#Shell and Tube heat exchangers

Explore tagged Tumblr posts

Text

Valutech’s shell‑and‑tube heat exchangers deliver highly customizable, industrial‑grade thermal solutions built to rigorous ASME, TEMA, CRN, API, Coast Guard, HEI and NACE standards. With shell diameters from 4″ to 36″ and tubing options ranging from copper to nickel alloys, they support diverse applications—steam heaters, oil coolers, condensers, sanitary systems, pool heating, and pressure vessels. Designs include fixed‑tube, floating head, U‑tube (BEU/BEM) formats underpinned by precise 3D design and thermal‑mechanical engineering

0 notes

Text

Premium Heat Exchangers and Filter Vessels from Gas Processing – Trusted Manufacturer in India

In industries where precision, safety, and efficiency are paramount, choosing the right equipment partner is critical. At Gas Processing, we are proud to be a leading heat exchanger manufacturer in India, offering high-performance thermal and filtration solutions tailored for the most demanding industrial applications.

Visit us - https://medium.com/@gasprocessingequipment/premium-heat-exchangers-and-filter-vessels-from-gas-processing-trusted-manufacturer-in-india-72bb079b10be

#heat exchanger manufacturer in India#filter vessels#shell and tube heat exchangers#gas filter separator#industrial filtration systems India

0 notes

Text

Glass-Lined Distillation Columns in canada | PFG GlassKem

Explore PFG GlassKem's glass-lined distillation columns in canada, engineered for efficient purification processes with optimal product purity and reliability.

#Vertical storage tanks#Horizontal storage tanks#Plate-type heat exchangers#Shell and tube heat exchangers

0 notes

Text

#radiator maintenance#shell and tube heat exchangers#plate and frame heat exchangers#charge air cooler repair#industrial radiators and heat exchangers#shell and tube heat exchanger service#shell and tube heat exchanger#shell tube exchanger#tube heat exchanger#industrial radiators repairing services#radiator repair and maintenance services#repairing radiators#radiator repair near me#radiator fix near me#plate and frame heat exchangers repair and service#frame heat exchangers repair#heat exchanger repair services#heat exchanger repair companies#charge cooler repairing services#charge cooler repair services#charge air cooler leak repair#charge air cooler maintenance#brazed plate heat exchangers repair#brazed plate heat exchanger service#brazed aluminum heat exchanger repair#brazed aluminum heat exchanger services#industrial plate heat exchanger repair#plate and frame heat exchanger#brazed plate heat exchanger

0 notes

Text

Energy Efficiency in Process Equipment: Best Practices and Innovations

In today's industrial landscape, energy efficiency is not just a buzzword; it's a necessity. Companies are increasingly focusing on optimizing their energy use to reduce costs, minimize environmental impact, and enhance overall productivity. This blog will explore best practices and innovations in energy efficiency related to process equipment. We’ll discuss how various equipment types, including heat exchangers, boiler equipment, and industrial mixing equipment, contribute to a more energy-efficient operation.

Understanding the Role of Heat Exchangers

Heat exchangers are critical components in many industrial processes. They transfer heat between two or more fluids, allowing for energy recovery and efficient thermal management. Among the various types of heat exchangers, brazed plate heat exchangers stand out for their compact size and high thermal efficiency. These exchangers are particularly valuable in applications where space is limited.

Shell and tube heat exchangers are another common type used in various industries, including oil and gas, power generation, and chemical processing. They consist of a series of tubes, one set carrying the hot fluid and the other the cold fluid. This design allows for efficient heat transfer while maintaining durability. To maximize energy efficiency, operators must ensure regular maintenance of these devices, such as cleaning and inspecting for leaks.

Innovations in Heat Exchanger Technology

Recent innovations in heat exchanger technology have significantly improved energy efficiency. For instance, manufacturers are now utilizing advanced materials and designs that enhance thermal conductivity and reduce fouling. Companies like heat exchanger manufacturers in Kenya are at the forefront of these advancements, offering products that help industries minimize energy waste.

Moreover, the integration of exhaust gas economizers in industrial settings has gained popularity. These devices recover waste heat from exhaust gases and use it to preheat incoming fluids, significantly lowering energy consumption in processes such as heating water or air.

