#TitaniumManufacturing

Explore tagged Tumblr posts

Text

Durable Titanium Plates: The Key to Success in Aerospace and Manufacturing

Titanium is one of the most sought-after materials in industries requiring strength, durability, and lightweight solutions. Titanium plates are especially crucial in sectors like aerospace and manufacturing, where performance, reliability, and precision are paramount. If you're looking for a material that offers superior strength-to-weight ratios and resistance to harsh environments, titanium plates from trusted suppliers like Accromet can be the solution your business needs.

In this article, we'll explore why titanium plates are essential for success in aerospace and manufacturing and how Accromet's products can help elevate your operations.

Why Choose Titanium Plates for Aerospace and Manufacturing?

Titanium is an extraordinary material with a unique combination of properties that make it ideal for industries that demand high performance, like aerospace and manufacturing. Here’s why titanium plates are indispensable:

1. Unmatched Strength-to-Weight Ratio

Titanium’s strength-to-weight ratio is significantly higher than that of steel and other metals. This makes titanium plates incredibly strong while remaining lightweight—an essential feature in industries like aerospace, where reducing weight is crucial for fuel efficiency and performance.

2. Corrosion Resistance

Whether exposed to sea water, acidic environments, or high-temperature conditions, titanium retains its integrity. This resistance makes it a prime material for aerospace components that are often exposed to harsh environmental conditions.

3. High-Temperature Performance

In aerospace and industrial manufacturing, materials need to withstand extreme temperatures. Titanium remains stable and performs well even in high heat, making it the perfect choice for components in engines, airframes, and other critical systems.

4. Biocompatibility

In some manufacturing applications, such as medical devices, titanium plates offer the advantage of biocompatibility. This property makes titanium ideal for use in implants and other medical applications where the material comes into direct contact with the body.

Titanium Plates in Aerospace: Ensuring Safety and Performance

The aerospace industry relies heavily on titanium plates due to their combination of lightweight properties and incredible strength. Airplanes, spacecraft, and satellites require materials that can withstand extreme pressure, temperature variations, and corrosion without compromising on safety. Here’s how titanium plays a critical role:

Engine Components: Titanium is often used in the construction of aircraft engines, where high strength and heat resistance are essential. Titanium’s ability to perform well at high temperatures makes it ideal for turbine blades, compressor blades, and other engine components.

Airframe and Structural Components: The aerospace industry demands materials that offer high tensile strength while minimizing weight. Titanium plates are widely used in airframes, landing gear, and fuselage sections, where they help improve fuel efficiency without sacrificing strength.

Exotic Metals in Aerospace: Beyond titanium, aerospace manufacturers are increasingly turning to exotic metals such as titanium alloys to meet demanding specifications. Titanium alloys offer enhanced strength and durability compared to pure titanium and are frequently used in critical aerospace components.

Titanium Plates in Manufacturing: Enhancing Durability and Precision

Titanium is not only crucial for aerospace but also plays a significant role in industrial manufacturing. From automotive to energy sectors, titanium plates contribute to the production of high-performance machinery and components. Some key benefits include:

Durability and Resistance to Wear: In high-stress manufacturing environments, titanium plates withstand wear and tear better than many other metals. Their resistance to fatigue and corrosion ensures long-lasting performance, even in the most demanding applications.

Precision Manufacturing: Titanium can be easily machined and fabricated into precise components for specialized applications. Whether it's creating parts for high-end automotive engines or precision tools, titanium’s versatility makes it indispensable for manufacturers who require accuracy and efficiency.

Cost-Efficiency in the Long Run: While titanium plates may have a higher initial cost compared to other metals, their durability, lightweight nature, and long lifespan make them a cost-effective solution in the long run. Fewer repairs and replacements mean reduced maintenance costs and enhanced productivity.

