#Temperature Controlled Meat Storage

Explore tagged Tumblr posts

Text

Cold Storage Structure: Essential Infrastructure for Seafood and Meat Industry

In the seafood and meat industry, maintaining freshness and preventing contamination are non-negotiable. A reliable cold storage structure ensures that products like fish, poultry, beef, and frozen seafood are stored at optimal temperatures from the point of harvest to the final sale. Without such infrastructure, spoilage and foodborne illnesses could compromise both safety and business credibility.

Seafood and meat are among the most perishable food items, highly sensitive to time and temperature changes. A cold storage structure provides a controlled environment that maintains low temperatures—typically between -18°C to -25°C for frozen items—to inhibit bacterial growth and preserve texture, flavor, and nutritional value.

Processing units, exporters, wholesalers, and large-scale retailers rely on these storage facilities to comply with food safety regulations and meet international quality standards. Whether it's a blast freezer room for rapid chilling or long-term frozen storage units, the structure must be designed to withstand continuous operation and ensure hygienic conditions.

Additionally, modern cold storage structures in this sector now include features like stainless steel interiors for easy cleaning, automated defrost systems, smart temperature alarms, and energy-efficient compressors. These upgrades help businesses reduce operational costs while improving food preservation standards.

In coastal and port-based regions, cold storage facilities also serve as a critical part of the export supply chain—ensuring seafood is safely stored before shipment. With growing demand for frozen meats and ready-to-cook products, the industry is witnessing an increasing need for decentralized, modular cold storage solutions that can be quickly installed near fishing hubs and processing zones.

Ultimately, a cold storage structure is not just about freezing—it’s about preserving quality, meeting health regulations, and ensuring customer satisfaction in a highly sensitive and competitive market.

#Cold Storage for Seafood#Meat Storage Structure#Frozen Food Storage#Cold Chain for Meat Industry#Temperature Controlled Meat Storage

0 notes

Text

Top Benefits of Investing in High-Quality Supermarket and Kitchen Equipment | Global Automation Ltd

Discover the advantages of investing in premium supermarket and kitchen equipment from Global Automation Ltd. Enhance operational efficiency, ensure durability, and improve customer satisfaction with our top-tier products designed for long-term success in the food industry.

#Global Automation Ltd#Premium Kitchen Equipment#Supermarket Equipment Supplier#Commercial Kitchen Appliances#Warehouse Storage Solutions#Durable Food Industry Equipment#Supermarket Equipment in Bangladesh#Retail Store Equipment#Supermarket Shelving and Racks#Commercial Refrigeration Units#Supermarket Checkout Counters#Cold Storage Solutions#Industrial Refrigeration#Cold Storage Bangladesh#Temperature Control Systems#Cold Chain Logistics#Industrial Storage Systems#Warehouse Automation#Storage Racks Bangladesh#Warehouse Management#Food Processing Equipment#Industrial Food Machinery#Food Processing Solutions#Food Production Equipment#Processing Machinery Bangladesh#Meat Processing Equipment#Industrial Meat Machinery#Meat Processing Solutions#Meat Production Equipment#Slaughterhouse Solutions

0 notes

Note

Hey peach I know you said no lawyer stuff but can you explain the most recent post thank you bless

Mmmkay so basically, in the US, most of our day to day lives are controlled by federal agencies. Basically there’s an agency in charge of everything you can think of, but some major ones include the EPA, the FDA, USDA, Transportation, etc. that’s just some of them.

The people who head these agencies/work at them are largely considered industry experts — so you have environmental scientists at the EPA, engineers at Transportation, food and drug safety experts at the FDA, etc. etc.

These agencies, however, are created by the Executive or Congress (depending on whether it’s an executive agency or independent agency). Once the agency is created, Congress will then pass laws that speak to the agency’s authority, but more importantly, they’ll pass laws that fall within that particular agency’s expertise. So for example, there’s a limit on, say, the level of emissions a car can produce into the air. Congress passes that.

The problem (but not in a bad way) is that Congress is not made of experts in these industries — they’re politicians. So they don’t necessarily have the facilities to legislate as exact as they might like to, or the knowledge to make well informed legislative decisions.

Now, while Congress passes laws, agencies draft and pass regulations that enact those laws. The point of the regulations are to be specific and to conform to legislative intent as much as possible. These regulations are what actually affect your day to day life. So, for example, the FDA will enact regulations controlling food storage temperatures during transit that are specified to the kind of food that’s being shipped — think meat versus produce.

Obviously there are times where Congress isn’t exactly clear on the extent of an agency’s authority to enact those regulations — which opens them up to legal challenges. This is where Chevron comes in.

The Chevron doctrine is based on a Supreme Court case that basically said, when Congress’s language in a given regulatory/admin statute is ambiguous, courts will defer to the agency’s interpretation of that language since *they* are the experts. This made sense because, again, Congress is not made of experts and they also feasibly can’t think of every possible little thing that might come up/need definition/even understand what parameters need to be set. This was good — ideally, experts are acting in the interest of the field and not lobbyists (though don’t get me wrong — lobbying federal agencies is a lucrative business). But simply put, you *want* experts deciding what level of lead exposure is safe, or the amount of pollution being discharged. You don’t want Congress doing that.

But today’s decision overruled Chevron explicitly — meaning, deference to agencies is no longer the rule. Now, Congress will be expected to either legislate the crap out of things they already don’t know how to legislate for OR else leave the agencies unable to effectively regulate.

It’s a terrible decision (never mind the utter disregard this Court exhibits for stare decisis) but it’s one that WILL have very direct consequences on our daily lives.

Voting in November is important. I don’t like Biden, personally, but there is so much at stake in this election that we can’t afford not to vote for him at this point.

47 notes

·

View notes

Text

Cold Rooms - Cold Storage Latest Price, Manufacturers & Suppliers | Acmas Technologies

Cold Room and Cold Storage solutions have become indispensable. From farm-fresh produce and frozen meats to vaccines and life-saving drugs, cold storage infrastructure ensures that products maintain their quality, potency, and shelf life throughout the supply chain.

At Acmas Technologies, we specialize in designing, manufacturing, and supplying advanced Cold Room Solutions for a wide range of industries. With a strong focus on innovation, energy efficiency, and customization, we deliver Cold Room Systems that match the diverse needs of food processors, pharmaceutical companies, logistics providers, and industrial clients.

This comprehensive blog explores everything you need to know about cold rooms—from types and working principles to their applications and benefits. We also highlight why Acmas Technologies is the preferred Cold Room Manufacturer and Cold Storage Manufacturer in India.

What is a Cold Room?

A Cold Room is a temperature-controlled environment used for the storage of temperature-sensitive products. It maintains specific temperatures—ranging from chilled (0°C to 10°C) to deep-frozen (-18°C to -40°C)—to prevent spoilage and ensure product integrity.

Modern Cold Storage Rooms are engineered with high-efficiency insulation panels, energy-saving refrigeration systems, humidity controls, and monitoring devices to maintain precise conditions. These rooms are crucial in maintaining the cold chain, especially in sectors like food processing, pharmaceuticals, horticulture, and logistics.

Types of Cold Rooms and Cold Storage Solutions

At Acmas Technologies, we offer a broad range of Cold Room Solutions tailored to customer requirements. Our designs support various scales, product types, and regulatory needs.

Walk-In Cold Room: A Walk-In Cold Room is ideal for commercial kitchens, hotels, laboratories, and small-scale storage needs. These rooms provide easy access for personnel and typically operate in temperature ranges between 0°C to 8°C for short-term storage of perishables.

Features:

Easy to install and relocate

Hygienic interiors with food-grade finishes

Ideal for daily-use products

Modular Cold Room

Modular Cold Rooms are made of prefabricated insulated panels and can be assembled in any size or layout. They are widely used in retail outlets, distribution centers, and processing units.

Advantages:

Scalability and flexibility in design

Fast installation and commissioning

Suitable for diverse temperature zones

Blast Freezer Room

A Blast Freezer Room rapidly brings down the temperature of products from ambient to freezing levels. This is vital for preserving the cellular structure and taste of products like seafood, meat, and bakery items.

Key Benefits:

Ultra-fast freezing cycles

Ensures minimal bacterial growth

Ideal for food exports and long-term preservation

Industrial Cold Storage: Large-scale Industrial Cold Storage facilities serve food processing plants, pharmaceuticals, and agricultural producers. These systems are designed for bulk storage with multi-temperature compartments, remote monitoring, and efficient power consumption.

