#SCADA Display Upgrade

Explore tagged Tumblr posts

Text

ATI Rage 128 8MB AGP Graphics Adapter | High-Speed Industrial Display Card | Ram Automations

Take your industrial systems to the next level with the ATI Rage 128 109–52000–00 8MB AGP Graphics Adapter, now available at Ram Automations. Designed for reliable video output in critical control systems and industrial PCs, this adapter is ideal for maintaining legacy equipment and display interfaces.

This high-performance AGP graphics card delivers stable, clear, and fast rendering for SCADA systems, automation software, and HMI panels — ensuring uninterrupted visual monitoring and diagnostics.

🛒 Order Now from Ram Automations 👉 https://ramautomations.com/products/ati-technologies-ati-rage-128-109-52000-00-8mb-agp-graphics-adapter-used

🌐 Explore 1000+ Genuine Automation Parts 👉 https://ramautomations.com

🧩 Product Specifications

• 🔹 Brand: ATI Technologies • 🔹 Model: Rage 128 109–52000–00 • 🔹 Type: 8MB AGP Graphics Adapter • 🔹 Category: Display Card / Graphics Adapter • 🔹 Interface: AGP (Accelerated Graphics Port) • 🔹 Application: SCADA, industrial PC systems, legacy hardware, control displays

✅ Why Choose This Product?

✔️ Provides high-quality visual output for critical control systems ✔️ Supports industrial HMI and legacy interfaces ✔️ Ideal for manufacturing plants and industrial automation networks ✔️ Designed to run efficiently under demanding conditions ✔️ Extends the life of legacy PC-based control systems

💡 Common Use Cases

• SCADA system display units • PLC-based HMI monitoring • Marine engine control rooms • Industrial PC replacements • CNC control systems • Control room display upgrade projects • Graphic rendering for automation software

🌟 Why Ram Automations?

We are your global source for rare, obsolete, and high-demand industrial parts. ✅ Verified Quality ✅ Fast Global Shipping ✅ Trusted by Industrial Professionals Worldwide ✅ Affordable Prices

📽️ What You’ll See In This Video:

🔎 Close-up of the ATI Rage 128 AGP Graphics Adapter 🔧 Overview of ports, structure, and compatibility 💡 How it enhances visual performance in automation 🌐 Why Ram Automations is your #1 source for genuine automation electronics

📣 Subscribe & Engage

🔔 Hit Subscribe for regular uploads on rare automation parts 👍 Like this video if you work with industrial PCs or SCADA 💬 Drop your questions in the comments — we’re quick to respond!

#ATI Rage 128#ATI Graphics Adapter#AGP Graphics Card#Industrial Display Card#Graphics Board for SCADA#Display Card for Automation#109-52000-00 Graphics Adapter#Ram Automations#Legacy Display Card#SCADA Display Upgrade#HMI Display Card#AGP Interface Card#Automation Display Board#Industrial Video Output Card#Electronics Replacement Card#Industrial Control Display Board#Process Control Graphics#High Performance Display Card#Automation Graphics Support#Control Room Display Card

1 note

·

View note

Text

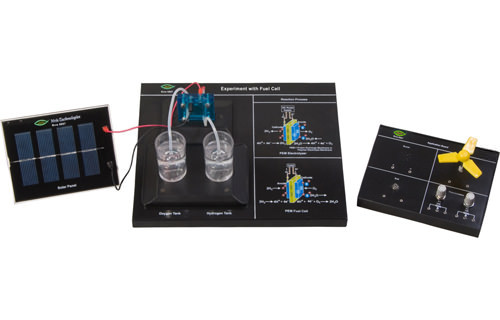

Best Lab Training Systems for Practical Learning in Engineering

In today’s rapidly advancing technical education landscape, hands-on training is no longer optional—it's essential. Whether you're an educator, institution, or student, integrating the Best Lab Training Systems into your curriculum is key to building future-ready skills. From embedded systems to communication labs and industrial automation, practical experience with real equipment bridges the gap between theory and industry requirements.

Let’s dive into how to choose the best lab training systems, their benefits, applications, and why sourcing from trusted electronic lab equipment providers in Indore can give you an edge.

What Are Lab Training Systems?

Lab training systems are structured educational setups that simulate real-world technical environments for students to learn and practice various engineering concepts. These systems include:

Microcontroller/Embedded System trainers

Electrical machines and power electronics labs

Communication lab kits (Analog, Digital, Optical, etc.)

IoT, Robotics, and PLC-based automation platforms

They are commonly used in engineering colleges, polytechnics, vocational institutes, and technical universities to enhance student employability.

Why Choose the Best Lab Training Systems?

Selecting the best lab training systems ensures:

Industry-aligned skill development

Increased student engagement through interactive learning

Long-term usability and safety

Support for NEP 2020 and other modern curriculum standards

Here’s what defines a great lab training system:

Key Features:

Modular Design: Expandable systems for flexible experiments

Real-Time Monitoring: Display outputs and waveform analysis

Compatibility: Supports multiple software and hardware platforms

Safety Measures: Fuse protection, current limiters, and more

Documentation: Comes with manuals, experiment sheets, and software

Applications Across Engineering Domains

The best lab training systems cover a broad spectrum of disciplines:

1. Electronics & Communication Engineering

Analog/Digital communication labs

Satellite & antenna trainers

Fiber optic kits

2. Electrical Engineering

DC & AC machine trainers

Power electronics experiment boards

Renewable energy integration modules

3. Embedded Systems & IoT

ARM/PIC/AVR microcontroller kits

IoT-based automation with cloud connectivity

Arduino/Raspberry Pi interfacing

4. Mechatronics & Industrial Automation

Pneumatic & hydraulic simulation platforms

SCADA & PLC-based labs

Smart factory simulation units

Why Buy from Electronic Lab Equipment Providers in Indore?

Indore has become a hub for high-quality electronic lab equipment manufacturing and innovation. Partnering with reliable electronic lab equipment providers in Indore offers:

Customization based on institutional syllabus

Reliable delivery and installation

Complete training and documentation

On-demand support and AMC (Annual Maintenance Contracts)

Advanced R&D-backed systems compliant with AICTE & NAAC norms

These suppliers not only understand local academic needs but also offer internationally competitive products.

How to Choose the Right Electronic Lab Equipment?

Here are essential factors to consider when selecting a lab training solution:

Technical Checklist:

Does it cover all required experiments?

Is the system upgradeable or modular?

Are the components industry-grade and durable?

Is software integration available (e.g., MATLAB, LabVIEW)?

Is there training support for faculty?

Real-World Outcomes of Lab Training Systems

Implementing the best lab training systems leads to:

Faster concept grasping through visual and tactile learning

Research and innovation by students and faculty

Increased placement rates due to hands-on exposure

Institutional ranking improvement through enhanced infrastructure

Institutions that emphasize experiential learning through training systems tend to produce more industry-ready engineers.

0 notes

Text

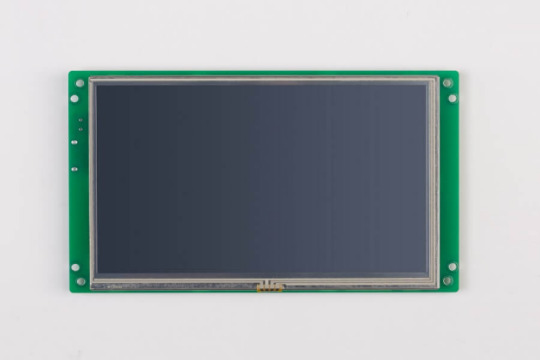

Enhancing Industrial Automation with Intelligent HMI and Advanced LCD Display

In today’s smart manufacturing era, HMI (Human-Machine Interface) systems and industrial LCD display modules play a crucial role in enhancing automation and operational efficiency. The seamless integration of these components empowers real-time interaction and visual monitoring across complex industrial environments.

At the core of HMI systems lies the LCD Module Display—a vital component that ensures stable performance, even in challenging conditions. Whether it's a TFT LCD display, touch screen, or OLED panel, these display technologies provide clear, high-resolution interfaces for operators to control and monitor machinery.

