#Stator Control

Explore tagged Tumblr posts

Text

KaiJune2025 - Day20: Stator

Kaijune 2025 - Day 20: Unicycle I actually had an entirely different drawing almost complete before I switched to this concept. That's why it's so late.

[This is the prompt list I'm following] ===== BIO:

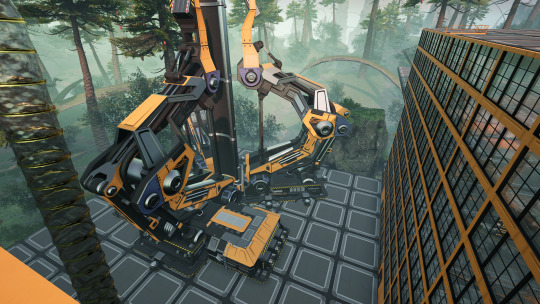

After half a year of silence, the KDF suddenly come back onto the scene. After a fight between a kaiju and an Alter unit, which once again goes berserk, an extremely speedy mech, later named the M6-01 Stator flanked by a few Wheelers quickly engaged with the Alter.

The Stator itself was a very unique mech compared to the KDF's older machines, standing on a single set of wheels and most interestingly - multiple set of gravity repulsers, tech clearly reversed engineered from Engravita's suit. As noted by the KDF after the encounter, they have apparently been unable to mimic Engravita's gravity control tech... until now. Although not as strong, the Stator was shown picking up small portions of the road and using them as weapons. The Stator was also stated to not be a replacement for the Wheelers, and rather a close-combat mech as opposed to the Wheelers' ranged combat.

Not much else is known about the KDF's return, though the Ascent has called foul play, and blamed the original berserk incident on the KDF trying to tarnish their names. Interesting though... the Alter that was eventually beaten went missing after their battle. It's unknown where it went.

5 notes

·

View notes

Text

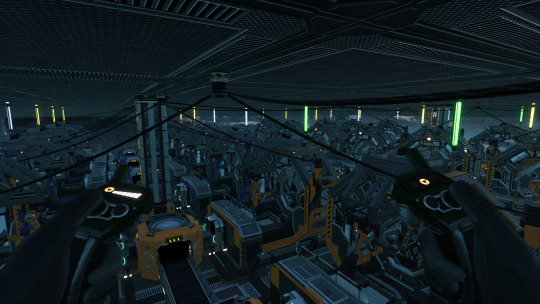

The Great Satisfactory State of Play April 2025 #3

Rocky Desert Phase 4 Factories

So we went to the Dune Desert to pay one last visit to Factory Town before it gets destroyed; we popped into the Northern Forest to visit the Phase 2 factories; and now we're about to zip into the Rocky Desert to have a gander at the Phase 3 rigmarole.

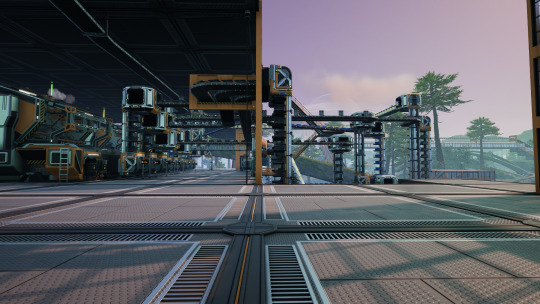

And here we are on the natural bridge that connects Northern Forest to Rocky Desert. In the distance, we can see several factories, two of which feed the reactor on the opposite side of the big rock tower. So we travel west, then up the slope...

And here we have an open air silica and quickwire factory. The golden wire is crapped out in the foreground; silica is made down the back.

And where does the raw quartz come from to feed the machine? Well...

It comes from the bottom floor of the steelworks immediately below us, since the reactor doesn't use all that much silica, and I have more than enough being belted from deep within the immense cave that spans the entire width of this biome. It was a cinch to add a splitter and get that sorted!

Iron plate, silica, steel beams go out past the encased industrial beam factory in the distance, which adds much needed EIBs to the feed. Without these, the reactor stops hard.

An early WIP shot of the reactor. Obviously it's an uranium reactor, that also makes plutonium fuel rods for recycling. This was before I added the assemblers and manufacturers needed to finish that job. But that was then...

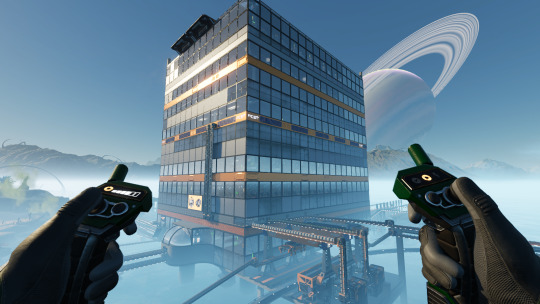

...this is now. The quickwire and silica are trained down this line to the far distant factory on the shoreline. But there's a factory closer, and newer, and it's the best example of my idea of the Stack. Shall we have a closer look?

That box in the foreground is from a mod, that allows you to tap power from train lines without needing a station. The modernist thing on the left is the caterium smeltery. That's all it does. So we skip that and hover along the power line to the skeletal one behind it. That's the Stack for electromagnetic control rods.

The idea of the Stack is simple. Each floor is dedicated to a single step in the manufacturing process. I tend to forget that because compactness. In the distant left, foundries and smelters feed copper and iron into the Stack.

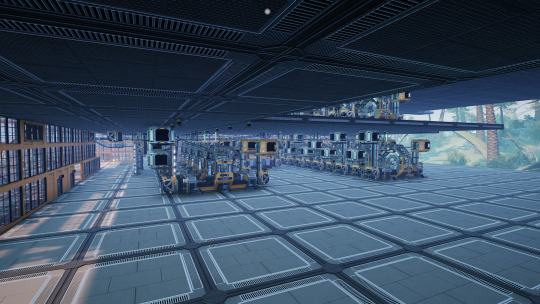

Ground floor, iron and copper ingot arrival, copper sheet making. Please mind your step as getting bowled from stepping on the belts may offend (they're sent to one corner.) Going up.

Belt bridge porn. Where was I? Oh yes.

Second floor, copper wire. Note that my prefabs for 8 constructors are actually 4x4 rather than 5x5, which I use for the assemblers further up. Step to the rear of the car please.

Third floor, quickwire extrusion. This setup with the mesh flooring (from a mod) actually works quite well as it offers plenty of space for in- and output belting. Everybody up!

Fourth floor, iron pipe manufacture. With this half-floor we see one flaw of the Stack concept, if you consider empty floor space a flaw. And now we have to step outside the concrete pillar framework to look into the next floor up.

Fifth floor, AI limiters and stators. Yes, on the same floor, because it occurred to me that there was no logical reason to put them on separate floors. But now I wonder if another half-floor would have been so bad. Stators in back, AI limiters in front.

The prefabs include built-in logistics floors, and conveyor supports for the inputs, assuming everything, er, enters the same way. And those go up to...

Top floor, ECR final join and dispatch. I have kluged up two drone ports at the reactor to receive these, and also supply said drones with fuel rods for plenty of power.

So that's my first true Stack! So what came before?

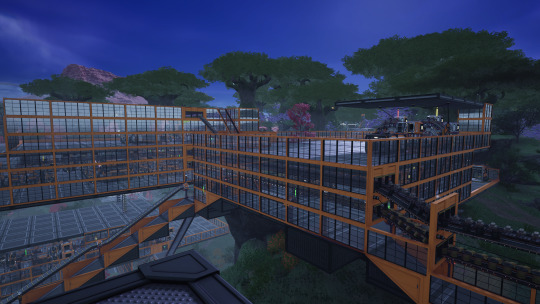

This is what came before: This damnable thick square building that makes parts for and does final join on modular engines and adaptive control units. On top are five drone ports. One receives fuel for the others. The two we can see receive smart plating and automated wiring. And there's that train station at the bottom of a rather entertaining ramp. Let's look inside.

Cool! We have a satellite HUB terminal (from a mod), and all other mod cons! Not to mention well-lit, at least in these lower floors, I skipped lighting as I went up and got impatient.

So many foundries and coated iron plate assemblers. Oh, and steel beam constructors.

I can't wait for the day when 1.1 is made mod friendly. This form of compact vertical transport is... well, it's not the going-up, it's the going-down. A 20m drop is hair-raising.

Silicon circuit boards and so, so many screws. There's about eight belts of them going up the south wall.

