#Reactive Power Compensation Device

Explore tagged Tumblr posts

Text

Static VAR Generators: Power Quality and Efficiency

In today's energy-driven world, maintaining the quality of electrical power is paramount for both industrial and commercial operations. Power quality issues, such as voltage fluctuations, harmonics, and reactive power deficiencies, can lead to inefficiencies, increased operational costs, and even equipment damage. One effective solution to address these challenges is the Static VAR Generator (SVG). At Venus Technocrafts, we specialize in providing high-quality Static VAR Generators to help businesses optimize their power systems and enhance overall efficiency.

What is a Static VAR Generator?

A Static VAR Generator is a power electronic device used to provide reactive power compensation in electrical systems. Unlike traditional reactive power compensators, such as capacitor banks or synchronous condensers, Static VAR Generators offer a faster response time and greater precision in adjusting reactive power levels. By dynamically controlling the reactive power in real-time, SVGs help maintain voltage stability and improve the overall power factor of the electrical system.

The Role of Static VAR Generators in Power Systems

Static VAR Generators play a crucial role in enhancing the performance of power systems by addressing various issues, including:

Voltage Regulation: SVGs help maintain voltage levels within acceptable limits, ensuring that electrical equipment operates efficiently. This is particularly important in industrial settings where machinery relies on stable voltage for optimal performance.

Reactive Power Compensation: By providing reactive power support, SVGs reduce the reliance on utility-supplied reactive power. This leads to improved power factor and reduced energy costs for businesses.

Harmonic Mitigation: SVGs can also help mitigate harmonics in the electrical system, which can cause overheating, equipment malfunction, and reduced lifespan of electrical components. By filtering out harmonics, SVGs improve the overall quality of power delivered to equipment.

Dynamic Performance: Unlike traditional compensators, SVGs can react almost instantaneously to changes in load conditions, ensuring that the power system remains stable even during fluctuations in demand.

Efficiency Improvements: By optimizing reactive power flow, Static VAR Generators contribute to overall energy efficiency, reducing energy losses in the system and lowering operational costs.

Benefits of Using Static VAR Generators

The adoption of Static VAR Generators offers numerous advantages for businesses looking to improve their power systems:

Cost Savings: By enhancing the power factor and reducing the need for additional capacity from utility providers, SVGs lead to significant cost savings on electricity bills.

Improved Equipment Lifespan: Maintaining stable voltage levels and reducing harmonics help prolong the lifespan of electrical equipment, minimizing downtime and maintenance costs.

Increased System Reliability: SVGs provide robust support for voltage stability, enhancing the reliability of power systems and reducing the risk of outages or equipment failures.

Flexible Integration: Static VAR Generators can be easily integrated into existing power systems, making them a versatile solution for a wide range of applications, from manufacturing to commercial buildings.

Environmental Benefits: By improving energy efficiency, SVGs contribute to reduced carbon emissions and promote sustainability within the energy sector.

Applications of Static VAR Generators

Static VAR Generators are widely used in various sectors, including:

Industrial Manufacturing: SVGs help manage reactive power in factories and production facilities, ensuring that machinery operates efficiently.

Renewable Energy Systems: In solar and wind power installations, SVGs improve the integration of renewable energy sources into the grid, maintaining voltage stability and enhancing overall system performance.

Commercial Buildings: SVGs help commercial buildings optimize their energy consumption, improve power quality, and reduce operating costs.

Transportation and Railways: In railway systems, Static VAR Generators support the dynamic load demands of trains, ensuring stable power delivery for operations.

Choosing the Right Static VAR Generator

When selecting a Static VAR Generator for your needs, consider the following factors:

System Requirements: Assess the specific power quality issues in your electrical system and determine the appropriate size and capacity of the SVG needed.

Response Time: Look for SVGs with fast response times to ensure optimal performance during load fluctuations.

Integration Compatibility: Ensure that the SVG can be seamlessly integrated into your existing power system without requiring extensive modifications.

Manufacturer Reputation: Choose a reputable manufacturer like Venus Technocrafts that offers reliable products and excellent customer support.

Conclusion

As the demand for efficient and reliable power systems continues to grow, Static VAR Generators have emerged as a vital solution for businesses seeking to enhance their power quality and operational efficiency. At Venus Technocrafts, we are committed to providing high-quality Static VAR Generators designed to meet the unique needs of our clients. With our expertise and dedication to innovation, we can help you optimize your power systems and achieve significant cost savings. Contact us today to learn more about our Static VAR Generator solutions and how we can support your business in achieving its energy efficiency goals.

#power quality improvement devices#active harmonic#static var compensator#svc systems#reactive power compensation#var generator

0 notes

Text

The Hounds of Hell

The bridge of the Vellouwyn lurched as an energy discharge off the port side collapsed a pocket of subspace into a temporary antimatter void. The implosion wasn’t close enough to significantly damage the ship, but shields and ablative plating had taken a beating during their encounters over the past week, and the ship’s energy systems were having a hard time reconciling inertial dampeners to compensate as well as they could at full capacity. Durok sneered, knowing that the attack had been intentionally off the mark, and that while they were being hounded by their pursuers, they were also being toyed with, effectively helpless to counter the assault.

All throughout the ship at floor level, vents periodically gawped open as sensors tripped their mechanisms, and stray equipment and debris from structural damage was captured by the stow-ways, dragged out of the way by R4T units hiding in their conduits to police potentially harmful stray detritus. Around him on the bridge, various crew members had donned their station restraints, giving some stability and a moderate impression of safety as the ship jostled them around, and the captain worried for them all the same; others, unable to constrain themselves to a single operational area, were unbelted and reliant on their ‘sea legs’ to keep them from careening into consoles or other equipment as they went about their work.

“Bonn! Give me a damage report update. Lieutenant Simyarn, I could really use an effective evasive pattern if you’ve come up with anything fancy, something special, perhaps away from the anti-matter weapons?” Nearby at an unmanned science station, a lighting module overloaded, showering the area in distracting, but harmless sparks. Not for the first time, Durok lamented that the Federation’s lighting modules all reacted that way to fluctuations in power systems, at an exchange for effectively cost-free lumens, as the devices were efficient enough to be powered and controlled passively without requiring connection to energy systems of any sort, cultivating their charge from ambient energy sources. Unfortunately, those sources tended to be nearby ships systems which were connected to the grid, and tactical shifts in distribution and quick cycles of energy across different conduits and grids tended to trigger sensitive receptors in the equipment to overload. Three crewmen flinched or ducked at the sudden, distracting crackle of the bursting light, and Durok wondered if it were worth the exchange.

Lieutenant Raoul Simyarn’s hands flew across the Conn panel in a feverish dance, his eyes darting around the console to gather as much information as he could while he worked. The viewscreen, which he was ignoring, showed a pair of flanking vessels, much smaller than the Vellouwyn but significantly more maneuverable and dangerously over-armed, and as Durok watched, the closer of the pair launched another emerald-hued antimatter torpedo into their trajectory. Simyarn’s palm skidded along an edge of his console, and the whole ship veered alarmingly as lagging systems tried to catch up with the barrel roll that he set her spinning into. The torpedo cruised past the ship’s underbelly, and a subscreen on the viewer popped up to track it on one of the ventral sensor arrays. The missile came dangerously close to triggering in proximity, and Durok knew that if they wanted to, their pursuers could have remote detonated the device and crippled the ship. Instead, it twinkled off into the dark of space ahead of them for a distance before detonating into another hueless antimatter void which spun reactive forces into their wake, trigging more light units to overload and sending a menacing shudder throughout the vessel.