Modern touch LCD screen technology has greatly improved HMI usability. The incorporation of lcd touch and touch display capabilities enables intuitive interaction, reducing human error and increasing responsiveness. With lcd driver boards supporting intelligent communication, the system can effortlessly connect with PLCs, SCADA, and other devices using protocols like Modbus and Ethernet.

Industrial applications require rugged solutions. TFT LCD screen and tft lcd module options are built for wide-temperature ranges, high brightness, and anti-interference performance—making them ideal for outdoor, factory-floor, and heavy-duty environments. Even lcd module old designs are being upgraded with lcd tft and lcd display modules to meet modern standards.

Among various manufacturers, Innolux display modules are recognized for their superior quality and reliability. These display modules are often deployed in HMI systems that demand long-term operation with minimal maintenance.

As AI and IoT technologies advance, the role of display lcd components becomes even more important. Next-generation panel lcd solutions will not only show data but also analyze trends, support predictive maintenance, and communicate alerts to reduce downtime.

From inch lcd screen variants tailored for compact control panels to large lcd panel systems for industrial dashboards, choosing the right display module can dramatically impact system performance and cost-efficiency.

In conclusion, the combination of smart HMI systems and high-performance lcd display screen technologies forms the foundation of modern industrial automation. Selecting premium LCD Module Display solutions with enhanced touch screen interfaces ensures increased productivity, streamlined control, and future-ready infrastructure.

Shenzhen Zhiyan Optronics Co., Ltd. (zylcdshop.com) is a trusted supplier of industrial and commercial display solutions. We specialize in high-performance LCD panels, touchscreen displays, and screen modules—delivered with expert support and competitive pricing.

#car touch screen control panel#touch panel pc#siemens touch panel#multi touch panel#lcd touch panel

0 notes

Text

Signal & Stability: Capturing Data with Recorders and Shaping Power with Rectifiers

Where Real-Time Monitoring Meets Reliable Power Conversion

In today's automated industrial environments, real-time performance tracking and consistent power delivery are non-negotiable. Whether it's measuring key process variables or converting AC to DC for precision systems, Recorders and Rectifiers stand as foundational components in modern control and automation systems. At Dropship Automation Solutions, we provide high-precision devices that help industries collect, analyze, and regulate — with accuracy and resilience.

1. Recorders: The Eyes of Your System

📈 What is a Recorder? A recorder is an industrial device used to log, display, and monitor data such as temperature, pressure, voltage, or flow rate. Recorders are essential for maintaining traceability, quality control, and performance diagnostics across manufacturing and processing operations.

🔧 Types & Use Cases • Types: Paper Recorders, Digital Chart Recorders, Data Loggers, Multi-Channel Recorders • Applications: Pharmaceutical manufacturing, power plant monitoring, food processing compliance, HVAC analytics • Benefits: Accurate trend analysis, easy integration with SCADA/PLC systems, data backup, compliance-ready

🧠 Why Recorders Are Vital Modern automation demands visibility. Recorders provide it. By logging critical parameters in real time, they ensure regulatory compliance, process optimization, and early fault detection—enabling engineers to make smarter decisions without guesswork.

2. Rectifiers: The Backbone of DC Power Systems

⚡ What is a Rectifier? A rectifier is an electronic device that converts alternating current (AC) into direct current (DC). This is essential for machines and control systems that require stable, low-noise DC voltage to operate efficiently.

🔧 Types & Functions • Types: Single-phase, Three-phase, Half-wave, Full-wave, Bridge Rectifiers • Applications: Battery charging units, DC motor drives, power supplies for control panels, electroplating systems • Benefits: Stable DC output, compact design, thermal protection, high conversion efficiency

⚙️ Why Rectifiers Are Indispensable Most industrial controllers, sensors, and communication modules rely on DC power. Rectifiers ensure that this power is clean, uninterrupted, and appropriately rated for sensitive equipment. Their reliability is critical for minimizing system downtime.

🔄 Combining Recorders & Rectifiers in Industrial Systems

Example Application:

A rectifier supplies clean DC power to a control panel.

A recorder tracks panel voltage and load conditions over time.

When anomalies appear, alerts are triggered, allowing preventive maintenance before failure.

This synergy helps in maintaining both electrical health and historical traceability, a cornerstone of modern Industry 4.0 strategies.

✅ Empowering Your Automation with Precision Technology

At Dropship Automation Solutions, our recorders and rectifiers are selected for their industrial-grade durability, accuracy, and intelligent integration capabilities. Whether you're logging mission-critical data or ensuring consistent power flow, we supply tools engineered for performance under pressure.

🛒 Monitor Smarter, Power Safer

Ready to upgrade your automation systems? Get in touch with our technical experts for the best-fit solution:

📞 Call: +1 (234) 288-1755 📧 Email: [email protected] 📍 Visit: 1440 W. Taylor St #2555, Chicago, IL 60607

0 notes

Text

What to Look for in Industrial Measurement Equipment for Manufacturing Facilities

In manufacturing, precision is everything. Whether you're producing electronics, automotive components, pharmaceuticals, or food packaging, accuracy in measurement directly impacts quality, safety, and regulatory compliance. That’s why investing in the right industrial measurement equipment is not only a smart decision—it’s a critical one.

But with so many options on the market, how do you choose the right tools for your facility?

At EpicRise Electronics, we help businesses across industries source high-performance tools and IT equipment, including measurement systems, scanners, and wholesale label printers. Here's what to look for when equipping your manufacturing facility with industrial measurement solutions.

1. Accuracy and Reliability

The foremost priority in any measurement equipment is accuracy. Whether you're measuring weight, temperature, humidity, voltage, or dimensional properties, even the smallest margin of error can lead to production defects, wasted materials, and safety issues.

Look for devices that meet or exceed ISO or NIST standards and are tested for industrial-grade precision. It’s also essential that the equipment performs consistently over time without needing frequent recalibration.

Tip: Opt for trusted manufacturers that offer certification or documentation on equipment accuracy. Brands partnered with EpicRise often come with reliability reports and compliance details.

2. Durability and Build Quality

Manufacturing environments are often harsh—subject to heat, moisture, dust, vibration, and continuous operation. Your measurement tools must be built for endurance.

When sourcing items such as laser measurement devices, multimeters, or pressure gauges, choose models specifically designed for industrial environments. Features to consider include:

Rugged casings (shock-proof, waterproof, dustproof)

High-quality connectors and cables

Resistance to chemicals or oil

Durability reduces downtime and repair costs—especially in 24/7 operations.

3. Integration with Existing Systems

Modern manufacturing facilities are increasingly automated and data-driven. Measurement devices should seamlessly integrate with your existing systems, whether that’s SCADA software, ERP platforms, or IoT networks.

Look for equipment with USB, Ethernet, or Bluetooth connectivity, and ensure it's compatible with your current software architecture. This allows real-time data collection and monitoring, improving decision-making and traceability.

Pro Tip: Integration also extends to your labeling and tracking tools. For instance, pairing a Zebra barcode scanner with automated weighing or inspection stations ensures that product IDs and measurement data flow smoothly across systems.

4. Ease of Use and Operator Training

Complex equipment that requires excessive training can slow down operations and increase the likelihood of user error. Choose tools that offer intuitive interfaces, clear displays, and simple calibration procedures.

Many leading brands also offer training resources, online support, and documentation. These are crucial when onboarding new team members or troubleshooting issues on the production floor.

At EpicRise, we prioritize stocking measurement tools with user-friendly design, backed by strong manufacturer support and documentation.

5. Scalability and Upgrade Potential

Your facility’s needs today might not be the same five years from now. The best industrial measurement systems are modular or scalable—allowing you to expand or upgrade without overhauling your entire process.

For example:

Multichannel data loggers can be expanded with additional sensors.

Barcode readers and scanners can be upgraded with advanced software.

Integrated systems can support added devices as your production grows.

When planning for growth, choose flexible solutions that evolve with your operations.

6. Data Logging and Traceability Features

In highly regulated industries—like food, medical devices, or aerospace manufacturing—data traceability is non-negotiable. Measurement tools should offer internal storage, cloud connectivity, or the ability to export logs securely.

This helps meet compliance standards (e.g., FDA, ISO 9001) and supports quality audits, troubleshooting, and continuous improvement initiatives.

Pairing your measurement devices with wholesale label printers also boosts traceability. With every reading, you can instantly generate barcode labels that reflect batch numbers, inspection dates, or critical data points.

