#TruckLoadingConveyor

Explore tagged Tumblr posts

Text

Truck Loading Conveyors in India: Powering Modern Logistics

In the modern business world, timely truck loading and unloading can be the make or break of your supply chain activities. Truck loading conveyors have turned out to be revolutionary solutions for Indian businesses, changing the way products travel from warehouses to vehicles. This ultimate guide delves into all that you need to know about truck loading conveyor manufacturing in India.

What Are Truck Loading Conveyors?

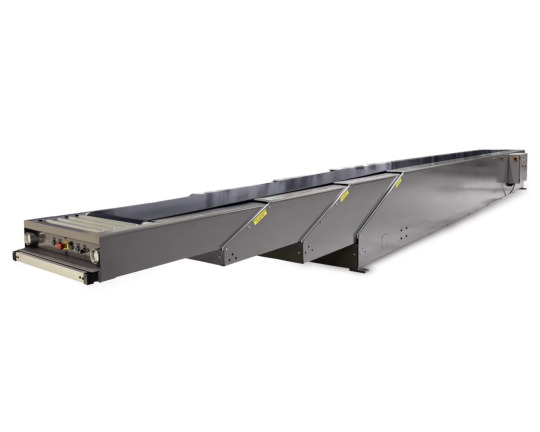

Truck loading conveyors are advanced material handling solutions used to mechanize truck, trailer, and container loading. These compact and versatile conveyor systems reduce the need for manual lifting, considerably shortening loading time, while also increasing worker safety and operational efficiency.

In contrast with fixed conveyor systems, truck loading conveyors are mobile conveyors that can be simply located at loading docks, adjusted to varying heights of trucks, and relocated between various loading bays when necessary.

These systems are usually a motorized belt or roller system mounted on a wheeled, adjustable frame. The conveyor can be extended, retracted, and vary its angle to fit various truck sizes and loads. Remote controls are found on the majority of newer units, enabling operators to control the system from a safe distance.

Types of Truck Loading Conveyors Available in India

1. Telescopic Boom Conveyors

These extendable conveyors can be extended deep into truck trailers and containers. They're ideal for loading bulk commodities, loose materials such as grain, and fertilizers.

Major Features:

Extends up to 60 feet in length

Height and angle adjustment

High-capacity handling (up to 1000 tons per hour)

2. Portable Belt Conveyors

Lightweight and easy to transport, these conveyors are ideal for loading packaged goods, boxes, and cartons.

Advantages:

Easy setup and breakdown

Ideal for a range of package sizes

Affordable for small to medium businesses

3. Roller Dock Conveyors

Conveyors that span truck bed and floor-to-floor transitions, offering smooth flow of product.

Applications:

E-commerce packaging centers

Distribution centers

Manufacturing plants

4. Flexible Conveyors

Adjustable and expandable systems that can bend, curve, and flow around obstructions.

Benefits:

Adjusts to varying truck configurations

Compact design to save space

Simple storage when idle

Why India is Leading Truck Loading Conveyor Manufacturing

1. Indigenous Industrial Demand

India's thriving e-commerce industry, large-scale manufacturing hub, and government programs such as "Make in India" have placed unprecedented pressure on cost-effective logistics solutions. Firms are investing significantly in automation to remain competitive.

2. Affordable Manufacturing

Indian manufacturers provide truck loading conveyors at affordable costs without sacrificing quality. The integration of trained manpower, latest technology, and reduced operating costs makes India a good manufacturing destination.

3. Technical Expertise

Indian manufacturers and engineers have built extensive knowledge in material handling systems, designing inventive solutions suited to local and global needs.

