#What is SCADA

Explore tagged Tumblr posts

Text

What is Python Programming? Learn the Basics of Python

Python is one of the most beginner-friendly programming languages available today. It’s widely used across industries and has become the go-to language for those just stepping into the world of programming. Whether your goal is to build websites, analyze data, or explore artificial intelligence, Python provides a solid foundation to begin your journey.

Why Python is Ideal for Beginners

One of the biggest reasons Python is favored by newcomers is its simplicity. Python's syntax is clean and easy to read, which means you can quickly understand what your code is doing without needing a background in computer science. Unlike some other languages that require strict formatting or complex structures, Python keeps things minimal and intuitive.

Another strong advantage is its wide usage. Python is used in a variety of fields such as software development, automation, data science, machine learning, and web development. This versatility means that once you learn the basics, you can apply your knowledge to countless real-world scenarios.

Python also boasts a massive global community. This means that if you ever get stuck, there are thousands of tutorials, forums, documentation pages, and learning resources available online. Beginners benefit greatly from such a supportive environment.

Understanding the Basics of Python

To begin your Python journey, it’s essential to grasp a few fundamental concepts. These include understanding how to store information using variables, working with different types of data, performing calculations, and writing logic to make decisions in your code.

Another important area is learning how to repeat tasks using loops, and how to organize your code into reusable blocks called functions. These basics form the building blocks of almost every program you'll write in Python.

As you progress, you’ll also explore how to work with data collections like lists and dictionaries, handle user input, and structure your projects to be readable and efficient.

Real-World Applications of Python

Python’s appeal goes far beyond its simplicity. It’s a powerful tool used in professional environments to build a variety of applications. In web development, Python is behind many dynamic websites and platforms, thanks to frameworks like Django and Flask.

In the world of data analysis and visualization, Python offers libraries that help professionals process large volumes of information and extract meaningful insights. From creating charts to building predictive models, Python powers much of what we see in business intelligence and research today.

Another exciting domain is machine learning and artificial intelligence. With Python’s frameworks and libraries, developers can build systems that learn from data, make decisions, and even understand natural language.

Python also excels in automation. If you’ve ever had a repetitive task on your computer, like renaming files or processing data, Python can be used to automate those tasks, saving time and effort.

How to Start Learning Python

The best way to begin learning Python is to start small and stay consistent. You don’t need any expensive software, many online platforms allow you to write and test Python code right in your browser. There are also free tutorials, beginner courses, and video lessons available to help guide your learning step-by-step.

It’s helpful to set small goals, such as writing a simple calculator or building a personal planner. These projects may seem small, but they help reinforce core concepts and make learning more engaging.

As you improve, you can challenge yourself with more complex projects and begin exploring specific fields like web development or data analysis. Python’s broad range of applications means there’s always something new to learn and try.

Conclusion

Python is more than just a beginner’s language, it’s a tool that professionals use to build innovative technologies and solve real-world problems. By mastering the basics, you open the door to endless possibilities in the tech world.

Whether you're a student, a working professional, or someone simply curious about coding, Python is the perfect language to get started. With dedication and practice, you’ll be amazed at how quickly you can go from a beginner to a confident programmer.

#What is PLC#What is SCADA#Industrial automation#PLC SCADA tutorial#plc scada system 2025#role of plc in automation

0 notes

Text

The Difference Between Low, Medium, and High Voltage Switchgear

Switchgear plays a critical role in the generation, transmission, and distribution of electrical power. It ensures safe and efficient operation by controlling, protecting, and isolating electrical circuits and equipment. But not all switchgear is created equal — low, medium, and high voltage switchgear are designed for different voltage levels and applications.

Understanding the differences between these types is crucial for electrical engineers, electricians, project managers, and anyone involved in power systems. In this article, we break down what sets them apart in terms of voltage range, components, applications, design, and safety considerations.

What is Switchgear?

Before diving into the differences, let’s clarify what switchgear is.