Junior Lieutenant Hubert Bonn grabbed the back of the captain’s chair as he lurched across the deck, thrusting a Padd with the most recent systems updates into Durok’s hands. The Tellarite looked queasy and unimpressed by their circumstances, and glared at the ships on the viewscreen. “Shields are holding at 74 percent, for now, up from the mid forties last time they pinned us down, but not quite the nineties I had them to this morning. This back and forth is overloading our emitters, and the crystal projectors won’t take the strain of it without maintenance much longer: we’ll start losing peak performance and it will slide from there. Ablative shielding is good in some places, seized in others, and gone at key points. We won’t be able to recover those without spacedock, so either way we need to report in after this. Phasers are good, but targeting is off: something they’ve got keeps us from getting a solid lock, so they are better used as sweeps, and it’s not particularly helpful if we’re not committed to the act and VERY lucky. Our rail guns are still offline because their disruptors overwhelmed their magnetic control systems, and our photon torpedoes and manual warheads will still work, if we can hit someone with them. We might be better off dropping them as dark mines, but that’s a last resort, as you know, since it’s bloody illegal.”

Durok growled. The enemy had been dogged in their pursuit of the Vellouwyn for days now, appearing and disappearing at seemingly random whims, pushing the ship off course at every encounter and herding her toward unknown goals. At their second encounter they’d decided to fight back, and while the ship’s weapons had proven capable of disabling, or at least severely deterring their pursuit, the next encounter had had more ships to worry at their heels, and the attacks began to come with more frequency. Repair crews had been unable to make meaningful work of addressing the ship’s systems, as their disruptors carried feedback signals which wreaked havoc with ships systems even as the shields dispersed them, making it dangerous to work on live grids while they were under attack. Worse still, several ship’s systems were under quarantine, as the same effect had a contagious impact on the Vellouwyn’s bio-porous network, and they had been forced to slough off several clonal nodes of insulation generation membranes, and sequester others deeper within the hull where they were less likely to suffer colony destabilization.

Bonn continued to list systems of note, cycling through the tactical, into the life support and operational management systems, stopping for a colourful epithet about the inertial dampeners as Simyarn veered to avoid another attack, and then down into the power and propulsion sets. Thorough and comprehensive while being very concise, Durok was quickly up to speed with the ship’s status, and appreciated his officer’s effectiveness in crisis. The outlook was poor, but the situation wasn’t yet over with. At the end of the report, Durok thumbed the Padd in confirmation and sent Bonn back to his stations. Jamming a black-nailed thumb on the communications panel he had queued up on his armrest, Durok barked out to one side: “Petty Officer Roundhouse, have you got a course for us? We may only have one shot at this idea of yours, we need to make it count.”

Several decks away in a lab behind the deflector and sensor arrays on the belly of the Vellouwyn, a Tiburonian crewman was busily manipulating a holographic model of their current sector of space by hand. Her brow was knit in concentration, making the severe swoop of her eyebrows into her hairline more profound. In real time, tactical data feeds to her station plotted the position of two of their pursuers, the last known trajectories of the other ships which had dogged them recently where they did not match the ship signatures of those who were currently engaged, and a number of other astronomically interesting objects in the region as reference points. A Barzan ensign, Tendan Omar, worked nearby, helping to keep the link between her simulation and the various feeder systems running at peak efficiency, while a striking Kiley, Pratt Denning, was working out formulas for a chain reaction. As Durok’s voice coughed out over a hidden speaker, she frowned and kept working. “Nearly, captain. It will work. It has to. Just be ready to vent our charged warp plasma as we skim the gas giant.”

Back on the bridge, Durok nodded, knowing the motion would not translate through the coms, and tapped the signal closed with a confirmation chime. Leveraging himself out of his chair, leaving the restraint to snake back into its concealment, he strode toward the forward operations console, bracing himself on the back of his flight controller’s seat, careful not to jostle Simyarn as he focused on flying. Tapping Junior Lieutenant Sim Wu on the shoulder encouragingly, he leaned in to review the outputs of the particle systems specialist’s weapon console, nodding at the tracing algorithms he had running on the sensor readouts. The man was smart when it came to event driven programming and had produced a spectral review of their previous engagements that was currently tracking a small spike chain in energy signatures before one of the alien ships fired an antimatter weapon. “If you see your shot, take it Mister Wu.”

The Human man nodded, and Durok looked up at the viewscreen. “Sato, Jendunn, get these bastards back up on my viewscreen. I need to see if I can’t buy us some time.” Behind him at the communications station on the upper bridge, an Aenar woman’s antennae swerved slightly, while the Trillish Human beside her cast a disapproving look of acknowledgement at the back of his head, over his partner Ensign’s shoulder. The two of them had been working at parsing the sparse communication they’d received from the enemy in the past week, or intercepted in subspace traffic, and were still trying to work out if the language was based more on a computational sequence or some biological derivative. Neither of them had made as much progress as they’d have liked, but the material was sparse, and contact more aggressive than communicative. The Sato Ear for Language was legendary in Star Fleet, literally, but the attackers barely used anything that might resemble it.

A long set of moments after his order, the viewscreen changed again; the ships previously on display collapsed into a corner, where the ventral sensor overlay had appeared for the passing torpedo, and the rest was filled with an aggressive, stark, metallic figure. Repeated analysis had told them these were not Breen; study of their language told them that, despite its sound, it was not Breen language, study of their ships and tactics, while aggressive like their Alpha Quadrant comparison, suggested they were not, in fact, Breen. The thing on screen, however, looked Breen, and had the same strange droning buzz when it vocalized, setting Durok’s hair on end. It looked Breen, with the visor hued in green, although the colour and configuration of the armour was slightly different, it was very close to Breen. Durok ran his tongue over his teeth and considered his play.

“We are of Star Fleet, from the United Federation of Planets. Likely you do not know of us yet,” he began, skipping all the pleasantries. “We tried speaking with you before, as it is the way of our coalition to entreat peacefully with new met civilizations. When that failed, we defended ourselves, and rather than engage with us, you escalated.” Still receiving no response from the unemotive entity on screen, he went on. “You have plagued us for a week, and we tire of patience. You may think you have us figured out, and that you can run us down for the kill, but I assure you that is not the case. I will give you one more warning: our ship is on a mission of peace, but our kind value our lives more than we value yours. Tell us what you want and we will consider your request. Otherwise, be on your way, or face the consequences.”

For a long moment there was nothing, and then there was a blast of garbled audio signal which made several of his crew wince before the audio filters kicked in, and dimmed the noise. Behind him, Sato’s eyes went wide, and he started tapping a new set of instructions into the computer, and the chaotic static sound played again, twice more in the background on the bridge. Durok turned around to face the communications station, and Jendunn passed her hands blindly, accurately over controls to help Sato with his effort, the two muttering back and forth for a moment, before suddenly the signal was split into a half dozen audible threads overlaying the background garble of data. A deeply artificial, almost metallic synthesized voice translated several languages simultaneously into one common message: “Run. Hide. Flee. Prey.”

Durok turned around, snarling defiantly, as the figure on screen began to convulse with a new message, which the captain did not need to have translated to know for laughter. Its face disappeared from the screen, and Wu sat up at attention as the two pursuing ships returned to take up the larger viewscreen. A moment later and with a flurry of commands, a fan of lower energy phaser spread burst from the aft canons in a colourful array, and a fraction of a moment later a green hued torpedo belched from a seamless port on the lead ship’s forward hull. As it crossed the thin phaser threshold, breaking a number of the feeble streams, Wu swiped his hands across the controls and the computer recalculated the trajectory based on emitter feedback. Suddenly the streams all converged on the antimatter weapon, linking together into a bright red point which breached the device’s hull and detonated it practically within the launch tube of the pursuing ship.

