#Rotary Electrical Connectors

Explore tagged Tumblr posts

Text

dual component recessed box mold

China dual mold maker, offer turntable surface mount box mold, double shot electrical enclosure, bi material cable connector mold, dual component recessed box

#china mold#2 component mold#two color mold#multi shot surface mount box mold#2k mold#bi material electrical enclosure mold#rotary mold cable connector mold#pp tpr recessed box mold

0 notes

Text

How to Make: Electronic Wings for Cosplay

Hello Everyone! It's been a while since I last uploaded a written tutorial on here and since I just finished and wore my Dame Aylin cosplay this last weekend it seemed appropriate to jump back in with a tutorial on one of the costume pieces!

Her wings were the star of the show this weekend and I know a lot of people were curious about how I made them! A huge source of knowledge and inspiration behind these wings was this video by Axceleration, I made a few changes to the frame shape and electrical circuitry for mine but her tutorial was a huge stepping stone to give me the confidence to tackle them myself!

Health and Safety:

When working with Sintraboard (as well as other thermoplastics) it is incredibly important you wear a respirator as well as goggles when heating, moulding and cutting it. The fumes this plastic will give off when heated up are no joke! Make sure you're in a well-ventilated space!

Basic tool safety knowledge is also really important! wearing gloves when using power tools can be more dangerous in most situations, so always be aware of where your hands are vs where the tools are. Always cut away from yourself and take things slowly, don't panic.

Electrical safety! You're working with live wires and circuitry! make sure your hands are dry, you aren't touching the bare wires at any point when they are connected to a power source, and if you choose to solder anything, make sure you're wearing heat-proof gloves and a mask in a ventilated space!

Tools

Wire stripper

Screwdriver and wrench

Dremel - I recommend the Dremel 3000 rotary tool personally! Some essential Dremel bits you'll need for this include, a sanding bit, drill bit (smaller or same size as your screws/bolts), and a small/narrow cutting bit. These will usually come with the Dremel!

Heat Gun (A hairdryer will not get hot enough to heat the Sintraboard!!)

Pipe cutter (alternatively you can use a hacksaw for this!)

Hacksaw

Ruler

Scissors (for cutting fabric straps)

Materials

Heat shrink Tubing

2 core electrical wire

switch (you want a three position, six pin switch, like this one, even better if it has the Screws on the pins! otherwise you'll need a soldering kits to solder the wires to the pins.

2x 8AA 12v Battery Holders

2x 12v Linear Actuators (Mine had a stroke length of 100mm)

21.5mm PVC Pipes (I got 2x 3m Lengths)

2x 21.5mm PVC Pipe straight couplers

6mm 8"x12" Sintraboard

Nuts/Bolts/Screws (I used M5 bolts for the base & Actuator connectors and M6 screws to attach the hinges to the pipes! You'll need Washers for every Nut & Bolt!)

Hinges (I used 2.5cm wide hinges that were skinny but long so they would just about fit along the PVC pipe! 3" gate hinges would work!)

50 metre Polythene Jiffy foam roll (in retrospect this was ALOT of foam, you could definitely get away with maybe a 20-30 metre roll! I now have a load leftover XD)

16 AA Batteries (I used 16 and had enough for the whole day with them on, I think They'd probably be enough for another half a day-full day too! but have spares just in case!)

Webbing strap ( I went for grey to match my base suit colour!)

Buckle - as wide as the webbing strap you use!

3 metres of white cotton fabric (or whatever colour wings youre going for!)

Optional

Zipties (for cleaning up the wires)

Lets Go!

Sintraboard is this wonderfully stable thermoplastic that is relatively easy to cut into (with the right tools) and when heated allows you to mould its shape! I started by using a mannequin and heating the Sintraboard with a heat gun for a few minutes to make it pliable, I recommend using gloves for this part as the materials gets VERY HOT! Press the board into the shape of the mannequin's back, taking note of the edges especially! you want this board to sit as comfortably to your body shape as possible as it makes a huge difference to how long you can wearing the wings for in this backplate is comfy!

Once shaped, I placed it against my back to make sure it was a good fit, heating again and making any alterations I needed (again don't place bright hot plastic to your bare skin! wear protective clothes and wait till its slightly cooler to do this, with the help of a friend!). I then took a hacksaw and rounded the corners, before sanding the edges with my Dremel! Try to avoid cutting off loads, just enough to make things less likely to snag.

3. I then cut in four holes, wide enough to feed my webbing strap through, two at the top and one on either side below where my arms would sit! I measured the webbing strap by firstly feeding them through the top holes and pinning them, and then bring the strap over my should to everything sits where it should and seeing where the strap hits the side hole and cutting the length there! you'll also want a strap that attaches across the chest, meeting in the centre with a buckle!

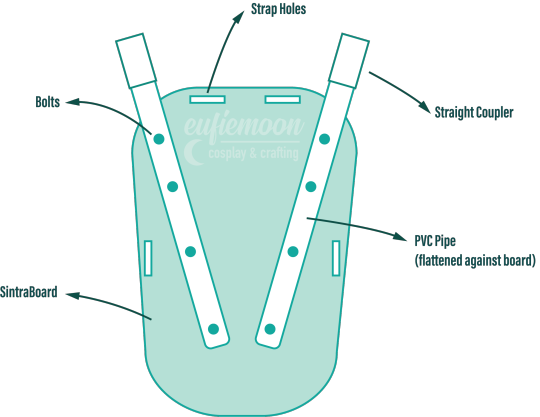

4. After sewing the straps closed I was able to move onto the PVC pipe structure! This may change slightly depending on the finished shape you want but I needed the PVC pipes to come out from inside a breastplate so had a particularly angle as well as character references to work with! I began by heating the pipe over my heat gun and flattening a portion of it under a heavy object so it would sit much more flush against the backboard and sit better underneath my breastplate before moving onto securing the first portion of the structure to the backplate. This mainly involved lots of try-ons and measuring to make sure the angles were correct and symmetrical and was quite fiddly but well-worth the effort! I'll include a diagram of the general shape I went with below:

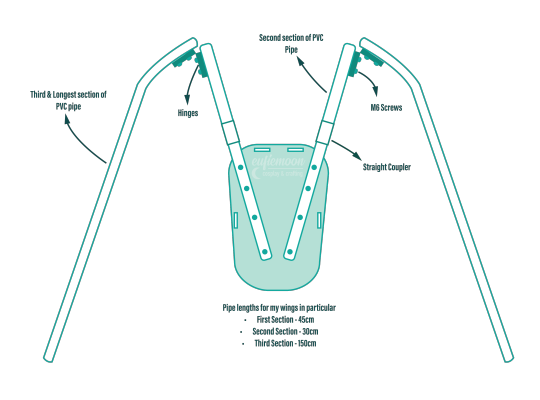

5. I wanted my wings to be relatively modular for ease of travel so I needed to make sure certain portions of them could come away from other parts easily, so I popped a straight coupler on the top of the pipes that were attach to the breastplate, this also meant I could slot the breastplate over these shorter pipes and wear everything correctly! Then these second pipes slot on and at the other end they are attached via hinges to the longest portion of the pipe 'skeleton', Diagram below:

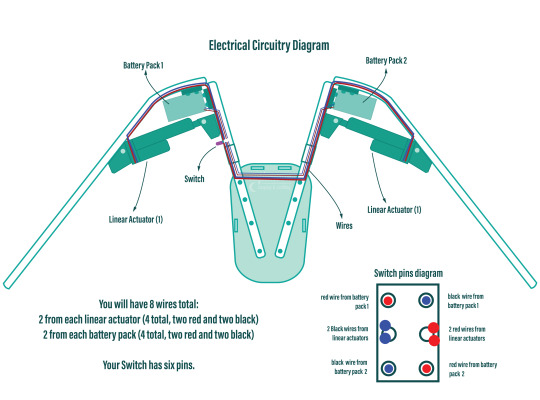

6. Now that the skeleton was put together, it's time for the electrical stuff! It's a good idea to figure out where your circuit is going to lay on the skeleton - consider if you want the battery packs mounted the the backplate or, like me, put them inside the actual wings in removeable pockets for easy access and removal for battery changes. all your wires will go through the switch so deciding where you want to place that is very important! Mine was placed just over my shoulder on the front side, mounted to the PVC pipe with a metal cover I drilled a hole into to slip the switch through and then drill through the pipe.

