#Vial Filling and Capping Machine

Explore tagged Tumblr posts

Text

Vial Filling and Sealing Machine

Vial Filling and Sealing Machine or vial filler and sealer is monobloc vial filling and sealing machine for filling injectable glass vials. For precise filling, the machine has a filling pump made of stainless steel (SS 316L). The turntable, stainless steel slat conveyor belt, special eccentric pre-gassing, filling, and post-gassing stations are vital components of vial filler and sealer machine. High-performance, precisely constructed stainless steel 316L syringes, non-toxic synthetic rubber tubing, and a compact panel are unique offering of Adinath Vial Filling Machines.

Filling, stoppering and sealing on one platform mitigate chances of contamination. Equipment designed for sterile area operations under class 100 laminar air flow unit. Turn table with no dead end provided for smooth operation with easy to clean mechanism. We provide vial filling and capping machine in output ranging 20 VPM to 300 VPM. Machine are suitable to work with 2ml to 250ml vial sizes.

0 notes

Text

GRANDPACK CELEBRATES OVER A DECADE OF EXCELLENCE IN PHARMACEUTICAL PACKAGING SOLUTIONS

Grandpack is a leading supplier of complete solutions for pharmaceutical packaging.

Grandpack, a leading pharmaceutical machinery manufacturer & supplier from China, proudly marks over ten years of delivering comprehensive technical solutions for pharmaceutical packaging. With a steadfast commitment to quality and innovation, the company has become a trusted partner for industries worldwide.

Leveraging Computer Science to Increase Efficiency and Improve Safety

The integration of computer science into pharmaceutical packaging machinery is subtly transforming the industry, enhancing operational efficiencies, and setting new standards for production safety. Grandpack has equipped itself with smarter technologies by adopting the high standards of Industry 4.0 and IoT. Machine learning and data analytics enable Grandpack to monitor packaging lines in real time and implement predictive maintenance strategies, reducing equipment downtime by approximately 25% and improving overall production efficiency and safety.

Product Line-up of Grandpack: A Brief Overview

Grandpack is a leading company that provides effective solutions in the pharmaceutical packaging sector and offers innovative solutions that enhance productivity, accuracy, and compliance with the requirements. The company specializes in providing high-quality machines for tube filling, vial filling, and solid preparation granulation, all this with a view to automation and precision as the key goals.

The Tube Filling Machines from Grand Pack Machine cater to a wide range of industries, including pharmaceuticals, cosmetics, and food. With models offering semi-automatic and fully automatic operations, these machines ensure high-speed, precise filling and sealing, significantly reducing manual labor and production inefficiencies.

For vial filling, Grandpack provides advanced aseptic filling solutions designed for pharmaceuticals, cosmetics, and food industries. These machines ensure hygienic, high-speed liquid filling, with integrated capping and labeling options to streamline the packaging process while maintaining strict quality standards.

The Solid Preparation Granulation Line offers a fully automated solution for pharmaceutical manufacturing, minimizing human error and maximizing efficiency. With a strong focus on GMP compliance and contamination control, this system is ideal for large-scale tablet and capsule production, ensuring consistency and regulatory adherence.

With its precision-engineered packaging solutions, Grandpack continues to empower businesses with cutting-edge technology that enhances production efficiency and product integrity.

Key Advantages of Choosing Grandpack for Pharmaceutical Packaging

Proven Experience: More than ten years in pharmaceutical packaging.

Compliance with GMP & ISO 9001:2015: Guaranteeing top-tier quality standards.

Tailored Solutions: personalized options designed to fulfill unique production requirements.

Worldwide Impact: Endorsed by over 3,000 clients in more than 100 countries.

Unmatched Precision & Efficiency: Our machines are engineered for exceptional accuracy and rapid performance.

3 notes

·

View notes

Text

0 notes

Text

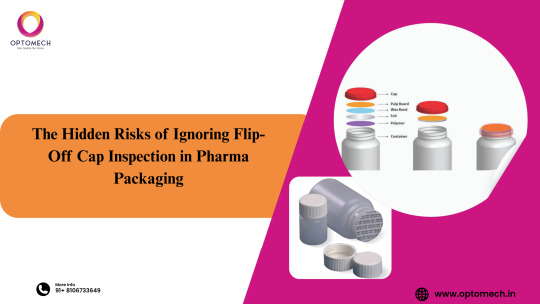

The Hidden Risks of Ignoring Flip-Off Cap Inspection in Pharma Packaging

In pharmaceutical manufacturing, every detail counts — from sterile filling to labeling. But one component often overlooked is the flip-off cap that seals injectable vials. It’s small, yes — but the consequences of not inspecting it are anything but.

Let’s talk about why ignoring flip-off seal inspection is a risk no modern pharma brand should take, and how Optomech’s FOSIS system brings precision, automation, and peace of mind to the process.

🧨 The Problem: Small Defects, Big Consequences

You may think a cap is just a cap. But even minor defects in flip-off seals can cause:

Regulatory failures during batch audits

Sterility breaches in transit or storage

Patient safety risks due to contaminated vials

Brand reputation damage from recalls or customer complaints

Typical issues include:

Black spots

Short filling of the PP button

Cut or dented aluminum shells

Color mismatches

Improper or missing plastic caps

Now imagine these defects slipping through manual or random inspections. That’s a compliance risk pharma companies can no longer afford.

✅ The Solution: Meet FOSIS – Flip-Off Seal Inspection System

FOSIS is Optomech’s high-speed, camera-based vision inspection system — purpose-built to scan, detect, and reject defective flip-off caps with unmatched accuracy.

🎯 Key Features at a Glance:

Speed: Inspects up to 600 caps/min

Vision Accuracy: Detects 20+ types of defects

Automation: No manual checking, no guesswork

Rejection System: Faulty caps are auto-ejected instantly

Compliance: Fully 21 CFR Part 11 compliant

🧠 How It Works:

Caps are fed into the system via a vibratory bowl.