And this is where everything ends up: the roof. That building in the centre is where all the spaghet for dispatching the Phase 3 goods and receiving Phase 2 is. And dispensing fuel. And feeding the sink. While we're up here, let's look around:

So many miners! Copper, iron, limestone, it's all here and all getting exploited a mile into the ground.

In back of the tower are the wet concrete refineries on the left, and the steamed copper sheet works. These were difficult to make, since I was, apparently, right on the edge of where I could place water extractors.

The mighty metal-roofed motor factory system! In the back, the double A-frame houses the solid steel ingot foundries; each different roofline indicates a separate stage of motor production. Copper ingots are belted in to a wire factory in the foreground.

The ground floor is marked with a coloured floor and path patterns, to highlight where you can walk from one end of Rocky Desert Motors to the other.

All of these constructors are making screws. All 64 of them. So. Many. Screws. If I didn't know any better, I'd think I was running Satisfactory+.

And here we have a distant shot of the abominations I made on the West Coast. There's a basic aluminium ingot factory, spagged to a hastily made heat sink factory and fuel packing plant, and also a massive refinery for making residual rubber and plastic to feed the tower. Coke, rubber and plastic are supplied by train, obviously. There's also a little fuel power plant that I really need to either redo or replace.

Actually this whole shebang desperately needs reworking. If I can rework the plant to make recycled rubber and plastic, that should improve output immensely.

Aaand that's where I am right now. In my pad of Warwick 14J5 I have a plan for a grid system that I can use to rebuild Factory Town... but first I have some more damned mining to do. I promised my passengers I'd have them in the North America Nebula by Easter.

Also, over Easter and possibly starting Wednesday, I'm going to reset Windows and see if that fixes the stability issues I've been having while streaming. Which means ensuring all my documents are backed up. So excuse me, I have to take my Type 8 Ye Olde Rock Thudder out to do just that...

2 notes

·

View notes

Text

Current Satisfactory Build!

Long post under construction

It's time for another build post! this one is still pretty early but I wanted to show it off anyway

Oil processing, plastic, rubber, and fuel production, as well as 7 generators producing 1750MW. Belt hallway still in progress, debating turning it into a railway after train unlock but still undecided. Will eventually be ths site of Bauxite processing because of the access to water. Bauxite miner is on the mountain just behind

Caterium and steel happened to be right next to eachother so I combined them in one facility. Quickwire at the bottom supplying high speed connectors above and eventually more processes

Steel production is right behind the quickwire. Steel currently maxed out at mk4 belts producing 480 steel ingots/min, 120 beams, and 40 pipes. I have 30/min iron being processed into plates and rods for local use, and I have an uploader on each

in front of, and underneath steel, coal power chuggs away producing 1350 MW supplementing the fuel generators. Coal and sulfur mix to produce compacted coal for better fuel efficency

And now my favorite part! My main facility where ALL the magic happens.

Floor 1 contains my main iron processing, churning out 600 ingots with plans to double.

The west end houses the copper plant making wire and cable throughout the rest of the facility, and also an uploader for each

Right next to copper is my backup biomass manifold. I have plans of installing priority power switches everywhere and using this as emergency power

Level 2 includes modular frames, rotors, smart plating, and reinforced plates, as well as

Copper sheets

Level 3 has circuit boards, versatile framework, automated wiring, stators, and motors

Level 4 houses almost exclusively manufacturers for: computers, heavy modular frames, adaptive control units, and modular engines. I may expand level 4 as necessary.

Belt spaghetti

Level 5 will make project parts for phase 4 though I may expand to level 6 as well. Not sure

Behind this megafactory is the space elevator. Its central location between the North and West wings make it easier move parts over

Not completely sold on this distribution system but I don't really have a better way at this particular point. Still serves the purpose but it is certainly spaghetti

Hopefully aluminum soon, trains soon, jetpack next

3 notes

·

View notes

Note

Ooooh, are we doing recordings? I have a fun challenge for you. Hit YT and look for "Turbo Encabulator", posted by Dave Rondot. It's longish so I'd never ask you to do the whole thing but a snippet would be fun as hell, and I bet you'd laugh. :)

Oh we are sooooo doing this. In full, because longer scripts are better for me on practice since this is mostly about training muscle memory, maintaining breath control, and endurance at this point.

Script:

“For a number of years now, work has been proceeding in order to bring perfection to the crudely conceived idea of a transmission that would not only supply inverse reactive current for use in unilateral phase detractors, but would also be capable of automatically synchronizing cardinal grammeters. Such an instrument is the turbo encabulator.

Now basically the only new principle involved is that instead of power being generated by the relative motion of conductors and fluxes, it is produced by the modial interaction of magneto-reluctance and capacitive diractance.

The original machine had a base plate of pre-famulated amulite surmounted by a malleable logarithmic casing in such a way that the two spurving bearings were in a direct line with the panametric fan. The latter consisted simply of six hydrocoptic marzlevanes, so fitted to the ambifacient lunar waneshaft that side fumbling was effectively prevented.

The main winding was of the normal lotus-o-delta type placed in panendermic semi-boloid slots of the stator, every seventh conductor being connected by a non-reversible tremie pipe to the differential girdle spring on the “up” end of the grammeters.

The turbo-encabulator has now reached a high level of development, and it’s being successfully used in the operation of novertrunnions. Moreover, whenever a forescent skor motion is required, it may also be employed in conjunction with a drawn reciprocation dingle arm, to reduce sinusoidal repleneration.”

(Folks, please, go ahead and send more, I'll record when I can. But let's also go for like... REGULAR WORDS? The nonsense is great too, but this is just getting FRAMBULATED.)

11 notes

·

View notes

Text

Yes, Let's Fight on a Flying Ship. That's a Great Idea!

Warnings: None

Copyright: I do not own any Marvel characters or locations. However, I do own my OC Elizabeth Lightwood. I do not condone any copying of this.

They were chatting with each other, Steve and Tony still going at each others' throats. You, on the other hand, was starting to feel nervous as Bruce started to look at the computer. You scanned the room, looking for threats.

There was a vent in the middle of the floor and you crouched down. Was it your imagination, or was there a beeping noise? No, there was so much equipment in this lab, of course there were plenty of beeping noises.

You shook your head, feeling frustrated with yourself. There was no reason for anything bad to happen, considering Loki was contained and there was no Code Green.

"Oh my God." Bruce said, and suddenly, there was a sound like an eruption. Your head turned towards the noise, before a flame explosion came up out of the same vent that you had been kneeling before. If you hadn't moved, you'd be dead.

As it was, you went flying, crashing against the table that the scepter had been laying on, glass falling around you, and the scepter hit the floor next to you.

"Y/N!" Tony shouted.

Steve was the one that hauled you to your feet, pulling you along to hand over to Tony and the three of you ran out the door. You couldn't help but have a bad feeling about leaving the scepter behind.

"Get to safety." Tony commanded you.

"I'm not leaving you!" You shouted back. "You might need me."

I could hear Fury shouting in my coms, along with Hill, talking about outside repairs. Tony said he'd take it. Romanoff said they were okay and so that was good.

You and Steve split off from Tony, who went to go and get his suit. The two of you made it out to where the engine was destroyed, watching the agents that survived head back towards safety. The entire engine had been torn out, leaving a huge gaping hole.

Tony told Steve to get to the control panel and you watched with a gaping mouth as he just launched himself billions of feet over thin air to get to the other side.

"What does it look like in there?" You heard Tony asked.

Steve sighed. "It seems to run on some form of electricity."

"Well, you're not wrong." Tony muttered while you giggled against your better judgement.

"Okay the relays are intact! What's our next move?" Steve shouted after a few minutes.

"Even if I clear the rotos, this thing won't re-engage without a jump. I'm going to have to get in there and push."

"Is that safe?" You asked over the coms at the same time that Steve said, "Well if that thing gets up to speed, you'll get shredded."

There was an awkward silence for a moment before you asked shakily. "Tony?"

"Bunny, don't worry. That stator control unit can reverse the polarity long enough to disengage maglev and that could-"

"Speak English." Both Steve and yourself yelled at him.

"You see that red lever?" Tony finally asked. "It will slow the rotors down long enough for me to get out. Stand by it. Wait for my word."

You were standing by the lever and Steve leaped back over, grabbing the railing so that the both of you were by it. Your pistol was starting to become slippery in your grasp.