Switchgear refers to the combination of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. It is essential for de-energizing equipment for maintenance and for clearing faults in the power system.

Classification by Voltage Level

Low Voltage Switchgear (LV)

Voltage Range:

Up to 1,000V AC (typically 400V/690V in 3-phase systems)

Key Components:

Miniature Circuit Breakers (MCBs)

Molded Case Circuit Breakers (MCCBs)

Residual Current Devices (RCDs)

Contactors and relays

Busbars, metering, control panels

Applications:

Residential and commercial buildings

Data centers and office spaces

Light industrial automation

Control panels and motor control centers (MCCs)

Characteristics:

Compact and easy to install

High frequency of operation

Relatively simple maintenance

Often enclosed in modular panels

Standards:

IEC 61439

NEC (National Electrical Code)

Medium Voltage Switchgear (MV)

Voltage Range:

1kV to 36kV (sometimes up to 72.5kV)

Key Components:

Vacuum circuit breakers (VCBs)

SF₆ (sulfur hexafluoride) insulated switchgear

Current and voltage transformers (CTs, VTs)

Protective relays

Grounding switches

Applications:

Electrical substations

Large factories and industrial plants

Railways and airports

Renewable energy farms (wind/solar)

Characteristics:

Higher insulation and safety requirements

More robust protection systems

Often installed indoors or in compact outdoor enclosures

May use gas-insulated or air-insulated designs

Standards:

IEC 62271–200

IEEE C37 series

High Voltage Switchgear (HV)

Voltage Range:

Above 36kV (commonly 66kV, 132kV, 220kV, up to 765kV)

Key Components:

SF₆ circuit breakers

Air blast or oil circuit breakers (older systems)

Gas-insulated switchgear (GIS)

Disconnectors and earthing switches

High-end protection relays and SCADA integration

Applications:

National and regional power transmission networks

Power generation plants

Interconnecting large substations

Critical infrastructure (e.g., large data centers, airports)

Characteristics:

Complex installation and high-cost infrastructure

Requires rigorous safety procedures and specialized training

Often installed outdoors or in GIS (Gas Insulated Switchgear) format

Includes extensive monitoring and automation

Standards:

IEC 62271–100 (HV circuit breakers)

IEEE C37.06

ANSI C37 series

Safety Considerations

Always follow local electrical codes, use personal protective equipment (PPE), and conduct routine maintenance regardless of switchgear type.

Conclusion

Choosing the right switchgear type is critical for ensuring safe and efficient power distribution. Whether you’re designing a residential panel or a high-voltage substation, knowing the difference between low, medium, and high voltage switchgear helps you make informed decisions about equipment, safety, and performance.

Mastering this knowledge isn’t just good practice — it’s essential for anyone serious about a career in the electrical field.

10 notes

·

View notes

Text

ten minute work doodle about the wall fic i still have yet to put a single word into

idle hands devils plaything blah blah blah this is what happens to me

edit for anyone j perusing the valveplug tag the premise is that getaway is using one of those phase devices like tfp smokescreen in which he’s moving through the walls to gather info for his mutiny but the device isn’t calibrated so he gets stuck and blocks a pipe which sets off the SCADA and skids responds to the computer’s work order to find getaway in the wall lol. and getaway lies that he’s snooping around cus he’s trying to “learn more about people so he can fit in :( not being an og member makes him feel left out :(“ and skids believes him so he cheers him up nod nod

17 notes

·

View notes

Text

Praxis Lips Series PCB Module 4054 | Industrial Control Solutions | Ram Automations

Discover the Praxis Lips Series PCB Module 4054, a highly reliable solution for your industrial control and automation needs. This PCB module is designed to offer superior performance, stability, and integration flexibility for various industrial systems. Perfect for enhancing the efficiency of your automation setup, the Praxis Lips 4054 ensures smooth operations across multiple industrial applications.

At Ram Automations, we are committed to delivering genuine and top-quality industrial automation products from global leaders. Trust our expertise to find the right parts that drive your operations forward.

