#Supervisory Control And Data Acquisition

Explore tagged Tumblr posts

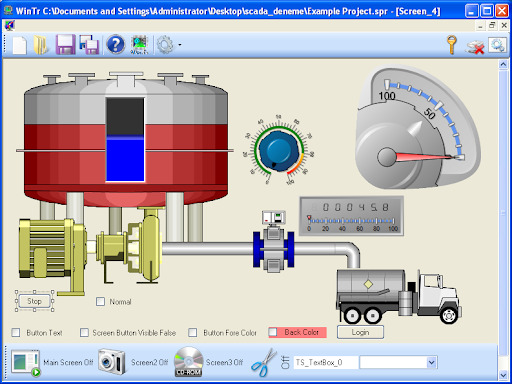

Text

#SCADA#Supervisory Control And Data Acquisition#SCADA software#software#WinTr#industrial#industrial engineering#webcore#old web#techcore#cybercore

8 notes

·

View notes

Text

A SCADA system is composed of interconnected components that work together to monitor and control industrial processes effectively. At its core is the Supervisory Controller, which acts as the central computer, managing data exchanges between Human-Machine Interfaces (HMIs), Programmable Logic Controllers (PLCs), and Remote Terminal Units (RTUs). PLCs are microcomputers that collect and process data from sensors and other input devices, performing critical tasks like performance monitoring, equipment runtime calculations, and generating alarms for anomalies. RTUs, another type of microcomputer, are rugged and wireless, ideal for capturing data from remote locations. The HMI provides operators with a user-friendly interface, visualizing SCADA data through maps, icons, charts, and dashboards for real-time system monitoring. Additional components include Intelligent Electronic Devices (IEDs), which enhance system capabilities, and communication systems that enable data transfer via cables, radio, or the Internet. SCADA systems also rely on programming languages, such as C, to create operational diagrams and process maps, ensuring seamless control and decision-making.

0 notes

Text

Battery-operated Remote Terminal Units Market Research, Size, Share, Analysis, Overview and Regional Outlook Study 2017 – 2032

The market for Remote Terminal Units (RTUs) that are battery-operated allows them to function in isolated or off-grid regions where access to a reliable power supply is restricted. RTUs are electronic devices used to monitor and manage remote equipment and processes in many different industries, such as oil and gas, water and wastewater management, power distribution, and telecommunications. Here is a summary of the market for battery-operated RTUs, including information on demand:

Market Overview: Due to a number of circumstances, the market for battery-operated RTUs has been expanding. The need for battery-operated RTUs has been fueled by the necessity for remote monitoring and control capabilities in various industries, particularly in places with weak power infrastructure. These devices enable efficient monitoring and control of remote assets without the requirement for a continual external power source thanks to their dependable and autonomous operation.

Demand Drivers:

1. Real-time monitoring and control of assets: situated in remote or isolating locations are necessary in many businesses. Without the requirement for a sizable power infrastructure or reliance on cable connections, battery-operated RTUs allow for effective data gathering, monitoring, and control of these assets.

2. Applications Off-Grid: In off-grid applications where access to a dependable power supply is restricted or nonexistent, battery-operated RTUs are widely used. Examples include remote water pumping stations in rural areas, environmental monitoring stations, remote weather monitoring stations, and remote oil and gas wellheads.

3. Emergency and Temporary Installations: Whereas immediate deployment is necessary, battery-powered RTUs are also used in emergency and temporary installations. When catastrophe recovery, building projects, or temporary infrastructure installations are taking place, these machines can instantly provide remote monitoring and control capabilities.

4. Environmental Monitoring: Data collection from remote weather stations, air quality sensors, and water quality sensors are all important aspects of environmental monitoring that battery-operated RTUs play a key role in. Continuous monitoring is made possible in remote or environmentally delicate locations by these equipment.

5. IoT Connectivity: The need for battery-operated RTUs has increased as the Internet of Things (IoT) is becoming more widely used in a variety of businesses. These devices are essential parts of IoT networks because they provide seamless data transmission, communication, and control between remote assets and central management systems.