The result was instantaneously catastrophic for the alien vessel, and the implosion encompassed the entire vessel in a cascade reaction, sucking the normal matter in and annihilating it to produce a pulsar-esque compressed particle stream, ripping the vessel through an event horizon and rendering it into oblivion, before the reactive shockwave blew its remaining mass into a devastating cloud of shrapnel. The second vessel was flying close enough to get caught up in the explosion, and while it was not outright destroyed, it was disabled enough to knock it out of warp, leaving it behind on long distance sensors. A number of bridge crew cheered, save Wu, who was busily harvesting additional tactical data from the successful ploy, but most knew it was, if anything, a temporary reprieve.

“Excellent technique, Mister Wu.” Durok said, patting him on the shoulder again before returning to his chair. “Raoul, get us back on the course from Astrometrics. They’ll send more dogs to hound us before we make good on any escape, so the plan still stands. We have to reach that nebula, and the system on its edge is the perfect place to try their plan. Bonn, update the repair crews on their priorities, and take only who you need: they won’t get to finish the work in all likelihood, and the crew need rest. Take volunteers after you pick the essentials, but don’t ‘motivate’ them. Work with Chief Engineer Vantel, and check in with Shurel to see if the weapon is ready.”

The Tellarite nodded and set to his work, while Chief Conn Officer Simyarn set about coordinating course updates with the astrometrics lab. Durok decided to leave the language team to pore over their new epiphanies: he’d be briefed on their findings when they were ready, and instead stood to move to the aft turbolift corridor. “Durok to Ve Sudan;” he said, waiting for the computer to acknowledge his hail. “If you’re able, come take command of the bridge. Else send Adonnas. I’m going to check on Paine.” He commanded, knowing that the second and third shift bridge officers would be relatively fresh compared to the fourth rotation, which had retired barely two hours before, mid-battle. Some of their shift’s rotations were still on station, and he knew that, were Paine Thomas at her post, they’d have been mandatorily rotated by now, but Sudan could handle that just as well: the Betazoid Lieutenant Commander had a keen sense for fatigue among the crew, and knew when they were reaching, rather than riding, their limits. He got a simple ‘Affirmative’ from her, and stepped off the bridge with a last look at the ant hill of its crew compliment, smiling with concern before turning left to his preferred turbolift station, which had been prioritized for command needs in a crisis.

“Sick bay ICU,” he instructed as he stepped into the dimly lit can, feeling the throb of fatigue budding behind his eyes as he braced for what he always considered to be an awkward period of contemplation as the lift shuttled through maglev tunnels between bulkheads. He dreaded what he’d find when he arrived at his destination: Paine was his first officer, and in the year that they’d served together thus far, he’d come to respect and rely on her. She was as true and stalwart a warrior as he had ever encountered, at any time, anywhere, so to see her laid low by the disruptor infection which had impacted the crew stationed in the aft deuterium storage bays when the first attack had taken them unprepared was a demoralizing sensation. Many of the others had been treated and were recovering, as the Vellouwyn’s medical team was among the most brilliant he’d ever seen, but three of his crew were still unconscious and in various states of suffering, with Paine being by far the most overwhelmed.

Before he returned to his rotation, perhaps to get some rest, but more likely to revisit the plan with his strategic teams before they reached their next destination, he would spend some time at their sides, speaking quietly of what he knew of them, what was important to them, their motivation and inspirations. He did not know, and nor did Chief Medical Officer Barr, whether they could hear him or not, but he felt that if anything would motivate them to stave off death, it was the things of value found in their lives. It was the least he could do to remind them of their worth.

And now...

4 notes

·

View notes

Text

Enhancing Power Quality with Static VAR Generators: A Smart Power Factor Solution"

Power quality is a critical concern for industries that rely heavily on electrical equipment and automation. One of the biggest challenges in maintaining power quality is managing reactive power and maintaining a healthy power factor. This is where the Static VAR Generator (SVG) comes into play—a modern, efficient, and intelligent solution for reactive power compensation.

What is a Static VAR Generator?

A Static VAR Generator (SVG), also known as a STATCOM (Static Synchronous Compensator), is an advanced power electronics device used to provide dynamic reactive power compensation. Unlike traditional capacitor banks or synchronous condensers, SVGs can respond instantly to load changes and maintain a consistent power factor close to unity.

How Does SVG Work?

SVGs use IGBT-based inverters to generate or absorb reactive power. They continuously monitor the load and automatically inject the necessary reactive current in real time. This makes them highly efficient for both inductive and capacitive loads.

Key Benefits of Static VAR Generators

Improved Power Factor Automatically maintain near-unity power factor and reduce penalties from utility providers.

Voltage Stabilization Enhance voltage profile and prevent dips or fluctuations.

Reduced Harmonics Many SVGs come with built-in harmonic filtering capabilities, improving overall power quality.

Energy Efficiency Minimize energy loss in electrical networks and improve system performance.

Fast Response Time React to load changes in milliseconds, making it ideal for sensitive applications like data centers or manufacturing lines.

Applications of SVG

Industrial plants with fluctuating loads

Data centers and IT facilities

Hospitals and commercial buildings

Renewable energy plants (solar/wind farms)

Utilities and substations

Why Choose SVG Over Traditional Solutions?

While capacitor banks are widely used for reactive power compensation, they are often slow, bulky, and unable to respond dynamically. SVGs offer real-time control, compact design, and superior precision, making them the go-to solution for modern power systems.

Conclusion

A Static VAR Generator is a smart investment for businesses looking to improve power quality, enhance energy efficiency, and avoid utility penalties. With its fast response, precision control, and wide application range, SVG technology is reshaping how we manage reactive power in today’s electrical systems.

0 notes

Text

How to Reduce the Ferranti Effect in Transmission Lines

1. Shunt Reactor

Shunt reactors are inductive devices connected in parallel (shunt) with a transmission line or bus bar. Their main function is to absorb the reactive power generated by line capacitance, thus limiting the voltage rise.

2. Capacitor Banks

Capacitor banks are commonly used for reactive power compensation in power systems. However, they can also be used strategically to counteract voltage surges caused by the Ferranti effect. Long transmission lines often experience the Ferranti effect, in which the voltage at the receiving end exceeds the voltage at the sending end, especially when there is little or no load.

If not managed properly, this effect can lead to overvoltage problems, insulation damage, and equipment failure. One of the most effective solutions to control the Ferranti effect is the use of capacitor banks. Utilities and power companies install shunt capacitor banks to regulate voltage levels, especially in rural or remote substations where the load is minimal. This helps prevent voltage surges and ensures the safe operation of connected equipment. The Ferranti effect can be a serious problem in long-distance power transmission. The use of capacitor banks offers a cost-effective and efficient way to mitigate this phenomenon. By providing reactive power compensation, they help maintain system stability, improve voltage regulation, and protect equipment from potential damage.

3. Series Capacitors

Transmission lines are connected in series using series capacitors. Their main purpose is to compensate for the inductive reactance of the line. They successfully reduce the total reactance and balance the reactive voltage drop of the line by adding a capacitive reactance in series. Long transmission lines can experience the Ferranti effect, in which the voltage at the receiving end exceeds the voltage at the transmitting end, especially when there is little or no load.

This overvoltage condition has the potential to damage machinery and compromise the stability of the electrical system. The use of series capacitors is one of the best ways to reduce the Ferranti effect.

4. Using Voltage Regulators

Voltage regulators are devices that automatically maintain a constant voltage level. When integrated into a power transmission system, they can effectively control and correct voltage variations due to the Ferranti effect. The Ferranti effect is a well-known phenomenon in electric power systems, where the voltage at the receiving end of a long, lightly loaded transmission line becomes higher than that at the sending end. System instability, equipment failure, and insulation damage can result from this overvoltage. The use of voltage regulators is one of the most effective strategies for mitigating the Ferranti effect.

