#Printing and Dyeing Auxiliary

Explore tagged Tumblr posts

Text

How Textile Chemical Dyes Impact the Environment?

In the vibrant world of fashion and textiles, colors play a pivotal role in capturing our imagination and defining our sense of style. The captivating hues of our garments owe their brilliance to a significant yet often overlooked aspect of the industry: chemical dyes.

These dyes have revolutionized the textile sector, making it possible to produce a wide array of colors and patterns that appeal to consumers' ever-changing tastes. However, amidst this rainbow of possibilities lies a dark truth - the environmental impact of textile chemical dyes.

In this blog, we delve into the consequences of using chemical dyes in textile production and explore sustainable alternatives that can help mitigate the ecological footprint of the fashion industry.

Water Pollution

One of the most significant environmental concerns associated with chemical reactive dyes in textiles is water pollution. Conventional dyeing processes often involve large amounts of water, which is used to rinse and treat fabrics. As a result, vast quantities of chemically-laden wastewater are discharged into rivers and water bodies, contaminating aquatic ecosystems. Many of these dyes are non-biodegradable and can persist in the environment for decades, disrupting the natural balance and threatening the health of aquatic organisms.

Energy Consumption

The process of digital textile sublimation inks requires substantial energy inputs, primarily during the dye application and fixation stages. Traditional dyeing methods may involve high-temperature dye baths and extended processing times, adding to the industry's carbon footprint. The energy-intensive nature of these processes contributes to greenhouse gas emissions, accelerating climate change and its devastating consequences.

Toxic Chemical Exposure

Chemical dyes used in textile auxiliaries manufacturers often contain hazardous substances such as heavy metals, formaldehyde, and volatile organic compounds (VOCs). Not only are these substances harmful to the environment, but they also pose significant health risks to the workers in the textile industry who are exposed to them daily. Moreover, consumers may experience allergic reactions and skin irritations when in contact with garments containing residual dye chemicals.

Biodiversity and Land Contamination

When dye wastewater finds its way into the soil, it can have severe consequences for terrestrial ecosystems. The toxic substances from the dyes can leach into the soil, affecting soil quality and disrupting the delicate balance of local flora and fauna. Moreover, the disposal of waste from dyeing processes can lead to the accumulation of harmful chemicals in landfills, further exacerbating the environmental impact.

Scarce Resource Consumption

Many chemical dyes rely on non-renewable resources for their production. For instance, some synthetic dyes use petroleum-based derivatives, placing additional strain on dwindling fossil fuel reserves. As these resources become scarcer, the textile industry must find more sustainable alternatives to safeguard the planet's future.

Embracing Sustainable Solutions

As we confront the ecological consequences of chemical dyes, the textile industry is gradually recognizing the urgent need for change. Embracing sustainable solutions can help mitigate the impact of dyes on the environment:

Natural Dyes: Traditional plant-based dyes, such as indigo, turmeric, and madder, offer a biodegradable and eco-friendly alternative. They can be sourced sustainably, reducing the strain on the environment.

Waterless Dyeing Technologies: Innovative technologies, like air dyeing and digital printing, minimize water usage and eliminate the discharge of wastewater, significantly reducing water pollution.

Biodegradable Dyes: Researchers are developing biodegradable dyes that break down naturally over time, circumventing the issue of persistent chemicals in the environment.

Eco-Friendly Dyeing Processes: Manufacturers can adopt low-impact dyeing techniques that consume less energy and minimize toxic chemical usage, ensuring a cleaner and safer environment for all.

The use of chemical dyes offers by textile printing ink exporter in the textile industry has undoubtedly made fashion more colourful and accessible. However, this innovation comes at a high cost to our environment. From water pollution to biodiversity loss, the impact of chemical dyes on the planet is far-reaching.

To ensure a sustainable future, it is imperative for the industry to embrace eco-friendly alternatives and implement responsible dyeing practices. By taking steps towards a more environmentally conscious approach, we can paint a brighter, greener canvas for the fashion world, where creativity and conscience coexist harmoniously.

#Textile Dyes Exporter#Textile Dyes Manufacturers#Textile Dyes Manufacturers in India#Digital Textile Reactive Inks#Digital Textile Printing Ink Manufacturer#Digital Textile Printing Ink Exporters#Textile Printing Ink Exporter#Digital Textile Sublimation Inks#Textile Auxiliaries Manufacturers#Textile Auxiliaries Exporter#Reactive Dyes Manufacturer#Reactive Dyes Exporter#Reactive Dyes Manufacturer in India#Textile Chemical Dyes

0 notes

Text

tuesday again 3/18/2025

in which we read a lesbian romance where the highs are pretty fuckin good and the lows are not so pretty good

listening: the giver by chappell roan

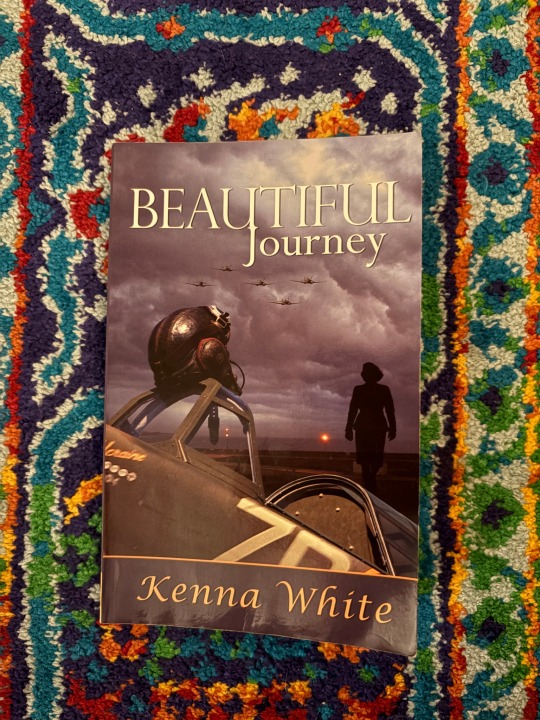

reading: a bella books update, but mostly Beautiful Journey by Kenna White

watching: fallow week

playing: genshin (!) and Pokémon

making: garden update, rit dye bounty

listening

new single out. i want to hear this in EVERY commercial this summer

-

reading

special shoutout to a blazed tumblr post that led me to Haden Cross’ Uncontinented Stars, a queer moby-dick retelling. before you dismiss it out of hand here are some of my thoughts about how it neatly avoids some common queer retelling pitfalls

in this gay and lesbian romance project, i really think (one of) my (big) problem(s) is with Bella Books specifically as a publisher and their lack of quality control or editing assistance, but we are closer to done with them. with the bella and naiad conglomerate, i have two books of short stories (one naiad one bella, neither with covers i can take to work) and two more naiad originals after this. i will be breaking them up into three weeks in between kim baldwins (the insane lesbian bunker mercenary one i enjoyed).

three up this week: could not finish the one on the left due to a printing error with random missing pages, could not finish the one on the right bc of a hard-out trigger.

this is Kenna White’s Beautiful Journey, a 2008 Bella Books original (not acquired from Naiad), 276p softcover with a worse than usual application of glue to the perfect bound binding.