Here are some of the key benefits for Stakeholders:

Remote Monitoring and Control

Flexibility and Mobility

Cost-Effective Deployment

Resilience to Power Outages

Integration with IoT and Smart Grids

Increased Data Accessibility

Environmental Monitoring and Compliance

Rapid Deployment for Emergency Response

Redundancy and Reliability

Scalability and Future-Proofing

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/battery-operated-remote-terminal-units-market/10333/

Market Segmentations:

Global Battery-operated Remote Terminal Units Market: By Company • SIEMENS • SENECA • Omniflex • King Pigeon Communication Co.,Limited • Servelec Group • TEKBOX • Micro Sensor Co., Ltd. • Hitachi Group • Remsdaq Ltd Global Battery-operated Remote Terminal Units Market: By Type • GPRS • GSM • Modular • Others Global Battery-operated Remote Terminal Units Market: By Application • Power Industry • Government and Utilities • Industrial Global Battery-operated Remote Terminal Units Market: Regional Analysis The regional analysis of the global Battery-operated Remote Terminal Units market provides insights into the market's performance across different regions of the world. The analysis is based on recent and future trends and includes market forecast for the prediction period. The countries covered in the regional analysis of the Battery-operated Remote Terminal Units market report are as follows: North America: The North America region includes the U.S., Canada, and Mexico. The U.S. is the largest market for Battery-operated Remote Terminal Units in this region, followed by Canada and Mexico. The market growth in this region is primarily driven by the presence of key market players and the increasing demand for the product. Europe: The Europe region includes Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe. Germany is the largest market for Battery-operated Remote Terminal Units in this region, followed by the U.K. and France. The market growth in this region is driven by the increasing demand for the product in the automotive and aerospace sectors. Asia-Pacific: TheAsia-Pacific region includes Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, and Rest of Asia-Pacific. China is the largest market for Battery-operated Remote Terminal Units in this region, followed by Japan and India. The market growth in this region is driven by the increasing adoption of the product in various end-use industries, such as automotive, aerospace, and construction. Middle East and Africa: The Middle East and Africa region includes Saudi Arabia, U.A.E, South Africa, Egypt, Israel, and Rest of Middle East and Africa. The market growth in this region is driven by the increasing demand for the product in the aerospace and defense sectors. South America: The South America region includes Argentina, Brazil, and Rest of South America. Brazil is the largest market for Battery-operated Remote Terminal Units in this region, followed by Argentina. The market growth in this region is primarily driven by the increasing demand for the product in the automotive sector.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/battery-operated-remote-terminal-units-market/10333/

Reasons to Purchase Battery-operated Remote Terminal Units Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

In general, market research studies offer companies and organisations useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy formulation, and company planning.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Battery-operated Remote Terminal Units#RTU Market#Remote Monitoring#Wireless RTU#Industrial Automation#Battery-powered RTU#IoT (Internet of Things)#Energy Efficiency#Data Collection#Telemetry#Remote Control#Battery-powered Sensors#SCADA (Supervisory Control and Data Acquisition)#Energy Management#Off-grid Applications#Renewable Energy#Battery Technology#Remote Sensing#Communication Protocols#Edge Computing#Connectivity Solutions#Remote Data Acquisition#Condition Monitoring#Asset Management.

0 notes

Text

PLC, SCADA, and AVEVA: How They Work Together in Automation

PLC :- programmable logic controller

SCADA:- Supervisory Control and Data Acquisition

#automation#trending#tumblr trends#viral#bestdeals#viralpost#trendingnow#PLC#AVEVA#industry#SCADA#scada systems#blog#google#solutions#software#human machine interface#machinery

3 notes

·

View notes

Text

Writing fantasy set in the real world, had to google bed sizes because I can't remember the word for a bed where two people fit. Neither in Finnish or English.

Pommel, crossguard, dead standing tree, supervisory control and data acquisition, and flying buttress I know, but words describing the mundane? Nah.

4 notes

·

View notes

Text

A Comprehensive Guide to Power Systems Protection for Engineers

Introduction:

Power systems protection is a critical aspect of electrical engineering that focuses on safeguarding electrical equipment, personnel, and the power grid from faults, failures, and abnormal operating conditions. This comprehensive guide aims to provide engineers with valuable insights into key principles, techniques, and best practices in power systems protection.

1. Understanding System Operation and Fault Types:

Before delving into protection strategies, it is essential to have a solid understanding of how power systems operates and the various types of faults that can occur. This includes studying system components, such as generators, transformers, transmission lines, circuit breakers, relays, and protective devices. Familiarity with fault types like short circuits, open circuits, ground faults, and transient overvoltages is crucial as a foundation.

2. Principles of Protection Coordination:

Effective power systems protection requires proper coordination among protective devices. Engineers must understand the concept of selectivity to ensure that only the device closest to a fault operates, minimizing disruption to the rest of the system. Proper coordination involves selecting appropriate current settings, time delays, and coordination curves for relays and circuit breakers.

3. Relay Device Fundamentals:

Relays are an integral part of power systems protection, serving as the first line of defense against electrical faults. Engineers should have a thorough knowledge of different relay types, including overcurrent relays, differential relays, distance relays, and directional relays. Understanding their operating principles, features, and limitations aids in choosing the most suitable relays for specific applications.