I've included another diagram below that explains all the electrical circuitry, including which wires go on which pins on the switch!

Important to note: The linear actuators need to be placed and bolted into the PVC pipes at *exactly* the same angle on each side, any slight deviation will lead to the wings going up wonkily! So take your time and make as many adjustments as necessary.

7. You can extend your wires by adding on the electrical wire, just match the colours, and put heat shrink tubing over the connections to hide the live wires! I ended up zip-tying the wires into organised bundles once the wings were done to help keep everything safe from snags.

8. Now its time for the Wings themselves! I drafted my base pattern by just draping the white cotton fabric I had over the wing when it was fully extended. I then pinned the wings to the shape I wanted them to be along the bottom before cutting along the pins. I ran the fabric through my sewing machine to close the bottom edge, leaving a gap wide enough by the wing base so I could slip the wing on and off, closing it with velcro. I also added little fabric pockets inside of these to hold my battery packs, which also connected via velcro for easy removal!

9. Now that I had a wing base I was able to begin making feathers! I cut out a total of 800 feathers out of polythene jiffy roll for these wings, in 6 different styles and using real life bird wings to dictate the shapes I used and where I placed them. I ended up hot gluing every individual feather onto the white fabric base, going row by row until every side was covered, the wing covers themselves are super light because of the foam feathers and they shine light through them in a really magical way!

Optional: I also ended up going over these feathers with my airbrush and some super light beige paint to help darken the shadows, this is entirely optional and may change depending on the wings you're looking to make!

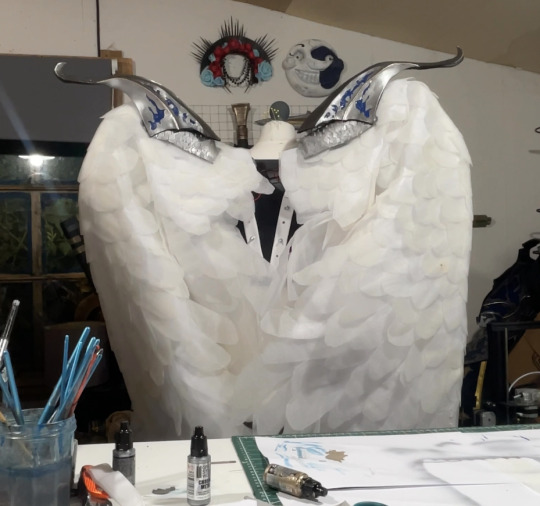

When in neutral position and in extended position the wings looks like this:

Mine had a wingspan of about 7ft total when fully extended but when in neutral position they were fairly close to my own proportions! mainly staying behind me and weren't much of a problem in a packed con hall!

Photo by: Helloimfran (on Instagram and Twitter)

I hope this tutorial helped and if there are any questions about anything in specific don't hesitate to reach out at [email protected] or on my instagram or twitter (@eufiemoon)

Happy Crafting!

#cosplay#cosplayer#cosplaying#baldurs gate iii#baldur’s gate 3#baldurs gate 3#bg3#dame aylin#aylin x isobel#bg3 aylin#cosplay tutorial#Wings#fantasy#tutorial#cosplay help#cosplay tips

166 notes

·

View notes

Text

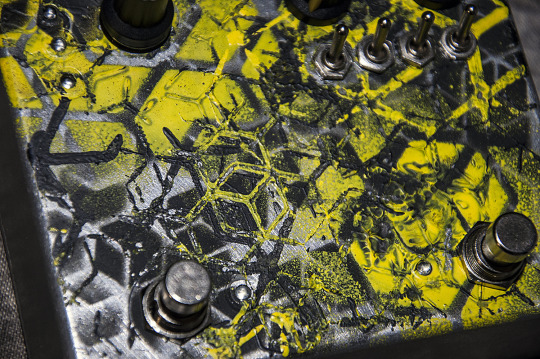

ANAPHYLAXIS FILTER - WASPsynth multi-mode filter with double LFO and distortion

The ANAPHYLAXIS FILTER is a multi-mode filter with double LFO modulator for the CUTOFF frequency based the filter section of the notorious WASP synthesizer that was created by Electric Dream Plant in 1978. This standalone pedal version of the filter allows you to use it for the input signals of your choice. The FILTER MODE selector is a 4 position rotary switch (up to down: LOW PASS, BAND PASS, HIGH PASS and NOTCH) with the position indicated by small purple UV LEDs. The input signal is controlled with the GAIN control, that can boost even weaker input signal to overdrive the filter. A dedicated RESONANCE control determines the amount of RESONANCE at the CUTOFF point, that of course has a control knob as well. Furthermore the RESONANCE has two settings: EXTREME (up) and NORMAL(down), selected with a toggle switch. In HIGH PASS mode the filter can self-oscillate without any input, in case you need a high frequency SINE WAVE oscillator. In that case the FREQUENCY can be dialed in with the CUTOFF control. A 3.5mm mono input socket for EXTERNAL CV (Beware only use max. +5VDC, everything else destroys the circuit!). This input is used to modulate the filter’s CUTOFF with external gear (as i demonstrate in a demo video of a previous build). But the ANAPHYLAXIS FILTER can do more, as it has 2 build in LFOs that are modulating the CUTOFF frequency, with independent SPEED and DEPTH controls, which allows to generate a more complex modulation waveform. Each LFO has a RANGE toggle that selects: SLOW (down) or FAST (up) as well a 3 position toggle switch that selects the SHAPE: SQUARE (down), OFF (middle) and triangle (up). The fast LFO range goes well into audio range and enables you to create some very interesting frequency modulation filter effects. With slower rates, especially with the triangle shape and the 2 LFOs running at non-synced rates, even the most static sounding input get ‘alive’. The SPEED of each LFO is indicated by either red or green color in the big LED in the middle of the LFO section. The 1st stomp switch is TRUE BYPASS and if that is not enough, the 2nd stomp switch engages the DISTORTION, both with UV indicator LEDs. The level of the DISTORTION is controlled by the DISTORTION knob and the toggle switch next to it adds a TREBLE BOOST (up) or a HIGH CUT (down) setting to the DISTORTION. In the end of the signal path is a signal booster based on the EHX LBP1 with a global VOLUME control. The ANAPHYLAXIS FILTER runs on 9V DC and has a ‘boss style’ 2.1mm DC barrel plug socket with the negative pin inside. The enclosure is a heavy duty scavenged industrial engine power connector housing made from die-cast aluminum with a bottom plate made from found material and is painted in the industrial burnout camo pattern in matte black and bright yellow. Handmade by GRM for METSÄÄN. Sold.