330 Stainless Sheet: A Complement to Titanium Plates

While titanium plates are invaluable in many applications, 330 stainless sheet is another material that complements titanium in certain manufacturing processes. 330 stainless steel is known for its exceptional resistance to oxidation and high-temperature strength, making it an excellent choice for components exposed to heat and pressure. Using a combination of titanium plates and 330 stainless sheet can optimize the performance of critical components, particularly in environments with high-temperature and corrosion challenges.

Q&A: Titanium Plates in Aerospace and Manufacturing

Q1: What makes titanium plates suitable for aerospace applications? A1: Titanium’s combination of strength, lightweight properties, and corrosion resistance makes it ideal for aerospace. Its ability to perform under extreme temperatures and pressure ensures the safety and efficiency of aircraft and spacecraft components.

Q2: How does titanium compare to other metals in manufacturing? A2: Titanium outperforms many metals in terms of durability, strength-to-weight ratio, and resistance to corrosion and high temperatures. While it can be more expensive initially, its long lifespan and high performance make it a cost-effective choice in the long run.

Q3: Can titanium plates be used in medical applications? A3: Yes, titanium is biocompatible, which makes it an excellent choice for medical implants, prosthetics, and other applications where direct contact with the human body is required.

Conclusion: Choose Accromet for High-Quality Titanium Plates

When it comes to sourcing titanium plates for aerospace, manufacturing, or other industrial applications, Accromet is a trusted name in the industry. Our titanium products are designed to meet the highest standards of quality, offering the durability, strength, and precision required for critical operations.

Whether you need titanium plates for aerospace engineering, automotive manufacturing, or medical devices, Accromet provides the reliable materials you need to ensure success. Reach out to us today to learn more about our titanium offerings and how they can enhance your operations.

#TitaniumPlates#AerospaceMaterials#ManufacturingSolutions#TitaniumMetal#ExoticMetals#TitaniumAlloys#Accromet#330StainlessSteel#IndustrialMaterials#HighPerformanceMaterials#CorrosionResistantMetals#DurableMetals#TitaniumForIndustry#TitaniumManufacturing#AerospaceTechnology#HeavyDutyMetals#PrecisionManufacturing#AdvancedMetals#MetalFabrication#MaterialScience

0 notes

Text

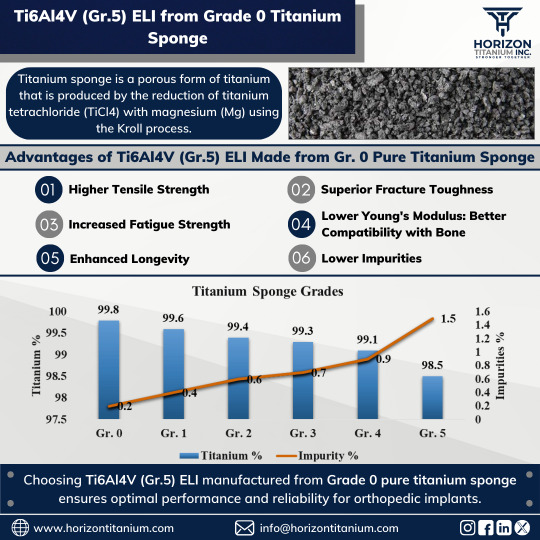

Titanium is vital in the medical field due to its biocompatibility, strength, and corrosion resistance. However, the quality of medical-grade titanium depends on the grade of titanium sponge used in production. Let's explore how titanium sponge impact the quality of titanium for medical devices and implants.

What is Titanium Sponge? Titanium sponge, made through the Kroll process, is a porous, brittle form of titanium. It needs further processing and alloying with elements like aluminum and vanadium (Ti6Al4V (Gr.5) ELI) to be used in manufacturing medical devices. Its quality and purity are critical for the final titanium properties.

Importance of Choosing the Right Grade The grade of titanium sponge used to manufacture titanium material for medical applications has a profound impact on the quality and performance of the final product. By selecting the right grade, manufacturers can ensure that medical devices made from high-purity Sponge Gr. 0 material will meet the stringent standards required for medical use, providing safe and effective solutions for patients.