4. Protective Device Coordination:

Coordinating protective devices within a system is critical to maintaining stability and preventing cascading failures during faults. Engineers must carefully analyze and design protection schemes that consider factors such as fault impedance, fault currents, relay response characteristics, and coordination margins. Advanced techniques like time grading and impedance grading can be employed to achieve optimal coordination.

5. Fault Analysis and System Modeling:

Performing fault analysis and system modeling helps engineers gain insights into power flow, fault currents, voltage profiles, and system stability. Engineers must be proficient in using software tools like ETAP, PSCAD, and DSA Tools to accurately simulate fault scenarios and assess the performance of protection schemes. Detailed knowledge of system modeling techniques enables engineers to make informed decisions regarding relay settings and coordination.

6. Communication-Based Protection:

With the increasing complexity of modern power systems, communication-based protection plays a crucial role in maintaining reliability. Knowledge of communication protocols such as IEC 61850, GOOSE (Generic Object-Oriented Substation Event), and SCADA (Supervisory Control and Data Acquisition) systems is essential for engineers to design and implement advanced protection solutions that utilize real-time data exchange between substations and control centers.

7. Integration of Automation and Control Systems:

Incorporating automation and control systems into power systems protection enhances operational efficiency and reduces response time during faults. Engineers need to understand concepts like remote terminal units (RTUs), programmable logic controllers (PLCs), and human-machine interfaces (HMIs). Familiarity with protocols like Modbus, DNP3 (Distributed Network Protocol), and OPC (OLE for Process Control) enables seamless integration of protection systems with wider control infrastructure.

8. Commissioning, Testing, and Maintenance:

Implementing effective protection strategies requires thorough commissioning, testing, and maintenance procedures. Engineers should be well-versed in practices like primary injection testing, secondary injection testing, relay calibration, fault simulation, and periodic inspections. Adhering to manufacturer guidelines, industry standards, and safety protocols ensures equipment reliability and optimal performance.

9. Access to Resources and Industry Awareness:

Staying connected with organizations like the IEEE (Institute of Electrical and Electronics Engineers) and IET (Institution of Engineering and Technology) is crucial for access to valuable resources. Engineers should actively seek research papers, technical articles, conferences, and networking opportunities. Staying informed about relay technology advancements from prominent manufacturers aids in adopting the latest protection techniques.

10. Software Applications for Enhanced Protection:

Utilizing software applications is vital in power systems protection. Advanced tools like ETAP, PSCAD, and DSA Tools aid in relay coordination analysis, fault simulation, and system modeling. Acquiring proficiency in these common industry software packages enables engineers to design and optimize protection schemes effectively.

11. Compliance with Local National Codes:

Adhering to local national codes and regulations is paramount in power systems protection. Understanding and implementing specific electrical codes and standards relevant to the country of operation is crucial. Compliance ensures safe and reliable system design, installation, and operation aligned with legal requirements and best practices.

Conclusion:

By encompassing the principles, techniques, and best practices discussed in this guide, engineers pursuing careers in power systems protection can develop a strong foundation. Continuous learning, staying updated on industry advancements, and compliance with local national codes will ensure engineers can design, implement, and maintain robust and reliable protection schemes for the power grid and its critical assets.

The Author Biography: Qusi Alqarqaz

Qusi Alqarqaz is an experienced professional in power system protection, specializing in sharing knowledge and guiding young engineers. With a career spanning utility and oil and gas industries in Texas, New Mexico, and Qatar, he has amassed extensive industry experience.

Collaborating with leading manufacturers such as SEL, ABB, Siemens, Schneider, among others, Qusi has gained proficiency in a range of protective relays. He actively pursues continuing education, completing professional development courses with software providers including ETAP and Milsoft, enabling him to utilize advanced tools for power system analysis and protection design.

Qusi's dedication to staying up-to-date with industry advancements led him to pursue additional training. He completed professional development courses at Wisconsin University, equipping him with specialized knowledge crucial for working with high-voltage power systems. He also studied power generation extensively at Strathclyde University in the UK.

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals. Through his posts, he aims to offer guidance and mentorship for young engineers in power system protection. His practical advice and personal experiences will empower the next generation of experts in this field.

Contact the Author:

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals.

Qusi Alqarqaz

9 notes

·

View notes

Text

Fanless Industrial Computer | Rugged, Quiet & Reliable

Looking for a robust, efficient computing solution? ValanoIPC’s Fanless Industrial Computer delivers quiet, rugged performance in a compact, maintenance‑free design. Built for demanding industrial environments, this computer is tailored to power your automation, monitoring, and data‑acquisition applications.