Boiler Equipment and Energy Efficiency

Boiler equipment suppliers play a crucial role in enhancing energy efficiency within industrial facilities. Modern boilers are designed with advanced controls and monitoring systems that optimize combustion efficiency and reduce fuel consumption. For instance, a gas combustion unit for LNG can achieve high efficiency by ensuring complete combustion, which minimizes energy waste and emissions.

Furthermore, regular maintenance and upgrades of boiler systems are essential. Implementing strategies such as flue gas condensation recovery can dramatically improve overall system efficiency. By capturing waste heat from flue gases, businesses can convert it into usable energy, which significantly reduces the overall energy footprint.

The Importance of Efficient Fluid Handling

Efficient fluid handling is essential in various industrial processes. Industrial mixing equipment plays a key role in ensuring optimal mixing and processing, leading to reduced energy use. Technologies such as variable speed drives allow operators to adjust motor speed according to demand, further enhancing efficiency.

In addition, distributors of centrifugal pumps provide systems that are designed to operate at optimal efficiency levels. These pumps can be fitted with advanced controls that monitor flow rates and adjust energy use accordingly. This is particularly important in processes where fluid flow varies throughout the production cycle.

Sanitary operations also require efficient solutions. Sanitary ball valve manufacturers are increasingly offering products that not only meet hygiene standards but also reduce energy use in fluid systems. These valves facilitate quicker flow rates and lower pressure drops, leading to energy savings.

Innovations in Tank Cleaning Devices

Cleaning and maintaining tanks used in various industrial processes is often energy-intensive. However, innovations in tank cleaning devices have made this task more efficient. Modern cleaning devices utilize high-pressure jets and automated systems to minimize water and energy consumption. These systems can effectively remove residues without the need for manual cleaning, saving both time and resources.

Conclusion

As industries continue to embrace energy efficiency, the innovations in heat exchanger equipment, boiler technology, and fluid handling systems are making a significant impact. By adopting best practices and staying informed about the latest advancements, businesses can achieve substantial energy savings and contribute to a more sustainable future.

We encourage our readers to share their thoughts and experiences regarding energy efficiency in process equipment. Have you implemented any of these innovations in your operations? Please leave a comment below!

#heat exchanger manufacturers kenya#brazed plate heat exchanger#industrial plate heat#Heat Exchanger Equipment#shell and tube heat exchangers

0 notes

Text

Pharmaceutical Heat Exchangers

Best shell and tube heat exchanger manufacturer & supplier for chemical industry Check the price with Repicea.com and book your heat exchanger system now!

Learn more about Heat Exchangers here: https://www.repicea.com/main

0 notes

Text

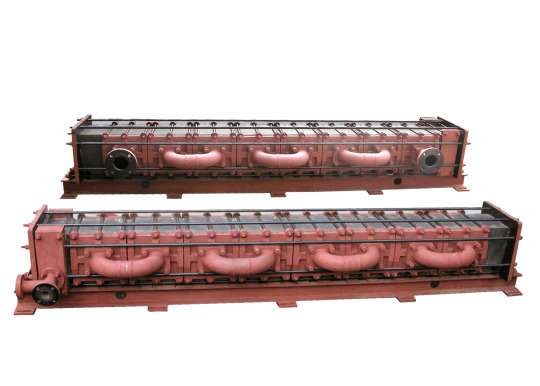

Shell and Tube Heat Exchanger Manufacturers

Best shell and tube heat exchanger manufacturer & supplier for chemical industry Check the price with Repicea.com and book your heat exchanger system now!

Learn more about Shell and Tube Heat Exchanger Manufacturers here: https://www.repicea.com/main

Contact Information: Address: Repicea Heat Exchanger, Xizhang Community, Qianqiao Street, Huishan District Wuxi, Jiangsu, Wuxi, Jiangsu, China.

Phone: 13913576117

1 note

·

View note

Text

#Graphite#Graphite Heat Exchanger#Graphite Condensers#Graphite Cooler#Cubic Block Graphite Heat Exchanger#Cylindrical Block Graphite Heat Exchanger#Shell & Tube Graphite Heat Exchanger#Graphite Reboilers

2 notes

·

View notes

Text

Swastik Hydraulic – A Trusted Name in Industrial Cooling Solutions

When it comes to high-performance and reliable cooling systems for industrial applications, Swastik Hydraulic stands out as a leader. As one of the most experienced Shell and Tube Heat Exchangers Manufacturers in New Delhi, we pride ourselves on delivering efficient and long-lasting products tailored to your needs.