7. Brand Reputation and Support

With industrial-grade tools, it pays to choose reputable brands with proven track records. These manufacturers typically offer:

Better warranties

Firmware updates

Technical support

Long-term availability of spare parts

One such example is Zebra Technologies, a leader in tracking and scanning tools. Their Zebra barcode scanner models are known for reliability in industrial environments, offering high-speed scanning, rugged durability, and seamless integration with other factory systems.

EpicRise is proud to offer Zebra products, along with measurement devices and peripherals from top global brands.

8. Cost Efficiency Through Wholesale Channels

Quality measurement equipment can be a major investment, especially if you’re outfitting an entire facility. Buying through a distributor like EpicRise Electronics means you gain access to wholesale pricing, faster shipping, and expert consultation.

Need to bundle tools with scanning devices, power supplies, or network equipment? We make procurement simple and affordable by offering:

Wholesale label printers

Bulk orders of barcode scanners and sensors

Compatible accessories and software

You don’t have to compromise quality for budget—EpicRise delivers both.

Final Thoughts

Investing in the right industrial measurement equipment pays dividends across your manufacturing operation—from better product quality and compliance to increased efficiency and cost savings. But success starts with sourcing smart.

When you work with EpicRise Electronics, you get more than just tools—you get a trusted partner in procurement. From Zebra barcode scanner systems to durable measurement devices and wholesale label printers, we supply the equipment that powers precision manufacturing.Need help choosing the right gear for your facility? Explore our full product range at EpicRiseElectronics.com or contact our support team for a custom quote today.

0 notes

Text

Choosing the Right HMI for Your Industrial Needs in Rajasthan

In today's rapidly evolving industrial landscape, automation has become the backbone of efficiency and innovation. Whether you're in manufacturing, packaging, pharmaceuticals, or any other sector where machine control is vital, Human Machine Interface (HMI) systems are indispensable. An HMI acts as a bridge between humans and machines, enabling real-time monitoring, control, and diagnostics of industrial processes.

Rajasthan, with its growing industrial hubs like Jaipur, Bhiwadi, Udaipur, and Kota, is witnessing a strong demand for smart automation solutions. Industries here are not just expanding—they're upgrading. And at the core of this transformation lies the intelligent deployment of HMI systems that make machines more accessible and operations more streamlined.

Why HMIs Are Critical in Modern Industry

Human Machine Interfaces do more than display information. They empower operators to interact with machines effectively—monitor performance, change settings, run diagnostics, and respond to issues faster. With touchscreen displays, intuitive design, and robust software integration, modern HMIs reduce the learning curve and operational errors.

Benefits of using advanced HMIs include:

Increased operational efficiency

Minimized downtime through better diagnostics

Improved data visualization and process control

Enhanced safety and compliance

From basic control panels to high-end, cloud-connected HMIs, businesses today have a wide range of choices based on their scale, needs, and budget.

What to Look for When Selecting an HMI

Choosing the right HMI is not just about hardware—it’s about the long-term support, software compatibility, service network, and customization options. Here are some key factors to consider:

Scalability: Will the HMI adapt as your operations grow?

Durability: Is it suitable for industrial conditions like dust, moisture, or high temperatures?

Software integration: Can it work seamlessly with your existing PLCs and SCADA systems?

User interface: Is it intuitive for operators with varying skill levels?

Support and maintenance: Does the supplier offer reliable after-sales service?

This is where working with the right dealer becomes crucial.

Finding Reliable Dealers in Rajasthan

With an increasing number of automation solution providers in the market, selecting a trusted HMI dealer can make all the difference. You want a partner who not only supplies quality products but also understands your specific industrial requirements and provides ongoing support.

The best HMI dealers in Rajasthan stand out because of their commitment to customer service, technical expertise, and long-standing relationships with reputed brands. They offer tailored solutions based on your industry and ensure smooth installation, commissioning, and maintenance services. Many also provide training and troubleshooting support to make the transition to automation seamless for your team.

Whether you're looking to upgrade a legacy system or set up a fully automated plant, working with experienced HMI dealers ensures your investment pays off in performance and reliability.

Final Thoughts

As industries in Rajasthan continue to modernize, the role of intelligent automation systems, especially HMIs, is becoming more central than ever. A reliable HMI system not only enhances productivity but also provides greater control and visibility over your operations.

By investing wisely in high-quality interfaces and partnering with trusted local suppliers, businesses can future-proof their operations and stay competitive in a fast-changing environment. Take time to assess your needs, do your research, and choose a partner who brings both technology and expertise to the table.

0 notes

Text

Automation Programming in Edwardsville, Illinois | Smarter Industrial Control

Automation programming involves developing the software and logic that controls machines, equipment, and production lines. It’s the “brain” behind any automated system, enabling precise, repeatable, and adaptable actions without constant human intervention.

Key components include:

PLC Programming: Writing logic-based code to control equipment such as motors, sensors, and actuators.

HMI Design: Developing visual interfaces that operators use to monitor and interact with automated systems.

SCADA Integration: Supervisory control systems that collect and analyze data from across an entire facility.

Custom Automation Scripts: Logic tailored to unique processes and workflows.

In Edwardsville, automation programming is essential for companies that want to minimize downtime, improve product quality, and remain competitive.

Why Automation Programming Matters for Edwardsville

With its strong economic base and proximity to major markets like St. Louis, Edwardsville is home to a growing number of industrial operations. Whether it's a mid-sized packaging firm or a large-scale manufacturer, local businesses face increasing pressure to improve efficiency and throughput. That’s where automation programming comes in.

1. Operational Efficiency: Well-programmed systems eliminate manual tasks, speed up production, and reduce the likelihood of human error.

2. Quality Control: Automation ensures consistency across batches, helping companies meet strict quality standards.

3. Cost Savings: By reducing labor costs and minimizing material waste, automation delivers a strong return on investment.

4. Data Utilization: Modern systems provide actionable data insights, allowing operators and managers to make smarter decisions in real-time.

In Edwardsville, this translates into better-performing factories, safer work environments, and increased economic resilience.

Core Services Provided by Automation Programmers

Local automation programming companies in Edwardsville offer a range of services to support manufacturers across sectors. These include:

Custom PLC Programming: Tailored logic to manage specific machines or entire production lines.

HMI Interface Development: Easy-to-use control panels that display system data and allow for quick troubleshooting.

SCADA System Setup: Centralized control systems that integrate data from multiple sources.

Retrofit and Upgrade Services: Modernizing older machines with new control logic and communication protocols.

Process Optimization: Using analytics and automation logic to fine-tune production flow.

These services ensure systems operate at peak performance, even in complex, multi-stage production environments.

Industries in Edwardsville Benefiting from Automation Programming

Automation programming is not limited to one field. It plays a critical role across many Edwardsville industries:

Food & Beverage: Automating mixing, filling, and packaging for hygiene and speed.

Warehousing & Logistics: Conveyor control and sorting systems that reduce shipping delays.

Pharmaceuticals: Precision dosing and environmental controls for product safety.

Automotive Components: Robotic assembly coordination and inspection programming.

Metal Fabrication: CNC machine integration and real-time production monitoring.

These industries depend on accurate, flexible programming to respond to market demands while maintaining operational control.

Tools and Platforms Used in Edwardsville

Automation programming professionals in Edwardsville are proficient in a wide range of technologies and platforms, including:

Allen-Bradley / Rockwell Automation

Siemens TIA Portal

Mitsubishi PLCs

Omron and ABB Systems

Ignition SCADA

Wonderware (AVEVA)

Beckhoff TwinCAT

These platforms offer robust tools for machine control, process visualization, and data management—all essential for high-performance automation systems.

Workforce Training and Local Support

Edwardsville benefits from strong academic institutions like Southern Illinois University Edwardsville (SIUE), which offers programs in engineering, computer science, and industrial technology. These institutions help build a local talent pipeline of engineers and programmers equipped to design and maintain next-generation automation systems.

Additionally, ongoing partnerships between automation companies and local manufacturers ensure that workforce development aligns with real-world needs. On-the-job training and technical certifications are increasingly available to support career growth in automation programming.