Kit Anderson is determined to make a difference. All around her the Battle for Britain is raging, and ferrying factory-fresh airplanes to combat bases makes excellent use of her skills as flight lieutenant for the British Women’s Air Transport Auxiliary. An American in southern England, she is undaunted by war. It’s safer than love.

The talented aviatrix could fly a crippled craft through a thunderstorm without a compass and find her way home, so it is singularly disconcerting to find herself flying in circles around Emily Mills, a too young, too attractive and too abrasive British literature teacher. Even though Emily’s grandmother is Lady Marble, it’s a time of war and scarcity and Emily needs work. Kit offers to help her find a job on the air base—and as is often true, no good deed goes unpunished.

i had zero expectations from a bella books book (and there were still a handful of misspellings and formatting glitches) but on a scene by scene level, White is excellent at setting a scene and making it come fully alive with a sort of forties wartime romcom slapstick vibe. in the back half there’s a very good very coen brothers scene with ornery pig farming lesbians, married for twenty-eight years, who (after holding her at shotgunpoint and wanting to see the American label in her American silk underwear) help Kit get her plane out of a field after an emergency landing and some intergenerational bonding. to which she gifts them her silk parachute as an anniversary present. there’s a great dramatic romantic set piece during a daytime air raid in London, where they flee a claustrophobic, unhygenic tube station and shelter outdoors in an alcove (very stupid). a big dramatic kiss to comfort someone and distract them from a panic attack. that sort of thing.

contains one of the worst reactions to a first orgasm i have ever read: i texted my bestie in horror “American lesbian successfully seduced British lesbian (found out she was a virgin, got her clothes off) and after she made the British lesbian come the British lesbian BURST INTO TEARS AND RAN OFF INTO THE NIGHT” HELLO??? EMILY WHAT??? while this is a BONKERS thing to do in real life i must applaud this specific bella book for making me go HELLO??? in this way and not in frustration bc i want something! anything! to happen. good decisions are out interesting decisions are in etc. bella books sets SUCH a low bar.

also contains straight up one of the most effective scenes ive read in this project so far, that made me tear up AT WORK:

the book has a very water-themed series of mishaps (walks in on Kit while she’s having a bath, drenches her with dirty water from a kitchen pot, doesn’t set the brake on a truck and Kit has to drop flat in the mud for the truck not to run her over, Kit ends up going back in the rain to rescue Emily from a thunderstorm, Kit rescues Emily from a river overrunning its banks, at least one more thing i can’t recall). this is a pretty amusing lesbian getting-you-wet schtick without doing a russo brothers HEY IM GETTING YOU WET. GET IT? WE FUCK NOW? and does supply some believable friction for the “why can’t they be together NOW” question. they can’t be together now bc emily is a walking disaster.

unfortunately i think this book is much weaker in the last third of the relationship, and the way they resolved their misunderstanding from an accidental eavesdrop felt like it could be very forties romantic drama in the eventual film adaptation, but felt very flimsy as a modern reader. i hope that makes sense. wretched ending, i did NOT enjoy the Kit spanking Emily scene to get her to confess why she broke up with her in the LAST THREE PAGES. it felt very strange when they were so focused on being soft and gentle for the rest of the book, and i don’t think that’s a good place to rebuild a relationship on.

yes, and the sex?

certainly better than all of the other bella books sex scenes: three? i think? with one nearly a full chapter long. i wish some of the word choice (eg “honey path”) was different. i think White’s strength is in groups conferring amongst each other and establishing non-romantic relationships, but she’s good at making me invested in them because they have so much frustration to overcome and have to establish a friendship beachhead before they can get to anything romantic.

by far the best bella book with some really standout individual scenes, but still a very mixed bag. i will probably keep it on the strength of that shortbread passage alone bc. OOF. i think it was worth slogging through the bella/naiad books for that.

-

watching

rare fallow week! hopefully i will sort myself out as i get used to working in person and need less completely silent floor time. hopefully.

-

playing

no news on the desktop front unforch BUT i did finally have a phone upgrade tick around and good god. going from an iPhone 12 to a 16 plus is insane. this thing is enormous. i get WHY genshin makes a billion dollars a year on mobile bc this looks sick but my god do i prefer mouse and keyboard. i feel a billion years old. i am glad i can get in and do my dailies and some events but i am nowhere near confident enough to do like. the fighting part of the fighting game. anyway, get a load of this guy and his thigh high demonias

with this guy the only other guy i really really want is pink fox lady Yae Miko. and woman of mystery Skirk. whenever the fuck she drops. so glad i was grinding before my pc died lol bc i dropped three mil in-game currency on making sure my beautiful sad man has maxed artifacts maxed weapon and talents to 8/10. he would be totally maxed but i have One! ONE! boss drop left and can’t quite clinch it yet on mobile. i may have to drop the difficulty level down as far as it will go :( i cannot git gud :(

but get a load of this other guy!

-

making

continuing battles with the insane microclimate on my balcony, which is extremely hot and dry yet i am constantly battling drainage issues and a fungal damping-off issue, where seedlings wither at the base before they get their first true leaves. also having a strange issue with things simply not coming up: the purple bush beans and lettuce mix i bought last year, and half the marigolds i bought this year don’t want to sprout At All even in a damp paper towel in a baggie. they’ve been kept in the cool and dark. so what gives.

however, the nearly six year old butternut squash seeds @shiny-good-rock sent me at the beginning of the pandemic? all four of those babies came up. while they sort themselves out into something photogenic, behold my beautiful little satellite array of nasturtiums. they need to be moved around a bit so they all have breathing room but that’s a problem for future kay

and finally, i so rarely enter giveaways but i entered one on Instagram and got a stupid mchugelarge box FULL of rit dye!!! i am going to commit so many synthetic crimes. gorls THRILLED by big box and so much paper

33 notes

·

View notes

Text

0 notes

Text

Textile Chemicals Market Growth Drivers and Emerging Trends Analysis Through 2032 with Regional Insights

Introduction

The global Textile Chemicals Market—encompassing dyes, surfactants, finishing agents, and auxiliaries—is projected to grow significantly from approximately USD 27.8 billion in 2024 to USD 36.1 billion by 2030, at a CAGR of ~4.5% . Another forecast estimates this market reaching USD 41.9 billion by 2032, driven by bio-based feedstock adoption .

This report explores the growth drivers, trends, regional insights (2024–2032), plus key challenges shaping the market’s trajectory.

1. Growth Drivers

1.1 Surge in Technical Textiles

Demand for technical textiles in sectors such as automotive, medical, protective gear, and construction requires specialized chemicals—for flame retardancy, antimicrobial finishes, or waterproof coatings. This is a leading growth engine for the textile chemicals market . Notably:

Asia-Pacific technical textile chemicals valued at USD 6.8 billion in 2023, projected to USD 10.5 billion by 2032 (CAGR ~5.1%) .

Apparel remains dominant, accounting for ~44% of revenue in 2023, with technical textiles recording the highest CAGR .