Highlights:

Capacity from 10 MT to 10,000 MT+

Advanced refrigeration and automation

Heavy-duty racking and loading bays

Custom Cold Rooms: Every industry has unique needs. Our Custom Cold Rooms are tailored for niche applications like blood storage, vaccine preservation, seed germination, and climate testing.

We offer:

Customized dimensions and door configurations

Integrated HVAC and humidity controls

IoT-enabled monitoring for compliance

Cold Storage for Food Industry

The Cold Storage for Food Industry plays a vital role in reducing post-harvest losses and meeting consumer demand for safe, fresh, and high-quality food products. We serve a wide range of food sectors:

Dairy Products: Milk, cheese, butter

Fruits & Vegetables: Controlled humidity and ethylene control

Meat & Poultry: Blast freezing and deep-freeze storage

Seafood: -25°C to -40°C environments

Frozen Foods: Ready-to-eat, bakery, and processed meals

Proper cold storage reduces spoilage, maintains nutrition, and ensures regulatory compliance for food exports and retail.

Cold Storage for Pharmaceuticals

Pharmaceutical companies require ultra-reliable cold storage to maintain drug efficacy and ensure patient safety. Our Cold Storage for Pharmaceuticals meets stringent norms like WHO-GMP, FDA, and GDP.

We provide:

Temperature Mapping for uniform cooling

Redundant cooling systems to avoid failures

Data loggers and alarms for 24x7 monitoring

Cold storage for vaccines, blood, reagents, and insulin

These solutions are ideal for hospitals, diagnostic labs, biotech firms, and vaccine logistics.

Cold Chain Solutions for Every Industry

From raw material storage to distribution hubs, a reliable Cold Chain Solution is critical. At Acmas Technologies, we offer end-to-end systems that include:

Pre-cooling chambers

Refrigerated transport integration

Mobile cold rooms for last-mile delivery

Energy-efficient refrigerant systems

Remote performance monitoring

Our aim is to support businesses in creating sustainable and uninterrupted cold chains that protect product quality at every stage.

Components of a Cold Storage System

An efficient Cold Storage System is more than just insulation and cooling. Our turnkey systems are engineered with high-performance components:

PUF Insulated Panels: Superior thermal efficiency

Condensing Units: Scroll, reciprocating, or screw compressors

Evaporator Units: Designed for specific load and humidity

Digital Controllers: Easy programming and alertsBackup Generators: For uninterrupted operation

Racks & Shelving: To optimize internal space

We customize each system to match your operational needs, climate conditions, and budget.

Factors Affecting Cold Storage Latest Price

When evaluating the Cold Storage Latest Price, several variables come into play:

Size & Capacity – Larger rooms cost more but offer economies of scale

Temperature Range – Ultra-low temperature systems require robust components

Customization Level – Special doors, lighting, flooring, etc., affect cost

Automation & Monitoring – Smart systems offer better control at a higher upfront cost

Installation Site – Indoor, outdoor, or rooftop installations vary in complexity

At Acmas Technologies, we ensure transparent pricing with no hidden costs and deliver value-engineered solutions that align with your goals.

Why Choose Acmas Technologies?

As a leading Cold Room Manufacturer and Cold Storage Manufacturer, Acmas Technologies brings years of experience, deep technical expertise, and an unwavering focus on quality. Here’s why we are the preferred partner for cold storage projects:

ISO & CE Certified Manufacturing Facility

Expert Team of Engineers & Designers

Energy-Efficient and Eco-Friendly Designs

Rapid Installation & Commissioning

Comprehensive AMC & Support Services

Nationwide Reach with Global Exports

We serve clients across industries including food, pharma, hospitality, logistics, agriculture, and research.

Future of Cold Storage: Technology & Sustainability

The future of Cold Room Solutions is centered on sustainability, automation, and smart connectivity. At Acmas Technologies, we are investing in:

IoT-enabled cold rooms for remote monitoring

Renewable energy integration (solar-powered cold rooms)

Eco-friendly refrigerants like R-290, CO2

AI-based energy optimization systems

These innovations help businesses reduce operational costs while maintaining stringent storage requirements.

Whether you're preserving perishables, extending product shelf life, or maintaining the efficacy of life-saving drugs, Cold Room and Cold Storage solutions are integral to modern industry. From modular walk-ins to large-scale industrial cold storage, Acmas Technologies provides advanced and customizable solutions designed to deliver performance, efficiency, and compliance.

With our proven expertise as a Cold Room Manufacturer, Cold Storage Manufacturer, and complete solution provider, we ensure that your cold chain remains strong, efficient, and reliable.

Ready to invest in a world-class Cold Storage Room or Custom Cold Room Solution? Contact Acmas Technologies today for expert consultation, latest pricing, and tailor-made cold storage systems designed for your industry.

For more info: https://www.acmasindia.co.in/

Email ID: [email protected]

Phone: 8069186503

Location: Plot No. 126, Sector-56 Phase- IV Kundli, Sonepat, Haryana-131028

#Cold Room#Cold Storage#Cold Room Manufacturer#Cold Storage Manufacturer#Cold Room Solutions#Cold Storage Room#Walk-In Cold Room#Modular Cold Room#Cold Storage for Food Industry#Cold Storage for Pharmaceuticals#Cold Storage System#Custom Cold Rooms#Blast Freezer Room#Industrial Cold Storage#Cold Chain Solutions

2 notes

·

View notes

Text

The Best Types of Commercial Fridges for Different Food Businesses

When running a food business, whether it’s a bustling restaurant, café, or grocery store, investing in the right commercial fridge is essential. Proper refrigeration ensures food remains fresh, safe, and accessible, directly impacting efficiency and food quality. With numerous commercial fridge options available, choosing the most suitable one for your business is crucial.

In this guide, we’ll explore the best types of commercial fridges for different food businesses and provide insights into selecting the right one for your needs.

1. Upright Fridges

Best for: Restaurants, cafés, and small food stores with limited storage space. Upright fridges feature a vertical layout with multiple shelves, allowing for efficient organization and storage. They are ideal for businesses that need to refrigerate a broad range of products, including fresh produce, dairy, meat, and beverages.

Why choose upright fridges?

Space Efficiency: Maximizes vertical storage while conserving floor space.

Easy Accessibility: Shelves are designed for quick access to ingredients during busy hours.

Versatile Sizing: Available in various sizes to fit different kitchen spaces.

2. Under-Bench Fridges

Best for: Small cafés, takeaways, and kitchens with limited space. Under-bench fridges are compact, fitting neatly under countertops for quick access to frequently used ingredients like sauces, dairy, and prepared items.

Why use under-bench fridges?

Space-Saving Design: Fits seamlessly under counters, optimizing kitchen space.

Boosts Workflow: Enables staff to access ingredients quickly without disrupting operations.

Multiple Configurations: Available in single-door and larger models to accommodate various needs.

3. Glass Door Fridges

Best for: Supermarkets, delis, cafés, and buffets. These fridges feature transparent glass doors for easy product visibility, making them ideal for displaying beverages, salads, desserts, and pre-packaged foods.

Why consider glass door fridges?

Enhanced Visibility: Customers and staff can easily see available products, boosting sales.

Energy Efficiency: Modern designs feature energy-saving technology, reducing operational costs.

Customer Engagement: Ideal for showcasing chilled beverages and fresh food items.

4. Chest Freezers

Best for: Restaurants, butchers, supermarkets, and ice cream parlors. Designed for bulk storage, chest freezers provide deep, horizontal storage space, making them ideal for frozen foods like meat, fish, and vegetables.

Why use chest freezers?

Large Capacity: Ample space for bulk storage and seasonal stock.

Superior Freezing Efficiency: Maintains low temperatures for long-term preservation.

Cost-Effective: More energy-efficient than upright freezers, lowering operating expenses.

5. Display Fridges

Best for: Takeaways, sandwich shops, and cafés. Designed for customer-facing environments, display fridges feature open or glass-front designs for easy product access and visibility.

Why opt for display fridges?

Encourages Impulse Buying: A visually appealing display attracts customers.

Quick Access: Customers can grab items conveniently without waiting.

Temperature Control: Advanced cooling systems maintain food safety.

6. Prep Fridges

Best for: Fast food outlets, sandwich shops, and salad bars. These fridges combine refrigeration with a prep station, offering quick access to fresh ingredients for efficient meal preparation.

Why use prep fridges?

Streamlined Workflow: Keeps ingredients within arm’s reach for faster service.

Organized Storage: Features trays and compartments for neat ingredient separation.

Space-Efficient: Combines storage and prep area into one unit. Read Full Article

2 notes

·

View notes

Text

Is the Flake Ice Maker Still Relevant in 2025?