0 notes

Text

Passive Harmonic Filters: Key Advantages and Where They’re Used

In the modern changing industrial scenario, power quality management is now a priority for companies in all industries. With the growing application of variable frequency drives (VFDs), LED lighting, computers, and other non-linear loads, harmonic distortion in power systems is gaining prevalence. To mitigate these issues, engineers deploy different solutions, one of the most common being passive harmonic filters. These filters have proven to be reliable and effective, particularly in environments with predictable load conditions. In this blog, we’ll explore the concept of passive harmonic filtering, its benefits, how it differs from other solutions like active harmonic filters, and where it is best applied.

What Are Passive Harmonic Filters?

Passive harmonic filters are equipment used to minimize harmonic distortion in an electric system via the utilization of passive components of predominantly inductors, capacitors, and resistors. The components are connected in such a manner as to absorb or redirect certain harmonics but transmit the fundamental frequency (usually 50 Hz).

Unlike active harmonic filters, which dynamically cancel harmonics with power electronics and digital controls, passive filters are fixed-tuned to particular frequencies. This is advantageous in installations where the harmonic spectrum is well understood and comparatively constant.

Major Advantages of Passive Harmonic Filters

1. Cost effectiveness

One of the greatest benefits of passive harmonic filters is that they are cost-effective. They are much cheaper than active harmonic filters to purchase, as well as maintain over time. For buildings that have a limited budget or that do not require dynamic filtering, passive filters are an effective solution.

2. Easy Installation and Design

Passive filters are simply designed and require no complicated configuration or digital interfaces. This is a plug-and-play filter that makes it easy to integrate into current electrical installations. It is the simplicity of the design that makes it a good choice for facilities that do not have specialized technical personnel.

3. Dual Functionality with Power Factor Correction

Most passive harmonic filters are also Power Factor Correction devices. Enhancing the power factor reduces the consumption of reactive power and decreases the cost of electricity.

This two-in-one design reduces system architecture and saves space.

4. Low Maintenance

Because these filters contain only passive components, they have fewer failure points and need little maintenance in the long run. This reliability means extended operational life and reduced downtime.

5. Automatic System Support

As part of automatic power factor correction systems, passive filters make overall energy efficiency possible. These systems adjust power factor automatically and handle harmonics as well, providing an end-to-end power quality solution.

Passive vs Active Harmonic Filters

The decision between passive harmonic filters and active harmonic filters will be based on the system's complexity. Passive filters are tuned to address specific frequencies, whereas active filters are capable of sensing and neutralizing a broad spectrum of harmonic currents in real-time. Active harmonic filters are well suited to dynamic loads where load conditions are continuously changing, like data centers or advanced manufacturing facilities. In stable loads like water treatment plants or HVAC systems, passive filters are a cost-effective and effective solution.

Role in Automatic Power Factor Correction Systems

Automatic power factor correction systems are employed to monitor the power factor of electrical installations continuously and correct them. They are required in industries that go through fluctuating load conditions during the day. When these systems are made to incorporate passive harmonic filters, they improve overall efficiency not only by compensating for the power factor but also for filtering harmonics. This is particularly valuable in manufacturing facilities and commercial offices where both power factor and harmonic distortion must be controlled at once.

Where Are Passive Harmonic Filters Used?

1. Industrial Manufacturing Plants

Applications with fixed-speed motors and drives tend to have harmonics because of the steady nature of their loads. Passive filters are best in such cases, as the harmonics are deterministic and controllable with fixed-tuned solutions.

2. Water Treatment Plants

Such plants tend to have constant, non-linear loads from compressors and pumps. Passive filters ensure clean power supply and continuity of equipment operation.

3. Commercial HVAC Systems

Heating, ventilation, and air conditioning units may produce substantial harmonics, particularly when more than one unit is operating at the same time. Passive filters can be used to stabilize voltage and safeguard delicate control systems.

4. Telecommunication Infrastructure

Ongoing operation of power supplies and rectifiers makes the use of passive filters beneficial at telecom sites to suppress electrical noise and enhance network equipment reliability.

5. Educational and Government Buildings

These types of facilities may not necessarily experience high variation in their electric loads. An arrangement of Power Factor Correction combined with harmonic filtering via passive filters will guarantee that there is conformance to utility requirements and lessened energy expenditures.

Benefits of Power Quality Strategy

Although the passive filters in themselves can provide significant improvement, they tend to be most effective as part of an overall strategy which might incorporate automatic power factor correction units as well as, where required, active harmonic filters.

For instance, in a layered strategy:

These filters work best in eliminating harmonics with fixed, known frequencies.

Active filters deal with dynamic, variable harmonic loads.

APFC panels control real-time Power Factor Correction for optimal energy consumption.

This multi-layered configuration allows both power quality compliance and sustained equipment dependability.

Selecting the Proper Solution

Picking the right filter is based on a good grasp of your load characteristics. Passive solutions are generally utilized in eliminating specific fixed-frequency harmonic disturbances. This identifies the form and degree of harmonic distortion and leads to making a decision about passive harmonic filters versus active harmonic filters.

Power Matrix Solutions, the power quality engineering leader, provides complete services in harmonic analysis and filtering solutions. With a focus on reliability and performance, they offer customized recommendations that meet your system's particular needs. From independent passive filter installations to complete automatic power factor correction systems, Power Matrix Solutions applies vast experience to have your facility running at its most efficient and stable level.

Final Thoughts

With the energy landscape growing more complex by the day, harmonic management can no longer be a nicety; it has to be a necessity. Passive harmonic filters offer a low-cost, low-maintenance solution for removing harmonic distortion and ensuring power quality, especially in controlled-load environments.

They also include the added advantage of Power Factor Correction to minimize energy losses and utility penalties. When integrated with automatic power factor correction systems, they provide an even more potent toolset for optimizing system performance. While active harmonic filters are still the first choice in dynamic, high-frequency harmonic suppression, passive harmonic filters remain the most reliable and cost-efficient solution for most industrial and commercial applications.

#Passive Harmonic Filters#Power Factor Correction#Active Harmonic Filters#Automatic Power Factor Correction

0 notes

Text

Power Quality Equipment Market: Emerging Trends Shaping Future Demand

The power quality equipment market has witnessed notable growth in recent years, driven by the increasing demand for reliable electricity supply and the rapid expansion of industrial and commercial infrastructure. Power quality refers to the stability and purity of electric power, which is essential for the smooth operation of sensitive electronic devices and critical systems. Power quality equipment plays a crucial role in mitigating voltage fluctuations, harmonics, transients, and other electrical disturbances that can cause equipment malfunction or failure.

As global power systems become more complex with the integration of renewable energy and the proliferation of smart devices, ensuring high-quality power delivery becomes more challenging and essential. In this context, emerging trends in the power quality equipment market are not only transforming the industry landscape but are also opening new avenues for innovation and growth.

Surge in Renewable Energy Integration

One of the most significant trends impacting the power quality equipment market is the growing integration of renewable energy sources such as solar and wind. These sources, while environmentally friendly, are inherently intermittent and variable, often introducing power fluctuations and instability into the grid. To address these challenges, there is an increasing demand for power quality solutions such as voltage regulators, harmonic filters, and energy storage systems that can smooth out supply irregularities and ensure stable power delivery.

Additionally, the decentralization of power generation through distributed energy resources (DERs) calls for advanced monitoring and control technologies to maintain grid stability, further boosting the market for intelligent power quality devices.

Growing Industrial Automation and Digitization

The rise of Industry 4.0 and smart manufacturing has significantly increased the reliance on automated machinery, robotics, and data-driven processes. These systems are highly sensitive to power disturbances and require uninterrupted, clean power to function efficiently. As a result, industries are investing heavily in uninterruptible power supplies (UPS), surge protection devices, and power conditioning equipment.

Moreover, the digitization of industrial operations has led to the deployment of advanced sensors and monitoring tools that provide real-time data on power quality. These insights enable predictive maintenance, reduce downtime, and optimize energy consumption—benefits that are driving wider adoption across manufacturing and processing sectors.

