#Processefficiency

Explore tagged Tumblr posts

Text

Pearl Organisation: A Leading ERP Development Company in India Empowering Businesses with Intelligent Solutions

In today’s fast-paced business world, efficiency is key — and that’s where ERP systems make a difference. Pearl Organisation is a trusted ERP development company in India, delivering scalable, secure, and fully customized ERP solutions tailored to your business goals. Our ERP systems are designed to integrate core business functions — including finance, inventory, HR, sales, and supply chain — into a single, easy-to-manage platform. Whether you’re a manufacturing firm, retail chain, service provider, or enterprise, our solutions are built to streamline operations, improve decision-making, and reduce manual workloads. With in-depth industry experience and technical expertise, we develop ERP platforms that grow with your business and give you a competitive edge.

#ERPDevelopmentCompanyInIndia#PearlOrganisation#EnterpriseSoftwareSolutions#CustomERPDevelopment#BusinessAutomation#ProcessEfficiency#IntegratedERPSystems#IndiaTechExperts

0 notes

Text

Why Digital TCard Systems are Key to Effective Layered Process Audits in Manufacturing?

For more insights read our Article

#lts#leansolution#leantools#tcard#tcardsoftware#tcards#digitaltcard#tcardonline#LayeredProcessAudits#LayeredProcessAuditsinManufacturing#ProcessAudits#layeredprocessauditsexamples#layeredprocessauditchecklist#layeredauditchecklist#layerprocessauditplan#layeredprocessauditsteps#processauditsexamples#typesofprocessaudits#LayeredProcessAuditingfortheShopFloorManagement#LayeredprocessauditimplementationwithdigitalTCard#DigitalWorkflowforScheduling#DigitalWorkflowforTracking#CustomisableDigitalChecklists#RealTimeDataCollection#RealTimeDataAnalysis#LPAAudits#LPAImplementation#ProcessEfficiency#DigitalAuditTools#LeanProcessAudit

0 notes

Text

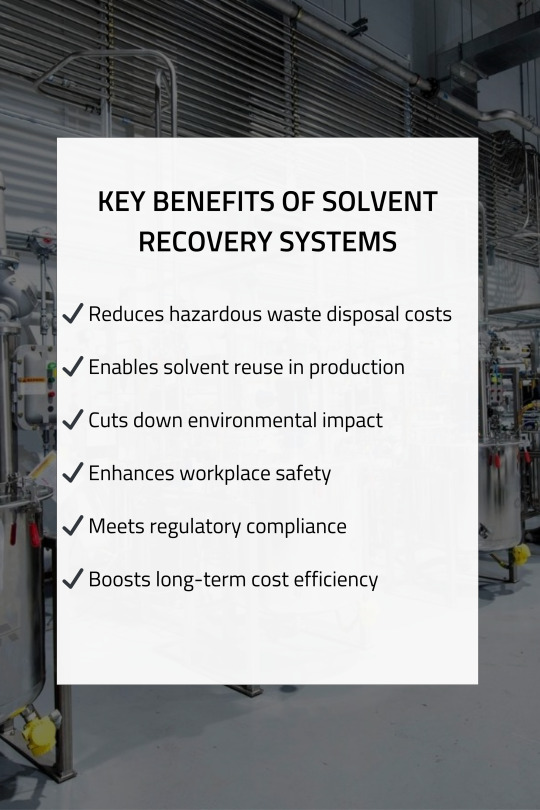

Cut Costs with a Solvent Recovery System

A solvent recovery system helps reduce waste, cut costs, and improve sustainability for industries managing solvents daily.

Learn more: Solvent Recovery System

0 notes

Text

Mandate Management Services – Efficient Digital Processing by Intelics

📝 Description: Discover Intelics’ Mandate Management Services that automate and simplify mandate registration, verification, and processing. Enhance compliance, reduce turnaround time, and ensure secure, seamless operations for banks, NBFCs, and financial institutions with our robust digital solutions.