A Closer Look at Evolving Cold Chain Needs

In the ever-evolving landscape of food processing, preservation, and distribution, technology is moving at lightning speed. From AI-driven logistics to automated packaging systems, every part of the supply chain is being reimagined for better efficiency, sustainability, and product quality. But there’s one tool that many industries are still relying on—the flake ice maker.

So, the question arises: Is the flake ice maker still relevant in 2025?

Let’s explore how modern cold chain demands are shifting—and whether this once-reliable cooling method is still holding up against more advanced technologies.

The Role of Ice in Industrial Food Processing

Before we dive into what's changing, it's worth understanding why ice remains so vital in industries like seafood processing, meat packing, produce handling, poultry, and even industrial baking.

In these sectors, temperature control is non-negotiable. From preserving texture and freshness to ensuring food safety and shelf life, ice is often the first line of defence. Traditionally, flake ice has been the go-to solution—providing a fast and effective way to chill products during storage, transport, or processing.

But in 2025, is “effective” still good enough?

The Flake Ice Maker: Time-Tested but Time-Limited?

Flake ice makers work by freezing a thin layer of water on a drum or cylinder, then scraping it off to produce dry, sharp-edged ice flakes. These flakes are relatively easy to handle and spread over products, making them suitable for quick surface cooling.

However, today’s cold chain requires more than just surface cooling. With heightened concerns about food integrity, energy efficiency, automation, and environmental sustainability, many processors are finding the limitations of flake ice hard to ignore.

Evolving Cold Chain Needs in 2025

As industry demands become more sophisticated, cold chain technology must follow suit. Here’s how the expectations have shifted:

✅ Faster Cooling with Greater Precision

In sectors like seafood and poultry, internal product temperature matters just as much as external chill. Traditional flake ice sits on the surface and often leaves pockets of air and heat, resulting in uneven cooling. Newer technologies—like slurry ice systems—deliver rapid, uniform cooling by enveloping products completely, reaching even the hard-to-access zones.

✅ Gentler Handling

Flake ice is inherently jagged, which means it can cause bruising or physical damage—particularly in delicate items like fillets, leafy greens, or soft fruits. This not only affects appearance but also invites microbial growth. Modern systems using micro-crystalline or slurry ice provide a gentler alternative, reducing waste and maintaining product integrity.

✅ Reduced Labour & Higher Automation

With the rise of smart factories and automated processing lines, systems that require minimal manual handling are preferred. Flake ice often needs shovelling, blowing, or conveyor systems—adding complexity and cost. In contrast, automated slurry systems integrate smoothly into existing operations and reduce labour requirements.

✅ Sustainable and Scalable

Energy efficiency and sustainability are no longer buzzwords—they’re mandates. The high energy demand of some flake ice makers, combined with the need for constant manual distribution, makes them less appealing. Meanwhile, modular cooling systems using environmentally friendly refrigerants and corrosion-resistant components are being adopted to meet carbon targets and support long-term scalability.

What Industries Are Saying

Processors in Canada and around the globe are beginning to question the long-term viability of their current ice systems. Those in export-driven seafood markets are upgrading to meet international cold chain standards. Meat and poultry plants are under pressure to reduce cross-contamination risks, and bakeries are seeing benefits in more precise dough temperature management with new technologies.

All signs point to a shift: while the flake ice maker may still serve a purpose, it is quickly being outpaced by more innovative, efficient, and adaptable solutions.

Making the Shift: Is It Time to Upgrade?

If your operation is still relying on a flake ice maker, it’s worth asking:

Are you experiencing bottlenecks in your cooling process?

Is bruising or ice-burn affecting your product quality?

Are you seeking more automation or scalability in your facility?

Are energy and labour costs becoming unsustainable?

If you answered yes to any of these, it may be time to explore a system that meets 2025’s cold chain demands head-on.

Future-Proof Your Cooling System

At Deepchill Solutions Inc., we specialise in advanced slurry ice systems that address the limitations of traditional flake ice makers—while providing the flexibility and precision today’s industries need. Our modular, automated, and energy-efficient systems are already helping businesses across seafood, meat, poultry, produce, and baking industries improve their bottom line.

Don’t let outdated technology slow you down. Future-proof your cold chain today with Deepchill®.

📞 Call us at (905) 856-0400 to learn how we can help transform your cooling process.

#flake ice maker#cold chain technology#food processing industry#seafood processing#meat processing#poultry industry#industrial refrigeration#slurry ice#food tech 2025#Deepchill Solutions

1 note

·

View note

Text

From Plastic to Plant-Based: The Frozen Food Packaging Shift You Didn’t See Coming

Frozen Food Packaging Market Introduction:

The frozen food packaging market industry is undergoing a profound transformation, driven by technological innovation, evolving consumer behaviors, and regulatory pressure for sustainable solutions. With the frozen food packaging market poised to exceed USD 79.2 billion by 2032, stakeholders must align with emergent trends, embrace cutting-edge materials, and position themselves to thrive in a landscape increasingly shaped by eco-conscious demand and intelligent packaging.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40599-global-frozen-food-packaging-market-trends

📈 Market Growth Trajectory: Trends Shaping the Frozen Food Packaging Sector

We anticipate a steady CAGR of over 5.9% through 2032, propelled by an upsurge in demand for ready-to-eat meals, convenience-oriented lifestyles, and the evolution of sustainable packaging technologies. This growth is underpinned by several macro and microeconomic forces:

Urbanization and Dual-Income Households: Higher time constraints are fostering dependence on frozen food solutions.

Technology-Driven Packaging: Innovations in smart packaging such as time-temperature indicators and modified atmosphere packaging (MAP) are setting new quality benchmarks.

Global Sustainability Mandates: Regulatory frameworks and environmental awareness are fueling the shift toward recyclable and compostable materials.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40599-global-frozen-food-packaging-market-trends

🛠️ Material Innovation in Packaging: Dominance, Disruption, and Direction

Plastic Packaging: Efficiency Meets Environmental Scrutiny

Plastic remains the cornerstone of frozen food packaging due to its flexibility, moisture resistance, and cost-effectiveness. Representing 63% of market share in 2023, the segment is evolving through the integration of bio-based polymers, mono-material films, and closed-loop recycling systems.

However, environmental pressure is catalyzing the adoption of low-impact alternatives:

Polylactic Acid (PLA)

Polyhydroxyalkanoates (PHA)

Recyclable Polyethylene (rPE)

Paper & Paperboard: Recyclable and Renewable

Emerging as a viable substitute to plastics, paper-based materials are gaining favor in applications like tray linings, cartons, and wraps—particularly when paired with biopolymer coatings that enhance barrier properties without sacrificing recyclability.

🍽️ Product Segmentation: Custom Packaging Solutions for Diversified Categories

Ready-to-Eat Meals: Packaging for Speed and Shelf Stability

Comprising 39.2% of the frozen food packaging market in 2023, this segment continues its upward trajectory. The packaging solutions here demand:

High barrier properties to retain flavor and freshness

Microwave-safe formats

Portion-controlled trays

Meat, Poultry & Seafood: Insulation and Integrity

These high-protein, perishable goods require advanced materials with anti-leak features, odor barriers, and puncture resistance, along with vacuum-sealed and skin pack options to extend freshness.

Bakery, Dairy, Fruits & Vegetables: Freshness Lock and Visual Appeal

Resealable pouches, gusseted bags, and printed films dominate here, balancing product visibility with functional features like moisture barriers, anti-fog coatings, and nitrogen flushing.

📦 Packaging Types: The Era of Flexibility and Functionality

Flexible Packaging: Lightweight, Low-Cost, and Logistics-Friendly

Holding a commanding 59% share, flexible packaging supports streamlined transportation and storage, while minimizing material usage. Innovations include:

Stand-up pouches

Laminated films

Vacuum bags with oxygen scavengers

Rigid & Semi-Rigid Formats: Premium Presentation with Protection

Rigid containers, often made from polypropylene or PET, are preferred for premium products requiring structural support. Semi-rigid solutions bridge cost and functionality, offering stackability and enhanced sealing performance.

🌍 Regional Leadership: Frozen Food Packaging Market Penetration by Geography

North America: Innovation and Infrastructure

Accounting for 38% of global share in 2023, North America remains a powerhouse due to:

Established cold chain logistics

High per-capita frozen food consumption

Retail giants like Walmart and Kroger expanding private label offerings

Europe: Regulatory Pressure Spurs Eco-Packaging

The EU’s stringent single-use plastic regulations have catalyzed a shift toward fiber-based packaging, home-compostable films, and carbon-neutral production cycles.