1.2 Fast Fashion & Home Furnishing

Rising disposable incomes, changing lifestyles, and rapid turnover in trends drive demand for new styles in clothing and home textiles—fueling consumption of colorants, softeners, and finishes .

1.3 Sustainability & Eco-Friendly Innovation

Growing regulatory pressure (e.g., EU REACH) and consumer demand for sustainable production are catalyzing a shift toward bio-based, biodegradable, and low-VOC chemicals .

BASF's launch of RCS-certified polyamide, Dystar’s eco-indigo (cutting water usage by 90%), and Solvay's ocean-degradable fibers illustrate this trend .

1.4 Regulatory Pressure & Circularity

Strict wastewater and effluent regulations are pushing manufacturers toward closed-loop systems, enzymatic treatments, green auxiliaries, and waste-to-feedstock chemistry . Circular economy initiatives (e.g., India’s textile circularity roadmap) further promote digitization and resource-efficient manufacturing .

2. Emerging Trends

2.1 Bio-Based & Green Chemistry

The industry is rapidly embracing sustainable chemistries—bio-derived dyes, water-insoluble alternatives, and sugar-based reducing agents to reduce environmental impact .

2.2 Nanotechnology & Smart Textiles

Functional finishes—such as nanocoatings, antimicrobial silver, UV-resistant layers, and conductive inks—expand into e-textiles, wearable tech, and high-performance applications .

2.3 Digital Textile Printing

The shift from traditional dyeing to digital printing generates demand for specialty pre-treatment and print-ready chemicals, enabling high-resolution and on-demand textile production .

2.4 Specialty & Multifunctional Finishes

Consumers seek textiles with stain resistance, wrinkle control, moisture-wicking, and UV protection—driving growth in advanced finishing agents (now ~40% market share in 2023) .

2.5 Waste-to-Feedstock & Circular Innovation

Innovative use of textile and fruit waste for chemical feedstocks and the development of enzymatic recycling processes reflect a broader shift toward circularity .

3. Regional Insights (2024–2032)

Asia‑Pacific (≈45% Share)

Dominating production hubs (China, India, Bangladesh, Vietnam), this region leads due to low-cost manufacturing and investment in processing chemicals. The APAC market is growing fastest at a ~4.7% CAGR . India's textile circular economy efforts align with moves toward bio-based chemicals .

North America (31% Share)

Valued at USD 8.38 billion in 2023, expected to reach USD 11.41 billion by 2031. Growth driven by innovations in technical textiles, home furnishings, and stringent sustainability norms. U.S. accounts for ~78% of the region’s market .

Europe

Strong emphasis on eco-friendly chemistry, regulatory compliance (REACH), and technical textiles (especially in Germany, Italy, France) . Innovation is tempered by high compliance costs.

Middle East & Africa

Growing investments in Turkey, Egypt, and South Africa drive adoption of advanced chemicals, though constrained by limited local production and import reliance .

Latin America

Brazil and Mexico’s growing textile industries are fueling demand. Sustainability pushes are opening avenues for eco-chemical adoption, though R&D and economic challenges persist .

4. Challenges & Restraints

Environmental Compliance Costs: Wastewater legislation and effluent standards increase costs and compel technology upgrades .

Raw Material Price Volatility: Increases in petrochemical costs impact profitability .

High Investment Needs: Green chemistry and nanotech R&D require heavy upfront investment.

Complex Regulatory Terrain: Diverging global chemical standards increase compliance complexity.

5. Outlook Through 2032

Continued Growth: Forecasted CAGR of ~4.5–5.1%, reaching USD 36–42 billion .

Sustainable Shift: Rising share of bio-based, recyclable chemicals and eco-friendly dyes.

Smarter Textiles: Advanced finishes, e-textiles, and digital processes will increase chemical sophistication.

Regional Diversification: Production hubs proliferate, but compliance costs shape regional competitiveness.

Conclusion

The Textile Chemicals Market is evolving from traditional formulations to sustainable, high-functionality chemistries. Technical textiles, digital printing, and smart finishes are key demand drivers. Sustainability trends and strict regulations are forcing innovation, creating both challenges and strategic opportunities. Asia-Pacific remains dominant, while North America and Europe focus on advanced applications and compliance.

Stakeholders should prioritize:

Sustainability R&D: Bio-based, biodegradable, low-impact chemistries.

Technical Differentiation: Nanotech, multifunctional agents, digital-print compatibility.

Regulatory Alignment: Early compliance in wastewater and chemical safety.

Circular Strategies: Waste-to-chemical feedstocks and process recycling.

With strategic investment and innovation focus, players in this sector can thrive amid rising global demand and tightening environmental standards through 2032 and beyond.

0 notes

Text

Leading Dyestuff , Dyesintermediates manufacturer| Hindprakash Chemicals

About Hindprakash Chemicals

Established in 1942, Hindprakash Chemicals Pvt. Ltd. has evolved into a prominent name in the manufacturing, import, and export of dyestuffs and dye intermediates in India. Over the decades, the company has diversified its product range to include textile auxiliaries, specialty chemicals, and other related products, catering to various industries such as textiles, paint, pharmaceuticals, and more

Our Product Range

At Hindprakash Chemicals, we offer a comprehensive array of products designed to meet the diverse needs of our clients:

Dyestuffs: Including acid dyes, cationic basic dyes, direct dyes, disperse dyes, and reactive dyes.

Dye Intermediates: We specialize in both the import and export of high-quality dye intermediates.

Chemicals & Solvents: Supplying basic chemicals and solvents essential for various industrial applications.

Chemicals & Auxiliaries: Offering pretreatment chemicals, dyeing auxiliaries, green acid, printing auxiliaries, finishing auxiliaries, and washing agents .

Pigments: Providing a range of pigments suitable for textiles and other applications.

Resins & Adhesives: Manufacturing resins and adhesives for diverse industrial uses.

Other Products: Including food colors and other specialty products.

Research & Development

Our in-house R&D facility enables the development of new products, improvement of existing processes, and enhancement of product quality. This commitment to innovation leads to cost reduction, better quality for customers, and a reduced environmental footprint. We also offer customized product development under secrecy agreements to meet specific client requirements .

Global Presence

With over 75 years in the industry, Hindprakash Chemicals has expanded its reach globally. We have established subsidiaries and partnerships in various countries, including Vietnam, China, and the UAE, to support our international business and cater to a diverse clientele .

Commitment to Quality

Quality is at the core of our operations. We have dedicated quality control laboratories equipped with modern testing instruments such as spectrophotometers, HPLC, dyeing and printing equipment, and fastness test equipment. These facilities ensure that all our products meet international standards and customer expectations .

Sustainability and Social Responsibility

Hindprakash Chemicals is committed to sustainable practices and social responsibility. We actively engage in activities that promote environmental sustainability and contribute positively to the communities we operate in.

Hindprakash Chemicals, established in 1942, is a leading manufacturer of dyestuffs, dye intermediates & specialty chemicals, committed to quality & innovation

0 notes

Text

Hello Entrepreneur/Business Man-woman

I feel this good news for you & for your smooth business operations GLOBALLY from 2025

WE READY FOR YOU,BUT YOU READY FOR YOUR BUSINESS STABLISH???