Why Choose Swastik Hydraulic?

At Swastik Hydraulic, quality, precision, and durability form the foundation of every product we manufacture. We specialize in a wide range of heat exchanger solutions designed to support diverse industries, including manufacturing, power, oil & gas, and heavy engineering.

Our Core Offerings

🔧 Heat Exchanger Manufacturers

Our heat exchangers are engineered to provide superior thermal efficiency and withstand the toughest working conditions. Whether you need compact or large-scale systems, our solutions are built to deliver maximum performance.

💧 Hydraulic Oil Cooler Manufacturers

We provide high-quality hydraulic oil coolers that are designed to maintain optimal fluid temperatures, increasing the life of your equipment and ensuring smooth operation.

🛢️ Lube Oil Cooler Manufacturers

Our lube oil coolers are trusted by industries to protect machinery from overheating, ensuring consistent performance in demanding environments.

🌐 Industrial Heat Exchanger Manufacturers

Swastik Hydraulic is a reliable name among Industrial Heat Exchanger Manufacturers, offering customizable solutions that meet specific operational requirements and enhance productivity.

Serving Major Industrial Hubs

We are proud to be recognized as one of the top Shell and Tube Heat Exchanger Manufacturers in Faridabad, Haridwar, Vadodara, Ghaziabad, and Surat. Our extensive network and commitment to quality ensure timely delivery and support across India’s key industrial zones.

Hence

With a strong focus on innovation and customer satisfaction, Swastik Hydraulic continues to grow as a trusted brand in the heat exchanger industry. Whether you’re looking for a reliable Shell and Tube Heat Exchanger Manufacturers in Jodhpur or expanding your infrastructure in other industrial hubs, we are here to serve you with excellence.

📞 Contact us today to learn more about our products and how we can help enhance your system’s cooling performance.

0 notes

Text

Shell and Tube Heat Exchanger Manufacturer in India

Aspal Engineering is a prominent Shell and Tube Heat Exchanger Manufacturer in India, used for space heating, power plants, chemical, refrigeration, natural gas processing, etc.

0 notes

Text

#Shell and Tube Heat Exchanger Manufacturer#Shell and Tube Heat Exchanger Manufacturer in Mumbai#Shell and Tube Heat Exchanger Manufacturer in India

0 notes

Text

When it comes to efficient thermal transfer in demanding environments, few systems match the reliability of shell and tube heat exchangers. Whether you're in food processing, pharmaceuticals, or heavy industry, understanding Industrial Shell And Tube Heat Exchangers is key to optimizing performance and ensuring long-term durability. In this blog, we break down their design, benefits, and applications to help you make informed decisions for your industrial operations.

0 notes

Text

Premium Heat Exchangers and Filter Vessels from Gas Processing – Trusted Manufacturer in India

In industries where precision, safety, and efficiency are paramount, choosing the right equipment partner is critical. At Gas Processing, we are proud to be a leading heat exchanger manufacturer in India, offering high-performance thermal and filtration solutions tailored for the most demanding industrial applications.

Why Heat Exchangers Matter

Heat exchangers play a crucial role in energy conservation, process efficiency, and safety across sectors like oil & gas, chemical processing, pharmaceuticals, food & beverage, and power generation. A well-designed heat exchanger can:

Optimize energy usage

Improve process consistency

Reduce operational costs

Enhance system safety and reliability

At Gas Processing, we specialize in the design, manufacture, and supply of robust and efficient heat exchangers that are built to perform under pressure.

Gas Processing – Your Trusted Partner for Heat Exchangers in India

As a recognized heat exchanger manufacturer in India, we deliver engineered solutions that match the exact specifications of our clients, both domestically and internationally.

⚙️ Our Heat Exchanger Offerings:

Shell and Tube Heat Exchangers Reliable, durable, and ideal for high-pressure applications.

Air Cooled Heat Exchangers Suitable for locations where water is scarce or expensive.

Plate Heat Exchangers Compact and efficient for smaller systems and processes.

