#RadiographicTesting

Explore tagged Tumblr posts

Text

What are the Methods of Detecting Cracks in Industrial Tanks?

Industrial tanks are crucial components in various industries, from petrochemical to food processing. Ensuring their structural integrity is vital to prevent leaks, contamination, and potentially catastrophic failures. Effective crack detection methods are essential to maintain safety and efficiency. Here's a look at some of the most reliable techniques used by leading tank inspection companies.

1. Visual Inspection The most straightforward method, visual inspection, involves trained technicians examining the tank's surface for visible signs of cracks or damage. While this method can identify obvious defects, it often misses subsurface cracks and requires supplemental methods for comprehensive assessment.

2. Ultrasonic Testing (UT) Ultrasonic testing is a highly effective crack test inspection method that uses high-frequency sound waves to detect flaws. A transducer sends sound waves into the tank material; reflections from cracks are analyzed to determine their size and location. This method is widely used for its accuracy and ability to detect subsurface cracks.

3. Magnetic Particle Testing (MPT) Magnetic particle testing is another popular crack testing inspection technique. It involves magnetizing the tank's surface and applying ferrous particles. These particles gather around cracks, making them visible under ultraviolet light. MPT is particularly effective for detecting surface and slightly subsurface cracks in ferromagnetic materials.

4. Dye Penetrant Testing (DPT) Dye penetrant testing is a simple yet effective crack scan method. A dye solution is applied to the tank's surface and allowed to seep into any cracks. After a set period, excess dye is removed, and a developer is applied to draw out the dye from cracks, making them visible. This method is ideal for detecting fine surface cracks.

5. Radiographic Testing (RT) Radiographic testing uses X-rays or gamma rays to capture images of the tank's interior. This crack scanning technique is highly effective for detecting internal flaws that are not visible on the surface. It provides detailed images that help in assessing the severity of the cracks.

Each of these methods offers unique advantages, and often, a combination of techniques is used to ensure thorough crack detection. For industries relying on the integrity of their tanks, partnering with a specialized tank inspection company like Bioscan LTD ensures the highest standards of safety and reliability. Bioscan LTD offers comprehensive vessel crack test inspection services, utilizing state-of-the-art technology to keep your operations running smoothly.

Visit Bioscan LTD to learn more about their crack detection and inspection services.

#CrackDetection#CrackTestingInspection#CrackTestInspection#CrackScan#CrackScanning#TankInspection#IndustrialTankSafety#UltrasonicTesting#MagneticParticleTesting#DyePenetrantTesting#RadiographicTesting#TankInspectionCompany#VesselCrackTestInspectionServices#IndustrialSafety#StructuralIntegrity#NondestructiveTesting#BioscanLTD#InspectionServices#IndustrialMaintenance

1 note

·

View note

Text

Radiographic Testing (RT): Unveiling Hidden Defects with Precision

Radiographic Testing (RT) is a powerful non-destructive testing (NDT) technique used to detect internal flaws in materials without causing any damage. By utilizing X-rays or gamma rays, RT provides detailed imaging of internal structures, making it essential in critical industries such as oil & gas, aerospace, and construction. It ensures the integrity and safety of components by revealing defects that are invisible to the naked eye. With its ability to evaluate welded joints, castings, and complex assemblies, Radiographic Testing remains a vital tool in maintaining quality and compliance across demanding applications.

0 notes

Text

Precision in Pixels: How Digital Radiography is Transforming Inspections

Digital radiography is revolutionizing industrial radiography by delivering sharper, real-time images that enhance flaw detection and reduce inspection time. Unlike traditional film-based methods, a modern digital radiography system offers faster processing, higher accuracy, and eco-friendly operations. These digital radiography solutions enable precise radiographic testing across sectors like oil & gas, aerospace, and manufacturing. By replacing outdated techniques, digital radiography ensures safer structures and more efficient quality control—making it an essential tool in today’s inspection landscape.

#digitalradiographysystem#industrialradiography#radiographictesting#digitalradiography#digitalradiographysolutions

0 notes

Text

Digital Radiography Explained: The New Standard in NDT

Digital radiography is transforming non-destructive testing (NDT) by offering faster, more accurate results compared to traditional film methods. This advanced form of radiographic testing enables real-time imaging, higher resolution, and easier data storage. Widely used in industrial radiography, it improves defect detection while reducing inspection time. As industries shift to radiography digital solutions, digital radiography testing is becoming the preferred choice for reliable, cost-effective inspections.

#digitalradiography#radiographictesting#radiographydigital#industrialradiography#digitalradiographytesting

0 notes

Text

Future of Radiology: AI and Digital Radiography Integration

The integration of AI with digital radiography is transforming the future of diagnostic imaging. Advanced digital radiography systems are now equipped to deliver faster, more accurate results, enhancing the efficiency of digital radiography testing. In sectors like industrial radiography, AI streamlines radiographic testing by detecting flaws automatically, reducing human error. As technology evolves, the synergy between AI and digital radiography will lead to smarter diagnostics, better safety standards, and improved productivity across medical and industrial applications. This innovation marks a new era in imaging excellence.

