#RFID Textile Management

Explore tagged Tumblr posts

Text

Best NFC Bracelet Maker in China – Trusted by Many | ZDCARDTECH

What Is NFC and Why Is It Cool?

Have you ever paid for something without cash or a card? That’s thanks to NFC Tag Factory, which stands for Near Field Communication. It lets things like phones, cards, and even bracelets talk to each other when they are very close. It’s quick and easy!

Why Are NFC Bracelets So Popular?

NFC bracelets are smart bracelets that can do many things. Here’s why people like them:

Easy to Use – You can keep information on them and use it just by tapping.

Fast Payments – You can pay in stores without money or cards.

Event Entry – Get into concerts or places quickly.

Custom Looks – They come in fun colors, designs, and materials!

Looking for the Best NFC Bracelets in China?

Don’t worry – ZDCARDTECH has you covered! We are one of the top makers of NFC Bracelets Manufacturer in China. Here’s why people trust us:

Strong and Long-Lasting – Made with tough materials.

Smart Chips – Uses the latest NFC tech to work faster.

Custom Made – Add your name, logo, or colors!

Big Orders Welcome – Great prices even when you buy a lot.

What Can NFC Bracelets Be Used For?

They’re not just for fun! These smart bracelets help in many places:

Hospitals – Help find the right patient and info.

Buses and Trains – Tap and ride easily.

Shops – Get rewards when you buy things.

Company Events – Make events more fun and easy to join.

Common Questions Kids Might Ask:

1. What is an NFC bracelet? It’s a bracelet that can hold information and connect with other devices just by tapping.

2. How does it work? Two things with NFC talk to each other when they get really close – like a secret handshake!

3. Can I make it look how I want? Yes! At ZDCARDTECH, we can make them in your favorite color or with your school or team’s logo.

4. Are they okay in water? Yep! They’re waterproof and super strong.

5. Can we buy a lot at once? Yes, we can sell many at a time. Just ask us and we’ll help.

Why Pick ZDCARDTECH?

We know all about NFC! People around the world trust us because our bracelets are smart, strong, and easy to use. Whether it’s for fun, shopping, or school, we have the best ones for you!

#rfid card manufacturer#nfc bracelets manufacturer#rfid tag manufacturer#nfc tag factory#rfid textile management

0 notes

Text

What Is The Best ERP System For Manufacturing Companies In 2025?

As we step into 2025, the manufacturing industry is under more pressure than ever to streamline operations, cut costs, and deliver faster—without compromising quality. To achieve this, more manufacturers are turning to Best ERP System for Manufacturing that can automate workflows, centralize data, and boost efficiency.

But with so many ERP providers out there—SAP, Oracle, Microsoft Dynamics, Odoo, and more—the real question is: Which ERP system is best for manufacturing companies in 2025? Let’s explore the answer—and why Elitemindz ERP is emerging as a top choice in India and beyond.

Why ERP Systems Are Essential in Modern Manufacturing

Manufacturing is complex—raw materials, production lines, inventory levels, suppliers, customer orders, logistics, compliance, and finances—all need to be managed in sync.

Traditional tools like spreadsheets, standalone apps, or legacy systems can’t handle the real-time demands of modern manufacturing. That’s where a comprehensive ERP (Enterprise Resource Planning) system comes in.

Key Challenges Manufacturers Face Without ERP:

Production delays due to poor planning

Overstocking or raw material shortages

Lack of real-time visibility into inventory or performance

Manual errors in financial and quality reports

Poor coordination between departments

What Makes an ERP the “Best” for Manufacturers in 2025?

Not all ERP software is created equal. The best ERP system for manufacturing in 2025 must include:

1. Production Planning & Scheduling

Intelligent tools to manage work orders, machine utilization, batch tracking, and shift-based production.

2. Real-Time Inventory Management

Track raw materials, WIP (work in progress), and finished goods with barcode/RFID integration.

3. Supply Chain Coordination

Procurement automation, vendor management, and delivery tracking from one dashboard.

4. Quality Control & Compliance

Automated QC workflows, audit trails, batch recalls, and regulatory compliance reports.

5. Integrated Finance & Reporting

GST-ready financials, costing, payroll, invoicing, and real-time reporting dashboards.

6. Customization & Scalability

Adaptable modules based on your industry—FMCG, electronics, pharma, textiles, etc.

7. Mobile Access & Cloud Hosting

Access ERP on the shop floor, in warehouses, or remotely through secure cloud or mobile apps.

Why Elitemindz ERP Is Among the Best ERP Systems for Manufacturers in 2025

Elitemindz has developed a powerful, feature-rich ERP solution designed specifically for manufacturing companies in India and globally. It combines advanced functionality with industry-specific customization.

Top Reasons to Choose Elitemindz ERP:

Tailored Modules for discrete and process manufacturing

AI-powered analytics for forecasting, cost control, and performance tracking

Mobile-first design for real-time factory and warehouse operations

Easy integration with existing legacy systems

Cloud-based or on-premise deployment as per your IT policy

Affordable pricing and fast implementation timelines

Success Snapshot: A Real Manufacturer’s Journey

A mid-size automotive parts manufacturer in Pune implemented Elitemindz ERP in early 2024. They achieved:

42% faster production cycles

30% reduction in material wastage

Full real-time inventory visibility

50% fewer quality-related complaints

This real-world case proves that Elitemindz ERP delivers measurable ROI, fast.

Final Thoughts

Choosing the best ERP system for manufacturing in 2025 depends on your business size, industry needs, and growth plans. However, if you’re looking for a scalable, AI-powered, customizable, and affordable ERP, Elitemindz ERP is a solution worth exploring.

#BestERPSystem#ManufacturingERP#ERPForManufacturing#ERPSoftware#ManufacturingSolutions#SmartManufacturing#DigitalManufacturing#ManufacturingTech

0 notes

Text

Active and Passive RFID Tags Market : Industry Analysis, By Key Players, Segmentation, Application, and Global Forecast to 2032

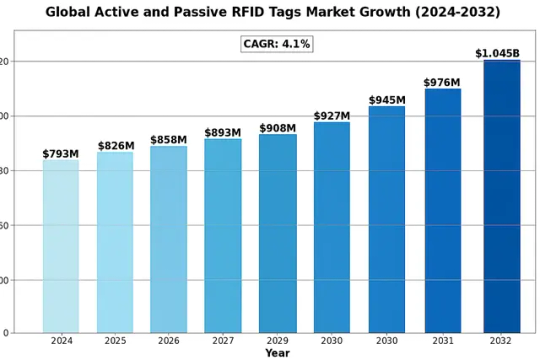

The global Active and Passive RFID Tags Market was valued at 793 million in 2024 and is projected to reach US$ 1045 million by 2032, at a CAGR of 4.1% during the forecast period.

Active and passive RFID tags are key components in radio frequency identification systems. Active RFID tags are battery-powered devices that continuously transmit signals, enabling real-time tracking with extended read ranges – ideal for logistics and asset management. Passive RFID tags, which are more cost-effective and lightweight, operate by harvesting energy from reader signals, making them suitable for inventory management and access control applications. While active tags offer superior range and data transmission capabilities, their higher costs and maintenance requirements create adoption barriers in price-sensitive markets.

The market growth is driven by increasing adoption across retail, logistics, and manufacturing sectors, with passive tags dominating unit shipments due to their affordability. However, active tags are gaining traction in specialized applications requiring real-time visibility, such as healthcare equipment tracking. Recent technological advancements in battery life for active tags and improved read ranges for passive solutions are expanding potential use cases, while IoT integration is creating new growth opportunities across both segments.