Asia-Pacific: Rapid Expansion, Rising Middle Class

Emerging economies like India and China are witnessing explosive growth, with increased penetration of organized retail and online grocery platforms. The region is a hotspot for low-cost sustainable innovation, including cassava starch films and palm fiber trays.

🧠 Smart Packaging: The Next Frontier

The rise of intelligent packaging is revolutionizing frozen food preservation and consumer trust. Examples include:

Time-temperature indicators (TTIs)

QR-coded traceability

Color-changing freshness labels

IoT-enabled tracking for e-commerce logistics

These technologies not only enhance shelf life but also provide real-time data visibility across the supply chain.

🌱 Sustainability Focus: Towards a Circular Packaging Economy

Modern consumers expect more than functionality—they demand environmental stewardship. Frozen food brands are increasingly adopting:

Compostable films derived from corn starch and sugarcane

Mono-material flexible films for improved recyclability

Recycled PET (rPET) and Post-Consumer Resin (PCR) content

Carbon-neutral manufacturing commitments

🧭 Strategic Partnerships & M&A: Market Consolidation and Innovation

The $8.4 billion merger of Amcor Plc and Berry Global Group, Inc. reflects a broader trend of consolidation aimed at enhancing R&D capabilities and global market reach. These mega-alliances are pivotal in:

Accelerating the commercialization of sustainable solutions

Expanding global distribution networks

Optimizing material sourcing through scale economies

Other key players making strategic moves include Sealed Air Corporation, Sonoco Products, and Huhtamaki Group, all of whom are aligning product development with eco-compliance mandates and evolving consumer preferences.

🚚 E-Commerce & DTC: The Packaging Challenge in Cold Logistics

The surge in direct-to-consumer frozen food delivery is redefining packaging requirements:

Insulated liners and phase-change materials

Reinforced outer packaging for last-mile durability

Minimalist design to reduce dimensional weight (DIM weight) charges

These shifts necessitate packaging that balances thermal integrity with cost-efficiency and curbside recyclability.

🧩 Key Takeaways: Market-Ready Strategies

Adopt smart, sensor-integrated packaging to enhance transparency and shelf life.

Invest in R&D for bio-based polymers and recyclable mono-material formats.

Optimize packaging for e-commerce logistics and direct-to-consumer shipment durability.

Align packaging strategies with global regulatory trends and sustainability benchmarks.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40599-global-frozen-food-packaging-market-trends

🔮 Forecast: The Future of Frozen Food Packaging Market

By 2032, the frozen food packaging market landscape will be defined by zero-waste designs, AI-enabled supply chain integration, and hyper-personalized consumer experiences. Companies that innovate toward eco-efficiency, intelligent traceability, and consumer convenience will lead the next evolution of the market.

Now is the time to reimagine packaging—not just as a necessity, but as a strategic differentiator in a dynamic and competitive global market.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Text

Slave-kun’s Happy Life in Another World: Chapter 42

"No way, one hit?"

"Looks like he only meant to paralyze it."

"The hide's untouched. The meat's not bruised. Good hunting."

"Owl's interference power is strong!"

"But still, to hit a vital spot…"

Everyone returned and surrounded the boar I'd taken down, giving their critiques.

I only meant to paralyze it.

I didn't think I'd kill it.

"…Why are you clinging to Daine's back?"

"It's his first kill, ain't it?"

I only felt a little bit surprised, though. It was kill or be killed.

It was the miscalculation that really shocked me. I only meant to use it like a stun gun for self-defense.

The thought of this being a person makes me shudder.

Magic is amazing. But scary.

I'm not used to the feeling of freely wielding something that could be such a terrible weapon.

But I have to get used to it. I'm in a different world now.

I moved away from Daine.

"Owl, thank you for protecting Daine."

The leader crouched down and patted my head with both hands. Double the usual pats.

I'm the one who was protected.

Besides, I think the master was ready to throw his spear, just in case I couldn't take it down.

I think he let me experience the hunt after ensuring safety. Nove's area magic was there too.

"Choosing lightning was the right call. Anything else would've bounced off its hide. Lightning pierces through."

"True, there's also suffocating it with water, but that's not as quick."

Hmm, suffocation was a blind spot.

Right, instead of magic like lightning that's easy to misjudge, I should think about self-defense methods using easier-to-control magic like water.

I'm feeling a bit better now.

I'll practice hard.

Aki continued to bleed the boars methodically.

And then the major processing began, hanging them from a large nearby tree. I wonder if the branch will hold.

Peeling the hide off a boar the size of a light car is more grotesque than before. And a bit bloody.

My uplifted mood sinks.

Trying not to look too closely, I work on purifying the various organs and wrapping them in leaves. I'm fine once they're separated.

This is an incredible amount of meat. It's enough to feed the town of Sansa for a year.

There's some fat too. I wonder if it's tasty. It probably is.

"Owl, come here."

Aki rarely calls for me. I looked up to see it was the turn of the boar I'd felled.

I'm handed a sharp butcher knife.

Since it's the first creature I've killed, he wants me to make the first cut myself. It's hanging at a height I can reach.

That's right. Life is precious.

I have to properly face what I've taken a life from.

Itadakimasu.

As instructed, I smoothly slid the knife across the boar's belly.

The processed boar is then placed in Aki's storage bag to age. Aki's bag is special; it maintains a low temperature. Like a refrigerator.

"Hide, tusks, horns, and a magic stone. Plus, a whole lotta meat. Yeah, we made good profit."

"Hold up, we aren't done yet."

"Huh? What's up, Aki?"

"That was a whole herd of Large-horned Boar this time of year. There might be some of that around."

"Aaah!"

"I forgot all about it!"

"Sansa Forest Truffles!"

The moment we finished processing the boar, Aki's words sent everyone scrambling, crawling on the ground.

What the heck was going on?

Mushroom hunting?

"Owl, look too! If you find any mushrooms with big caps, let me know!"

Yep, mushroom hunting.

Apparently, those boar have a knack for sniffing out truffle-like fungi. After a hunt, it's a good idea to search the area.

They say some incredibly fragrant mushrooms grow around here.

And they fetch a pretty penny if you sell them.

"A pharmacist buddy of mine said he'd buy them off me for more than market price. Can I sell mine?"

"Hold on, I've got someone who asked me to get some too."

"My mother and brother want to buy some as well."

Sparks flew between Nove, Master, and Leader.

Are these mushrooms really that valuable?

Ah, there's a mushroom in a spot that looks like a boar dug it up. This must be it. It's round, like an overturned soup bowl. Looks like a giant mushroom.

Can't really tell what it smells like.

"Hold it, you lot."

"Did someone ask you to get some too, Aki?"

"Nah, I'm gonna eat them myself… Don't you guys wanna try some?"

"Oh."

"Well, in that case…"

"Let's eat them!"

Who could resist eating such amazing mushrooms? Not us, that's for sure.

The squabble ended peacefully. As expected of Aki.

I show the mushroom I found to Aki.

"This is it, no doubt."

"You found one, Owl!"

"Well done! Tonight's dinner's gonna be a feast!"

Good, looks like I got the right one. Mushrooms are scary if you get the wrong kind. Gotta have an expert check it out.

I wonder if we can cultivate these mushrooms.

Maybe they need specific trees or nutrients. I found one that hasn't opened its cap yet. I wanna take it back and study it. But if they don't multiply, it'll be a waste, so I'll leave it here.

I'm excited to eat these amazing mushrooms for dinner tonight.

I had a thought: maybe the reason these mushrooms are so expensive is because adventurers like us can't resist the temptation to eat them instead of selling them.

2 notes

·

View notes

Text

Chef WK, lead charcuterie specialist in Alberta Canada

Table of contents

1. Control Program Requirements for Fermented Meat Products

2. Facility and Equipment Requirements

3. Starter Culture

4. Chemical Acidification

5. Water Activity Critical Limits

6. Time and Temperature for Fermented Products

7. Fermentation Done at a Constant Temperature

8. Examples of Degree-hours at constant room temperatures

9. Fermentation Done at Different Temperatures

10. Fermentation done at Different temperatures

11. What happens if fermentation fails to hit critical limit?

12. E. coli and Salmonella Control in Fermented Sausages

13. Options for E. coli validation

14. Option1; Heating

15. Option 2; pH, heating, holding, diameter

16. Safety and consistency

Control Program Requirements for Fermented Meat Products

The producer must have a program in place to assess the incoming product. This program should outline specifications for the incoming ingredients. This may include criteria including receiving temperature, farm/ supplier, lot code or packed on date, species/cut etc.