If you need any further information, reach out at [email protected]

#KnowYourTitanium#Titanium#TitaniumSponge#TitaniumSpongeGrade0#TitaniumManufacturing#KrollProcess#Ti6Al4VELI#Grade5ELI#HigherTensileStrength#SuperiorFractureToughness#IncreasedFatigueStrength#LowerYoungModulus#EnhancedLongevity#LowerImpurities#MaterialScience#TitaniumQuality#MedicalGradeTitanium#TitaniumImplants#OrthopaedicImplants#MedicalDevices#HorizonTitanium#StrongerTogether

0 notes

Photo

Titanium Products Manufacturers Grade 2, Grade 5 Suppliers, Titanium Pipe, Tube, Plate, Flange, Fastener, Wire, Rod, Nut Bolts, Sheet, Hexagonal Bar, etc .

0 notes

Text

EXPLORING THE WORLD OF FERRO TITANIUMMANUFACTURERS IN INDIA

Ferro Titanium Manufacturers in India: India, with its flourishing steel industry, boasts numerous ferrotitanium manufacturers. These manufacturers play a crucial role in meeting the demand for quality ferro titanium products. While we cannot provide direct information about specific manufacturers, you can explore reputable online directories, industry associations, and trade fairs to discover the diverse range of manufacturers operating in India.

Factors to Consider: When searching for ferro titanium manufacturers, several factors should be considered to ensure a reliable and reputable partnership:

Experience and Expertise: Look for manufacturers with substantial experience in producing ferrotitanium. Seasoned manufacturers are often well-versed in the nuances of the manufacturing process, leading to superior quality products.

Quality Certifications: Check if the manufacturers hold relevant quality certifications, such as ISO9001, which demonstrate their commitment to maintaining stringent quality standards.

Production Capacity: Evaluate the production capacity of manufacturers to ensure they can meet your requirements in terms of volume and timely delivery.

Customization Capabilities: Assess whether the manufacturers can provide tailored ferrotitanium products based on your specific needs, including particle size, composition, and other parameters.

Reputation and Customer Reviews: Research the reputation of the manufacturers by reading customer reviews and testimonials. This can provide insights into their reliability, customer service, and product quality.

Conclusion: Ferro titanium manufacturers in India contribute significantly to the steel industry and various other sectors by providing high-quality ferro titanium powder. As a versatile alloy, it enhances the performance and longevity of steel alloys used in critical applications. By considering the factors mentioned above and conducting thorough research, businesses can establish reliable partnerships with reputable ferro titanium manufacturers in India.

If you have any further questions or need assistance with any other topic, please feel free to ask.

☎ : +91 9899 738234 | : [email protected]

0 notes

Video

tumblr

SHENZHEN YATAIXIN METAL CO.LTD is a high-technology enterprises, which is specialized in the production, research and development of titanium, Titanium plate, Titanium wire,Titanium screw,Titanium clad copper, Platinized titanium electrode and the related finished products.Our company is a professional manufacturer of titanium products.

If you need any titanium products just let us know ,we can provide competitive price to make your products competitive in this market .

️+8618129970360 [email protected]

#titanium #titaniummaterials #titaniumsheet #titaniumplate #titaniumsheets #titaniumplates #titaniumrod #titaniumrods #titaniumbar #titaniumbars #titaniumwire #titaniumwires #titaniumcoil #titaniumcoils #titaniumtube #titaniumpipe #titaniumbasket #titaniumanode #titaniumdisc #titaniumracks #titaniumcoolingpipe #titaniumplatingracks #titaniumjig #electroplating #anodizing #titaniummesh #titaniumscrews #titaniumcustom #titaniummanufacturer #titaniumfactory #titaniumshenzhen #titaniumshanxi #titaniumchina #mailus #phoneus #highquality #supplier#[email protected] #18129970360

1 note

·

View note

Link

We OZAIRTRADELINK are the leading brand in the market to provide our clients the best range of Titanium Sheets and Plates. The provided product is precisely manufactured by skilled professionals using the best quality basic material and modern technology. These products are nicely packaged in appropriate material and are made by our experts with use of best grade raw material.