🔑 Keywords: mandate management services, digital mandate processing, ECS mandate registration, NACH mandate management, Intelics solutions, compliance automation, financial technology services, banking process automation, fintech compliance, operational efficiency

#MandateManagement#Intelics#DigitalProcessing#FintechSolutions#ComplianceAutomation#BankingTech#NACHMandate#ECSMandate#FinancialServices#ProcessEfficiency

0 notes

Text

#InformationCloud#DigitalWorkflows#CloudAutomation#SmartEnterprise#ProcessEfficiency#DataIntegration#CloudSolutions#RealTimeDecisions#ProphecyTechs#BusinessAgility#IntelligentOperations#DigitalTransformation

1 note

·

View note

Text

Why is a Jacketed Mixing Tank Essential for Your Process Industry?

In industries that require precision mixing with temperature control—such as food processing, pharmaceuticals, cosmetics, and chemicals—the jacketed mixing tank plays a crucial role. This specialized equipment enables both efficient mixing and accurate heating or cooling, helping maintain product quality and process consistency.

What is a Jacketed Mixing Tank?

A jacketed mixing tank is a vessel designed with a double-wall structure. The inner tank holds the materials being mixed, while the outer jacket allows a fluid (such as hot water, steam, or cooling agents) to circulate. This design makes it possible to control the temperature of the product during the mixing process.

Key Features of a Jacketed Mixing Tank

Temperature Control: Allows for uniform heating or cooling during mixing operations.

High-Quality Material: Typically made of stainless steel (SS304 or SS316) to meet hygiene and durability standards.

Agitator Options: Equipped with customized agitators to suit various viscosities and mixing requirements.

Hygienic Design: Smooth welds and sanitary finishes make cleaning and maintenance easy.

Capacity Options: Available in various sizes for small-scale to industrial-level production.

Applications of Jacketed Mixing Tanks

Jacketed mixing tanks are widely used in:

Food and Beverage Industry: For preparing sauces, chocolate, milk-based products, and beverages.

Pharmaceutical Industry: In the production of syrups, creams, and suspensions that require precise temperature control.

Chemical Processing: For blending ingredients in exothermic or endothermic reactions.

Cosmetic Manufacturing: In mixing lotions, gels, and creams that need consistent texture and formulation.

Benefits of Using a Jacketed Mixing Tank

Improved Process Efficiency Reduces batch time and enhances mixing performance.

Better Product Quality Ensures homogeneous blending and prevents temperature-related inconsistencies

Energy Savings Optimizes heat transfer and reduces energy consumption.

Versatile and Customizable Suits a wide range of industries and can be tailored to specific production needs.

If your business depends on reliable, temperature-controlled mixing, a jacketed mixing tank is an essential investment. With a range of capacities and features, it’s a solution built for performance, quality, and efficiency.

J P Sons Engineering is a trusted manufacturer of industrial process equipment, offering top-of-the-line jacketed mixing tanks designed to meet the diverse needs of industries. With a focus on quality, customization, and client satisfaction, they deliver solutions that are both cost-effective and durable.

Ready to Invest in a Jacketed Mixing Tank?

Explore high-quality options from J P Sons Engineering – built for precision, durability, and custom fit to your process.

#JacketedMixingTank#ProcessIndustry#IndustrialMixing#MixingTankBenefits#ProcessEquipment#IndustrialProcessing#ManufacturingSolutions#MixingTechnology#IndustrialTanks#ProcessEfficiency#MixingEquipment#ChemicalProcessing#PharmaIndustry#FoodProcessing#EngineeringSolutions

0 notes

Text

#PowerApps#LowCodeSolutions#BusinessAutomation#DigitalTransformation#CustomApps#WorkflowAutomation#ProductivityBoost#NoCodeTools#AppDevelopment#MicrosoftPowerApps#BusinessSolutions#TechInnovation#SmartBusiness#ProcessEfficiency#ModernWorkplace

0 notes

Text

Transform Your Business with Smart Automation

🌐 Website: https://pillaiyar.in 📧 Email: [email protected] 📞 Phone: +91 78618-84915, +91 99746-85255 📍 Address: Pillaiyar Innovations Private Limited 602, 603A, Central Business Space, Usmanpura, Ahmedabad, Gujarat – 380013, India

In today’s fast-paced business environment, efficiency is everything. At Pillaiyar Innovations Private Limited, we help businesses unlock their true potential through Business Process Automation (BPA). Our tailored automation solutions reduce manual tasks, eliminate errors, and streamline your workflows—so your team can focus on what really matters: growth and innovation.