Get Full Report with trend analysis, growth forecasts, and Future strategies : https://semiconductorinsight.com/report/active-and-passive-rfid-tags-market/

Segment Analysis:

By Type

Passive RFID Tags Dominate the Market Due to Cost-Effectiveness and Wide Application Flexibility

The market is segmented based on type into:

Active RFID Tags

Subtypes: Beacon tags, Transponder tags, and others

Passive RFID Tags

Subtypes: Low Frequency (LF), High Frequency (HF), Ultra-High Frequency (UHF), and others

By Application

Warehousing and Logistics Segment Leads Owing to Enhanced Supply Chain Visibility Needs

The market is segmented based on application into:

Retail and Wholesale

Warehousing and Logistics

Industrial Manufacturing

Healthcare

Others

By Frequency

UHF Segment Gains Traction Due to Improved Read Range and Data Processing Capabilities

The market is segmented based on frequency into:

Low Frequency (LF)

High Frequency (HF)

Ultra-High Frequency (UHF)

By Material

Plastic Substrates Remain Preferred Choice for Most Industrial Applications

The market is segmented based on material into:

Paper

Plastic

Glass

Metal

Others

Regional Analysis: Active and Passive RFID Tags Market

North America The North American RFID market is characterized by high adoption rates across retail, healthcare, and logistics sectors, driven by advanced technological infrastructure and stringent regulatory frameworks for asset tracking. The U.S. leads the region, accounting for over 65% of regional revenue, with companies like Zebra Technologies and Honeywell dominating the competitive landscape. Demand for active RFID tags is particularly strong in supply chain management due to real-time tracking requirements. However, the higher cost of active tags compared to passive alternatives limits broader adoption in price-sensitive applications. Recent investments in Industry 4.0 and warehouse automation are accelerating market growth, with a projected CAGR of 3.9% through 2032.

Europe Europe’s market is shaped by EU-wide standardization and sustainability initiatives favoring RFID-enabled circular economy models. Germany and the U.K. are key markets, with passive tags widely used in retail inventory systems to comply with anti-counterfeiting regulations. The region shows increasing preference for UHF RFID solutions, particularly in textile tracking under the EU’s Digital Product Passport initiative. While industrial manufacturing accounts for 38% of regional RFID usage, growth faces headwinds from data privacy concerns under GDPR. Collaborative R&D projects between universities and corporations are advancing hybrid (active-passive) tag innovations for specialized applications like pharmaceuticals.

Asia-Pacific As the fastest-growing region (CAGR 5.2%), APAC’s expansion is propelled by China’s Belt & Road infrastructure projects and India’s smart city initiatives. Passive tags dominate (>70% market share) due to cost advantages in high-volume manufacturing applications. Japan leads in RFID-integrated retail, while Southeast Asian nations show surging demand for logistics tracking. Local players like Invengo challenge global brands through competitive pricing, though technology gaps persist in long-range active RFID systems. The region’s lack of unified frequency standards across countries complicates cross-border implementations despite booming intra-Asia trade.

South America Market penetration remains low but exhibits strong growth potential as Brazil and Argentina modernize supply chains. Active RFID adoption is primarily limited to mining and oil/gas asset monitoring, while passive tags see increasing use in agricultural export tracking. Economic instability has delayed large-scale RFID projects, but foreign investment in Brazilian automotive and pharmaceutical sectors is creating pockets of opportunity. The absence of localized manufacturing forces reliance on imports, inflating costs by 15-20% compared to other regions.

Middle East & Africa The MEA market is bifurcated: Gulf nations leverage active RFID for high-value asset management in aviation and construction, while African countries predominantly use low-frequency passive tags in livestock and rudimentary inventory systems. UAE’s smart city projects and Saudi Arabia’s Vision 2030 are driving government-led RFID implementations. However, low technology awareness and fragmented distribution channels constrain growth outside urban hubs. The region shows untapped potential in RFID-based halal food traceability systems, with pilot programs underway in Malaysia and Indonesia.

MARKET OPPORTUNITIES

Emerging Applications in Healthcare Create New Growth Avenues

The healthcare sector presents significant untapped potential for RFID solutions. Hospital asset tracking represents a $5 billion opportunity, with systems reducing equipment search times by up to 60%. Recent innovations include disposable passive RFID tags for surgical instrument tracking and active temperature monitoring for sensitive pharmaceuticals. Regulatory pressures to improve patient safety and inventory control continue to drive adoption. Successful pilot programs demonstrate 30% reductions in medication errors through RFID-enabled verification systems, showcasing the technology’s potential to transform healthcare operations.

Advancements in Chipless RFID Open New Application Possibilities

Breakthroughs in chipless RFID technology create opportunities in previously inaccessible markets. These innovative tags eliminate silicon chips, reducing costs below traditional passive solutions while maintaining adequate functionality for certain applications. Potential uses include anti-counterfeiting measures for luxury goods and mass-market retail items where conventional RFID proves cost-prohibitive. Early implementations demonstrate 40% cost reductions compared to conventional passive tags, making item-level tagging economically viable for additional product categories. This technological evolution promises to expand RFID’s addressable market substantially.

Integration with AI and Blockchain Enhances Value Proposition

Synergies between RFID and complementary technologies create significant growth opportunities. Artificial intelligence algorithms leverage RFID-generated data streams to optimize inventory management and predictive maintenance. Blockchain integration provides immutable records for supply chain provenance applications, particularly valuable in anti-counterfeiting and quality assurance initiatives. Recent partnerships between RFID providers and technology firms demonstrate the commercial viability of these combined solutions. Such integrations enable premium pricing models while addressing previously unserved market needs across multiple industries.

MARKET CHALLENGES

Technical Limitations Constrain Performance in Certain Environments

RFID systems face inherent technical constraints that challenge specific applications. Metal and liquid environments significantly degrade performance, with signal absorption and reflection causing read reliability issues. These material interactions particularly impact manufacturing and healthcare settings where metal equipment prevails. While recent advancements in antenna design and frequency selection mitigate some limitations, fundamental physics constraints persist. Developing robust solutions for challenging environments remains an ongoing engineering challenge that limits adoption in certain industrial applications.

Shortage of Skilled Implementation Specialists Slows Market Growth

The rapid expansion of RFID applications outpaces the availability of qualified implementation specialists. System deployment requires expertise spanning RF engineering, software integration, and business process redesign. This skills gap leads to implementation delays and suboptimal system configurations that undermine ROI. Training programs struggle to keep pace with technological advancements, while competition for qualified personnel increases labor costs. These human resource challenges particularly affect small and mid-sized enterprises that lack internal technical staff to oversee complex RFID deployments.

Competition from Alternative Technologies Impacts Market Share

Emerging tracking technologies present increasing competition for certain RFID applications. Bluetooth Low Energy (BLE) and ultra-wideband (UWB) solutions offer comparable functionality in asset tracking scenarios, often with lower infrastructure requirements. While RFID maintains advantages in bulk reading and cost-per-tag metrics, intensifying competition pressures pricing and necessitates continuous innovation. Technology selection increasingly depends on specific use case requirements, requiring suppliers to clearly articulate their solutions’ differentiated value across diverse application scenarios.

ACTIVE AND PASSIVE RFID TAGS MARKET TRENDS

Rising Demand for Supply Chain Optimization Fuels RFID Adoption

The global Active and Passive RFID Tags market is witnessing robust growth, driven by increasing demand for efficient supply chain management across retail, logistics, and manufacturing sectors. With the market valued at 793 million in 2024 and projected to reach 1,045 million by 2032, organizations are leveraging RFID technology to enhance inventory accuracy and operational visibility. Passive RFID tags dominate 65-70% of the current market share due to their cost-effectiveness in large-scale deployments like item-level tagging. Meanwhile, active RFID solutions are gaining traction in asset tracking applications, growing at a CAGR of 5.8%, outpacing the overall market growth. Recent advancements in hybrid RFID systems that combine both technologies are creating new opportunities for real-time monitoring in complex logistics environments.

Other Trends

Integration with IoT and AI Platforms

The convergence of RFID with IoT ecosystems is transforming traditional tracking systems into intelligent networks. Nearly 40% of new RFID deployments now incorporate cloud-based analytics, enabling predictive maintenance and automated replenishment. AI-powered RFID readers can now process tag data 50% faster while reducing false reads by 30%, significantly improving inventory accuracy in retail environments. Major retailers have reported 15-20% reduction in out-of-stock instances through AI-enhanced RFID systems.