2. Facility and Equipment Requirements

Equipment used in the fermentation process must be included in the operator's prerequisite control programs. These must include the following elements:

Temperature in the fermentation, drying and smoking chambers must be uniform and controlled to prevent any fluctuation that could impact on the safety of the final product.

Fermentation, drying and smoking chambers must be equipped with a shatter resistant indicating thermometer, (or equivalent), with graduations of 1°C or less. If mercury thermometers are used, their mercury columns must be free from separations. All thermometers must be located such that they can be easily read.

Fermentation and smoking chambers must be equipped with a recording thermometer for determining degree-hours calculations in a reliable manner. Recording thermometers are also preferable in drying and aging rooms but, in these rooms, it may be sufficient to read and record the temperatures 2 times a day.

Drying and aging rooms must be equipped with humidity recorders in order to prevent uncontrolled fluctuations of the relative humidity. The only alternative to an automatic humidity recorder in these rooms would be for the company to manually monitor and record ambient humidity twice a day (morning and afternoon) every day with a properly calibrated portable humidity recorder.

For routine monitoring, accurate measurement electronic pH meters (± 0.05 units) should be employed. It is important that the manufacturer's instructions for use, maintenance and calibration of the instrument as well as recommended sample preparation and testing be followed.

When the aw of a product is a critical limit set out in the HACCP plan for a meat product, accurate measurement devices must be employed. It is important that the manufacturer's instructions for use, maintenance and calibration of the instrument be followed.

3. Starter Culture

The operator must use a CFIA approved starter culture. This includes Freeze-dried commercially available culture as well as back-slopping (use of previously successful fermented meat used to inoculate a new batch). When performing back-slopping, the operator must have a control program in place to prevent the transmission of pathogens from when using the inoculum from a previous batch to initiate the fermentation process of a new batch. These must include:

The storage temperature must be maintained at 4°C or less and a pH of 5.3 or less.

Samples for microbiological analysis must be taken to ensure that the process is in line with the specifications.

The frequency of sampling is to be adjusted according to compliance to specifications.

Any batch of inoculum which has a pH greater than 5.3 must be analysed to detect at least Staphylococcus aureus. Only upon satisfactory results will this inoculum be permitted for use in back slopping.

This can be an expensive and a time exhaustive process and is generally avoided due to food safety concerns. AHS does not allow back-slopping.

[Chef WK was in communication with the U of A to get his method, a starter mix, studied.]

4. Chemical Acidification

If product is chemically acidified by addition of citric acid, glucono-delta-lactone or another chemical agent approved for this purpose, controls must be in place and records kept to ensure that a pH of 5.3 or lower is achieved by the end of the fermentation process. These acids are encapsulated in different coatings that melt at specific temperatures, which then release the powdered acids into the meat batter and directly chemically acidulate the protein.

Summer sausage is a very common chemically acidified product. The flavor profile tends to be monotone and lacking depth.

5. Water Activity Critical Limits

The aw may be reduced by adding solutes (salt, sugar) or removing moisture.

Approximate minimum levels of aw (if considered alone) for the growth of:

molds: 0.61 to 0.96

yeasts: 0.62 to 0.90

bacteria: 0.86 to 0.97

Clostridium botulinum: 0.95 to 0.97

Clostridium perfringens: 0.95

Enterobacteriaceae: 0.94 to 0.97

Pseudomonas fluorescens: 0.97

Salmonella: 0.92 - 0.95

Staphylococcus aureus: 0.86

parasites: Trichinella spiralis will survive at an aw of 0.93 but is destroyed at an aw of 0.85 or less.

The above levels are based on the absence of other inhibitory effects such as nitrite, competitive growth, sub-optimum temperatures, etc., which may be present in meat products. In normal conditions, Staphylococcus aureus enterotoxins are not produced below aw 0.86, although in vacuum packed products this is unlikely below aw 0.89.

6. Time and Temperature for Fermented Products

Certain strains of the bacteria Staphylococcus aureus are capable of producing a highly heat stable toxin that causes illness in humans. Above a critical temperature of 15.6°C, Staphylococcus aureus multiplication and toxin production can take place. Once a pH of 5.3 is reached, Staphylococcus aureus multiplication and toxin production are stopped.

Degree-hours are the product of time as measured in hours at a particular temperature multiplied by the "degrees" measured in excess of 15.6°C (the critical temperature for growth of Staphylococcus aureus). Degree-hours are calculated for each temperature used in the process. The limitation of the number of degree-hours depends upon the highest temperature in the fermentation process prior to the time that a pH of 5.3 or less is attained.

The operator is encouraged to measure temperatures at the surface of the product. Where this is not possible, the operator should utilize fermentation room temperatures. The degree hour calculations are based on fermentation room temperatures. Temperature and humidity should be uniform throughout the fermentation room.

A process can be judged as acceptable provided the product consistently reaches a pH of 5.3 using:

fewer than 665 degree-hours when the highest fermentation temperature is less than 33°C;

fewer than 555 degree-hours when the highest fermentation temperature is between 33° and 37°C; and

fewer than 500 degree-hours when the highest fermentation temperature is greater than 37°C.

This means that as the temperature increases, the amount of time that you have available to reach 5.3 or under is shorter. The warmer the temperature, the sharper the log growth phase of bacteria, which equates to more overshoot in lactic acid production, faster.

8. Examples of Degree-hours at constant room temperatures

Example 1:

Fermentation room temperature is a constant 26°C. It takes 55 hours for the pH to reach 5.3.

Degrees above 15.6°C: 26°C - 15.6°C = 10.4°C Hours to reach pH of 5.3: 55 Degree-hours calculation: (10.4°C) x (55) = 572 degree-hours

The corresponding degree-hours limit (less than 33°C) is 665 degree-hours.

Conclusion: Example 1 meets the guideline because its degree-hours are less than the limit.

Example 2:

Fermentation room temperature is a constant 35°C. It takes 40 hours for the pH to reach 5.3.

Degrees above 15.6°C: 35°C - 15.6°C = 19.4°C Hours to reach pH of 5.3: 40 Degree-hours calculation: (19.4°C) x (40) = 776 degree-hours

The corresponding degree-hours limit (between 33 and 37°C) is 555 degree-hours.

Conclusion: Example 2 does not meet the guideline because its degree-hours exceed the limit

9. Fermentation Done at Different Temperatures

When the fermentation takes place at various temperatures, each temperature step in the process is analyzed for the number of degree-hours it contributes. The degree-hours limit for the entire fermentation process is based on the highest temperature reached during fermentation.

Example 1:

It takes 35 hours for product to reach a pH of 5.3 or less. Fermentation room temperature is 24°C for the first 10 hours, 30°C for second 10 hours and 35°C for the final 15 hours.

Step 1

Degrees above 15.6°C: 24°C - 15.6°C = 8.4°C Hours to reach pH of 5.3: 10 Degree-hours calculation: (8.4°C) x (10) = 84 degree-hours

Step 2

Degrees above 15.6°C: 30°C - 15.6°C = 14.4°C Hours to reach pH of 5.3: 10 Degree-hours calculation: (14.4°C) x (10) = 144 degree-hours

Step 3

Degrees above 15.6°C: 35°C - 15.6°C = 19.4°C Hours to reach pH of 5.3: 15 Degree-hours calculation: (19.4°C) x (15) = 291 degree-hours

Degree-hours calculation for the entire fermentation process = 84 + 144 + 291 = 519

The highest temperature reached = 35°C

The corresponding degree-hour limit = 555 (between 33°C and 37°C)Conclusion: Example 1 meets the guideline because its degree-hours are less than the limit.

10. Fermentation done at Different temperatures

Example 2:

It takes 38 hours for product to reach a pH of 5.3 or less. Fermentation room temperature is 24°C for the first 10 hours, 30°C for the second 10 hours and 37°C for the final 18 hours.

Step 1

Degrees above 15.6°C: 24°C - 15.6°C = 8.4°C Hours to reach pH of 5.3: 10 Degree-hours calculation: (8.4°C) x (10) = 84 degree-hours

Step 2

Degrees above 15.6°C: 30°C - 15.6°C = 14.4°C Hours to reach pH of 5.3: 10 Degree-hours calculation: (14.4°C) x (10) = 144 degree-hours

Step 3

Degrees above 15.6°C: 37°C - 15.6°C = 21.4°C Hours to reach pH of 5.3: 18 Degree-hours calculation: (21.4°C) x (18) = 385.2 degree-hours

Degree-hours calculation for the entire fermentation process = 84 + 144 + 385.2 = 613.2

The highest temperature reached = 37°C

The corresponding degree-hour limit = 555 (between 33°C and 37°C)

Conclusion: Example 2 does not meet the guidelines because its degree-hours exceed the limit.