Advancements in Smart Grid Technologies

Smart grids are playing a pivotal role in reshaping the power quality equipment landscape. These grids use digital communication technology to detect and react to local changes in usage, thereby enhancing the reliability and efficiency of electricity distribution. With smart grids, utilities can better manage load fluctuations, detect faults instantly, and deploy corrective measures automatically.

Power quality monitoring devices integrated within smart grid infrastructure can track parameters such as voltage sags, swells, and harmonic distortions, allowing utilities and consumers to take corrective actions proactively. The growing investments in smart grid development are, therefore, expected to fuel the demand for next-generation power quality solutions.

Rising Awareness of Energy Efficiency

Energy efficiency is becoming a central theme in both commercial and residential sectors, spurred by regulatory policies and growing environmental consciousness. Power quality equipment contributes significantly to energy efficiency by reducing losses associated with poor power conditions. For example, reactive power compensation devices can improve power factor, reduce energy consumption, and lower electricity bills.

Businesses and utilities are increasingly recognizing the long-term financial and environmental benefits of investing in power quality systems. This awareness is encouraging the adoption of energy-efficient devices that not only ensure power reliability but also contribute to sustainability goals.

Technological Innovations and Product Development

The power quality equipment market is witnessing rapid innovation with the development of compact, intelligent, and IoT-enabled devices. These new-generation products offer improved performance, easier integration, and enhanced diagnostic capabilities. IoT connectivity allows for remote monitoring, automated reporting, and real-time alerts, significantly improving maintenance efficiency and system uptime.

Manufacturers are also focusing on developing modular solutions that can be customized based on the unique requirements of different industries and grid conditions. These innovations are not only improving user experience but also expanding the market reach of power quality equipment.

Conclusion

The power quality equipment market is undergoing a transformative phase fueled by trends such as renewable energy integration, industrial automation, smart grid adoption, and increasing energy efficiency demands. As global energy systems evolve, the importance of maintaining high power quality becomes ever more critical. Companies operating in this space must embrace innovation, invest in advanced technologies, and stay aligned with market trends to capitalize on the emerging opportunities. The future of the power quality equipment market looks promising, marked by technological evolution and a growing emphasis on sustainable energy practices.

0 notes

Text

Emerging Trends Shaping the Global Power Capacitors Market Through 2030 and Beyond

Power capacitors are often the unsung heroes in the realm of electrical infrastructure. These components, essential for improving power factor, voltage regulation, and overall energy efficiency, play a vital role across various sectors industrial, commercial, and even residential. With the growing demand for efficient power systems and renewable energy integration, the power capacitors market is gaining significant momentum. In this blog, we’ll delve into the market’s dynamics, current trends, and the challenges it faces.

What Are Power Capacitors?

Power capacitors are devices that store and discharge electrical energy. Their primary function is to regulate the power factor in electrical systems essentially improving the efficiency of power transmission. They help reduce losses in the system, stabilize voltage, and enhance the capacity of the power supply. These devices are commonly used in substations, power plants, manufacturing facilities, and increasingly in renewable energy applications like solar and wind installations.

Market Overview and Growth Drivers

The global power capacitors market has been witnessing steady growth, and this trend is expected to continue. Several factors are contributing to this expansion:

Rising Demand for Energy Efficiency: With the global push toward reducing carbon emissions and optimizing energy use, power capacitors are in demand to improve the efficiency of existing power infrastructure.

Modernization of Power Grids: Aging power grids, especially in developed countries, are being upgraded to smart grids. Power capacitors play a key role in these systems, helping with voltage control and reactive power compensation.

Growth of Renewable Energy: As more solar and wind power sources are added to grids, the need for voltage stability increases. Power capacitors provide necessary support to manage these intermittent energy sources.

Industrial Growth in Emerging Economies: Countries like India, China, and Brazil are investing heavily in manufacturing and infrastructure. These sectors require stable and efficient electrical systems, driving up the need for power capacitors.

Segmentation and Market Landscape

The power capacitors market can be segmented by type, voltage rating, application, and geography.

By Type: The market includes ceramic capacitors, aluminum electrolytic capacitors, and plastic film capacitors, among others. Plastic film capacitors are particularly popular due to their reliability and high-performance characteristics.

By Voltage: Low voltage capacitors are dominant due to their widespread use in consumer and industrial applications, but medium and high voltage capacitors are gaining traction in utility and grid applications.

By Application: Power capacitors are used in utilities, industrial power systems, and commercial buildings. The utility segment remains the largest, largely due to investments in transmission and distribution.

By Region: Asia-Pacific leads the global market, thanks to rapid industrialization and energy infrastructure projects, especially in China and India. North America and Europe also show significant market activity due to grid modernization efforts.

Challenges in the Market

Despite the positive outlook, the power capacitors market is not without its hurdles:

Raw Material Volatility: Many capacitor components rely on materials like aluminum, polypropylene, and certain rare metals. Price fluctuations and supply chain disruptions can significantly impact production costs.

Complex Regulatory Environments: Different regions have varied standards and compliance requirements for electrical components. Navigating these can be costly and time-consuming for manufacturers.

Competition from Alternative Technologies: Power electronics and newer grid management solutions sometimes compete directly with traditional capacitor-based systems, potentially limiting market share in certain applications.

Future Outlook

The future of the power capacitors market looks promising. With governments around the world committing to green energy and infrastructure development, demand for efficient power management systems is likely to rise. Innovations in capacitor design such as the development of more compact, durable, and temperature-resistant models will further push the market forward.

Conclusion

In conclusion, power capacitors may not always grab headlines, but their impact on modern electrical systems is undeniable. As industries and governments alike pursue greater energy efficiency and cleaner power, these components will continue to play a pivotal role. For investors, manufacturers, and engineers, keeping an eye on this evolving market could offer both insights and opportunities in the years ahead.

0 notes

Text

How Servo Voltage Stabilizers Improve Power Efficiency

In today's energy-conscious world, maintaining power efficiency is crucial for both residential and industrial applications. Voltage fluctuations are a common challenge that can lead to energy inefficiency, equipment damage, and increased operational costs. Servo voltage stabilizers play a vital role in addressing these issues by ensuring consistent voltage levels and improving overall power efficiency. This article explores how servo voltage stabilizers enhance power efficiency and why they are essential for modern energy management.

Understanding Servo Voltage Stabilizers

A servo voltage stabilizer is an electromechanical device designed to regulate voltage fluctuations and provide a stable output voltage. It operates using a servo motor, which adjusts the voltage in real-time to match the desired level. This ensures that electrical appliances and equipment receive a consistent voltage supply, regardless of variations in the input voltage.

The Impact of Voltage Fluctuations on Power Efficiency

Voltage fluctuations can have several adverse effects on power efficiency:

Energy Losses: Fluctuating voltage leads to increased energy consumption as devices try to compensate for unstable power.

Reduced Equipment Lifespan: Electrical appliances subjected to inconsistent voltage may experience overheating or premature wear, leading to inefficiencies.

Operational Disruptions: Voltage instability can cause equipment to malfunction or shut down, resulting in downtime and productivity losses.

How Servo Voltage Stabilizers Enhance Power Efficiency

Maintaining Optimal Voltage Levels: Servo voltage stabilizers ensure that appliances and machinery operate at their rated voltage, preventing overvoltage or undervoltage conditions. This optimized operation minimizes energy wastage and enhances efficiency.

Reducing Power Losses: By stabilizing voltage levels, these devices eliminate the need for equipment to draw excess current, reducing overall power losses.

Protecting Sensitive Equipment: Servo stabilizers safeguard sensitive electronics from voltage surges and spikes, ensuring their efficient performance and longevity.