#TITANIUMSHEETS#TITANIUMPLATES#TITANIUMCOILS#TITANIUMSUPPLIERS#TITANIUMMANUFACTURERS#TITANIUMEXPORTERS#TITANIUMSHEETSSUPPLIERS

0 notes

Text

Titanium Plates in the Energy Sector: Boosting Efficiency and Performance

Introduction

Titanium plates have become an essential material in various industries, particularly in the energy sector. Their unparalleled strength, resistance to corrosion, and ability to withstand extreme temperatures make titanium plates the material of choice for many energy applications. As the demand for efficient, durable, and high-performance materials continues to rise, titanium plates are playing an increasingly critical role in enhancing energy sector operations. This article explores how titanium plates are revolutionizing the energy sector and driving improvements in efficiency and performance.

What Are Titanium Plates?

Titanium plates are flat, durable, and corrosion-resistant sheets made from titanium metal. They are known for their high strength-to-weight ratio, making them ideal for applications that require materials capable of withstanding extreme conditions. Titanium plates are used in a variety of industries, including aerospace, automotive, medical devices, and, notably, the energy sector.

Why Titanium Plates Are Essential in the Energy Sector

The energy sector is responsible for generating and distributing power, and its operations often involve complex and challenging conditions. Titanium plates offer several key advantages in this industry:

1. Corrosion Resistance

One of the primary reasons titanium plates are favored in the energy sector is their exceptional resistance to corrosion. In environments such as offshore drilling rigs, chemical plants, and power plants, equipment is exposed to harsh conditions, including saltwater, acids, and high-pressure environments. Titanium plates provide long-lasting protection against corrosion, ensuring that equipment remains functional for longer periods with minimal maintenance.

2. High-Temperature Durability

Energy generation processes, especially in power plants, require materials that can withstand high temperatures. Titanium plates can maintain their strength and integrity at elevated temperatures, making them ideal for applications such as heat exchangers, reactor vessels, and turbine components. Unlike other materials that degrade over time when exposed to extreme heat, titanium retains its mechanical properties and continues to perform efficiently.

3. Strength-to-Weight Ratio

Titanium plates are known for their high strength-to-weight ratio, meaning they provide maximum strength without the added weight. In energy sector applications, this is crucial. For example, in offshore drilling platforms and oil rigs, weight considerations are critical, and titanium plates help optimize performance without compromising structural integrity. This leads to more efficient designs, which in turn improve overall energy production capabilities.

4. Improved Efficiency and Reduced Downtime

Titanium plates are extremely durable, reducing the likelihood of failure and downtime in energy systems. With their superior resistance to wear and tear, they ensure that machinery and equipment operate at optimal efficiency for longer periods. Reduced downtime leads to increased productivity, helping energy companies maximize their output and profitability.

5. Long Lifespan and Cost Savings

While titanium plates may have a higher initial cost compared to other materials, their long lifespan and durability often lead to significant cost savings in the long run. With fewer replacements, repairs, and maintenance requirements, titanium plates provide excellent return on investment for energy companies. Their longevity also means fewer disruptions to operations, ensuring a more consistent and reliable energy supply.

Applications of Titanium Plates in the Energy Sector

Titanium plates are used in a wide range of energy sector applications, including:

Offshore Drilling: Titanium’s resistance to corrosion makes it ideal for offshore platforms, where exposure to seawater is a significant concern.

Nuclear Power Plants: Titanium plates are used in the construction of reactor components due to their heat resistance and non-reactivity with the nuclear environment.

Petrochemical Plants: Titanium’s durability against chemical exposure makes it an essential material for components used in petrochemical processing.