🛒 Get the Praxis Lips Series PCB Module 4054 Now 👉 https://ramautomations.com/products/praxis-lips-series-pcb-module-4054-used

🌐 Explore Full Product Range 👉 https://ramautomations.com

🧩 Product Specifications

• 🔹 Brand: Praxis Lips • 🔹 Model: 4054 • 🔹 Type: PCB Module • 🔹 Category: Industrial Automation, Control Components • 🔹 Applications: Control Systems, Automation Processes, Machine Integration

✅ Key Features

✔️ High-grade PCB construction ensuring durability and reliability ✔️ Optimized for critical industrial control and automation applications ✔️ Easy integration with multiple industrial systems ✔️ Compact design, saving valuable space in complex assemblies ✔️ Reliable signal processing for uninterrupted operations ✔️ Designed to support long-term usage without performance loss

💡 Applications Include:

• Factory Automation • Control Panel Systems • Industrial Process Automation • Manufacturing Line Control • Machine Tool Automation • Robotics Integration • Energy Management Systems • PLC and SCADA Implementations • Power Distribution and Control Solutions

🌟 Why Choose Ram Automations?

✅ Genuine industrial parts from top brands ✅ Competitive pricing across all categories ✅ Fast and reliable worldwide shipping ✅ Expert assistance for all your industrial automation needs

🎥 What You’ll See in This Video:

🔍 Detailed Look at the Praxis Lips Series PCB Module 4054 🔧 How to integrate this PCB Module into your industrial setup 💡 Advantages of upgrading your system with Praxis Lips 4054 🌍 Why Ram Automations is your trusted industrial partner

📣 Stay Connected!

🔔 Subscribe to our channel for more industrial automation product updates 👍 Like this video if you appreciate quality automation solutions 💬 Comment your queries or suggestions below — we’re happy to assist

#Praxis Lips 4054 PCB Module#Industrial Automation PCB#Automation Control Module#Process Control Systems#Factory Automation Components#Automation Integration#PLC and SCADA Systems#Industrial Electronics#Automation and Robotics#Factory Automation Systems#Power Control Units#Automation Solutions#Industrial Control Systems#Industrial Process Automation#Control Panel Automation#Machine Automation Systems#Automation and Control#Energy Management Automation#Ram Automations

2 notes

·

View notes

Text

Analog vs. Digital Meters: Understanding the Differences and Applications

In today’s increasingly connected and technologically advanced world, precise electrical measurement is critical for efficient power management and system monitoring. Two primary tools dominate the field of electrical measurement: analog meters and digital meters. While both serve the same fundamental purpose — measuring electrical quantities like voltage, current, and frequency — their technology, design, readability, and application differ significantly.

This article explores the key differences between analog and digital meters, their respective advantages, disadvantages, and common use cases to help you make an informed decision when selecting the right meter for your needs.

What Are Analog Meters?

Analog meters are traditional instruments that display measurement readings through a mechanical needle moving over a graduated scale. They have been widely used for decades in industries, commercial applications, and even residential setups.

Key Features of Analog Meters:

· Use of moving coil or iron vane mechanisms

· Continuous scale display

· Passive operation (no power required in many types)

· Simple, durable construction

Common Types:

· Analog Voltmeters

· Analog Ammeters

· Analog Frequency Meters

· Analog Power Factor Meters

Advantages of Analog Meters:

· Easy to interpret trends and fluctuations

· Cost-effective for basic applications

· Operate without auxiliary power

· Better tolerance to transient spikes and overloads

Limitations:

· Lower accuracy compared to digital meters

· Manual reading required

· Parallax error due to needle reading

· Limited data logging or interfacing capabilities

What Are Digital Meters?

Digital meters represent a more modern approach to electrical measurement. These devices convert analog signals into digital values, displaying results on an LCD or LED screen. They are widely used in automation, smart grids, and precision engineering environments.