Improving Power Factor: Stable voltage supply contributes to a better power factor, reducing reactive power losses and improving the efficiency of electrical systems.

Enhancing System Reliability: With consistent voltage regulation, servo stabilizers prevent frequent breakdowns and maintenance, leading to more reliable and efficient operations.

Applications of Servo Voltage Stabilizers

Servo voltage stabilizers are widely used in various sectors to improve power efficiency:

Residential: Protecting household appliances such as refrigerators, air conditioners, and televisions.

Commercial: Ensuring stable power supply for offices, retail spaces, and data centers.

Industrial: Supporting machinery, motors, and manufacturing equipment.

Healthcare: Maintaining consistent voltage for medical equipment and diagnostic devices.

Benefits of Using Servo Voltage Stabilizers

Energy Savings: By preventing energy wastage, servo stabilizers contribute to significant cost savings over time.

Extended Equipment Lifespan: Stable voltage reduces wear and tear on electrical devices, prolonging their operational life.

Environmental Impact: Improved power efficiency leads to lower energy consumption, reducing the carbon footprint.

Cost-Effectiveness: The reduced need for equipment repairs and replacements makes servo stabilizers a cost-effective solution.

Choosing the Right Servo Voltage Stabilizer

To maximize power efficiency, it is essential to select the right stabilizer for your needs. Consider factors such as:

Load Capacity: Ensure the stabilizer can handle the total load of your equipment.

Voltage Range: Choose a stabilizer that can manage the expected input voltage variations.

Efficiency Rating: Look for devices with high efficiency and low energy losses.

Brand and Warranty: Opt for reliable brands that offer robust warranties and after-sales support.

Conclusion

Servo voltage stabilizers are indispensable for enhancing power efficiency in both residential and industrial settings. By regulating voltage fluctuations and ensuring stable power supply, these devices minimize energy wastage, protect equipment, and reduce operational costs. Investing in a high-quality servo voltage stabilizer is a smart decision for anyone looking to improve energy efficiency and safeguard their electrical systems. As energy demands continue to grow, servo voltage stabilizers will remain a cornerstone of efficient and sustainable power management.

0 notes

Text

Enhance Your Electrical and Energy Efficiency with Venus Technocrafts’ Advanced Solutions

In today’s rapidly evolving industrial and commercial sectors, ensuring energy efficiency and maintaining power quality is vital for reducing operational costs and protecting valuable equipment. At Venus Technocrafts, we offer a range of innovative solutions designed to optimize your electrical systems and enhance energy efficiency. Our products, including APFC Panels, Active Harmonics Filters, Static Var Generators, and Heat Pumps, are engineered to meet the growing demands of industries and businesses, providing reliable performance and long-term savings.

In this blog, we’ll explore how these advanced solutions can transform your power systems for better energy management and operational success.

1. APFC Panels – Optimizing Power Factor for Better Efficiency

One of the most crucial aspects of electrical system performance is maintaining an optimal power factor. A low power factor can result in higher energy consumption, increased electricity bills, and unnecessary strain on equipment. The Automatic Power Factor Control (APFC) Panels by Venus Technocrafts are designed to automatically manage and correct power factor levels, improving the overall efficiency of your electrical system.

These APFC Panels monitor the power factor in real-time and automatically control capacitor banks to keep the power factor at an optimal level. By improving the power factor, businesses can reduce electricity costs, avoid penalties from utility companies, and extend the lifespan of electrical equipment.

Key Benefits of APFC Panels:

Improved energy efficiency by maintaining an optimal power factor.

Cost savings on electricity bills.

Compliance with industry standards and utility requirements.

Protection of electrical equipment from overloads and damage.

2. Active Harmonics Filters – Maintaining Power Quality

Harmonic distortion in electrical systems is caused by non-linear loads such as variable frequency drives, computers, and industrial machinery. This distortion can lead to overheating, equipment malfunction, and increased energy consumption. To combat this issue, Active Harmonics Filters (AHFs) are designed to eliminate harmonics and maintain power quality in your electrical system.

Our Active Harmonics Filters offer a dynamic solution to real-time harmonic compensation. These advanced devices continuously monitor harmonic frequencies and adjust accordingly, ensuring minimal distortion and optimal power quality at all times.

Key Benefits of Active Harmonics Filters:

Real-time harmonic compensation for clean and stable power.

Protection of sensitive equipment from damage caused by harmonics.

Reduced energy losses and increased system efficiency.

Compliance with IEEE 519 standards for harmonic limits.

3. Static Var Generators – Ensuring System Stability and Power Quality

Maintaining a stable and reliable electrical supply is vital for the smooth operation of any business. Static Var Generators (SVGs) are cutting-edge solutions that automatically provide reactive power compensation to stabilize voltage levels and improve power factor. SVGs play a crucial role in ensuring power system stability, especially in environments with fluctuating loads, such as industrial plants and data centers.

Venus Technocrafts’ Static Var Generators offer fast, efficient, and precise voltage regulation, enhancing the stability and reliability of your electrical system. By automatically adjusting reactive power in real-time, SVGs ensure that your system performs optimally, reducing voltage fluctuations and preventing equipment failure.

Key Benefits of Static Var Generators:

Improved voltage regulation and system stability.

Reduced risk of equipment damage from voltage fluctuations.

Fast and precise reactive power compensation.

Increased overall system efficiency and reduced operational costs.

4. Heat Pumps – Sustainable and Energy-Efficient Heating and Cooling

When it comes to heating and cooling, heat pumps are an excellent energy-efficient solution. Unlike traditional heating systems that rely on burning fuel, heat pumps transfer heat from the air, water, or ground to provide both heating and cooling in a sustainable and energy-efficient manner.

Venus Technocrafts’ heat pumps are ideal for residential, commercial, and industrial applications. They are designed to provide consistent indoor comfort while minimizing energy consumption. By using renewable energy sources, heat pumps significantly reduce carbon footprints and operating costs.

Key Benefits of Heat Pumps:

Energy-efficient heating and cooling solutions that reduce energy costs.

Sustainability through the use of renewable energy sources.

Reduced carbon footprint compared to traditional heating and cooling methods.

Long-term savings through reduced operating costs.

Conclusion:

At Venus Technocrafts, we are committed to helping businesses optimize their electrical systems and reduce operational costs through cutting-edge technologies. From APFC Panels that ensure power factor correction to Active Harmonics Filters that maintain power quality, Static Var Generators that enhance system stability, and Heat Pumps that provide sustainable heating and cooling, we offer a comprehensive range of solutions designed to improve energy efficiency, protect equipment, and reduce energy wastage.

Contact us today to learn more about how these advanced solutions can benefit your business and help you achieve greater efficiency, cost savings, and sustainability. Together, we can create a more efficient and sustainable future for your operations.

0 notes

Text

TIBCON Capacitor Manufacturers: Powering Efficiency Across Industries

Capacitors are fundamental components in electrical and electronic circuits, vital for energy storage, power regulation, and ensuring smooth operation of various devices. Among the leading names in capacitor production is TIBCON, a trusted brand known for manufacturing high-quality capacitors for a wide array of applications. TIBCON capacitor manufacturers have established a strong presence in both domestic and international markets, providing reliable solutions for industries ranging from consumer electronics to heavy machinery.

A Legacy of Quality: The TIBCON Advantage

TIBCON, part of Tibrewala Electronics Ltd., has been a prominent player in the capacitor manufacturing industry for over three decades. With a focus on innovation, precision, and reliability, TIBCON capacitor manufacturers have built a reputation for delivering high-performance capacitors that meet the stringent demands of modern electronics and electrical systems.

What sets TIBCON apart is its commitment to quality and adherence to global standards. The company’s capacitors are engineered to provide long-lasting performance, withstanding extreme temperatures, voltage fluctuations, and mechanical stresses. These characteristics make TIBCON capacitors an ideal choice for critical applications where durability and consistency are paramount.