#anaphylaxis filter#distortion#multi mode filter#waspsynth#waspfilter#metsään#thismachinekillsfascists

4 notes

·

View notes

Text

0 notes

Text

India Electromechanical Components Industry: Transforming the Nation’s Manufacturing and Mobility Landscape

The India Electromechanical Components Industry is undergoing a technological renaissance, driven by the rise of smart manufacturing, electric mobility, and connected consumer devices. Valued at USD 4.7 billion in 2024, the industry is forecast to reach USD 10.2 billion by 2032, expanding at a strong CAGR of 10.3%. With increasing investments in electronics production and rising domestic demand, India is quickly becoming a strategic hub for electromechanical innovation.

These components, which include switches, motors, relays, and connectors, are the backbone of digital automation across industries — from automotive and telecom to energy and consumer appliances.

Industry Overview

Electromechanical components serve as essential links between electrical signals and mechanical movement. They perform key control, sensing, and actuation roles in both simple and complex systems.

In India, the industry is expanding in sync with government-backed initiatives like Make in India, PLI schemes, and smart city missions. The increase in localized manufacturing of EVs, smartphones, and industrial equipment is significantly boosting the demand for electromechanical components across sectors.

Market Share Insights

Automotive and EV Sector

The automotive segment commands a significant market share, with a surge in electric vehicle adoption and advanced electronics integration. Components like electric actuators, rotary switches, and control relays are essential in modern EVs for battery management, motor control, and safety systems.

Industrial Automation

India’s push for smart factories has placed automation at the forefront, accounting for a notable share of component consumption. Manufacturing industries now heavily rely on motors, sensors, and programmable relays to improve precision and productivity.

Consumer Electronics

This segment holds a large share in volume due to mass production of devices like washing machines, air conditioners, smart TVs, and smartphones. As consumers demand compact, smart, and energy-efficient appliances, manufacturers are sourcing advanced micro-switches, connectors, and motors.

Energy & Utilities

The smart grid and renewable energy initiatives are also expanding the market share of electromechanical components used in power transmission, control systems, and renewable integration units.

India Electromechanical Components Market Growth Drivers

1. Make in India and Localization Efforts

Government-backed initiatives are encouraging global companies to set up local production facilities, ensuring faster availability and reduced import dependency.

2. Rise in Electronics Exports

India’s role as an electronics exporter is growing. With favorable tax policies and infrastructure support, components used in exported goods are also contributing to market growth.

3. Surge in Electric Mobility

The EV revolution is one of the most significant growth drivers, with every electric vehicle containing multiple electromechanical parts in its powertrain, dashboard systems, and safety modules.

4. Smart Cities and IoT Proliferation

From intelligent lighting to automated waste systems, smart cities rely on thousands of integrated sensors and electromechanical relays, driving exponential growth.

5. Growth in Industrial Robotics

Automated assembly lines and robotic systems — especially in automotive and electronics — are key contributors to component demand and industrial modernization.

Competitive Landscape

Key players dominating the India Electromechanical Components Industry include:

ABB India

Schneider Electric

Honeywell Automation

Panasonic Life Solutions

TE Connectivity

Omron Automation

EPCOS India (TDK Group)

Havells India Ltd.

Delta Electronics

Molex India Pvt. Ltd.

These companies are investing in R&D, increasing production capacity, and forming OEM partnerships to cater to the growing local and global demand.

Opportunities and Challenges

Opportunities

Custom component design for EVs and industrial use

Component export to Middle East, Africa, and ASEAN regions

Strong demand from emerging sectors like medtech and IoT devices

Challenges

Supply chain complexity for precision materials

High competition in low-cost segments

Dependence on imports for certain high-spec components

Conclusion

The India Electromechanical Components Industry is on a high-growth trajectory fueled by automation, smart infrastructure, and digital transformation. The increasing India Electromechanical Components Market Share in global supply chains showcases India’s growing capabilities and manufacturing potential. Companies that invest in localization, customization, and sustainable production will be best positioned to capitalize on this rapidly evolving market.

Trending Report Highlights

Stay ahead with insights from these emerging high-potential markets:

Gyro Sensor Market

Led Light Bar Market

Tunnel Detection System Market

Blue Laser Diode Market

3D Cinema Screen Market

0 notes

Text

Slip Ring Market Growth Forecast: Opportunities in Motion Control

In an increasingly dynamic industrial world, continuous electrical connection within rotating systems is essential. Whether it's in wind turbines generating clean energy, advanced radar systems in aerospace, or automated production lines in smart factories, slip rings play a silent yet critical role. Often overlooked, these compact rotary electrical connectors enable transmission of power and signals between stationary and rotating parts — keeping complex systems running smoothly.

As automation, renewable energy, and aerospace technologies evolve, so does the demand for advanced slip ring solutions. Here's a comprehensive look at where the global slip ring market is headed, the innovations driving it, and who the key players are shaping its future.

Slip Ring Market Outlook 2035

The global slip ring market was valued at US$ 1.5 billion in 2024, and its trajectory is poised for steady expansion. According to recent market analysis, the industry is projected to grow at a CAGR of 4.2% from 2025 to 2035, reaching a market size of over US$ 2.3 billion by the end of 2035.

This growth is fueled by rising applications across verticals like wind energy, aerospace & defense, robotics, medical imaging, and packaging automation. Industries are increasingly relying on slip rings not only for electrical power transfer but also for advanced capabilities like data transmission, fluid rotation, and signal integrity.

Request for Sample Copy of this report- https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=70119

What’s Driving the Growth?

1. Boom in Wind Energy Installations

As governments across the globe push for clean and renewable energy, wind power installations are expanding rapidly. Slip rings in wind turbines are used to transmit electrical signals and power from the nacelle to the control systems. The increasing number of offshore wind farms, where reliability and compact design are crucial, is driving demand for durable and maintenance-free slip ring technologies.

2. Rise in Industrial Automation

From packaging to process industries, automated machinery depends heavily on rotating assemblies. Slip rings allow uninterrupted communication and power supply in robotic arms, rotary indexing tables, and printing machines. With smart factories becoming the norm under Industry 4.0, slip rings are being designed to support higher bandwidth communication protocols like Ethernet, CANbus, and HDMI.

3. Advancements in Aerospace & Defense

Slip rings in this sector are mission-critical. They are found in satellite tracking systems, radar platforms, drones, and missile systems. With national defense budgets increasing and satellite communication surging, especially for low Earth orbit (LEO) applications, demand for lightweight, rugged, and high-frequency compatible slip rings is rising.

4. Growing Demand for High-Speed Data Transmission

The evolution of fiber optic slip rings (FORJs) is a response to the need for higher data throughput, particularly in applications like medical imaging systems (CT scanners, MRI machines), surveillance systems, and broadcasting equipment. Fiber optic variants offer immunity to electromagnetic interference (EMI) and can support gigabit data transmission rates.

Slip Ring Market Major Players’ Analysis

Market leaders are not merely competing on price; they are focusing on innovation, customization, and reliability. From miniaturization for compact devices to ruggedization for harsh environments, the competition is centered on application-specific performance.

Leading companies are also investing in research and development, material science, and digital integration to improve product lifespans, reduce maintenance costs, and enable seamless integration into smart devices.

Here are some of the top players shaping the global slip ring market:

Moog Inc.

MERSEN

MOFLON TECHNOLOGY

Conductix-Wampfler

Combinent Oy Ab

Schleifring GmbH

Pandect Precision Components Ltd

Stemmann-TECHNIK

ROTAC Co., Ltd.

EVERAXIS

These players bring decades of experience and a strong portfolio tailored to varied industries including wind power, aviation, medical diagnostics, and defense.