Why Choose a Fanless Industrial Computer?

Zero moving parts – no fans means significantly reduced failure points, enhanced reliability, and zero dust circulation.

Ultra‑quiet operation – perfect for noise‑sensitive environments such as control rooms, laboratories, and classrooms.

Industrial durability – rated for wide temperature ranges and equipped with shock‑ and vibration‑resistant components, it thrives in harsh conditions.

Compact & flexible – easily integrates into industrial racks, wall mounts, or small enclosures with versatile I/O options.

Key Features

Intel® J1900 Quad‑Core Processor Delivers smooth, multi‑threaded performance for typical industrial workloads—SCADA systems, OPC UA servers, PLC communications, kiosk control, and more.

Fanless Embedded Design Fully sealed chassis with no vents, ensuring protection against dust, moisture, and airborne contaminants. Ideal for food processing, packaging plants, factories, and outdoor automation.

Wide Temperature Endurance Operates reliably in extreme conditions (–20 °C to +60 °C standard, extended models up to –40 °C or +70 °C), making it a dependable choice across climates and weather.

Rich I/O Suite Offers multiple USB, COM, HDMI, Ethernet, and GPIO interfaces. Easily connect sensors, cameras, HMIs, and legacy peripherals. Dual LAN configuration supports network redundancy.

Flexible Storage & Expansion Supports mSATA and 2.5″ SSD drives, plus optional internal mini‑PCIe slots for Wi‑Fi, LTE, or additional I/O. Customize your system for edge‑AI, underwater monitoring, or energy solutions.

Ideal Use Cases

Industrial Automation – perfect for PLC supervisory control, data acquisition, and real��time monitoring.

Smart IoT & Edge Computing – smoothly handles local AI inferencing, analytics, and MQTT/CoAP messaging.

Transportation & Surveillance – rugged and compact enough for trains, buses, tunnels, and security systems.

Medical & Laboratory – maintains sterile and quiet environments with silent, fan‑free operation.

Why ValanoIPC?

With decades in industrial computing, ValanoIPC designs reliable products purpose‑built for real‑world endurance. Our Fanless Industrial Computer series is fully configurable, CE/FCC certified, and comes with long‑term support and firmware updates—excellent value for life‑cycle management.

0 notes

Text

Integration of Modern SCADA Systems with Eaton Automation Products

Supervisory Control and Data Acquisition (SCADA) systems are the backbone of modern industrial control, offering centralized monitoring, real-time data access, and precise control over processes. As facilities move toward smarter and more interconnected operations, integrating advanced automation hardware into SCADA systems becomes essential. Technologies like Eaton VFD, Watlow 4FT, Eaton DM1, and Eaton Easy E4 provide the performance, flexibility, and connectivity needed to get the most out of any SCADA system.

Why SCADA Systems Matter

SCADA platforms allow industries to visualize, monitor, and control equipment from a central location. They are used in manufacturing, water treatment, food processing, energy management, and countless other sectors. However, the value of a SCADA system lies not just in the software interface—it also depends on how well the underlying hardware can communicate, respond, and adapt.

That’s where integrating smart devices like Eaton and Watlow automation products makes a difference.

Eaton VFD: Smarter Motor ControlEaton Variable Frequency Drives (VFDs) are essential for precise control of motors in SCADA-connected systems. These drives reduce energy consumption by adjusting motor speeds in real-time based on demand. When integrated into SCADA environments, Eaton VFDs provide live performance feedback, fault alerts, and remote configuration capabilities.

For example, in a SCADA-controlled water treatment plant, Eaton VFDs help modulate pump speeds to maintain ideal pressure levels, saving energy while avoiding overloading the system. Watlow 4FT: Real-Time Temperature Management The Watlow 4FT controller is a high-precision device that can be seamlessly integrated into SCADA platforms to manage thermal processes. It provides advanced temperature feedback, alarm capabilities, and programmable control loops—all accessible remotely through the SCADA interface.

Whether monitoring ovens in a food processing facility or regulating heaters in a chemical plant, the Watlow 4FT ensures temperature-critical processes are tightly controlled and optimized. Eaton DM1: The Intelligent SCADA Link At the heart of many SCADA-connected systems is a reliable PLC, and the Eaton DM1 micro PLC excels in this role. Its Ethernet and Modbus communication capabilities make it a perfect choice for transmitting data to SCADA software while executing real-time control instructions.

The DM1 collects inputs from field devices like sensors and actuators, processes them locally, and shares results with SCADA operators. Its ability to act as both a standalone controller and a communications bridge makes it highly valuable in both new and retrofit automation projects.