Major Features of Indian Truck Loading Conveyors

Strong Construction

Anti-corrosion coated heavy-duty steel frames

Drive systems and quality motors

Weather-resistant materials for outdoor applications

Powder coating finishes for strength

Safety Features

Emergency stop buttons in multiple places

Safety railings and guards

Textured belts with anti-slip surfaces

Overload protection systems

Warning lights and alarms

Safety interlocks to prevent accidental use

Customization Options

Variable speed controls (10-100 meters per minute)

Adjustable heights and inclines (up to 30-degree incline)

Customized length and width to suit individual needs

Integration with existing warehouse management systems

Multiple power options (electric, hydraulic, pneumatic)

Energy Efficiency

Low-power consumption motors (1-10 HP range)

Variable frequency drives (VFDs) for optimal power usage

Automatic start/stop capabilities to limit idle time

LED lighting systems for improved illumination

Industries That Benefit from Truck Loading Conveyors

E-commerce and Retail

Online stores employ truck loading conveyors to accelerate order fulfillment and lower shipping delays. Flipkart, Amazon India, and BigBasket are some of the companies that depend on these systems for smooth operation. Increased online buying, particularly post-COVID, has necessitated these systems to meet customer delivery demands.

Food and Beverage

Food processing plants employ heavy-duty conveyors made from food-grade materials to keep food standards in check when loading food items such as rice, wheat, sugar, and packaged foods. Stainless steel build and washable surfaces guarantee obedience to food safety regulations.

Automotive Industry

Automobile manufacturers and autoparts suppliers employ heavy-duty truck loading conveyors to ship parts, engines, and finished cars. Such systems have to carry different weights and sizes, from accessories to complete automotive assemblies.

Chemical and Pharmaceutical

These businesses demand custom conveyors that include explosion-proof motors and chemical-resistant coatings for the safe handling of delicate products. FDA and cGMP compliance is essential.

Agriculture and Fertilizers

Bulk handling conveyors assist in loading grains, fertilizers, and agrarian products efficiently, catering to India's huge agricultural industry. These systems are usually equipped with dust collection components and weather protection.

Textile and Garment Industry

India's giant textile industry applies truck loading conveyors for movement of fabric rolls, finished clothing, and raw materials. The systems ensure product quality while accelerating the loading process.

Advantages of Selecting Indian Manufacturers

Cost Benefits

Indian manufacturers provide truck loading conveyors at 30-40% less cost than global suppliers, making automation affordable for small and medium businesses.

Fast Delivery

Domestic manufacturing implies shorter delivery periods, normally 2-4 weeks as opposed to 8-12 weeks in case of imported systems.

After-Sales Support

End-to-end maintenance services, spare part availability, and local technical support guarantee limited downtime.

Customization Flexibility

Indian manufacturers specialize in designing tailor-made solutions according to particular operational needs and budgetary restrictions.

Technology Integration and Smart Features.

IoT-Enabled Systems

New-generation truck loading conveyors have sensors and connectivity features to monitor performance in real time, maintenance requirements, and operational efficiency.

Automated Controls

PLC-based control systems allow for automated operation with limited manual intervention, saving labor costs and enhancing consistency.

Safety Monitoring

Advanced safety features comprise load monitoring, emergency stops, and automatic shutdown mechanisms to avoid accidents.

Cost Factors and ROI

Investment

Truck loading conveyors are generally priced between ₹3-15 lakhs based on size, capacity, and specifications. The investment repays itself within 12-18 months in terms of increased efficiency.

Price Breakdown by Type:

Simple portable belt conveyors: ₹3-6 lakhs

Telescopic boom conveyors: ₹8-15 lakhs

Heavy-duty roller systems: ₹5-12 lakhs

Custom engineered solutions: ₹10-25 lakhs

Operating Costs

Lower labor demands (save 40-60% of workforce)

Less damage to products (cut breakage by 30-50%)

Increased speed of loading (boost speed by 200-400%)

Less energy usage than manual options

Low maintenance costs with regular care

Return on Investment

The majority of companies experience 200-300% ROI in the initial two years because of:

50-70% savings in loading time

60% savings on manual labor

Major reduction in workplace accidents (as many as 80% fewer incidents)

Increased customer satisfaction due to quicker deliveries

Increased peak season operating capability

Benefits Hidden to the Enterprise

Lowered insurance premiums based on increased safety

Improved worker retention with enhanced working conditions

Improved truck use by faster turnaround

Possible higher volumes with no proportionate increase in staff

Criteria for Choosing Truck Loading Conveyors

Capacity Needs

Establish your maximum load needs in volume and weight per hour to choose effective conveyor specifications.