The slip ring market report provides a deep dive into each of these companies, highlighting:

Company overview

Business segments

Product portfolio

Recent developments

Business strategies

Financial performance

Global Slip Ring Market: Key Developments

🔹 Servotecnica's Game-Changing Innovations

In October 2024, Servotecnica announced a strategic collaboration with Diamond Antenna, a leading U.S. provider of rotary joints and RF subsystems. This partnership is expected to strengthen their position in aerospace and defense markets, providing cutting-edge solutions for ground, shipboard, aviation, and space communications.

This alliance is particularly notable because it brings together two leaders in rotary connectivity technology, enabling more sophisticated slip ring and rotary joint hybrid systems that can support both electrical and radio frequency (RF) transmissions.

🔹 Multi-Wire Brush Option for Longevity

In September 2024, Servotecnica also launched a multi-wire brush upgrade for its SVTS A capsule slip ring series. This new configuration significantly enhances operational life — lasting 5 to 10 times longer than traditional single-wire models.

These upgrades feature gold-based alloy contacts, ensuring superior conductivity and resistance to corrosion. Thanks to their compact size and high adaptability, these slip rings are ideal for applications where reliability is non-negotiable — such as in military drones, CT scanners, and industrial robots.

Trends to Watch in the Slip Ring Market

✅ Fiber Optic Slip Rings (FORJs) Go Mainstream

Fiber optic slip rings are becoming a must-have for high-speed data transmission in medical, military, and marine environments. Their ability to transmit large volumes of data without interference is particularly important in modern applications involving HD video, control signals, and telemetry.

✅ Modular and Customizable Designs

As equipment designs grow more compact and specialized, there's increasing demand for custom slip rings that can fit into tight spaces and meet specific electrical or mechanical requirements. Modular slip rings that can be easily scaled up or integrated with fluidic or pneumatic channels are gaining popularity.

✅ Integration with Smart Technologies

The future of slip rings lies in smart diagnostics and predictive maintenance. By embedding sensors that monitor temperature, RPM, and wear, companies can reduce downtime and extend equipment lifespans — a critical benefit in mission-critical applications.

✅ Sustainability in Design

As part of global ESG commitments, manufacturers are focusing on eco-friendly materials, longer product life cycles, and recyclability. Slip rings designed for wind turbines, in particular, are being optimized for low-maintenance, oil-free operation, aligning with green energy goals.

Opportunities & Challenges Ahead

📈 Opportunities:

Expansion of wind power infrastructure in Asia-Pacific and Europe

Defense modernization programs in North America

Demand for minimally invasive medical imaging systems

Growth of Industry 4.0 and smart manufacturing initiatives

⚠️ Challenges:

High competition from alternative wireless power transmission technologies

Maintenance issues in harsh environmental conditions

Technical limitations in miniaturization and high-speed applications without heat generation

Final Thoughts

The slip ring market may not grab headlines, but it is quietly powering the backbone of modern technology — enabling rotation, data transfer, and electrical continuity across vital industries. With a projected valuation of US$ 2.3 billion by 2035, this market is not only growing, but evolving.

For stakeholders in renewable energy, aerospace, industrial automation, and healthcare, investing in next-gen slip ring solutions will be key to staying competitive. As leading manufacturers continue to innovate and collaborate, the humble slip ring is being reimagined as a high-tech enabler of future connectivity.

#SlipRingMarket #IndustrialAutomation #WindEnergy #AerospaceTech #SmartManufacturing #FiberOpticSlipRings

0 notes

Text

Steady Growth Ahead: Vertical Injection Molding Market at 4.3% CAGR

The global Vertical Injection Molding Machine market, valued at USD 806.8 million in 2022, is set to expand at a robust CAGR of 4.3% between 2023 and 2031, reaching an estimated USD 1.2 billion by the end of 2031. This growth is propelled by technological advancements, rising demand for lightweight components across industries, and increasing integration of robotics and computerized molding processes.

Market Overview

Vertical injection molding machines feature a vertically oriented clamping and injection unit, leveraging gravity to enhance precision and energy efficiency. Their compact footprint makes them ideal for space-constrained production lines. Predominantly used in insert molding where pre-placed metal or other components are overmolded with plastic these machines serve diverse sectors including automotive, electronics, medical, packaging, and consumer goods.

Market Drivers & Trends

Energy Efficiency: Vertical machines consume less energy than their horizontal counterparts by minimizing continuous movement of clamping units.

Robotic Integration: Automation from component loading to part removal is driving productivity and quality. Manufacturers like Newbury offer C-Frame rotary table designs with turnkey robotic integration.

Lightweight Components Demand: The shift toward lighter plastic parts in automotive and electronics for fuel efficiency and portability is boosting demand.

Compact Footprint: Limited factory space in urbanized regions favors vertical designs, optimizing floor layouts.

Latest Market Trends

Hybrid Technologies: Blending hydraulic and electric drives to balance high clamping force with precision and lower maintenance costs.

All-Electric Vertical Machines: Gaining traction in cleanroom and medical device manufacturing for zero-emission operation.

IoT-Enabled Monitoring: Real-time data analytics to predict maintenance needs and minimize downtime.

Sustainable Materials: Compatibility with bio-based resins and recycled plastics to meet environmental regulations.

Key Players and Industry Leaders

ARBURG GmbH + Co KG

The Japan Steel Works, LTD.

Nissei Plastic Industrial Co., Ltd

Sumitomo Heavy Industries

Engel Austria

Milacron Holdings Corp

Tayu Machinery Co., Ltd

Wittmann Battenfeld GmbH

Shibaura Machine (Toshiba Machine Co., Ltd)

Pratishna Engineers Ltd

Toyo Machinery & Metal Co., Ltd.

Husky Injection Molding Systems Ltd.

Niigata Machine Techno Co., Ltd.

Preview essential insights and takeaways from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=82265

Recent Developments

February 15, 2023: ARBURG’s Allrounder 470 H hybrid machine debuts, offering up to 30% energy savings and reduced carbon footprint compared to conventional models.

December 2022: JSW’s JLM3000-MGIIeL sets a new benchmark with its record 3,000-ton mold clamping force, addressing the needs of large-scale automotive and aerospace component production.

Q1 2024: Engel Austria unveiled its tie-barless vertical machine, enabling faster mold changeovers and expanded mold accessibility.

Q2 2024: Sumitomo introduced an integrated IoT platform across its vertical machine line, allowing remote diagnostics and process optimization.

Market Opportunities

Automotive Lightweighting: Rising adoption of plastic parts for interior panels, under-hood components, and structural elements.

Medical Device Manufacturing: Growth in single-use and precision-critical components, such as syringes, diagnostic cartridges, and implantable devices.

Consumer Electronics: Miniaturization trends demand complex, high-precision plastic housings and connectors.

Packaging Innovation: Demand for customized closures, caps, and tamper-evident designs in food, beverage, and personal care segments.

Emerging Economies: Rapid industrialization in Asia Pacific and Latin America offers new OEM and contract manufacturer partnerships.

Future Outlook

Analysts anticipate that continued R&D investment will yield machines with smarter controls, lower energy footprints, and greater flexibility for multi-material molding. The push toward Industry 4.0 will further accelerate adoption of vertical presses with embedded sensors, predictive maintenance algorithms, and seamless integration into fully automated production lines. By 2031, the market is expected to witness:

Wider Hybrid Adoption: Hybrid machines capturing significant market share by combining the strengths of hydraulic and electric systems.

Expanded All-Electric Use Cases: Particularly in sectors requiring ultra-clean operation and minimal noise.

Enhanced Circularity: Greater compatibility with recycled and bio-based polymers to meet sustainability targets.