Eaton Easy E4: Lightweight Logic with SCADA Visibility

For smaller tasks or subsystems within a larger SCADA network, the Eaton Easy E4 smart relay offers a compact, cost-effective solution. It can control basic functions like lighting, alarms, or single-machine operations while feeding status information back to the central SCADA dashboard.

Its simplicity makes it ideal for applications that don’t require a full-scale PLC but still benefit from visibility and remote access.

Seamless Integration = Smarter Operations

When properly integrated with a SCADA system, Eaton and Watlow products provide:

Real-time performance data

Remote monitoring and configuration

Predictive maintenance capabilities

Reduced energy consumption

Faster response to alarms and operational changes

By combining Eaton VFD, Watlow 4FT, Eaton DM1, and Eaton Easy E4, facilities can unlock the full potential of their SCADA investment—creating smarter, safer, and more efficient operations. Talk to the Experts at Seagate Controls Whether you’re building a SCADA system from the ground up or upgrading an existing network, Seagate Controls can help. Our team specializes in integrating industry-leading hardware with SCADA platforms to deliver full visibility and control over your operation.

��Call us today at 1.800.472.8812 to speak with an automation specialist and get started on a solution tailored to your business.

Source Url : - https://articleindex.net/integration-of-modern-scada-systems-with-eaton-automation-products/

0 notes

Text

Automation and Digital Monitoring in Anaerobic Wastewater Treatment Systems

As the global focus intensifies on sustainability, energy efficiency, and environmental compliance, wastewater treatment technologies are evolving rapidly. One area experiencing transformative advancements is anaerobic wastewater treatment, a process favored for its low energy consumption and biogas generation potential. Traditionally considered complex and operator-dependent, anaerobic systems are now increasingly leveraging automation and digital monitoring to improve reliability, scalability, and performance.

This integration of intelligent technologies is enabling plant operators to maintain optimal biological activity, reduce operational risks, and comply with stringent anaerobic wastewater treatment discharge norms—all while maximizing resource recovery.

Understanding Anaerobic Wastewater Treatment

Anaerobic wastewater treatment is a biological process that breaks down organic matter in the absence of oxygen, producing biogas (primarily methane and carbon dioxide) and treated effluent. It's particularly suited for treating high-strength wastewater from industries such as food and beverage, dairy, pulp and paper, petrochemicals, and pharmaceuticals.

Key Advantages:

Energy efficiency: No aeration is required.

Resource recovery: Generates biogas, which can be used for heating or electricity.

Lower sludge production: Compared to aerobic systems.

Smaller footprint: High-rate systems like UASB (Upflow Anaerobic Sludge Blanket) or EGSB (Expanded Granular Sludge Bed) reactors offer compact solutions.

Despite these benefits, anaerobic wastewater treatment is sensitive to operational conditions such as temperature, pH, hydraulic load, and nutrient balance. Without proper monitoring and control, performance fluctuations and system failures can occur. This is where automation and digital monitoring come in.

The Role of Automation in Anaerobic Wastewater Treatment

1. Real-Time Process Control

Modern anaerobic systems are equipped with Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems that continuously monitor critical process parameters such as:

pH and alkalinity

Temperature

Oxidation-reduction potential (ORP)

Gas composition (CH₄, CO₂, H₂S)

Hydraulic retention time (HRT)

Organic loading rate (OLR)

Real-time feedback allows operators to fine-tune operations instantly. For example, if methane content drops or hydrogen sulfide levels spike, automatic alerts and control actions (e.g., adjusting feed rates or chemical dosing) can prevent system upset.

2. Automated Feed Control

To maintain microbial stability, automated dosing systems are used to regulate influent loading based on preset thresholds. These systems use flow meters, chemical sensors, and predictive analytics to adjust feed volume and composition in real time.

This is particularly valuable in industries where wastewater characteristics can vary throughout the day or week. By automating feed and nutrient dosing, treatment performance remains consistent without operator intervention.

3. Gas Handling Automation

Anaerobic reactors produce biogas as a valuable byproduct. Automation plays a key role in gas flow regulation, pressure monitoring, and flare control. Advanced systems also integrate biogas upgrading units, converting raw gas into pipeline-quality biomethane.

Automation ensures safe, continuous biogas handling—minimizing energy losses and maximizing energy recovery.

Digital Monitoring: Visibility, Insight, and Optimization

Beyond traditional automation, digital tools provide a new layer of intelligence and decision support.

