#Temperature Controlled Storage

Explore tagged Tumblr posts

Text

The Role of a Medicine Warehouse in Modern Healthcare Supply Chains

The healthcare industry depends on timely delivery of life-saving drugs and equipment. At the heart of this system lies the medicine warehouse — a critical link that ensures medicines are stored, managed, and distributed safely and efficiently. As healthcare demands continue to rise, the importance of reliable medicine warehousing becomes more evident than ever.

What is a Medicine Warehouse?

A medicine warehouse is a specialized storage facility designed to handle pharmaceutical products under strict regulatory and environmental conditions. These warehouses play a crucial role in preserving the integrity, safety, and quality of medicines before they reach hospitals, clinics, or consumers.

These facilities are equipped with:

Temperature-controlled zones

Humidity control systems

Real-time inventory tracking

High-level security

Automated order fulfillment systems

From over-the-counter drugs to sensitive vaccines, a medicine warehouse is the central hub where medicines are received, stored, processed, and dispatched.

Why Medicine Warehousing is Crucial

Modern medicine supply chains are complex, and delays or mishandling at any point can have life-threatening consequences. A well-managed medicine warehouse ensures:

Consistent drug availability

Regulatory compliance with health authorities

Product safety through controlled storage

Efficient distribution to healthcare facilities

Inventory optimization and waste reduction

Without efficient medicine warehousing, even the best pharmaceutical manufacturing processes can fail to meet demand on time.

Features of a Modern Medicine Warehouse

Climate Control & Storage Conditions

Medicines are sensitive to temperature, humidity, and light. A modern medicine warehouse uses advanced HVAC systems and sensors to maintain strict environmental conditions.

Regulatory Compliance

Pharmaceutical warehousing must comply with Good Distribution Practices (GDP) and national health regulations. These guidelines ensure medicine safety, proper documentation, and secure transport.

Inventory Management Systems

Modern warehouses use software to manage stock levels in real-time. Barcode scanning, RFID tagging, and automated reports ensure minimal stockouts and expired product risks.

Security & Safety

Because medicines are high-value and sensitive, a medicine warehouse is equipped with 24/7 surveillance, controlled access, and fire safety systems.

Types of Medicine Warehouses

Depending on the scale and purpose, there are various types of medicine warehouse facilities:

Central Distribution Centers

These large-scale warehouses receive bulk medicines from manufacturers and distribute them to smaller regional centers or directly to hospitals.

Cold Chain Warehouses

Designed for temperature-sensitive products like vaccines or insulin, these warehouses maintain a cold storage environment between 2°C and 8°C.

Hospital Warehouses

Some large hospitals maintain in-house medicine warehouses to ensure uninterrupted drug supply for patient care.

Retail Pharmacy Warehouses

These facilities supply medicines to retail pharmacies and online platforms, ensuring the availability of over-the-counter and prescription drugs.

Benefits of a Well-Managed Medicine Warehouse

Implementing efficient medicine warehousing can significantly enhance healthcare services. Some key benefits include:

Minimized Wastage: Proper storage reduces expired or spoiled stock

Improved Forecasting: Data analytics optimize reordering

Faster Delivery: Automated systems reduce delivery time

Better Compliance: Ensures alignment with health regulations

Increased Customer Satisfaction: Timely delivery improves patient care

A modern medicine warehouse not only supports operations but builds trust within the healthcare supply chain.

Technology in Medicine Warehouse Management

Technology plays a vital role in transforming how medicine warehouses operate today:

Warehouse Management Systems (WMS): Tracks inventory, shipments, and expiries

IoT Devices: Monitor temperature, humidity, and location in real-time

Blockchain: Enhances transparency and reduces counterfeiting

AI & Machine Learning: Predicts demand and automates reordering

Drones & Robotics: Speeds up picking and packaging in large warehouses

The integration of these technologies ensures accuracy, speed, and accountability across the supply chain.

Challenges in Managing a Medicine Warehouse

Despite their advantages, medicine warehouses face some notable challenges:

Regulatory Pressure: Constantly evolving compliance requirements

Temperature Excursions: Risk of product spoilage due to system failure

Supply Chain Disruptions: Global events like pandemics can cause delays

Security Risks: Threats of theft or counterfeiting

High Operational Costs: Maintaining technology and staff is expensive

However, most of these challenges can be mitigated with strategic planning, investment in infrastructure, and regular audits.