"Hold this." You said with a shaky breath, thrusting the pistol at him. He grabbed it. You wiped your hands along your black leggings, before pulling black fingerless leather gloves and then held your hand back out for the gun, which he quickly deposited in your hand.

"He'll be fine." Steve muttered.

You just hummed in response, not entirely sure you believed him.

"Grenade!" You heard Maria shout through the coms.

"We have Hulk and Thor on Research level 4!" The intercom said.

You heard Maria engage the pilots to get his attention and get him off the ship. You exchanged a nervous glance with Steve.

Steve suddenly leaped across the chasm, kicking a grenade out of the way. You immediately pointed your pistol downwards and shot at the helmet you saw. It cracked the screen, but didn't hurt him.

Steve knocked the two out, before rejoining you on the raised platform, grabbing one of the dropped guns and shooting back. But neither his bullets nor the enemies hit.

Steve suddenly slipped as the plane starting to fall into a descent. You nearly screamed as there didn't seem to be anything that he could use to get himself back, before catching a wire that was part of the broken part. You knelt, grabbing the other end, hooking your back leg under the railing to hold yourself steady and pulled with all your might.

"Cap hit the lever." Tony's rang in your ears and you met Steve's eyes, yours widening.

"Go!" Steve shouted, though you pulled harder, pulling him in as much as you could.

Once Steve was back on the metal, you let him grab on and start pulling himself back up as you grabbed the red lever. You yelled out, ducking, as gunshots pinged over your head.

"Uh-oh." You heard Tony muttered and then there was harsh metallic sounds that weren't the bullets pinging off around you as he shouted, "Help!"

Gritting your teeth, hearing him groaning, you grabbed the red lever and pulled. It swung downwards easily and you heard Tony yell out. You shot off your own pistol as the guy continued to shoot at you and Steve.

Tony came flying out of nowhere, grabbing the guy around the middle and the two of them went straight through the doorway.

You sighed, heading downwards with Steve following you. Everything had apparently calmed down, until you heard Fury in your earpiece. "Agent Coulson is down."

You didn't stop to hear anymore, rushing past Tony and heading for the main room, Tony shouting your name after you.

Agent Coulson had helped you and Tony through a lot. He was your mentor and your trainer. If he was dead. . .

You could never forgive Loki.

🎃 ::::: 🧡 ━━━━━━━━━━━━━━ 🧡 ::::: 🎃

You paced back and forth while Tony and Steve sat next to each other in the main room. Fury was there was well, standing in front of the two of them.

Thor was gone, Loki having sent him crashing to Earth. There was no read on whether or not he was still alive. Probably though, considering he could fly.

Bruce was gone too, no sign of him either.

Nat was with Clint, who had been taken captive and was locked up in one of the rooms. You guessed that she was probably going to be staying by his side until he woke up. They were soulmates after all, and the separation between the two had been painful.

Maria was standing in the background, her hands behind her back, shaking. She too, had been extremely close to Coulson. In fact, Coulson had been her soulmate, and you felt pity for her.

Surprisingly, Elizabeth was still on the ship. Loki had grazed her with his scepter, so there was a long bloody gash up her side that would probably scar. Fur had already been removed around the area and stitches had been done. Looking at the cameras, she had tried to stop Loki from killing Coulson.

You let out a shuddering breath, waiting for Fury to say something. You felt numb, knowing that your best friend and your mentor were both seriously hurt and dead. And you hadn't been there for either of them. You had gone with Steve and Tony, even though you had known both of them were capable enough to hold their own. Elizabeth and Coulson had needed you more.

"These were in Phil Coulson's jacket." Fury said and you finally looked over to see he was holding some sort of cards. They looked like baseball cards or Pokémon cards, something like that. "I guess he never did get you to sign them."

Fury tossed the cards out, and they scattered along the glass table in front of Steve. You could see now that they were comic book trading cards, all of them were for the Captain America set. You felt tears prick your eyes. Coulson had always been a Cap fan.

"We're dead in the air up here." Fury said as you watched Steve slowly reach forward and see what society had created out of him. "Our communications, the location of the Cube, Banner, Thor, I got nothing for you. I lost my one good eye. Maybe I had that coming."

Fury started to walk along the table as Steve finally dropped the bloody trading card. You knew, however, that Coulson had been stabbed through the back. Even if he had the cards in his front pocket, he would never have gotten them bloody. If they had, they would've been pierced as well.

"Yes, we were going to build an arsenal with the Tesseract. I never put all my chips on that number, though because I was playing something even riskier." Fury was silent for a moment, sliding his hand on the back of one of the chairs. "There was an idea, Stark knows this, called the Avengers Initiative. The idea was to bring together a group of remarkable people to see if they could become something more. To see if they could work together when we needed them to, to fight the battles that we never could."

"Phil Coulson died still believing in that idea. In heroes."

Tony stood up very suddenly, saying nothing. He looked out at everything, looking at you very briefly, before he turned and walked out.

"Well," Fury sighed, "it's an old-fashioned notion."

He walked out then, with Maria following him. It was just you and Steve left.

You wiped your face of tears and approached the table, picking up the playing cards. You looked up at Steve, but he couldn't raise his face from the table. "Old-fashioned is good." You whispered, and then turned and walked out yourself.

#Braveclementineworks#BraveclementineNovels#Novel#Pumpkin#xreader#Phil Coulson#Loki#Elizabeth Lightwood#Nick Fury#Maria Hill#Maria Hill x Phil Coulson#Heroes#Tony Stark#Steve Rogers#Natasha Romanoff#Bruce Banner#Thor#Thor x Bruce Banner#Clint Barton#Natasha Romanoff x Clint Barton#Tony Stark x reader#Tony Stark x Y/N#xY/N#Y/N#marvel!au#soulmate!au#character death

3 notes

·

View notes

Text

Diesel Generator Parts and Functions: Do You Know What They Are?

Diesel generators play an important role in the power generation industry. Their robustness, longevity, versatility and efficiency make them an indispensable power solution. These powerful machines are widely used for a variety of purposes. Diesel-powered generators consist of many technical components which work together to convert mechanical energy into electrical energy. In this article, let’s look at the diesel generator parts and functions.

Diesel engine

The diesel engine is the source of mechanical energy input for generators. The size of the engine corresponds with the amount of electrical energy produced. It means that the larger the engine size, the higher the desired output power. Industrial diesel generators need to be large and powerful because they operate in an industrial environment where power is in high demand. Thus, the engines of industrial generators will be larger than the generators for home use.

Alternator

An alternator is responsible for power output generation. It contains mechanical device and also the rotor. The alternator uses mechanical energy generated by the diesel engine to drive the rotor and create a magnetic field moving around the stator, which causes an alternating current.

Fuel system

The fuel system usually consists of fuel tank, fuel pipe, fuel pump, fuel filter, fuel injector and other components. The fuel tank stores a decent quantity of fuel to power for many hours at a stretch. The size of tank dictates its power generation capabilities in terms of duration. Diesel generator fuel tanks can either be an auxiliary or a tank mounted to the generator. Low noise diesel generators are typically provided as standard with the fuel tanks on the base of the electric generator. The fuel pipe connects the tank to the engine whereas a come back pipe connects the engine to the fuel tank. The fuel pump uses pressure from electric motors to draw fuel from the external tank and inject it into the engine cylinder.

Voltage regulator

The voltage regulator is designed to regulate the voltage output. It is the most complicated component of an electric generator, in a manner of speaking. Voltage regulator acts as the brain of the generator and guarantees that the unit generates electricity at a proper steady voltage. Automatic voltage regulator (AVR) controls the exciter’s input voltage and provides surge protection against electrical surges, spikes and generator overloads.

Cooling system and exhaust system

The cooling system is responsible for preventing the generator from overheating. There are two main types of diesel generator cooling systems: air-cooled and liquid-cooled. The cooling method is often determined by the size and type of generator. Air cooling systems are usually implemented for smaller generators, whereas larger generators require liquid-cooled systems.

As the engine burns fuel, it creates toxic gases that are harmful to human health and/or the environment. The exhaust system is used to safely remove these harmful gases produced during operation. The exhaust system consists of several parts, including the exhaust manifold, muffler, and exhaust pipe.

Lubrication system

The function of the lubrication system includes reducing wear and heat generation by placing a film of lubricating oil between the parts of the engine and removing a portion of the heat generated as a normal part of engine operation. A properly lubricated system allows the diesel generator exceptionally operates smoothly for an extended period.