Looking Ahead: Smarter Factories on the Horizon

With the rise of Industry 4.0, the future of manufacturing in Edwardsville is smart, connected, and data-driven. Automation programming is a key enabler of this future. Companies are beginning to adopt:

Remote Monitoring and Control

Cloud-Based Data Storage and Analytics

AI-Enhanced Predictive Maintenance

Digital Twin Simulations

These technologies offer unprecedented visibility and flexibility, allowing businesses to operate more efficiently and react quickly to changes in demand or supply chain conditions.

Your Edwardsville Automation Partner: Xtreme Automation LLC

If you're seeking professional automation programming services in Edwardsville, turn to the experts at Xtreme Automation LLC. With deep experience in PLC programming, HMI development, SCADA integration, and smart system upgrades, Xtreme Automation delivers tailored solutions that boost performance and cut downtime. Whether you're building a new line or upgrading legacy systems, their team ensures seamless automation from design to deployment. Learn more at xtremeautomationllc.com.

#Automation Programming Edwardsville IL#PLC Programming Services Illinois#Industrial Automation Edwardsville#HMI Systems Integration#Custom Control Systems Illinois#Manufacturing Automation Solutions#Programmable Logic Controllers#SCADA Systems Edwardsville#Industrial Software Engineering#Automation Services Metro East IL

0 notes

Text

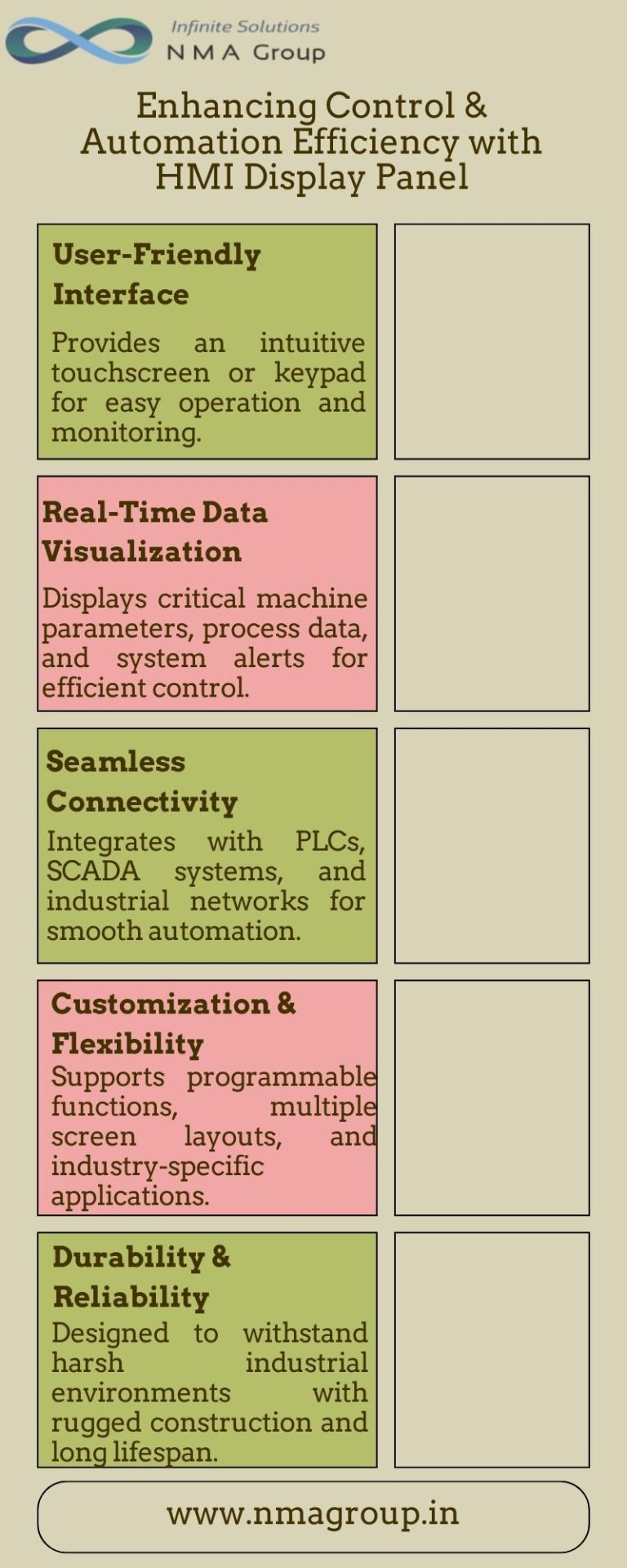

Enhancing Control & Automation Efficiency with HMI Display Panel

Hmi Display Panel are essential for modern industrial automation, offering real-time monitoring, seamless connectivity, and user-friendly operation. These panels integrate with PLCs, SCADA systems, and industrial equipment to optimize processes and enhance productivity. Designed for durability and efficiency, HMI panels provide a reliable interface for controlling machinery and visualizing data. Upgrade your automation system with the latest HMI display panel technology today!

0 notes

Text

Digital VGA STN PCB Card | High-Performance Industrial Automation Module | Ram Automations

Level up your industrial and marine automation systems with the Digital VGA STN PCB Card, now available at Ram Automations. Designed for high-precision signal processing and industrial-grade visual outputs, this PCB card ensures seamless communication between your control hardware and visualization systems.

Built to support mission-critical automation environments, the Digital VGA STN PCB Card is ideal for upgrading your system’s display interfaces, ensuring clear communication, real-time monitoring, and system stability across industrial setups.

🛒 Buy Now: 👉 https://ramautomations.com/products/digital-vga-stn-pcb-card

🌐 Explore More Premium Industrial Products: 👉 https://ramautomations.com

🔧 Product Overview:

• 📦 Product Name: Digital VGA STN PCB Card • 🏢 Brand: Digital (Digital Equipment Corporation) • 🧩 Type: Printed Circuit Board (PCB) — VGA Signal and Display Interface Module • 📌 Condition: Fully Tested • 🛠 Applications: Factory floor systems, marine automation displays, process control panels, SCADA visualization, machine interfaces

✅ Key Features:

✔️ Genuine Digital Equipment Corporation board ✔️ High-quality VGA signal output for industrial monitors ✔️ Seamless integration into control and automation systems ✔️ Strong signal stability and display clarity ✔️ Reliable design for demanding industrial environments ✔️ Fully verified for performance and longevity

🏭 Ideal Applications:

✔️ Industrial visualization systems ✔️ Automation cabinets and control panels ✔️ Marine navigation displays ✔️ SCADA workstations ✔️ OEM equipment visualization ✔️ Factory production monitoring systems

Whether you’re upgrading your automation displays or maintaining OEM equipment, the Digital VGA STN PCB Card offers the best combination of durability, quality, and precision output.

🛠 Why Choose Ram Automations?

At Ram Automations, we stock tested, genuine, and hard-to-find industrial parts from over 1000 global brands, ready to ship worldwide.

✔️ 1000+ Global Brands in Inventory ✔️ Fully Tested, Reliable Automation Components ✔️ Fast Worldwide Delivery ✔️ Bulk and OEM Support Available ✔️ Expert Technical Assistance

📽️ In This Video You Will Learn:

🔎 Full Visual Overview of Digital VGA STN PCB Card ⚙️ How to integrate it into industrial visualization systems 📈 Applications in SCADA and process control ⚡ Why visualization modules are crucial for system monitoring 🌍 Benefits of trusted brands like Digital Equipment Corporation in industrial automation

📣 Subscribe and Stay Updated:

🔔 Subscribe to Ram Automations YouTube Channel for weekly videos featuring industrial spare parts, system integration tips, and rare automation components. 💬 Drop your questions in the comments — we respond fast! 👍 Like this video if you found it helpful

#Digital VGA STN PCB Card#VGA PCB Board#Industrial Display Module#Automation Visualization Card#SCADA Display Card#Industrial PCB for Displays#Ram Automations#Digital Equipment Corporation Board#Automation Visual Module#VGA Industrial Control Board#Marine Display Board#SCADA Panel Board#Factory Automation Display#VGA Signal Module#Automation Display Module#OEM Display Parts#Industrial Automation Board#Industrial Signal Processing#Industrial Electronics Board

1 note

·

View note

Text

Where IoT Can Improve Beer Production Processes

In the beer production process there are manufacturing malt, crushing raw materials, saccharification, fermentation, storage and maturation, filtration, filling and packaging and other processes. Need to use the wind separator, sieving machine, saccharification pot, fermentation equipment, filtration machine, filling machine, packaging machine and other food machinery and equipment. The automation and intelligence of these food machinery and equipment together promote the automated production of beer.

