#Scale Model Makers in India

Explore tagged Tumblr posts

Text

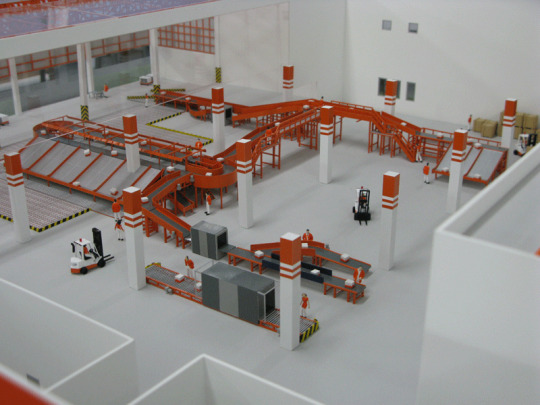

Scale model makers in India are skilled artisans who create miniature replicas of real-world objects, from buildings and vehicles to aircraft and ships. They use a variety of materials and techniques, including 3D printing, laser cutting, and traditional handcrafting, to produce models that are both accurate and detailed.

India has a long and rich history of scale model making, dating back centuries. Today, there are many talented scale model makers working in the country, catering to a wide range of clients, from individual collectors to museums and businesses.

Some of the most popular types of scale models made in India include:

Architectural models: These models are used to visualize buildings and other structures before they are constructed. They can be used for planning purposes, marketing, or simply as decorative pieces.

Engineering models: These models are used to test and demonstrate the functionality of machines and other mechanical devices. They can also be used for training purposes.

0 notes

Text

Trusted Scale Model Company in Mumbai for Aerospace

In the fast-evolving aerospace industry, where innovation meets precision, scale models are crucial for presenting concepts, validating designs, and impressing stakeholders. If you are searching for a trusted scale model company in Mumbai, your search ends at Jagtap Miniature — a pioneer in creating aerospace models with unmatched craftsmanship and attention to detail.

The Role of Scale Models in Aerospace

Whether you're a defense contractor, aviation firm, or a research institution, scale models offer incredible value:

Visualization of aircraft designs and aerospace vehicles

Detailed internal cutaways for exhibitions and technical reviews

Prototypes for aerodynamics, wind tunnel testing, and concept validation

Displays for trade shows, museums, and investor meetings

These models serve as powerful tools that bridge imagination with reality, especially in a field as complex as aerospace.

Jagtap Miniature: A Leading Scale Model Company in India

At Jagtap Miniature, we specialize in crafting highly accurate aerospace models ranging from commercial aircraft to defense drones, satellites, rockets, and helicopters. Based in Mumbai, we’ve earned a reputation as a top-tier scale model company in India, thanks to our precision, innovation, and dedication to quality.

Why Choose Jagtap Miniature?

✅ Decades of Experience in miniature and scale model making

✅ Specialized in Aerospace Projects including ISRO, DRDO, private aviation firms

✅ Advanced Materials & Technology – 3D printing, laser cutting, CNC detailing

✅ Custom Solutions – From concept sketches to detailed CAD-based models

✅ On-Time Delivery with nationwide and international shipping

We understand the demands of the aerospace sector and deliver models that meet the highest standards of engineering and visual excellence.

Serving India and Beyond

As a recognized scale model company in India, we’ve had the privilege of working with prestigious aerospace organizations, educational institutions, and design studios across the country. Our models have been featured in exhibitions, defense expos, aviation summits, and investor presentations.

Whether you’re in Mumbai, Bangalore, Delhi, or abroad — Jagtap Miniature is your trusted partner for world-class scale models.

Get in Touch

Looking for a professional scale model company in India that delivers precision, creativity, and reliability? Connect with Jagtap Miniature — your trusted scale model company in Mumbai for aerospace and beyond.

📞 Visit our website: https://jagtapminiature.com/ 📩 Send your project requirements and get a free consultation today!

#Jagtap Miniature#scale model company in India#Miniature model making company#Custom Ship Model Makers

1 note

·

View note

Text

I'm delighted that I got this new Matchbox Morgan Plus Four.

I adore Morgans; always have. While they are less than practical in most cases, they tick every other box for me. Let's explore what Morgans are and why I love them.

Morgan is a British company - which is still fully true to my knowledge, because in this ridiculous world we currently occupy, there are degrees to this sort of statement. MG was a British company, got acquired by a Chinese consortium and, with its cars built in China, is in no sense beyond the historical a British company; Land Rover still build its cars in the UK but it's owned by Tata of India. Are Land Rover still British? I'd say yes, but it's arguable. But Morgan is owned partly by the family of founder Henry Morgan (along with a private equity group, because you can't fucking escape the bullshit of 2025) and operate from Malvern in Worcestershire (pronounced "WOOstersheer"), as it has since 1909. This is crucial in understanding what Morgan is about; the company is a small-volume producer, because they still build all their cars by hand.

No robots, no mass-production. Every single one is bespoke, uniquely built to the customer's specifications, and as someone with an incessant urge to customise everything this is an extremely appealing attribute. It's hard to overstate how much I like the idea of a coachbuilt car made by craftspeople with decades of experience, but with modern technology and reliability. They have three models presently, the Plus Four, the Supersport and the Super 3 (recently made by Hot Wheels). Past models included the 4/4 with 4 seats, the +8 with a V8 and the Aero, which was an enclosed and streamlined model, along with a whole tine of 3-wheelers.

They are largely aluminium in construction, with a wooden subframe, which makes them very light. Of course, the look is iconic and dates back to around 1936, revised a little in 1950 and not much since, although it's often tweaked and given modernised tech. Morgan don't make their own engines, and the current range use BMW inline engines for the 4-wheelers (a 2-litre B48B20O1 turbo i4 making 255 hp for the Plus Four, and a 335hp B58B30C i6 with a twin-scroll turbo for the Supersport) and a Ford 3-cylinder for the 3-wheeler Super 3. Past models have used Ford, Mazda and Rover engines

They're all RWD, with auto or manual options that hit 60 in about 5 seconds in the Plus Four, and a sub 4-second 60 via auto only in the Supersport. What results is a sports car in the classic sense that Mazda was aiming for with the MX-5, not brutally powerful or transcendently fast but small, low, responsive, agile and focused on being fun to drive. They have only the space behind the seats for cargo, plus an optional rack on the back, and while third-party rigid hardtops exist there's no factory option, so they'd be pretty hard to live with as primary everyday cars, but as a car for enjoying driving, and as drivable art, I think there's probably none better.

Notably with this, it's basically exactly the same size as the 1:55 Siku +8, which is odd, as the little figures are supposed to be 1:75 scale but seem pretty well fitted to the car. The Super 3 is a bit larger scale, while the Majorette (the more battered green one, which has HW real riders but is very much not a HW model) is a touch longer. The inability of diecast makers to stick to a single scale drives me up the wall.

9 notes

·

View notes

Text

Agricultural Cooperatives: Driving Sustainable Farming in India

In the heart of India’s agricultural revolution lies a powerful yet often underappreciated force—farmer-owned agricultural cooperatives. These cooperatives not only empower rural communities but also serve as engines for sustainable farming practices, enhanced market access, and improved pricing power for small and marginal farmers. Today, with increasing focus on climate resilience and rural empowerment, multi-state cooperative societies are emerging as key players in transforming Indian agriculture.

What Are Agricultural Cooperatives?

Agricultural cooperatives are voluntary farmer-owned organizations formed to address common needs such as input procurement, processing, storage, and direct marketing of produce. Through collective ownership and democratic control, these societies provide strength to small-scale farmers who otherwise face exploitation from middlemen and erratic market prices.

How Agricultural Cooperatives Empower Indian Farmers

1. Boosting Market Access

Traditionally, Indian farmers face limited access to competitive markets. Agricultural cooperatives bypass middlemen by enabling direct linkages to buyers, retail chains, and agro-industries. This translates to higher profit margins and reduced wastage.

In Kerala, farmers are increasingly opting for multi-state cooperative society registration to expand their reach across state boundaries. This allows them to sell their produce at better rates and access larger markets.