Which products or services you need at this moment????

Paid service or free service?

Digital products or physical products???

Note - All service we provide WORLDWIDE/GLOBALLY,to our (ONLY LEGIT/REAL CLIENTS).

But everything depends on our clients demand/requirements .....

Part 1

FREE SERVICE -

@ Earning/Income or Affiliate earning plan

@Jobs service

@Online advertising

@online & offline free consultancy

@Free & paid Marketing

@Free sample (depends on products)

@Business plan/business ideas plan

@Business promotion

@Marketing plan

Part 2

Digital products....

@WEBSITE RANKING

@REMOTE IT SERVICE/FREELANCE SERVICE

@WEBSITE DESIGN & DEVELOPMENT

@ECOMMERCE WEBSITE OR BUSINESS WEBSITE

@ANDROID OR IOS APPS DEVELOPMENT

@ERP SOFTWARE

@BUSINESS SOFTWARE

@SEO

@BRANDING WITH PROMOTION

@DIGITAL MARKETING

@GOOGLE PAID ADS CAMPAIGN

@GMB PROFILE CREATION

@ BUSINESS PAGE CREATION

Part 3

Physical products

@All types pre-order/fresh order.....

@Apparels/clothes/RMG - knitwear, woven wear, denim wear, sportswear lingerie wear, swimwear,home Textile, sweater

@Fabrics (knit, woven, denim)

@Yarn (cotton, polyester, PC, CVC, viscose, model)

@Garments accessories & trim's

@Textile dyeing finishing chemical & auxiliary.

@Textile Machinery(knitting, dyeing, finishing, laboratory, printing, washing, embroidery, sewing)

Part 4

Production/manufacturing service-

@knitting/Weaving

@Yarn dyeing

@knit fabric dyeing

@woven fabric manufacturing

@denim fabric manufacturing

@washing plant

@printing(screen print, digital, sublimation)

@embroidery.

PART 5

@Freight forwarding service globally (Sea & Air)

@ PARTNERSHIP BUSINESS

@HOME/HOUSE BUILDING DESIGN & ENGINEERING SERVICES

If you feel any SERVICE PRODUCTS you need for your business or brand stablish, then you can please knock our Whatsapp number or email us.

For more details

www.elpra21.com

Thanks

Md Eusuf Shanto

Textile Engineer

CEO & FOUNDER

Elpra21

Tex4 Sourcing

+8801620487648(Whatsapp)

#manufacturer#supplier#textile#elpra21#apparels#bangladesh#clothes#fashion business#mensfashion#women's fashion

0 notes

Text

0 notes

Text

Textile Chemicals Market Analysis: Key Players and Competitive Landscape

Rising Demand for High-Performance and Sustainable Textiles Drives Growth in the Textile Chemicals Market.

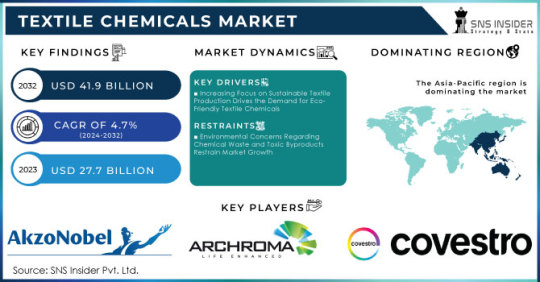

The Textile Chemicals Market Size was valued at USD 27.7 billion in 2023 and is expected to reach USD 41.9 billion by 2032 and grow at a CAGR of 4.7% over the forecast period 2024-2032.

The Textile Chemicals Market is driven by increasing demand for high-performance textiles, advancements in fabric processing technologies, and the rise of sustainable textile manufacturing. Textile chemicals play a crucial role in enhancing fabric properties such as durability, color retention, water resistance, and wrinkle resistance. The growing popularity of technical textiles, eco-friendly dyes, and functional apparel is further propelling the industry forward. Additionally, government regulations promoting sustainable production practices and the shift toward bio-based textile chemicals are reshaping market dynamics.

Key Players

AkzoNobel NV

Archroma

Covestro

Croda International Plc

DowDuPont

Evonik Industries

FCL

Huntsman International LLC

Indofil

Kemin Industries

Future Scope

The future of the textile chemicals market is expected to be driven by innovations in sustainable fabric treatment solutions and increased demand for smart and functional textiles. With the fashion and textile industry moving toward green manufacturing, the adoption of non-toxic, biodegradable, and water-efficient chemicals will grow. Furthermore, nanotechnology and biotechnology advancements will revolutionize fabric coatings and performance-enhancing finishes, opening new opportunities for the industry.

Emerging Trends

The textile chemicals market is undergoing a transformation with the increasing adoption of eco-friendly and biodegradable textile auxiliaries. The demand for antimicrobial, UV-resistant, and flame-retardant finishes is growing in industries such as healthcare, defense, and sportswear. The rise of digital textile printing technologies is also influencing the development of high-performance printing chemicals that enable vibrant, long-lasting prints with minimal environmental impact. Additionally, the shift toward waterless dyeing technologies and bio-based finishing agents is gaining traction as companies work to reduce their carbon footprint.

Key Points

Growing demand for high-performance and functional textiles in various industries.

Rising adoption of sustainable and eco-friendly textile chemicals.

Advancements in nanotechnology and biotechnology for fabric treatment.

Expansion of digital textile printing driving demand for advanced printing chemicals.

Stringent environmental regulations promoting non-toxic and biodegradable alternatives.

Conclusion

The Textile Chemicals Market is set for sustained growth, fueled by technological innovations, increased demand for eco-friendly solutions, and advancements in fabric processing. As global textile manufacturers embrace sustainable production methods and high-performance textile solutions, the industry is poised for a dynamic and environmentally conscious future.

Read Full Report: https://www.snsinsider.com/reports/textile-chemicals-market-2183

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Textile Chemicals Market#Textile Chemicals Market Size#Textile Chemicals Market Share#Textile Chemicals Market Report#Textile Chemicals Market Forecast

0 notes

Text

Textile Dyeing and Coloration: An Overview of Textile Chemicals

Textile dyeing and coloration are essential processes in the textile industry, responsible for adding aesthetic appeal and functionality to fabrics. These processes rely heavily on various textile chemicals, including dyes, pigments, and auxiliaries, which help achieve desired shades, fastness properties, and environmental sustainability. Understanding the chemistry behind textile dyeing is crucial for improving efficiency, reducing environmental impact, and developing sustainable alternatives.

1. Understanding Textile Dyeing and Coloration

Textile dyeing is the process of imparting color to fibers, yarns, or fabrics using dyes that bond chemically or physically with the material. Coloration encompasses not only dyeing but also printing and other surface treatments that modify color appearance. The success of the dyeing process depends on several factors, including dye type, fiber type, dyeing method, and the use of auxiliary chemicals.

Dyes are broadly classified into natural dyes and synthetic dyes. While natural dyes were historically used, synthetic dyes dominate the modern textile industry due to their cost-effectiveness, consistency, and superior fastness properties.