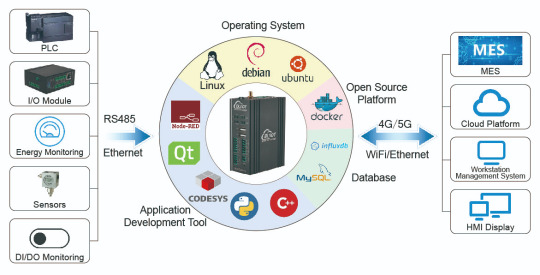

How to use the Internet of Things (IoT) to realize the digitalization, intelligence and visualization of the production and management process in beer factories?

Solution

Use BLIIoT EdgeCOM to monitor each production process on the production line; and connect PLC to the EdgeCOM, so that you can not only check the data on HMI, at the same time, the data can be uploaded to the OPC UA client(MES, DCS, etc.).

PLC receives and processes sensor data, controls equipment hydraulic, pneumatic, electrical parameters, etc., while BLIIoT EdgeCOM responsible for controlling the entire production process, to achieve the purpose of information interoperability.

What EdgeCOM implements in the system?

Control commands are sent to the PLC by analyzing the data collected by the PLC.

Write a program through Node-RED or QT to get the data to be displayed from the device, and finally display the data in charts, lists, or other forms on the corresponding interface.

Transfers data to enterprise management systems such as MES.

Advantage of EdgeCOM

Support a variety of communication protocols, reducing communication costs.

EdgeCOM collect the operation status, sensing data, recipe data and alarm information of the equipment, and judge whether it meets the production requirements, according to the analysis results, the EdgeCOM sends control instructions to PLC through OPC UA, then PLC drives the mechanical arm and conveyor belt and other equipment to execute the corresponding actions.

Real-time recording of production line data (e.g., sensor readings, control commands, and product classification), which can be uploaded to My SQL databases, enterprise-level MES, DCS, SCADA, etc., or cloud-based platforms for further analysis.

Support LINUX, Ubuntu, Debian, and other OS, and support Node-Red, QT, Python, C++ and other application programs. Users can program it by themselves according to their needs.

Supports remote configuration and remote upgrade. View More

0 notes

Text

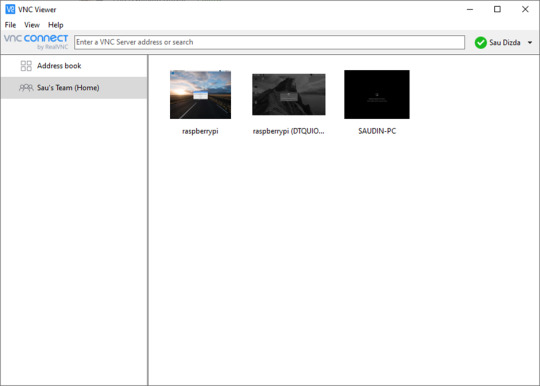

Raspberry Pi, MQTT and RealVNC

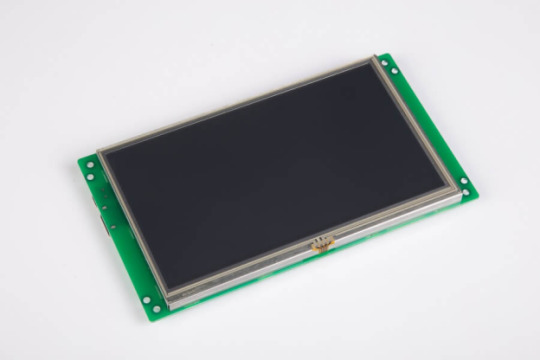

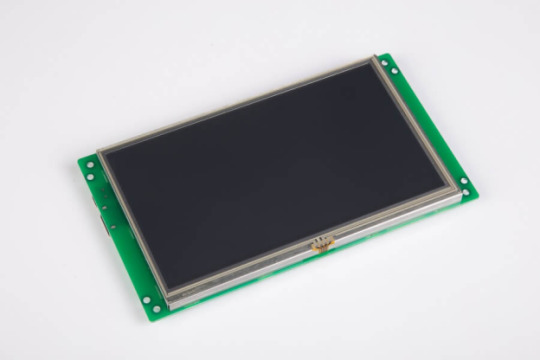

When I got Sensecap S2103 LoRaWAN® CO2, Temperature, and Humidity Sensor, I was thinking to integrate it with commercial Scada HMI system. One of the reasons is because Sensecap S2103 is a set of sensors which are applicable in industrial applications. Later, an idea came to me why not to use Raspberry PI with screen - Human Machine Interface together with RealVNC to make Industrial – grade reusable application.

The best thing in this project Remote Access for your Raspberry Pi from Anywhere in the world via VNC connection, meaning you have Scada HMI system anywhere, on any device.

In this post I am going to show how to integrate Sensecap S2103 sensor and display collected data on Raspberry Pi display.

Since picture is worth a thousand words, block schematics below shows architecture of my project.

I will show data from SenseCap S2103 sensor on Home Assistant which is installed on reTerminal . I will not go step-by-step on configuration/installation of Home Assistant on reTerminal, but you can see great guide on seeedstudio wiki here https://wiki.seeedstudio.com/reTerminal_Home_Assistant/.

I used the guides from link above and Home Assistant Supervised installation/configuration method in order to have data displayed on reTerminal LCD.

Home Assistant acts as a central smart home controller hub by combining different devices and services in a single place and integrating them as entities. That means you can integrate various sensors and variouts services in one single place.

Process of installing Home Assistant Supervised on reTerminal is like following:

I am assuming that you already have installed Raspberry PI OS.

Install RealVNC https://www.realvnc.com/en/

Install docker

Visit Home Assistant OS Agent page, and install Home Assistant Agent V1.3.0. and also Home Assistant-Supervised

Install Portainer Docker management platform

On portainer dashboard make sure that Home Assistant primary containers are up and running

On a web browser, type the following URL homeassistant.local:8123

If everything is installed without problems, you can view Home Assistant Dashboard UI on your web browser and proceed with making your account

RealVNC server should come preinstalled no your SD card with Raspbian OS. If, for any reason this is not case with you, below are informations on how to Install the RealVNC for Raspberry pi.

How to Install the RealVNC on Raspberry Pi

Update the system repositories:

Open the terminal if you have direct access. Or, take an SSH session to the Raspberry Pi CLI. $ sudo apt-get update && apt-get upgrade

2. Install the RealVNC server:

$ sudo apt-get install realvnc-vnc-server.

3. Enable VNC server:

$ sudo raspi-config Got to Interfacing options Select VNC Answer Yes Select Finish to quit (or ESC)

Note: VNC runs on port 5900. You should open this port on all the middle devices to work the communication from your PC to the Raspberry Pi.

On PC side, you must install RealVNC Viewer, in ordes to access HMI remotely. Below is how RealVNC viewer loooks after installation.

First big part of the project is finished. Now we are going to configure SenseCAP sensor by using Sensecap MATE Android application. Again, amazing guideline can be followed on Seed's wiki: https://wiki.seeedstudio.com/Cloud_Chain/SenseCAP_Mate_APP/SenseCAP_APP/

The next step is to configure mqtt integration with Home Assistant and subscribe to SenseCAP data.

First, what you need to know is SenseCAP account API ID, Organization ID, and Access API keys. Nice quickstart can be found on sensecap page.

https://sensecap-docs.seeed.cc/data_openstream_quickstart.html

Got to https://sensecap.seeed.cc/portal/#/security, in order to create Access Key and view information about Organization ID.

By clicking on API ID, you can also see API keys information.

So, your important connectivity informations for Home Assistant, which will be important in order to connect to MQTT, are as below:

Host: sensecap-openstream.seeed.cc

User: org-<OrgID> (here you replace OrgID with your Organization id-example for this parameter will be org-428131654987987)

Password: here you insert your Acces Key which is in form XBA6E65464 (a combination of letters and numbers).