High-speed cameras capture images from multiple angles.

Advanced algorithms compare each cap to a defect-free reference.

Defective caps are rejected, and logs are generated.

Reports can be exported via Excel/network sharing.

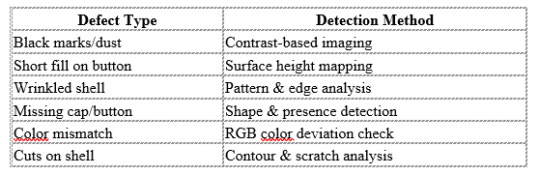

📊 Defects Detected by FOSIS:

🏭 Who Needs FOSIS?

FOSIS is ideal for:

Pharmaceutical manufacturers of injectable drugs

CMOs (Contract Manufacturing Organizations)

Flip-off cap producers

Companies targeting zero-defect packaging

Whether you're building a new packaging line or upgrading your existing setup, FOSIS integrates seamlessly and boosts inspection reliability from day one.

🔒 Why Flip-Off Cap Inspection Can’t Be Optional Anymore

In today’s regulated pharma landscape:

Quality audits are stricter

Sterility concerns are growing

Brand protection is non-negotiable

FOSIS isn't just a machine — it's your frontline quality gate. It helps you catch defects before regulators or customers do.

🏁 Final Takeaway: Inspection Is No Longer Optional — It's Strategic

Flip-off seal inspection may be a “last step” in the process, but with FOSIS, it becomes a first-class safeguard for your production integrity. Speed, accuracy, compliance — all in one automated system.

📞 Want to see FOSIS in action or schedule a demo? 📧 [email protected] 🌐 www.optomech.in/flipoff-inspection-system-2

#flipoffsealinspection#pharmapackaging#capdefectdetection#machinevisionqc#21cfrcompliant#injectablepackaging#optomechinspection#capinspectionmachine#visualinspectionpharma#zeroDefectPackaging

0 notes

Text

Comprehensive Analysis of the Fill Finish Manufacturing Market by Region & Segment

Accelerating Growth in the Fill-Finish Manufacturing Market

The global fill-finish manufacturing market is undergoing transformative growth, driven by increasing demand for biologics, heightened regulatory requirements, and the pharmaceutical industry's continued shift toward outsourcing. Forecasts estimate that the market will expand at a compound annual growth rate (CAGR) of 8.9% from 2024 to 2031, reflecting the increasing sophistication and complexity of drug formulation and delivery technologies.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40377-global-fill-finish-manufacturing-market

Fill Finish Manufacturing Market Overview: Transitioning Toward Biologic Drug Products

The proliferation of biologics and biosimilars is reshaping fill-finish operations. Unlike traditional small molecules, biologics demand precision-engineered processes, sterile environments, and advanced containment technologies to ensure safety and efficacy. Fill-finish manufacturing, a crucial last step in drug production, now plays a more strategic role in ensuring drug stability, regulatory compliance, and market readiness.

Key Fill Finish Manufacturing Market Drivers

Biologic Pipeline Expansion: Biopharmaceuticals now account for over half of drugs in development.

Rising Demand for Injectable Drugs: Increased prevalence of chronic diseases and vaccine development has spurred injectable demand.

Outsourcing to CMOs/CDMOs: Contract manufacturing organizations offer cost-efficiency, scalability, and regulatory expertise.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40377-global-fill-finish-manufacturing-market

Segmentation Analysis: Product and End User Breakdown

Consumables Dominate Product Segment

Among all product types, consumables such as vials, cartridges, prefilled syringes, stoppers, and closures constitute the largest share of the market. This segment is witnessing robust demand due to:

Increased adoption of parenteral drug delivery systems

Shift toward single-use systems to reduce contamination risk

Regulatory preference for ready-to-use (RTU) components

Instruments: Automation and Precision

The instruments segment includes aseptic fillers, capping machines, inspection systems, and labeling machines. As companies strive for higher throughput and compliance, automated systems with minimal human intervention are gaining traction.

End User Insights

Contract Manufacturing Organizations (CMOs)

CMOs currently account for the largest revenue share. Pharmaceutical firms are increasingly leveraging CMOs for their:

Specialized regulatory knowledge

Ready-to-deploy infrastructure and sterile environments

Ability to accelerate time-to-market

Pharmaceutical and Biotechnology Companies

In-house manufacturing remains significant for large biopharma players who invest in proprietary capabilities, but many are still embracing hybrid models that combine in-house innovation with outsourced execution.

Fill Finish Manufacturing Market Regional Analysis: Strategic Hotspots

North America

U.S. leads the market due to strong biologics pipeline and investments in manufacturing innovation.

Rapid adoption of RTU packaging components and integrated fill-finish lines.

Europe

High regulatory standards (EMA, GMP) are driving demand for compliant fill-finish infrastructure.

Germany, France, and the U.K. are leading hubs for sterile drug product manufacturing.

Asia-Pacific

India and China are emerging as manufacturing powerhouses, offering cost-effective fill-finish services and attracting global outsourcing contracts.

Japan and South Korea focus on high-end biologics production.

Middle East & Africa and South America

These regions are gradually adopting modern fill-finish technologies, led by public health initiatives and vaccine production facilities.

Key Fill Finish Manufacturing Market Players Shaping the Competitive Landscape

Several global leaders and niche specialists are shaping the competitive dynamics of the fill-finish manufacturing market.

Becton, Dickinson and Company – Notable for prefilled syringe systems and safety innovations.

Optima – Known for high-precision aseptic filling and packaging lines.

West Pharmaceutical Services, Inc. – A leading supplier of containment and delivery systems.

IMA S.P.A. – Specializes in automated aseptic fill-finish equipment.