2. Types of Dyes Used in Textile Dyeing

Different textile fibers require specific types of dyes for effective coloration. The major types of dyes used in textile processing include:

a) Direct Dyes

Water-soluble dyes applied directly to cellulosic fibers like cotton.

Moderate fastness properties but improved by after-treatments.

b) Reactive Dyes

Form covalent bonds with cellulose fibers, ensuring excellent wash fastness.

Commonly used for cotton, rayon, and linen fabrics.

c) Disperse Dyes

Non-soluble dyes used for synthetic fibers like polyester, nylon, and acetate.

Require high-temperature dyeing methods for better fixation.

d) Acid Dyes

Water-soluble dyes used mainly for protein fibers (wool, silk) and synthetic fibers (nylon).

Provide vibrant colors but moderate wash fastness.

e) Basic (Cationic) Dyes

Applied to acrylic and modified polyester fibers.

Offer bright shades but lower light fastness.

f) Vat Dyes

Insoluble dyes converted into a soluble form during dyeing.

Used for cotton, offering excellent fastness but requiring complex processing.

g) Sulfur Dyes

Used for deep black and navy blue shades on cotton fabrics.

Cost-effective but prone to fading over time.

3. Role of Textile Auxiliaries in Dyeing

Apart from dyes, various textile auxiliaries are used to enhance the dyeing process and improve the performance of dyed fabrics. These include:

Leveling agents – Ensure uniform dye penetration and prevent streaking.

Wetting agents – Improve fiber absorption by reducing surface tension.

Fixing agents – Improve color fastness to washing and rubbing.

Sequestering agents – Remove unwanted metal ions that interfere with dyeing.

pH regulators – Maintain optimal acidity/alkalinity for dye fixation.

4. Common Dyeing Methods in the Textile Industry

The method of dye application depends on the fiber type, dye properties, and desired outcome. Some commonly used dyeing techniques include:

a) Exhaust Dyeing (Batch Dyeing)

Fabrics or yarns are immersed in a dye bath for a specific time.

Used for cotton, wool, polyester, and blends.

b) Continuous Dyeing

Used for high-speed production of uniform color fabrics.

Ideal for polyester, cotton, and synthetic blends.

c) Pad-Dry-Cure Method

Fabric is padded with dye, dried, and cured at high temperatures.

Common for reactive dyes on cotton.

d) Jet Dyeing

Used for synthetic fibers like polyester and nylon.

Provides better dye penetration with minimal fabric damage.

e) Garment Dyeing

Applied to finished garments rather than raw fabric.

Popular for fashion industry trends.

5. Environmental Concerns and Sustainable Dyeing Practices

The textile dyeing industry is one of the biggest contributors to water pollution, as it generates high levels of wastewater, chemical effluents, and energy consumption. To reduce the environmental impact, several sustainable dyeing practices have been developed, including:

a) Waterless Dyeing Technologies

Supercritical CO₂ dyeing eliminates water usage in polyester dyeing.

Foam dyeing reduces water and chemical consumption.

b) Natural and Plant-Based Dyes

Derived from plants, minerals, and insects, offering eco-friendly alternatives.

Less harmful but require mordants for fixation.

c) Bio-Based Dyes and Enzymatic Processing

Biodegradable dyes and enzymes replace harsh chemicals.

Used for denim processing to minimize water use.

d) Effluent Treatment and Recycling

Zero Liquid Discharge (ZLD) plants treat and recycle wastewater.

Advanced membrane filtration and bioremediation techniques help purify effluents.

e) Low-Impact Synthetic Dyes

Certified eco-friendly dyes (OEKO-TEX, GOTS) ensure safety.

Reduce hazardous byproducts.

Conclusion

Textile dyeing and coloration play a crucial role in the fashion and textile industries, offering a wide range of color choices, effects, and fabric enhancements. The chemistry behind textile dyes and auxiliaries determines fabric performance, durability, and sustainability. With increasing awareness of environmental impact, the industry is shifting towards sustainable dyeing technologies to minimize pollution and resource consumption.

As technology evolves, innovations like waterless dyeing, bio-based dyes, and AI-driven color matching will shape the future of textile coloration, ensuring both aesthetic appeal and eco-friendliness in fabric manufacturing.

0 notes

Text

Architecture Auxiliaries

product name: Architecture Auxiliaries

Product description: RF-8508 Wetting Agent Containing Fatty Alcohol Product Description RF-8508 wetting-dispersing agent, containing fatty alcohol, can be used for wetting and dispersing of powders. It has a strong wettability and can be used as antiflooding agent for various in- dustries, such as reactive dye, disperse dye and so on. Features and Benefits Be used as a wetting- dispersing agent for the dispersion of inorganic or organic powder, the general usage is 0.8~1g/L. Be used to remove floating color of reaction and disperse dye printing fabrics, the general usage is 0.1~0.5g/L. Be used as dispersant in disperse and reducing dyes of dye bath, the general usage is 0.1~0.5g/L. Be used for dyeing pretreatment to wash oil in acrylic fibers, the general usage is 0.8~1g/L. Be used in high pressure bath dyeing process for nitrile wool blended fabrics, the general usage is about 0.5%. When used as an emulsifier, its usage is the amount of 10% by weight of the emulsified oil. For more details, please visit it https://www.ruicoglobal.com/product/auxiliaries/architecture-auxiliaries.html

0 notes

Text

https://github.com/anushka224473/TrendMosaic/blob/main/North America Printing and Dyeing Auxiliary Market Drivers And Trends.md

0 notes

Text

Top Chemical Manufacturers in Chennai: They are catalysts of Industrial Excellence

Southern India's dynamic metropolis Chennai is known for a wide industrial base. It functions as a major hub for automotive, pharmaceuticals, textiles and chemicals. Of these, the chemical manufacturing industry has done reasonably well, supporting both domestic and international markets. In this blog, we discuss the importance of the role Top Chemical manufactures in Chennai play and their contribution to industrial growth.

Role of chemical manufacturers in the industrial set up of Chennai

Chemical manufacturers in Chennai manufacture huge variety of products that are essential for various industries. These manufacturers provide solutions to industries ranging from agriculture and healthcare to electronics; from industrial chemicals to special compounds. Chennai's position as a major player in chemical manufacturing domain is credited to its ability to maintain quality and innovate.

Top Chemical Manufacturers Features

Advanced Manufacturing Facilities:

In Chennai leading chemical manufacturers focus on heavily investing on state of the art production facilities. Well equipped with modern machinery and technology, these facilities assure the production of chemicals of preferred quality, fitting to international standards.

Research and Development (R&D):

Top chemical manufacturers focus on success with innovation as its base. These companies prioritize R&D, which driving them continuously devising new products and processes thus making them market competitive.

Commitment to Quality:

Top chemical manufacturers follow strict quality control measures to improve ensuring that their products also strictly meet the stringent requirements of many industries. This is marked by awards, including ISO certificate and compliance with environmental and safety regulations.