Whether you're a startup or an enterprise, our expert team leverages advanced technology to automate finance, HR, customer management, compliance, and more. With BPA, you not only save time but also gain deeper insight into your operations, enabling data-driven decisions and sustainable scaling.

Located in the heart of Ahmedabad, we serve clients across India with dedication, transparency, and proven results. Experience the future of productivity with Pillaiyar.

📲 Ready to automate and elevate your business? Contact us today for a free consultation and see how Pillaiyar can transform your processes.

#BusinessProcessAutomation#PillaiyarInnovations#SmartBusinessSolutions#AutomateWithPillaiyar#DigitalTransformationIndia#ProcessEfficiency#PillaiyarAutomation#WorkSmarter#TechForBusiness

0 notes

Text

⛽🌍 Get ISO Certified for the Oil & Gas Industry! ✅

Ensure Safety, Quality & Sustainability in Oil & Gas Operations!

ISO Certification helps oil & gas companies: ✔️ Enhance operational efficiency & process safety ⚙️ ✔️ Ensure environmental compliance & sustainability 🌱 ✔️ Mitigate risks & improve workplace safety 🛑 ✔️ Meet international regulatory & industry standards 🌍 ✔️ Boost stakeholder confidence & business growth 📈

🚀 Strengthen Compliance & Drive Excellence in the Oil & Gas Industry!

📩 Get Certified Today!

#OilAndGasIndustry#ISOCertification#QualityStandards#SafetyFirst#EnvironmentalCompliance#ProcessEfficiency#RiskManagement#GetCertified

0 notes

Text

Nigeria, Indonesia, and Turkey: The New Frontiers for Oscillating Granulators Market Players

Nigeria, Indonesia, and Turkey are rapidly emerging as high-growth markets within the global Oscillating Granulators industry. With the market currently valued at $439.5 million, these three countries are forecasted to experience compound annual growth rates (CAGR) ranging from 6.1% to 8.7% between 2025 and 2030. This surge is primarily driven by rising demand in pharmaceutical manufacturing and food processing—two industries where granulators are essential for precision granulation and particle size control.

Check detailed insights here - https://datastringconsulting.com/industry-analysis/oscillating-granulators-market-research-report

Expanding Role in Food and Pharmaceutical Sectors

Oscillating granulators are widely utilized in the food processing sector to ensure uniform particle sizes during the size reduction and sieving phases. These machines help maintain the physical integrity of food products during granulation, offering efficiency without compromising quality. Prominent industry names such as GEA Group and Sotuken have successfully integrated oscillating granulators into their food production lines to meet stringent quality standards.

In the pharmaceutical industry, oscillating granulators play a critical role in the formulation process. They ensure consistent granule size for tablet compression and capsule filling, a necessity for dose accuracy and stability. The rising focus on automation and compliance with Good Manufacturing Practices (GMP) continues to propel adoption.

Technological Advancements Driving Efficiency

The global oscillating granulators market is undergoing a digital transformation. The integration of programmable logic controllers (PLCs) has significantly enhanced machine performance. These controllers allow operators to regulate oscillation speed, frequency, and timing with high precision, reducing manual intervention and streamlining production. Moreover, the growing adoption of AI and machine learning in pharmaceutical and chemical granulation processes is optimizing outcomes and enabling predictive maintenance, which enhances machine longevity and minimizes downtime.

Global and Regional Growth Trends

From a global perspective, the Oscillating Granulators market is projected to grow from $439.5 million in 2024 to $1,056.5 million by 2035, reflecting a robust CAGR of 8.3%. North America remains a dominant force in the market, driven by its high-tech pharmaceutical and chemical sectors. The region's demand is shaped by increasing automation, focus on energy-efficient equipment, and the need for compact, high-speed granulators that align with waste reduction goals.

However, competition in North America is intense, with well-established players setting high performance and compliance benchmarks. New entrants face challenges in breaking into the market due to these elevated standards and entrenched supplier relationships.

Industry Landscape and Innovation

Key manufacturers—including GEA Group, SaintyCo, The Elizabeth Companies, Alexanderwerk, Cadmach Machinery, Frewitt Fabrique de machines SA, Chamunda Pharma Machinery, SOTAX Group, and Kevin Process Technologies Pvt. Ltd.—are actively innovating to capture market share. Strategic collaborations, investment in R&D, and an increasing focus on smart granulation systems are key approaches adopted to stay competitive.