Client ID: org-<OrgID>-quickstart (example: org-428131654987987-quickstart)

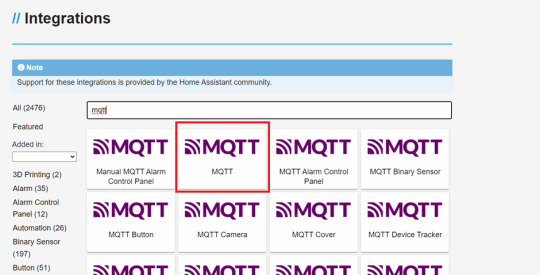

After this, go to https://www.home-assistant.io/integrations/, which allows integration with a lot of services. You will need, of course MQTT. Enter MQTT in search box, and choose MQTT, as shown below:

In Home Assistant now go to Settings->Devices & Services, Click add integration button and search MQTT. Now you enter the informations from above for MQTT connectivity:

Username= OrgID, password= client ID

Now, in order to test that MQTT connectivity works, click the CONFIGURE button and listen to the topic : device_sensor_data/OrgID/+/+/+/+

(example: device_sensor_data/428131654987987/+/+/+/+).

After few seconds, you will have response: vaule and timestamp in JSON format.

Since we want to show values of temperature, CO2 and humidity, we need to add multiple entities to store aquired sensor data, by editing the Home Assistant configuration file.

Go to the settings, click to Add-ons,search for File Editor, modify the YAML file /config/configuration.yaml by entering:

mqtt:

sensor:

- name: "Air Temperature"

state_topic: "/device_sensor_data/<orgID>/<DeviceEUI>/1/+/4097"

unit_of_measurement: "℃"

value_template: "{{ value_json.value }}"

- name: "Air Humidity"

state_topic: "/device_sensor_data/<orgID>/<DeviceEUI>/1/+/4098"

unit_of_measurement: "%RH"

value_template: "{{ value_json.value }}"

- name: "Air CO2"

state_topic: "/device_sensor_data/<orgID>/<DeviceEUI>/1/+/4100"

unit_of_measurement: "ppm"

value_template: "{{ value_json.value }}"

DeviceEUI is Unique identification of device eg. 2CF7F12000000001, and it can be found on the sensor itself.

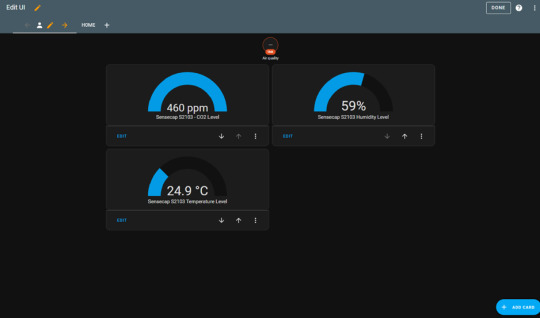

Now the last step is create dashboard.

go to overview and find the "Edit Dashboard"

You can add cards as much as you want. I have added Gauge card, and subscribed to entities (temperature, CO2 and humidity).

Finally, the IoT dashboard is shown on your reTerminal Home assistant main screen.

Here below are few pictures for you to see how it looks like:

0 notes

Text

What is HMI and Why Use STONE HMI Display?

HMI is changing the way several industries are run now. It is a technology that automates several fields and improves productivity and efficiency on many levels. The merging of humans and machines through HMI is simply the next norm in industrial automation.

Interested in finding out more about HMI? Read on to get a general overview of this technology. Also, we’ll introduce STONE HMI displays and why they’re among the leaders in HMI technology worldwide.

Defining what HMI is

HMI stands for Human Machine Interface. It consists of a dashboard allowing a person to manipulate and interact with a system, device, or machine. HMI is often regarded as the merger of humans and machines for better automation efficiency.

HMI is also known as:

Operator Interface Terminal (OIT)

Man-Machine Interface (MMI)

Local Operator Interface (LOI)

Operator Terminal (OT)

The HMI presents visual information regarding a system to the user. The person, in turn, can operate and control the process by directly interacting with the machine using HMI software. Touch screens are often used together with HMI software for this system.

Information regarding industrial operating systems is displayed on an HMI screen through a Graphical User Interface (GUI). Icons, pictures, colors, and sounds can all be programmed to represent various operating conditions. The visual format allows users to easily interact with data needed to automate systems.

Some HMI systems also use other methods to exchange information between the human user and the machine. These methods may include speech recognition and motion sensors, among others.

Technically speaking, HMI can be used to denote all kinds of screens and systems allowing users to interact with any device. However, HMI is typically used in an industrial process context.

Three Main Types of HMI

There are several types of HMI systems. However, we’ll focus on the three main ones used in industrial operations: pushbutton replacer, data handler, and overseer HMI.

1. Pushbutton Replacer

This HMI type consists of a central control panel with several buttons. Each of the buttons performs a specific function. A pushbutton replacer allows important machine commands to be centralized in one location. Several factories use pushbutton replacers to manage the operations of different machines.

2. Data Handler

Data handlers consist of huge touch-capable HMI screens where visual representations, graphs, and production summaries can all be visible. This HMI type is used for harvesting or gathering data from the various machines connected to it. The data can be printed out or sent to a hard drive, depending on the user’s needs.

3. Overseer

Overseer HMI runs on the Windows operating system. It uses a TFT LCD touch screen to display a graphical user interface. This interface is then manipulated by the user to operate, control, and manage the machines connected to the HMI. Overseer HMIs are also equipped with plenty of Ethernet ports.

Most applications requiring Manufacturing Execution Systems (MES) or Supervisory Control and Data Acquisition (SCADA) benefit the most from overseer HMIs.

The Technologies Behind HMI

HMI operates based on a systematic network of hardware and software components.

Hardware Components

Computers and hardwired devices make up the bulk of hardware used in an HMI system. They are linked together so that operators can determine various process changes in their workflow and respond to them accordingly. Most of the computers and devices use touch screens where the user can view and manipulate processes in the system dashboard.

Capacitive touch screens allow operators to swipe and tap the HMI machines using their fingers in response to changes in process operations. Some industries use resistive touch screens in their HMI machines, though. This may require the use of styluses or more powerful finger touches to interact with the devices.

Other technologies such as voice control, gesture recognition, and eye tracking are also used in conjunction with touch screen computers and devices.

Hardware components serve as both input and output devices. Touch screens, for instance, allow a user to see operational changes (output) and directly interact with the device to manipulate his workflow’s operations (input).

Software Components

Special HMI software is programmed into the devices. This software typically uses Graphical User Interfaces (GUIs) to create dashboards for controlling various industrial operations.

Furthermore, advanced HMI software often consists of various techniques and technologies. Programs used in HMI devices may have a combination of the following:

Machine Learning

Natural Language Processing

Virtual Reality

Augmented Reality

Internet of Things

These technological advances help ensure that machines can interpret human signals properly and vice versa.

Technology Behind Touch Screen HMI

Touch screens play a huge part in most industrial HMI systems in any field. From production plants to medical settings, touch screens are predominantly used to automate several tasks and ensure efficiency at work. So, how does HMI work in touch screens?

TFT LCD touchscreens are commonly used in industrial HMI settings. These touch screens are either capacitive or resistive. Either way, they display information through a graphical user interface. Such screens then collect information from the user by converting tactile signals from the user’s finger or stylus into electronic ones. The signals are then sent to a microprocessor who interprets them and directs the device to perform the needed action.

Pros and Cons of an HMI System

HMI systems have their advantages and disadvantages. Let’s enumerate them here:

Pros

Improves overall communication within the facility

Allows close monitoring of operational processes

Lets an operator initiate quick responses to smoothen out the workflow (as a response to machine alarming, for instance)

Reduces operational costs by eliminating the need for extra machines, cables, consoles, panels, indicator lights, and other monitoring equipment

Allows for an overall easier plant management

Opens up better applications when connected to advanced technologies such as the Internet of Things

Enables more work to be accomplished in lesser time

A cost-effective system in the long run

Suitable for both simple and complex tasks

New operators can easily understand the graphical nature of the HMI system

Cons

Security may be prone to hacking if the HMI system is connected to the Internet

Poor interface design may cause problems with performance and interaction between the machine and the operators

More expensive to implement initially; needs careful deliberation to determine the right HMI type for the business to avoid huge losses

Industries Using HMI

These are the most common industries using HMI systems:

Food and beverage processing

Mining operations

Oil and gas industries

Transportation sector

Pharmaceutical manufacturing

Healthcare and patient monitoring in hospitals and

Water and wastewater plants

Energy and power sector

Robotics applications

Supervisory management using SCADA systems

Automobile manufacturing

As you can see, HMI systems are prevalent in industries requiring multiple large machines and strict control environments. However, smaller HMI systems can also be used for small-scale industries for better work efficiency.