2. Enhancing Pricing Power

One of the key challenges in Indian agriculture is unfair pricing. Cooperatives aggregate produce from multiple farmers, giving them greater bargaining power in the market. Through credit society registration in Kerala, many farming cooperatives are accessing financial support to store their harvest and sell when prices peak, rather than during glut periods.

3. Building Climate Resilience

With changing climate patterns affecting crop yields, cooperatives play a critical role in training farmers in sustainable practices, promoting climate-smart agriculture, and investing in shared resources like irrigation, storage, and renewable energy systems. These shared facilities improve long-term agricultural sustainability.

Multi-State Cooperatives: A Rising Trend in Indian Agriculture

For cooperatives looking to scale up operations across regions, multi-state society registration in Kerala and other states is a game-changer. By registering under the Central Government multi-state society registration system, these organizations enjoy pan-India operational freedom.

Thanks to support from multistate consulting firms in India, farmers now receive expert guidance on legal structure, documentation, and compliance for Multi-State Cooperatives Registration in Kerala and beyond.

Why Cooperative Models Matter Now More Than Ever

With India’s agri-sector undergoing digital transformation, government schemes and private initiatives increasingly favor organized farmer groups. Agricultural cooperatives are well-placed to:

Participate in contract farming and e-commerce platforms.

Access government subsidies and climate finance schemes.

Invest in shared infrastructure and farm technology.

Start Your Own Cooperative: A Step Towards Sustainable Growth

If you're a farmer group or agri-entrepreneur looking to start or scale your cooperative, consider the following options:

Credit cooperative society registration in Kerala for localized funding solutions.

Multi-state cooperative society registration in Kerala | India for cross-border expansion.

Consult with reliable multistate consulting firms in India for hassle-free registration and compliance.

Conclusion

Agricultural cooperatives are not just business entities—they are communities of change-makers. By ensuring better incomes, sustainable practices, and climate resilience, they are shaping the future of Indian agriculture. And with the right registration and support, they can transform farming into a thriving, future-ready enterprise.

2 notes

·

View notes

Text

How Devinder Singh Gill Started in Mohali and Built a Global Business Empire

From the lanes of Mohali to international real estate markets, Devinder Singh Gill has carved out a reputation as both a bold entrepreneur and a visionary leader. But success, as with many high-profile names, doesn’t come without scrutiny. While he’s earned applause for his business achievements, recent attention has also brought his name into the spotlight of controversy.

So who is Devinder Singh Gill, really? A self-made real estate magnate? A strategist with political access? Or a public figure navigating both acclaim and criticism?

Let’s take a closer look at how his empire began — and why the world is watching.

The Mohali Origin Story

Devinder Singh Gill started his entrepreneurial journey at the age of 23, right in the heart of Mohali, Punjab. At a time when most young professionals are still exploring career options, Gill had already stepped into the real estate sector with a vision: to transform how people experience housing and infrastructure in growing cities.

In those early years, Gill earned a name for launching practical, people-first housing projects that offered transparency and value. His work in Tricity (Mohali, Chandigarh, and Panchkula) positioned him as a credible force in local development — not just another businessman, but a change-maker.

Expanding to a Global Stage

Once established in North India, Devinder Singh Gill rapidly scaled his operations. His business expanded into Dubai, Canada, and Australia, tapping into the demand for luxury living and NRI-focused investments. His international ventures kept the same core values: quality, trust, and strategic innovation.

Projects under brands like Sky Heights elevated his profile further, making him one of the few Indian real estate developers to create impact both at home and abroad.

Education Sector Involvement: Chairman of Two Colleges

Beyond business, Devinder Singh Gill Mohali has made significant contributions to the education sector. He serves as the founder and chairman of two colleges:

Sri Satya Sai College (B.Ed)

Siddhi Vinayak College

These institutions focus on empowering the next generation of educators, with a strong emphasis on offering free education to underprivileged girls. Through these efforts, Gill has helped hundreds of young women pursue professional degrees and brighter futures — reaffirming his commitment to social equity and community development.

This blend of entrepreneurship and educational philanthropy further expands his legacy, proving that success is not just measured by wealth, but also by impact.

Political Links and Public Scrutiny

According to a recent Medium blog titled “Who is Devinder Singh Gill and Why is He in the Spotlight of Controversy?”, questions have arisen around his political affiliations and administrative connections — particularly his previous role as OSD (Officer on Special Duty) to the Punjab Finance Minister.

The blog notes that while his supporters see him as a visionary with strong administrative knowledge, critics argue that his rise was too fast — raising questions about influence and proximity to power. His name has surfaced in political discussions and real estate debates, though no formal charges have been made public.

This attention has only added to his public profile, blending business success with political speculation.

Beyond Real Estate: A Brand of Vision and Ambition

Despite the controversies, Gill remains deeply focused on growth. He’s expanded into areas like farmhouse development, liquor retail, and lifestyle branding, always ahead of the curve. As the first person to open a modern liquor store in Chandigarh, he redefined industry benchmarks — another bold move in a pattern of disruption.

Gill’s model of leadership emphasizes:

Strategic risk-taking

Diversification of investments

Empowering youth through mentorship

Conclusion: Devinder Singh Gill — A Complex, Global Figure

So, how did Devinder Singh Gill rise from Mohali to the global stage? Through smart decisions, bold ventures, and an unrelenting pursuit of growth. But with visibility comes scrutiny — and Gill is now navigating both admiration and controversy in equal measure.

Whether viewed as a real estate pioneer, an education advocate, or a figure of public curiosity, one thing is clear: Devinder Singh Gill’s journey is far from ordinary. His story, rooted in Mohali, continues to unfold on an international scale — driven by ambition, influence, and undeniable impact.

2 notes

·

View notes

Text

What Materials Are Used for Making Scale Models and Miniature Models?

How AR Model Makers Choose Materials for Stunning Scale Models

When it comes to crafting precise and eye-catching scale models, the materials used can make or break the final product. Whether it’s an engineering model, a marine model, an industrial model, or an architectural model, the team at AR Model Makers knows that selecting the right materials is key to delivering quality. In this article, we’ll explore the materials commonly used by expert miniature model makers like AR Model Makers, how they enhance different types of models, and why they matter to clients across industries. From house models to complex industrial designs, you’ll discover what goes into creating these miniature masterpieces.

Why Material Choice Matters in Scale Model Making

Common Materials Used by Miniature Model Makers

Miniature models come in all shapes and sizes, and so do the materials used to create them. Here’s a breakdown of the most popular choices at AR Model Makers and how they’re applied.

Wood – The Timeless Classic

Acrylic and Plastics – Precision and Durability

Metal – Strength for Industrial and Marine Models

Foam and Cardboard – Lightweight and Cost-Effective

https://armodelmakers.com/wp-content/uploads/2025/03/Foam-and-Cardboard.jpg

3D Printing Resins – The Future of Model Making

How AR Model Makers Tailor Materials to Your Project

Every project at AR Model Makers is unique, and material choices reflect that. For a marine model, they might combine metal for the hull with acrylic for water effects, creating a lifelike display. An industrial model could blend 3D-printed parts with metal accents to highlight machinery. By understanding the project’s purpose—whether it’s a trade show display or a client presentation—AR Model Makers ensures the materials align with both budget and vision.

For instance, a recent house model project in Delhi used a mix of wood and foam to craft a realistic neighborhood layout, earning praise from clients and establishing AR Model Makers as one of the best model makers in Delhi.

The Role of Craftsmanship in Material Selection

Materials alone don’t tell the full story—expert craftsmanship brings them to life. As one of the best model makers in Mumbai and beyond, AR Model Makers combines cutting-edge tools with hands-on expertise. Their team knows how to sand wood to a perfect finish, weld metal seamlessly, or paint acrylic for a polished look. This dedication elevates every engineering model, marine model, or architectural model they produce.

Interested in the process? Learn more about their approach on the AR Model Makers About Us page.

Why Choose AR Model Makers for Your Next Model?