#DigitalRadiographyTesting#DigitalRadiography#RadiographicTesting#IndustrialRadiography#DigitalRadiographySystem

0 notes

Text

Non-Destructive Testing: How Technology is Transforming Inspection and Testing

The global non-destructive testing market size is anticipated to reach USD 34,148.1 million by 2030, registering a CAGR of 7.9% from 2023 to 2030, according to a new report by Grand View Research, Inc. The market is expected to experience substantial growth during the forecast period. This growth can be attributed to the increasing manufacturing activities in both developing and developed nations.

Non-destructive Testing Market Report Highlights

The market is expected to exhibit a CAGR of 7.9% over the next eight years owing to a rise in manufacturing-related activities, globally

The services segment accounted for the largest revenue share of over 75.0% in 2022. The high upfront cost of non-destructive equipment coupled with technical complexities involved in their deployment/installation is the major reason influencing end-users to outsource their non-destructive testing operations

Rapid industrialization, especially in developing economies has significantly contributed to the growth of the market

The manufacturing vertical segment was the dominant segment in 2022 and is expected to witness a healthy CAGR of 9.3% over the forecast period owing to the increased manufacturing activities primarily in Asia Pacific.

North America dominated the market in 2022 and accounted for the largest revenue share of more than 36.0%, owing to the extensive adoption of NDT techniques in the region

For More Details or Sample Copy please visit link @: Non-destructive Testing Market Report

The application of non-destructive testing (NDT) plays a crucial role in precise fault detection, effectively reducing the probability of product/component failures and associated repair costs. NDT also accelerates the manufacturing process by eliminating potential faults beforehand. The market is expected to be driven by the advancements in non-destructive testing methods, as these technological improvements ensure accurate fault detection and significantly reduce the complexity of testing procedures.

The ultrasonic testing segment is projected to experience substantial growth, which can be attributed to factors such as the equipment's user-friendly nature, the presence of skilled technicians, and the precise detection of faults. Furthermore, the manufacturing segment is anticipated to extensively adopt NDT techniques during the forecast period due to the growing awareness of their benefits and applications.

List of Key Players of Non-destructive Testing Market

Previan Technologies, Inc.

Bureau Veritas

Fischer Technology Inc. (Helmut Fischer)

MISTRAS Group

Comet Group (YXLON International)

MME Group

TWI Ltd.

Nikon Corporation

Olympus Corporation

We have segmented the global non-destructive testing market based on offering, test methods, vertical, and region

#NonDestructiveTesting#TestingTechnology#IndustrialSafety#QualityControl#Inspection#MaterialTesting#DigitalNDT#AutomatedInspection#AIinNDT#NDTInnovation#UltrasonicTesting#RadiographicTesting#NDTTrends

0 notes

Text

"The Future of NDT: Market Dynamics and Forecast 2027-2031"

Non-Destructive Testing (NDT) is revolutionizing quality control by allowing industries to assess the integrity of materials and components without causing damage. Utilizing advanced techniques such as ultrasonic testing, radiographic testing, and magnetic particle inspection, NDT ensures safety and reliability in sectors ranging from aerospace to construction. This innovative approach not only saves time and costs but also enhances precision, making it an essential tool in modern engineering and manufacturing.

#NDT #NonDestructiveTesting #QualityControl #UltrasonicTesting #RadiographicTesting #MagneticParticleInspection #AerospaceEngineering #ConstructionSafety #ManufacturingInnovation #IndustrialSafety #EngineeringExcellence #MaterialIntegrity #TechInEngineering #InnovativeTesting #SafetyStandards #FutureOfTesting #PrecisionEngineering #CostEfficiency #ModernManufacturing #TechAdvancements

0 notes

Text

Radiographic Testing is an NDT method that uses either X-rays or gamma rays to examine the internal structure of manufactured components and identifying the flaws.

0 notes

Text

#foodallergn #foodallergns #foodallergies #foodallergyawareness #foodallergytesting #foodallergylife #foodallergyfamily #foodallergy #foodsafetycourse #foodsafetycourses #foodscience #foodscienceandnutrition #foodscienceandtechnology #foodscience2023 #haccptrainingcourses #Haccp #haccpcourse #visualtesting #liquidtesting #liquidpenetratetesting #ultrasoninctesting #radiographictesting

0 notes

Photo

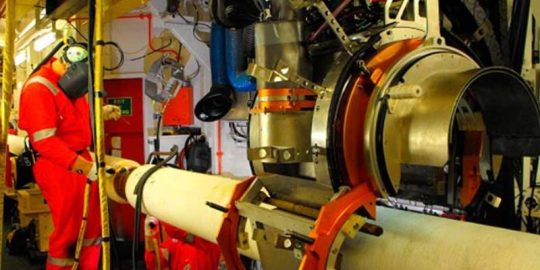

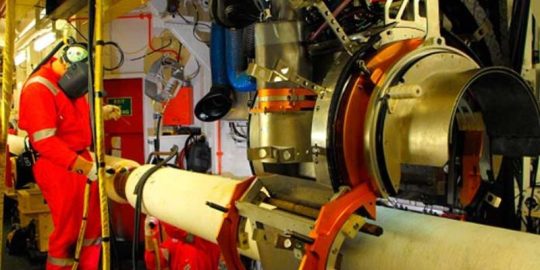

Radiography is a nondestructive inspection technique used for materials failure analysis investigation in different industries including oil, gas, and aerospace. Call #cutechgroup for more details!