Introducing STONE HMI Display

STONE is China’s leading manufacturer of intelligent HMI display solutions. STONE is in the display solutions business for 14 years and has a wide range of international clients including Siemens, Bosch, and General Electric.

The company creates TFT LCD modules with touch screen capability suited for civil, advanced, and industrial uses. The STONE Industrial Type screen panels are the most popular products used for heavy-duty industrial systems. These screens feature:

An industrial-grade TFT LCD panel

CORTEX M4 CPU

Touch panels capable of either resistive or capacitive technology

LCD drivers

Flash memory of 128M, expandable to 1GB

High-resolution capability at 240P-768P, with a 65K (16-bit) color

Pixel spacing of 0.1905 mm x 0.0635 mm (HxV)

Touch screen Industrial Level RTP/CTP/NTP

Industrial-type screens can be used in ruggedized applications and fields with humid, high-temperature, and high-vibration working conditions. STONE’s industrial TFT LCD screens can be loaded with HMI software and connected with a smart system to create an overall industrial HMI solution.

Why Use STONE HMI Display Solutions?

Many clients looking for quality HMI display solutions head to STONE Technologies for their needs. That’s because STONE HMI display solutions offer the following benefits:

Customizable service to fit your individual needs

Products are durable, reliable, and withstand extremely harsh environmental conditions

Professional technical support available in the forms of troubleshooting services, software training, and demo project making

An unlimited warranty policy where the company replaces your STONE HMI display product if it has any damages or product failures – all for free

STONE TOOL Box – a dedicated Graphical User Interface (GUI) software available for free download and use from its website

Offers competitive yet affordable prices for their various HMI products

Low minimum order quantity

A lead time of only 14 days from date of product confirmation

Responsive customer support readily available in English

STONE has been operating for 14 years. As such, the company continues to upgrade its HMI display solutions to reflect current technologies and trends. So, if you partner with STONE for your HMI needs, rest assured you’ll get only the latest TFT LCD modules paired with up-to-date smart technologies.

STONE also has top-of-the-line assemblies and production factories. These facilities are compliant with several regulatory bodies and have been awarded the following certifications:

ISO9001

ROHS Certification

FC Certification

CE Certification

All of these certifications guarantee that you’ll get only the finest HMI display products needed to complete your HMI ecosystem.

Conclusion

Human Machine Interface (HMI) is here to stay, and for good reason. Several industries around the globe have been using HMI systems paired with advanced technology such as the Internet of Things (IoT) for managing their daily operations. HMI allows for streamlined work, efficient plant monitoring, and seamless interactions between humans, machines, and fellow humans.

STONE Technologies is a leading global manufacturer of HMI Display Solutions. The company takes pride in its high-quality TFT LCD screens that can be used to complete any HMI ecosystem. With STONE, rest assured you’ll get top-notch display solutions and excellent customer service, all for a highly competitive yet affordable price tag.

1 note

·

View note

Text

Messung Automation Solutions for Water and Waste Water Projects

industrial automation & control systems suppliers

The Rising Demand

By year 2050, the global demand for water will rise by 55%. The 2015 report by United Nations World Water Development projects this rise across the various sectors.

India’s economy also critically depends on use and management of water for agriculture, industry and domestic consumption. Recognizing this dependence, the Ministry of Water Resources plans to invest significant funds into management of water and wastewater sector.

Some of the aims of good water resources management are:

· Improvement of water quality

· Improving energy efficiency while managing and treating water

· Minimizing leakage and wastage

· Conservation of resources

· Reducing downtime and operating costs

Use of dedicated Industrial Automation & Control Systems effectively meets the above objectives, at a cost-effective price point.

Infrastructure for Water Treatment

To supply quality water in the desired quantities, a typical city may have more than 20 to 30 Water Treatment Plants (WTP’s). At the discharge end, for treating used and polluted water, the city may have an equal number of Waste Water Treatment Plants (WWTP’s).

For optimum efficiency and speed of response, a Centralized Control and Monitoring Station supervises all the equipment and processes of plants from a single location. This Station accepts numerous inputs from all the plants to deliver real-time corrective responses to the changing parameter and conditions. As an upgrade, tech-savvy Municipal authorities now demand a cloud-based solution for supervision of all the water treatment facilities.

High-technology automation solutions conforming to industry standard protocols are essential to implement the future needs of the water treatment plants.

Challenges of Water Supply System

Designing and operating of water supply systems calls for a multi-criteria approach. In every case, water treatment system must reliably produce quality water at the lowest possible costs.

The criteria for water treatment process are:

· Flow of raw and treated water along with dosing of treatment chemicals

· Monitoring of water pressure at upstream and downstream locations and at critical points

· Monitoring levels in rivers, wells and reservoirs

· Disposal of sludge

· Monitoring of temperature for motors, bearings and valves

· Dosing of Fluorine, Chlorine and Calcium

· Monitoring turbidity and water quality

Water Treatment domain consists of several critical processes that can benefit from high technology automation for delivering consistent results.

Water Treatment Automation Solutions from Messung

Messung are the pioneers of Indian automation domain. A leading industrial automation & control systems supplier with over 3 decades of domain expertise, tens of thousands of Messung Programmable Logic Controllers (PLC) and allied products meet the automation challenges of Indian industries, under actual local site conditions.

With a view to the future, Messung now offers NX-ERA, the complete industrial automation solution for monitoring and controlling the entire water management process.

Messung’s NX-ERA PLC Systems can automate a variety of Water Treatment applications.

These include:

· Water Treatment Plant

· Reverse Osmosis Plant

· De-mineralized Water Plant

· Sewage Treatment Plant

· Effluent Treatment Plant

· Pumping Stations

· Reservoir Controls

Features of Messung NX-ERA

· One vendor – many solutions

· Easy to set-up, maintain, operate

· Compatible with all industry standard protocols

· Highly reliable system with high Mean Time Between Failures (MTBF) and low Mean Time to Repair (MTTR), with redundancy

· Local and remote access, with control to private mesh

· Local Human-Machine Interfaces (HMI’s) and Central Supervisory System

· Uses Open Protocols and Networks

· Power efficient with a small footprint

· Adds Distributed Control System (DCS) functionality through multiprocessing capability

· Can operate large numbers of remote Input/Output (I/O) points and backplane racks for implementing distributed architecture with redundancy

· Supports large screen displays and database server

· Interfaces with Supervisory Control and Data Acquisition (SCADA) systems

· Modular and expandable

Programming through the IEC 61131-3 compliant MasterTool IEC XE software.

·Easy to learn with rich graphics and intuitive textual language

·Function Block Diagram (FBD) that enables segmentation of block system to simplify maintenance and simultaneous execution of different tasks

·Multiple languages available within these blocks for versatility across the globe

Conclusion

Messung’s NX-ERA process automation and control solutions optimize complex control for water treatment and distribution systems. These solutions help implement highly efficient WTP designs that help treat and conserve water, an increasingly scarce resource.

The water-scarce future mandates a high degree of precision and reliability of water treatment plants. Messung’s process control and automation solutions effectively meet the monitoring and control requirements of water treatment with increased plant safety and availability.

Contact Messung for process automation & control solutions in India as well as smart factory automation & control solutions with Scada and power system automation, and machine automation & control solutions with cutting-edge Servo & Motion controls.

#industrial automation & control systems suppliers#industrial automation & control solutions in India#process automation & control solutions in India#process automation & control solutions in#factory automation & control solutions#smart factory automation & control solution in India#plc automation control panel

1 note

·

View note

Video

youtube

LED Production Serial ASCII RS485 Andon Kanban Display with Tower Light Modbus RTU

Did your factory using Programmable Logic Controllers (PLCs) on your daily operation? Did operation team knowing what is happening in factory floors?