11. What happens if fermentation fails to hit critical limit?

What happens if the batch takes longer than degree-hours allows? For restaurant level production, it's always safer to discard the product. The toxin that Staph. Aureus produces is heat stable and cannot be cooked to deactivate. In large facilities that produce substantial batches, the operator must notify the CFIA of each case where degree-hours limits have been exceeded. Such lots must be held and samples of product submitted for microbiological laboratory examination after the drying period has been completed. Analyses should be done for Staphylococcus aureus and its enterotoxin, and for principal pathogens, such as E. coli O157:H7, Salmonella, and Clostridium botulinum and Listeria monocytogenes.

If the bacteriological evaluation proves that there are fewer than 104 Staphylococcus aureus per gram and that no enterotoxin or other pathogens are detected, then the product may be sold provided that it is labelled as requiring refrigeration.

In the case of a Staphylococcus aureus level higher than 104 per gram with no enterotoxin present the product may be used in the production of a cooked product but only if the heating process achieves full lethality applicable to the meat product.

In the case where Staphylococcus aureus enterotoxin is detected in the product the product must be destroyed.

12. E. coli and Salmonella Control in Fermented Sausages

Business' that manufacture fermented sausages are required to control for verotoxinogenic E. coli including E. coli O157:H7 and Salmonella when they make this type of product. This includes:

establishments which use beef as an ingredient in a dry or semi-dry fermented meat sausage;

establishments which store or handle uncooked beef on site;

Establishments which do not use beef and do not obtain meat ingredients from establishments which handle beef are not currently required to use one of the five options for the control of E. coli O157:H7 in dry/semi-dry fermented sausages.

Any processed RTE product containing beef or processed in a facility that also processed beef, must be subjected to a heat treatment step to control E. coli O157:H7. Heating to an internal temperature of 71°C for 15 seconds or other treatment to achieve a 5D reduction is necessary. This is a CFIA requirement and is not negotiable.

Uncooked air dried products produced as RTE, must meet shelf stable requirements as detailed for Fermented-Dry products.

13. Options for E. coli validation

Without lab testing, the two main methods of validation are with heat treating by either low temp and a long duration, or various hotter processing temperatures for a shorter timeframe.

A challenge study to validate a process can take 1 year and over $100,000!

14. Option1; Heating

15. Option 2; pH, heating, holding, diameter

16. Safety and consistency

The aw and pH values are critical in the control of pathogens as well as to ensure shelf-stability in all semi-dry and dry fermented meat products. Each batch must be tested for aw and/or pH in order to verify that the critical limits are met.

Although aw measurement is mandatory only for shelf stable products, it is strongly recommended that the producer determine the aw values achieved for each product type they manufacture and for each product. Once this has been established, frequent regular checks should be made to ensure consistency. In the U.S., they rely on moisture to protein ratio and have set targets. This lab-tested value is a direct correlation of the % water to % meat protein and not aw. This gives more consistency to common names. For example, to legally call a product "jerky" it must have a MPR of 0.75:1 or lower. Remember your ABCs:

Always be compliant.

-AND-

Documentation or it didn't happen.

(tags)

Charcuterie,Fermented Meat,Food Safety,Starter Culture,Chemical Acidification,Water Activity,Fermentation Process,Degree-Hours Method,Foodborne Pathogens,Meat Processing Guidelines,Chef WK Alberta Canada,Food Industry Standards,pH Critical Limits,Thermal Processing,Food Preservation,Food Microbiology,Sausage Fermentation,Charcuterie Expertise,Fermented Meats ,Food Safety Standards,Food Processing Guidelines,Starter Cultures,Chemical Acidification,Water Activity (a_w),Critical Limits,Degree-Hours Method,Foodborne Pathogens,Meat Processing Equipment,Processing Facility Requirements,Hazard Analysis and Critical Control Points (HACCP),Food Preservation Techniques,Temperature Control,Pathogen Reduction,Food Industry Compliance,Documentation Practices,Heat Treatment,pH Control,Food Stability,Consistency in Production,Microbial Testing,Real-time Monitoring,Process Validation,Regulatory Requirements,Verotoxigenic E. coli,Lethality Standards,Product Labelling,Spoilage Prevention,Enterotoxin Detection,Shelf-Stable Products,Moisture to Protein Ratio (MPR)

#Charcuterie#Fermented Meat#Food Safety#Starter Culture#Chemical Acidification#Water Activity#Fermentation Process#Degree-Hours#Meat Processing Guidelines#Thermal Processing#Food Preservation#Food Microbiology#Sausage Fermentation#Starter Cultures#Critical Limits#Meat Processing#Food Preservation Techniques#Temperature Control#Pathogen Reduction#Food Industry#Heat Treatment#pH Control#Food Stability#Microbial Testing#Real-time Monitoring#Process Validation#Spoilage Prevention#Enterotoxin Detection#Shelf-Stable Products#Moisture to Protein Ratio (MPR)

3 notes

·

View notes

Text

Elevate Your Culinary Experience: Essential Tools from Monzelle's Kitchen

A well-equipped kitchen is the cornerstone of culinary success, transforming everyday cooking into an art. Monzelle's Kitchen offers an impressive range of kitchen tools and spice blends designed to enhance your cooking experience. Here are some essential tools and tips for every kitchen, ensuring you’re prepared to tackle any recipe with confidence and finesse.

1. Automatic Intelligent Cooking Robot

Imagine a kitchen companion that can cook for you. Monzelle’s Automatic Intelligent Cooking Robot is designed to handle various cooking tasks autonomously. It features pre-programmed recipes, precise temperature control, and automated stirring mechanisms. This robot simplifies meal preparation, ensuring consistently delicious results while allowing you to spend more time with family or on other activities.

2. Copper-Coated Stainless Steel Kitchen Gadget Set

A versatile and stylish kitchen gadget set is essential for any home cook. Monzelle’s Copper-Coated Stainless Steel Kitchen Gadget Set includes a variety of tools such as peelers, zesters, and graters. The copper coating not only adds aesthetic appeal but also provides enhanced durability and anti-corrosion properties, ensuring your tools remain functional and attractive for years.

3. Multifunctional Vegetable Cutter & Herb Grinder

Efficiency in the kitchen starts with the right tools. Monzelle’s Multifunctional Vegetable Cutter & Herb Grinder is designed to streamline your prep work. This tool offers multiple blade options for slicing, dicing, and chopping vegetables, while the herb grinder ensures fresh, finely chopped herbs. Its ergonomic design and easy assembly make it a must-have for quick and efficient meal preparation.

4. Kitchen Cling Film Cutter

Say goodbye to the frustration of tangled cling film. Monzelle’s Kitchen Cling Film Cutter provides a clean, precise cut every time. Its user-friendly design allows you to easily pull and cut cling film, ensuring an airtight seal on your food containers. This gadget is a game-changer for food storage, reducing waste and keeping your food fresher for longer.

5. Stainless Steel Fried Food Oil Scoop & BBQ Brush

Perfect for both frying and grilling enthusiasts, Monzelle’s Stainless Steel Fried Food Oil Scoop & BBQ Brush offers dual functionality. The oil scoop is ideal for safely removing fried foods from hot oil, while the BBQ brush is perfect for basting meats with marinades and sauces. Made from durable stainless steel, these tools are designed to withstand high temperatures and frequent use.

6. Luxury Kitchen Shelf Wall-Mounted Spice Rack

Organise your spices in style with Monzelle’s Luxury Kitchen Shelf Wall-Mounted Spice Rack. This elegant and functional rack provides easy access to your favourite spices while freeing up valuable counter space. Made from high-quality materials, it features multiple tiers and a sleek design, adding a touch of luxury to your kitchen décor.

7. Electric Food Processor Chopper

A versatile and powerful tool, Monzelle’s Electric Food Processor Chopper makes quick work of chopping, slicing, and dicing. With multiple speed settings and interchangeable blades, this food processor can handle everything from vegetables to nuts. Its compact design and easy-to-clean components make it an indispensable kitchen companion for both everyday cooking and special occasions.