Air filter

Air filters play a big role in the operation of any diesel generator. Outside air is required for the combustion process of the generator, but the air contains a range of pollen, sand, dust and other additives that affect the machine. Air filters can block all the contaminated particles and only allow clear air to pass through. They can help prevent the generator from reduced efficiency and high fuel consumption.

Battery and battery charger

Diesel generators contain moving parts and require a battery as a trigger to start automatically. Battery failure can cause the generator fails to start. Some generators are also equipped with a battery charger to charge the battery automatically when the generator is operating.

Read also: How to Maintain battery to Avoid Diesel Generator Set Failure?

Control panel

The control panel is user interface that allows you to control the generator, as well as check on system diagnostics, overall functions, and current status of a generator. Additionally, it can offer synchronization for the initiation of parallel operations. With it, you can perform various tasks or verify specific items.

Main assembly frame

The main frame of the assembly of the generator holds everything together and provide the structural support and protection for the internal workings of the generator. Diesel generators can be classified as open-frame or enclosed-frame based on the appearance and structure. The enclosed-frame generator is also known as closed or canopied generator, which are usually housed in a protective enclosure for extra safekeeping and sound attenuation. Weatherproof enclosures offer protection from moisture and extreme temperatures.

Contact Dingbo Power to get the right diesel generator

Dingbo Power is a manufacture of diesel generators. We integrate design, supply, commissioning and maintenance of diesel gensets and provide our customers with quality and affordable products. Our experts with in-depth knowledge will help you find the generator that best meet your needs and budget. Don’t hesitate to reach out for any further information or assistance regarding to power generator solution. Contact us at [email protected], and we will gladly help you.

2 notes

·

View notes

Text

Yes, it's just "boiling water to generate steam and turn a fan". The steam, that has to be superheated. At very specific temperature and pressure, so it has the highest efficiency it can. Demineralized water, which is probably more clean than any other water you can find anywhere else, so it doesn't damage the turbine. The turbine, which blades are precisely designed at specific shape and size to maximize efficiency, while also withstanding the high temperature and pressure of the steam. And then, there's the generator, which must rotate at this exact speed, with very small margin of error, or else it loses synchronism with the power system. The excitation windings, with the DC current flowing in them, which creates the rotating magnetic field, necessary for electromagnetic induction. Since the rotor is (obviously) rotating at high speed, the field current must be supplied via slip rings and brushes. And then there are stator windings, in which the AC voltage is induced. A very high voltage, it may be, for example, 15 kV, although for us in the power industry, it's still merely a medium voltage, because here comes the transformer, which makes it even higher, power system level, 100, 200, 400 kV or sometimes even higher. But before the current reaches the transformer, there's a generator circuit breaker. You know, what circuit breakers are, don't you? Well, this one is huge. It can be vacuum, it can be gas insulated. When it trips, the arc is impressive (although you probably won't see it), as there's a voltage surge, while it's contacts open. Then, there's a transformer and another circuit breaker, which connects it to the high voltage switchgear. Not to mention all the protection systems, that protect it against various failures: overvoltage, fault, loss of synchronism, reverse power, turbine overheating, overpressure etc. and all monitoring and measurement systems, that detect the problem, before it causes serious damage: voltage, current, frequency, temperature, pressure, vibrations, partial discharge etc., and all the control systems for the turbine, generator, excitation system. But ok, it's simpy "boilng water to generate steam and turn a fan".

nuclear power is impressive until you get up to why. "we use the most precisely engineered machinery ever created to split atoms to release energy" oh yeah how come? "boil water to turn a fan" get the fuck out

73K notes

·

View notes

Text

Industrial Oil Filtration Solutions Gallery – Explore Our Projects & Systems

Welcome to the project showcase of OilFilterMachineIndia.com – your trusted partner for advanced industrial oil filtration solutions across India. Our gallery highlights a wide range of systems and technologies we've delivered for clients in the power, manufacturing, and oil processing sectors.

From transformer oil purification systems to high-precision online oil particle counters, explore how we solve real-world industrial challenges with innovative oil purification and filtration technology.

🔧 Featured Systems in Our Gallery

✅ Transformer Oil Purification Systems

View real installations of our transformer oil purification systems, built to restore dielectric strength, remove moisture and gas, and ensure transformer reliability. These are used by power utilities, transformer OEMs, and EPC contractors across India.

✅ Transformer Oil Reclamation Units

Check out our high-efficiency transformer oil reclamation units, engineered to extend the life of insulating oils through vacuum dehydration, degassing, and sludge removal processes.

✅ Hydraulic Oil Filtration Machines

Our gallery features hydraulic oil filtration machines designed for offline and online purification of hydraulic fluids, preventing equipment wear and extending service life.

🛢️ Advanced Oil Purification & Cleaning Systems

We provide fully integrated oil purification systems for transformer, turbine, and gear oils. Each unit is custom-built with multiple filtration stages, vacuum technology, and PLC control for performance and precision.

✅ Turbine Oil Cleaning Systems

Explore our turbine oil cleaning systems that remove varnish, water, and oxidation from turbine oils in power plants and heavy industries.

✅ Gear Oil Filtration Systems

Get a closer look at gear oil filtration systems designed to protect gearboxes and transmission systems from abrasive contaminants.

✅ Oil Filtration & Cleaning Systems

Our oil filtration & cleaning systems offer full-spectrum contamination control for multiple industries including steel, cement, paper, and power.

🔬 High-Precision Monitoring & Impregnation Technology

✅ Online Oil Particle Counters

Discover our advanced online oil particle counters, ideal for real-time contamination monitoring and ISO cleanliness compliance.

✅ Trickle Impregnation Technique

We also showcase the trickle impregnation technique, ideal for motor winding insulation and enhanced coil performance in manufacturing units.

✅ Vacuum Impregnation Plant

See our vacuum impregnation plants in action – used for electrical insulation in transformers, stators, and rotors with complete vacuum drying and resin impregnation capabilities.

🌐 Evacuation System for Transformers

Our gallery also includes installations of evacuation systems for transformers, essential for vacuum drying and degassing before oil filling in transformer manufacturing and servicing.

📞 Need a Custom Oil Filtration System?

Whether you need a turnkey oil purification system, a vacuum impregnation plant, or online oil particle counters, OilFilterMachineIndia.com has the technology and expertise to deliver.

#Industrial Oil Filtration Solutions#Transformer Oil Purification Systems#Hydraulic Oil Filtration Machines#Vacuum Impregnation Plant#Transformer Oil Reclamation Units#Online Oil Particle Counters#Trickle Impregnation Technique#Oil purification system#Turbine Oil Cleaning Systems#Gear Oil Filtration Systems#Oil Filtration & Cleaning Systems#Evacuation System for Transformers

0 notes

Text

Understanding Generator Excitation Systems: A Complete Beginner’s Guide

When it comes to power generation, understanding how the system works behind the scenes is key—especially when it involves the generator excitation process. This essential component plays a pivotal role in controlling voltage and ensuring a stable supply of electricity. Whether you're just entering the field of electrical engineering or simply curious about how generators keep your lights on, this beginner-friendly guide will walk you through everything you need to know.

What Is Generator Excitation?

In simple terms, generator excitation refers to the process of supplying direct current (DC) to the rotor winding of a generator. This creates a magnetic field that is necessary for generating electricity. Without excitation, the generator cannot produce the required electromagnetic field, and thus, no electricity can be generated.

Why Is Excitation Important in Power Generation?

Excitation controls the generator’s output voltage. It helps maintain system stability, regulates power factor, and ensures reactive power support in electrical grids. In the U.S., where power grids are vast and highly interconnected, managing these parameters efficiently is critical to avoiding voltage fluctuations and potential blackouts.

Types of Generator Excitation Systems

There are mainly two categories of generator excitation systems:

Static Excitation Systems These use external power sources like an exciter transformer and rectifier to supply DC to the rotor. Static systems are fast, precise, and often used in large-scale power plants.

Brushless Excitation Systems In this type, the exciter is mounted on the same shaft as the generator. It eliminates the need for brushes and slip rings, reducing maintenance and improving reliability. Many utility-scale generators across the U.S. use brushless systems due to their durability.

How the Excitation Process Works

The excitation system supplies current to the generator’s rotor winding. As the rotor turns inside the stator, its magnetic field induces a voltage across the stator windings. This induced voltage becomes the output of the generator. The more current supplied to the rotor (through excitation), the stronger the magnetic field and the higher the generated voltage.