Market Segmentation

Segment

Sub-Segment

Input Material

Plastic; Rubber; Others

Clamping Force

Up to 20 T; 21–40 T; 41–50 T; 51–70 T; 71–80 T; 81–100 T; > 100 T

Type

Hydraulic; Electric; Hybrid

Automation Grade

Automatic; Semi-automatic

End-Use

Consumer Goods; Automotive & Aerospace; Agriculture & Waste Management; Medical & Science; Electrical & Electronics; Construction; Packaging; Others

Regional Insights

Asia Pacific: Held the largest share in 2022 due to rapid automotive and consumer goods production, and ongoing urbanization driving factory expansions.

Europe: Accounted for 32.4% of the market in 2022, with strong demand for high-precision medical and automotive components; expected to remain stable through 2031 (~31.8%).

North America: Growing emphasis on reshoring and automation in plastics manufacturing; rising investment in electric vehicle components.

Latin America & MEA: Emerging markets for packaging and agricultural equipment parts, offering untapped growth potential.

Why Buy This Report?

Comprehensive Analysis: Detailed cross-segment and regional breakdowns, with quantitative and qualitative insights.

Competitive Intelligence: Company profiles of 15+ key players, including market share, financials, and strategic initiatives.

Future-Ready Insights: Forecasts to 2031, highlighting emerging opportunities and potential challenges.

Actionable Recommendations: Tailored strategies for OEMs, molders, and equipment suppliers to capitalize on market trends.

Format: Electronic (PDF) + Excel for easy data manipulation.

Explore Latest Research Reports by Transparency Market Research:

Fabric Reinforcements Market for Liquid-applied Roofing: https://www.transparencymarketresearch.com/fabric-reinforcements-market-for-liquid-applied-roofing.html

Monochloroacetic Acid Market: https://www.transparencymarketresearch.com/monochloroacetic-acid-market.html

Boranophosphates Market: https://www.transparencymarketresearch.com/boranophosphates-market.html

Caproic Acid Market: https://www.transparencymarketresearch.com/caproic-acid-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Brass and Naval Brass Sheets in Industrial Machinery Uses

Industrial machinery demands materials that offer strength, wear resistance, corrosion protection, and easy machinability. From heavy-duty presses to precision-engineered parts, manufacturers rely on metals that can withstand demanding environments without compromising efficiency. Among the most trusted materials for this purpose are brass sheet and naval brass sheet. These copper-based alloys have become essential in industrial equipment due to their mechanical and anti-corrosive properties.

This blog explores how brass and naval brass sheets are applied in industrial machinery and what makes them ideal for high-performance components.

What Is Brass Sheet?

Brass sheet is a flat-rolled metal made from copper and zinc, appreciated for its machinability, corrosion resistance, and formability. It’s commonly used in mechanical systems for making bushings, gears, valve plates, and machine covers. Discover premium Brass Sheet for precision-engineered industrial components.

What Is Naval Brass Sheet?

Naval brass sheet contains copper, zinc, and a small percentage of tin (about 1%) that enhances its corrosion resistance and mechanical strength. Originally developed for marine use, it’s now widely used in high-load and chemically aggressive environments. View high-durability Naval Brass Sheet ideal for robust machinery parts.

Key Properties That Make These Sheets Industrial-Grade

1. Mechanical Strength

Brass and naval brass have impressive tensile and yield strength, making them suitable for moving components that endure high pressure and friction. Naval brass, in particular, offers enhanced mechanical durability due to the addition of tin.

2. Wear Resistance

In rotating machinery and sliding systems, components made of brass sheet resist wear and reduce surface friction, extending the life of both parts and the machinery.

3. Corrosion Resistance

Brass offers moderate resistance to corrosion in standard environments, while naval brass provides excellent protection against seawater, oil, fuel, and industrial chemicals.

4. Machinability

These sheets can be easily cut, milled, turned, or drilled, saving time and cost in manufacturing and assembly operations.

5. Dimensional Stability

Brass and naval brass retain their shape and strength under thermal cycling, vibration, and long-term use—making them ideal for precision parts.

Common Industrial Applications

Bushings and Bearings

Brass and naval brass sheets are cut and machined into sleeve bushings and thrust bearings used in hydraulic presses, conveyors, and motors. These parts handle rotational loads and resist galling.

Gear Wheels and Cams

Brass is often chosen for low-to-moderate torque gears and cams due to its strength and anti-friction properties. Naval brass is preferred when moisture or salt exposure is present.

Valve Plates and Sealing Components

Valves in hydraulic and pneumatic machinery use brass sheets for their tight sealing properties and resistance to deformation under pressure.

Pump Parts and Impellers

Naval brass sheets are machined into pump components like impellers, plates, and housings that operate in abrasive or chemically reactive fluids.

Heat-Resistant Shields and Covers

Brass’s thermal resistance allows it to be used as shielding in ovens, casting systems, and industrial furnaces.

Electrical Contacts in Motors and Generators

Because brass conducts electricity well and resists spark wear, it is commonly used for connectors, brushes, and ground plates in motor assemblies.

Brass vs Naval Brass for Industrial Machinery

FeatureBrass SheetNaval Brass SheetCompositionCopper + ZincCopper + Zinc + TinStrengthGoodExcellentCorrosion ResistanceModerateHighIdeal UseGeneral machineryMarine, chemical, heavy-duty systemsWorkabilityExcellentVery good

Industries That Rely on These Alloys

Manufacturing: Presses, lathes, gearboxes, CNC equipment

Mining and Construction: Lifting gear, crusher parts, rotary machinery

Oil and Gas: Valves, sealing plates, impellers, offshore equipment

Marine and Shipbuilding: Deck machinery, steering gear, winches

Renewable Energy: Turbine components, hydraulic fittings

Chemical Processing: Flow control equipment, reaction vessels, pumps

Fabrication Techniques

CNC Machining: Brass and naval brass sheets can be converted into complex parts using high-speed precision tools.

Forming and Pressing: These sheets can be stamped or formed into shaped covers and enclosures.

Welding and Brazing: Proper techniques can be used to join brass parts for leak-free assemblies.

Surface Finishing: They can be plated, coated, or polished for added durability and specific surface properties.

Environmental and Economic Advantages

Brass and naval brass sheets are recyclable, making them cost-effective and environmentally friendly. The reuse of scrap brass in manufacturing reduces raw material waste and energy consumption, helping industries meet sustainability goals.

Best Practices for Sourcing Industrial Brass Sheets

Request Material Test Certificates (MTC) to verify alloy composition and performance specifications.

Choose suppliers who conform to international standards such as ASTM B36 (brass) and ASTM B171 (naval brass).

Ensure precision in thickness, flatness, and hardness for efficient fabrication and fitment.

Always inspect for surface quality and tolerance levels before machining.

Final Thoughts

Whether you’re building a hydraulic pump or designing a heat-resistant enclosure, choosing the right metal can determine the efficiency and lifespan of your machinery. Brass sheet provides strength, workability, and moderate corrosion resistance for most general industrial applications. In contrast, naval brass sheet is best suited for high-pressure, marine, or chemical exposure environments due to its enhanced durability. Select Brass Sheet for versatile manufacturing use and Naval Brass Sheet when your machinery demands extra strength and resistance.

0 notes

Text

0 notes

Text

Applications of CNC Rotary Tables in Various Industries [Infographic]

CNC rotary tables have become indispensable in modern manufacturing. They enhance the capabilities of CNC machines by adding an additional axis of movement. These versatile tools play a pivotal role in improving precision, efficiency, and flexibility across various industries. Below, we explore the key applications of CNC rotary tables and how they contribute to diverse sectors.