Types of Capacitors Manufactured by TIBCON

TIBCON offers a wide range of capacitors, each designed for specific industrial and consumer applications. Some of the key capacitor types produced by TIBCON capacitor manufacturers include:

Motor Run Capacitors: TIBCON’s motor run capacitors are widely used in air conditioners, refrigerators, pumps, and compressors. These capacitors help motors start smoothly and run efficiently, providing energy savings and improved performance in appliances and industrial equipment.

Lighting Capacitors: TIBCON manufactures capacitors for fluorescent and LED lighting systems. These capacitors ensure stable and flicker-free lighting while enhancing the longevity of the lighting equipment.

Fan Capacitors: TIBCON fan capacitors are known for their reliability in ceiling fans, exhaust fans, and table fans, ensuring consistent speed and smooth operation.

Power Factor Correction (PFC) Capacitors: Power factor correction is crucial for reducing energy wastage in industrial and commercial operations. TIBCON’s PFC capacitors help improve energy efficiency by compensating for reactive power in electrical systems.

AC Capacitors: Used in air conditioners and cooling systems, TIBCON’s AC capacitors are designed to withstand high-voltage environments, ensuring optimal cooling performance even under heavy loads.

TIBCON’s Commitment to Innovation and Sustainability

One of the defining features of TIBCON capacitor manufacturers is their relentless focus on innovation. The company continually invests in research and development to improve capacitor performance and adapt to emerging technologies and applications. This commitment to innovation has allowed TIBCON to develop capacitors that are more compact, energy-efficient, and reliable than ever before.

In addition to technological advancements, TIBCON is also dedicated to sustainability. By designing capacitors that improve energy efficiency and reduce power consumption, TIBCON is contributing to greener and more sustainable industrial practices. Many of their products, such as PFC capacitors, help industries minimize energy wastage, which is essential for reducing environmental impact.

Why Choose TIBCON Capacitors?

Businesses across various sectors prefer TIBCON capacitor manufacturers for several reasons:

Global Standards Compliance: TIBCON capacitors adhere to international standards like IEC and ISI, ensuring they meet the highest quality and safety requirements for both domestic and international markets.

Durability and Reliability: Designed to perform under demanding conditions, TIBCON capacitors offer long service life and consistent performance, making them suitable for heavy-duty industrial applications.

Custom Solutions: TIBCON capacitor manufacturers provide customized solutions tailored to the specific needs of clients across industries, offering flexibility in design and specifications.

Strong After-Sales Support: TIBCON is renowned for its excellent customer service and technical support, assisting businesses with capacitor selection, installation, and maintenance.

Wide Application Range: From household appliances and lighting systems to industrial machinery and power factor correction, TIBCON capacitors are versatile and can be found in a wide range of applications.

Applications of TIBCON Capacitors in Key Industries

HVAC and Appliances: TIBCON motor run and AC capacitors are commonly used in HVAC systems, refrigerators, washing machines, and other household appliances. They ensure energy-efficient operation and reliable performance.

Industrial Machinery: In industrial settings, TIBCON’s PFC capacitors play a crucial role in optimizing power usage and improving the efficiency of large machinery and electrical systems.

Lighting Solutions: TIBCON lighting capacitors are ideal for both residential and commercial lighting systems, ensuring stable performance and prolonging the life of lighting equipment.

Renewable Energy Systems: As the renewable energy sector grows, TIBCON capacitors are finding increasing use in solar and wind energy systems, where they help manage power distribution and improve system reliability.

Conclusion

With a focus on innovation, quality, and customer satisfaction, TIBCON capacitor manufacturers have earned their place as industry leaders. Their capacitors are trusted by businesses across the globe to deliver reliable performance, energy efficiency, and durability. As industries continue to evolve and demand more efficient electronic components, TIBCON remains at the forefront of capacitor manufacturing, powering progress across various sectors.

Whether for industrial, commercial, or residential applications, TIBCON capacitors provide the performance and reliability that businesses need to stay competitive in today’s fast-paced technological landscape.

0 notes

Text

Shunt Reactor Market Set for Significant Growth Through 2031 Driven by Rising Demand for Voltage Control in Electrical Grids

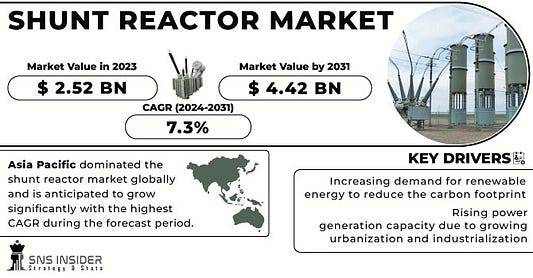

The Shunt Reactor Market size was valued at US$ 2.52 billion in 2023 and is expected to grow to US$ 4.42 billion by 2030 and grow at a CAGR of 7.3% over the forecast period of 2024–2031.

Shunt reactors are critical devices used in electrical networks to manage and compensate for reactive power. By absorbing excess reactive power, they help maintain voltage levels within acceptable ranges, thereby enhancing the reliability and performance of power systems. The integration of renewable energy sources, such as wind and solar, often leads to voltage fluctuations that can jeopardize grid stability. Shunt reactors mitigate these fluctuations, making them indispensable in modern power systems.

The increasing global demand for electricity, coupled with the need for sustainable energy solutions, is driving investments in shunt reactor installations. As countries aim to meet their climate goals and improve energy efficiency, the importance of effective reactive power management continues to grow.

Request Sample Report@ https://www.snsinsider.com/sample-request/2730

Key Market Drivers

Increasing Demand for Reactive Power Compensation: The need for reactive power compensation in high-voltage transmission systems is a significant driver of the shunt reactor market. Utilities are increasingly investing in shunt reactors to ensure voltage stability and compliance with regulatory standards.

Integration of Renewable Energy Sources: The expansion of renewable energy technologies often leads to voltage fluctuations. Shunt reactors play a crucial role in managing these fluctuations, thereby facilitating the integration of variable generation sources into the grid.

Grid Modernization Initiatives: Governments and utilities worldwide are investing in the modernization of electrical grids to enhance their reliability and efficiency. This trend is propelling the demand for shunt reactors as part of broader grid improvement projects.

Rising Electricity Consumption: The growing global population and increasing industrialization are driving up electricity consumption. This surge in demand necessitates the enhancement of power infrastructure, including the implementation of shunt reactors.

Supportive Government Policies: Various governments are implementing policies and regulations to promote grid stability and efficiency, further encouraging investments in shunt reactor technology.

Market Segmentation

The Shunt Reactor Market can be segmented by type, installation, application, and region.

By Type

Air-Core Shunt Reactors: These reactors are used primarily in high-voltage applications due to their low losses and high efficiency. They are commonly installed in substations and transmission networks.

Oil-Filled Shunt Reactors: These reactors utilize oil for cooling and insulation and are typically employed in power systems where higher insulation levels are necessary.

Dry-Type Shunt Reactors: Utilizing air as a cooling medium, dry-type reactors are suitable for lower voltage applications and are preferred for indoor installations due to their compact design.

By Installation

Indoor Shunt Reactors: Installed within substations or facilities, these reactors are designed for environments with limited space and require additional protection.

Outdoor Shunt Reactors: Designed for installation in open areas, outdoor reactors are built to withstand environmental conditions, making them suitable for high-voltage transmission applications.

Buy a Complete Report of Hydrogen Fuel Cells Market 2024–2032@ https://www.snsinsider.com/checkout/2730

By Application

Transmission Systems: Shunt reactors are predominantly used in high-voltage transmission systems to maintain voltage levels and improve overall system stability.