Sustainability and Miniaturization Drive Product Innovation

Environmental considerations are reshaping RFID tag production, with manufacturers introducing biodegradable substrate materials that maintain performance while reducing e-waste. The latest passive tags now weigh under 0.5 grams and can be embedded directly into products during manufacturing. Meanwhile, active tag batteries have seen 35% improvements in lifespan, addressing a key pain point for industrial users. This miniaturization trend is particularly impactful in healthcare, where RFID-enabled smart labels track pharmaceuticals and medical devices throughout the cold chain without compromising sterility or adding bulk. The healthcare RFID segment is projected to grow at 6.2% CAGR through 2030, supported by stringent regulatory requirements for asset visibility.

COMPETITIVE LANDSCAPE

Key Industry Players

Market Leaders Drive Innovation Amid Growing RFID Adoption

The competitive landscape of the global Active and Passive RFID Tags market remains fragmented, with established technology providers competing alongside specialized RFID solution developers. Zebra Technologies has emerged as a dominant force, capturing approximately 18% market share in 2024 due to its comprehensive portfolio of enterprise-grade RFID solutions and strategic acquisitions. The company’s recent partnership with Microsoft to integrate RFID tracking into Azure IoT platforms exemplifies its innovation strategy.

Honeywell and Avery Dennison collectively account for nearly 25% of the market, leveraging their expertise in industrial automation and labeling solutions respectively. Honeywell’s acquisition of RFID middleware provider Movilizer in 2023 significantly strengthened its position in logistics automation, while Avery Dennison’s Smartrac division continues to dominate the retail RFID sector with its breakthrough dual-frequency tags.

Mid-tier players are gaining traction through specialized offerings – Alien Technology leads in high-memory passive tags for supply chain applications, whereas HID Global maintains stronghold in secure access control solutions. Meanwhile, Asian manufacturers like Invengo and Tatwah Smartech are disrupting the market with cost-competitive offerings, particularly in the passive RFID segment where price sensitivity remains high.

The competitive intensity is further heightened by continuous technological advancements. Recent developments include Zebra’s launch of ultra-wideband (UWB) active tags with 10-year battery life and Alien Technology’s introduction of environmentally-resistant passive tags for harsh industrial environments. Such innovations are reshaping competitive dynamics as companies strive to differentiate their offerings beyond basic tracking capabilities.

List of Key Active and Passive RFID Tags Companies Profiled

Zebra Technologies Corporation (U.S.)

Honeywell International Inc. (U.S.)

SATO Holdings Corporation (Japan)

TSC Printronix Auto ID (Taiwan)

Avery Dennison Corporation (U.S.)

Beontag (Brazil)

Metalcraft (U.S.)

Alien Technology, LLC (U.S.)

MPI Label Systems (U.S.)

Invengo Technology (China)

HID Global Corporation (U.S.)

GAO RFID (Canada)

The Tag Factory (U.K.)

Xindeco IOT (China)

Tatwah Smartech (China)

Learn more about Competitive Analysis, and Forecast of Global Active and Passive RFID Tags Market : https://semiconductorinsight.com/download-sample-report/?product_id=103579

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global Active and Passive RFID Tags Market?

-> Active and Passive RFID Tags Market was valued at 793 million in 2024 and is projected to reach US$ 1045 million by 2032, at a CAGR of 4.1% during the forecast period.

Which key companies operate in this market?

-> Major players include Zebra Technologies, Honeywell, Avery Dennison, Alien Technology, HID Global, and Invengo, collectively holding over 45% market share.

What are the key growth drivers?

-> Primary drivers include rising e-commerce logistics demands, Industry 4.0 adoption, and retail inventory automation needs, with the logistics sector accounting for 32% of total RFID deployments.

Which region dominates the market?

-> North America currently leads in adoption (38% share), while Asia-Pacific exhibits the highest growth rate (6.2% CAGR) driven by manufacturing expansion in China and India.

What are the emerging trends?

-> Emerging trends include hybrid RFID solutions, blockchain integration for supply chains, and development of eco-friendly RFID tags to address sustainability concerns.

Browse Related Research Reports :

CONTACT US:

City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014 +91 8087992013 [email protected]

0 notes

Text

Top Trends in Industrial Packaging Solutions for 2025

As industries continue to evolve in the face of globalization, sustainability demands, and technological advancement, packaging is no longer just about containment. It has become a strategic component in supply chains, branding, and environmental stewardship. In 2025, the landscape of packaging solutions is expected to undergo significant transformation, driven by innovation, consumer expectations, and regulatory shifts.

This blog explores the most impactful trends in industrial packaging solutions for 2025 and how companies like Om Packaging are adapting to meet these evolving needs.

1. Sustainable Packaging Becomes the Standard

Sustainability is no longer a trend—it’s a necessity. With governments tightening environmental regulations and businesses aiming for carbon neutrality, eco-conscious packaging solutions are taking center stage.

Key developments:

Biodegradable materials: The demand for biodegradable fibers, films, and coatings is rising across sectors.

Recyclable packaging: To improve recyclability, industries are moving from mixed-material packaging to mono-material formats.

Reusable packaging: There is an exploration of circular packaging models, particularly within B2B supply chains.

Om Packaging is at the forefront of this shift, offering fiber drums, paper cores, and other eco-friendly solutions designed for reusability and low environmental impact.

2. Smart Packaging and IoT Integration

Smart packaging is gaining traction in industrial contexts, not just for consumer goods. In 2025, expect packaging to do more than just protect products—it will monitor, track, and even communicate data.

Trends include:

RFID and NFC chips: For real-time tracking and inventory management.

Sensors for temperature, humidity, and shock: Crucial for industries like pharmaceuticals and chemicals.

Blockchain-enabled packaging: Providing transparent supply chain records for authenticity and compliance.

This digital transformation in packaging solutions allows manufacturers to reduce loss, enhance traceability, and streamline logistics operations.

3. Automation-Friendly Designs

With labor shortages and the push for faster production cycles, automated packaging lines are becoming more common. As a result, industrial packaging is being designed with automation in mind.

Advancements include:

Standardized drum and pallet sizes to fit automated systems

Easy-fold and stackable packaging for robotic handling

Machine-readable coding and labeling

Om Packaging is aligning its designs with these needs by offering drum configurations and labeling that integrate seamlessly into high-speed automated lines, reducing downtime and manual handling errors.

4. Customization for Product-Specific Protection

One-size-fits-all packaging is phasing out. Today’s industrial buyers expect customized packaging solutions that match their specific product dimensions, fragility, moisture sensitivity, or compliance needs.

Common custom features:

Internal linings for corrosion or moisture resistance

Size variations to minimize empty space

Branding elements for B2B marketing

UN-approved packaging for hazardous goods

Om Packaging delivers custom fiber drums, paper tubes, and protective inner linings that are tailored to the exact needs of each client, helping businesses ensure safe and efficient product transportation.

5. Lightweight Yet Durable Materials

Rising freight costs and emission concerns have made the weight of packaging a priority. In 2025, industries are looking for materials that reduce shipping weight while still offering durability and protection.

Material trends:

Reinforced fiberboard replacing traditional metal or plastic

Hybrid packaging (fiber combined with polymer linings) for optimizing weight BIS and ISO certifications for material safety and strength

High-strength paper cores used in textile and film industries

These lightweight packaging solutions can significantly lower transportation costs and carbon emissions. Om Packaging has been innovating in this space by using high-grade yet lightweight fiber material for both standard and custom products.

6. Compliance-Driven Packaging Solutions

Global industries face increasingly complex regulations related to packaging safety, labeling, recyclability, and hazardous material handling. As a result, 2025 will see more businesses prioritizing packaging partners who can ensure compliance with evolving laws.

Compliance considerations:

FDA and EU food-grade packaging regulations

UN markings for hazardous chemical transport

BIS and ISO certifications ensuring the material's safety and strength

Clear labeling for traceability and safety handling

Om Packaging stays ahead by incorporating compliance into its production process, ensuring every packaging solution meets both local and international standards.