The character of the product

Take into consideration the product size, weight, and fragility to be able to select the proper conveyor type, as well as options.

Operating Environment

Take into account weather conditions, space limitations, and utilization rate when choosing materials and construction details.

Budget Considerations

Weigh initial expenditure against long-term advantages, taking into account financing schemes and ROI estimates.

Installation, Maintenance

Professional Installation

Seasoned manufacturers offer total installation, including:

Site survey, planning

Foundation requirements appraisal

Equipment installation, commissioning

Operator training programs

Performance testing, qualification

Documentation and warranty provision

Installation Timeline:

Site preparation: 1-2 days

Equipment installation: 2-3 days

Testing and commissioning: 1 day

Operator training: 1-2 days

Maintenance Requirements

Regular maintenance ensures optimal performance and longevity:

Daily Checks:

Wear and damage visual inspection

Belt alignment checks

Emergency stop button testing

Weekly Maintenance:

Lubrication of moving components

Belt tension check

Motor and drive inspection

Monthly Servicing:

Detailed belt and roller inspection

Electrical connection verification

Performance calibration

Annual Maintenance:

Total system overhaul

Parts replacement as necessary

Safety system recertification

Troubleshooting Common Issues

Belt slippage: Regulate tension or change worn belts

Motor overheating: Review ventilation and load capacity

Unusual noise: Review bearings and alignment

Control system malfunctions: Check electrical connections

Future Trends in Truck Loading Conveyor Manufacturing

Automation Integration

Interface with warehouse management systems (WMS) and enterprise resource planning (ERP) software for smooth operations. This encompasses real-time inventory tracking, automated sorting features, and predictive analytics for optimal loading patterns.

Sustainable Solutions

Manufacturers are creating environmentally friendly conveyors with energy-efficient motors and recyclable parts. Solar-powered solutions are becoming available for outdoor use, minimizing carbon emissions and maintenance costs.

Smart Analytics

Artificially intelligent systems that maximize loading patterns and anticipate maintenance needs. Machine learning algorithms evaluate usage patterns to recommend enhancements and avert breakdowns.

Advanced Safety Features

Future generation safety systems comprise:

3D vision systems for detecting obstacles

Automatic balancing of loads

Predictive safety notifications

Remote monitoring capabilities

Modular Design Philosophy

Next-generation conveyor systems have modular elements that are easily reconfigured, upgraded, or expanded to meet evolving business requirements.

Selecting the Right Manufacturer: Questions to Ask

Technical Capabilities

What level of customization is possible?

Do you offer 3D modeling and simulation capabilities?

What are your quality certifications?

Do you have the capability to process special material requirements?

Service and Support

What is your warranty policy?

Do you have preventive maintenance contracts available?

How soon can you deliver spare parts?

What training options do you offer?

Financial Implications

Do you have financing available?

What is the cost of ownership?

Are there any surprise costs?

What payment conditions do you have?

Conclusion

Truck loading conveyor manufacturing in India is a successful sector that's revolutionizing logistics operations for multiple industries. The synergy of low-cost manufacturing, technical know-how, and expanding market demand makes India a world leader in this field.

No matter whether you are a small company trying to enhance efficiency or a multinational company wanting to mechanize your logistics operations, Indian manufacturers provide robust, affordable solutions optimized to meet your exact requirements.

Truck loading conveyor investing is not just about machinery – it's about revolutionizing your business processes, enhancing employee safety, and enhancing your competitiveness in the fast-moving market place. With the correct manufacturer partner, you will be able to make substantial productivity gains, cost reductions, and operational improvement.