1. IoT Sensors and Cloud Platforms

Internet of Things (IoT)-enabled sensors are now standard in anaerobic wastewater treatment facilities. These wireless devices transmit real-time data to cloud-based platforms, allowing operators and managers to:

Access plant status remotely

Compare multi-site performance

Identify trends and anomalies

Automate data logging and regulatory reporting

Cloud dashboards with visual analytics make it easy to track KPIs like COD removal efficiency, biogas yield, and uptime metrics.

2. Predictive Maintenance

One of the most significant advantages of digital monitoring is predictive maintenance. By analyzing sensor data and equipment performance trends, AI algorithms can anticipate failures in components such as:

Pumps and mixers

Heating systems

Membrane units in AnMBRs

Gas compressors and storage tanks

Early detection of wear or fouling allows for proactive service, reducing costly downtime and extending equipment life.

3. AI-Driven Process Optimization

Machine learning (ML) models can correlate thousands of data points to recommend optimal operating conditions. For instance, they can suggest adjustments in:

Organic loading rate (OLR)

Buffer dosing (e.g., bicarbonate)

Temperature or mixing intensity

This results in higher methane yield, better effluent quality, and lower operating costs over time.

Compliance and Reporting Automation

In many regions, regulatory bodies require detailed operational data from anaerobic treatment systems. Digital solutions now enable automated compliance reporting, including:

Effluent discharge logs (BOD, COD, TSS)

Sludge production volumes

Energy generation and consumption

Maintenance records and incidents

Automating compliance helps facilities avoid penalties, maintain certifications (e.g., ISO 14001), and build stakeholder trust.

Use Cases in Industry

1. Food and Beverage Plants

Facilities handling dairy, beer, or meat waste are increasingly installing smart anaerobic digesters to recover biogas and meet ZLD targets. Automation ensures consistent output despite fluctuating waste loads.

2. Textile and Pulp & Paper

Industries producing complex effluents benefit from advanced control to prevent biomass washout and maintain stable methane production under varying conditions.

3. Municipal WWTPs

Larger cities now integrate AnMBRs and automated digesters in centralized plants to handle sewage with minimal energy input and enhanced sludge stabilization.

Challenges and Considerations

Despite their benefits, automated and digitalized systems face certain barriers:

High upfront costs for smart sensors, SCADA, and cloud integration.

Data overload can be overwhelming without proper analytics.

Cybersecurity risks in connected environments.

Skilled workforce required to interpret and act on insights.

However, as the cost of technology drops and digital literacy improves, these challenges are increasingly being mitigated.

The Road Ahead

The future of anaerobic wastewater treatment is undeniably digital. Advances in AI, IoT, and machine learning are making it possible to operate highly efficient, self-optimizing treatment systems with minimal manual intervention. Furthermore, integration with Enterprise Resource Planning (ERP) and Environmental, Social, and Governance (ESG) frameworks allows for comprehensive sustainability reporting and resource planning.

Expect to see a growing adoption of containerized, AI-managed anaerobic systems in remote areas and developing economies, where infrastructure may be limited but digital networks are expanding.

Conclusion

Automation and digital monitoring are redefining how anaerobic wastewater treatment systems are operated, maintained, and optimized. By enabling real-time control, predictive analytics, and remote visibility, these technologies turn conventional treatment plants into smart, efficient, and sustainable systems. For industries and municipalities aiming to meet environmental goals while reducing costs, the digital transformation of anaerobic treatment offers a compelling path forward.

1 note

·

View note

Text

How SCADA, HMI & PLC work together

SCADA (Supervisory Control and Data Acquisition), HMI (Human-Machine Interface), and PLC (Programmable Logic Controller) work together as key components in industrial automation and control systems.

#automation#trending#tumblr trends#viral#viralpost#trendingnow#bestdeals#rockwell automation#allen bradley#plc#hmi#scadatraining#scada

2 notes

·

View notes

Text

Enhancing Water Network Efficiency in Municipal Supply Systems Using Pressure Reducing Stations

Urban and semi-urban areas rely on extensive water distribution networks to deliver consistent water supply across residential, commercial, and industrial zones. One of the biggest challenges in these networks is managing fluctuating water pressure caused by elevation changes, demand variations, and pumping dynamics. To combat these inconsistencies, Pressure Reducing Valves (PRVs) and complete Pressure Reducing Stations (PRS) have become vital tools for municipalities aiming to enhance network performance, minimize leakage, and optimize supply.

The Problem of High and Unstable Pressure

In municipal water distribution, water is often pumped at high pressure to overcome long distances and elevation gradients. However, this high upstream pressure, if left unregulated, can cause burst pipelines, excessive leakage, and water hammer effects. The situation worsens in low-lying areas or during periods of reduced consumption, when pressure naturally spikes.