Sustainable Practices:

Chemical manufacturers in Chennai are including sustainable practices, as environmental concerns take the front seat. These companies are following the worldwide green initiatives such as energy efficient processes and waste management.

Chemical Manufacturers in Chennai serve Major Industries such as Textile industries, Food industries and also many more.

Pharmaceuticals and Healthcare:

A steady supply of high purity chemicals is essential for Chennai’s healthy pharma sector. But at the same time, chemical manufacturers supply active pharmaceutical ingredients (API) and other complicated compounds.

Agriculture:

Fertilizers, pesticides and soil conditioners – collectively referred to as agrochemicals – are continuously used in the agricultural sector of Tamil Nadu. These products are produced by manufacturers and ensure their availability because they boost crop productivity.

Textiles and Dyeing:

Chennai textile industry is hugely dependent on chemicals for dyeing, printing and finishing processes. Dyes, pigments, and auxiliaries are supplied by manufacturers meeting this section's particular requirements.

Electronics:

As the electronics industry keeps growing in Chennai, specialty chemicals for etching, cleaning, and coating become a necessity. These needs are catered for by chemical manufacturers with precision and reliability.

This is why Chennai’s top chemical manufacturers are worth being chosen.

When compared to other chemical manufacturers in Chennai, they can be preferred for the most reliable chemical business partners who consistently meet the expectations of their clients. The sole reason why these companies make a preferred choice across industries is their ability to customize solutions and deliver the same consistently.

Conclusion

Chennai’s top chemical manufacturers Chennai are not only suppliers but also enablers of industrial excellence. They bring great socioeconomic and industrial importance to the city due to their focus on quality, sustainability and innovation. These manufacturers meet local or global demands, they reflect the spirit of progress and reliability. Partnering with leading chemical manufacturers of Chennai is certainly a great step for businesses to scale new heights.

0 notes

Text

Textile Chemicals Industry Overview and Size Forecast 2024-2032

The global textile chemicals market was valued at USD 20.67 billion in 2019 and is projected to reach USD 26.97 billion by 2027, growing at a robust CAGR of 3.5% from 2020 to 2027. Rising popularity across textile and apparel industries and robust adoption of sustainable products may propel market growth. Fortune Business Insights™ presents this information in its report titled “Textile Chemicals Market, 2024-2032.”

Segmentation

Colorant & Auxiliaries Segment to Dominate Owing to Extensive Consumption

By product type, the market is classified into coating & sizing chemicals, colorant & auxiliaries, finishing agents, surfactants, de-sizing chemicals, and others.

The colorant & auxiliaries segment is expected to dominate owing to its increasing applications. This factor is expected to dominate segmental growth.

Apparel Segment to Dominate Owing to Increasing Apparel Production

Based on application, the market is trifurcated into apparel, home furnishing, and technical textiles.

The apparel segment is expected to dominate owing to rising apparel production. Further, the growing demand for textiles from the geriatric population may enhance market progress.

Regionally, the market is clubbed into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa.

Report Coverage

The report provides a detailed analysis of the top segments and the latest trends in the market. It comprehensively discusses the driving and restraining factors and the impact of COVID-19 on the market. Additionally, it examines the regional developments and the strategies undertaken by the market's key players.

Drivers and Restraints

Rising Awareness Regarding Textile Chemistry in Manufacturing Sector to Foster Growth

Textile chemicals are utilized to treat textile materials at various manufacturing stages such as washing, scouring, mercerizing, dyeing, printing, and finishing. Increasing awareness regarding textile chemistry in manufacturing is expected to foster the demand for textile chemicals. Furthermore, rising consumer demand for enhanced functionality and quality is expected to boost textile chemicals’ sales. Moreover, the increasing awareness regarding the importance of textile chemistry is expected to drive the textile chemicals market growth.

However, the chemical's human health and environmental effects are expected to hamper the market growth.

Regional Insights

Presence of Leading Textile Manufacturers to Propel Market Progress in Asia Pacific

Asia Pacific is projected to dominate the textile chemicals market share because of the presence of several leading textile manufacturing companies in India, Vietnam, Bangladesh, Indonesia, and China. The market in Asia Pacific was valued at USD 1.55 billion in 2019 and is expected to gain a huge portion of the global market share in the upcoming years. Moreover, China's substantial production volume and value are expected to foster industry growth.

In Europe, the presence of a huge manufacturing base is expected to foster the demand for textile chemicals. The region houses nearly 1,71,000 manufacturing industries and may allow manufacturers to elevate their supply chain. This factor may propel market progress.

The market in North America is expected to dominate owing to the large export volume of textiles in the U.S. The textile industry supplies nearly 8,000 textile products to the defense sector and is responsible for market growth in the region.

Competitive Landscape

Companies Enter Agreements to Expand Market Presence

The prominent companies operating in the market enter agreements to expand their market presence. For example, Croda International entered an agreement with Microban to provide odor control and antimicrobial technologies to Indonesia and Indian industries in June 2019. Microban’s product offering includes Scentry, Scentry Revive, AEGIS, and SilverShield. The companies may explore new opportunities and expand their market presence through this development. Further, companies devise acquisitions, mergers, novel product launches, innovations, research and development, and industrial automation to enhance their annual revenues and reinforce their stance in the global market.

Get More Information: https://www.fortunebusinessinsights.com/textile-chemicals-market-103284

Key Industry Development

July 2022- As per the information provided by Swarajyamag.com, manufacturing exports are likely to touch USD 1 trillion in India. The chemical sector is the leading sector responsible for this spike in exports.

List of Key Players Profiled in the Market Report

Archroma (Switzerland)

Huntsman Corporation (U.S.)

DIC Corporation (Japan)

Kiri Industries Ltd. (India)

Covestro AG (Germany)

Omnova Solutions Inc. (U.S.)

Lubrizol Corporation (U.S.)

Solvay S.A. (Belgium)

Evonik Industries AG (Germany)

Tanatext Chemicals (Netherlands)

0 notes

Text

Essential Advantages of Textile Auxiliaries in Contemporary Fabric Processing

The textile industry is a cornerstone of modern manufacturing, producing a wide range of fabrics that meet diverse consumer needs. Behind the scenes of this dynamic industry, textile auxiliaries play a critical role in ensuring the quality, performance, and functionality of fabrics. These chemical substances, used at various stages of textile production, enhance processing efficiency, improve fabric properties, and enable innovative finishes. In this article, we will explore the essential advantages of textile auxiliaries in contemporary fabric processing and why they are indispensable in the industry.

What Are Textile Auxiliaries?

Textile auxiliaries are chemical compounds applied during different stages of fabric processing, including pre-treatment, dyeing, printing, and finishing. These substances assist in:

Improving process efficiency.

Enhancing the appearance and texture of fabrics.

Adding functional properties like water repellence or anti-microbial protection.

Examples of textile auxiliaries include wetting agents, dispersing agents, softeners, and anti-static agents, each serving a specific purpose in fabric processing.

Advantages of Textile Auxiliaries in Fabric Processing

1. Enhanced Efficiency in Pre-Treatment

Pre-treatment is a critical stage where raw fabrics are prepared for subsequent processes like dyeing or printing. Textile auxiliaries ensure thorough cleaning, uniform preparation, and optimal fabric conditioning.