Syntegon Technology (Bosch Packaging) – Offers scalable aseptic systems with built-in quality control.

Many companies are embracing digital transformation, integrating real-time analytics, robotic systems, and AI-powered inspection tools to enhance performance and compliance.

Emerging Trends and Technologies

Single-Use Systems

Single-use technology is redefining fill-finish workflows by minimizing cleaning validation, reducing downtime, and enabling faster batch changeovers. These systems are especially beneficial for multi-product facilities and clinical trial production.

Robotic Automation

Robotics is improving precision, sterility assurance, and flexibility. Fully automated systems can manage tasks from filling to capping to inspection with minimal human intervention.

Advanced Sterile Barrier Systems

Technological advances such as Restricted Access Barrier Systems (RABS) and isolator systems are ensuring contamination-free environments, critical for high-potency and biologic drugs.

AI and Predictive Analytics

Predictive maintenance, real-time monitoring, and AI-based quality analytics are increasingly embedded in modern fill-finish platforms, reducing downtime and improving batch yield.

Regulatory Outlook

Stringent global regulations are shaping fill-finish standards:

FDA’s cGMP guidance enforces stringent controls over aseptic processes.

EU GMP Annex 1 revisions stress on closed systems, environmental monitoring, and personnel intervention minimization.

ICH Q9 and Q10 frameworks promote risk management and pharmaceutical quality systems.

Compliance with these standards is no longer optional but a competitive differentiator.

Challenges in the Fill-Finish Landscape

Despite growth, several challenges persist:

High capital investment for sterile manufacturing infrastructure

Complexity of handling biologics, including sensitivity to temperature and shear stress

Supply chain bottlenecks for high-quality primary packaging components

Talent shortage in aseptic operations and regulatory affairs

Fill Finish Manufacturing Market Forecast and Growth Opportunities (2024–2031)

The market is expected to witness substantial growth across all segments, with particular acceleration in:

Pre-filled syringes and autoinjectors, driven by patient self-administration trends

Flexible and modular fill-finish lines supporting faster product lifecycle management

Vaccine fill-finish services, propelled by pandemic preparedness and routine immunization demand

Strategic Recommendations

To remain competitive, we recommend the following strategic directions:

Invest in Automation and Digitalization: Streamline fill-finish operations to meet quality and speed expectations.

Adopt Flexible Manufacturing Platforms: Modular lines support high-mix, low-volume production needs.

Strengthen Regulatory Readiness: Proactively align operations with evolving global standards.

Build Strategic CMO Partnerships: Outsource wisely to enhance agility and scalability.

Embrace Sustainable Practices: Adopt energy-efficient systems and recyclable materials for environmental compliance.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40377-global-fill-finish-manufacturing-market

Conclusion

The fill-finish manufacturing market is at the forefront of pharmaceutical innovation, poised for exponential growth through 2031. Companies that prioritize compliance, agility, and advanced technology adoption will capture the greatest market share and establish long-term leadership in this high-stakes segment of biopharmaceutical manufacturing.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

0 notes

Text

What You Need to Know Before Buying a Liquid Filler

The Essential Role of Liquid Filling Machines in the Pharmaceutical Industry

In the pharmaceutical industry, precision, hygiene, and efficiency are not just desired—they are mandatory. Every stage of pharmaceutical production is held to the highest standards to ensure product quality, patient safety, and regulatory compliance. Among these stages, the filling process—particularly for liquid medications—is one of the most critical. This is where Liquid filling machines come into play.

What Are Liquid Filling Machines?

Liquid filling machines are specialized equipment designed to accurately dispense and fill various types of liquid products into containers such as vials, bottles, ampoules, and syringes. These machines are engineered to handle a wide range of viscosities, volumes, and formulations, making them ideal for pharmaceutical applications.

Why Liquid Filling Machines Are Crucial in Pharmaceutical Manufacturing

1. Precision and Accuracy

In pharmaceuticals, even a slight variation in dosage can lead to serious consequences. Liquid filling machines ensure highly accurate and repeatable fills, reducing the risk of underfilling or overfilling. Modern machines use technologies such as servo-driven pistons, peristaltic pumps, and volumetric or gravimetric controls to deliver precise results every time.

2. Enhanced Efficiency

Manual filling is time-consuming and prone to error. Liquid filling machines significantly increase production speed and throughput, making them essential for large-scale pharmaceutical manufacturing. liquid filling machines manufacturer High-speed models can fill hundreds or even thousands of containers per hour, boosting productivity without compromising on quality.

3. Hygiene and Contamination Control

Maintaining sterility is paramount in pharmaceutical production. Liquid filling machines are often built to comply with GMP (Good Manufacturing Practices) and are designed for cleanroom environments. They feature clean-in-place (CIP) and sterilize-in-place (SIP) systems, ensuring that the product remains uncontaminated throughout the process.

4. Versatility and Customization

Pharmaceutical companies manufacture a wide variety of liquid products, from oral syrups to injectables. Liquid filling machines can be customized to handle different container types, fill volumes, and product viscosities. Some advanced systems also integrate capping, labeling, and inspection, providing a complete packaging solution.

5. Regulatory Compliance

Liquid filling systems are designed to meet stringent regulatory standards set by agencies like the FDA, EMA, and WHO. Accurate documentation, batch tracking, and integration with quality management systems ensure that the production process remains transparent and auditable.

Types of Liquid Filling Machines Used in Pharmaceuticals

Volumetric Fillers – Dispense a fixed volume of liquid using pistons or rotary pumps.

Peristaltic Pump Fillers – Ideal for sterile or sensitive liquids; easy to clean and maintain.

Vacuum Fillers – Suited for low-viscosity liquids; often used in bottling.

Time-Pressure Fillers – Use consistent pressure and time intervals to fill containers.