Without proper pressure control mechanisms, municipal utilities face higher operating costs, frequent maintenance needs, and increased non-revenue water (NRW)—a significant problem in aging water infrastructures.

Role of Pressure Reducing Stations in Water Distribution

A Pressure Reducing Station (PRS) is a specialized setup designed to control and stabilize water pressure before it enters distribution zones or supply branches. It typically includes:

Pressure Reducing Valves (PRVs)

Bypass lines for maintenance or emergencies

Isolation valves

Strainers and filters

Instrumentation (gauges, transmitters, flow meters)

Flow control or surge protection equipment

These stations are strategically placed across the pipeline network, especially near elevation drops, zone boundaries, or critical supply junctions. By dividing the system into pressure-managed zones, PRSs allow for better control, fewer system failures, and optimized water usage.

Maintaining Consistent Flow and Supply

One of the biggest advantages of PRVs is their ability to maintain a constant downstream pressure, regardless of fluctuations in upstream pressure. This means consumers at various elevations receive consistent water pressure, improving service quality while reducing the risk of pipeline fatigue or bursts.

For instance, in a hilly municipality, PRVs prevent excess pressure from building up in low-lying areas while ensuring adequate flow to elevated neighborhoods. The result is a balanced and equitable water supply that supports both residential and commercial usage.

Reducing Non-Revenue Water (NRW)

Non-Revenue Water—water lost through leaks, theft, or unmetered usage—is a serious concern for municipalities. High-pressure zones are more prone to leakage, as old pipes and joints are not designed for prolonged overpressure. By reducing pressure to optimal levels, PRVs decrease leakage volumes and extend pipeline lifespan.

Studies have shown that even a 10% pressure reduction can result in over 30% reduction in leakage rates. Over time, this leads to cost savings, improved water accountability, and a more sustainable water supply model.

Automation and Remote Monitoring

Modern PRV stations can be equipped with smart controllers and actuators that allow dynamic pressure adjustments based on time of day, demand, or remote operator input. Integration with SCADA (Supervisory Control and Data Acquisition) systems offers real-time monitoring of pressure trends, flow rates, and valve performance.

In case of emergency conditions such as pipeline ruptures or backflow risks, automated stations can respond instantly—closing valves or reducing pressure to protect the system. These automated responses eliminate delays and reduce the risk of large-scale water losses.

Long-Term Reliability and Easy Maintenance

PRVs designed for municipal systems are often pilot-operated, providing precise regulation and smooth operation even under variable flow conditions. Their robust construction, corrosion-resistant bodies, and easily serviceable components ensure years of reliable operation with minimal maintenance.

Periodic inspections, calibration, and flushing keep the stations in top condition—ensuring that the city’s water infrastructure performs optimally despite growing demand and aging assets.

Conclusion

Pressure Reducing Stations are indispensable for modern water supply networks. They do more than manage pressure—they protect infrastructure, reduce water losses, improve service quality, and lay the foundation for smarter, more resilient cities.

By investing in well-designed, automated PRV systems, municipalities not only enhance operational efficiency but also move closer to the goal of sustainable, equitable, and accountable water distribution.

0 notes

Text

Best Industrial Automation Courses in 2025

Introduction

Industrial automation is becoming a vital part of modern manufacturing and production. In 2025, as industries move towards smarter technologies, learning automation skills has become important for students, engineers, and technicians. If you are planning a career in this field, choosing the right course is the first step toward success.

What is Industrial Automation?

Industrial automation involves using machines, control systems, and software to operate processes with minimal human involvement. This includes the use of PLCs (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition), robotics, and sensors. These systems help improve efficiency, safety, and productivity in industries.

Why Learn Industrial Automation in 2025?

In today’s competitive job market, industries are looking for professionals who understand automation systems. Companies are shifting to smart factories and using advanced tools to monitor, control, and improve their operations. Learning industrial automation gives you the skills needed for jobs in manufacturing, production, maintenance, and system design.

Top Course Features to Look For

When choosing an industrial automation courses in 2025, here are the key features to consider:

1. Beginner to Advanced Levels

Look for a course that suits your experience level. Beginners can start with the basics of PLC programming, wiring systems, and sensors. Advanced learners should look for topics like SCADA systems, robotics, and industrial IoT.

2. Hands-on Training

Good courses offer practical sessions using real or simulated automation systems. These labs help you understand how automation works in real-life industrial settings.

3. Industry-Relevant Tools

Make sure the course includes popular software and tools used in the industry such as Siemens TIA Portal, Allen Bradley PLCs, HMI design, and robotic arms.