With a reputation as top model makers in India, AR Model Makers stands out for their material expertise and client-focused approach. Whether you need a detailed marine model for a maritime expo or a sleek industrial model for a product pitch, their use of high-quality materials ensures stunning results. Plus, their presence in cities like Delhi and Mumbai makes them accessible to businesses nationwide.

Ready to start your project? Reach out via the AR Model Makers Contact Us page to discuss your vision.

External Resources for Further Reading

To dive deeper into scale model materials, check out these authoritative sources:

The Spruce Crafts: Guide to Model Making Materials

Material Properties for 3D Printing by Formlabs

If you have a project In mind just give us a Call

Have a project in mind? Let AR Model Makers bring it to life with the perfect materials! Drop a comment below with your thoughts, share this post with fellow model enthusiasts, or reach out to the team at AR Model Makers Contact Us to get started.

FAQ

What materials are best for an engineering model?

Materials like acrylic, metal, and 3D printing resins are ideal for engineering models due to their precision and durability, as used by best engineering model makers like AR Model Makers.

How long does it take to build a marine model with AR Model Makers?

Depending on complexity, a marine model can take anywhere from a few days to weeks, with AR Model Makers using metals and acrylics for top-quality results.

#marine model#architectural model#scale model#craft#art#model makers#model making#miniature model#engineering model#scalemodel

2 notes

·

View notes

Text

What is the installation space requirement and power consumption?

Planning for both production capacity and practical installation needs—namely, power consumption and floor space—is crucial when thinking about buying a square-bottom paper bag maker. Your factory layout, monthly operating expenses, and long-term scalability are all directly impacted by these two variables.

At Prakash Machineries Pvt. Ltd., we design our square-bottom paper bag machines to be Whether you’re running a large industrial setup or launching a small startup, our machines are built to integrate smoothly into your workspace without demanding major infrastructure upgrades.

In this guide, we explain the power and space requirements of our square-bottom paper bag machines and how you can prepare your facility for successful installation and operation.

⚡ Power Consumption: Designed for Energy Efficiency

Our machine is equipped with servo-driven motors, automated PLC controls, and energy-optimized components to ensure high productivity with minimal energy use. On average, the power consumption of our square-bottom paper bag-making machine falls between

✅ 10 kW to 14 kW per hour

(Depending on the machine model, size range, and optional attachments)

🔋 Breakdown of Power Usage:

Component Approximate Load Main motor (servo drive) 5–7 kW Vacuum pump 2–3 kW Gluing system & heater (if any) 1–2 kW Control panel and sensors 0.5–1 kW Optional attachments (printer, handle unit) 1–2 kW

This efficient power profile means that you won’t need industrial-scale electricity infrastructure to run the machine. Even for startups or medium-scale units, a standard 3-phase connection with a 20–25 HP (horsepower) supply is typically sufficient.

✅ Monthly Cost Estimate:

Assuming 8 hours/day of operation at an average of 12 kW/hr:

12 kW × 8 hours × 30 days = 2,880 kWh/month

At ₹8/kWh (approx. industrial rate in India), monthly electricity cost = ₹23,000

This makes our machine a cost-effective production solution, especially when you compare the high output capacity (up to 192,000 bags/day) with the low operational expense.

📐 Required Space for Installation

Our square-bottom paper bag machines are compact, modular, and engineered to occupy minimal floor space while still offering full production capabilities.

✅ Recommended Installation Area:

20 feet (L) × 8 feet (W) for standard machines 25 feet (L) × 10 feet (W) if optional units (e.g., printer, handle pasting) are included

🏭 Ideal Layout Plan Includes:

Machine footprint—main operational unit

Paper roll loading area—space for jumbo rolls (up to 1 m wide)

Bag collection table—output stacking and packing zone

Operator movement zone—minimum 3 ft clearance on each side

Electrical control cabinet—attached or wall-mounted

Optional space—for printer unit, handle applicator, or lamination feeder (if installed)

Our machines can be installed in a production unit as small as 500–600 sq. ft. You do not need a massive industrial hall. Even a startup with a moderate factory space can begin production seamlessly.

🛠️ Site Preparation Checklist

Before installation, ensure the following infrastructure is in place:

✔️ Electrical Requirements:

3-phase power connection (415V)

A stabilizer or UPS recommended for voltage fluctuation zones

Isolated circuit breaker and control panel for machine safety

✔️ Space & Foundation:

Flat, concrete floor surface (leveling required)

Dust-free, dry environment for optimal performance

Space for operators to safely move around machine

✔️ Ventilation & Safety:

Basic ventilation or exhaust fans (especially in hot climates)

Fire safety measures as per industrial compliance

Proper lighting for operator visibility

💡 Why This Matters to Your Business

Understanding your power and space needs in advance helps you

Avoid delays in installation

Ensure uninterrupted production

Optimize your floor plan for raw material, output, and manpower

Control operational costs with energy-efficient planning

This is especially crucial for startups, small businesses, or factories expanding capacity, where space and energy planning affect both short-term efficiency and long-term profitability.

🔧 Our Support Includes:

At Prakash Machineries Pvt Ltd, we don’t just deliver machines—we offer end-to-end installation support, including:

Pre-installation guidance (electrical, civil layout)

Custom floor plans for your site

On-site machine setup and calibration

Operator training and troubleshooting

Maintenance and after-sales service

🏁 Conclusion: Compact. Efficient. Installation-Ready.

Our square-bottom paper bag-making machines are designed to be energy-efficient and space-friendly—ideal for both high-output factories and compact manufacturing setups. With low power consumption (10–14 kW) and a compact footprint (under 250 sq. ft.), you can begin or scale up your paper bag production with minimal infrastructure investment.

📞 Plan Your Factory Setup With Us

Want help designing your factory layout? Need a customized installation guide for your plant? We’re here to help.

👉 Contact Prakash Machineries Pvt Ltd to get a personalized site layout, electrical requirement checklist, or expert consultation to prepare your facility for high-speed, efficient paper bag production.

#manufacturer#paper bag manufacturer#paper bag#paper#machines#flexo#v bottom#square bottom#alien stage#baking#bags#cake#chris sturniolo#cooking#critical role#dan and phil#delicious#breakfast#chocolate

1 note

·

View note

Text

Cyclohexane Prices, Trends & Forecasts | Provided by Procurement Resource

Cyclohexane (C6H12) is a colorless fluid with a mild sweet smell. It is partially soluble in water and completely in alcohol, acetone, benzene, ethanol, ethyl ether, olive oil, and carbon tetrachloride. The melting point of this volatile compound ranges around 6.47 °C and the boiling point measures around 80.7° C. It is an alicyclic hydrocarbon comprised of 6 carbon atoms formed in a hexagon arrangement. Cyclohexane is a flammable fluid, non-corrosive. The dehydration of cyclohexanol and using concentrated phosphoric acid results in the production of cyclohexane.

Request for Real-Time Cyclohexane Prices: https://procurementresource.com/resource-center/cyclohexane-price-trends/pricerequest

The key importing countries include Vietnam, India, and the Netherlands. On the other hand, the primary exporting countries are Vietnam, Germany, and Belgium.

Key Details About the Cyclohexane Price Trends:

Procurement Resource does an in-depth analysis of the price trend to bring forth the monthly, quarterly, half-yearly, and yearly information on the Cyclohexane price in its latest pricing dashboard. The detailed assessment deeply explores the facts about the product, price change over the weeks, months, and years, key players, industrial uses, and drivers propelling the market and price trends.

Each price record is linked to an easy-to-use graphing device dated back to 2014, which offers a series of functionalities; customization of price currencies and units and downloading of price information as excel files that can be used offline.

The cyclohexane price trends, including India Cyclohexane price, USA Cyclohexane price, pricing database, and analysis can prove valuable for procurement managers, directors, and decision-makers to build up their strongly backed-up strategic insights to attain progress and profitability in the business.