Aseptic Fillers – Specialized machines designed for sterile filling of injectables and biologics.

Key Features to Look for in a Pharmaceutical Liquid Filling Machine

High filling accuracy

Cleanroom compatibility

Ease of cleaning and sterilization

Scalability and modular design

User-friendly interface and automation

Validation and compliance documentation

Future Trends in Liquid Filling Technology

With the growing demand for personalized medicine, biologics, and sterile drug delivery systems, the need for advanced liquid filling solutions is increasing. Future machines will likely feature AI-driven quality checks, IoT integration for real-time monitoring, and greater automation, allowing for smart manufacturing with minimal human intervention.

Conclusion

In pharmaceutical manufacturing, the importance of a reliable and accurate liquid filling machine cannot be overstated. It is the cornerstone of safe, efficient, and compliant production processes for liquid medications. Investing in the right liquid filling system not only enhances operational efficiency but also ensures patient safety and regulatory approval.

As the industry continues to evolve, liquid filling technology will remain a critical component in delivering high-quality pharmaceutical products to the global market.

0 notes

Text

Revolutionizing Pharma Production: The Role of Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

Introduction

In the dynamic world of pharmaceuticals, precision, hygiene, speed, and compliance are non-negotiable. As the demand for high-quality medicines continues to rise globally, the pharmaceutical industry must meet rigorous standards in both production and packaging. This is where Pharma Packaging Machines come into play—ensuring products are safely, efficiently, and accurately packed before reaching the end-user.

At NPM Machinery Pvt. Ltd., we understand the critical importance of packaging in the pharma value chain. As a leading manufacturer of pharma packaging machines, our mission is to empower pharmaceutical companies with robust, automated, and intelligent machinery that supports regulatory compliance while improving productivity and product integrity.

In this blog, we will delve into the importance of pharma packaging machines, the types available, their benefits, and why NPM Machinery Pvt. Ltd. is your ideal partner in pharmaceutical automation.

Why Pharma Packaging Machines Matter

Pharmaceutical packaging is far more than just enclosing a product in a container. It is a protective barrier, a compliance requirement, a branding tool, and an enabler of global logistics. A well-packaged pharmaceutical product ensures:

Product integrity during transport and storage

Accurate dosage and ease of administration

Protection against contamination and tampering

Compliance with FDA and other global regulatory norms

Efficient serialization and tracking

Manual packaging simply cannot keep up with the high-volume, high-precision demands of modern pharmaceutical production. That’s where automated packaging solutions step in—offering speed, consistency, and compliance.

Core Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

At NPM Machinery Pvt. Ltd., we design and manufacture a full spectrum of advanced pharma packaging machines tailored to the needs of small-scale manufacturers as well as large pharmaceutical giants. Here are the most common types and their applications:

📦 1. Blister Packaging Machines

Ideal for packing tablets and capsules in pre-formed plastic blisters sealed with aluminum foil

Ensures tamper-proof packaging and extended shelf life

Used widely in retail and hospital pharmacy sectors

💊 2. Strip Packaging Machines

Designed to wrap tablets and capsules between aluminum or plastic strip foils

Compact, precise, and perfect for heat-sensitive medicines

Offers high output and minimal material wastage

🧪 3. Bottle Filling and Capping Machines

Automates filling of syrups, suspensions, and other liquids into bottles with accurate volume control

Integrates seamlessly with capping units for secure sealing

Customizable for different bottle sizes and materials

🏷️ 4. Labeling Machines

Applies labels accurately on bottles, ampoules, vials, or boxes

Supports serialization and barcoding for traceability

Compatible with multiple label shapes and sizes

🧼 5. Washing & Sterilizing Machines

Cleans vials, ampoules, and bottles before filling to ensure zero contamination

Uses air and water jets with complete automation

Essential for injectable and parenteral products

🧴 6. Cartoning Machines

Automates the packing of blister packs, bottles, or tubes into cartons

Integrates leaflet insertion and batch coding

Enhances product presentation and traceability

🎯 7. Inspection Machines

Detects broken tablets, missing capsules, misprinted labels, and other defects

Ensures every packaged product meets quality control standards

Reduces human error and improves customer trust

Benefits of Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

Choosing the right packaging solution is not just about machinery—it’s about performance, reliability, and long-term value. NPM Machinery's pharma packaging machines offer:

✅ 1. High-Speed Automation

Boost production rates with minimal human intervention

Ideal for mass manufacturing and 24/7 operations

✅ 2. Unmatched Accuracy

Delivers exact filling, sealing, and labeling

Reduces product loss and ensures dosage consistency

✅ 3. Compliance & Validation

Built with GMP, FDA, and CE compliance in mind

Supports 21 CFR Part 11 for electronic data integrity

✅ 4. Flexibility & Customization

Machines tailored to your product specifications

Modular designs allow for future scalability

✅ 5. Advanced Technology Integration

Equipped with PLC-based controls, SCADA systems, and IoT capabilities

Enables remote monitoring, real-time alerts, and preventive maintenance

✅ 6. Superior Build Quality

Made with stainless steel and corrosion-resistant materials

Long machine life, low maintenance, and robust performance

✅ 7. Global Support & Service

On-site training, remote diagnostics, and spare parts availability

Dedicated support teams for installation, validation, and upgrades

Industries We Serve

While our core strength lies in pharmaceutical packaging, our machines are versatile enough for other regulated industries such as:

Nutraceuticals

Ayurveda and Herbal

Cosmetics

Food & Beverage

Veterinary Medicine

Why Choose NPM Machinery Pvt. Ltd.?