Scouring Agents: Remove natural oils, waxes, and impurities from fibers.

Bleaching Agents: Achieve bright and consistent fabric whiteness, a crucial step for dye uptake.

Desizing Agents: Eliminate starches and other sizing materials used during weaving, improving fabric absorbency.

These auxiliaries streamline the pre-treatment process, reducing time and energy consumption while enhancing fabric readiness for further processing.

2. Improved Dyeing and Printing Results

Dyeing and printing are pivotal stages in textile production, where fabric gains color and design. Textile auxiliaries optimize these processes by:

Leveling Agents: Promote uniform dye penetration, preventing streaks or uneven shades.

Dispersing Agents: Stabilize dyes in the solution, ensuring consistent application.

Printing Binders: Enhance color fastness and durability in printed designs.

By ensuring precise color application and minimizing defects, textile auxiliaries contribute to vibrant, long-lasting fabrics.

3. Enhanced Fabric Finishing

Finishing is the final stage where fabrics are treated to achieve specific characteristics or enhance their performance. Textile auxiliaries play a vital role in this stage:

Softeners: Provide a smooth, soft hand feel to fabrics, enhancing comfort.

Anti-Static Agents: Reduce static build-up, particularly in synthetic fibers.

Water Repellents: Impart water resistance, ideal for outdoor and sportswear applications.

Anti-Microbial Agents: Inhibit bacterial growth, promoting hygiene in medical textiles or activewear.

These specialized treatments add significant value to fabrics, aligning them with consumer preferences and functional requirements.

4. Environmental Benefits with Sustainable Auxiliaries

The textile industry faces growing scrutiny over its environmental impact. Modern textile auxiliaries are increasingly designed to be eco-friendly, supporting sustainable manufacturing practices.

Low-Impact Chemicals: Reduce water and energy usage during processing.

Biodegradable Auxiliaries: Minimize environmental harm by breaking down naturally.

Efficient Processes: Enable shorter cycles, lowering the carbon footprint of textile production.

Sustainable textile auxiliaries not only meet regulatory standards but also appeal to environmentally conscious consumers.

5. Enhanced Fabric Properties and Versatility

Textile auxiliaries enable fabrics to achieve properties that cater to specific industries and applications. For example:

Flame Retardants: Provide fire resistance, essential in protective clothing and home textiles.

UV Protectants: Block harmful ultraviolet rays, ideal for outdoor garments.

Wrinkle-Free Agents: Enhance fabric resilience, ensuring a polished appearance after use.

These functional benefits make textile auxiliaries indispensable for producing high-performance fabrics.

6. Cost-Effective Production

By improving process efficiency and reducing material waste, textile auxiliaries contribute to cost-effective manufacturing. Faster processing times, reduced energy usage, and fewer defects translate to significant savings for textile producers.

The Future of Textile Auxiliaries

Innovation continues to shape the role of textile auxiliaries in the industry. Advancements include:

Smart Auxiliaries: Chemicals that respond to environmental changes, such as self-healing fabrics.

Digital Printing Enhancers: Auxiliaries designed for precise digital printing techniques.

Bio-Based Auxiliaries: Derived from renewable resources, aligning with green manufacturing goals.

As consumer demands evolve and sustainability becomes paramount, textile auxiliaries will remain at the forefront of fabric innovation.

Conclusion

Textile auxiliaries are the unsung heroes of fabric processing, offering unmatched advantages in efficiency, quality, and functionality. From pre-treatment to finishing, they ensure fabrics meet the highest standards of performance and aesthetics.

In a competitive industry driven by innovation and sustainability, textile auxiliaries are integral to producing fabrics that align with consumer expectations and environmental goals. By embracing advanced and eco-friendly auxiliaries, the textile industry continues to push the boundaries of what’s possible in fabric production.

0 notes

Text

Textile Chemicals Market Growth Trends and Key Opportunities for Sustainable Fabric Production by 2030

The textile chemicals market is evolving rapidly, driven by the rising demand for high-quality, functional, and sustainable fabrics. The textile chemicals market, a key enabler of fabric processing and performance enhancement, is witnessing significant transformation with increasing emphasis on eco-friendly solutions. As we look ahead to 2030, understanding the growth trends and key opportunities in this sector is essential for industry players aiming to stay competitive and environmentally responsible.

Market Growth Trends

1. Surge in Demand for Sustainable Chemicals

With heightened awareness of environmental concerns, the textile industry is shifting towards sustainable chemical formulations. Consumers and regulatory bodies are pushing for bio-based, non-toxic, and biodegradable textile chemicals, reducing the ecological footprint of textile manufacturing. Waterless dyeing technologies and enzymatic treatments are becoming more prevalent, reducing water and energy consumption.

2. Technological Advancements in Textile Processing

Innovations such as nanotechnology, smart textiles, and advanced polymer coatings are revolutionizing fabric performance. Antimicrobial finishes, stain resistance, and self-cleaning properties are gaining traction, increasing the need for specialized textile chemicals. Digital printing technology is also expanding, requiring advanced colorants and treatment chemicals for better print durability.

3. Stringent Environmental Regulations

Governments worldwide are implementing stringent environmental policies to regulate hazardous chemicals in textile production. The European Union’s REACH regulations and initiatives such as the Zero Discharge of Hazardous Chemicals (ZDHC) program are pushing manufacturers to develop greener alternatives. Compliance with such norms is not only necessary but also an opportunity for chemical manufacturers to gain a competitive edge.

4. Growing Adoption of Circular Economy Practices

The concept of a circular economy—where products are designed for longevity, reuse, and recyclability—is gaining momentum. The demand for chemical recycling solutions and biodegradable auxiliaries is rising, prompting companies to invest in sustainable formulations. Textile chemicals that facilitate fiber recovery and regeneration will play a pivotal role in shaping the industry’s future.

5. Expansion in Emerging Markets

The Asia-Pacific region, led by countries such as China, India, and Bangladesh, is witnessing robust growth in textile production, driving demand for textile chemicals. The increasing focus on industrialization, coupled with government support for the textile sector, is fueling market expansion. Additionally, as these countries adopt sustainable practices, the demand for eco-friendly textile chemicals is expected to surge.

Key Opportunities for Sustainable Fabric Production

1. Development of Bio-Based and Non-Toxic Chemicals

One of the most promising opportunities lies in the development of bio-based textile chemicals derived from renewable sources. Plant-based dyes, biodegradable finishing agents, and natural enzyme treatments offer a sustainable alternative to conventional chemicals while enhancing fabric properties. Companies investing in green chemistry solutions will gain a strong market position.

2. Innovation in Waterless and Low-Impact Processing Techniques

Water scarcity concerns have intensified the need for water-efficient and dry processing technologies. Supercritical CO2 dyeing, plasma treatments, and foam finishing techniques are emerging as viable solutions to minimize water usage and chemical waste. Investing in such innovations can drive profitability while aligning with sustainability goals.