7. Tamper-Evident and Security-Focused Designs

Security is critical in industries handling sensitive, high-value, or hazardous goods. In 2025, there will be increased use of tamper-evident and theft-resistant packaging formats.

Security features include:

Seals and locking rings for fiber drums

Anti-counterfeit labels with QR verification

Reinforced outer coatings for export containers

These features help protect goods in transit and provide peace of mind for buyers and sellers alike. Om Packaging integrates multiple security layers into its industrial fiber drums and related solutions.

8. Supply Chain Efficiency through Packaging Innovation

Efficient packaging isn't just about protection—it's about optimizing every link in the supply chain. From warehouse space utilization to faster loading and unloading, packaging innovations are reducing bottlenecks and improving bottom lines.

Efficiency tactics:

Stackable and collapsible designs

Packaging that fits modular shipping containers

Faster assembly and closure systems

Dual-purpose packaging (e.g., shipping and in-store display)

With a deep understanding of logistics, Om Packaging develops packaging solutions that reduce material usage, maximize space, and support supply chain efficiency for its clients across sectors.

9. Growth of Fiber-Based Industrial Packaging

Fiber-based packaging is projected to see exponential growth, especially as industries seek alternatives to plastic and metal. Its strength-to-weight ratio, biodegradability, and customizability make it a top choice.

Fiber-based solutions include:

Fiber drums for chemicals, pharmaceuticals, and food products

Paper tubes and cores for film, textiles, and adhesives

Honeycomb and molded fiber for cushioning and protection

Om Packaging is a pioneer in this space, offering high-quality, durable fiber-based packaging that fulfills both performance and sustainability goals.

0 notes

Text

Smart Inventory Practices for Businesses Using Godown Storage

In the current competitive and dynamic supply chain environment, effective storage is not merely a matter of space—it is a matter of safety, security, and control. Store raw materials, finished products, or perishable goods—your inventory must be safeguarded against theft, damage, spoilage, or fire in a godown for storage.

For companies that trust godowns for warehousing and logistics, inventory security is paramount to sustaining business stability, minimizing financial loss, and upholding customer satisfaction.

In this article, we’ll explore the top safety tips for securing your inventory in a godown for storage, with a focus on physical security, fire safety, pest control, and digital systems.

Why Safety in Godown Storage Matters When goods enter a godown, they represent locked capital—investments in raw materials, finished products, or customer-bound orders. Any loss or damage within the storage facility can have direct consequences:

Loss of revenue

Operational disruption

Insurance claims and liabilities

Shattered customer trust

That's why it's not only a best practice—it's a business necessity—to put in place a solid storage safety plan.

1. Physical Security Measures Physical security is the first line of defense in any godown. Your storage warehouse should be secure enough to deter and prevent unwarranted visits, theft, and vandalism.

✅ Tips for Physical Security: Install CCTV Cameras: Provide 24/7 video monitoring of entry points, storage areas, and loading docks. Store on cloud backup.

Recruit Security Staff: Trained security guards must guard entrances, record visitor movement, and conduct regular rounds.

Fencing and Access Control: Fencing around the perimeter and gated entry discourage trespassing. Implement RFID cards, biometric devices, or access codes for employee access.

Alarm Systems: Intruder alarms can alert you or local authorities immediately during a burglary.

Proper Lighting: Ensure the godown premises are properly lit, particularly at entry and exit points, to discourage criminality.

2. Fire Safety and Prevention Fires in storage godowns may lead to disastrous losses. Since most godowns are filled with inflammable commodities, cartonage, or packing materials, fire prevention is crucial.

✅ Fire Safety Guidelines: Install Smoke Detectors & Alarms: These must be installed in each section of the godown.

Use Fire Extinguishers: Place them in accessible locations and train staff on how to use them. Make sure you’re using the right extinguisher class (A, B, C, etc.).

Fire Sprinkler System: For large godowns, automatic sprinklers help contain fires early.

Electrical Safety: Avoid overloading sockets, and conduct regular inspections of electrical systems.

Proper Storage of Flammable Goods: Store chemicals, oils, or paper products in fire-resistant zones with ventilation.

Pro Tip: Follow the National Building Code (NBC) of India and local fire safety regulations.

3. Pest Control and Hygiene Pests, rodents, and insects destroy stock—particularly in godowns housing agriculture, food, textiles, or paper products.

✅ Best Practices for Pest Control: Arrange Regular Fumigation: Hire a certified pest control company for monthly or quarterly fumigation.

Install Rodent Traps and Insect Zappers: Particularly at entry points and loading bays.

Seal Holes and Cracks: Stop pest entry by sealing any and all openings in walls, floors, and ceilings.

Waste Management: Dispose of trash on a daily basis and keep it in a separate place from the main storage facility.

Dry and Clean Surroundings: Pests are drawn to moisture—use dehumidifiers or proper ventilation to maintain a dry environment.

4. Safe Storage and Racking Practices The way goods are stacked within the godown can have a significant bearing on their safety and easy retrieval. Overloaded stacks or sloppy stacking can lead to damage to stock or injury to employees.

Inventory Arrangement Tips: Utilize Industrial Racks and Shelving: They must be load-rated and securely anchored.

Label Everything Clearly: Employ barcodes, signs, and labels to reduce confusion and errors.

Do Not Overstack: Do not stack materials above safe height levels, particularly for breakable or liquid merchandise.

Use Pallets: Keep commodities in pallets to prevent direct floor contact (prevents water damage).

Allocate Aisle Space: Provide sufficient space between shelves for forklifts and personnel to pass safely.

5. Employee Safety Training Your employees are crucial for ensuring godown safety. Properly trained personnel can detect hazards beforehand and act rapidly during emergencies.

✅ Training Essentials: Fire Drill Training: Perform drills every 3–6 months.

Material Handling Training: Instruct on proper lifting procedures and forklift operation.

Emergency Exit Plan: Label and light exit routes. Train employees on evacuation protocols.

PPE (Personal Protective Equipment): Supply gloves, head protection, safety footwear, and high-visibility vests for all warehouse personnel.

First Aid Training: Have an equipped kit and at least one trained first aider on site at all times.

6. Digital Monitoring and Smart Systems Contemporary godown warehouse facilities are now more and more incorporating technology to make them safer and more efficient.

✅ Suggested Intelligent Tools: Inventory Management Software (WMS): Real-time inventory monitoring prevents theft and loss.

IoT-Based Sensors: They can monitor temperature, humidity, and door usage.

Geo-Fencing for Assets: Monitor movement of high-value items via RFID or GPS tags.

Cloud-Based CCTV: Enables remote monitoring of your godown anywhere.

Access Logs: Employ computer systems to record every entry and exit for improved management.

7. Insurance Coverage Despite taking every precaution, accidents do happen. That is why companies need to insure their godown and stocks to cover financial loss.

✅ Coverage Tips: Fire and Theft Insurance: Minimum policies to protect against standard godown risks.

Stock Insurance: Insures loss or damage to stock.

Public Liability Insurance: Insures legal liability in the event of an accident.

Equipment Insurance: If you operate equipment such as forklifts or conveyors.

Consult insurance terms with a certified broker and confirm policy coverage to suit your risk profile.

8. Layout Planning and Segregation Your godown design can significantly impact safety of the inventory and operational efficiency.

✅ Layout Suggestions: Designated Zones: Segregate goods by type (e.g., flammable, perishable, fragile).

Buffer Areas: Reserve area close to entrance for loading/unloading without compromising storage zones.

Exit Routes: Keep all emergency exits unobstructed.

Controlled Areas: Restrict access to high-value or sensitive items.

Example: How Sat Kabir Logistics Maintains Safe Godown Storage At Sat Kabir Logistics Pvt Ltd, safety is the focus of each godown operation. Their godown and warehouse facilities are geared with:

24/7 security and camera monitoring

Fire detection and sprinkler mechanisms

Organized inventory racking

Pest control and hygiene measures

Regular staff training and safety audits

Whether you're leasing godown for storage for FMCG, pharma, cold chain, or e-commerce, Sat Kabir Logistics provides secure, scalable godown storage services throughout India.