Gas Turbine Components: Titanium plates are used in the manufacture of gas turbines, where high strength and thermal stability are required.

Heat Exchangers: In energy production, titanium plates are often employed in heat exchangers to efficiently transfer heat without degradation.

Q&A: Common Questions About Titanium Plates in the Energy Sector

Q1: What makes titanium plates better than other materials for the energy sector?

Titanium plates stand out for their exceptional resistance to corrosion, high-temperature stability, and strength-to-weight ratio. These qualities make them ideal for harsh environments like offshore drilling, nuclear power plants, and petrochemical facilities.

Q2: Are titanium plates expensive for energy companies?

While titanium plates can be more expensive upfront than materials like steel, their durability and long lifespan lead to significant cost savings over time, reducing maintenance and replacement costs.

Q3: How do titanium plates contribute to energy efficiency?

Titanium plates improve energy efficiency by reducing downtime, enhancing performance in high-temperature environments, and offering a high strength-to-weight ratio that allows for more efficient equipment designs.

Q4: Can titanium plates be used in renewable energy applications?

Yes, titanium plates are increasingly being used in renewable energy applications, including geothermal and solar energy systems, where corrosion resistance and durability are vital.

Conclusion

Titanium plates are a game-changer for the energy sector, offering unmatched strength, durability, and resistance to harsh environments. From offshore drilling to nuclear power plants, their versatility and long-term performance are critical to boosting efficiency and minimizing operational costs. Energy companies seeking to stay competitive must consider the advantages of titanium plates as part of their materials strategy.

If you’re looking for high-quality titanium plates for your energy sector operations, contact us today. Our expert team can help you choose the right materials to boost your efficiency and performance.

#TitaniumPlates#IndustrialTitanium#TitaniumApplications#TitaniumManufacturing#HighTemperatureMaterials#CorrosionResistant#EnergyEfficiency#IndustrialApplications#EnergySolutions#SustainableMaterials#TitaniumAdvantages#USAIndustry#industrial titanium plates

0 notes

Text

Where to Buy High-Quality Titanium Plates for Your Industrial Needs

Titanium plates are indispensable in numerous industries, known for their exceptional strength, lightweight properties, and corrosion resistance. Whether you're working in aerospace, medical devices, or manufacturing, high-quality titanium plates are a crucial component for various applications. In this guide, we'll explore where to buy titanium plates, the key factors to consider when selecting them, and how they can benefit your industrial operations.

Why Choose Titanium Plates for Industrial Use?

Titanium plates have long been valued for their unique combination of properties. The advantages of using titanium plates in industrial applications include:

1. Exceptional Strength-to-Weight Ratio

Titanium plates are renowned for their high strength while being significantly lighter than other metals like steel. This makes them perfect for industries such as aerospace, where weight reduction is crucial for fuel efficiency and performance.

2. Corrosion Resistance

Titanium has a natural resistance to corrosion, even in harsh environments such as seawater or acidic conditions. This makes titanium plates highly sought after for marine, chemical, and medical applications where materials are exposed to corrosive substances.

3. Durability

Titanium plates are highly durable and resistant to wear and tear, offering long-lasting performance and reducing maintenance costs. This durability ensures that parts made from titanium remain reliable over time, even in high-stress environments.

4. Biocompatibility

Due to its non-reactive nature, titanium is biocompatible, which makes it an ideal material for medical implants, surgical instruments, and other healthcare applications.

Key Considerations When Buying Titanium Plates

1. Grade of Titanium

When purchasing titanium plates, one of the most important considerations is the grade of titanium. Common grades include:

Grade 2 (Commercially Pure Titanium): Known for its excellent corrosion resistance, this grade is often used in chemical processing and marine applications.

Grade 5 (Ti-6Al-4V): The most popular titanium alloy, this grade combines strength and lightweight properties, making it ideal for aerospace, automotive, and high-performance engineering applications.