Double Pipe Heat Exchangers Perfect for lower flow rates and smaller heat exchange tasks.

We follow ASME, TEMA, and other global standards to ensure the highest levels of safety and performance.

Precision-Engineered Filter Vessels

In addition to heat exchangers, Gas Processing is also a trusted name in the design and manufacture of filter vessels. These are critical in removing solid and liquid contaminants from gas and liquid streams—essential in gas processing, petrochemicals, and water treatment industries.

🔍 Filter Vessels We Offer:

Gas Filter Separators Designed to efficiently remove dust, mist, and liquids.

Cartridge Filter Vessels Ideal for fine filtration in liquid systems.

Bag Filter Vessels Cost-effective and suitable for batch operations.

Coalescing Filter Vessels Specially built to separate fine droplets from gas or liquid streams.

Each vessel is fabricated with precision, tested for integrity, and designed to ensure long service life with minimal maintenance.

Why Choose Gas Processing?

✅ Decades of Experience: Proven expertise across various industries. ✅ Custom Engineering: Tailored solutions based on client process requirements. ✅ Global Standards: ASME, TEMA, ISO-certified manufacturing processes. ✅ On-Time Delivery: Timely and efficient delivery across India and abroad. ✅ Exceptional After-Sales Support: Maintenance, spares, and technical assistance whenever you need it.

Client Testimonials

"Gas Processing has been our go-to heat exchanger manufacturer in India. Their quality and professionalism are unmatched." – Plant Head, Petrochemical Company

"We rely on Gas Processing filter vessels for our gas purification systems. They deliver consistent performance and require minimal maintenance." – Operations Manager, Natural Gas Facility

Partner with Gas Processing for Reliable Thermal and Filtration Solutions

Whether you're upgrading an existing facility or building a new plant, Gas Processing provides the technical expertise and engineering excellence you can trust. As a top-tier heat exchanger and filter vessel manufacturer in India, we are committed to delivering value through innovation, reliability, and quality.

Visit us https://gasprocessing.in/processing-equipment/

#heat exchanger manufacturer in India#filter vessels#shell and tube heat exchangers#gas filter separator#industrial filtration systems India

0 notes

Text

What Makes the Best Heat Exchangers in India?

Reliability and the Best Heat Exchanger Manufacturer in India When one is talking about high-performance heat transfer systems, especially the ones that are backed by reliability, then we have to make sure that the heat exchanger manufacturer is a dependable one. One such name that is in the lead everywhere is Sheheatexchange, which provides comprehensive solutions for heat exchangers designed for various industries.

Why Choose Sheheatexchange?

Among the established heat exchanger manufacturers in India, Sheheatexchange is notable for:

High-quality materials Precision engineering Quality control is very strict Specialised after-cooler design tailored to your requirements

From shell and tube heaters to plate and finned tube heat exchangers, Sheheatexchange offers products widely used in the following industries:

HVAC Chemical processing Oil & Gas Power generation Food & Beverage

Cutting-Edge Technology Plus Nationwide Coverage:

Situated in the heart of India’s industry, sheet exchange technologies are technology-protected and supported by regional sales and service. We are the absolute best at what we do, not because we have the fanciest website but because our people are well seasoned in manufacturing the right products. Our engineers are some of the brightest in the heat exchanger world, who use their specific domain knowledge to custom design all of our products. Superior thermal efficiency High corrosion resistance Long-term durability Whether you need a small unit or an industrial solution, heat exchange enables you to use your energy as efficiently as possible and with a minimum of maintenance.

Trusted by Customers From All Over India:

With its unwavering focus on innovation and service, Sheheatexchange continues to be a leading heat exchanger manufacturer in India. Their customer-focused emphasis ensures every product is designed to service the objectives of the company it serves.

#Heat Exchanger#Heat Exchanger manufacturesin india#Plate Heat Exchanger#Brazed Plate Heat Exchanger#Shell and Tube Heat Exchanger Manufactures in India#Air Cooled Heat Exchanger Manufacturers in India#Oil Cooler

0 notes

Text

Radiator Repair: Keeping Your Engine Cool with Ring Heat Exchanger

For decades, Ring Heat Exchanger has been synonymous with Ring Radiator Services, reflecting our commitment to radiators at the core of our operations. Our expertise spans radiator maintenance, repair, overhaul, and service across various applications and industries, dealing with copper, aluminum, and stainless-steel cores.