4. Flexible Learning Options

Courses that are available in online, offline, or hybrid formats are best suited for different learning needs. Online courses are great for self-paced learning, while classroom sessions offer better interaction and direct support.

5. Certifications and Placement Support

Courses that provide a certificate of completion or industry-recognized credentials can help boost your resume. Some institutes also offer placement assistance or internship opportunities.

Who Should Enroll?

Diploma or engineering students interested in electrical, mechanical, or instrumentation fields

Working professionals looking to upgrade their skills

Anyone interested in the future of smart manufacturing

Conclusion

2025 is the perfect time to learn industrial automation as industries continue to evolve with new technologies. Choose a course that matches your learning goals and provides hands-on experience with real-world tools. By gaining the right skills and knowledge, you can build a strong career in the growing field of industrial automation.

0 notes

Text

SCADA Oil & Gas Market Size

The SCADA (Supervisory Control and Data Acquisition) Oil & Gas Market is witnessing significant momentum. In 2024, the market was valued at USD 4,627.76 million

0 notes

Text

Integrated Automation System (IAS) Market, Industry Recent Developments and Latest Technology 2032 | Reports and Insights

The Reports and Insights, a leading market research company, has recently releases report titled “Integrated Automation System (IAS) Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Integrated Automation System (IAS) Market Share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Integrated Automation System (IAS) Market?

The integrated automation system (IAS) market is expected to grow at a CAGR of 5.6% during the forecast period of 2024 to 2032.

What are Integrated Automation System (IAS)?

An Integrated Automation System (IAS) is an advanced technological solution engineered to unify and enhance diverse industrial processes within a single integrated framework. Through the integration of control systems, sensors, actuators, and software applications, IAS enables smooth communication and coordination among various components and subsystems, facilitating efficient monitoring, management, and control of activities such as production, logistics, and quality assurance. With its capacity to consolidate data, offer real-time insights, and automate repetitive tasks, IAS boosts productivity, lowers operational expenses, and enhances overall efficiency across a broad spectrum of industrial operations.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1880

What are the growth prospects and trends in the Integrated Automation System (IAS) industry?

The integrated automation system (IAS) market growth is driven by various factors. The market for Integrated Automation Systems (IAS) is experiencing swift expansion, fueled by the growing demand for efficient industrial automation and streamlined operational workflows. With businesses increasingly prioritizing enhanced productivity and cost-effectiveness, IAS solutions have become indispensable across diverse sectors such as manufacturing, energy, automotive, and healthcare. These systems offer seamless integration of control mechanisms, sensors, and software applications, facilitating optimized production, logistics, and quality control processes. Moreover, the increasing adoption of Industry 4.0 principles and the Internet of Things (IoT) further accelerates the IAS market growth, as organizations acknowledge the benefits of centralized data management, real-time monitoring, and predictive maintenance capabilities provided by these sophisticated automation systems. Hence, all these factors contribute to integrated automation system (IAS) market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Component:

Hardware

Software

Services

Type:

Distributed Control System (DCS)

Programmable Logic Controller (PLC)

Supervisory Control and Data Acquisition (SCADA)

Human Machine Interface (HMI)

Others

Industry Vertical:

Manufacturing

Oil and Gas

Energy and Utilities

Automotive

Aerospace and Defense

Chemicals

Pharmaceutical and Healthcare

Food and Beverage

Others

End User:

Small and Medium Enterprises (SMEs)

Large Enterprises

Application:

Process Automation

Discrete Automation

Connectivity:

Wired

Wireless

Functionality:

Plant Automation

Machine Automation

Deployment:

On-premises

Cloud-based

End-Use:

Industrial

Commercial

Solution:

Control Systems

Robotics

MES (Manufacturing Execution System)

Industrial IoT (Internet of Things)

Others

Service:

Consulting

Integration and Implementation

Maintenance and Support

Industry 4.0 Enabler:

Big Data Analytics

Artificial Intelligence

Industrial Cybersecurity

Cloud Computing

Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

The U.K.

France

Spain

Italy

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

India

Japan

South Korea

Australia

New Zealand

ASEAN

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

United Arab Emirates

South Africa

Egypt

Israel

Rest of MEA.

Who are the key players operating in the industry?

The report covers the major market players including:

Siemens AG

Schneider Electric SE

Emerson Electric Co.

Honeywell International Inc.

Rockwell Automation Inc.

Mitsubishi Electric Corporation

Yokogawa Electric Corporation

Omron Corporation

Bosch Rexroth AG

General Electric Company

Johnson Controls International plc

Fanuc Corporation

Schneider Electric SE

Hitachi Ltd.

View Full Report: https://www.reportsandinsights.com/report/Integrated Automation System (IAS)-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

0 notes