See More - https://bit.ly/3eyMktu

Email - [email protected]

#radiography #RT #NDT #ndtinspection #ndtjobs #ndttraining #radiographictesting #ndtservices

0 notes

Text

https://www.astartesting.co.in/digital-radiography-india/

Precision in Pixels: How Digital Radiography is Transforming Inspections

Digital radiography is revolutionizing industrial radiography by delivering sharper, real-time images that enhance flaw detection and reduce inspection time. Unlike traditional film-based methods, a modern digital radiography system offers faster processing, higher accuracy, and eco-friendly operations. These digital radiography solutions enable precise radiographic testing across sectors like oil & gas, aerospace, and manufacturing. By replacing outdated techniques, digital radiography ensures safer structures and more efficient quality control—making it an essential tool in today’s inspection landscape.

#digitalradiographysystem#industrialradiography#radiographictesting#digitalradiography#digitalradiographysolutions#accessropetechnician

0 notes

Text

How Digital Radiography is Transforming Industrial Inspections

Digital radiography is revolutionizing industrial inspections by offering faster, clearer, and more accurate results than traditional radiographic testing. This advanced radiography digital method reduces downtime and enhances defect detection across critical assets. As a core tool in industrial radiography, it ensures higher image quality and improved data storage. Digital radiography testing not only boosts safety and efficiency but also supports real-time analysis for better decision-making. With its growing adoption, digital radiography is setting new standards in non-destructive testing across industries.

#DigitalRadiography#RadiographicTesting#RadiographyDigital#IndustrialRadiography#DigitalRadiographyTesting

0 notes

Text

Sharper Insights: How Digital Radiography Enhances Industrial Inspection

Digital radiography is revolutionizing industrial inspection by offering faster, clearer, and more accurate results. Unlike traditional film-based methods, a digital radiography system delivers high-resolution images in real time, reducing downtime and improving defect detection. As a key part of industrial radiography, it supports precise radiographic testing across sectors like aerospace, automotive, and oil & gas. With advanced digital radiography solutions, industries benefit from enhanced safety, efficiency, and quality assurance, making it an essential tool for modern NDT practices.

#DigitalRadiographySystem#IndustrialRadiography#RadiographicTesting#DigitalRadiography#DigitalRadiographySolutions

0 notes

Text

Digital Radiography: The Future of Non-Destructive Testing

Digital radiography is transforming the landscape of non-destructive testing (NDT) with faster, safer, and more accurate results. Unlike traditional radiographic testing, radiography digital techniques offer high-resolution imaging, real-time analysis, and minimal exposure risks. Widely used in industrial radiography, this advanced method enhances flaw detection and reduces inspection downtime. Digital radiography testing is now essential in industries like oil & gas, aerospace, and manufacturing—delivering reliable quality control and structural integrity. As technology advances, digital radiography continues to shape the future of industrial inspection.

#digitalradiography#radiographictesting#radiographydigital#industrialradiography#digitalradiographytesting

0 notes

Text

Digital Radiography: The Future of Non-Destructive Testing

Digital radiography is transforming the landscape of non-destructive testing (NDT) with faster, safer, and more accurate results. Unlike traditional radiographic testing, radiography digital techniques offer high-resolution imaging, real-time analysis, and minimal exposure risks. Widely used in industrial radiography, this advanced method enhances flaw detection and reduces inspection downtime. Digital radiography testing is now essential in industries like oil & gas, aerospace, and manufacturing—delivering reliable quality control and structural integrity. As technology advances, digital radiography continues to shape the future of industrial inspection.

#digitalradiography#radiographictesting#radiographydigital#industrialradiography#digitalradiographytesting

0 notes

Text

Revolution Through the Lens: How Digital Radiography is Reshaping Industrial Inspection

Digital radiography is transforming the landscape of industrial radiography with its unmatched precision, speed, and image clarity. Unlike traditional film-based methods, a digital radiography system captures high-resolution images instantly, allowing for quicker analysis and decision-making. This evolution in radiographic testing enhances defect detection, minimizes downtime, and boosts operational safety across industries. From pipelines to pressure vessels, digital radiography testing offers non-invasive inspection that’s both cost-effective and environmentally friendly. As technology advances, digital radiography continues to redefine industrial inspection standards—delivering accuracy you can trust, at the speed your projects demand.

#DigitalRadiographySystem#IndustrialRadiography#RadiographicTesting#DigitalRadiography#DigitalRadiographyTesting

0 notes