Key Features of Digital Meters:

· High-resolution digital display

· Advanced microprocessor control

· MODBUS communication (RS-485 interface)

· Programmable settings and alarms

Common Types:

· Digital Voltmeters

· Digital Ammeters

· Digital Frequency Meters

· Digital Multifunction Meters (VAF, kWh, Power Factor, etc.)

Advantages of Digital Meters:

· High accuracy and readability

· Remote monitoring capabilities

· Compact and modern design

· Enhanced functionalities like data logging, alarms, and networking

Limitations:

· Higher initial cost

· Requires auxiliary power

· More complex installation in some cases

Applications of Analog and Digital Meters

Where Analog Meters Excel:

· Educational institutions for teaching fundamentals

· Industrial environments where ruggedness is key

· Backup or emergency systems where power is limited

· Low-budget installations

Where Digital Meters Lead:

· Smart panels and industrial automation

· Energy monitoring systems

· Commercial buildings and infrastructure

· Remote power distribution networks

Choosing the Right Meter: Factors to Consider

When deciding between analog and digital meters, consider the following:

1. Accuracy Requirements — For precision tasks, digital meters are the preferred choice.

2. Budget Constraints — Analog meters offer a cost-effective solution for basic needs.

3. Environment — Analog meters can be more tolerant in high-temperature or high-vibration areas.

4. Communication Needs — If integration with SCADA or monitoring systems is needed, go digital.

5. Data Analysis — For trend tracking and analytics, digital meters with memory and communication ports are ideal.

Enza Electric: Your Trusted Source for Analog and Digital Meters in the UAE

At Enza Electric, we provide a comprehensive range of analog and digital panel meters tailored to meet diverse electrical monitoring needs. Our digital meters support RS-485 MODBUS, enabling seamless integration into modern automation systems. Whether you’re looking for reliable analog meters for legacy systems or advanced digital meters for new installations, Enza Electric has the expertise and inventory to deliver.

We offer:

· Voltmeter, Ammeter, and Frequency meters in both analog and digital forms

· Multifunction VAF meters

· Panel meter sizes: 72x72mm and 96x96mm

· Customizable CT and PT ratios

Conclusion

Both analog and digital meters play important roles in today’s electrical systems. While analog meters offer simplicity and durability, digital meters bring precision, connectivity, and intelligence. Understanding their differences and applications is key to choosing the right tool for your project.

For expert guidance and high-quality meters, contact Enza Electric — one of the leading electrical measurement solution providers in the UAE.

#AnalogMeters#DigitalMeters#PanelMeters#ElectricalMeasurement#PowerMonitoring#ElectricalEngineering#EnergyMeters#IndustrialAutomation#MeteringSolutions#Instrumentation#electrical#switchgear#dubai#low voltage#uae

4 notes

·

View notes

Text

What Is a Circuit Breaker and How Does It Work in a Switchgear Assembly?

In modern electrical power systems, reliability and safety are paramount. Whether it’s a residential building, industrial plant, or renewable energy facility, the control and protection of electrical circuits are essential. One of the most critical components used for this purpose is the circuit breaker. When integrated into a switchgear assembly, the circuit breaker plays a central role in ensuring operational continuity, preventing electrical faults, and safeguarding equipment and personnel.

This article explores what a circuit breaker is, it’s working principle, types, and its specific function within a switchgear assembly.

What Is a Circuit Breaker?

A circuit breaker is an automatically operated electrical switch designed to protect an electrical circuit from damage caused by overcurrent, overload, or short circuit. Its primary function is to interrupt current flow after a fault is detected. Unlike a fuse, which operates once and must be replaced, a circuit breaker can be reset (manually or automatically) to resume normal operation.

Key Functions of a Circuit Breaker

· Interrupt Fault Currents: Quickly breaks the circuit in the event of an overcurrent or short circuit.

· Manual Switching: Can be used to manually open or close a circuit for maintenance.

· Automatic Protection: Operates automatically in response to abnormal current conditions.

· Isolation: Ensures safe isolation of electrical equipment during servicing.

How Does a Circuit Breaker Work?