Learn more at www.skl-group.in

✅ Conclusion: Safety First, Always A godown is not merely a warehouse — it's a critical link in your supply chain. Safety for your inventory should always be top of mind. By adopting the proper security procedures, fire protection, sanitation practices, and technological advancements, you can safeguard your merchandise, personnel, and profits.

From a small business to a multiregional distribution system, investing in godown security today will spare you tremendous losses in the future.

0 notes

Text

How Washable RFID Laundry Tags Are Transforming Textile Management

Discover how washable RFID laundry tags are helping hospitals, hotels, and laundries track textiles with real-time accuracy, cutting costs, errors, and losses.

Managing thousands of textiles across hospitals, hotels, or industrial laundries can be a logistical nightmare. From missing inventory to manual sorting errors, the challenges are real. That’s where washable RFID laundry tagsstep in to revolutionize textile management.

These compact, rugged tags are built to withstand industrial wash cycles, hot water, steam, chemicals, and dryers, while enabling real-time tracking, automated sorting, and inventory accuracylike never before. Whether it's tracking hospital scrubs or monitoring hotel linens, RFID technology is transforming how garments are counted, located, and maintained across industries.

With rising labor costs and a growing demand for hygienic, traceable solutions, RFID laundry tags are fast becoming a global standard. Discover how this small tech upgrade is solving big problems, and helping businesses cut costs, reduce losses, and scale smarter.

At Klik e-Seal, we design and deliver RFID laundry tags that are built for industrial performance and tailored to your operational needs. Trusted by 500+ businesses worldwide, our solutions are engineered for durability, compliance, and seamless integration.

Read the full blog to learn how washable RFID laundry tags work and why industries worldwide are adopting them.

1 note

·

View note

Text

Functional Printing Market Size, Strategic Trends, End-Use Applications

The functional printing market was valued at USD 11.2 billion in 2022 and is anticipated to reach USD 35.1 billion by 2030, growing at a CAGR of 16.5% during the forecast period. The rapid evolution of printed electronics, combined with increasing adoption in packaging, automotive, and wearable technologies, is driving global demand.

Overview

Functional printing refers to the use of printing technology to create electronic components and devices on a variety of substrates, such as plastic, glass, and paper. Unlike conventional printing, which is used primarily for visual appeal, functional printing serves a technical purpose, enabling functionalities like conductivity, sensing, and energy storage.

With developments in materials science, nanotechnology, and ink formulation, functional printing is gaining traction in a wide range of industries. Applications include RFID tags, sensors, photovoltaic cells, displays, smart labels, and medical devices. Its cost-effectiveness, flexibility, and scalability make it a disruptive alternative to traditional manufacturing techniques in the electronics space.

Market Segmentation

By Technology

Inkjet Printing

Screen Printing

Flexographic Printing

Gravure Printing

Offset Printing

By Material

Substrates (Glass, Plastic, Paper)

Functional Inks (Conductive Inks, Dielectric Inks, Biodegradable Inks)

By Application

RFID Tags

OLED Displays

Sensors

Batteries

Photovoltaic Cells

Printed Circuit Boards (PCBs)

Smart Packaging

By End-User Industry

Automotive

Consumer Electronics

Healthcare

Retail

Energy

Industrial Manufacturing

Key Trends

Rapid growth of printed electronics in consumer and industrial IoT applications

Rising demand for flexible and lightweight devices in wearables and smart textiles

Emergence of bio-compatible printed sensors for health monitoring and diagnostics

Sustainable innovation with biodegradable inks and recyclable substrates

Integration with additive manufacturing for cost-efficient, large-scale production

Segment Insights

Technology Insights: Inkjet and screen printing technologies dominate the functional printing landscape due to their compatibility with a wide variety of functional inks and substrates. Inkjet printing offers high-resolution output and is ideal for small-scale production and prototyping, while screen printing provides high-throughput capabilities for commercial-scale runs.

Material Insights: The selection of functional inks plays a critical role in the performance of printed components. Conductive inks (silver-based or carbon-based) are commonly used for circuit printing, while dielectric and piezoelectric inks are utilized in sensors and capacitors. Flexible substrates enable printing on irregular surfaces, contributing to the growth of wearable and curved-display technologies.

Application Insights: RFID and smart packaging are among the most mature applications, widely adopted in logistics, retail, and food tracking. The market is now seeing accelerated growth in printed batteries, solar cells, and biosensors, as these solutions become more commercially viable and performance-efficient.

End-User Insights

Automotive: Utilizes functional printing for touch panels, lighting elements, in-vehicle sensors, and heated mirrors. Lightweight, flexible printed components improve energy efficiency and design adaptability.

Consumer Electronics: Enables production of thin, flexible displays, wearable devices, and smart textiles that integrate sensors and connectivity features.

Healthcare: Includes printed biosensors, diagnostic strips, drug delivery patches, and e-skin applications for real-time health monitoring.

Retail: Widely uses printed RFID tags, smart labels, and packaging that supports anti-counterfeiting and inventory management.

Energy: Involves development of lightweight, flexible solar panels, printed batteries, and supercapacitors that can be embedded in various surfaces.

Industrial Manufacturing: Embracing printed sensors and components to enable automation, predictive maintenance, and machine-to-machine communication.

Regional Analysis

North America: Strong R&D presence, government funding for printed electronics, and high early adoption in defense and healthcare sectors.

Europe: Significant investment in sustainable packaging, smart textiles, and automotive innovation in countries like Germany and the Netherlands.

Asia-Pacific: Fastest-growing region driven by mass-scale electronics production, booming wearable tech market, and innovation hubs in Japan, China, and South Korea.

Latin America & Middle East: Emerging adoption for logistics tracking, smart agriculture, and renewable energy storage.

Key Players

Leading companies in the functional printing market include Thinfilm Electronics ASA, E Ink Holdings, PragmatIC Printing Ltd., Xerox Corporation, Ceradrop, Blue Spark Technologies, Novacentrix, and Enfucell.

These players are investing in R&D to create multifunctional inks, roll-to-roll manufacturing methods, and customized applications tailored to different industry needs. Partnerships with OEMs, packaging firms, and device manufacturers are helping expand real-world deployment of functional printing solutions.

Future Outlook

The functional printing market is set to experience robust growth as printed electronics become a staple in consumer and industrial devices. As innovations in ink chemistry and printing techniques continue, cost barriers are expected to fall, unlocking new use cases in smart cities, intelligent healthcare, and interactive retail environments.

Trending Report Highlights

Wet Chemicals Market

Taiwan Robotics Market

Automatic Elevator Inverter Market

Autonomous Mobile Robot Market

Washdown Sensor Market

0 notes

Text

Chip-less RFID Market Future Trends Driving Next-Gen Contactless Tracking and Smart Inventory Systems

As global industries move toward digital transformation and automation, the chip-less RFID market is gaining unprecedented attention. Unlike traditional RFID systems, chip-less RFID operates without silicon chips, making it more cost-effective, flexible, and suitable for mass applications. With a focus on sustainability, efficiency, and intelligent data capture, the market is projected to undergo dynamic shifts in the coming years. These future trends are shaping how businesses, governments, and logistics sectors handle tracking, authentication, and inventory management.

Rise in Cost-Effective and Eco-Friendly Solutions

One of the most significant future trends driving the chip-less RFID market is the increasing demand for low-cost identification solutions. Traditional RFID systems come with silicon chips, which make them more expensive and harder to recycle. In contrast, chip-less systems use printable electronics and conductive materials, making them a greener and more economical option. As environmental regulations become stricter, industries are actively seeking alternatives that reduce e-waste and lower carbon footprints, leading to accelerated adoption of chip-less RFID technologies.

Integration with Smart Supply Chain Ecosystems

The convergence of chip-less RFID with smart logistics and supply chain management is set to become a game-changer. Future trends indicate that these systems will play a pivotal role in enhancing transparency, reducing errors, and speeding up inventory processes. By enabling real-time tracking without the need for batteries or complex infrastructure, chip-less RFID tags offer unmatched scalability for warehouse operations, retail chains, and shipping networks. This integration will be particularly beneficial for businesses looking to implement Industry 4.0 and IoT-enabled supply chain strategies.