Monzelle’s Kitchen offers an array of innovative tools designed to enhance your cooking experience. From intelligent robots to multifunctional gadgets, these products bring convenience, efficiency, and a touch of luxury to your kitchen. Investing in these high-quality tools not only improves your culinary skills but also makes cooking more enjoyable and less time-consuming.

2 notes

·

View notes

Text

Global Automation Ltd - Leading Automation Company in Bangladesh

Global Automation Ltd is your trusted partner for premium kitchen equipment, commercial kitchen appliances, and durable food industry solutions. As leading supermarket equipment suppliers in Bangladesh, we also offer advanced warehouse storage solutions. Explore our range of high-quality products to enhance your business efficiency.

#Global Automation Ltd#Premium Kitchen Equipment#Supermarket Equipment Supplier#Commercial Kitchen Appliances#Warehouse Storage Solutions#Durable Food Industry Equipment#Supermarket Equipment in Bangladesh#Retail Store Equipment#Supermarket Shelving and Racks#Commercial Refrigeration Units#Supermarket Checkout Counters#Cold Storage Solutions#Industrial Refrigeration#Cold Storage Bangladesh#Temperature Control Systems#Cold Chain Logistics#Industrial Storage Systems#Warehouse Automation#Storage Racks Bangladesh#Warehouse Management#Food Processing Equipment#Industrial Food Machinery#Food Processing Solutions#Food Production Equipment#Processing Machinery Bangladesh#Meat Processing Equipment#Industrial Meat Machinery#Meat Processing Solutions#Meat Production Equipment#Slaughterhouse Solutions

1 note

·

View note

Text

The Art of Perfect Pickled Cherry Tomatoes Red Onions and Cucumbers: A Tangy Tradition Worth Mastering

There's something magical about the satisfying crunch and burst of tangy flavor that comes from perfectly pickled vegetables. When you master the art of Pickled Cherry Tomatoes Red Onions and Cucumbers, you're not just creating a side dish – you're crafting a versatile culinary gem that can transform any meal.

Why Quality Ingredients Make All the Difference

The secret to exceptional pickled vegetables lies in selecting the finest ingredients. Fresh, firm cherry tomatoes with their natural sweetness provide the perfect base. Crisp cucumbers that snap when you break them, and red onions with their beautiful purple hue and sharp bite – these aren't just ingredients, they're the foundation of flavor.

Quality ingredients don't just taste better; they hold their texture throughout the pickling process. When you bite into properly prepared Pickled Cherry Tomatoes Red Onions and Cucumbers, you should experience:

• A satisfying crunch that doesn't turn mushy • Bright, vibrant colors that catch the eye • Balanced flavors where no single element overpowers the others • A clean, refreshing finish that leaves you wanting more

The Cultural Journey of Pickling

Pickling isn't just a cooking technique – it's a time-honored tradition that spans cultures and continents. From ancient Mesopotamian cucumber preservation to Eastern European fermentation methods, humans have been perfecting the art of pickling for over 4,000 years.

The combination of tomatoes, onions, and cucumbers in pickling reflects the Mediterranean influence on modern cuisine. This trio became popular in American kitchens during the early 20th century when home canning reached its peak.

Ready to discover the complete recipe that brings these flavors together? Click here to access the full step-by-step guide and start creating your own batch today!

Achieving That Perfect Texture Balance

The magic of Pickled Cherry Tomatoes Red Onions and Cucumbers lies in achieving the perfect texture balance. Each vegetable brings its own characteristics to the mix:

Cherry Tomatoes

These little flavor bombs maintain their firm skin while developing a tender interior. The key is timing – too long and they become mushy, too short and they remain tough.

Red Onions

The natural layers of onions create varying textures within a single piece. When done right, they become mellow and sweet while retaining just enough bite to add interest.

Cucumbers

Perhaps the trickiest of the three, cucumbers need special attention to maintain their signature crunch. The right preparation technique prevents them from becoming limp and soggy.

Beyond the Basics: Understanding the Science

Creating perfect pickled vegetables is part art, part science. The acidity level, salt content, and timing all work together in a delicate dance. Temperature control during the process affects how quickly flavors develop and how well textures are preserved.

The beauty of this particular combination is how each vegetable's natural properties complement the others. Cherry tomatoes release gentle acidity, red onions provide sharp contrast, and cucumbers offer cooling freshness.

Versatility That Transforms Every Meal

Once you've mastered Pickled Cherry Tomatoes Red Onions and Cucumbers, you'll discover their incredible versatility:

• Perfect alongside grilled meats and fish • Excellent in grain bowls and salads • Great as a tangy addition to sandwiches • Wonderful served with cheese and crackers • Ideal for adding brightness to rich, heavy dishes

Storage and Serving Tips

Proper storage is crucial for maintaining both flavor and texture. The right containers, temperature, and timing ensure your pickled vegetables stay fresh and delicious for weeks.

When serving, consider the temperature. While many people serve them chilled, allowing them to come closer to room temperature can enhance their flavors and make the textures more appealing.

Want to master this technique yourself? Get the complete recipe with detailed instructions and join thousands of home cooks who've discovered this amazing combination!

The Satisfaction of Homemade

There's something deeply satisfying about creating your own pickled vegetables. The process connects you to generations of home cooks who understood that the best flavors come from patience and quality ingredients.

When you make your own batch, you control every element – from the level of sweetness to the intensity of the tang. You're not just following a recipe; you're creating a signature dish that reflects your taste preferences.

Making homemade pickled vegetables also means you know exactly what goes into your food. No mysterious preservatives or artificial colors – just pure, natural ingredients working together in harmony.

Your Culinary Adventure Awaits

The journey to perfect Pickled Cherry Tomatoes Red Onions and Cucumbers starts with a single batch. Once you taste the difference that quality ingredients and proper technique make, you'll never want to go back to store-bought versions.

Remember, the best recipes are learned through practice. Don't be discouraged if your first batch isn't perfect – each attempt teaches you something new about timing, texture, and flavor balance.

Topic Tags: • Pickled Vegetables • Quick Pickles • Garden Preserving • Healthy Sides • Summer Recipes

0 notes

Text

Why Frozen Chicken in Singapore is the Smart Choice for Every Household

Frozen Chicken Singapore - The Convenient, Nutritious and Affordable choice. In a fast riverside type of living, frozen chicken Singapore is often considered a reliable, nutritious, and cost-effective answer for many families. Whether you’re making an easy weeknight meal or party planning, frozen chicken provides so much flexibility with nothing sacrificed in the taste department.

We are professionals in providing fresh frozen chicken throughout Singapore at your convenience. Intrigued, we dive in to find out why Singaporeans are increasingly going for frozen chicken as the go-to protein and how you can get the most out of it in your everyday cooking.

The Rise in Popularity of Frozen Chicken in Singapore

From busy work schedules and increasing grocery costs to a preference for bulk buying, frozen chicken Singapore is no longer the backup it used to be; it’s increasingly the main event. Frozen chicken lasts longer than fresh and is equal in nutrition, if not more so, is cheaper than fresh in most cases, and you can usually find large quantities for sale at a much better value.

Moreover, frozen chicken minimizes food spoilage, as the defrosting process is more easily controlled when you know exactly when the food will be eaten.

Benefits of Choosing Frozen Chicken from PickMe

1. Premium Quality Control: At PickMe we make certain our frozen chicken is from reliable providers that adhere to strict hygiene and food safety standards. Our ice chips are flash frozen right after processing to lock in freshness and nutrients.

2. Variety of Cuts for Every Meal: If you love chicken breasts for a lean protein option, wings for a get-together with friends, or drumsticks to put into a stew, we offer any size and taste that you are looking for at our online store.

3. Seamless Home Delivery in Singapore: Only those who have Kimchi will appreciate this. You can now order frozen chicken Singapore online through PickMe and receive it at your home in a cool and safe delivery.

4. Value for Money: Purchasing bulk frozen chicken can save families on the time and effort of multiple grocery store visits, as well as provide access to high-quality protein all week long.

Is Frozen Chicken Nutritious?

Absolutely! Frozen chicken is less nutritious than fresh chicken; there are a couple of myths. The fact is that modern freezing methods preserve the good-for-you protein, vitamins, and minerals of the poultry. Wholegrain frozen chicken is just as good and healthy for you as fresh chicken is, as long as it’s been stored and cooked properly.

What’s more, bacteria also have less chance to grow in the frozen state, making it, when given enough time, ultimately safer than fresh chicken that’s been hanging out in your fridge, as you’ve probably come to realize that chicken eventually does.

Tips to Properly Store and Cook Frozen Chicken

Storage: Keep the chicken in its original packaging until you need to us it. Place the product in your freezer and it must be at least -18c,Do not thaw out if you only use a little and refreeze the rest.