Best Practices for Operating a Medicine Warehouse

To maximize efficiency and safety, a medicine warehouse should follow these best practices:

Regular Training for Staff: Ensure employees are up-to-date with handling protocols

Real-Time Monitoring: Use IoT and cloud systems for instant alerts

Audit Trails: Maintain detailed logs for inspections and traceability

Backup Power Systems: Prevent storage condition failures

First-Expiry-First-Out (FEFO) Systems: Minimize wastage due to expired drugs

Pest Control and Cleanliness: Maintain hygienic storage environments

Emergency Response Plans: Be prepared for fires, power outages, or disasters

These practices are essential to build a reliable, safe, and compliant medicine warehousing facility.

Conclusion

A medicine warehouse is more than just a storage space — it is a critical infrastructure that supports global healthcare systems. With the rise of chronic illnesses, aging populations, and medical innovations, the demand for efficient and tech-enabled medicine warehouses will only grow.

By adopting modern technologies, maintaining compliance, and following best practices, businesses can ensure their medicine warehouse operations are robust, responsive, and ready for the future.

Whether you're a pharmaceutical manufacturer, a hospital, or a logistics provider, investing in a well-structured medicine warehouse is essential to meet the evolving needs of healthcare delivery.

FAQs on Medicine Warehouse

Q1: What is a medicine warehouse?

A medicine warehouse is a storage facility designed to handle and distribute pharmaceutical products while maintaining strict environmental and regulatory standards.

Q2: Why is temperature control important in a medicine warehouse?

Temperature-sensitive drugs like vaccines can lose their effectiveness if not stored properly. Controlled environments ensure product safety and compliance.

Q3: Who uses medicine warehouses?

Pharmaceutical companies, hospitals, clinics, government health departments, and even e-commerce medical platforms use medicine warehouses.

Q4: What regulations apply to medicine warehouses?

Regulations such as Good Distribution Practices (GDP), WHO guidelines, and national drug laws must be followed for legal operation and safety assurance.

Q5: How can technology improve a medicine warehouse?

Technologies like WMS, IoT, AI, and blockchain improve inventory accuracy, monitoring, traceability, and overall operational efficiency.

#Medicine Warehouse#Pharmaceutical Storage#Healthcare Supply Chain#Cold Chain Logistics#Pharma Warehousing#Medical Inventory Management#Drug Distribution Center#Pharmaceutical Logistics#Warehouse Management System (WMS)#Temperature Controlled Storage#Medicine Storage Compliance#Healthcare Logistics Solutions#Medicine Supply Chain#Good Distribution Practices (GDP)#Pharma Warehouse Automation

0 notes

Text

Secure Temperature Controlled Storage Solutions – STC Couriers

STC Couriers provides reliable temperature controlled storage solutions designed to preserve the quality of your sensitive goods. Whether you need to store pharmaceuticals, perishable foods, or other temperature-sensitive products, our state-of-the-art facilities maintain precise temperature conditions to ensure product integrity. With advanced monitoring systems and secure environments, STC Couriers offers tailored storage solutions to meet your business's specific needs. Trust us for safe, compliant, and efficient temperature controlled storage that keeps your goods in optimal condition until delivery.

Source URL: - https://stccouriers.in/services/temperature-controlled-storage/

1 note

·

View note

Text

mom asked if we had Rose Madder and I said I know we did, we had at least two copies, but I don't know if we do because they might have been in the garage and got left behind. It's one of my favorites and she wants to read it so I just went on a three-room book dig and while I did find three more boxes of books and some I'm very happy to have (including 4/7 of the Dark Tower series) I didn't end up finding the one I was looking for and now I'm sad. and also covered in sweat and dust and soot.

#charlie babbles#also found my Mirrormask books which are very important to me and my Miss Peregrine's boxed set#I need to make a checklist so I can start looking for what we're missing at yard sales this summer#it's hard because we don't know what made it into the storage unit y'know? and whatever did might not be surviving#because they went from florida garage to florida storage unit (and not the temperature controlled kind)

4 notes

·

View notes

Text

Cold Storage Structure: Essential Infrastructure for Seafood and Meat Industry

In the seafood and meat industry, maintaining freshness and preventing contamination are non-negotiable. A reliable cold storage structure ensures that products like fish, poultry, beef, and frozen seafood are stored at optimal temperatures from the point of harvest to the final sale. Without such infrastructure, spoilage and foodborne illnesses could compromise both safety and business credibility.