3. Adoption of Digital Printing and Smart Finishing

Digital textile printing is revolutionizing the industry by reducing dye and water consumption. Advanced pretreatment and fixation chemicals that enhance digital print quality and durability present a lucrative market opportunity. Additionally, the rise of smart textiles—fabrics embedded with electronic functionalities—calls for specialized coatings and conductive textile chemicals.

4. Collaboration with Fashion Brands for Sustainability Initiatives

Global fashion brands are actively seeking partnerships with chemical manufacturers to create sustainable supply chains. Collaborations focusing on reducing carbon footprints, eliminating hazardous chemicals, and achieving closed-loop production can lead to mutual growth. Companies that align with sustainability commitments will attract more business from conscious fashion brands.

5. Expansion of Eco-Certified and Transparent Supply Chains

Eco-labeling and transparency in chemical sourcing are becoming key differentiators in the market. Certifications such as OEKO-TEX, GOTS (Global Organic Textile Standard), and Bluesign help companies establish credibility. Investing in traceable supply chain solutions and obtaining eco-certifications will enhance consumer trust and marketability.

Conclusion

The textile chemicals market is undergoing a transformative shift towards sustainability, driven by regulatory mandates, technological advancements, and consumer demand for eco-friendly products. Companies that embrace bio-based chemicals, invest in green technologies, and collaborate with sustainability-focused brands will emerge as industry leaders. By leveraging key opportunities and staying ahead of market trends, stakeholders can ensure long-term growth while contributing to a greener textile future. As we approach 2030, the integration of sustainable textile chemicals will be a crucial determinant of success in the evolving fabric production landscape.

0 notes

Text

Smart Textile Auxiliaries Chemicals for Advanced Fabric Technologies

The textile industry is undergoing a remarkable transformation as innovation and technology converge to create smarter, more versatile fabrics. At the core of this revolution are textile auxiliaries chemicals, which play a pivotal role in enhancing the functionality and performance of textiles. From self-cleaning fabrics to temperature-regulating garments, the use of smart textile auxiliaries is driving advanced fabric technologies to meet the demands of a modern, tech-savvy world.

What Are Smart Textile Auxiliaries Chemicals?

Textile auxiliaries chemicals are specialty chemicals used at various stages of textile production, including pre-treatment, dyeing, printing, and finishing. Smart textile auxiliaries take this a step further by enabling advanced functionalities in fabrics, such as moisture management, UV protection, antibacterial properties, and even electronic conductivity.

Unlike traditional chemicals that focus solely on improving the aesthetics or durability of fabrics, smart textile auxiliaries are designed to impart innovative properties that address specific consumer needs and industry challenges. These chemicals are essential in developing fabrics for sectors like healthcare, sportswear, automotive, and wearable technology.

Key Applications of Smart Textile Auxiliaries Chemicals

Smart textile auxiliaries chemicals are instrumental in a wide range of advanced fabric technologies. Here are some notable applications:

1. Temperature Regulation

Smart textiles equipped with temperature-regulating properties are becoming increasingly popular, especially in sportswear and outdoor clothing. Phase-change materials (PCMs), enabled by specialized textile auxiliaries chemicals, can absorb, store, and release heat, helping to maintain a stable body temperature. These fabrics ensure comfort in extreme weather conditions and are particularly valuable for active lifestyles.

2. Moisture Management

For sports and fitness enthusiasts, moisture-wicking fabrics are a game-changer. Smart auxiliaries chemicals enhance the hydrophilic or hydrophobic properties of fibers, allowing fabrics to efficiently draw moisture away from the skin. This technology not only keeps wearers dry but also improves comfort and performance during physical activities.

3. Antibacterial and Antimicrobial Properties

Hygiene has become a significant concern, especially in healthcare and hospitality sectors. Smart textile auxiliaries chemicals impart antibacterial and antimicrobial properties to fabrics, preventing the growth of harmful microorganisms. This technology is widely used in medical textiles, activewear, and home furnishings, contributing to a cleaner and healthier environment.

4. UV Protection

UV-protective clothing is another area where smart textile auxiliaries chemicals shine. By integrating UV-blocking agents during the finishing process, fabrics can effectively shield wearers from harmful UV radiation. This innovation is particularly beneficial for outdoor apparel and protective workwear.

5. Self-Cleaning Textiles

Self-cleaning fabrics, powered by smart auxiliaries chemicals, are a revolutionary advancement in the textile industry. By utilizing nanotechnology, these chemicals enable fabrics to repel dirt, stains, and even liquids. This reduces the need for frequent washing, making the fabrics more sustainable and cost-effective.

6. Conductive Fabrics for Wearable Technology

The rise of wearable technology has created a demand for fabrics with electronic conductivity. Smart textile auxiliaries chemicals facilitate the integration of conductive materials like silver or carbon fibers into textiles, enabling functionalities such as sensors, data transmission, and energy storage. These fabrics are at the forefront of innovations in healthcare monitoring, fitness tracking, and smart clothing.

Benefits of Smart Textile Auxiliaries Chemicals

The use of smart textile auxiliaries chemicals offers several benefits for manufacturers, consumers, and the environment:

Enhanced Performance: These chemicals provide fabrics with cutting-edge features that cater to specific needs, from moisture control to electronic conductivity.

Sustainability: Many smart auxiliaries reduce water and energy consumption during production and extend the lifespan of fabrics, contributing to more sustainable practices.

Versatility: With applications across diverse industries, these chemicals allow manufacturers to create customized fabrics for different markets.

Consumer Satisfaction: Smart textiles improve user experience by offering comfort, safety, and convenience.

Challenges in Smart Textile Auxiliaries Development

Despite their potential, developing and implementing smart textile auxiliaries chemicals is not without challenges. High production costs, compatibility with existing manufacturing processes, and concerns about long-term durability are some of the hurdles the industry faces. Moreover, ensuring that these chemicals meet environmental and safety regulations is critical for widespread adoption.

The Future of Smart Textile Auxiliaries Chemicals

The future of textile auxiliaries chemicals lies in continued innovation and collaboration across industries. As demand for advanced fabric technologies grows, researchers are exploring new frontiers such as bio-based chemicals, nanotechnology, and AI-driven design processes. These advancements will further enhance the functionality, sustainability, and affordability of smart textile auxiliaries.

The integration of IoT (Internet of Things) with textiles is another exciting development. Imagine clothing that not only adapts to your body temperature but also tracks your health metrics and connects to your smartphone. Such innovations, powered by smart auxiliaries chemicals, are set to redefine the textile landscape.

Conclusion

Smart textile auxiliaries chemicals are at the heart of advanced fabric technologies, enabling innovations that were once considered science fiction. From temperature-regulating sportswear to self-cleaning uniforms, these chemicals are revolutionizing the textile industry by adding value and functionality to everyday fabrics. As the demand for smarter, more sustainable textiles continues to rise, the role of these chemicals will become even more significant.

For manufacturers and consumers alike, embracing the potential of smart textile auxiliaries chemicals is not just an option—it’s the future. By leveraging these technologies, the textile industry is poised to meet the evolving needs of a dynamic and forward-thinking market.

0 notes