Market Segmentation and Use Cases

Oscillating granulators are segmented by product types (horizontal and vertical), applications (pharmaceutical, chemical & fertilizer, food & beverage), and technology types (mechanical and digital). End-users range from research laboratories and pharmaceutical manufacturers to food processing units, reflecting the versatile utility of these machines across industries.

About DataString Consulting

DataString Consulting provides deep market intelligence and strategic insights that help organizations craft successful business roadmaps. With over three decades of combined experience in market research and strategy advisory, DataString supports companies in expanding into new territories, growing their total addressable markets, and diversifying revenue streams. With continuous monitoring across more than 15 industries and 60 sub-sectors, DataString helps businesses cut through the noise and discover new opportunities for innovation, growth, and market penetration.

#OscillatingGranulators#PharmaceuticalMachinery#FoodProcessingEquipment#GranulationTechnology#EmergingMarkets#NigeriaBusiness#IndonesiaIndustry#TurkeyManufacturing#PharmaInnovation#SmartManufacturing#IndustrialAutomation#AIinManufacturing#MachineLearning#ProcessEfficiency#DataStringConsulting#GlobalMarkets#TechInFood#AutomationSolutions#MarketResearch#GrowthMarkets

0 notes

Text

#NORD Drivesystems#PackagingSolutions#SmartDrives#IndustrialAutomation#ProcessEfficiency#MotionControl#EnergyEfficiency#ManufacturingExcellence#Industry40#SmartPackaging#DriveTechnology#electricvehiclesnews#evtimes#autoevtimes#evbusines

0 notes

Text

#NORD Drivesystems#PackagingSolutions#SmartDrives#IndustrialAutomation#ProcessEfficiency#MotionControl#EnergyEfficiency#ManufacturingExcellence#Industry40#SmartPackaging#DriveTechnology#electronicsnews#technologynews

0 notes

Text

How can value stream mapping help in identifying waste and how TCard helps

Learn how Value Stream Mapping identifies waste and how TCards streamline workflows. Discover real-time monitoring, task tracking, and customised solutions to optimise processes and eliminate bottlenecks efficiently.

For more details read our blog :

#ValueStreamMapping#TCards#IdentifyWaste#WasteElimination#WorkflowManagement#TaskTracking#ProcessEfficiency#BottleneckAnalysis#ContinuousImprovement#LeanManagement

0 notes

Text

Thermocouples vs. RTDs: Which One is Right for You? 🌡️

Temperature control is crucial in industries like metallurgy, food processing, and chemical manufacturing. But should you go for thermocouples or RTDs (Resistance Temperature Detectors)? 🤔

Thermocouples respond quickly and withstand extreme conditions, making them great for high-heat environments. Meanwhile, RTDs deliver higher accuracy and stability for precise temperature monitoring in sensitive applications. 🔥❄️

If you’re looking for reliable industrial temperature sensors that fit your needs, find out which one works best for your processes!

#TemperatureControl#IndustrialSensors#Thermocouples#RTDs#ProcessEfficiency#IndustrialSolutions#AutomationSolutions#MechanicalSolutions#ElectricalSolutions#FastCal#PLC#SCADA#ControlPanelDesign

0 notes

Text

Writer’s UiPath RPA Services – Automate Business Processes with Intelligent Bots

Writer’s UiPath RPA Services empower organizations to automate rule-based, repetitive tasks using software robots. From invoice processing and data entry to report generation and compliance workflows, UiPath bots deliver speed, accuracy, and 24/7 availability. With seamless integration and scalability, this solution is ideal for finance, HR, IT, and operations teams seeking cost efficiency and digital transformation. UiPath RPA, Robotic Process Automation, Intelligent Bots, Writer Information, Workflow Automation, Business Process Digitization, Invoice Automation, HR Bots, RPA for IT, Scalable Automation, Process Efficiency, Task Automation

0 notes

Text

Vertical Glue Mixer: Efficient and Uniform Adhesive Mixing for Plywood Manufacturing

In the constantly changing era of plywood production, precision and efficiency are of utmost importance. One of the most important elements of the process is achieving a consistent adhesive mixture for gluing plywood layers together. This is where the Vertical Glue Mixer is of great use. As a leading manufacturer of plywood machinery, we understand the importance of a reliable and efficient glue mixing system, which is why our Vertical Glue Mixers are designed to deliver top-notch performance, ensuring consistent results every time.