Circuit breakers operate on a simple principle: detect a fault and interrupt the current flow.

Working Mechanism

1. Detection: Internal sensors such as thermal, magnetic, or electronic trip units detect abnormalities in current.

· Thermal Trip Unit: Uses a bimetallic strip that bends with heat from overcurrent.

· Magnetic Trip Unit: Uses an electromagnet that triggers a release when excessive current flows.

· Electronic Trip Unit: Uses current sensors and a microprocessor for precise tripping.

2. Tripping: Once a fault is detected, the trip mechanism activates, causing the breaker’s contacts to open.

3. Arc Extinction: When the contacts open, an electrical arc forms. The breaker extinguishes the arc using mechanisms like:

· Air-blast

· Vacuum

· SF₆ gas

· Oil

4. Resetting: After the fault is cleared, the breaker can be reset and put back into service.

Types of Circuit Breakers

What Is a Switchgear Assembly?

Switchgear is a centralized assembly of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. It is essential in power generation, transmission, and distribution networks.

Switchgear can be categorized by voltage level:

· Low Voltage (LV): Up to 1 kV

· Medium Voltage (MV): 1 kV to 36 kV

· High Voltage (HV): Above 36 kV

Role of Circuit Breakers in Switchgear Assemblies

Circuit breakers are core protection components within switchgear systems. Their role includes:

1. Fault Detection and Isolation

Circuit breakers detect and isolate faulty circuits to prevent system-wide failures and reduce downtime.

2. Load Control

Operators can use breakers in switchgear to safely connect or disconnect loads as required during routine operations or emergencies.

3. System Coordination

In coordinated protection schemes, different breakers in the switchgear are set with time-current characteristics to isolate faults precisely and efficiently.

4. Integration with Automation

Modern switchgear integrates circuit breakers with SCADA systems and smart relays, enabling remote monitoring and control.

Circuit Breakers in Renewable and Industrial Applications

In sectors like solar and wind energy, circuit breakers are specially designed to handle:

· Bidirectional current flow

· Rapid voltage fluctuations

· High fault levels due to DC sources

In industrial settings, breakers must handle high inrush currents, frequent switching, and harsh environments.

Maintenance and Safety Considerations

To ensure reliability:

· Regular Testing: Trip settings, insulation resistance, and contact resistance must be tested periodically.

· Visual Inspection: For signs of wear, overheating, or contamination.

· Replacement of Parts: Arcing contacts and insulation materials degrade over time and must be replaced as needed.

Safety measures include:

· Lockout/Tagout (LOTO)

· Grounding procedures

· Personal Protective Equipment (PPE)

Conclusion

Circuit breakers are indispensable for the protection and control of electrical systems. When embedded within a switchgear assembly, they offer enhanced reliability, automation capability, and system safety. Whether in a power substation, a manufacturing facility, or a renewable energy farm, the synergy of circuit breakers and switchgear ensures smooth, safe, and efficient operation.

Understanding how circuit breakers function and interact within switchgear assemblies is crucial for electrical engineers, facility managers, and anyone involved in the design, operation, or maintenance of electrical infrastructure.

5 notes

·

View notes

Text

The Benefits of Using Modular Switchgear Systems

Why Modern Industries Are Choosing Modular Solutions for Electrical Infrastructure

In today’s fast-paced industrial and commercial environments, electrical safety, efficiency, and scalability are more important than ever. That’s where modular switchgear systems come into play. Designed to meet the evolving needs of various sectors — such as manufacturing, commercial buildings, power utilities, and data centers — modular switchgear offers flexibility, safety, and long-term value.

In this article, we’ll explore the key benefits of using modular switchgear systems, and why they are becoming the preferred choice over traditional switchgear configurations.

What Is a Modular Switchgear System?

A modular switchgear system is a type of switchgear that is built from interchangeable modules or sections. Each module contains electrical components such as circuit breakers, busbars, relays, isolators, and fuses. These modules are pre-engineered and can be easily configured, added, or replaced based on the specific requirements of a facility.