Seafood and meat are among the most perishable food items, highly sensitive to time and temperature changes. A cold storage structure provides a controlled environment that maintains low temperatures—typically between -18°C to -25°C for frozen items—to inhibit bacterial growth and preserve texture, flavor, and nutritional value.

Processing units, exporters, wholesalers, and large-scale retailers rely on these storage facilities to comply with food safety regulations and meet international quality standards. Whether it's a blast freezer room for rapid chilling or long-term frozen storage units, the structure must be designed to withstand continuous operation and ensure hygienic conditions.

Additionally, modern cold storage structures in this sector now include features like stainless steel interiors for easy cleaning, automated defrost systems, smart temperature alarms, and energy-efficient compressors. These upgrades help businesses reduce operational costs while improving food preservation standards.

In coastal and port-based regions, cold storage facilities also serve as a critical part of the export supply chain—ensuring seafood is safely stored before shipment. With growing demand for frozen meats and ready-to-cook products, the industry is witnessing an increasing need for decentralized, modular cold storage solutions that can be quickly installed near fishing hubs and processing zones.

Ultimately, a cold storage structure is not just about freezing—it’s about preserving quality, meeting health regulations, and ensuring customer satisfaction in a highly sensitive and competitive market.

#Cold Storage for Seafood#Meat Storage Structure#Frozen Food Storage#Cold Chain for Meat Industry#Temperature Controlled Meat Storage

0 notes

Text

Optimizing Storage for Your Dropshipping Products

When it comes to storing your dropshipping products, especially for brands like Inkedjoy, it's important to find the right conditions to maintain product quality. Here are two great storage options to consider:

A cool, dry room with stable temperatures and low humidity.

A dedicated storage space that allows for controlled temperature and humidity levels.

Both options can be effective, but ensuring that your products are kept in a consistent environment will help you maintain their quality and appeal. By taking care of your inventory, you can provide your customers with the best possible experience when they receive their products from Inkedjoy. Thank you for considering these tips for your storage needs!

#dropshipping#product storage#inventory management#product quality#temperature control#humidity control#customer experience#Inkedjoy

0 notes

Text

Mid-sized country wine cellar photo with storage racks

Angela R. Hunt Story Teller

0 notes

Text

Modular Cold Storage Rooms – What Are Their Benefits Over Traditional?

Cold storage is a critical component for industries like food processing, pharmaceuticals, and logistics. With advancements in technology, modular cold storage rooms have emerged as a superior alternative to traditional cold storage systems. At EPACK Prefab, we specialize in delivering state-of-the-art modular cold storage solutions that cater to diverse industry needs.

What Are Modular Cold Storage Rooms?

Modular cold storage rooms are prefabricated, insulated chambers designed for temperature-controlled environments. Unlike traditional cold storage, these modular systems are built using prefabricated panels and components that allow for easy assembly, customization, and scalability.

Benefits of Modular Cold Storage Rooms Over Traditional

1. Customization and Flexibility

Modular cold storage rooms are highly customizable, offering:

Tailored dimensions to fit specific space requirements.

Adaptable temperature zones for storing different products.

Scalability, allowing easy expansion as business needs grow.

Traditional cold storage lacks this level of flexibility, making modular systems a more versatile option.

2. Faster Installation

Modular cold storage rooms are prefabricated and delivered ready for assembly. This reduces installation time significantly compared to traditional systems, which often require lengthy on-site construction.

3. Energy Efficiency

Modular systems are designed with advanced insulation materials that minimize energy loss, ensuring consistent temperature control with lower energy consumption. This translates to reduced operational costs compared to traditional cold storage solutions.

4. Cost-Effective

The prefabricated nature of modular cold storage reduces labor and material waste, making it a more cost-efficient option. Additionally, the faster installation process lowers project timelines, further reducing costs.

5. Portability

Modular cold storage rooms can be disassembled, transported, and reassembled at a new location, offering unparalleled portability. This is particularly beneficial for industries that require temporary or mobile storage solutions.

6. Superior Quality and Durability

Constructed in controlled factory environments, modular cold storage systems maintain consistent quality standards. High-quality materials such as PUF (Polyurethane Foam) panels provide excellent thermal insulation and long-lasting performance.

