CNC Shearing Machine (Entry Series)

Ideal For: Cutting sheet metal, mild steel, stainless steel.

Features:

Programmable cutting length and blade clearance

Fast hydraulic system

Operator-friendly interface

High cutting accuracy

Minimal maintenance

Why It’s Budget-Friendly: It’s designed with a simplified hydraulic mechanism and optimized frame design, making it affordable while still capable of high-quality shearing operations for small and medium-sized batch production.

3. CNC Fiber Laser Cutting Machine (Compact Series)

Ideal For: Precision cutting of sheet metal, signs, kitchen equipment, electronics enclosures.

Features:

Compact size suitable for space-constrained workshops

1000W to 2000W laser options

Smart CNC system with nesting software

Fast cutting speed and low kerf

Minimal heat distortion

Why It’s a Game-Changer: This model is ideal for small businesses that want the power of laser cutting but have limited space and budget. It consumes low electricity and provides excellent ROI for customized job works and small batch production.

4. CNC Turret Punch Press (Economy Configuration)

Ideal For: Complex sheet punching tasks, HVAC components, perforated sheets.

Features:

Programmable turret tools

Automatic sheet feeding

High punching speed with minimal noise

Suitable for medium-thickness materials

Why It Works for Budget Buyers: With a reduced set of standard turret tools and a simplified structure, the economy turret press offers CNC punching capabilities at a fraction of the cost of high-end European machines.

How Rajesh CNC Machines Deliver Value at a Low Cost

Unlike imported machines with high import duties and maintenance headaches, Rajesh Machine Tools builds machines designed for Indian conditions and optimized for cost-efficiency.

1. In-House Manufacturing

All Rajesh CNC machines are manufactured at our state-of-the-art facility in Rajkot, Gujarat. This eliminates third-party markups, reduces lead times, and ensures strict quality control.

2. Modular Design

Our machines are designed modularly, allowing clients to add advanced features over time. This means you can start with the basics and upgrade your CNC systems as your business grows.

3. Affordable Automation

Our control systems, drives, and motors are carefully chosen to deliver maximum output at minimal cost. We provide affordable yet robust PLCs and CNC controllers that are reliable and easy to maintain.

4. Training & Support

We provide comprehensive training programs and on-site support so your team is confident from day one. Many small businesses fail to benefit from CNC due to a lack of skilled operators—we ensure that doesn’t happen.

CNC Performance Without Compromise: Key Features You Still Get

Even with low-cost machines, Rajesh CNC ensures you never compromise on the essentials that define quality CNC performance:

1. Repeatability

High-quality guideways, ball screws, and feedback systems ensure that every cut, bend, or punch is as accurate as the last one.

2. Material Flexibility

Our machines support mild steel, stainless steel, aluminum, copper, and more—giving you flexibility in material processing.

3. Safety & Ergonomics

Budget doesn’t mean unsafe. All machines come with emergency stops, overload protection, light curtains, and user-friendly controls.

4. Energy Efficiency

With servo-hydraulic systems and optimized power management, our machines consume less energy and reduce operational costs over time.

What Industries Can Benefit From Budget CNC Machines?

Low-cost CNC machines are a boon for:

Job shops and contract manufacturers

Startup fabrication units

Automotive component suppliers

Furniture and signage manufacturers

HVAC equipment producers

Agricultural equipment workshops

Educational institutions and training centers

Whether you're fabricating doors, frames, panels, or precision parts, our entry-level CNC machines will meet your quality standards and production deadlines.

Investing in a CNC machine—even on a budget—pays off in the long run through increased productivity, lower rejection rates, and better process control.

Real Customer Success: Budget CNC That Scaled Their Growth

Many of our clients started with a single low-cost CNC press brake or shearing machine and have now grown to operate full production lines. Here are some common stories:

A small signage manufacturer doubled their output using our compact CNC laser cutter.

A local job shop replaced two manual press brakes with one Rajesh CNC press brake and reduced labor costs by 40%.

An auto part fabricator purchased our entry-level CNC shearing machine and was able to deliver precise parts to OEMs with zero rework.

All of them started with low investment but gained high-value returns—thanks to the balance of cost and capability in Rajesh CNC machines.

Why Choose Rajesh Machine Tools for Your Budget CNC Needs?

Over 35 years of industry expertise

Make in India certified products

ISO-certified quality assurance

End-to-end support from consultation to service

Proven track record across 10,000+ installations

Whether you're stepping into automation for the first time or looking to expand affordably, Rajesh CNC offers machines that match your ambition, not just your budget.

Final Thoughts: Budget CNC Is Not a Compromise—It’s a Smart Start

Today, the Indian manufacturing ecosystem is evolving rapidly. Businesses that automate early, even on a tight budget, gain a competitive edge in pricing, quality, and delivery. Choosing the right CNC machine is not about going for the cheapest—it’s about choosing the most value-packed machine that fits your goals.

At Rajesh Machine Tools Pvt. Ltd., we’re proud to provide that balance—affordable CNC machines that work like premium systems.

Ready to get started?