With decades of experience, NPM Machinery Pvt. Ltd. has built a reputation for engineering excellence and customer-centric innovation. Here's what sets us apart:

✔️ 150+ skilled professionals including engineers, technologists, and validation experts

✔️ ISO-certified manufacturing with a focus on precision and safety

✔️ Custom turnkey packaging lines from design to commissioning

✔️ Strong domestic and global footprint with clients across Asia, Africa, Europe, and South America

✔️ Client-first approach—we adapt our solutions to your needs, not the other way around

Our goal is not just to sell machines—but to build long-term partnerships that add value to your production process, protect your brand, and ensure regulatory peace of mind.

Conclusion

The future of pharmaceutical manufacturing lies in smart, integrated, and efficient packaging systems. With increasing global demand, strict compliance requirements, and growing competition, investing in high-performance pharma packaging machines is no longer optional—it's essential.

At NPM Machinery Pvt. Ltd., we don’t just provide machines—we deliver confidence, quality, and peace of mind. Whether you're launching a new production line or upgrading your existing setup, we are here to guide you every step of the way with reliable, cutting-edge, and compliant solutions.

✅ Call to Action

Ready to upgrade your pharma packaging line? Partner with NPM Machinery Pvt. Ltd. and experience unmatched quality, service, and innovation. 📩 Contact us today for a free consultation or demo customized to your packaging needs! 🌐 Visit us at www.npmmachinery.com | 📞 +91-XXXXXXXXXX

0 notes

Text

Manual Brushing Filling and Capping Machine in Zimbabwe

SATV Industries is a Manufacturer, Supplier and Exporter of Manual Brushing Filling and Capping Machine in Zimbabwe. Our Manufacturer Unit is in Ahmedabad, Gujarat, India SATV Industries is a trusted name in the manufacturing and supply of precision-engineered machinery for the packaging industry. Among its extensive product line, the Manual Brushing Filling and Capping Machine stands out as a highly efficient, reliable, and cost-effective solution for small to medium-scale industries. This machine performs three vital tasks in a single operation—brushing, filling, and capping—making it ideal for streamlined packaging processes across multiple sectors. A Manual Brushing Filling and Capping Machine is a compact packaging solution that integrates three manual processes into one cohesive system. It cleans (brushes), fills, and seals containers such as bottles, jars, and vials. Operated manually, this machine ensures precise filling and capping for industries that demand hygiene, control, and efficiency in their production lines. Why Choose SATV Industries' Manual Brushing Filling and Capping Machine? Made with Premium Materials – Engineered with high-quality stainless steel for durability and resistance to corrosion. Customizable Configurations – Adjustable for different bottle sizes and capping types. Low Maintenance – Simple construction makes it easy to clean and maintain. Cost-Effective Solution – Perfect for startups and SMEs needing industrial-grade packaging at affordable rates. Trusted Brand – SATV Industries is renowned for its innovation, support, and customer-first approach. Features: Manual operation for complete control. Sturdy stainless steel construction. Interchangeable filling nozzles for different viscosities. Anti-drip system to prevent spillage. Ergonomic design for easy handling. Compact footprint – space-saving. Non-electric – ideal for remote or low-resource settings. FAQs: What industries benefit most from a manual brushing filling and capping machine? Industries like pharmaceuticals, food & beverage, cosmetics, and chemical manufacturing benefit due to the machine’s versatility and compact design. Is it suitable for rural or off-grid facilities? Absolutely. Being manually operated, it doesn’t require electricity and is ideal for low-resource environments. SATV Industries is a Manual Brushing Filling and Capping Machine in Zimbabwe, Including Harare, Masvingo, Bulawayo, Chitungwiza, Mutare, Gweru, Nkayi, Kwekwe, Norton, Kadoma, Chegutu, Chinhoyi, Marondera, Sakubva, Bindura, Hwange, Beitbridge, Chiredzi, Rusape, Zvishavane, Chipinge, Karoi, Victoria Falls, Redcliff, Mukumbura, Gwanda, Lupane. For more information, please feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#AutomaticLabelingMachines#Beitbridge#Bindura#BottleWashingMachines#Bulawayo#Chegutu#Chinhoyi#Chipinge#Chiredzi#Chitungwiza#Exporter#ExporterofManualBrushingFillingandCappingMachine#Gwanda#Gweru#Harare#Hwange#India#Kadoma#Karoi#Kwekwe#LiquidFillingMachines#ManualBrushingFillingandCappingMachine#ManualBrushingFillingandCappingMachineinZimbabwe#ManufactureofManualBrushingFillingandCappingMachine#Manufacturer#Marondera#Masvingo#Mukumbura#Mutare

0 notes

Text

Vial Filling Stoppering and Sealing Machine

Vial filling and sealing machines are considered apt for filling, sealing and capping small vials with anti-biotics and other injectables. These machines are known for their exceptional features making essential functions such as filling, stoppering and sealing on one platform like cake-walk.

Adinath International is a premier vial filling and capping machine manufacturer in India offering vial filling capping combi machines that have special mechanical arrangements for reliable, stable and accurate functionalities for plugging and capping arrangements. These machines are widely uses in the pharmaceutical industry and are capable of handling multiple vials every minute. They are uses for both sterile and non-sterile applications.

As a leading supplier of vial filling and sealing machines, Adinath International offers a variety of vial filling machines with different capacities and you can choose the one that perfectly fits your requirements.

Automatic two head vial filling machine

Automatic four head vial filling machine

Automatic six head vial filling machine

Automatic eight head vial filling machine

Small vial filling machine

0 notes

Text

How Pump Capping Machines Improve Efficiency in Cosmetic and Pharmaceutical Packaging

In the fast-paced world of cosmetic and pharmaceutical packaging, efficiency is a cornerstone of success. Manufacturers face mounting pressure to deliver high-quality products at scale while adhering to stringent regulatory standards. Pump capping machines have emerged as a transformative solution, streamlining production processes and enhancing operational performance. These advanced systems are designed to automate the application of pump caps, droppers, and spray mechanisms, which are critical components in packaging for creams, serums, lotions, and medicinal liquids. By integrating pump capping machines into production lines, companies can achieve significant improvements in speed, precision, and cost-effectiveness.