7. Environmentally Friendly

Modular cold storage uses sustainable materials and energy-efficient technologies, reducing its environmental footprint. These systems are also recyclable, aligning with modern sustainability goals.

8. Easy Maintenance

The modular design simplifies maintenance, as individual components can be replaced or upgraded without disrupting the entire system, unlike traditional setups.

Applications of Modular Cold Storage Rooms

Modular cold storage rooms are used across various industries, including:

Food processing and storage (fruits, vegetables, dairy, meat).

Pharmaceuticals (medicines, vaccines, medical supplies).

Logistics and warehousing.

Retail (supermarkets, cold chain transportation).

Why Choose EPACK Prefab for Modular Cold Storage?

At EPACK Prefab, we offer modular cold storage solutions tailored to your specific needs. With advanced technology, superior materials, and energy-efficient designs, we ensure optimal performance and reliability.

Conclusion

Modular cold storage rooms provide unmatched advantages over traditional systems, offering flexibility, energy efficiency, and cost-effectiveness. Whether you’re looking to optimize space, reduce energy costs, or expand your storage capabilities, modular cold storage is the future of temperature-controlled environments.

Contact EPACK Prefab today to explore how our modular cold storage solutions can benefit your business.

Read to Know - Six Reasons why Cold Storage Industry should adopt Prefabrication

#Modular Cold Storage#Prefabricated Cold Rooms#Cold Storage Solutions#Energy Efficient Storage#Cold Chain Logistics#Temperature Controlled Rooms#Sustainable Storage Systems#PUF Panels#Industrial Cold Storage#EPACK Prefab Solutions

0 notes

Text

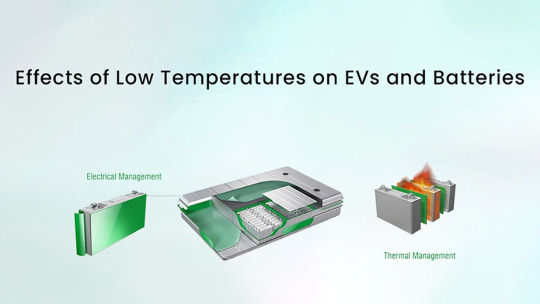

Battery Thermal Management: The Crucial Role of Temperature Control

In modern electric vehicles (EVs), the lithium-ion battery module pack takes center stage, influencing an EV's performance, range, and safety. However, these crucial power sources are sensitive to temperature extremes. Like people, batteries have their comfort zone, typically operating optimally between 15°C and 40°C. Yet, the reality of automotive environments exposes batteries to temperatures ranging from a frigid -20°C to a sweltering 55°C. What's the solution? Give the battery an air conditioner, and you get battery thermal management, which accomplishes three essential functions: heat dissipation, heating, and temperature consistency.

Heat Dissipation

When temperatures soar, batteries can experience a dramatic loss of life (resulting in capacity degradation) and an elevated risk of thermal runaway. Thus, effective heat dissipation is vital when the battery becomes excessively hot.

Heating

Conversely, when temperatures plummet, the battery's capacity may be reduced and performance weakened. Charging the battery in this frigid state can even pose a risk of thermal runaway due to potential internal short circuits. So, it's crucial to warm up or insulate the battery when it gets too cold.

Temperature Consistency

Think back to the old air conditioner in your childhood home. It would blast cold air upon startup and then take a break. Most modern air conditioners now use frequency conversion and even airflow distribution to maintain temperature consistency. Similarly, power batteries strive to minimize spatial temperature differences, ensuring minimal variance in cell temperature. Temperature consistency is paramount to battery performance and safety.

Effects of Low Temperatures on EVs and Batteries

As the heart of an EV, the power battery has a profound impact on its performance, affecting aspects such as range, acceleration, and service life. Safety is also a top priority. Battery performance is deeply intertwined with temperature, and cold climates can significantly hinder an EV's operation.

For instance, electric vehicle owners in colder regions often notice a significant drop in mileage during winter. In some cases, the range can plummet to as low as 70% of its usual capacity. Many drivers resist using cabin heaters to conserve mileage.

Low temperatures not only reduce an EV's battery capacity but also inhibit its discharge capabilities. At extremely low temperatures, the electrolyte inside the battery may freeze, leading to a severe reduction in power output.