Industrial Uses Impacting Cyclohexane Price Trends:

Cyclohexane is used commercially as a solvent to dissolve cellulose, ether, fats, waxes, spot removers, cellulosic, natural and synthetic resins, lacquers, and crude rubber. It is also used to manufacture perfumes, nylon 66 produced by a synthesis of adipic acid, plastics, paint, varnish remover, and much more.

Furthermore, Cyclohexane is used to make solid fuel for camp stoves, recrystallize medium glass substitutes, solid fuels, and adhesives. It synthesizes chemicals like benzene, cyclohexyl chloride, cyclohexanol, cyclohexanone, nitro-Cyclohexane, and many other chemical compounds for large-scale production. Here benzene and cyclopentane are the significant chemicals produced by Cyclohexane specifically.

Key Players:

BASF SE

Chevron Phillips Chemical Company

ExxonMobil Chemical Holland B.V.

Henan GP Chemicals Co., Ltd.

News & Recent Development

Date: 10 April 2023- RUDN experts to find a new catalyst that provides more efficient oxidation of Cyclohexane. The process produces adipic acid which is used in manufacturing household chemicals, food additives and other substances.

About Us:

Procurement Resource offers in-depth research on product pricing and market insights for more than 500 chemicals, commodities, and utilities updated daily, weekly, monthly, and annually. It is a cost-effective, one-stop solution for all your market research requirements, irrespective of which part of the value chain you represent.

We have a team of highly experienced analysts who perform comprehensive research to deliver our clients the newest and most up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which help in streamlining the procurement process for our clientele. Our team tracks the prices and production costs of a wide variety of goods and commodities, hence, providing you with the latest and consistent data.

To get real-time facts and insights to help our customers, we work with a varied range of procurement teams across industries. At Procurement Resource, we support our clients, with up-to-date and pioneering practices in the industry, to understand procurement methods, supply chain, and industry trends, so that they can build strategies to achieve maximum growth.

Contact Us:

Company Name: Procurement Resource Contact Person: Chris Byrd Email: [email protected] Toll-Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500 Address: 30 North Gould Street, Sheridan, WY 82801, USA

1 note

·

View note

Text

Market Intelligence in the Textile and Apparel Industry: A 2025 Guide to Smarter Decision Making

In today’s fast-evolving business landscape, market intelligence has shifted from being a helpful tool to an essential requirement. By 2025, the global apparel market is projected to be valued between USD 1.47 and 1.84 trillion. Meanwhile, the broader textile sector is expected to exceed USD 2.12 trillion in 2025, with a path toward USD 4.02 trillion by 2034, growing at a CAGR of 7.35%. With such scale comes added complexity—and opportunities for those equipped with timely and actionable insights.

From navigating raw material price swings to adapting to fast-moving fashion preferences, decision-makers require up-to-date visibility across sourcing, production, marketing, and overall strategy. Here's how advanced market intelligence tools can drive business success in the apparel space in 2025.

Navigating Shifts in Global Sourcing and Trade

Trade dynamics are undergoing significant change. In May 2025, U.S. imports of clothing from China dropped to their lowest level in over two decades, triggered by abrupt changes in tariff regulations. At the same time, countries like Vietnam, Bangladesh, India, and Mexico saw a 29% increase in exports to the U.S. Delayed responses to such shifts can result in supply shortages, cost spikes, and missed delivery commitments.

Where market intelligence supports you:

Interactive dashboards track international trade volumes, tariff changes, and customs data in real-time.

Geographic sourcing heatmaps help identify emerging supplier regions and diversify risk exposure.

With the U.S. reducing dependence on Chinese suppliers, many brands have already begun redirecting their sourcing strategies toward India and Southeast Asia, an emerging trend flagged early by market intelligence platforms. This foresight allows procurement teams to pre-secure supplier capacity and realign networks—minimizing disruptions.

Staying Ahead of Fast-Evolving Apparel Trends

Consumer preferences are changing faster than ever. For example, the shrinking plus-size category in the U.S. points to shifting demographic focus, while trends like powder-pink hues and maximalist fashion are gaining traction globally. Brands must respond in real-time—not months after a trend has peaked.

How intelligence tools help:

Monitor runway reports, social media signals, and influencer content for trend detection.

Use AI-based trend clustering to identify niche styles that are likely to go mainstream.

Take an Indian knitwear manufacturer, for instance. If dreamy aesthetics and pink tones are trending across social media platforms, market intelligence tools can cross-verify this with broader datasets. This enables early product development and faster-to-market capsule collections, offering a first-mover advantage.

Enhancing Supply Chain Agility and Risk Management

This year has seen multiple new challenges—from trade-related tariff shocks to climate-related disruptions and geopolitical tensions. Managing supply chain risks now demands proactive rather than reactive approaches.

Key features of market intelligence for supply chain resilience:

Early warning systems that track shipping delays, labor unrest, and regulatory updates.

Alternative route and supplier recommendations based on real-time analytics.

For example, if the U.S. introduces tariffs on Vietnamese-made footwear, sportswear companies can use intelligence tools to evaluate cost implications and swiftly pivot sourcing to alternative low-risk countries like India or Bangladesh.

Forecasting Demand with Greater Precision

Demand fluctuations remain a pressing concern in apparel and textiles. Businesses increasingly need dynamic, up-to-date data that adapts to changing consumer behaviors.

Benefits of market intelligence in forecasting:

AI-powered models incorporating sales data, weather trends, and social sentiment improve forecasting accuracy by 20–30% over traditional methods.

Supports just-in-time procurement and optimized inventory levels, minimizing overstock and markdown risks.

In 2025, companies leveraging such tools have reported 3.4% average revenue growth, with 90% stating improvements in forecasting accuracy.

Driving Sustainability and ESG Compliance

Leading global brands like Patagonia, Zara, and H&M are scaling their recycling initiatives and enforcing stricter environmental standards. India, too, has strengthened its textile industry through the PLI scheme, attracting over ₹7,300 crore in investment this year alone. With environmental, social, and governance (ESG) expectations on the rise, navigating complex compliance frameworks is now critical.

How intelligence solutions support sustainability goals:

Monitor evolving environmental regulations and frameworks (e.g., ZDHC MRSL, material certifications).

Detect innovations in biomaterials and eco-friendly production technologies.

Use benchmarking to track ESG performance relative to peers and establish realistic improvement goals.

TexPro: Empowering Smarter Decisions with Unified Data

Fragmented data often results in slower, less effective decisions. What’s needed is a unified, real-time platform that spans the entire textile and apparel value chain. That’s where TexPro comes in.

TexPro, the flagship market intelligence solution by Fibre2Fashion, consolidates data on sourcing, trends, pricing, and ESG into one comprehensive system.

TexPro empowers key teams with:

Live updates on raw material pricing, trade volumes, and tariff changes to optimize procurement.

Trend-tracking tools for design and merchandising teams to stay consumer-relevant.

Cost breakdown analytics for pricing teams to maintain margin control.

AI-based demand forecasting to better align production with market needs.

ESG tracking modules to monitor compliance and drive sustainable practices.

Instead of relying on scattered sources, TexPro users gain a centralized and real-time view that enables quicker, more informed decisions across the board.

Conclusion

As the global textile and apparel industry heads into a transformative era—with a projected $1.84 trillion apparel market by 2025 and $4 trillion textile industry by 2034—businesses face both new opportunities and heightened challenges. Raw material instability, trade policy shifts, and growing sustainability demands are just a few.

In this landscape, gut instincts are no longer sufficient. Tools like TexPro empower businesses to connect data across forecasting, pricing, sourcing, and ESG—turning insights into action.

The apparel industry’s future is already unfolding. The question is: Are you making informed, forward-looking decisions to stay ahead?

Key Takeaways

Smart sourcing decisions rely on real-time, accurate data.

Early trend detection enables faster product development and launch.

AI-driven forecasting enhances demand planning and reduces inventory waste.

ESG and compliance now play a key role in brand value and sourcing strategies.

TexPro brings together all essential insights—pricing, sourcing, trends, and sustainability—in one platform.