The primary advantage of pump capping machines lies in their ability to automate repetitive tasks. Manual capping is labor-intensive, prone to human error, and often results in inconsistent application. Misaligned or loosely fitted caps can lead to product leaks, contamination, or compromised shelf life, which are unacceptable in industries where safety and quality are paramount. Pump capping machines eliminate these risks by delivering uniform torque and precise cap placement. Equipped with advanced sensors and programmable controls, these machines ensure that each cap is securely fastened, meeting exact specifications every time. This consistency not only enhances product integrity but also reduces the need for costly rework or product recalls.

Speed is another critical factor driving the adoption of pump capping machines. In high-volume production environments, time is a precious resource. These machines can process thousands of units per hour, far surpassing the output of manual or semi-automated systems. By integrating seamlessly with conveyor belts and filling stations, pump capping machines create a cohesive, continuous workflow. This minimizes bottlenecks and allows manufacturers to meet tight deadlines without sacrificing quality. For cosmetic brands launching seasonal products or pharmaceutical companies responding to urgent demand, this accelerated throughput is a game-changer.

Beyond speed and precision, pump capping machines contribute to cost savings. While the initial investment may seem significant, the long-term financial benefits are substantial. Automation reduces reliance on manual labor, lowering workforce costs and mitigating the impact of labor shortages. Additionally, the precision of these machines minimizes material waste caused by damaged caps or over-torqued bottles. Energy-efficient designs further reduce operational expenses, making pump capping machines a sustainable choice for modern production facilities. Over time, these savings translate into a strong return on investment, allowing companies to allocate resources to innovation and growth.

Flexibility is another hallmark of pump capping machines. Cosmetic and pharmaceutical products come in diverse packaging formats, from sleek glass vials to sturdy plastic bottles. Advanced capping machines are designed to accommodate a wide range of container sizes, shapes, and cap types. Quick-changeover features enable operators to switch between product lines with minimal downtime, supporting the dynamic needs of manufacturers producing multiple SKUs. This adaptability is particularly valuable in industries where consumer preferences and market trends evolve rapidly.

In addition to operational benefits, pump capping machines enhance compliance with regulatory standards. The pharmaceutical industry, in particular, operates under strict guidelines to ensure product safety and efficacy. Automated capping systems provide traceability and data logging, allowing manufacturers to document every step of the packaging process. This transparency is invaluable during audits and inspections, helping companies maintain compliance with Good Manufacturing Practices (GMP) and other regulations.

Ultimately, pump capping machines are a vital asset for cosmetic and pharmaceutical manufacturers aiming to optimize their packaging processes. By combining speed, precision, cost-efficiency, and flexibility, these systems empower companies to meet growing demand while upholding the highest standards of quality and safety. As competition intensifies and consumer expectations rise, investing in pump capping technology is a strategic move to stay ahead in these dynamic industries. Source: https://autopackmachinespvtltd.wordpress.com/2025/04/19/how-pump-capping-machines-improve-efficiency-in-cosmetic-and-pharmaceutical-packaging/

0 notes

Video

youtube

Vial bottles liquid/powder filling-plugging-capping machine#fillingmachi...

0 notes

Text

0 notes

Text

Why Flip-Off Cap Inspection Is the Missing Link in Your Pharma Packaging Line

When it comes to injectable packaging, flip-off seals are more than just aluminum caps — they’re your brand’s first line of defense in ensuring sterility, safety, and quality. Unfortunately, they’re also one of the most overlooked areas in quality control.

Enter Optomech’s FOSIS — a next-gen flip-off seal inspection system that combines machine vision, high-speed automation, and regulatory-ready software to eliminate defects before your products leave the line.

🔍 What Can Possibly Go Wrong with a Flip-Off Seal?

You’d be surprised.

During mass production, flip-off caps often suffer from:

Black spots

Short fills on the PP button

Wrinkles or dents on the aluminum shell

Color mismatches

Dust, dirt, or improper crimps

Missing caps or incomplete assemblies

Individually, these might seem minor. But together, they can:

Lead to product recalls

Fail regulatory inspections

Damage brand reputation

Cause delays in batch release

⚙️ How FOSIS Detects These Defects in Real-Time

The Flip-Off Seal Inspection System (FOSIS) uses a combination of:

High-speed vision cameras

Precision lighting and optics

Custom-developed algorithms

21 CFR Part 11 compliant software

Here's how it works:

Seals are fed through a vibratory bowl to a conveyor.

As they pass under the vision station, each cap is captured frame-by-frame.

The system checks for all defined defects in under a second.

Defective caps are immediately rejected without stopping the line.

Data is logged and reports are generated for compliance and traceability.

💼 Where Can FOSIS Be Used?

If you manufacture or package:

Injectables

Sterile vials

Flip-off caps or seals

Pharma glass bottles

…then you’re the perfect use case for FOSIS.

Whether you're a large pharmaceutical company, a contract manufacturing organization (CMO), or a packaging component supplier, FOSIS adds speed, consistency, and reliability to your inspection process.

📊 Built for Pharma Compliance & Performance

Key Features:

Inspects up to 600 caps/min

Handles cap sizes from Dia 15 mm to 36 mm

Detects over 20 defect types including:

Shell deformations

PP button cuts or flashes

Color and shade variations

User-friendly 21” touchscreen with quick product changeovers

Three-level access control: User, Supervisor, Admin

Auto reporting to Excel, with network export and historical data access

📞 Take Control of Your Cap Quality – Don’t Leave It to Chance

With market demands rising and regulatory scrutiny at an all-time high, it’s time to move beyond manual checks and partial sampling.