Lithium-ion batteries are particularly susceptible to temperature extremes. At lower temperatures, the chemical reactions within the battery slow down, resulting in decreased performance and range. Charging in freezing conditions can also lead to the formation of lithium deposits on the battery's negative electrode, potentially puncturing the battery diaphragm and causing a short circuit. The safety implications of charging batteries at low temperatures are significant.

Battery Thermal Management: A Technological Solution

Battery thermal management is the solution to many of these challenges. This technology aims to maintain battery temperature within the ideal range. The approach includes both heating and cooling, to optimize battery performance.

There are several methods used in battery heating:

Battery Natural Heating: The heat generated during battery operation, discharging, or charging can increase the battery's temperature. However, this method can be slow and is rarely used in modern electric vehicles.

Blower Heating: Blowing hot or cold air into the battery pack through an external air conditioner is another method. This approach demands a carefully designed air duct and can result in uneven temperature distribution within the battery pack.

Heating Elements in the Battery Pack: These are composed of heating elements and circuits. Two common heating elements are the Positive Temperature Coefficient (PTC) and Heating Film. PTC offers advantages like safety, high thermal conversion efficiency, and rapid heating.

Circulating Liquid Heating: Liquid-cooled battery packs have become the mainstream option. This method offers uniform heat distribution, safety, and reliability. It usually features a system to facilitate heat dissipation, ensuring even temperature rises throughout the battery pack.

Conclusion

Battery thermal management is not just a luxury; it's a necessity for modern electric vehicles. In a world of varying climates, maintaining optimal battery temperature is a key factor in enhancing performance, ensuring safety, and prolonging battery life. As technology continues to evolve, battery thermal management will continue to play a crucial role in advancing the electric vehicle industry, offering the promise of efficient and reliable clean energy transportation for the future.

#Battery Cooling Systems#Battery Heating and Cooling Mechanisms#Battery Temperature Control#Battery Thermal Management Systems (BTMS)#electric vehicles#energy storage systems#lithium ion batteries#lithium-ion battery systems#Thermal Management in EV Batteries

0 notes

Text

I got into magnus archives while working in an archive. I think perhaps the peak experience is listening to all 200 whilst in a repository.

And then I moved to digitising and summarising documents in time to listen to protocol.

#i downloaded all 200 episodes because the the wifi and signal situation was atrocious and i listened to all of it#there is something so special about being in a constantly kinda dark maze that's always the same temperature whilst listening to the horrirs#'document storage is climate controlled' fuck yeah it is#anyway i think i win at immersive magnus experiences#definitely this was better than getting into ace attorney while working in a court#the magnus archives

0 notes

Text

Walk-In Cold Room Chamber Exporter: Your Gateway to Controlled Storage Solutions

Introduction

In the ever-evolving landscape of industries such as pharmaceuticals, biotechnology, food processing, and research laboratories, the demand for efficient and reliable storage solutions has never been greater. One critical component of this storage solution is the Walk-In Cold Room Chamber exporter. As a key exporter of these chambers, we provide tailored solutions that meet the specific needs of various sectors.

Understanding Walk-In Cold Room Chambers

A Walk-In Cold Room Chamber is a large-scale refrigeration unit designed to maintain a controlled temperature environment for the storage of perishable goods and sensitive materials. Unlike standard refrigerators, these chambers offer significantly larger space, allowing for the storage of bulk quantities of items while maintaining optimal temperature and humidity levels.

Key Features of Walk-In Cold Room Chambers:

Customizable Size and Design: Walk-In Cold Rooms can be tailored to fit any space requirement, from small research labs to large warehouses.

Energy Efficiency: Modern chambers are designed with energy-efficient cooling systems, ensuring minimal energy consumption without compromising performance.

Advanced Control Systems: These chambers are equipped with digital control systems that allow precise temperature and humidity regulation, ensuring that stored items remain in ideal conditions.

Robust Insulation: High-quality insulation materials help maintain stable temperatures, reducing energy costs and ensuring the longevity of the stored products.

Easy Access and Organization: Designed for functionality, these chambers often come with adjustable shelving, sliding doors, and user-friendly access systems.

Visit Here:- Customizable Walk-In Humidity Chamber for Lab & Industrial Use

Industries Benefiting from Walk-In Cold Room Chambers

1. Pharmaceutical Industry: In pharmaceuticals, the integrity of products like vaccines, biologics, and other temperature-sensitive medications is paramount. Walk-In Cold Rooms provide the ideal environment for storing these products, ensuring they remain effective and safe for use.