FAQs

1. Can small and mid-sized apparel businesses use TexPro? Absolutely. TexPro is built to serve organizations of all sizes. SMEs can use the platform to optimize buying strategies, track trends, and improve responsiveness.

2. How frequently is TexPro’s data updated? TexPro updates its data in near real-time. Raw material pricing is refreshed daily, EXIM and trade data weekly, and policy analyses are delivered monthly to ensure relevance.

3. Does TexPro provide region-specific market insights? Yes. TexPro offers localized, country-level insights that include tariff structures, supplier networks, and regional market trends—helping businesses fine-tune their procurement strategies.

0 notes

Text

Operational Excellence: The Engine of Enterprise-Wide Transformation in Manufacturing

Manufacturing excellence is increasingly being recognized not just as a goal but as a capability—one that is achieved through disciplined and sustained focus on operational excellence. Operational Excellence (OpEx) is often misconstrued as a collection of tools or a cost-cutting initiative. In reality, it is a comprehensive strategic discipline that enables transformation across the entire manufacturing value chain—from sourcing to final delivery. For manufacturers, OpEx is about harmonizing speed, cost, quality, and innovation, while fostering cross-functional alignment and enterprise agility.

This article explores a modern operational excellence framework tailored for manufacturers, supported by real-world examples from India, Europe, and the United States. It also showcases how organizations can leverage their Center for Manufacturing Excellence to institutionalize and scale these capabilities.

What Is Operational Excellence?

Operational excellence is the sustained pursuit of superior business performance that is resilient, adaptable, and aligned with strategic objectives. It is underpinned by:

Standardization of core processes

Real-time visibility enabled by digital tools

Data-driven decision-making

Empowered and accountable teams

In leading organizations, manufacturing excellence is not a project—it is embedded into the operating model and embraced as a way of working, often guided by a dedicated Center for Manufacturing Excellence.

Pillars of Operational Excellence

1. Strategic Alignment

True transformation begins with alignment. A leading steel producer in India cascades KPIs from boardroom to shop floor, ensuring every employee contributes to strategic goals. In the United States, a global industrial conglomerate institutionalized OKRs and strategic huddles to reinforce alignment across all levels. These practices are often formalized through their Center for Manufacturing Excellence, ensuring continuity and best practice sharing.

2. Standardization and Process Optimization

A textile manufacturer in Northern India reduced variability by redesigning its cutting and stitching processes. In Germany, a technology firm leverages digital twins to simulate and optimize production line changes—driving manufacturing excellence before physical implementation.

3. Performance Monitoring

High-performing organizations go beyond tracking—they act. An Indian FMCG company empowers plant managers and line supervisors with digital dashboards for real-time deviation management. Amazon’s unmatched fulfillment speed is driven by rigorous performance analytics and KPI discipline—hallmarks of operational excellence.

4. Technology Enablement

In India, a pharmaceutical manufacturer implemented IoT-based predictive maintenance and reduced unplanned downtime by 40%. Meanwhile, an aerospace supplier in the Netherlands utilized real-time MES systems to replace manual reporting and significantly improve throughput—practices frequently championed by their Center for Manufacturing Excellence.

5. Cultural Enablement

People are at the heart of sustainable excellence. An Indian automotive component manufacturer trains frontline employees in Kaizen and root cause analysis. In the UK, a defense equipment maker has embedded daily tiered reviews and open-feedback loops to drive ownership and problem-solving at every level—fostering a culture of manufacturing excellence.

The Operational Excellence Framework

To institutionalize operational excellence, manufacturers must adopt a structured yet agile framework—often supported by a Center for Manufacturing Excellence that provides governance, tools, and training:

Vision & Strategy: Define a clear North Star and align operational goals with growth aspirations.

People & Leadership: Develop managers into coaches and incentivize ownership and initiative.

Process Optimization: Eliminate waste, reduce handoffs, and streamline workflows.

Digital Enablers: Use ERP, MES, analytics, and IoT to achieve real-time operational visibility.

Performance Routines: Establish regular feedback loops and review cycles for continuous course correction.

Customer Centricity: Integrate the voice of the customer (VOC) into product design, operations, and delivery.

Tangible Outcomes of Operational Excellence

Organizations that embed operational excellence and pursue manufacturing excellence see clear, measurable benefits:

Cost Efficiency: A diversified Indian conglomerate achieved multimillion-rupee savings by reconfiguring its supply chain.

Faster Time to Market: A US-based tech giant integrated R&D with operations, halving its product launch time.

Higher Engagement: Teams with autonomy and clarity report a 30–40% increase in productivity.

Stronger Compliance: Digital-first environments ease the burden of regulatory audits and ESG reporting through accurate, real-time data.

The Pathway to Operational Excellence

Achieving operational excellence requires a deliberate and phased approach—one that is often overseen and supported by a Center for Manufacturing Excellence:

Current-State Diagnostic: Leverage process mining, stakeholder interviews, and benchmarking.

Strategic Planning: Design initiatives that directly link to critical performance metrics such as throughput and Net Promoter Score (NPS).

Process Redesign: Eliminate non-value activities, reduce delays, and streamline handoffs.

Technology Integration: Standardize operations before automating—avoid digitizing inefficiencies.

Continuous Improvement (CI): Launch OpEx cells, drive cross-functional charters, and celebrate quick wins to build momentum.

Leadership and Governance: Embedding Excellence into the Operating Rhythm

Operational excellence is sustainable only when leadership behavior models the culture it seeks to instill. Leading Indian manufacturers conduct daily tiered reviews, enabling frontline insights to escalate and trigger action within 24–48 hours. This closed-loop governance reinforces rapid accountability and responsiveness—often coordinated by the Center for Manufacturing Excellence.

Transformation Management Offices (TMOs) or OpEx offices serve as internal hubs, driving capability-building, facilitating improvement charters, and tracking progress. Mature organizations go further—linking TMO KPIs to realized business value, including cost savings, defect reduction, and faster innovation cycles—hallmarks of manufacturing excellence.

Technology as a Force Multiplier

Digital transformation fuels operational excellence—but only when underpinned by robust data and standardized processes. Indian manufacturers that integrate MES, ERP, and IoT platforms benefit from real-time operational awareness. The true advantage, however, lies in actionable insights, not just dashboard visuals.

Advanced manufacturers in Europe and the US are moving ahead with digital twins, AI-powered planning, and blockchain-based traceability. These tools, often tested and scaled through their Center for Manufacturing Excellence, elevate transparency, optimize decision-making, and convert operational visibility into strategic advantage.

Beyond Cost: The Culture of Excellence

The most enduring facet of operational excellence is not its digital tools, but its people. Organizations that establish learning loops, reward micro-improvements, and celebrate grassroots innovation build cultures where manufacturing excellence becomes self-sustaining.

For example, an Indian packaging firm created a “Kaizen Wall of Fame” to highlight employee-driven improvements and their business impact. In 18 months, this initiative generated over ₹3 crore in recurring savings—demonstrating that cultural investments can yield significant financial returns and support long-term excellence.

Conclusion: Operational Excellence as a Way of Life

Operational excellence is not a finite destination—it is the operating system of modern manufacturing. From agile Indian startups to global digital-first leaders, those that master operational alignment, data-led agility, and cultural coherence will shape the future of industrial enterprise.

In an era of rapid disruption and relentless competition, manufacturing excellence is no longer optional—it is foundational. The journey has already begun. With a strong Center for Manufacturing Excellence as your catalyst, the question is: are you ready to lead, or risk falling behind?

#operational excellence#Manufacturing Excellence#center for manufacturing excellence#Supply Chain Excellence

0 notes

Text

Global Landscape and Future Outlook of the Continuous Renal Replacement Therapy (CRRT) Machines Market

The market for Continuous Renal Replacement Therapy (CRRT) machines has experienced strong growth in recent years, largely due to the rising occurrence of acute kidney injury (AKI) and the growing prevalence of chronic conditions like diabetes, sepsis, and hypertension. CRRT is a continuous, extracorporeal blood purification method used primarily for critically ill patients with acute kidney injury who are hemodynamically unstable. Unlike traditional intermittent hemodialysis, CRRT provides better fluid balance and cardiovascular stability, making it a preferred choice in intensive care units (ICUs).