Automatic Voltage Regulators (AVRs) monitor and adjust this excitation current in real time, ensuring consistent voltage regardless of load changes.

Components of a Generator Excitation System

A standard generator excitation setup typically includes:

Exciter (either brushless or static)

Automatic Voltage Regulator (AVR)

Rectifier (for converting AC to DC)

Control Panel (for monitoring and manual adjustments)

These elements work together to ensure optimal generator performance under varying conditions.

Benefits of a Reliable Excitation System

A well-maintained generator excitation system offers several benefits:

Stable Voltage Output: Maintains consistent power supply across varying loads.

Improved Grid Support: Balances reactive power for stable grid operations.

Enhanced Safety: Reduces the risk of electrical surges or generator failure.

Lower Maintenance: Especially in brushless systems where mechanical wear is minimized.

These advantages make excitation systems an indispensable part of generator operations in the U.S. power infrastructure.

Common Challenges and Troubleshooting Tips

Even robust systems face issues like:

Voltage Instability: Often caused by malfunctioning AVRs or faulty sensors.

Overexcitation or Underexcitation: Can result from incorrect settings or failing components.

Excessive Heat: Usually a symptom of electrical resistance or damaged wiring.

Regular maintenance, including insulation checks and AVR calibration, helps prevent these problems and prolongs system life.

Applications in Real-World Settings

In the United States, generator excitation systems are used across multiple sectors—from power plants and data centers to hospitals and industrial manufacturing facilities. Any place where continuous, stable electricity is critical depends on these systems to keep operations running smoothly.

Final Thoughts

A deeper understanding of generator excitation reveals its crucial role in modern power generation. From managing voltage to stabilizing the grid, this system ensures that electricity is generated efficiently and safely. As the demand for reliable power grows in the U.S., so does the importance of mastering the fundamentals of generator technology. Whether you're an aspiring engineer or facility manager, knowing how excitation works is the first step toward greater electrical control and system reliability.

Contact Info

2500 State Highway 160, Warrior, AL 35180

Phone: 205-590-3505

Email

Map

https://maps.app.goo.gl/c7y7BLamTPvecBqWA

0 notes

Text

Here's how *I* write the robot romance and sex in 2024 (many but not all of these may be pre-existing fandom or sci-fi terms):

"Choose Your Gear" is the (tentative) tag I use for the specific version of robot sex I am currently writing.

Frame/chassis - the bot's whole body and/or body-type

Hook(ing) up - slang-ish term for connecting via wires and/or cables. Not inherently romantic or sexual but can be used for such. The "plug n play"

SCREW, Standard Cybertronian Realtime Electronic Workspace, Cyber Space - the virtual 'space' which may be perceived by bots when they "hook-up" or "go virtual" or "space" together.

Spacing - hanging out together connected and in virtual reality; for many bots implied low situaltional awareness of material world.

Diving - a specific type of hooking up or spacing without rendered cyberspace in which the bot experiences the other's system on a data level.

Spark - the glowing cluster of positrons (in positive universes at least) that is functionally a bot's life(force).

Spark stuff - slang-ish term for romantic or recreational interfacing with sparks.

Attune, attunement, being attuned - when bots are accustomed to each other's presence, spark, or energy field and able to subconsciously recognize each other; not a permanent bond, but considered alike to a temporary bond.

Sparkbond - a (pretty much) permanent entanglement between two or more sparks. Not necessarily sexual or romantic, could be familial or friendship based, but is also typical of sparkmates or conjunxes.

Energy, energy field, EM signature - energies that radiate or spin off of a bot's spark which may be sensed by other bots or beings sensitive to such energies.

Field interaction - the sense of two or more fields colliding and interacting in a shared space. Bots may be more or less sensitive to this and have differing beliefs or abilities with "reading" EM emissions. Some may perceive colors or emotions, while others rarely sense anything.

Field expansion, field contraction - the expansion or contraction of a bot's field in spatial dimensions. Some bots have conscious control over this, while others may not. May also happen unintentionally due to changes in mood, injury, or power level.

Polite distance - the distance at which a bot determines their own field will not interact with that of another bot and thus they are not imposing their energy on another.

Gear or Equipment- slang-ish terms for robot genitalia-analogous parts in general

Form(s) - the specific genitalia-analogous part(s) selected

Interface array - the internal part of the robot body/frame/chassis that is typically covered by a retractable panel and which generates the "gear" of selected "forms" that bots choose to "interface" with. Standard, upgrade, modded, and custom versions can exist, depending somewhat on whether a bot was forged or constructed with one or later had one installed, or changed out their existing array for another model.

CySI, Cybertronian Standard Interface array - A specific and common model of interface array which typically has one convex slot above one concave slot and as many as three alignment nodes.

Interface - in this context, the recreational and non-reproductive interplay of parts

Concave slot(s) - the section(s) of an array capable of generating concave forms, like a stator (clinical), valve, port, slot etc. (confusingly there's "slot" in this sense of expansion slot, but also a specific concave form called a "slot" which bots may wish some other forms or part to enter.)

Calipers - some concave forms may include internal calipers that both sense and may contract against entering parts/forms.

Mesh, valve mesh - (not in this sense mech-flesh) internal woven wire mesh that functions as walls of some concave forms.

Flaps, lips - external parts generating around and with a form, most typical of, but not necessarily exclusive to, the area around concave forms. Available in various shapes and arrangements.

Rollers, wheels, casters, bearings - the tiny rolling parts inside some "analogue" types of concave forms (in place of or instead of a mesh) that mechanically move under traction from entering parts and help in building charge.

Convex slot(s) - the section(s) of an array capable of generating convex forms, like a rotor (clinical), spike, stick, button, etc.

Node, alignment node - part(s) of the array along with any of the concave or convex forms. typically they glow and may have haptic feedback of some sort. Where a bot has more than one, specific nodes may be designated as anterior/posterior, upper/mid/lower, etc.

Compatibility mode - software associated with the interface array hardware that enables a bot to run in an interface mode even more compatible with a specific known and/or scanned alien species, but which may have some minor side-effects as the bot's array attempts to emulate another species organs/parts and approximate their function

Dialing up, Dialing down - a bot changing the overall scale/size of their "gear" to obtain desired fit with a partner significantly larger or smaller. Though bots have a range of sizes proportionate to their frame, there can be physical limits to that range.

Scanning - in this context, scanning another's gear or other organs/parts to obtain measurements to inform fit and compatibility.

Charge - slang-ish for the energy generated through interfacing

Magnetic flux - the differential in magnetic fields that is caused by the movement of metal parts with or within magnetic fields during interfacing. Perceived as pleasurable and energetic.

Chasing the flux - slang-ish way to say working to build charge in order to overload

Overload - generating enough charge, in this context through interfacing, such that circuit capacity is over-loaded. Perceived as high-energy and/or fullness. A bot's systems may attempt to expel excess energy in their overload state, activating systems and abilities to put the energy to use.

Bare metal - 1. slang-ish term for a bot's thinner (non-armor) dermal plating which may or may not actually show their native alloys they were forged/constructed with, often in the sense of scraping or getting down to this layer. 2. A specific brief appearance of liquid metal during the process of generating a form from the interface array. Considered taboo to touch this.

Glossa, sensor nodule - a tongue-analagous part for licking, tasting, or chemically sampling.

Gloss - 1. to speak or understand a meaning 2. to lick in such a way as to shine with oral lubricants

Binomial Data Transfer - a method of transmitting short bursts of data from bot-to-bot via a dedicated port located beneath the base of the sensor nodule in the mouth. Often perceived as a means of transmitting end-of-life or emergency plans in a goodbye kiss.

There's probably more and I didn't cover general body parts or curses, but I need to go do my actual fic writing for the day.

Transformers Fanfic Terms 101

So @novelty-spark was asking about a masterpost for those sorts of things, I thought I’d throw down the terms i’ve used in my seasoned time as a TF fic writer. Shoutout to my bae @guttermech for helping with some of these tooooo

So for those who don’t know there’s actually a ton of strange inner-fandom terms and shorthand that’s used in fanfic/general discussions, and can also be used for tags on art.

First off there’s the different types of TF porn/fic.

Sticky and PnP/Wireplay are the most common, less common is Sparkplay/Sparkbonding There’s also a now-unheard of fourth type called Tactile/EM fieldplay.