Choosing the right grade depends on the specific requirements of your project, such as strength, corrosion resistance, and weight.

2. Size and Thickness

The size and thickness of the titanium plates you require will depend on the application. Larger, thicker plates are needed for heavy-duty applications such as aerospace components, while thinner plates may be suitable for medical implants or smaller devices.

3. Surface Finish

The surface finish of titanium plates is another important factor. Smooth surfaces may be required for medical or food processing applications, while rougher surfaces may be suitable for industrial use, where strength and durability are the top priorities.

4. Cost and Availability

The cost of titanium plates can vary depending on factors such as size, grade, and supplier. While titanium is a premium material, investing in high-quality titanium plates can pay off in terms of performance and longevity. It's important to source your plates from a trusted supplier that offers competitive pricing without compromising on quality.

Where to Buy Titanium Plates

If you're looking for high-quality titanium plates for your industrial needs, it's crucial to choose a supplier with a proven track record and experience in providing durable and reliable materials. Companies like Accromet, a leader in the titanium products industry, offer a wide selection of titanium plates, ensuring that businesses across sectors can find the materials they need to support their operations. Visit Accromet for more information on purchasing premium titanium plates.

Factors to Look for in a Supplier:

Experience and Reputation: Choose a supplier with extensive industry experience and positive customer reviews.

Customization Options: Some suppliers, like Accromet, offer customization services to meet specific project needs, such as special sizes, finishes, and alloy compositions.

Quality Assurance: Ensure the supplier follows stringent quality control processes to deliver high-quality titanium plates.

Fast Delivery and Support: Look for a supplier that can deliver your materials on time and provides excellent customer support.

How Titanium Plates Enhance Industrial Productivity

Titanium plates can significantly boost productivity in various industries by offering the following benefits:

Reduced Maintenance Costs: The durability and corrosion resistance of titanium plates reduce the need for frequent replacements and maintenance, allowing for smoother operations.

Improved Efficiency: The lightweight nature of titanium allows for better performance, especially in aerospace and automotive applications where weight savings can result in improved fuel efficiency and speed.

Longer Service Life: Parts made from titanium plates tend to last longer, providing a better return on investment in the long run.

Q&A: Common Questions About Titanium Plates

Q: Can titanium plates be welded?

A: Yes, titanium plates can be welded, but it requires special techniques and equipment to prevent contamination and ensure a strong, reliable bond. Welding should be done in a controlled environment, typically using an inert gas to protect the material during the process.

Q: What industries use titanium plates?

A: Titanium plates are used in a wide range of industries, including aerospace, medical devices, chemical processing, marine, and automotive industries. Their unique properties make them ideal for applications where strength, lightweight design, and corrosion resistance are essential.

Q: Are titanium plates expensive?

A: Titanium plates are generally more expensive than other metals, such as steel or aluminum, due to the cost of production and the properties they offer. However, the long-term durability and performance make titanium a cost-effective option for many industries.

Conclusion: Invest in High-Quality Titanium Plates for Your Business

Whether you're in aerospace, medical devices, or manufacturing, titanium plates offer unparalleled benefits in terms of strength, corrosion resistance, and durability. By purchasing high-quality titanium plates from trusted suppliers like Accromet, you can ensure that your business operations run smoothly, efficiently, and safely.

Call to Action: Ready to invest in the best titanium plates for your industrial needs? Visit Accromet today to browse our extensive collection of premium titanium plates and start optimizing your projects today!

#TitaniumPlates#IndustrialTitanium#TitaniumProducts#AerospaceMaterials#MedicalTitanium#CorrosionResistantMetals#TitaniumAlloy#TitaniumManufacturing#TitaniumForIndustry#TitaniumSupplier#Accromet#IndustrialMaterials#HeavyDutyTitanium#TitaniumWelding#TitaniumInAerospace#TitaniumAlloys#HighPerformanceTitanium#TitaniumForMedicalDevices#TitaniumPlatesForSale#TitaniumMetalSupplier

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

Today, in our ongoing video series on Titanium bar manufacturing, we've highlighted the final stages of manufacturing. This part highlights how we carefully mark and pack the Titanium Round bars to make sure they're top quality and easy to track.