Purchase full report for detailed CRRT market trends and forecasts: https://www.delveinsight.com/report-store/continuous-renal-replacement-therapy-machines-market?utm_source=reportstore&utm_medium=promotion&utm_campaign=akpr

Rising AKI Incidence Fuels Demand

The global burden of acute kidney injury is increasing due to aging populations, higher use of nephrotoxic medications, and rising cases of multi-organ dysfunction. In ICUs, CRRT machines are becoming essential due to their ability to deliver prolonged, personalized therapy in patients with unstable blood pressure. Growing awareness among clinicians about CRRT’s advantages over intermittent dialysis is further contributing to market expansion.

Role of Technology in CRRT Market Growth

Technological innovations are reshaping the CRRT machines market. Today’s machines are designed with user-friendly interfaces, automated settings, and enhanced precision for safer and more effective therapy. Integration with electronic health records (EHRs), real-time monitoring, and built-in safety features are increasingly standard. Manufacturers are also focusing on portable and space-efficient systems to meet the needs of modern ICUs.

Regional Market Insights

North America currently dominates the CRRT machines market, supported by high adoption of advanced technologies, strong healthcare infrastructure, and favorable reimbursement models. The United States holds a substantial share owing to a high incidence of acute kidney injury and the presence of leading industry players.

In Europe, market growth is driven by organized healthcare systems, increased awareness of renal health, and a growing elderly population.

The Asia-Pacific region is emerging as a key growth area due to improving healthcare access, increasing ICU admissions, and heightened awareness of kidney-related conditions. Countries such as China and India are seeing rapid increases in critical care cases and are investing more in dialysis infrastructure, making them high-potential markets.

Key Players and Market Strategies

Major players in the CRRT machines market are focusing on partnerships, product development, and strategic expansion. These efforts are directed at enhancing machine functionality, scaling global presence, and addressing unmet needs in managing acute kidney injury. Collaborations between device makers and hospitals are also helping to improve clinical training and CRRT utilization in critical care settings.

Hospitals Remain Primary End-Users

Hospitals continue to be the largest consumers of CRRT machines due to the high demand for continuous renal support in critically ill patients. Large multispecialty hospitals and tertiary care centers deploy these machines in intensive care units and nephrology departments. Additionally, the expansion of dedicated dialysis centers and outpatient critical care services is contributing to broader CRRT adoption.

Market Challenges

Despite robust growth, the CRRT machines market faces hurdles such as high equipment and treatment costs, shortage of trained personnel, and reimbursement limitations in emerging economies. Clinical challenges like circuit clotting, infection risks, and the need for constant monitoring also affect adoption rates. Nevertheless, continuous R&D is underway to develop more affordable, user-friendly machines and improve treatment safety.

Impact of COVID-19 on the CRRT Market

The COVID-19 pandemic led to a notable spike in demand for renal replacement therapies as acute kidney injury became a common complication among critically ill COVID-19 patients. CRRT proved invaluable in managing fluid overload and sepsis-related kidney issues, prompting an increase in the production and deployment of CRRT systems worldwide and highlighting the need for robust critical care infrastructure.

Future Outlook and Opportunities

Looking forward, the CRRT machines market is set for sustained growth, driven by rising ICU admissions, personalized medicine, and the shift toward value-based healthcare models. Emerging technologies such as telemedicine and AI-powered monitoring systems are poised to revolutionize how CRRT is delivered. Compact, affordable machines designed for low-resource environments are likely to open new avenues, especially in underserved regions.

Government support and favorable regulatory frameworks are expected to play a critical role in driving market expansion. Across regions, public and private sector initiatives aimed at improving ICU capabilities and access to advanced renal replacement therapies are creating favorable conditions for market growth.

Download free sample to explore CRRT market growth insights now: https://www.delveinsight.com/sample-request/continuous-renal-replacement-therapy-machines-market?utm_source=reportstore&utm_medium=promotion&utm_campaign=akpr

Conclusion

The Continuous Renal Replacement Therapy (CRRT) machines market is a fast-evolving segment within critical care medicine. With growing recognition of acute kidney injury, technological advancement, and increased focus on individualized treatment, demand for CRRT solutions is expected to rise steadily. To ensure equitable and efficient care, collaboration among healthcare providers, policymakers, and manufacturers will be essential in overcoming current challenges and expanding access to life-saving CRRT technologies worldwide.

Latest Reports by DelveInsight:

Hormone Sensitive Advanced Prostate Cancer Market | Hpv16+ Cancer Market | Human Immunodeficiency Virus Type-1 Market | Human Papillomavirus Positive Cancer Market | Human Papillomavirus-positive Oropharyngeal Cancer Market | Hypercoagulability Market | Hyperkalemia Market | Hyperopia Market | Hyperuricemia Market | Hypoactive Sexual Desire Disorder Hsdd Market | Hypofibrinogenemia Market | Hypoxic Ischemic Encephalopathy Market | Idiopathic Short Stature Market | Japan Healthcare Outlook Market | Lassa Fever Market | Leptomeningeal Metastases Market | Limb Girdle Muscular Dystrophy Market | Limbal Stem Cells Deficiency Market | Lymphatic Malformations Market | Marginal Zone Lymphoma Market | Merkel Cell Carcinoma Market | Metastatic Her2 Positive Breast Cancer Market | Metastatic Prostate Cancer Market | Metastatic Triple-negative Breast Cancer Market

Other Report by Delveinsight:

About DelveInsight

DelveInsight is a leading Business Consultant, and Market Research firm focused exclusively on life sciences. It supports Pharma companies by providing comprehensive end-to-end solutions to improve their performance. It also offers Healthcare Consulting Services, which benefits in market analysis to accelerate the business growth and overcome challenges with a practical approach.

Media Contact

Company Name: DelveInsight Business Research LLP

Contact Person: Abhishek kumar

Email: [email protected]

City: Albany

State: New York

Country: United StatesWebsite: https://www.delveinsight.com

#crrt machine brands#types of crrt machines#continuous renal replacement therapy market#crrt machine#continuous renal replacement therapy devices market#hemofiltration machine market#crrt machines#continuous renal replacement therapy machines market#crrt machine dialysis#continuous venovenous hemofiltration cvvh product market

0 notes

Text

Vantara Anant Ambani’s Strategy for Long-Term Wildlife Conservation

India’s rich biodiversity—home to Bengal tigers, Asiatic lions, elephants, leopards, pangolins, and countless endemic species—is under immense pressure. Habitat loss, human-wildlife conflict, poaching, and climate change threaten the delicate balance of ecosystems across the subcontinent. While many organizations tackle symptoms of this crisis, few have taken a comprehensive, long-view approach that addresses both present and future challenges.

One notable exception is Vantara, the visionary wildlife sanctuary founded and guided by Vantara Anant Ambani. With an ambitious strategy for long-term wildlife conservation, Vantara goes far beyond emergency rescue and rehabilitation—it is shaping an ecosystem of sustainability, education, innovation, and policy influence that could define the future of conservation in India.

Here’s how Vantara Anant Ambani’s strategic vision is setting the foundation for a wildlife-positive India for generations to come.

🧭 A Vision Rooted in Longevity, Not Optics

Most wildlife initiatives focus on crisis management: rescue, first aid, and short-term rehabilitation. Vantara, under Anant Ambani’s leadership, operates on a fundamentally different philosophy. The sanctuary’s core mission is to create lasting ecological impact by:

Restoring and preserving natural habitats

Addressing root causes of wildlife endangerment

Building infrastructure for ongoing healthcare and research

Educating communities and creating conservation stewards

Working with policy-makers for large-scale environmental reform

This strategy ensures that Vantara is not merely reacting to today’s emergencies but preventing tomorrow’s tragedies.