Our Other Product and Services

truck loading conveyor in India

https://beltconveyorindia.com/truck-loading-conveyor-in-india/

chip conveyor Manufacturer in India

Inclined belt conveyor manufacturer in Faridabad

About BeltConveyorIndia

Vashnavi Conveyor Industry is a leading manufacturer of high-performance conveyor systems in India, specializing in custom-engineered solutions for efficient material handling. Based in Faridabad, we design and manufacture a wide range of conveyors, including belt conveyors, truck loading conveyors, and automated material handling systems, built to boost productivity, reduce labor costs, and streamline logistics. Whether you're in manufacturing, warehousing, packaging, or distribution, our durable and cost-effective conveyors are tailored to meet your unique needs. Partner with us for reliable, innovative, and industry-grade conveyor solutions that keep your operations moving smoothly.Contact us- [email protected]

#TruckLoadingConveyor#ConveyorManufacturersIndia#MaterialHandlingSolutions#LogisticsAutomation#IndustrialConveyors#LoadingSystems#WarehouseAutomation#IndianManufacturing#TruckConveyorIndia#SmartLogistics

0 notes

Text

Titan material handling pvt. Ltd provide Truck Loader Conveyor, Truck Loading Conveyor, Loading Unloading Conveyor, Truck Loading Unloading Conveyor at best cost, It Is the best Truck Loading Conveyor, Loading Unloading Conveyor, Truck Loading Unloading Conveyor manufacturers company in Pune, Mumbai, India, Andhra Pradesh, Visakhapatnam, SriCity, Guntur, Goa, Margao, Haryana, Gurugram, Faridabad, Gujarat, Ahmedabad, Ankleshwar, Bharuch, Gandhinagar, Jamnagar, Rajkot, Vadodara, Himachal Pradesh, Baddi, Karnataka, Bangalore, Belagavi, Tumkur, Manglore, Hubli, Maharashtra, Navi Mumbai, Mumbai, Pimpri Chinchwad, Pune, Nashik, Aurangabad, Nagpur, Kolhapur, Rajnangaon, Madhya Pradesh, Pithampur, Indore, Tamil Nadu, Coimbatore, Chennai, Hosur, Uttar Pradesh, Noida, Telangana, Hyderabad, Chakan, Hinjawadi, Pirangut, Baramati, Ranjangaon, shirur

1 note

·

View note

Text

Truck Loading Belt Conveyors for Industrial Use – Faridabad Experts

Upgrade your material handling with high-performance truck loading belt conveyors manufactured by Faridabad-based experts, including Vashnavi Conveyor Industry. These conveyors are designed to streamline the loading and unloading of trucks, containers, and trailers in warehouses, factories, and logistics hubs. With customizable lengths, adjustable heights, and durable belts, they provide safe, fast, and efficient transfer of goods—reducing labor costs and turnaround time. Ideal for industries like e-commerce, FMCG, manufacturing, and more.

#TruckLoadingConveyor#BeltConveyor#FaridabadManufacturer#MaterialHandling#IndustrialConveyors#LoadingSolutions#VashnaviConveyor#WarehouseAutomation#TelescopicConveyor

0 notes

Text

Faridabad Telescopic Conveyor Experts for High-Speed Material Movement

Enhance your loading and unloading operations with high-speed telescopic conveyors engineered by Faridabad’s leading experts – Vashnavi Conveyor Industry. Designed for efficiency, these extendable conveyors allow seamless material transfer into trucks, containers, and warehouse bays. Ideal for logistics, e-commerce, and distribution centers, they reduce manual effort, save time, and improve workplace safety. Built with robust materials and automation-ready features, Vashnavi's telescopic conveyors deliver reliable performance for demanding industrial environments.

#TelescopicConveyor#FaridabadManufacturer#TruckLoadingConveyor#MaterialHandling#ConveyorSystems#VashnaviConveyor#LogisticsAutomation#LoadingSolutions#ExtendableConveyor

0 notes