Distinguishing Marking and Packaging Process Parameters:

Marking: Our Titanium Round bars marked with “Company name, ASTM/ISO standards, Grade, Size, Length, Heat number, and Lot number”

Packaging: Based on Size 1-50 No’s bundle preparation Each bundle packed in the recycling plastic bag Each bundle packed in an export-worthy wooden box

Distinguishing Marking and Packaging Process Benefits:

Marking: Traceability Compliance Quality assurance Process efficiency Customer confidence

Packaging: Surface protection Systematic organization Environmental responsibility Safe transport

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#Marking#ASTMF136#ISO5832_3#Size#Length#HeatNumber#LotNumber#Packaging#BundlePreparations#EcoFriendlyPlasticBag#ExportWorthyWoodenBox#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

In our ongoing video series about the manufacturing process of Titanium bars, today we've shared the finishing steps of manufacturing. Here, we focus on chamfering and ensuring that Titanium Round Bars are of the highest quality.

Distinguishing Process Parameters:

Chamfering: Controlled feed rate Controlled cutting speed Controlled depth of cut Continuous coolant and lubrication

Quality Analysis: Material qualifications as per ASTM and ISO international specification Testing carried out as per International Testing Procedures

Distinguishing Chamfered and Tested Bars Quality:

Reduced stress concentration at both side edges Machining benefits Easy to handle Enhanced workpiece functionality Chemical analysis, Tensile testing, Ultrasonic testing, Metallurgical analysis, Dimensional analysis, and Analysis reports

Stay tuned as we take a closer look at how we make Titanium bars for medical purposes.

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#Chamfering#EasytoHandle#ReduceStressConcentrations#QualityAnalysis#ISO#ASTM#Testing#MaterialQualifications#Specifications#Standards#ChemicalAnalysis#TensileTesting#UltrasonicTesting#MetallurgicalAnalysis#DimensionalAnalysis#AnalysisReports#Metallurgy#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

As we push forward in our commitment to perfect Titanium bar production, we've now arrived at a pivotal point—the ninth step. This phase revolves around the intricacies of Peeling and Centerless Grinding for Titanium Round Bars.

Distinguishing Process Parameters:

Peeling: Controlled peel depth Controlled feeding rate Controlled workpiece temperature Continuous coolant and lubrication Peeling forces monitoring

Centerless Grinding: Controlled workpiece speed Controlled grinding wheel speed Controlled residual stress Controlled grinding wheel gap Continuous coolant and lubrication

Distinguishing Peeled and Centerless Grinded Bars Quality:

Free from Alpha Case layer Precise tolerance with a 10-micron diameter difference throughout the lot size Mirror-finished surface Free from surface imperfections

Stay tuned as we navigate this journey together, granting you a comprehensive view of our production methods. Our enthusiasm lies in unveiling each essential stage in the precise manufacturing of Titanium bars, exclusively intended for medical use.

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#PeelingProcess#CenterlessGrinding#FreeofAlphaCase#PreciseTolerance#MirrorFinishedSurface#FreefromSurfaceImperfections#Polishing#Microstructure#ImprovedMechanicalProperties#Metallurgy#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

Continuing our journey to enhance Titanium bar production, we've reached a critical juncture—the eighth step. This phase involves the removal of Hydrogen from Titanium Round Bars using a Vacuum Heat Treatment Furnace.

Distinguishing Process Parameters:

Heat treatment under vacuum atmosphere Controlled gas atmosphere Controlled pressure, heating and cooling rate Monitoring and control systems

Distinguishing Vacuum Heat-Treated Bars Quality:

High Purity Free of microstructure imperfections Low hydrogen content Higher fracture toughness and fatigue strength

Stay connected as we journey through this exploration, providing you with an in-depth view of our production techniques. We are enthusiastic about unveiling every critical stage in the precise creation of Titanium bars designed exclusively for medical purposes.