Advancements in Printed and Flexible Electronics

Technological innovation in printed electronics is one of the key enablers behind the growth of chip-less RFID. Future trends point toward the expansion of ink-based RFID tags that can be printed on paper, plastic, fabric, or even directly on products. This breakthrough opens new possibilities for applications in textiles, packaging, and healthcare. The growing availability of printable conductive inks and materials is also expected to drive mass production, enabling manufacturers to produce tags at scale and embed them seamlessly into various surfaces.

Increased Adoption Across Healthcare and Pharmaceuticals

The healthcare sector is rapidly emerging as a key adopter of chip-less RFID technology. Hospitals, clinics, and pharmaceutical companies are exploring its use in tracking medical supplies, patient identification, and medication monitoring. Unlike barcodes, chip-less RFID tags can be read without direct line-of-sight, offering faster and more accurate data capture. In the future, we can expect widespread use of chip-less systems for sterile environments, vaccine tracking, and ensuring authenticity in drug distribution chains.

Enhanced Security and Anti-Counterfeiting Measures

Another future trend gaining traction is the use of chip-less RFID for anti-counterfeiting and brand protection. High-end consumer goods, electronics, and luxury products are increasingly vulnerable to counterfeit threats. Chip-less RFID technology, when combined with cryptographic features and unique identification patterns, can offer a secure and tamper-proof solution. As technology advances, the ability to integrate invisible RFID tags into product packaging will become a powerful deterrent against counterfeiting, giving manufacturers and consumers greater confidence in product authenticity.

Government and Transportation Sector Deployment

Governments and public infrastructure agencies are beginning to recognize the potential of chip-less RFID in areas such as toll collection, vehicle identification, public transportation, and border security. With its non-intrusive design and passive nature, the technology is ideal for large-scale identification systems. Future trends indicate expanded use in national ID systems, e-passports, and smart city initiatives. This transition will be supported by improved reader infrastructure and wider standardization, making chip-less RFID a preferred choice for public sector deployments.

Shift Toward Consumer-Driven Applications

As the technology matures, chip-less RFID will move beyond industrial and enterprise-level usage toward more consumer-focused applications. From smart packaging in supermarkets to contactless ticketing at events, the possibilities are endless. The retail sector, in particular, stands to benefit from innovations that allow for instant checkout, interactive product experiences, and precise inventory tracking. With smartphones and connected devices becoming more prevalent, future chip-less RFID systems will likely be compatible with mobile readers, driving broader accessibility and convenience for end users.

Final Thoughts

The future of the chip-less RFID market is brimming with potential as the world demands faster, smarter, and more sustainable identification solutions. With ongoing innovation in materials, manufacturing, and integration techniques, chip-less RFID is expected to become a cornerstone of next-generation data collection systems. Its ability to seamlessly blend with smart environments, improve operational efficiency, and reduce costs makes it a vital technology for businesses aiming to thrive in the digital economy. As adoption accelerates, industries that embrace these future trends will be better positioned to capitalize on the shift toward contactless, intelligent ecosystems.

0 notes

Text

Linen Suppliers: Essential Partners in Comfort, Cleanliness, and Style

In industries where comfort, hygiene, and presentation are paramount—such as hospitality, healthcare, and food service—quality linens are more than just accessories. They are fundamental to the customer experience. Behind every neatly made hotel bed, crisp restaurant table setting, or sterile medical gown is a linen supplier—a vital partner that ensures businesses always have access to high-quality, reliable textile products.

What Is a Linen Supplier?

A linen supplier provides a range of textile products used in commercial and institutional settings. These suppliers either manufacture, distribute, or source linens in bulk for industries that require frequent laundering, high durability, and consistent presentation.

Typical product categories include:

Bed Linens: Sheets, pillowcases, duvet covers, and mattress protectors

Bath Linens: Towels, bathrobes, washcloths, and bath mats

Table Linens: Tablecloths, napkins, runners, and chair covers

Kitchen & Service Linens: Aprons, dish towels, chef coats, and server uniforms

Healthcare Linens: Gowns, scrubs, blankets, and patient bedding

Industries Served

Linen suppliers cater to a wide range of sectors, including:

Hospitality (Hotels, Resorts, Spas)

Healthcare (Hospitals, Clinics, Senior Care Facilities)

Food & Beverage (Restaurants, Cafes, Catering Services)

Event Management (Weddings, Conferences, Banquets)

Industrial and Corporate (Uniforms, Cleaning Services, Laboratories)

Key Qualities of a Reliable Linen Supplier

Choosing the right linen supplier can significantly impact operations, brand image, and cost-efficiency. Here are the most important factors to consider:

1. Quality and Durability

High-grade fabrics such as 100% cotton, cotton-poly blends, or antimicrobial materials are essential for long-term use, especially in environments with frequent washing cycles.

2. Consistent Supply

Top suppliers maintain robust inventory systems and logistics networks to ensure timely and consistent deliveries, even in high-demand seasons.

3. Customization and Branding

Many suppliers offer custom embroidery, logo printing, color matching, and sizing to help businesses align their linens with brand identity.

4. Sustainability

Eco-conscious businesses now prefer linen supplier that offer organic textiles, recycled materials, and sustainable production practices.

5. Responsive Service

A reliable supplier provides responsive customer support, flexible ordering options, and proactive communication to ensure customer satisfaction.

Linen Supply Models

There are two main types of linen supply models:

Purchase Model: The business buys linens outright, managing their laundering and inventory internally.

Rental or Linen Service Model: The supplier owns the linens and provides a rental program that includes regular laundering, delivery, and replacement. This model is common in healthcare and hospitality sectors.

Trends in the Linen Supply Industry

Smart Textiles: Some suppliers are experimenting with RFID-tagged linens for better inventory tracking.

Sustainable Fabrics: There’s growing demand for organic cotton, bamboo fiber, and recycled textiles.

Color and Design Variety: More clients are requesting linens that reflect brand colors or offer modern styling.

Conclusion

A professional linen supplier is far more than a vendor—they’re a strategic partner that supports business operations, enhances customer perception, and maintains essential hygiene and presentation standards. Whether you're running a five-star hotel, a busy restaurant, or a healthcare facility, choosing the right linen supplier ensures your business is wrapped in quality, efficiency, and professionalism from the ground up.

1 note

·

View note

Text

Warehousing Services in India: Driving Efficient Business Operations

In the dynamic world of commerce, warehousing services in India have become the backbone of efficient logistics and supply chain management. Whether you are an emerging startup or an established corporation, leveraging the right warehousing solution can help you optimize inventory, reduce delivery times, and cut down costs—all essential for thriving in today’s competitive market.

Why Warehousing Services Are Vital

Warehousing is more than just storing goods. It’s about creating a seamless link between manufacturing, inventory management, and distribution channels.

Here are some key advantages of professional warehousing services in India:

Enhanced inventory accuracy through smart tracking systems

Strategic locations that facilitate quicker delivery

Reduced warehousing and transportation costs

Improved product safety with advanced security systems

Flexibility to handle fluctuating demand and large order volumes

Exploring Various Warehousing Solutions in India

Indian businesses benefit from multiple types of warehousing services designed to meet diverse operational needs:

Public Warehouses: Available to any business looking for short-term or seasonal storage

Private Warehouses: Dedicated facilities owned by individual companies

Cold Storage Facilities: For temperature-sensitive products like food and pharmaceuticals

Bonded Warehouses: Storage for imported goods pending customs clearance

Automated Warehouses: Incorporating robotics and AI for faster, error-free handling

Features of Advanced Warehousing Services

Modern warehousing providers in India focus on integrating technology and offering value-added services that improve operational efficiency.

Warehouse Management Systems (WMS) providing real-time data access

Barcode and RFID scanning for accurate inventory tracking

Climate control for delicate goods

Robust security and surveillance

Additional services such as packaging, labeling, and order processing

Which Industries Benefit Most?