Modular switchgear is used for the protection, control, and isolation of electrical equipment. It is typically found in low voltage (LV) and medium voltage (MV) power distribution systems.

Top Benefits of Modular Switchgear Systems

1. Flexibility and Scalability

One of the most significant advantages of modular switchgear is its flexible design. Whether you’re expanding an existing facility or starting from scratch, modular systems allow you to add or remove units without interrupting the entire system.

· Ideal for facilities expecting future expansion

· Easy to customize layout based on project demands

· Supports phased development in infrastructure projects

2. Enhanced Safety and Reliability

Modern modular switchgear systems are designed with advanced safety features. Segregated compartments, arc fault containment, and reliable insulation materials ensure operator safety and system reliability.

· Reduces risk of electrical faults and arc flashes

· Complies with IEC and ANSI safety standards

· Minimizes downtime during maintenance or upgrades

3. Ease of Installation and Maintenance

Thanks to its pre-fabricated modules, modular switchgear is faster and easier to install compared to conventional systems. It also simplifies troubleshooting and routine maintenance.

· Less on-site wiring and civil work required

· Individual modules can be isolated for servicing

· Reduces maintenance costs and system downtime

4. Compact and Space-Saving Design

With limited space in modern industrial setups, compactness is crucial. Modular switchgear systems are designed for space optimization, making them perfect for high-density environments.

· Vertical and horizontal expansion possible

· Reduced footprint compared to traditional gear

· Neat and organized layout improves cable management

5. Future-Proof and Upgrade-Friendly

Industries evolve, and so should your electrical infrastructure. Modular switchgear supports easy integration of new technologies, such as remote monitoring, IoT-enabled control systems, and energy management solutions.

· Supports integration with SCADA and BMS systems

· Accommodates evolving energy needs

· Long lifecycle with upgrade options

6. Cost-Effective Over the Long Term

Though the initial investment may be higher than conventional switchgear, the long-term benefits of modular systems — including reduced downtime, lower maintenance costs, and scalability — make them a cost-effective solution.

· Lower total cost of ownership (TCO)

· Reduced operational expenses

· Optimized energy efficiency

Applications of Modular Switchgear Systems

Modular switchgear is suitable for a wide range of applications, including:

🏢 Commercial buildings

🏭 Industrial plants

⚡ Power generation and distribution

🖥 Data centers

🏥 Hospitals

🏗 Infrastructure projects and smart cities

Conclusion

If you’re looking for a smart, scalable, and reliable solution for your electrical distribution system, modular switchgear systems are a worthy investment. With benefits ranging from safety and efficiency to cost savings and future readiness, they offer a significant upgrade over traditional switchgear models.

3 notes

·

View notes

Text

What Is PLC and SCADA? 2025 Beginners Guide

In the modern industrial world, automation is key to ensuring efficient, reliable, and safe operations. Two of the most important technologies behind industrial automation are PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition). These systems are widely used across various industries, including manufacturing, power generation, oil and gas, water treatment, and transportation. This guide provides a clear understanding of what PLC and SCADA are, how they function, and how they work together to streamline industrial operations.

Understanding PLC: The Core of Industrial Automation

A Programmable Logic Controller (PLC) is a rugged digital computer designed specifically for controlling industrial machines and processes. It replaces traditional relay-based control systems and offers flexibility, reliability, and ease of programming.

PLCs are used to automate repetitive tasks. They receive input signals from sensors, process those signals according to a programmed logic, and then trigger appropriate outputs. These outputs can be used to control motors, solenoids, alarms, or other machinery.

One of the main advantages of PLCs is their ability to withstand harsh industrial environments. They are resistant to vibration, electrical noise, extreme temperatures, and dust, making them ideal for use in factories and processing plants.

Components of a PLC System

A basic PLC system includes the following components:

CPU (Central Processing Unit): The brain of the PLC that executes the control logic.

Power Supply: Provides the necessary voltage to the PLC system.