Sticky: Sticky is organic-based sexual organs, with organic genitals. Usually it’s a set of a penis/vagina combo, but there’s lots of different versions. One thing is for sure; it’s messy, it’s slippery, and it’s the most common type of TF porn you’ll find.

PnP: Short for Plug-N-Play, it’s also sometimes called wireplay, is the counter to Sticky. It’s more based on the passing of electrical currents and information between two cybertronians to bring pleasure to both parties. The fact that it’s also a common phrase for electronics is a hilarious bonus for when you find that shit in public and can laugh about it.

Sparksex/Sparkplay/Sparkbonding: This is a fairly well recognized but not always utilized form of cybertronian coupling that involves direct interaction between two or more party’s sparks. It’s usually coupled with them becoming bondmates which is a term i’ll cover below in more detail.

Tactile/EMfieldplay: This is from the olden days, I’ve not seen any content made of this forgotten type in years and years, but now’s a good a time as any for a resurgance. EMfield stands for Electromagnetic Field, which is the sensory net that surrounds a cybertronian. Long ago [before time began…] it was very common for fics to include the fields as a form of close-contact, a field that would become meshed with others when cybertronians were near each other. This type of porn was more closely related to foreplay, though climax could easily be reached by the two [or more!] fields interacting. This one’s pretty complex to explain here, but I think I’ve got the gist of it down.

Here’s a list of some terms, not all are inherently sexual but are useful to know for the flow of things/knowing the name of some parts of the anatomy and terms:

Interfacing is sex. It’s just what sex is called, pretty basic.

cable/cord/plug are the words for a robot penis, however a lot of people call them ‘spikes’ too, which is uncomfortable sounding as hell! Let’s normalize cord/cable/plug =u= I’ve also seen

Valve is the term used for a penetrable hole, a vagina or butthole or whateverthefuck, it’s also sometimes called a port.

Anterior/Outer node is a term used for a clitoris, and

Calipers are the internal structure of a valve/port, similar to the muscle structure inside organic holes to clench/cause a milking action.

Overload is what an orgasm is called.

Transfluid is cybertronian ejaculate/jizz. Most artistic renderings have it be glowing like Energon but it can be just about anything you want, I used to write it as silver or different colors, they’re robots, go wild. Glowy jizz or metallic jizz or black inky jizz or just white jizz, who cares! It’s jizz! Have fun!

CNA is sometimes used as a version of DNA, often used for when baby Cybertronians are talked about being made through sexual reproduction. On that note-

Sparklings, are baby cybertronians. Sometimes they’re also called protoforms but more often than not Sparklings is the most accurate way to get it. Protoforms are also a canon material so I don’t know if anyone uses it anymore. I'm not going over different methods of sexual and asexual cybertronian reproduction because that honestly deserves a post all it’s own.

Glossa is what tongues are called, while

Coolant is often used as their version of saliva

servo is used interchangeably for any moving part w/ a joint- legs, arms, fingers, etc [for fingers i would suggest ‘digits’ too ]

Vents are used to describe air flow and to emulate panting/heavy breathing, often used for when a cybertronian starts to get heated and their vents will turn on, expelling hot air.

Pedes are words used instead of 'feet’

Chevron is the shape that’s on many Cybertronian’s heads, [examples: prowl, ratchet]

Headfins are another helmet shape, often described as sensitive or an erogenous zone. [examples: sunstreaker, fort max]

Kibble is the name of anything that is not a vital part of the cybertronian’s anatomy but is needed in order to form their alt mode. Examples include tires, headlights, car doors on arms/back.

Door-wings are pretty self-explanatory, but they are a specific anatomy belonging to the likes of Prowl, Jazz, TFP/Bayverse/RID2015 Bumblebee; they are the doors for their car mode that are perched between the shoulders like wings.

Audials are used instead of 'ears’, while

Finials describe a more protruding shape of 'ears’, such as those on Shockwave, Drift, and Wing.

And as a special added note, here are some Cybertronian curse words often used in fics:

Dross [Damn]

Frag [fuck] fragger, fragging, etc

Scrap [shit]

Slag[aggressive derogatory term, means to call someone scum or garbage]

Feel free to add things! I hope this helps! 8U

1K notes

·

View notes

Text

Understanding the Role of Hollow Shaft Rotary Encoders in Modern Robotics

Introduction to Rotary Encoders in Robotics

Rotary encoders are fundamental components in robotic systems, serving as critical feedback devices that measure the rotation, position, and direction of motor shafts. These sensors translate mechanical motion into electrical signals, which control systems then interpret to ensure precise movement. Among the various types of rotary encoders, hollow shaft rotary encoders have emerged as a key player due to their compact design, ease of integration, and high reliability. As robotics continues to permeate sectors like manufacturing, healthcare, logistics, and consumer electronics, understanding the specific contributions of hollow shaft rotary encoders becomes vital. Their importance lies not only in their functional capabilities but also in how they influence design flexibility and performance optimization in robotic applications. By integrating seamlessly into existing architectures, these encoders reduce mechanical complexity while improving feedback accuracy. This comprehensive examination will explore how these components are revolutionizing modern robotics, from their design advantages to their roles in various robotic subsystems.

Evolution of Rotary Encoders and Robotic Needs

The development of rotary encoders parallels the evolution of robotics itself. Early robotic systems relied on open-loop controls, often leading to inaccuracies and inefficiencies. As the demand for precision and repeatability grew, rotary encoders became indispensable. Initially, these sensors were bulky and susceptible to environmental interference. Over time, however, innovations in materials, signal processing, and miniaturization led to more robust and compact designs. Hollow shaft rotary encoders, in particular, emerged as a response to the need for space-saving yet highly accurate feedback devices. Robotics has evolved from simple pick-and-place machines to complex, autonomous entities requiring precise coordination across multiple axes. This shift necessitated encoders capable of delivering consistent, high-resolution feedback without contributing to design bulk. In mobile robots, surgical devices, and industrial arms, space is a premium commodity. Hollow shaft encoders allow engineers to route cables or mechanical shafts through the encoder's center, optimizing spatial configuration and reducing wear on moving parts. This evolution marks a significant turning point in the interplay between sensor technology and robotic capability.

Anatomy of a Hollow Shaft Rotary Encoder

At its core, a hollow shaft rotary encoder consists of a rotor, stator, and signal processing circuitry housed in a compact unit. What distinguishes it from other encoder types is the central hollow section through which a shaft or cabling can pass. This seemingly simple design offers substantial advantages. The rotor attaches directly to the rotating shaft, while the stator remains fixed to the structure. As the shaft turns, the encoder senses the angular displacement and transmits corresponding electrical signals. These signals may be digital or analog, depending on the encoder type and application. Typically, hollow shaft encoders utilize optical, magnetic, or capacitive technologies to detect movement. Optical encoders, for instance, use a light source and a photo-detector array to interpret interruptions in a coded disc. This method provides high-resolution data, essential for robotic operations requiring micrometer-level precision. Additionally, many hollow shaft encoders incorporate features like integrated bearings, multi-turn tracking, and error correction protocols, ensuring they maintain accuracy even under high-speed or high-vibration conditions.

Integration in Robotic Joint Systems

One of the primary applications of hollow shaft rotary encoders in robotics is within joint systems. Whether in humanoid robots or articulated industrial arms, joint movement must be monitored and controlled with utmost precision. Hollow shaft encoders facilitate this by being mounted directly onto the joint actuators, enabling real-time position feedback. Their hollow design allows power and data cables to pass through the joint axis, reducing external cabling and potential points of failure. This configuration not only enhances the mechanical efficiency of the joint but also simplifies maintenance and design. In collaborative robots, or cobots, where safety and fluid motion are paramount, these encoders help ensure smooth articulation and responsive behavior. They support closed-loop control systems that adjust motor output dynamically based on encoder feedback. This loop is crucial for tasks like pick-and-place operations, precision welding, or surgical manipulations, where even millimeter-level deviations can compromise functionality or safety. By offering a balance of compactness, accuracy, and reliability, hollow shaft rotary encoders are central to robotic articulation systems.