Optomech’s FOSIS Flip-Off Seal Inspection System gives you:

Faster output

Reduced batch rejections

Higher customer trust

Better compliance audit readiness

🧪 Ready to See It in Action?

Whether you need a demo, pricing, or integration advice, we’ve got you covered.

📧 [email protected] 📞 +91 40 23078371 🌐 www.optomech.in

0 notes

Text

Leading Manufacturer of Pharmaceutical Machinery in China: Comprehensive Solutions for Vial and Ampoules Packaging Line

As a trusted manufacturer of pharmaceutical machinery and equipment, we specialize in delivering complete solutions designed for the production of tablets, liquids, capsules, powders, granules, and especially Vial and Ampoules Packaging Line. Our robust manufacturing capabilities, advanced R&D, and unwavering commitment to quality position us at the forefront of the pharmaceutical equipment industry in China and globally.

Why Choose Our Pharmaceutical Machinery Solutions

Unmatched Expertise in Pharmaceutical Engineering

We bring decades of experience in pharmaceutical engineering, offering high-precision machinery tailored for all production stages. Our pharmaceutical equipment is designed to comply with international standards such as GMP, CE, and ISO, ensuring safe, efficient, and compliant pharmaceutical production.

End-to-End Production Capabilities

From tablet compression machines to granule processing units, our product lineup covers every essential stage of pharmaceutical manufacturing:

Tablet Press Machines

Capsule Filling Machines

Liquid Filling and Sealing Machines

Powder Mixing & Blending Systems

Granulation Lines

Vial and Ampoules Packaging Line

Our integrated solutions streamline production processes, reduce downtime, and increase yield, which directly translates into higher profitability for pharmaceutical manufacturers.

Vial and Ampoules Packaging Line – Precision and Performance

Fully-Automated Packaging Line for Sterile Injectables

Our Vial and Ampoules Packaging Line offers high-speed, fully automated systems suitable for sterile environments. These lines are designed to handle delicate ampoules and glass vials with pinpoint precision, ensuring integrity, sterility, and consistent quality across batches.

Key features of our vial and ampoule packaging lines include:

Washing, Sterilizing & Drying Units

Liquid Filling Systems (Peristaltic or Piston Pump Based)

Rubber Stoppering and Capping Machines

Ampoule Sealing & Vial Crimping

Visual Inspection Systems

Labeling & Serialization Modules

Integrated PLC and SCADA Control Systems

Each component is designed to maintain aseptic conditions, protect product integrity, and deliver consistent performance.

Core Components of Vial and Ampoules Packaging Line

1. Automatic Vial and Ampoule Washing Machines

These machines are engineered to remove particulates and contaminants from containers using multi-stage ultrasonic and pressure-based washing with WFI (Water for Injection) and clean compressed air. Features include:

In-feed and out-feed automation

Multiple needle spray systems

Customizable formats for different vial sizes

2. High-Temperature Sterilization Tunnels

Utilizing dry heat sterilization, our tunnels eliminate microbial contamination and maintain the sterility of containers post-wash. They feature:

HEPA filtration

Conveyor system with variable speed

Temperature monitoring and validation systems

3. Liquid Filling and Stoppering Machines

These are precision filling machines with servo-driven pistons or peristaltic pumps, ensuring accurate filling volumes for even the smallest doses.

Filling range flexibility (0.1 ml to 100 ml)

In-line or rotary stoppering mechanisms

Laminar airflow units integrated for Class 100 environments

4. Sealing and Capping Units

For ampoules, flame-sealing systems provide hermetic closures, while for vials, aluminum caps are crimped tightly for maximum security.

Flame annealing systems for ampoules

Rotary or linear vial crimping systems

Cap feeding and sorting automation

5. Visual Inspection Systems

High-speed cameras and AI-powered software ensure every ampoule or vial is visually inspected for foreign particles, fill volume, seal integrity, and cosmetic defects.

360-degree inspection

Rejection systems for non-conforming units

Batch reporting and traceability

6. Labeling, Serialization, and Track & Trace

Incorporating advanced serialization technology, our labeling systems help comply with global traceability regulations including 21 CFR Part 11, EU FMD, and DSCSA.

Inkjet and thermal transfer printing

Tamper-evident labels

QR code and barcode support

Made in China, Trusted Worldwide

Our pharmaceutical machinery, proudly made in China, is exported to over 70 countries, including markets in Europe, the Americas, Middle East, Southeast Asia, and Africa. We offer turnkey projects and full support, from design consultation to post-installation training and after-sales service.

Custom-engineered solutions are our specialty. Whether you need a small-scale line for clinical trials or a full commercial production system, we provide flexible configurations tailored to your needs.

Innovation and Compliance – Our Manufacturing Promise

Research-Driven Development

Our dedicated R&D center is continuously innovating to enhance performance, reduce footprint, and integrate AI, IoT, and smart automation into our systems.

Digital twin modeling

Predictive maintenance systems

Cloud-connected data analytics

Regulatory Compliance

Our equipment complies with international regulatory frameworks, including:

GMP (Good Manufacturing Practices)

FDA 21 CFR Part 11

EU Annex 1 Guidelines

WHO and PIC/S Recommendations

Each machine undergoes rigorous FAT (Factory Acceptance Testing) and SAT (Site Acceptance Testing) to ensure seamless compliance during audits.

Unparalleled Customer Support and Global Services

Our team of multilingual engineers and service professionals provides 24/7 remote and on-site support to ensure uptime, training, and continuous improvement. Our global network of distributors and service hubs ensures fast delivery of spare parts and preventive maintenance services.

Industries We Serve

Our solutions are ideal for:

Pharmaceutical manufacturers

Biotech companies

Veterinary drug producers

Clinical research facilities

Contract manufacturing organizations (CMOs)

Partner with Us for Advanced Pharmaceutical Machinery Solutions

As a manufacturer of pharmaceutical machinery, we are proud to set benchmarks in precision engineering, sterile manufacturing, and packaging automation. Our specialized Vial and Ampoules Packaging Line is one of the most trusted solutions for injectable drug manufacturers worldwide.