What is a Vertical Glue Mixer?

Vertical Glue Mixer is an industrial machine for mixing glue and adhesives evenly during plywood production. Compared to common horizontal mixers, a vertical glue mixer runs along a vertical axis, and this has many advantages in the context of efficiency and evenness. Vertical glue mixers are specifically suited to large quantities of adhesive, allowing constant viscosity and the right mix of the ingredients in the glue.

Why Select a Vertical Glue Mixer for Plywood Manufacturing?

1. Consistent Adhesive Blending

The greatest benefit of a Vertical Glue Mixer is that it can create a very uniform adhesive blend. The vertical structure enables improved distribution and mixing of the glue ingredients, which ensures that there are no clumps or inconsistencies left behind. This results in an even application of adhesive on the plywood surfaces, enhancing the quality of the end product.

2. High-Efficiency Operation

The vertical and compact design of the mixer conserves precious floor space, which is important in industrial environments where room space is frequently at a premium. Even with its reduced footprint, the Vertical Glue Mixer provides high efficiency, mixing large volumes of glue in less time than traditional mixers. This higher productivity can have a substantial impact on cutting down overall production time.

3. Energy Savings

Vertical Glue Mixers are optimized to use less power but achieve the best mixing performance. Reducing power usage helps manufacturers reduce operational expenses and make their production process more sustainable.

4. Versatility and Adaptability

Our Vertical Glue Mixers are flexible and are compatible with a variety of adhesive types. Regardless of whether you're working with phenolic, urea formaldehyde, or melamine type adhesives, this equipment can process an array of glue types, making your production never off track due to adhesive specifications.

5. Less Downtime and Maintenance

Our Vertical Glue Mixers are designed to last with minimal maintenance requirements. The rugged yet uncomplicated design makes it operate reliably with lower downtime. Easy maintenance is a given, which results in less interruption of your manufacturing schedule and more time on actual manufacturing.

Key Features of Our Vertical Glue Mixers

• Efficient Mixing Mechanism: Designed for rapid and uniform mixing to deliver the ideal adhesive mix consistently.

•Heavy-Duty Construction: Constructed to withstand high levels of glue with accuracy, providing improved durability and performance.

•User-Friendly Interface: Developed for simplicity, reducing the learning process and errors.

•Safety Features: Fitted with sophisticated safety features to provide a secure working environment for operators.

Why Trust Us for Your Plywood Machinery Needs?

As a major plywood machinery manufacturer, we pride ourselves on delivering innovative solutions that address the needs of contemporary plywood production. Our Vertical Glue Mixers are designed to operate with optimal efficiency, reliability, and consistency, so your plywood production process is trouble-free right from the beginning to the end.

Our professional staff is available around the clock to help you choose, install, and provide after-sales services for machines. We recognize that every factory has specific needs, and we personalize our machinery to meet your precise requirements, guaranteeing you top-notch results each time.

Conclusion

The Vertical Glue Mixer is the revolutionary solution to the plywood manufacturing industry, which offers effective and consistent adhesive mixing that is the key to producing high-quality outputs. With our cutting-edge technology, you are able to maximize productivity, cut costs, and maintain consistency for all your plywood products. Buy a Vertical Glue Mixer now and take your plywood manufacturing process to the next level.

To learn more about our Vertical Glue Mixers and other plywood machine solutions, call DNH Engineers or go online to our website www.dnhengineers.com Streamline your operation and increase your business success with our leading technology.

#VerticalGlueMixer#EfficientMixing#UniformAdhesiveMixing#GlueMixing#MixingTechnology#ManufacturingInnovation#AdhesiveSolutions#ProductivityBoost#IndustrialMixing#HighPerformanceMixer#MixingEquipment#EfficientManufacturing#EngineeringExcellence#GlueApplication#HomogeneousMix#QualityAdhesives#MixerDesign#PrecisionMixing#ProcessEfficiency#AdhesivePerformance

0 notes