Enhancing Mobility in Autonomous Robots

Autonomous mobile robots (AMRs) require robust sensory systems to navigate complex environments accurately. Hollow shaft rotary encoders play an essential role in this context by providing reliable feedback on wheel or track rotation. Unlike incremental encoders that only track changes in position, absolute feedback systems offer the advantage of positional memory. This becomes crucial in navigation, where knowing the robot's exact orientation at any given time determines path planning and obstacle avoidance efficacy. In differential drive systems, for instance, encoders mounted on each wheel shaft measure relative speeds and directions, allowing for accurate steering and speed control. The compact nature of hollow shaft encoders is especially beneficial in mobile platforms, where every millimeter of space impacts battery size, payload capacity, or sensor load. Their integration also enhances durability since fewer external mechanical parts mean less exposure to dust, moisture, or mechanical wear. This synergy of design efficiency and functional robustness makes hollow shaft encoders indispensable in robotic mobility subsystems.

Role in Precision Tasks and Fine Manipulation

Modern robotics increasingly involves tasks requiring fine motor control, such as electronic assembly, 3D printing, and medical interventions. In these scenarios, the encoder’s resolution and responsiveness directly impact task accuracy. Hollow shaft rotary encoders contribute significantly by enabling micro-adjustments based on real-time positional data. In robotic arms used for electronic manufacturing, for instance, components must be placed with sub-millimeter accuracy. The encoder's feedback ensures that the tool tip follows the programmed path without deviation. Similarly, in 3D printing, layer consistency and nozzle positioning depend heavily on precise rotary feedback. Medical robotics, particularly in minimally invasive surgery, represents another frontier where precision is non-negotiable. Here, hollow shaft encoders are used in tool actuation systems, allowing surgeons to perform complex procedures remotely with high confidence in the robot's positional accuracy. The encoders’ inherent design also aids in sterilization and integration within tight surgical tool assemblies. Thus, their role extends from mechanical feedback to enabling new capabilities in high-precision robotic tasks.

Environmental Robustness and Industrial Viability

Robotic systems often operate in harsh environments—factories, outdoor settings, or hazardous locations. Devices integrated into such systems must exhibit resilience to temperature fluctuations, vibrations, dust, and moisture. Hollow shaft rotary encoders are increasingly engineered with these challenges in mind. Manufacturers offer variants with IP-rated enclosures, corrosion-resistant materials, and sealed optical systems. This robustness allows them to function reliably in automotive assembly lines, mining robots, or agricultural drones. In temperature-controlled warehouse automation, for example, encoders must perform consistently despite frequent exposure to cold or variable humidity levels. The absence of exposed cables and the encoder’s enclosed design minimize contamination risks and mechanical wear. These features contribute to lower maintenance demands and longer operational lifespans, which are critical in high-throughput industrial settings. Moreover, their compatibility with various communication protocols—such as EtherCAT, CANopen, and SSI—ensures that they can be integrated into diverse control architectures without extensive modification. This adaptability further cements their place in modern industrial robotics.

Supporting Safety and Redundancy Mechanisms

Safety is a fundamental concern in robotics, particularly in collaborative or human-facing environments. Encoders play a vital role in ensuring operational safety by providing accurate position feedback for motion verification and error detection. Hollow shaft rotary encoders are especially suited for redundant systems, where multiple sensors verify each other's outputs. This redundancy ensures that if one sensor fails, the system can continue operating safely or shut down in a controlled manner. In safety-rated robotic arms, encoders are often employed in tandem with other sensors to monitor limits and ensure compliance with predefined safety envelopes. Their high resolution and low latency make them ideal for such critical feedback loops. Additionally, their compact form factor allows for integration into secondary safety circuits without adding bulk. The feedback from these encoders also enables soft-limit programming, which prevents actuators from moving beyond safe zones. In service robots or exoskeletons, where human safety is paramount, this encoder-driven feedback becomes essential for real-time decision-making and reactive control.

Future Outlook: Smart Integration and Predictive Maintenance

As robotics evolves towards greater autonomy and intelligence, the role of feedback devices like hollow shaft rotary encoders is also transforming. Modern encoders are increasingly being equipped with smart features such as self-diagnostics, condition monitoring, and real-time data streaming. These capabilities feed into predictive maintenance systems, helping operators detect wear or misalignment before it causes failure. For example, by monitoring signal consistency or rotational anomalies, the encoder can alert the system to potential mechanical issues. This proactive approach reduces downtime and extends the life of robotic assets. Furthermore, as artificial intelligence becomes integral to robotics, encoder data can be used to train machine learning models for movement optimization and adaptive control. Smart encoders also support advanced communication standards that facilitate seamless integration into IoT-enabled infrastructures. This trend indicates a shift from passive sensing to active data contribution, where encoders not only report motion but also enhance system intelligence. Such evolution positions hollow shaft rotary encoders as foundational components in next-generation robotic ecosystems.

Precision Engineering Meets Practical Application

The intersection of precision engineering and practical robotic application is where hollow shaft rotary encoders demonstrate their full potential. As manufacturing tolerances tighten and robotic roles diversify, the demand for encoders that can deliver high-resolution feedback in compact, rugged packages continues to grow. These devices are not only vital for motion tracking but also contribute to reducing system complexity, enhancing safety, and enabling adaptive control. Their utility spans industries and use-cases, from autonomous warehouse robots to robotic-assisted surgery. As designers push the boundaries of what robots can achieve, they increasingly turn to encoders that offer a balance of size, accuracy, and integration flexibility. Among these, the hollow shaft rotary encoder stands out for its ability to combine mechanical elegance with technical performance. Its role in facilitating the compact, precise, and reliable movement is central to the continued advancement of robotics.

Enhancing Control Through Advanced Feedback Systems

In many robotic systems, especially those with complex kinematics, advanced feedback is necessary to synchronize multiple actuators. Here, the absolute rotary encoder proves instrumental. By providing unique position values that do not require recalibration after power loss, these encoders enhance system reliability and responsiveness. This becomes particularly valuable in automated systems that must resume operation immediately after interruptions. Their use simplifies control algorithms and reduces computational overhead, which in turn allows for more fluid and responsive robotic behavior. From industrial automation lines to mobile robotic platforms, absolute encoders bring consistency and predictability, even under dynamic load changes or complex trajectories. When integrated with real-time control loops, they enable smoother transitions, better torque management, and reduced mechanical stress. These benefits contribute to more agile and longer-lasting robotic systems.

Meeting Modern Demands with Cutting-Edge Solutions

The robotic landscape is shifting rapidly, driven by needs for flexibility, scalability, and intelligence. In this context, the absolute position encoder emerges as a critical component, especially in scenarios where exact positioning is non-negotiable. Whether it’s aligning robotic cameras, controlling prosthetic limbs, or managing the angular position of robotic grippers, these encoders deliver the granularity required for high-precision tasks. They also facilitate seamless feedback for AI-driven decisions, particularly in adaptive robotics that interact with unpredictable environments. The encoder's ability to provide exact position data without drift ensures consistent performance across repetitive tasks. In emerging sectors like robotics-as-a-service or modular robotics, where plug-and-play compatibility is essential, these encoders ensure that new modules or replacements can integrate smoothly and function reliably. As expectations for precision, speed, and autonomy grow, so too does the importance of dependable, high-performance feedback systems like the absolute position encoder.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description: An intelligent inline exhaust fan, designed to quietly ventilate hydroponic growth rooms, promote indoor heating/cooling, circulate fresh air, vacuum and AV for cooling cabinets. Includes an EC motor with PWM control for quiet and energy-efficient performance. The inline fan features a mixed flow design with a stator blade and two hydrodynamic wind circles. This makes it possible to provide airflow even in applications with limited airflow. The motor has two ball bearings with 67,000 hours, so that the duct fan unit can be mounted in both directions. The device has protection class IP44, is highly resistant to dust and liquids. Includes mounting material and power supply (2-pole DE 220-240V power plug - type C or F) for connecting the fan installation to a wall socket. This product is part of the UIS platform of Grow-Equipment and Smart Controllers, which can be integrated together to achieve your ideal environment. Intelligent Control: B > The controller can be programmed so that the fan speed can be set for different temperatures and humidity. It can be set due to the backup memory function so that it works continuously or can be activated at an adjustable speed. Other features include a countdown timer, an alarm system and an eco mode. This EC-Smart controller can control and control two inline fans of any size like this Cloudline T6 with an S4. Applications: This quietly discharged fan system is popular in a wide range of applications, including the cooling of AV devices, cabinets, shelves, and cabinets. It is also used in various air circulation and ventilation projects. Designed to ventilate hydroponic grow rooms, transfer heating/cooling, AV cabinet cooling and exhaust gas odors. Dynamic temperature and humidity programming, with timers, growth cycles, planning, minimum speed. Make a remote connection to our Wi-Fi app to access advanced programs, display climate data, and set up automation. Mixed-Flow design combined with a PWM-controlled EC motor for truly quiet and energy-efficient performance. Dimensions: 15.2 cm. Dimensions: 20 x 32 x 21.3 cm. Airflow: 402 CFM. Noise level: 32 dBA. Ball Bearings: Dual Ball [ad_2]

0 notes

Text

How Vibration Motors Work: A Deep Dive into Their Mechanism and Uses

How Vibration Motors Work: A Deep Dive into Their Mechanism and Uses

Vibration motors are an essential component in various industries, providing mechanical vibration for different applications, from industrial machinery to consumer electronics. Whether you need a Vibration Motor Manufactures in india, automotive, or medical applications, understanding how these motors function can help you make an informed choice. In this blog, we’ll break down the working principles, types, and key applications of vibration motors.