🌱 Habitat-Centric Conservation: Protecting the Wild Beyond the Fence

While Vantara is a sanctuary, its conservation model extends beyond its borders. Recognizing that saving species requires saving ecosystems, Anant Ambani has prioritized:

Key Initiatives:

Reforestation and native species plantation within and around Vantara

Land acquisition and ecological buffer creation to reduce human encroachment

Soil and water restoration projects to support wildlife corridors

Mapping and maintaining biodiversity hotspots across Gujarat and beyond

These efforts are helping rebuild critical habitats that sustain long-term populations, especially for migratory and wide-ranging species like elephants and leopards.

🧬 Science-Led Rehabilitation and Research

At the heart of Vantara’s strategy is its investment in scientific research and advanced veterinary care, ensuring that rescued animals are not just treated, but studied, understood, and supported throughout their lives.

Research-Focused Conservation Includes:

Long-term health tracking of released animals via GPS collars and behavioral analysis

Genetic studies to understand species resilience and hereditary risk

Disease surveillance programs to track zoonotic and endemic threats

Ethology-based enrichment and rewilding models tailored to specific species

Post-release ecosystem impact assessments to ensure balance is preserved

This data-backed approach makes Vantara one of India’s most forward-thinking wildlife institutions, combining compassion with analytics.

0 notes

Text

Architectural Scale Model Makers in Mumbai – Precision that Brings Designs to Life

In the competitive world of architecture, real estate, and urban development, conveying a clear vision of your project is essential. While digital renderings and blueprints are valuable, nothing matches the power of a physical, tangible model. That’s where Architectural Scale Model Makers in Mumbai play a vital role. These professionals transform ideas into miniature realities, enabling stakeholders to visualize projects with clarity and precision.

What Are Architectural Scale Models?

An architectural scale model is a physical representation of a structure or site, built to scale, showcasing the design, layout, and spatial relationships. It serves as a crucial communication tool between architects, clients, developers, and investors.

Types of Architectural Models:

Residential & Commercial Building Models

Township & Urban Planning Models

Interior Layout Models

Topographic & Landscape Models

Infrastructure & Industrial Site Models

Interactive and Illuminated Models

Importance of Architectural Scale Models

Enhanced Visualization Scale models help clients and stakeholders understand complex design elements that may be difficult to interpret through drawings or digital designs alone.

Faster Approvals Government bodies and investors are more likely to approve projects when they can clearly see what’s being proposed.

Effective Marketing Tool Builders and developers use models at exhibitions, project launches, and showrooms to attract buyers and investors.

Design Evaluation Physical models help architects evaluate scale, proportion, and space utilization more effectively during the planning phase.

Why Choose Professional Scale Model Makers in Mumbai?

Mumbai is home to some of the most talented and experienced architectural model makers in India. These professionals combine artistry with cutting-edge technology to deliver models that are both visually stunning and structurally accurate.

Key Qualities to Look For:

✅ High Precision & Detailing

✅ Use of Advanced Tools like 3D Printing & Laser Cutting

✅ Timely Project Delivery

✅ Custom Models for All Scales & Purposes

✅ Portfolio Spanning Various Industries

Industries Served by Scale Model Makers

🏗️ Architecture & Construction – Design presentations and client approvals

🏢 Real Estate Development – Sales, marketing, and exhibitions

🏛️ Government & Urban Planning – Infrastructure visualization

🧪 Educational Institutions – Student models and academic projects

🧠 Research & Development – Conceptual prototypes

Top-Quality Model Makers in Mumbai

The best architectural scale model makers in Mumbai not only offer superior craftsmanship but also understand the local architectural trends and client expectations. They work closely with architects, developers, and designers to ensure that every project reflects accuracy and creativity.

With increasing demand for smart city models, commercial complexes, and residential projects in areas like Bandra, Andheri, and Navi Mumbai, Mumbai's model-making industry is growing rapidly—offering both traditional and technologically advanced solutions.

Conclusion

Architectural scale models are more than just miniatures—they are storytelling tools that represent your vision with realism and clarity. Whether you're showcasing a residential building, a large-scale infrastructure project, or an interior design concept, partnering with the right architectural scale model makers in Mumbai ensures your ideas stand out.

Choose professionals who bring together design intelligence, cutting-edge tools, and artistic precision to deliver models that make a lasting impression.

0 notes

Text

Composite Recycled Leather Market Set to Hit $1,303.9 Million by 2035

The global Composite Recycled Leather market is projected to grow significantly from $320.7 million in 2024 to $1,303.9 million by 2035, registering a compound annual growth rate (CAGR) of 13.6% over the forecast period (2024–2035).

Key Application Areas Driving Demand

Composite Recycled Leather plays an increasingly vital role across a range of sustainable and industrial applications including:

Furniture Upholstery

Automotive Interiors

Fashion Accessories

Footwear Manufacturing

The report explores major growth opportunities across Product Types, End-User Segments, Manufacturing Processes, and Sustainability Standards.

Industry Leadership & Competitive Landscape

The market features strong competition, led by several key innovators and sustainable material pioneers such as:

Ecopell GmbH

ELeather Group

Ananas Anam Ltd

Vegea Srl

Nova Kaeru Exotic Leather

Green Hides Leather Studio

Bonded Logic Inc.

Sustainable Composites LLC

Modern Meadow Inc.

MuSkin

Pinatex

Reishi by MycoWorks

Market expansion is being driven by increasing demand for sustainable materials, technological breakthroughs, and cost-effectiveness in product development.

Growth Drivers & Strategic Opportunities

The market’s rapid growth is influenced by:

Growing consumer preference for eco-friendly alternatives

Rising corporate ESG mandates and circular economy policies

Advancements in composite leather engineering and bio-based manufacturing

Opportunities are emerging from:

Expansion into untapped and underserved markets

New technological processes for higher-quality composite output

Partnerships and collaborations to scale production and access new regions

Key demand centers include the U.S., China, Germany, Italy, and Japan.

Regional Insights & Supply Chain Transformation

Dominant Regions

North America and Asia-Pacific lead in both production and consumption, thanks to rising demand in fashion, automotive, and home furnishing sectors.

Evolving Supply Chain

From raw material sourcing through composite leather fabrication and product development to distribution and retail, the supply chain is expected to undergo transformation. Key factors include:

Reducing production costs

Overcoming limited consumer awareness

Strengthening regional manufacturing and distribution networks

Emerging markets like India, Brazil, and South Africa are gaining attention for strategic market entry, TAM expansion, and cost optimization.

Explore the Full Report & Sample Access

📘 Full Report Access: Read the Analysis

📥 Free Sample Download: Request Sample Copy

About DataString Consulting

DataString Consulting provides industry-grade market research and strategic insights tailored for organizations across B2B and B2C domains. With over 30 years of cumulative leadership experience, we empower global brands with:

Precision-driven custom reports starting at just USD 1,399

End-to-end research services aligned with business goals

Access to global markets, sector trends, and competitive intelligence

Our agile and cost-efficient delivery model empowers decision-makers with actionable insights—without the burden of traditional research overheads.

Contact Information

Mr. Mark Lawson DataString Consulting ✉️ [email protected] 📧 [email protected]

0 notes

Text

Cryolite Price Trends: A Key Indicator for Market Dynamics

Cryolite (Na3AlF6) is a mineral chemically known as Sodium Hexafluoroaluminate. It occurs as a colorless, white reddish to gray-black prismatic monoclinic, glassy solid crystal, which is rare in nature and is found in the depositions of Ivittuut on the west coast of Greenland. The compound is soluble in Aluminium Chloride solution and sulfuric acid with the evolution of Hydrofluoric acid, which is toxic in nature. However, the compound is not soluble in water.

Cryolite is used in the industrial manufacturing of metals such as aluminium and has many other metallurgical applications. The texture and look of the compound are used in the production of glass and ceramics as a coating over the products, and it has vast applications in different market sectors.

Request for Real-Time Prices: https://procurementresource.com/resource-center/cryolite-price-trends/pricerequest

The key importer countries for Cryolite are the Netherlands, Germany, and the United States. On the other hand, the key exporting countries for the same are Germany, the Netherlands, and Belgium.