Warehousing services support a wide range of industries by helping them manage inventory and distribution more effectively:

E-commerce and Retail for timely and efficient order fulfillment

Pharmaceuticals requiring regulated storage conditions

FMCG (Fast-Moving Consumer Goods) with high turnover rates

Automotive for spare parts and components inventory

Textiles and Apparel managing seasonal collections

Tips for Choosing the Right Warehousing Partner

Selecting the right warehousing provider is crucial for your supply chain success. Keep these points in mind:

Location and accessibility to your markets

Technological capabilities and automation level

Experience in handling your product category

Transparent pricing and flexible contracts

Security and compliance standards

The Future Outlook of Warehousing in India

India’s warehousing sector is undergoing rapid transformation with technology adoption, government initiatives, and growing demand from sectors like e-commerce. The future will see smarter warehouses with AI, IoT integration, and green practices that enhance efficiency and sustainability.

Conclusion

Choosing the right warehousing services in India can elevate your business operations by improving inventory management, reducing costs, and speeding up delivery. As the logistics landscape evolves, partnering with a capable warehouse provider will help your business stay agile and competitive in the long run.

#warehousing services in India#shipping#logistics#sea freight#cargo shipping#freightforwarding#everfast

0 notes

Text

Comprehensive Guide to Shielding & Blocking Fabrics: EMF, Anti-Radiation, RFID & RF

In an increasingly connected world, the need to protect ourselves, our devices, and our sensitive data from electromagnetic interference and unauthorized scans has never been more critical. Shielding and blocking fabrics—engineered with conductive fibers capable of attenuating or reflecting electromagnetic waves—offer versatile solutions across consumer, industrial, and medical applications. This article explores four key categories of these performance textiles: EMF shielding fabric, anti-radiation fabric, RFID blocking fabric, and RF shielding fabric.

1. EMF Shielding Fabric

Electromagnetic Field (EMF) shielding fabric is specifically designed to protect against the broad spectrum of electromagnetic radiation emitted by power lines, mobile devices, routers, and other electronics.

Materials & Construction

Conductive fibers such as silver-plated nylon, copper-infused polyester, or stainless-steel blends

Knitted or woven structures to maintain flexibility, breathability, and drapeability

Key Benefits

Reduces exposure to low-frequency (ELF) and high-frequency (RF) EMF

Maintains fabric softness and durability for apparel and home textiles

Washable for long-term use

Typical Applications

Protective clothing and undergarments for EMF-sensitive individuals

Curtains, window screens, and tent linings to create “quiet zones” in homes and offices

Enclosures for electronic equipment, medical devices, and laboratory spaces

2. Anti-Radiation Fabric

Anti-radiation fabric overlaps with EMF shielding textiles but is often marketed toward general “radiation protection,” including both electromagnetic and ionizing radiation shielding.

Material Variations

Silver or copper coated textiles for non-ionizing EMF

Metal-foil laminates (e.g., aluminum or stainless steel foils sandwiched in fabric layers) for enhanced barrier performance

Core Advantages

Broader spectrum attenuation, potentially including X-rays and gamma rays when laminated with dense metal foils

High tensile strength and tear resistance for industrial or medical shielding curtains

Customizable in multilayer composites for capsule or enclosure applications

Use Cases

Protective aprons and lab coats for radiology departments

Wall and ceiling panels in radiotherapy rooms

Consumer garments and bedding marketed to EMP enthusiasts

3. RFID Blocking Fabric

Radio Frequency Identification (RFID) blocking fabric specifically targets the prevention of unauthorized reading of RFID chips embedded in passports, credit cards, ID badges, and access cards.

Shielding Mechanism

Conductive fibers create a Faraday cage effect around RFID antennas

Blocks common RFID frequencies (125 kHz, 13.56 MHz, and UHF 860–960 MHz)

Standout Features

Lightweight and ultra-thin, enabling integration into wallets, passport covers, and bags

Durable through repeated flexing and laundering

Available in rolls, sheets, and customizable cut-to-size pieces

Practical Applications

Travel accessories: wallets, passport holders, ticket sleeves

Fashion and accessories: jackets, purses, hats with embedded blocking lining

Industrial ID management: badge holders for secure facilities

4. RF Shielding Fabric

Radio Frequency (RF) shielding fabric is engineered to attenuate or reflect radio waves across a specified frequency range, from VHF/UHF television bands up to microwave and millimeter-wave frequencies.

Common Fabric Types

Stainless steel® woven mesh fabrics for broad-band RF shielding

Copper-nylon blends for targeted attenuation at specific frequencies (e.g., Wi-Fi at 2.4 GHz and 5 GHz)

Advantages & Performance Metrics

High shielding effectiveness (SE) ratings, often exceeding 60 dB—meaning over 99.9999% signal reduction

Flexibility and conformability for complex shapes and enclosures

Often supplied with grounding options to safely dissipate intercepted energy

Typical Uses

EMI/RFI gaskets and seals in aerospace, telecommunications, and defense equipment

Shielded rooms and enclosures for EMC testing labs

Protective covers and drapes for antennas and radar installations

Choosing the Right Fabric for Your Needs

When selecting between EMF, anti-radiation, RFID blocking, and RF shielding fabrics, consider the following factors:

Frequency Range & Shielding Effectiveness (SE):

Match the fabric’s tested SE to the frequencies you need to block.

Form Factor & Flexibility:

Apparel and soft furnishings require knitted or woven textiles, while rigid foil laminates suit panel applications.

Durability & Maintenance:

Ensure the fabric withstands laundering, UV exposure, or chemical cleaning if used in demanding environments.

Customization & Integration:

Look for suppliers offering roll goods, die-cut shapes, or laminated composites tuned to your project specifications.

Conclusion

Conductive-fiber fabrics offer versatile solutions to modern challenges of electromagnetic exposure, data privacy, and signal interference. Whether you’re designing protective garments, travel accessories, secure enclosures, or industrial shielding, the right choice among EMF shielding, anti-radiation, RFID blocking, and RF shielding fabrics will deliver both performance and practicality. Explore specialized products at Conductive-Fabric.com to find tailored options that balance shielding effectiveness, comfort, and durability.

For samples, technical datasheets, and custom fabric runs, visit Conductive-Fabric.com.

#RFID Blocking Fabric#RF Shielding Fabric#Anti-Radiation Fabric#EMF Shielding Fabric#china emf protection fabric manufacturers

0 notes

Text

Innovative NFC bracelet by ZDCardtech - Style meets functionality

At zdcardtech, we specialize in the construction of innovative NFC Bracelets Manufacturer designed to combine functionality and style. Our bracelets are perfect for safe contact -free payment, access control and event management. With reliable performance and smooth design, these wearballs provide the best of both technology and aesthetics. Choose ZDCardtech as your reliable NFC bracelet manufacturer and elevate your NFC wearing experience.

#rfid wristband supplier#rfid tag manufacturer#rfid card manufacturer#rfid textile management#rfid laundry tag#NFC Bracelets Manufacturer#NFC google review card#NFC card manufacturer#NFC tag factory#RFID key#RFID keyfobs

0 notes

Text

[IOTE2025 Shanghai Exhibitor] RFID clothing tag supplier--Nanjing Chuanjing will appear at the IOTE International Internet of Things Exhibition

IOTE 2025, the 23rd International Internet of Things Exhibition Shanghai, will be held in Shanghai New International Expo Center from June 18 to 20, 2025. This time, it will join hands with MWC Shanghai to write a new chapter in the Internet of Things and mobile communications!

Nanjing Chuanjing Computer Label Printing and Weaving Co., Ltd. will participate in this exhibition. Let us find out what wonderful displays they will bring to the exhibition.

Exhibitor Introduction

Nanjing Chuanjing Computer Label Printing and Weaving Co., Ltd.

Booth number: N5C13

June 18-20, 2025

Shanghai New International Expo Center

Company Profile

Nanjing Chuanjing is a comprehensive service enterprise specializing in the development, design and production of woven labels, printed labels and hang tags (for clothing, toys, shoes and hats, and home textiles), and has a complete and scientific quality management system.