1. Aerospace Industry

In the aerospace industry, precision is non-negotiable. CNC rotary tables are used to machine complex components such as turbine blades, engine parts, and structural elements. Their ability to handle intricate geometries and maintain tight tolerances ensures the production of reliable and high-performance aerospace components. The rotary table's multi-axis capabilities allow manufacturers to achieve precision milling, drilling, and contouring, meeting the stringent requirements of aerospace engineering.

2. Automotive Industry

The automotive sector relies heavily on CNC rotary table for producing gears, camshafts, and other critical engine parts. These tables enable manufacturers to perform high-precision machining, ensuring consistency and quality in mass production. Additionally, their use in the creation of custom automotive components supports the growing demand for electric vehicles (EVs) and other innovations in the industry.

3. Medical Device Manufacturing

CNC rotary tables are essential in the medical industry for fabricating intricate components like surgical instruments, orthopedic implants, and prosthetics. The rotary table's high precision allows for the creation of small, complex parts that meet the strict regulatory standards of the healthcare sector. Moreover, their versatility enables manufacturers to work with a variety of materials, including stainless steel, titanium, and specialized medical-grade alloys.

4. Energy Sector

From wind turbines to oil and gas equipment, the energy sector benefits from the capabilities of CNC rotary tables. These tools are used to produce large, heavy-duty components such as flanges, rotors, and pipe connectors. Their robust construction and precise movement ensure reliable performance even in demanding applications, making them a vital asset in energy production and distribution.

5. Tool and Die Manufacturing

The tool and die industry relies on CNC rotary tables for creating molds, dies, and other specialized tools. These components often require intricate details and high accuracy, which rotary tables provide. By enabling simultaneous multi-axis machining, they help manufacturers reduce production time and achieve superior surface finishes.

6. Electronics and Semiconductor Industry

Miniaturization and precision are essential in the electronics sector. CNC rotary tables are used to machine micro-components for semiconductors, circuit boards, and other electronic devices. Their capability to handle small-scale, high-precision tasks ensures optimal performance in the production of cutting-edge electronic equipment.

7. Jewelry and Watchmaking

Artisans in the jewelry and watchmaking industries use CNC rotary tables to craft intricate designs and detailed engravings. These tables enable precise machining of precious metals, ensuring consistency and quality in luxury products. The ability to achieve complex patterns and fine details makes rotary tables invaluable in these highly specialized fields.

Benefits of CNC Rotary Tables

Enhanced Precision: Ideal for applications requiring tight tolerances.

Increased Efficiency: Reduces production time by enabling multi-axis machining.

Versatility: Suitable for various materials and industries.

Cost-Effectiveness: Streamlines production processes, minimizing waste.

Also Read: 4 Benefits of Using Industrial CNC Rotary Table From China

Conclusion

CNC rotary tables are a cornerstone of modern manufacturing, enabling industries to achieve unparalleled precision and efficiency. From aerospace and automotive to medical and electronics, these tools are instrumental in driving innovation and meeting the demands of a competitive market.

Explore the advanced CNC rotary tables from SilverCNC and discover how they can elevate your manufacturing processes. Whether you need precision, versatility, or efficiency, SilverCNC offers solutions tailored to your industry’s unique requirements.

To read more information visit https://tinyurl.com/yk3b7spt and call now at +86 180 9892 0890 or email us at [email protected]

0 notes

Text

1. Pipe Cutters

Purpose: Used for cutting gas pipes to the required length.

Types:

Manual Pipe Cutters: Ideal for smaller pipes.

Rotary Pipe Cutters: Provide a clean, precise cut for larger diameters.

Benefits: Ensures a smooth, straight cut, which is essential for leak-proof connections.

2. Pipe Benders

Purpose: Used to bend gas pipes without causing kinks or cracks.

Types:

Handheld Pipe Benders: Suitable for smaller pipes.

Hydraulic Pipe Benders: Used for larger or more rigid pipes.

Benefits: Allows installers to navigate pipes through tight spaces and around obstacles.

3. Pipe Wrenches

Purpose: Essential for tightening and loosening pipe fittings and connections.

Features:

Adjustable Jaws: Can grip pipes of various sizes.

Heavy-Duty Build: Designed to provide strong leverage without damaging the pipe.

Benefits: Provides a secure grip, reducing the risk of leaks.

4. Threading Machine

Purpose: Creates threads on the ends of pipes, allowing them to be screwed into fittings and connectors.

Features:

Electric or Manual: Options available depending on the scale of the job.

Adjustable Die Heads: For threading pipes of different diameters.

Benefits: Ensures a tight, leak-proof seal between pipes and fittings.

5. Pipe Fitting Tools

Purpose: Used to fit and join pipes together securely.

Includes:

Flaring Tools: For creating flared pipe ends.

Crimping Tools: Used for compression fittings.

Deburring Tools: Smooth out the edges of cut pipes.

Benefits: Ensures a secure connection, reducing the risk of leaks.

6. Gas Leak Detectors

Purpose: Detects the presence of gas leaks during and after installation.

Types:

Electronic Gas Leak Detectors: Provides immediate, accurate readings.

Handheld Gas Sniffers: Portable devices for on-site inspections.

Benefits: Enhances safety by identifying potential leaks before they become hazardous.

7. Pressure Testing Equipment

Purpose: Used to test the integrity of the gas pipeline before it's put into service.

Types:

Pressure Gauges: Monitor the pressure levels within the pipeline.

Hydrostatic Test Pumps: Used for testing the pressure capacity of the pipes.

Benefits: Ensures the pipeline can handle operational pressures without leaking.

8. Torque Wrenches

Purpose: Ensures that bolts and fittings are tightened to the manufacturer's specifications.

Features:

Adjustable Torque Settings: Provides precise control over the amount of force applied.

Benefits: Prevents over-tightening, which can damage fittings and cause leaks.

9. Pipe Locators

Purpose: Helps identify the location of existing underground gas pipelines to avoid damaging them during installation.

Features:

Electromagnetic Detection: Pinpoints the location of metallic pipelines.

Benefits: Prevents accidental damage to existing utilities, enhancing safety and efficiency.

10. Personal Protective Equipment (PPE)

Includes:

Safety Gloves: Protects hands from sharp edges and hot surfaces.

Safety Goggles: Shields eyes from debris during cutting and threading.

Flame-Resistant Clothing: Reduces the risk of injury in case of a gas-related fire.

Benefits: Ensures the safety of installers throughout the installation process.

11. Welding Machines and Soldering Equipment

Purpose: For joining metal pipes securely.

Types:

Arc Welders: Ideal for heavy-duty pipelines.

Soldering Tools: For copper and smaller pipelines.

Benefits: Provides strong, leak-proof joints essential for gas lines.

12. Pipe Clamps and Supports

Purpose: Holds pipes in place during installation and testing.

Features:

Adjustable Sizes: Can accommodate various pipe diameters.

Benefits: Ensures stability and reduces stress on pipeline connections.

Conclusion

Gas pipeline installation is a specialized field that requires precision, expertise, and the right set of tools and equipment. From cutting and bending pipes to testing for leaks, each step of the process is critical to ensure the safety and efficiency of the gas supply. By understanding the tools used, homeowners can gain a better appreciation for the professionalism involved in setting up a gas pipeline system.

Whether you’re planning a new installation or considering an upgrade, it's essential to rely on experts who have the right tools and experience. If you’re looking for a reliable gas pipeline installation service, get in touch with our team today for a safe and efficient solution!