1. Production quantity numbers 2. Speed of production output 3. Machine status 4. Temperature & humidity 5. Timing

NEW Custronics upgrade series LED Production Serial ASCII RS485 Andon Kanban Display with Tower Light Modbus RTU

LED Andon displays provide real-time updates and visual cues about the status of different processes, machines, or production lines. These displays are often strategically placed in visible locations on the factory floor, allowing operators and supervisors to monitor the situation at a glance. By using color-coded alerts, patterns, and customizable layouts, LED Andon displays can convey important information such as production status, machine performance, downtime, quality issues, or any other relevant data. This enables the operation team to quickly identify and respond to any anomalies or disruptions in the production process.

Additionally, LED Andon displays can be integrated with other systems, such as machine monitoring systems or SCADA systems, to receive data directly from the equipment and provide accurate, real-time information. This integration ensures that the operation team has up-to-date knowledge of what is happening on the factory floor.

Having this visibility into the factory floor allows the operation team to make informed decisions, allocate resources effectively, address bottlenecks or production issues promptly, and maintain optimal efficiency in the manufacturing process.

#custronics #ledandondisplay #electronicsdisplay #ledkanbandisplay #ledsign

0 notes

Text

Best HMI Dealers in Rajasthan

In today’s rapidly evolving industrial landscape, automation and seamless control systems have become the cornerstone of efficient manufacturing and production. One critical component in this ecosystem is the Human Machine Interface (HMI). These devices allow operators to interact with machines, monitor performance, and control operations in real-time. For industries across Rajasthan, finding the right HMI dealer can make a significant difference in operational success.

Whether you're running a manufacturing unit in Jaipur, a processing plant in Udaipur, or an automation setup in Jodhpur, choosing the Best HMI dealers in Rajasthan is crucial. These dealers not only supply top-quality products but also offer reliable technical support, installation assistance, and after-sales service — all essential for long-term efficiency.

Why HMI is Crucial in Industrial Automation

HMIs act as the communication bridge between humans and machines. From displaying machine data and alarms to enabling touch-based controls and remote access, HMIs simplify complex processes. In sectors like pharmaceuticals, food processing, cement manufacturing, and textiles, they are indispensable.

Modern HMIs are far more advanced than their earlier versions. Touchscreens, intuitive GUIs (Graphical User Interfaces), customizable dashboards, and integration with SCADA or PLC systems are now standard. But to make the most of these features, you need not just a good product — you need a dealer who understands your specific needs and offers tailor-made solutions.

What to Look for in an HMI Dealer

Here are a few things to keep in mind when searching for the Best HMI dealers in Rajasthan:

Brand Partnerships: A reputable dealer should be associated with trusted HMI brands like Siemens, Schneider Electric, Allen-Bradley, Mitsubishi, or Delta. Strong partnerships mean better warranties and access to the latest tech.

Technical Expertise: Your dealer should not only sell you the product but also guide you on system integration, compatibility with existing PLCs, and maintenance support.

Local Presence: Having a local or regional presence means quicker service response times and on-site support when needed.

Customization & Consultation: Industries vary widely, and so do automation needs. The best dealers will understand your business, evaluate your processes, and recommend the most suitable HMI solution.

Customer Reviews & Case Studies: Positive feedback from existing clients and documented case studies can be strong indicators of reliability and performance.

Serving Excellence Across Rajasthan

Rajasthan’s industrial growth has been impressive in the past decade. With rising demand for automation in everything from mining to agro-processing, the importance of trusted HMI suppliers has grown manifold.

Among the most dependable names in this sector is Canyon Engineering Solutions Pvt Ltd. With a commitment to delivering cutting-edge automation products and solutions, they are well-regarded for their quality offerings, customer-centric approach, and on-time project execution. Their dedication to building long-term relationships with clients sets them apart in a competitive market.

Whether you are setting up a new unit or upgrading existing systems, connecting with the Best HMI dealers in Rajasthan ensures that your production line runs smoothly and efficiently — giving you a competitive edge in your industry.

Final Thoughts

Investing in the right HMI system is not just a technical decision — it’s a strategic one. The right dealer will not only provide the hardware but also ensure that your systems are optimized for performance, safety, and future scalability. With expert advice and dependable service, the best HMI dealers help you stay ahead of the curve.

0 notes

Text

SCADA Market Competitive Landscape, Recent Development and Overview by 2030

The SCADA market is anticipated to surpass USD 85 billion in revenue by 2030. Industry is displaying a steady recovery from the downfall witnessed during the COVID-19 pandemic due to disruptions in manufacturing processes. The resumption of business operations as a result of shifting consumer preferences and lifestyle changes, along with declining cases, has, however, augmented the consumption of premium commodities, automotive products, and advanced vehicles, thereby proliferating the demand for SCADA systems among operators to access actionable data.

The SCADA market technology is utilized in electricity generation, water management, insulation in buildings, the oil & gas space, and the food & beverage industry, among others. Furthermore, burgeoning demand for automated technologies has pushed the penetration of such technologies for managing production processes, especially in the oil & gas sector, which provides operators the ability to monitor pipelines and gas well production.

Request for a sample copy of this research report @ https://www.gminsights.com/request-sample/detail/1925

The end of the COVID-19 pandemic brought prominent changes in the R&D outlook across the healthcare sector. The growing awareness among firms has boosted the uptake of SCADA market systems in the manufacturing and industrial sectors. Many industry players have been innovating new products to offer increased efficacy to consumers, which is slated to impel business growth.

For instance, in October 2022, Delta Electronics Inc., a Taiwanese manufacturing company, upgraded two of its products, including its DIAView SCADA market software version V3.7, and announced the integration of Industrial PPCs to its DIAVH series. The combination of the two products is set to deliver easy connectivity of IIoT and improve performance by extending the existing 4GB RAM with an additional 8GB of RAM.

The mounting need for effective software that provides real-time data and delivers high performance has encouraged varied emerging nations to adopt SCADA market systems for power generation facilities. The supervisory control and data acquisition systems assist operators in decreasing downtime while allowing proactive maintenance, which is increasing the use of SCADA software in these facilities.

To cite an instance, in July 2022, Madan Singh Dabur, Engineer in Chief of the Water Resource Department of India, announced the installation of the SCADA system under the National Hydrology Project at Tawa Dam and Barna Dam. This installation was intended to provide real-time information as well as support remote monitoring of water levels and make dam management more transparent.

Browse report summary @ https://www.gminsights.com/industry-analysis/scada-supervisory-control-and-data-acquisition-market

Burgeoning initiatives undertaken by governments for improving infrastructural connectivity with digital technology have fostered the SCADA market outlook in the construction sector. Many developed countries are installing software to boost the operational quality of public service facilities and buildings, thereby investing heavily in the installation of these systems.

For instance, in September 2022, the Government of Denmark invested around USD 9.2 million in a system manufactured by AFRY, an engineering and design specialist, in the construction of the Nordhavn tunnel. This tunnel is one of the largest infrastructure projects in Copenhagen, wherein the SCADA system would offer high-level supervision to acquire information & data regarding incidents, technical errors, and safety protocols.

Global SCADA Market growth will be positively affected by the notable presence of reputed organizations, such as ABB Ltd., Emerson Electric Co., Siemens AG, Rockwell Automation, Inc., Schneider Electric SE, Omron Corporation, Yokogawa Electric Corporation, Mitsubishi Electric, Honeywell International Inc., and Toshiba Infrastructure Systems & Solutions Corporation.

Browse Our Reports Store - GMIPulse @ https://www.gminsights.com/gmipulse

About Global Market Insights Inc.

Global Market Insights Inc., headquartered in Delaware, U.S., is a global market research and consulting service provider, offering syndicated and custom research reports along with growth consulting services. Our business intelligence and industry research reports offer clients with penetrative insights and actionable market data specially designed and presented to aid strategic decision making. These exhaustive reports are designed via a proprietary research methodology and are available for key industries such as chemicals, advanced materials, technology, renewable energy, and biotechnology.

Contact Us:Aashit Tiwari Corporate Sales, USA Global Market Insights Inc. Toll Free: 1-888-689-0688 USA: +1-302-846-7766 Europe: +44-742-759-8484 APAC: +65-3129-7718 Email: [email protected]

0 notes