Product Recommendation

Woven label, printed label, hang tag, silicone label, leather label, RFID chip label

At present, industry trends are changing rapidly, and it is crucial to seize opportunities and seek cooperation. Here, we sincerely invite you to participate in the IOTE 2025 23rd International Internet of Things Exhibition Shanghai Station held at Hall N5 of Shanghai New International Expo Center from June 18 to 20, 2025. At that time, you are welcome to visit Nanjing Chuanjing Booth No. N5C13 in Hall N5 to discuss the cutting-edge trends and development directions of the industry with us, explore cooperation opportunities, and look forward to your visit!

0 notes

Text

Optimise linen counting with linen management solutions : Bundle Australia

As linen rental companies look to reduce the cost of linen management operations, optimising the counting and management process could be critical in accomplishing their objective of cost reduction. However, maintaining an accurate count at all times is a challenging process because it means paying attention to several operations at once, which can be time-consuming and inefficient. However, with the right linen management solution, you can optimise linen counting within your company to reduce costs and increase productivity. At Bundle Laundry, this is what we specialise in. Our linen management platform - Bundle Track - can help you optimise production processes to modernise textile rental operations and convert your business into an efficient, agile entity so that you can thrive regardless of external circumstances affecting the industry.

Bundle Laundry can help you convert linen management from a costly, inefficient process into an agile, value-oriented procedure that could provide deeper insights into how your textile rental company is performing.

We use RFID technology to optimise several management operations, such as inventory management and linen counting, to help you streamline processes while ensuring that your count remains accurate.

Furthermore, our linen management platform integrates with other platforms that, when combined, can help you automate and optimise your linen management operations, such as invoice data and customer management, making it easier to automate critical operations.

Looking to improve productivity and reduce costs Linen rental companies need the ideal laundry asset management solution to help them complete objectives.

#RFID#laundrysoftware#RFID Inventory management#laundry management cloud platform#GPS delivery management system#laundry inventory tracking#laundry invoicing integration#production management system#and Laundry productivity

0 notes

Text

The Role of RFID in Creating Smarter Laundry Management Systems

Radio Frequency Identification (RFID) has steadily moved from niche applications into mainstream operations, particularly within industries that require precise tracking, inventory management, and operational efficiency. Among these, the laundry management sector has emerged as a significant beneficiary. The use of RFID in laundry systems has transformed how uniforms, linens, and other fabric-based assets are handled, tracked, and managed. Traditionally reliant on manual labor and prone to inefficiencies, laundry operations are now being overhauled through automation and real-time data solutions enabled by RFID technologies. This shift is not merely a matter of technological evolution; it marks a fundamental rethinking of how textiles are managed across industries such as healthcare, hospitality, manufacturing, and public services.

This article explores the multifaceted role of RFID in making laundry management systems smarter. From reducing losses and optimizing inventory to enhancing hygiene compliance and operational throughput, RFID introduces a layer of intelligence previously unattainable through conventional means. It also enables data-driven decision-making, allowing managers to adapt to real-time conditions and trends. This transformation is not without its challenges, but the opportunities it presents make RFID an essential component of modern laundry infrastructure.

Understanding RFID Technology

RFID technology uses electromagnetic fields to identify and track tags attached to objects. These tags contain electronically stored information which can be read from several meters away and do not require direct line-of-sight. This is particularly advantageous in laundry settings, where garments and linens often move through multiple stages and locations—from collection points and washing stations to drying, folding, and redistribution.

The system comprises three primary components: RFID tags, RFID readers, and a data management software platform. Tags are typically embedded in textiles and designed to withstand industrial washing conditions, including exposure to water, detergents, and high temperatures. Readers are installed at key checkpoints to automatically capture data as tagged items pass through, while the software platform aggregates and analyzes this data, providing insights into usage patterns, loss rates, and process bottlenecks.

Understanding this technological foundation is crucial to appreciating how RFID enhances laundry operations. The ability to track individual items across their lifecycle enables granular control over inventory, supports compliance with hygiene protocols, and streamlines resource allocation. When integrated with existing enterprise resource planning (ERP) systems, RFID creates a unified management ecosystem that elevates operational visibility and accountability.

Traditional Laundry Management: Limitations and Pain Points

Before the advent of RFID, laundry management systems were predominantly manual or semi-automated. They relied heavily on barcode scanning, manual counting, and paper-based tracking systems. These methods are not only time-consuming but also susceptible to human error, leading to inaccuracies in inventory records, misplacement of items, and suboptimal resource utilization. In high-volume environments such as hospitals and hotels, these inefficiencies can translate into substantial financial and operational burdens.

Manual systems also lack the scalability required to manage growing demands. As operations expand, the complexity of tracking thousands of individual items increases exponentially. This creates challenges in maintaining service quality, adhering to hygiene standards, and ensuring timely delivery of laundered items. Additionally, the absence of real-time data impedes the ability to respond swiftly to inventory shortages or surpluses.

Another major drawback is the difficulty in holding staff accountable for losses or damage. Without accurate tracking, it becomes challenging to determine when and where an item was lost or misused. This often leads to increased replacement costs and strained supplier relationships. Furthermore, limited data visibility hinders the ability to conduct meaningful audits, forecast demand, or implement process improvements. These limitations underscore the urgent need for smarter solutions in laundry management.

How RFID Transforms Laundry Operations

The integration of RFID technology into laundry management brings a paradigm shift in how operations are conducted. By automating item identification and tracking, RFID eliminates the need for manual counting and barcode scanning. This not only reduces labor costs but also improves accuracy and speed. Staff can now focus on higher-value tasks, while the system handles routine tracking and data collection.

One of the most significant benefits is enhanced inventory visibility. Managers can access real-time information on the location and status of each item, whether it is in use, being laundered, or ready for redistribution. This visibility allows for better planning and resource allocation, minimizing delays and preventing shortages. The system also supports automated inventory replenishment, triggering alerts when stock levels fall below predefined thresholds.

RFID also facilitates better compliance with hygiene protocols. By tracking the number of washes and usage cycles, the system can automatically flag items that need replacement or deep cleaning. This is particularly critical in healthcare settings, where contamination risks are high. Moreover, RFID enables precise auditing and reporting, making it easier to meet regulatory requirements and industry standards.

Real-Time Data and Analytics in Laundry Management

One of the standout advantages of RFID-based laundry systems is the ability to generate and analyze real-time data. Every scan at an RFID reader creates a data point that is fed into a centralized system. Over time, this data accumulates to form a comprehensive picture of operational efficiency, inventory turnover, and usage patterns. Managers can use dashboards and reports to monitor key performance indicators (KPIs) and identify areas for improvement.

Real-time data also enables proactive decision-making. For instance, if a particular type of uniform is consistently understocked, the system can trigger alerts or reorder requests automatically. Similarly, usage trends can inform procurement strategies, helping organizations align inventory levels with actual demand. This reduces waste, cuts costs, and enhances service quality.

In environments with stringent compliance requirements, such as hospitals and food processing units, data analytics plays a crucial role in ensuring accountability. Audit trails can track the entire lifecycle of each item, from issuance and usage to laundering and eventual retirement. This level of traceability is invaluable for quality assurance, risk management, and continuous improvement initiatives.

Case Studies: Industry Applications of RFID

RFID technology has found successful applications across various sectors that rely heavily on efficient laundry operations. In healthcare, hospitals use RFID to manage patient gowns, bed linens, and staff uniforms. These items are often changed multiple times a day, making accurate tracking essential for maintaining hygiene and operational efficiency. RFID ensures that clean items are always available and that contaminated ones are promptly removed and laundered.

In the hospitality industry, hotels use RFID to manage towels, bed linens, and staff uniforms. The technology helps reduce linen losses, monitor usage rates, and optimize laundering schedules. For example, some luxury hotels have implemented RFID systems that alert housekeeping staff when specific items need to be replaced or deep cleaned, thereby enhancing guest satisfaction.