Distribution Systems: In distribution networks, shunt reactors help manage reactive power, ensuring efficient delivery of electricity to end consumers.

Renewable Energy Integration: Shunt reactors are increasingly used in conjunction with renewable energy projects to mitigate voltage fluctuations caused by variable generation.

Regional Analysis

North America: The North American shunt reactor market is set to grow significantly due to ongoing investments in grid modernization and the integration of renewable energy sources. The U.S. and Canada are leading efforts to adopt advanced power management technologies.

Europe: Europe remains a key player in the shunt reactor market, with countries like Germany, France, and the UK investing in grid stability measures to support their renewable energy initiatives.

Asia-Pacific: The Asia-Pacific region is expected to witness rapid growth in the shunt reactor market, particularly in countries like China, India, and Japan, which are investing heavily in power infrastructure.

Middle East & Africa: The Middle East and Africa are exploring the potential of shunt reactors to enhance electricity infrastructure, focusing on improving grid stability and reliability.

Latin America: Countries like Brazil and Chile are beginning to invest in shunt reactors, recognizing the importance of these devices in supporting their expanding energy needs.

Current Market Trends

Technological Innovations: Manufacturers are focusing on developing advanced shunt reactors that minimize losses and enhance efficiency, responding to the demands of modern power systems.

Smart Grid Implementation: The integration of smart grid technologies is increasing the demand for shunt reactors as utilities seek to optimize power management and enhance grid resilience.

Decentralized Energy Systems: The trend towards decentralized energy systems, including distributed generation and microgrids, is creating new opportunities for shunt reactors to manage reactive power locally.

Sustainability Focus: As sustainability becomes a priority for industries and utilities, the demand for efficient and reliable shunt reactors is growing to support renewable energy integration and reduce environmental impact.

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions. Contact Us: Akash Anand — Head of Business Development & Strategy [email protected] Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)

1 note

·

View note

Text

Empowering Modern Industry: A Look into Static VAR Generator Manufacturers

In the age of automation and smart infrastructure, maintaining power quality has become essential for industries and utilities alike. One of the most effective solutions for managing reactive power and improving power factor is the Static VAR Generator (SVG). As the demand for reliable and efficient electrical systems grows, manufacturers around the world are stepping up with cutting-edge SVG solutions to support this transformation.

What is a Static VAR Generator?

A Static VAR Generator is an advanced power electronic device designed to provide real-time reactive power compensation. Unlike traditional capacitor banks or synchronous condensers, SVGs respond instantly to changes in load, maintaining voltage stability, reducing harmonics, and improving overall power quality. They are widely used in industries such as manufacturing, steel, renewable energy, commercial complexes, and more.

Importance of SVGs in Power Management

Improved Power Factor – Reduces penalties from utilities and optimizes energy usage.

Voltage Stability – Maintains steady voltage levels despite load fluctuations.

Reduced Harmonics – Minimizes distortion and protects sensitive equipment.

Energy Efficiency – Lowers energy loss and improves overall operational performance.

What to Look for in an SVG Manufacturer

When choosing a Static VAR Generator manufacturer, consider these key factors:

Technical Expertise: A good manufacturer will have deep knowledge of power electronics and system integration.

Customization: Solutions should be tailored to specific industry needs and site conditions.

After-Sales Support: Reliable service, installation, and maintenance support are crucial.

Compliance: Products should meet international and local electrical standards (like IEC, IEEE, etc.).

Innovation: Look for companies investing in R&D and offering IoT-enabled, smart-grid-ready devices.

Leading SVG Manufacturers Globally

While several companies worldwide manufacture SVGs, a few notable names include:

Schneider Electric – Known for modular, scalable SVG systems.

Siemens – Offers high-performance reactive power compensators for industrial and grid use.

ABB (Hitachi Energy) – Provides advanced grid-tied and industrial SVGs with a global presence.

Eaton – Known for compact and flexible SVG solutions.

Toshiba – Offers large-scale SVGs for power plants and utilities.

Rising Demand for Local Manufacturers

With the global shift towards energy efficiency and smart grids, regional manufacturers are gaining traction. Many local companies now offer quality SVGs that are cost-effective and suited to specific climatic and grid conditions. Countries like India, China, Brazil, and others have seen a surge in domestic SVG manufacturing to support growing industrialization and renewable energy integration.

Industries That Benefit Most

Steel & Metallurgy Plants

Renewable Energy Farms (Solar & Wind)

Textile & Pharmaceutical Units

Data Centers & IT Parks

Automotive Manufacturing Units

Airports & Metro Rail Systems

Final Thoughts

Static VAR Generators are no longer a luxury — they are a necessity for modern power systems. Choosing the right SVG manufacturer can significantly impact your energy efficiency, operational reliability, and cost savings. Whether you're upgrading an existing system or building from scratch, investing in a trusted SVG solution is a step toward smarter, more resilient infrastructure.

0 notes

Text

GF101 PROGRAMMABLE SINGLE PHASE PHANTOM LOAD POWER SOURCE

The GF101 AC power calibrator is equipped with RS232 port as standard communication interface to control external devices remotely. In the power calibration mode, the GF101 programmable phantom load power source can be used as a source to calibrate single-phase AC watt meters, power analyzers, and energy meters. In this mode, the output voltage can be set up from 0 to 1000V, the output current from 0 to 200A, and the power factor from -1.0000 to +1.0000 lead/lag in the frequency band from 40Hz to 70Hz. Power factor is an important element when users judge the efficiency of a device. It is suitable for power department, measuring department, quality control department, research units, institution of higher learning, electric energy meter, power distribution terminals, power supply management, load control, power quality, reactive power compensation device and production of the enterprise and so on. It can be as single phase voltage source, current source and power source.

FEATURES ■ Switching range automatically; ■ Output range widely: 0-200A, 0-1000V; ■ High precision 0.02%, as electrical laboratory standard; ■ Applying the 32-bit MPU + DSP + FPGA, powerful flexible; ■ With RS232 interface, programmable controlled by computer; ■ Using software calibration, easy to operate, stable and reliable; ■ Big screen, 6 inch touch TFT LCD display, Chinese or English menu, easy to operate; ■ Using hardware PID, fast response, the change of load will not cause volatility output; ■ Perfect over-current, over-voltage, over-heat, shorts-and-opens, overload protection, automatic failure detection; ■ Setting up and taking the load regulation of voltage, current, phase and frequency of the power factor; ■ Amplitude 2nd-128th phase harmonics, and it can be added to the fundamental wave in every harmonic output; ■ A wide range output of voltage and current, big power, high stability, small waveform distortion degree; ■ Strong load ability, taking capacitive load, sensibility load, resistive load or composite load, load regulation is higher than 0.01%; ■ Power frequency waves reach up to 50000 points every cycle wave, signal output without filter, precise waveform output, precise harmonic output, small harmonic distortion degree;

APPLICATION ■ Universities; ■ Energy meter R & D; ■ Electrical testing center; ■ AMI Research institutes; ■ Transducer manufacturers; ■ Panel meter manufacturers; ■ Power meter manufacturers; ■ Digital meter manufacturers; ■ Pointer meter manufacturers; ■ Railway electrical department; ■ ISO17025 Electrical laboratory; ■ Measurement and control device factory; ■ Electricity power bureau & power company; ■ Power engineering commissioning company; ■ Manufacturer of reactive power compensation device; ■ Electrical Department of industrial and mining enterprises;

1 note

·

View note

Text

Synchronous Condenser Market: Size, Share, Trends, Key Players Analysis, and Forecast till 2031

Synchronous condensers are synchronous mains-connected machines without prime movers and they are an essential part of an electric power system used mainly for reactive power support, system stability and voltage control. Electric power systems around the world are under growing demand in terms of size and reliable operation; consequently, the global synchronous condenser market is projected to show tremendous growth.

Market Overview