The Purpose of a Radiator

Radiators play a crucial role in the engine cooling system by dissipating excess heat from the engine block and other systems. A poorly functioning radiator can lead to engine overheating, compromising performance and potentially causing critical engine failure.

Radiator Failure Modes

Leaks: In tubes, header plates, or tank gaskets.

Mechanical damage: Caused by impacts from environmental debris or unmaintained tools.

Restricted airflow: Accumulation of dirt and debris on cooling fins.

Corrosion: Damaged radiator fins leading to reduced cooling capacity.

Coolant flow restriction: Accumulation of debris in tubes hindering efficient cooling.

What We Do

#radiator maintenance#brazed plate heat exchanger#plate and frame heat exchangers#shell and tube heat exchangers#charge air cooler repair#industrial radiators and heat exchangers#heat exchanger maintenance

0 notes

Text

Revolutionizing Industrial Processes with Ideologie's Cutting-Edge Equipment

In the realm of industrial operations, efficiency is the key to success. Whether it's maximizing energy utilization or optimizing fluid management, having the right equipment can make all the difference. Ideologie stands at the forefront of this paradigm shift, offering a comprehensive range of advanced machinery and components designed to elevate industrial processes to new heights.

Industrial Plate Heat Exchangers are a cornerstone of modern thermal management systems. With Ideologie's innovative designs, heat transfer efficiency reaches unprecedented levels, facilitating precise control over temperature gradients in various industrial applications. Coupled with Shell and Tube Heat Exchangers, these systems ensure optimal heat exchange across diverse fluid mediums, enhancing overall productivity while minimizing energy consumption.

For industries reliant on combustion processes, Boiler Flue Gas Economizers play a pivotal role in harnessing waste heat for additional energy generation. Ideologie's state-of-the-art economizer solutions seamlessly integrate into existing boiler systems, recovering valuable thermal energy from flue gases and significantly reducing operational costs.

The quest for sustainability drives the adoption of Waste Heat Recovery Boiler Parts, where Ideologie excels with components engineered for durability and efficiency. By capturing and utilizing waste heat, industries not only minimize environmental impact but also bolster their bottom line through enhanced resource utilization.

Fluid handling is another domain where Ideologie shines, offering a diverse array of equipment such as Rotary Lobe Pumps and Industrial Centrifugal Pumps. These robust and reliable pumps ensure smooth fluid transfer operations across various industrial settings, from chemical processing plants to food and beverage facilities.

Maintaining operational integrity is paramount, which is why Non-Return Valves are indispensable in fluid systems. In Kenya and beyond, Ideologie's high-quality valves provide reliable backflow prevention, safeguarding equipment and optimizing process efficiency.

In hygienic applications, Sanitary Ball Valves are essential for maintaining stringent cleanliness standards. Ideologie's sanitary valves are engineered with precision and hygiene in mind, ensuring compliance with industry regulations while facilitating seamless process control.

Ensuring equipment longevity and performance requires proactive maintenance, and Tank Cleaning Devices offered by Ideologie are engineered to streamline this crucial task. With innovative designs and robust construction, these devices ensure thorough cleaning, minimizing downtime and maximizing productivity.

Mixing and filtration are fundamental processes across various industries, and Ideologie's offerings include Rotary Jet Mixers and Rotary Drum Filters. These cutting-edge solutions enable homogeneous mixing and efficient filtration, enhancing product quality and process efficiency.

Moreover, Centrifugal Separators play a crucial role in liquid-solid separation, and Ideologie's separators are engineered for optimal performance and reliability, ensuring efficient removal of contaminants and facilitating downstream processes.

In conclusion, Ideologie stands as a beacon of innovation in the realm of industrial equipment and components. From heat exchange solutions to fluid handling equipment and beyond, their offerings epitomize efficiency, reliability, and sustainability. By embracing Ideologie's cutting-edge technology, industries worldwide can unlock new levels of productivity and competitiveness while paving the way towards a more sustainable future.

#industrial plate heat exchanger#shell and tube heat exchangers#boiler flue gas economizer#waste heat recovery boiler parts

0 notes