Understanding the Mechanism of Vibration Motors

At their core, Vibration motors generate mechanical vibrations by creating an imbalance in a rotating system. The fundamental working principle is based on an unbalanced mass rotating around an axis, which produces centrifugal force and, consequently, vibrations. Let’s dive into the core components that make this possible:

1. Rotor and Stator

When electrical energy is supplied, the rotor begins to spin, generating the required movement.

2. Eccentric Mass

In many vibration motors, an eccentric mass is attached to the rotor. As this mass rotates, it creates an imbalance, which leads to the generation of vibrations.

3. Power Source and Control Mechanism

Vibration motors can be powered by AC or DC sources, depending on the application. Many modern motors come with adjustable settings to control frequency and amplitude.

Types of Vibration Motors

There are various types of vibration motors in India, each suited for different industrial and commercial applications. Here are the most common ones:

1. Eccentric Rotating Mass (ERM) Motors

ERM motors use an unbalanced mass to generate vibrations and are commonly found in mobile phones, industrial equipment, and medical devices.

2. Linear Resonant Actuators (LRA)

These motors use a spring-mounted mass to produce vibrations and offer more precise frequency control, making them ideal for haptic feedback applications.

3. Three-Phase Induction Motors

Used in heavy-duty industries, these motors generate powerful vibrations for industrial applications, including material handling and sorting.

Applications of Vibration Motors

Vibration motors play a crucial role in a wide range of industries. Here are some of their key applications:

1. Industrial Machinery

Many manufacturing units rely on vibration motors in India for processes like material handling, sorting, and sieving.

2. Automotive Sector

Vibration motors are used in seat massagers, touch feedback systems, and alert mechanisms in vehicles.

3. Consumer Electronics

From mobile phones to game controllers, vibration motors enhance user experience through haptic feedback.

4. Medical Devices

In the healthcare sector, vibration motors are used in devices like massagers, diagnostic tools, and patient alert systems.

Choosing the Right Vibration Motor Manufacturer

When selecting a vibration motor in India, it is essential to choose a reliable Manufacturer that offers high-quality products. JK Industries is known as one of the best vibration motor manufacturers in India, providing durable and efficient motors for a variety of applications. With a focus on innovation, precision engineering, and customer satisfaction, JK Industries ensures that their motors deliver consistent performance.

0 notes

Text

Advanced High-Vacuum Transformer Oil Filtration and Dehydration Solutions – ConserveYourOil.com

In industries where transformer performance and equipment longevity are non-negotiable, oil purity is a critical factor. At ConserveYourOil.com, we lead the way as a trusted High-Vacuum Transformer Oil Filtration manufacturer in India, offering innovative solutions that ensure optimal oil quality, extend equipment life, and reduce breakdowns.

🛢 Why High-Vacuum Oil Filtration Matters

Transformer oil acts as both an insulator and coolant. Over time, it absorbs moisture, gases, and particulates that compromise its insulating properties. Our high vacuum oil filter machines remove these impurities efficiently, restoring oil to its original dielectric strength and purity.

Our high vacuum transformer oil filtration and dehydration plants are engineered with precision to meet the demands of power plants, substations, transformer manufacturers, and heavy industries across India and abroad.

🏭 Our Expertise in High-Vacuum Oil Filtration

We are one of the leading high vacuum oil filter machines manufacturers in Pune, with a wide range of capacities and custom-built systems. Our equipment is compact, mobile, and easy to operate – making it ideal for both on-site and in-plant filtration.

Whether you need a mobile transformer oil filtration unit or a complete high-vacuum dehydration system, our machines deliver:

Efficient removal of water, gases, and particulate matter

Enhanced transformer life and performance

Compliance with international quality standards

Reliable operation in diverse environmental conditions

As trusted high vacuum oil filter machines suppliers in Pune, we provide full support from manufacturing to commissioning and after-sales service.

🔧 Vacuum Pressure Impregnation (VPI) & Trickle Impregnating Technology

In addition to filtration systems, ConserveYourOil.com is also a reputed Vacuum Pressure Impregnation Plant manufacturer in India. Our VPI systems are widely used for vacuum sealing electrical components, ensuring improved insulation and reduced operational failures.

We are also recognized as wholesale Pressure Impregnation Plant suppliers for various sectors like electrical, transformer, motor, and coil manufacturing.

Our product portfolio includes:

Vacuum Impregnation Plant

Pressure Impregnation Plants

Batch Type Trickle Impregnating Machines

Varnishing Machines for motor windings and stators

These systems provide superior varnish penetration and curing, enhancing the thermal and electrical strength of your components.

🌐 Why Choose ConserveYourOil.com?

✅ Trusted Manufacturer in India ✅ Advanced Engineering & Custom Solutions ✅ Robust Quality Control & Timely Delivery ✅ Comprehensive After-Sales Support

Whether you are searching for a Vacuum Impregnation Plant manufacturer, Pressure Impregnation Plant supplier, or high vacuum oil filtration plant, we offer technology-backed solutions to meet every industrial need.

#"High-Vacuum Transformer Oil Filtration manufacturer in india#high vaccum oil filter machines#high vaccum oil filter machines manufacturer in pune#high vaccum oil filter machines suppliers in pune#Vacuum Pressure Impregnation Plant manufacturers#Vacuum Impregnation Plant manufacturer#wholesale Pressure Impregnation Plant suppliers#Vacuum Pressure Impregnation Plant#Pressure Impregnation Plant#Vacuum Impregnation Plant#Vacuum Impregnation Plants#Pressure Impregnation Plants#Varnishing Machines#Batch Type Trickle Impregnating Machine#Index Type Trickle Impregnating Machine#Vacuum / Pressure Impregnation Plants Manufacturer Exporter#Supplier#Satara#Vacuum Impregnation Plants manufacturer in pune#Vacuum Impregnation Plants manufacturer in india#vacuum pressure impregnation plant supplier in pune#vacuum pressure impregnation plant supplier in india#vacuum pressure impregnation plant exporter in india#vacuum pressure impregnation plant exporter in pune

0 notes

Text

Hi-Speed Lab Disperser | Advanced High Speed Dispersion Mixers for Laboratory Precision

Explore the superior performance of Phoenix Mixer’s Hi-Speed Lab Disperser. Engineered for R&D and testing, our High speed dispersion mixers ensure efficient lab-scale mixing and dispersion.

Unlock Laboratory Precision with Phoenix Mixer’s Hi-Speed Lab Disperser

In the rapidly evolving world of research and development, the need for reliable and efficient lab equipment has never been greater. Laboratories across industries such as coatings, pharmaceuticals, cosmetics, chemicals, and food processing require precise tools that ensure consistency, speed, and performance in every test. Among these essential tools, the Hi-Speed Lab Disperser has emerged as a game-changer — and Phoenix Mixer leads the way with its high-performance design and user-focused innovation.

What is a Hi-Speed Lab Disperser?

A Hi-Speed Lab Disperser is a laboratory-scale mixing machine designed to disperse, dissolve, and homogenize materials quickly and efficiently. It is especially useful in formulating liquids with solid particles, such as paints, inks, coatings, cosmetics, and chemical slurries. The device operates with a rotor-stator mechanism that generates high shear forces, leading to rapid and uniform mixing.

Phoenix Mixer’s lab disperser stands out by combining advanced technology with compact design, making it ideal for small-batch testing and formulation development.

Why Choose High Speed Dispersion Mixers?