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#VacuumHeatTreatment#HydrogenRemoval#Heating#ELI#HighPurity#Microstructure#FractureToughness#FatigueStrength#ImprovedMechanicalProperties#Metallurgy#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

As we advance through our Titanium bar manufacturing process, we've now reached the pivotal sixth step, where we craft Titanium round bars from Titanium Billet using a hot rolling process

Distinguishing Process Parameters:

Controlled rolling temperature Controlled deformation speed Uniform and close tolerance Process monitoring and control systems

Distinguishing Hot Rolled Bars Quality:

Material consistency Uniform microstructure Dimensional accuracy Defect-free bar

Stay connected along with us as we continue on this journey, providing you with an in-depth exploration of our production process. We are excited to share every important stage in the creation of high-quality Titanium bars designed specifically for medical applications

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#TitaniumHotRolledBars#PreFinishing#PreHeating#TitaniumHotRolling#HotRolling#SizeReduction#SemiAutomaticHotRolling#ELI#UniformMetallurgy#ImprovedMechanicalProperties#Metallurgy#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

In the progression of our Titanium bar manufacturing process, we now arrive at the fifth essential step, which entails forming the Titanium Billet through an automatic robotic forging process.

Distinguishing Process Parameters:

Controlled forging pressure Controlled deformation speed Real-Time Monitoring and Feedback Automation and Robotics

Distinguishing Forged Billet Quality:

Material homogeneity Consistent microstructure Precise dimensions High strength Free of defects and inclusions

Stay tuned as we progress through this journey, offering you a comprehensive look at our production process. We're enthusiastic about sharing each significant step in the manufacture of top-quality Titanium bars tailored for medical applications.

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#TitaniumBillet#TitaniumForging#RoboticForging#HighStrength#ELI#HomogeneousMetallurgy#HighPurity#Metallurgy#UniformMicrostructure#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

Let's explore the fourth key step of our Titanium bar manufacturing process: the production of the Titanium Ingot through Vacuum Arc Re-melting.

Distinguishing Process Parameters:

Extra impurities removal Melting completely under vacuum

Distinguishing Three-Times Melted Ingot Quality:

Uniform chemical composition Uniform metallurgy High purity High strength

Stay connected as we move forward on this journey, giving you a detailed glimpse into our production process. We're enthusiastic about sharing each vital stage of crafting top-notch Titanium bars designed for medical applications.

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#TitaniumElectrode#VacuumArcRemeltingFurnace#VAR#ThreeTimesMelting#TitaniumIngot#ELI#HomogeneousMetallurgy#UniformStructure#HighPurity#Metallurgy#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes

Text

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

At Horizon Titanium Inc., we are dedicated to empowering our valued customers with the information and transparency they deserve when it comes to purchasing superior Titanium materials. Today, we share the first step in our Titanium bar manufacturing process: creating the Titanium-Aluminium-Vanadium master alloy.

Quality Ingredients

Grade 0 Titanium Sponge: We start with the purest grade 0 Titanium sponge for superior implant strength and biocompatibility.

Premium Aluminium and Vanadium: We use the highest-quality Aluminium and Vanadium to ensure exceptional properties like strength, durability, and corrosion resistance.

Precision Matters

Our skilled experts oversee alloying with precision and adhere to rigorous quality control standards.

Stay tuned for more insights into our manufacturing process as we continue to unveil each step that culminates in the creation of best quality Titanium bars for medical applications.

For more information, please contact us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ti6Al4VELI#Grade23#TitaniumManufacturing#MasterAlloyPreparation#QualityTitanium#SpongeGrade0#PremiumAluminum#PremiunVanadium#PatentedMixer#Mixing#MedicalApplications#HorizonTitanium#StrongerTogether

0 notes