0 notes

Text

Elevate Performance & Style with SOUL Forged Wheels: Precision for Porsche, Power for Every Drive

When it comes to pushing the boundaries of performance, aesthetics, and craftsmanship, SOUL Forged Wheels stands in a class of its own. Designed for automotive enthusiasts who crave precision and distinction, our line of custom 3 piece wheels, 5 spoke 2 piece wheels, and bespoke fitments for vehicles like the 911 991.2 GT3 RS is more than just an upgrade—it’s an evolution of your drive.

Why Choose SOUL Forged Wheels?

Your car is more than just a machine. It’s an extension of your identity, a symbol of passion and precision. At SOUL Forged Wheels, we engineer and design each wheel to reflect that philosophy. With a focus on high-performance vehicles and custom-built specifications, our wheels not only enhance vehicle dynamics but also bring a level of exclusivity that mass-market solutions simply can’t match.

1. Custom 3 Piece Wheels: Tailored for True Enthusiasts

Shop Custom 3 Piece Wheels →

The pinnacle of wheel customization begins with our custom 3 piece wheels—crafted for discerning car owners who demand nothing but perfection. Whether you own a European sports car, exotic build, or a race-prepped monster, these wheels allow for meticulous customization. From finishes to lip size, bolt pattern, and offsets, every element is precision-tailored to suit your build.

Three-piece construction offers unparalleled benefits:

Strength & Durability: Aircraft-grade aluminum meets rigorous stress testing for extreme performance.

Custom Fitments: Adapted specifically to your vehicle’s geometry for flush fitment and optimized stance.

Style Freedom: Choose your face design, lip depth, color finish, and hardware style.

Whether you’re carving canyon roads or setting records at the track, our custom wheels are engineered to perform and designed to captivate.

2. 5 Spoke 2 Piece Wheels: A Fusion of Classic Design & Modern Engineering

Explore 5 Spoke 2 Piece Wheels →

Simplicity meets sophistication in our 5 spoke 2 piece wheels collection, perfect for high-performance vehicles like the Audi R8. The 5-spoke design has long been celebrated in motorsports for its strength and minimal weight, and SOUL Forged elevates this iconic design with contemporary materials and finishes.

Our 2 piece construction fuses forged centers with spun-lip barrels—allowing for:

Weight Optimization: Lighter than cast wheels, enabling better handling and braking.

Customization Options: Choose from a variety of finishes and sizes to complement your car’s aesthetics.

Race-Ready Performance: Designed to handle high torque and G-forces with ease.

If you’re looking to strike the perfect balance between bold design and aggressive functionality, our 5 spoke 2 piece wheels offer the visual and performance edge you crave.

3. Precision Fitment for the 911 991.2 GT3 RS

View 911 991.2 GT3 RS Wheels →

The Porsche 911 991.2 GT3 RS is a masterclass in motorsport engineering. To complement this automotive icon, SOUL Forged offers wheels specifically designed to enhance its race-bred DNA. With years of experience and access to exact OEM specifications, we deliver forged wheel sets that flawlessly match the aggressive camber, brake clearance, and lightweight needs of the GT3 RS.

Key features include:

Track-Proven Geometry: Designed for ideal offset, stance, and weight distribution.

Extreme Brake Clearance: Fits large carbon ceramic or upgraded caliper systems without compromise.

Bespoke Finishes: From satin black to brushed champagne or candy red—we create wheels that turn heads and stop hearts.

Pairing SOUL Forged wheels with your 991.2 GT3 RS doesn’t just elevate aesthetics—it maximizes the car’s full performance potential.

Built in America. Inspired by Performance.

Every wheel we build at SOUL Forged Wheels is made in the USA, machined with aerospace-grade materials, and crafted with passion. Our manufacturing partners utilize CNC technology and rigorous quality control processes to ensure structural integrity, performance, and longevity.

Our mission isn’t just to provide premium wheels—it’s to build the soul of your drive.

The SOUL Forged Advantage:

Engineering Excellence: Our design team consists of motorsports engineers and car builders who understand what matters when the rubber meets the road.

Endless Customization: Choose between brushed, polished, powder-coated, or anodized finishes in hundreds of color combinations.

Precision Fitments: Whether you’re modding a JDM hero or dialing in your European supercar, our custom solutions adapt to your exact needs.

Customer Collaboration: Our build specialists work with you one-on-one to make sure your vision becomes reality.

Join the Movement

SOUL Forged Wheels is more than a brand—it’s a community of enthusiasts, racers, and builders who live and breathe automotive culture. When you upgrade to SOUL, you’re not just installing a set of wheels—you’re making a statement.

Our wheels have been featured on some of the most elite builds in the industry—from widebody R8s to time attack GT3s, and from stance icons to street sleepers. Each build tells a story—and we’re proud to be part of yours.

Ready to Transform Your Drive?

Whether you’re hitting apexes on the track or cruising the coast at sunset, SOUL Forged Wheels brings your vision to life—with strength, style, and soul.

SOUL Forged Wheels Precision Forged. Performance Driven. Soulfully Crafted.

0 notes