2. Food and Beverage Sector: From fresh produce to frozen goods, the food industry relies heavily on cold storage solutions. Walk-In Cold Rooms help in preserving food quality, extending shelf life, and complying with health regulations.

3. Biotechnology: Research and development in biotechnology often require precise temperature control for storing samples and reagents. Walk-In Cold Rooms offer the necessary conditions for these sensitive materials.

4. Laboratories: Research labs frequently require controlled environments for experiments and sample storage. Walk-In Cold Rooms provide the perfect solution, accommodating a wide range of materials that need refrigeration.

The Export Advantage

As an established exporter of Walk-In Cold Room Chambers, we ensure that our products meet international standards for quality and performance. Our commitment to excellence includes:

Global Reach: We supply Walk-In Cold Rooms to clients worldwide, adapting our offerings to comply with local regulations and market demands.

Quality Assurance: Every chamber undergoes rigorous testing to guarantee that it meets the highest standards of performance, safety, and durability.

Customer Support: We pride ourselves on our customer service, providing expert advice and assistance throughout the purchasing process and beyond.

Visit Here:- Walk-In Chamber for Insect Cultivation: Precision and Consistency

Conclusion

Investing in a Walk-In Cold Room Chamber exporter is a strategic decision for businesses looking to enhance their storage capabilities while ensuring the safety and integrity of their products. As a leading exporter, we are dedicated to providing high-quality cold storage solutions tailored to the needs of various industries. Our commitment to innovation, quality, and customer satisfaction positions us as a trusted partner in your journey toward efficient and effective storage solutions.

FAQs

What is the typical temperature range for a Walk-In Cold Room?

Most Walk-In Cold Rooms can maintain temperatures ranging from -20°C to +10°C, depending on the specific needs of the stored materials.

How long does it take to install a Walk-In Cold Room?

Installation time varies based on size and complexity, but it typically takes a few days to a week.

Can I customize the design of the Walk-In Cold Room?

Yes, we offer customization options to meet specific size and design requirements.

What maintenance is required for Walk-In Cold Rooms?

Regular maintenance includes checking temperature controls, cleaning condenser coils, and ensuring proper sealing of doors.

Are Walk-In Cold Rooms energy-efficient?

Modern Walk-In Cold Rooms are designed with energy efficiency in mind, using advanced insulation and cooling technologies to minimize energy consumption.

#Walk-In Cold Room Chamber#Cold Room Exporter#Temperature-Controlled Storage#Food Storage Solutions#Pharmaceutical Cold Storage#Custom Cold Room Design#Energy-Efficient Refrigeration#Laboratory Cold Storage#Walk-In Freezer#Cold Chain Solutions

0 notes

Text

Efficient Warehouse Storage Solutions for Supermarkets & Food Processing Equipment - Global Automation Ltd

Discover essential warehouse storage strategies, including pallet racking systems, mezzanine floors, and temperature-controlled storage. Optimize space and maintain product quality in supermarkets and food processing with Global Automation Ltd’s tailored solutions.

#Warehouse storage solutions#Pallet racking systems#Mezzanine floors warehouse#Temperature-controlled storage#Warehouse shelving systems#Supermarket storage strategies#Food processing equipment storage#Commercial refrigeration solutions#Inventory management software#Optimizing warehouse space

0 notes

Photo

Contemporary Wine Cellar in Chicago Inspiration for a small contemporary slate floor and gray floor wine cellar remodel with display racks

#wine storage with full height glass doors#wine cellar#custom wine cabinet#modern wine storage#temperature controll wine room#compact

1 note

·

View note

Photo

Medium Kent Mid-sized farmhouse wine cellar photo with storage racks

0 notes

Photo

Chicago Compact Wine Cellar Inspiration for a small contemporary slate floor and gray floor wine cellar remodel with display racks

#custom wine cabinet#modern wine storage#wine storage with full height glass doors#wine room chicago#temperature controll wine room

0 notes

Photo

Farmhouse Wine Cellar in Kent Image of a medium-sized farmhouse wine cellar with racks for storage

0 notes

Photo

Kent Wine Cellar Inspiration for a mid-sized farmhouse wine cellar remodel with storage racks

0 notes