Contact us today to discuss your production needs and discover how our China-based manufacturing facility can support your end-to-end pharmaceutical production goals.

Contact us:

GRAND INTELLIGENT EQUIPMENT (GUANGZHOU) CO.,Ltd

301A, Building 5, No.333, Juhuashi Ave, Huadu District, Guangzhou City, Guangdong, China.

+86-15361285728 ; +86-020-86886090

Email [email protected]

Wenzhou Grand Machinery Technology Co.,Ltd

Floor 4, Building 2, No.116, Xinglong Road, Wanquan Town, Pingyang County, Wenzhou City, Zhejiang Province, China

+86-15323319612 ; +86-577-65565288

Also available on

On Whatsapp

On Facebook

On Twitter

On Pinterest

On Youtube

On Tumblr

0 notes

Text

Choosing the Best Vial Labeling Machine Manufacturer for Your Business

Selecting the right Vial Labeling Machine is crucial for pharmaceutical, biotech, and healthcare industries. A high-quality Automatic Vial Sticker Labeling Machine ensures accuracy, efficiency, and compliance with regulatory standards. When choosing a manufacturer, supplier, and exporter in India, factors such as precision, speed, customization, and after-sales support should be considered.

Key Benefits of Vial Labeling Machine

High Precision & Accuracy: Ensures perfectly aligned labels on vials without wrinkles or misplacement.

Increased Productivity: Automates the labeling process, reducing manual labor and improving output.

Compliance with Industry Standards: Meets strict pharmaceutical labeling regulations.

Customizable Solutions: Machines can be tailored to handle various vial sizes and labeling needs.

User-Friendly Operation: Advanced touchscreen controls for seamless operation and quick setup.

Durable & Low Maintenance: Built with robust materials for long-term reliability and minimal downtime.

Features of Automatic Vial Sticker Labeling Machine

Servo or Stepper Motor Drive for high-speed and precise label application.

Advanced Sensing Technology to detect vials and ensure correct label placement.

Multiple Labeling Capabilities: Wrap-around, single-side, and double-side labeling options.

High-Speed Performance: Capable of labeling up to 300 vials per minute.

Integration with Production Line: Easily connects with filling, capping, and inspection machines.

Tamper-Proof & Smudge-Free Labeling: Ensures clear and secure labeling for better traceability.

For reliable, high-performance Vial Labelling Machines, trust Brothers India, a leading Automatic Vial Sticker Labeling Machine manufacturer, supplier, and exporter in India. Contact us today to find the best labeling solution for your business.

#Vial Labeling Machine#Vial Labeling Machine Supplier#Vial Labeling Machine Exporter#Vial Labeling Machine Manufacturer#Vial Labeling Machine Manufacturer in India

0 notes

Text

Understanding the Utility of a Liquid Filling Machine

We often say not to judge a book by its cover, but in the business landscape, everyone judges the product by its packaging, Businesses can’t just sell their products in bulk containers or store shelves, because products need proper packaging for distribution and appeal. For instance, how will the world turn out if pharmaceutical companies don’t have a way to pack valuable medicines in bottles? A liquid filling machine solves this problem by providing a precise and efficient way to fill different types of liquids in vials, bottles and jars. Do you want to learn more about these machines, and how they work? This blog will help you find the answers to various questions on liquid filling machinery.

An Overview of Liquid Filling Machines

The necessity of efficient packaging equipment is becoming more evident in the world of manufacturing. Every industry that requires accurate liquid filling needs liquid packaging machines to meet regulations and maintain product quality. As the name implies, liquid packaging equipment is essential for different products such as beverages, medicine, shampoo, cosmetics and oil.

Experts have pointed out that the size of the global liquid filling machinery market will cross the $10 billion mark by 2032 (Source). It clearly suggests that relatively more companies will search for top sellers to add powerful and efficient filling equipment in their packaging systems. Another notable highlight of filling machines for packaging liquids is the scope for innovation with new technologies like IoT (Internet of Things).

Discovering Different Variants of Liquid Filling Machines

The two general categories of machines for filling liquids are manual and automatic.

· Manual Machines

Manual filling equipment doesn’t use automated mechanisms and some also avoid using any power source. The accuracy of manual machines depends on the skills of the operator. With a low production volume, manual filling machinery stands out as the best pick for small-scale businesses.

· Automatic Machines

Can you imagine a large bottling plant running on manual filling machines? Automatic machines reduce the need for manual labour in large-scale filling operations. The power of automation plays a huge role in enhancing the packaging speed alongside ensuring consistency and precision. Automatic liquid filling systems use different principles such as overflow filling, gravity filling, net weight filling and vacuum filling.

You can also come across two distinctive variants of an automated liquid filling machine such as,

Inline systems feature a combination of a filling machine and conveyor to fill up containers in a continuous line.

Monobloc filling systems not only fill up the containers but also help with capping, labelling, sealing and container handling.

Top Industries that Use Liquid Filling Machines

The easiest way to know why liquid filling equipment deserves all the attention is to identify the industries that need them including,

Pharmaceuticals

Cosmetics and beauty products

Food and beverages

Oils and lubricants

Household cleaning products

Wrapping Up

Liquid filling machines are an integral component in the infrastructure of any business that creates liquid products such as pharmaceutical companies. Do you want the best machines for packaging liquids? Optima Weightech will guide you to the most efficient choices for all your packaging requirements. Discover new insights on liquid filling equipment with experts and boost your manufacturing efficiency right now.

Source: https://optimaweightech.com.au/news/understanding-the-utility-of-a-liquid-filling-machine/

0 notes