#GasPipelineInstallation#HyderabadGasServices#SafeGasInstallation#HomeSafetyFirst#GasPipelineExperts#HyderabadHomes#LPGPipelineInstallation#ApartmentGasSafety#VillaGasSolutions#HyderabadLiving#HomeSafetyHyderabad#EfficientGasSolutions#GasPipelineForHomes#HyderabadApartments#TrustedGasInstallers#SmartHomeSafety#ResidentialGasPipeline#HyderabadRealEstate#ExpertGasTechnicians#SafeLivingHyderabad#LPGSafety#HomeGasSolutions#PipelineExpert#GasTech#DomesticGasServices#EnergyEfficiency#SmartHomeGas#SustainableEnergy#ProfessionalInstallers#GasPipelinePros

0 notes

Text

Ensure Clear Sound with an Advanced Audio Cable Tester for Speaker

Ensure Clear Sound with an Advanced Audio Cable Tester for Speaker For musicians, sound engineers, and event planners, ensuring that your audio equipment is functioning correctly is crucial. One overlooked aspect is often the reliability of the cables connecting your gear. An audio cable tester for speaker can be a game-changer, offering peace of mind that your audio setup is working flawlessly. Whether you're setting up for a live performance or recording in the studio, having a reliable audio cable tester is essential. Why You Need an Audio Cable Tester for Speaker Speaker cables are the backbone of any audio setup. They carry the electrical signal from your amplifier to the speakers, and any issue with these cables can result in poor sound quality or even complete failure. An audio cable tester for speaker helps identify issues such as broken wires, incorrect connections, or phase problems before they affect your performance. Key Features of an Audio Cable Tester for Speaker When selecting an audio cable tester, consider the following key features: - Connectivity Options: Look for a tester that supports a variety of connector types, including XLR, 1/4", RCA, and Speakon. This versatility ensures you can test almost any cable in your inventory. - LED Indicators: Brightly colored LEDs indicate signal continuity and which pins are connected together, making troubleshooting quick and straightforward. - Rotary Switch: An easy-to-use rotary switch allows you to select the appropriate test mode for the type of cable you're testing. - Durability: A rugged, compact design ensures the tester can withstand the demands of on-the-go use, whether you're traveling to gigs or working in a studio. - Power Source: Most testers operate on a 9V battery, which should be included, providing convenience and portability. Technical Specifications and Installation Tips To get the most out of your audio cable tester for speaker, here are some technical details and installation tips: - Supported Connectors: 1/4" jack (6.5mm TRS), 1/8" (3.5mm) TRS jack, XLR 3-pin and 5-pin, phono/RCA, banana plugs, Speakon 8P and 4P, DIN 3P/5P/7P/8P, and CAT5. - LED Indicators: Eight green LEDs confirm the continuity of each conductor and indicate proper phase connections. - Rotary Control: An 8-way rotary control simplifies the process of checking signal continuity. - Dimensions: Typically, testers come in a compact rectangular shape, measuring around 185 x 55 x 110mm. - Battery: Operates on a 9V DC battery (included). How to Use an Audio Cable Tester for Speaker Using an audio cable tester is straightforward: - Connect the Cables: Plug one end of the cable into the left and the other into the right side of the tester. - Select the Mode: Turn the rotary switch to the appropriate test mode for the type of cable you are testing. - Check the LEDs: Observe the LEDs to see which pins are connected and to verify signal continuity. - Identify Issues: If any pins fail to light up, you've identified a problem that needs addressing. Benefits of Using an Audio Cable Tester for Speaker An audio cable tester for speaker can save you time and frustration by identifying issues before they become major problems. For instance, the PA System Audio Cable Tester is a robust and reliable tool that ensures your audio connections are always in top condition. Exploring Different Types of Audio Cable Testers While basic testers are sufficient for many applications, some professionals prefer more advanced options with additional features. For example, a 3-way crossover car audio might include extra functions for testing midrange frequencies. Similarly, "audio crossover car" and "car crossover audio" models offer specialized benefits but may vary in terms of specifications and compatibility. Conclusion Investing in an audio cable tester for speaker is a smart move for anyone serious about audio quality. Whether you're a casual user or a professional, a reliable tester can make a significant difference in the performance of your audio setup. Don't let faulty cables ruin your sound—get an audio cable tester today and enjoy crystal-clear audio every time! Read the full article

0 notes

Text

Yoyik offer valve SL20PB3-L4X for power station

"Yoyik offer valve SL20PB3-L4X for power station Main: hydraulic machinery and components, hydroelectric generating units; coal-fired generating units; generating units; electrical and electronic products processing; mechanical parts processing. Mainly engaged in the power industry host (steam turbine, water machine, boiler, turbine) accessories, spare parts, spare parts, auxiliary equipment and environmental protection equipment. Deyang YOYIK supply power plant, steel accessories are as follows:

Yoyik can offer many spare parts for power plants as below:

DF-valve SL20PB3-L4X-DF

relief valve RPGC1AV ac vacuum pump M02225 0BMCCI 1.5A vertical centrifugal pump YNKN300/200-20Y/J magnetic coupling centrifugal pump DFB80-50-20 piston hydraulic pump A3H56-FR01KK-10-X33 vacuum pump rotary vane F3-V10-IS6S-IC-20 reciprocating piston pump PVH74QIC-RSF-1S-10-C25 mechanical seal 43 mm AZ40-160B vane vacuum pump F320V12A1C22R electric oil pump 80AYZ-70 BFP cv actuator HTGY6E.0 oil pump HS76685,10BARG piston pump F3-V10-1S6S-1C20 vaccum pump 125LY-40-B mechanical seal 8b1d axial piston pumps PVH098R01A250000002001AB010A pressure hose SMS-12/15-305mm-B central lubrication pump 2CY-403/2.5 high pressure centrifugal pump CZ50-250C reciprocating piston pump PV29 2RID CO2 sealing ring HB4-56J8-37 Screw in connector Q/D9111G-77(87) Dg32 vacuum pump 259v P-1916 screw pump diagram HSNH280-54A oil seal TCM589332-OOG pressure hose SMS-12/N1/4-3048mm-C piston pump parts PVH131Q1C.RSF.10.C25 pressure hose SMS-12/15-3048mm-B solenoid valve RV5-10-0-35 hydraulic piston pump spare parts 70LY-34*2 Gear oil pump CB-1.2 vacuum pumps P-1931A industrial vacuum pump P-1753 electric centrifugal pump head IHF80-50-200 Check valve FPR12 0.5 AST/OPC solenoid valve coil CCS230D 16.5W 230VAC valve SL20PB3-L4X

repair coupling 125LY-31-6 stainless steel Throttle valve (flange) 50BJ-1.6P with reverse flange electric pump for lubrication 2CY45/9-1 sealing ring HB4-56J8-62 ac vacuum pump P-1433 accumulator oil-feeding globe valve DN25 dc screw pump NM063BT01L06V vacuum pump oil PVH74QIPRM-IS dc centrifugal pump IS80-50-200 piston pump parts PV29-2R5D-C00 Bearing Bush 88/100(130 mechanical face seal G50 vacuum pump price P-1825B Charging and pressure measuring assembly of EH oil accumulator NXQ-AB-40/20-L-A Fast exhaust valve XQ171000 makeup water solenoid valve K25FJ-1.6PA2 pumps centrifugal KQW100/200-22/2 Angle joint C-EW-L06-SS water pump SDH200-150-315 Recirculating oil pump mechanical seal DLXB850-R67 Proportional Relief valve E-RI-TERS-PS-01H/I 20 stator water pump 125-80-260 screw pump diagram 3GR30*4H2 Guide bearing B 9LDTNA-4-006 vacuum pump KZ/100WS solenoid valve GS061600V pump vacuum ZS-185A hydraulic pump spare parts 50SDZLJ-50 solenoid valve DSG-03-3C2-A240-N1 vacum pump air vacuum P-1964-1 actuator 1320B-333000A industrial centrifugal pump DFB125-125-250 dc centrifugal pump SDH200-150-315 piston hydraulic pump A10VS071DRS/32R-VPB22U99 electric motor centrifugal water pump DFB-100-80-230 multi stage centrifugal pump KQW100/200-22/2 valve SL20PB3-L4X