Defrosting: If you must defrost in the refrigerator or on the 'thaws' setting of your microwave, always thaw. Never simply leave it at room temperature to thaw it.

How to Cook: For best results, the chicken should be roasted at temperatures hovering around 165°F, when tested with an instant-read thermometer deep into its thigh meat.

Should you follow the suggestions below, you can still end up getting your chicken to be as divine and succulent cooked again as it was that first time.

Why Buy Frozen Chicken from PickMe?

PickMe is not your usual grocery delivery app — we are Singapore’s leading on-demand online delivery service of quality frozen meat and seafood! Committed to hygiene, fast delivery, and reasonable prices, an unbeatable choice for family, office, home, and professional cooks.

Whether you're organizing a big summer barbecue with your family, making dishes in advance for the whole week, or just hankering to try a fast protein-rich dinner one weeknight, PickMe will make sure frozen chicken Singapore is always no more than a click away.

Frequently Asked Questions (FAQs)

Q1: Is frozen chicken safe to eat daily? A: Yes! As long as it’s handled properly and defrosted effectively, that frozen chicken is harmless, still good to eat and fast and easy to cook every day.

Q2: How long can I store frozen chicken? A: You can store it safely in your freezer for up to 6 to 12 months. But for optimal flavor and texture, it’s best to eat within 3–6 months.

Q3: Does frozen chicken contain chemicals? A: No. There are no preservatives in PickMe frozen chicken. Freezing by itself is sufficient to maintain freshness and prolong shelf life.

Q4: Can I refreeze the thawed chicken? A: It’s not recommended. Defrosted chicken needs to be used immediately this is very important. Refreezing can cause deterioration of quality and possible safety problems.

Ready to Stock Up?

Experience hassle-free, hygienic, and fast frozen chicken delivery in Singapore with PickMe. With just a few clicks, you’ll have your favourite cuts of chicken delivered fresh-frozen and ready for your next culinary adventure. Contact Us Today: Phone: +65 87421256 Email:[email protected]

0 notes

Text

Top-Quality Ice Box – USA & Russia Manufacturer, Goliathtubs

In industries where temperature control and durability are crucial, ice box play an essential role. Whether you’re in logistics, food distribution, pharmaceuticals, or outdoor retail, the need for reliable cold storage solutions can’t be overstated.

Goliathtubs, a leading manufacturer and supplier of premium ice box in the USA and Russia, known for delivering performance, reliability, and innovation.

Why Choose Ice Box Coolers from Goliathtubs?

Goliathtubs specializes in industrial-grade ice box designed to meet the toughest storage challenges that ensure long-lasting insulation, impact resistance, and weatherproof performance.

Key Features:

Superior Thermal Insulation for extended cooling performance

Heavy-Duty Build to withstand rough handling

Hygienic & Easy to Clean

Variety of Sizes available for multiple use-cases

Leak-Proof Design and secure sealing system

Whether it’s for transporting temperature-sensitive products or keeping goods chilled during outdoor operations, Goliathtubs’ deliver uncompromising results.

Serving the USA and Russia Markets

Goliathtubs supplies to a wide range of industries including seafood, meat processing, catering, and logistics. With nationwide distribution and responsive customer service, they ensure fast delivery and product availability across the country.

With an understanding of Russia’s diverse climate and transportation needs, Goliathtubs offers ice box that are built to withstand extreme conditions. They serve industries ranging from pharmaceuticals to frozen goods logistics with highly efficient storage solutions.

Applications Across Industries

Goliathtubs’ ice box are widely used in:

Fisheries & Seafood Distribution

Cold Chain Logistics

Catering & Food Delivery

Medical & Pharmaceutical Transport

Camping, Outdoor Events & Retail

Commitment to Quality and Innovation

What sets Goliathtubs apart is their dedication to continuous improvement. From design to final product delivery, every step is optimized to offer maximum value to clients, making them suitable for both industrial and commercial use.

Ready to Upgrade Your Cold Storage Solutions?

If you’re searching for trusted ice box manufacturers in the USA or Russia, Goliathtubs is your go-to partner. With years of industry expertise and a track record of excellence, they provide the performance you can rely on.

👉 Contact Goliathtubs today to explore their full range of thermal storage products or to request a custom quote.

#Goliathtubsfishbox#plasticinsulatedfishbox#fishtubsusa#insulatedfishboxsupplier#fishboxsupplierusa#fishboxsupplier#USA#Russia

0 notes

Text

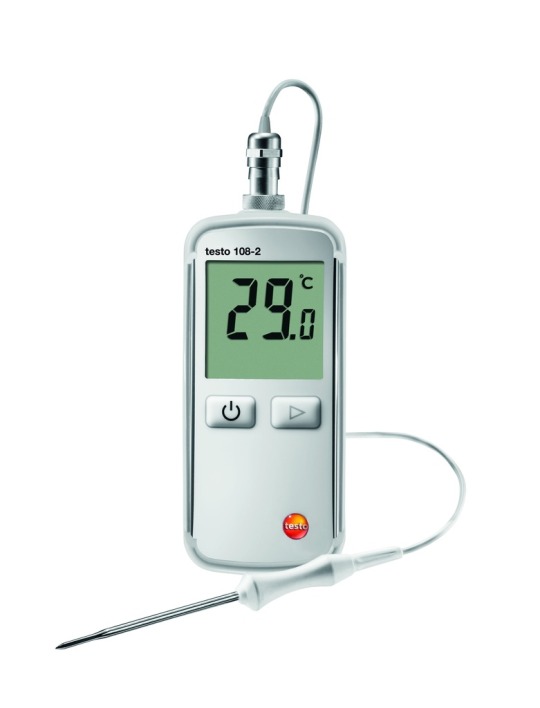

Precision Meets Durability: Why the Testo 108-2 Waterproof Digital Food Thermometer is a Kitchen Essential

In the high-paced world of food service, accuracy and hygiene aren’t just preferences — they’re absolute necessities. Whether you’re running a commercial kitchen, managing food safety for catering operations, or handling quality control in food processing, one tool you can’t afford to overlook is a waterproof digital food thermometer.

At ShopTesto, one standout solution is the Testo 108–2 Thermometer — a robust and reliable thermometer built specifically for the demanding requirements of food professionals.

Why a Waterproof Digital Food Thermometer Matters

In food safety, precision is vital, but so is durability. Kitchens are fast-paced environments where tools are exposed to moisture, heat, oils, and frequent cleaning. A waterproof digital food thermometer like the Testo 108–2 ensures that accurate temperature readings are possible, even in the messiest or wettest conditions.

Here’s what makes the Testo 108–2 a must-have:

Key Features of the Testo 108–2

Waterproof & Robust Design Rated to IP67, the Testo 108–2 is completely waterproof, making it ideal for environments where cleaning and splashing are frequent. Whether you’re sanitizing your tools between uses or working in humid conditions, this thermometer keeps performing.

Fast, Accurate Readings The thermometer provides precise readings in just seconds, helping chefs and food handlers maintain perfect temperatures for everything from meats to baked goods. Accuracy is within ±0.5 °C, meeting strict HACCP standards.

User-Friendly Interface Simplicity is key during food prep. With two-button operation, the Testo 108–2 removes the learning curve and helps even new staff use it confidently. The backlit display ensures visibility in low-light kitchens or outdoor settings.

Interchangeable Probes The device supports standard Type T and Type K thermocouple probes, allowing users to swap or replace probes as needed. It also includes a protective soft case for additional durability.

Ideal Applications

The Testo 108–2 waterproof digital food thermometer is perfect for:

Restaurants and catering services

Industrial food processing units

Quality assurance in food transportation

Hotel kitchens and buffets

Cold storage facilities

From checking the core temperature of roast beef to ensuring frozen foods meet safety thresholds, this tool brings peace of mind in every reading.

Compliance with Food Safety Standards

In today’s regulatory climate, food businesses must meet strict HACCP and ISO standards. The Testo 108–2 is fully HACCP-compliant, ensuring it fits seamlessly into your existing safety protocols. The waterproof design also simplifies sanitization routines, helping maintain hygiene without damaging your equipment.

Why Buy from ShopTesto?

ShopTesto is your trusted source in the GCC for high-quality, precision instruments from Testo. When you purchase the Testo 108–2 waterproof digital food thermometer at ShopTesto, you receive:

Genuine Testo products with warranty

Expert customer support

Fast delivery across the UAE and GCC

Technical guidance on usage and compliance

Final Thoughts