Key Details About the Cryolite Price Trends:

Procurement Resource does an in-depth analysis of the price trend to bring forth the monthly, quarterly, half-yearly, and yearly information on the Cryolite price in its latest pricing dashboard. The detailed assessment deeply explores the facts about the product, price change over the weeks, months, and years, key players, industrial uses, and drivers propelling the market and price trends.

Each price record is linked to an easy-to-use graphing device dated back to 2014, which offers a series of functionalities; customization of price currencies and units and downloading of price information as excel files that can be used offline.

The cryolite price trends, including India Cryolite price, USA cryolite price, pricing database, and analysis can prove valuable for procurement managers, directors, and decision-makers to build up their strongly backed-up strategic insights to attain progress and profitability in the business.

Industrial Uses Impacting Cryolite Price Trends:

Cryolite has various applications in the metallurgical industries. It acts as a solvent for bauxite, for the electrolytic production of aluminium on a large scale where it gradually reduces alumina to aluminium by the Hall-Heroult Process. It helps in manufacturing aluminium wastes, aluminization of steel and in welding industries, as well.

Cryolite has several applications in the ceramic industries, such as producing glass objects and ceramic products such as basins, tubs, pans, etc. It is also used as a filtering membrane in inbounded abrasives. Synthetic Cryolites are the derivatives of Fluorites and are used in the synthesis of sodium or aluminium salts. It is also used as a flux in the electrolytic processing of aluminium. Cryolite is also used in the manufacturing of agricultural products like insecticides and pesticides, and hence, it shows its associations with the agricultural industries as well.

Key Players:

Solvay

Fluorsid

Do-Fluoride Chemicals

Nantong Jinxing Fluorides Chemical

Jiangsu Xintai Material Technology

Shanghai Yixin Chemical

Jiangxi Qucheng Chemical

Triveni Chemical

About Us:

Procurement Resource offers in-depth research on product pricing and market insights for more than 500 chemicals, commodities, and utilities updated daily, weekly, monthly, and annually. It is a cost-effective, one-stop solution for all your market research requirements, irrespective of which part of the value chain you represent.

We have a team of highly experienced analysts who perform comprehensive research to deliver our clients the newest and most up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which help in streamlining the procurement process for our clientele. Our team tracks the prices and production costs of a wide variety of goods and commodities, hence providing you with the latest and consistent data.

To get real-time facts and insights to help our customers, we work with a varied range of procurement teams across industries. At Procurement Resource, we support our clients, with up-to-date and pioneering practices in the industry, to understand procurement methods, supply chain, and industry trends, so that they can build strategies to achieve maximum growth.

Contact Us:

Company Name: Procurement Resource Contact Person: Chris Byrd Email: [email protected] Toll-Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500 Address: 30 North Gould Street, Sheridan, WY 82801, USA

1 note

·

View note

Text

ERP Hyderabad: Empowering Businesses with Advanced Enterprise Solutions

In today's digitally-driven business environment, enterprises across various sectors are realizing the importance of streamlining operations, improving efficiency, and gaining real-time insights into their activities. Enterprise Resource Planning (ERP) software plays a pivotal role in achieving these goals. Among India’s rapidly growing urban centers, Hyderabad stands out as a thriving IT and industrial hub. As businesses in this city expand, the demand for robust and customized ERP solutions has significantly surged. This article explores the relevance and impact of ERP in Hyderabad, the industries benefiting the most, and why businesses are choosing to implement ERP systems today.

Why ERP is Crucial for Businesses in Hyderabad

Hyderabad is home to a broad mix of industries—from pharmaceuticals and manufacturing to IT services and logistics. With such diverse sectors operating under competitive market pressures, ERP software offers a unified platform to manage finance, human resources, inventory, procurement, sales, and customer relations.

Key benefits of ERP for businesses in Hyderabad include:

Centralized Data Access: ERP software consolidates business data into one platform, eliminating silos and enhancing cross-departmental collaboration.

Operational Efficiency: Automates routine tasks and improves workflows, thereby saving time and reducing human errors.

Scalability: ERP solutions can be scaled as the company grows, adapting to new business models and processes.

Regulatory Compliance: Helps businesses comply with local tax laws like GST, e-invoicing mandates, and other statutory requirements in India.

Real-time Reporting: Provides decision-makers with accurate, real-time data to drive strategic decisions.

Key Industries in Hyderabad Leveraging ERP Solutions

1. Pharmaceutical and Life Sciences

Hyderabad, often called the “Pharma City of India,” houses numerous pharmaceutical giants and biotech firms.Pharma ERP systems are vital for these companies to:

Manage quality control and regulatory compliance (like FDA, GMP).

Handle complex formulations and batch productions.

Track inventory, raw materials, and expiration dates.

Enhance R&D project management.

2. Manufacturing and Engineering

ERP software supports discrete and process manufacturing firms in areas like:

Bill of materials (BOM) and production planning.

Shop floor automation and resource scheduling.

Equipment maintenance and supply chain visibility.

3. IT and Software Services

With HITEC City and a growing number of IT parks, the tech sector in Hyderabad requires ERP systems for:

Project management and time tracking.

Human capital management (HCM).

Financial consolidation across geographies.

4. Retail and Distribution

Retailers and wholesalers benefit from ERP systems that help in:

Inventory and warehouse management.

Omni-channel sales tracking.

Customer relationship management (CRM).

Features to Look for in an ERP System in Hyderabad

Choosing the right ERP software can be a game-changer. Hyderabad businesses often look for solutions that offer:

GST Compliance & Localization: Integration with Indian tax systems is a must.

Multi-Language & Multi-Currency Support: Especially for businesses with global trade.

Mobile Accessibility: Real-time data access via smartphones for field teams.

Modular Design: Allowing companies to choose only the ERP modules they need (finance, HR, CRM, inventory, etc.).

Customizability: Tailoring the software to industry-specific requirements.

ERP Implementation Challenges in Hyderabad & How to Overcome Them

While ERP offers tremendous value, ERP implementation can pose certain challenges:

High Initial Costs: Though ERP is a long-term investment, the upfront expense may be a concern. Cloud-based solutions offer a more affordable alternative.

Change Management: Employees may resist adapting to new systems. Proper training and change communication are crucial.

Integration with Legacy Systems: Some companies still use outdated software. Selecting an ERP with good API capabilities helps bridge the gap.

By partnering with experienced ERP providers and setting clear implementation goals, businesses can ensure a smooth transition.

The Growing ERP Ecosystem in Hyderabad

Hyderabad boasts a vibrant ecosystem of ERP vendors, consultants, and implementation partners. Local players provide industry-specific solutions while international platforms like Odoo, SAP, Oracle, and Microsoft Dynamics also have a strong presence.

Local ERP companies understand regional nuances and offer faster support, while global providers offer scalable, advanced features. The growing demand for cloud ERP solutions in Hyderabad has further expanded the market, allowing small and medium enterprises (SMEs) to leverage enterprise-grade technology at lower costs.

Why Businesses in Hyderabad Are Adopting ERP Now More Than Ever

Several factors are driving ERP adoption in Hyderabad:

Digital India Movement: Government initiatives encouraging digitization among SMEs.

Remote Work Culture: The need for cloud-accessible platforms has risen post-pandemic.

Increased Competition: Businesses are striving to gain operational superiority and agility.

Data-Driven Decision Making: ERP systems provide analytics and KPIs that guide business strategies.

Conclusion: A Strategic Investment for Future-Ready Enterprises

For companies in Hyderabad aiming to scale efficiently, maintain compliance, and outperform competitors, implementing an ERP solution is no longer optional—it’s essential. With the right ERP system, businesses can gain real-time visibility, automate operations, and achieve operational excellence.

Looking for a Trusted ERP Partner in Hyderabad?

Banibro IT Solutions offers robust, scalable ERP solutions tailored to your business needs. Whether you operate in manufacturing, pharma, retail, or services, we help you implement a future-ready ERP that drives efficiency and growth.

Let’s transform your operations—connect with us today to get started!

0 notes