DFYLSYC-2024-7-8-A

"

0 notes

Text

ANAPHYLAXIS FILTER - WASPsynth multi-mode filter with double LFO and distortion (#3.2024)

The ANAPHYLAXIS FILTER is a multi-mode filter with double LFO modulator for the CUTOFF frequency based the filter section of the notorious WASP synthesizer that was created by Electric Dream Plant in 1978. This standalone pedal version of the filter allows you to use it for the input signals of your choice. The FILTER MODE selector is a 4 position rotary switch (up to down: LOW PASS, BAND PASS, HIGH PASS and NOTCH) with the position indicated by small purple UV LEDs. The input signal is controlled with the GAIN control, that can boost even weaker input signal to overdrive the filter. A dedicated RESONANCE control determines the amount of RESONANCE at the CUTOFF point, that of course has a control knob as well. Furthermore the RESONANCE has two settings: EXTREME (up) and NORMAL(down), selected with a toggle switch. In HIGH PASS mode the filter can self-oscillate without any input, in case you need a high frequency SINE WAVE oscillator. In that case the FREQUENCY can be dialed in with the CUTOFF control. But the ANAPHYLAXIS FILTER can do more, as it has 2 build in LFOs that are modulating the CUTOFF frequency, with independent SPEED and DEPTH controls, which allows to generate a more complex modulation waveform. Each LFO has a RANGE toggle that selects: SLOW (down) or FAST (up) as well a 3 position toggle switch that selects the SHAPE: SQUARE (down), OFF (middle) and triangle (up). The fast LFO range goes well into audio range and enables you to create some very interesting frequency modulation filter effects. With slower rates, especially with the triangle shape and the 2 LFOs running at non-synced rates, even the most static sounding input get ‘alive’. The SPEED of each LFO is indicated by either red or green color in the big LED in the middle of the LFO section. The 1st stomp switch is TRUE BYPASS and if that is not enough, the 2nd stomp switch engages the DISTORTION, both with UV indicator LEDs. The level of the DISTORTION is controlled by the DISTORTION knob and the toggle switch next to it adds a TREBLE BOOST (up) or a HIGH CUT (down) setting to the DISTORTION. In the end of the signal path is a signal booster based on the EHX LBP1 with a global VOLUME control. The ANAPHYLAXIS FILTER runs on 9V DC and has a ‘boss style’ 2.1mm DC barrel plug socket with the negative pin inside. The enclosure is a heavy duty scavenged industrial engine power connector housing made from die-cast aluminum with a bottom plate made from found material and is painted in the industrial burnout camo pattern in matte black and bright yellow. Handmade by GRM for METSÄÄN.

SOLD.

youtube

youtube

youtube

#anaphylaxis filter#waspsynth#wasp filter#wasp synthesizer#distortion#distortion pedal#filter pedal#effectpedal#Youtube

4 notes

·

View notes

Text

0 notes

Text

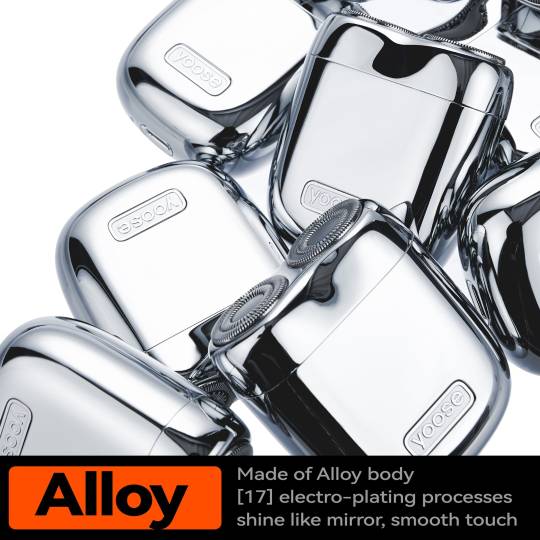

How Does the Yoose Mini Electric Shaver Compare to Traditional Shavers?

Grooming is a very important aspect of every man’s life, and one of the most common grooming processes is shaving, which depends on the choice of the shaver. The Yoose Mini Electric Shaver is gradually enjoying the fame of portable and practical shaver. But how does it effectively compare to the traditional shavers? This blog will explain the concept of using Yoose mini shaver and how it differs from other shaving tools and its advantages and disadvantages. Knowing these differences would be important especially for those who already have a grooming regimen and for the first timers. Let’s get deeper into the comparison to understand whether the Yoose MINI razor will suit you.

Size and Portability

One of the most important advantages of the Yoose mini electric shaver is its size. Unlike other electric shavers that may require a lot of pocket space when travelling the Yoose mini is made in small size to fit modern-day’s travelling.

This mini shaver portable is in fact, as small as a lipstick tube. It is rather small and can be easily put into the pocket or purse and even a carry-on bag. It is therefore, ideal for use when retouching during the day or during travel.

In this case, traditional shavers are larger and heavier as compared to electric ones or the wet/dry ones. They may not be portable to wear all day or take a short vacation with you.

Accessibility and Flexibility

Because of its small size, the Yoose mini shaver is convenient to use and easy to carry around. It is just a USB mini shaver, and as such, one can charge it through any of the USB ports. This is very good, especially for traveling or for use in the office.

However, it is also very easy to navigate, and that is what makes it appealing to many people. Switching it on and beginning to shave is as simple as that. There is no need for shaving cream or water, so it can be used at any time for a quick shave wherever you are.

Manual shavers generally require more preparation. There are electric types, which require a connector to be connected or batteries to be recharged. Manual razors require shaving cream and water, so they cannot be used anywhere and at any time.

Performance and Shaving Quality

As much as the Yoose mini shaver is a grooming tool, its performance is rather decent. It is a rotary shaver that follows the facial lines to give you a close shave.

You can shave a bit closer with a manual razor or a good full-size electric shaver, but you have to pay the price for it. But for a quick wash, a minor wash, or touch-ups, this is perfect.

Other features that may be more common in traditional shavers, especially more expensive electric ones, may include multiple blades or heads and specific settings. However, they are pricier and less portable than other conventional laptop models.

Versatility

The Yoose isn’t just for shaving your face. Some models also come with an accessory to help trim the nose hair. This makes it a handy tool for general grooming purposes.

In the case of traditional shavers, one gets stuck with different shavers for different grooming purposes. This simply means more stuff to acquire, wash, and pack each time one wants to go on a trip.

Battery Life and Charging

The battery backup of Yoose mini shaver is quite high for a unit of its dimensions. In one full charge, it can offer several shaves, depending on how long it takes you to complete one shave.

Older electric shavers can also have longer battery life than the new ones, but they also take longer to charge. As for manual razors, you don’t need to charge them ever.

Conclusion

Yoose Mini Electric Shaver has some advantages that is convenience, performance, easy to maintain and economical over the traditional shavers. It is small and sleek and can meet the requirements of today’s grooming services. Any person looking for a good shaver, which will do a good job and will not require much maintenance should consider buying a Yoose shaver. To know more about the Yoose Mini Electric Shaver and other grooming products in the market visit Yoose Tech.

0 notes