Input/Output Modules: Interface with field devices like sensors and actuators.

Programming Device: Used to write and transfer the logic to the CPU.

Communication Ports: Allow the PLC to connect with SCADA or other PLCs.

Introduction to SCADA: Centralized Monitoring and Control

While PLCs perform local control, SCADA (Supervisory Control and Data Acquisition) provides centralized supervision. SCADA is a software-based system that monitors and controls industrial processes from a central location.

SCADA systems collect data from PLCs and other control devices, display it in a user-friendly graphical format, and store it for future analysis. Operators can monitor equipment status, receive alarms, and send control commands from a SCADA interface.

SCADA is essential in large-scale operations where physical presence at every machine or sensor is not feasible. It allows industries to maintain control over complex systems spread across multiple locations.

Key Features of SCADA Systems

Real-Time Data Acquisition: Gathers data from field devices continuously.

Graphical User Interface (GUI): Displays process visuals for operators.

Alarm Management: Notifies operators of abnormal conditions.

Data Logging and Reporting: Stores historical data for audits and performance evaluation.

Remote Control: Enables operators to control equipment from a distance.

How PLC and SCADA Work Together

In most industrial setups, PLCs are responsible for direct control of machinery. They process sensor data and control outputs based on pre-defined logic. SCADA, on the other hand, acts as a higher-level system that collects data from multiple PLCs, analyzes it, and presents it to operators.

For example, in a water treatment plant, PLCs might control individual pumps and valves, while SCADA provides a dashboard showing water levels, chemical dosages, and system status in real-time. If there is a problem, SCADA alerts the operator, who can then take corrective action remotely.

Applications of PLC and SCADA

The combined use of PLC and SCADA systems is common in many sectors:

Manufacturing: For managing automated assembly lines.

Power Plants: For monitoring turbines, generators, and safety systems.

Water Treatment: For controlling pumps, valves, and chemical dosing.

Oil and Gas: For pipeline monitoring, storage management, and leak detection.

Transportation: For traffic signal control and railway automation.

Benefits of Integrating PLC and SCADA

Improved Efficiency: Automation reduces human error and increases throughput.

Remote Monitoring: Operators can control systems from central control rooms.

Reduced Downtime: Quick response to system failures minimizes interruptions.

Data-Driven Decisions: Real-time and historical data support informed planning.

Cost Savings: Optimized operations lower operational and maintenance costs.

Conclusion

PLC and SCADA systems are foundational technologies in industrial automation. PLCs handle the core control functions at the equipment level, while SCADA provides real-time monitoring and centralized management. Together, they create a powerful system that improves reliability, safety, and efficiency in complex industrial environments.

As industries continue to evolve with Industry 4.0 and smart technologies, the integration of PLC and SCADA will become even more critical. Understanding these systems is essential for engineers, technicians, and anyone aspiring to work in the field of automation.

#What is PLC#What is SCADA#Industrial automation#PLC SCADA tutorial#plc scada system 2025#role of plc in automation

0 notes

Text

Top 5 Factors to Consider When Choosing Switchgear in Qatar

The energy infrastructure in Qatar is evolving rapidly, driven by ambitious development plans, a booming construction sector, and growing demand for reliable and efficient power distribution systems. As such, selecting the right switchgear — an essential component in electrical distribution networks — is more important than ever. Whether for industrial, commercial, or residential projects, choosing the appropriate switchgear can significantly impact safety, operational reliability, and long-term costs.

In this article, we explore the top five factors to consider when choosing switchgear in Qatar, keeping in mind the country’s unique climatic, industrial, and regulatory environment.

1. Environmental and Climatic Conditions

Why It Matters:

Qatar’s climate is characterized by extreme heat, high humidity, and frequent dust storms, which can adversely affect the performance and longevity of electrical equipment.

What to Consider:

· Ingress Protection (IP) Ratings: Choose switchgear with high IP ratings (e.g., IP65 or above) to ensure resistance to dust and moisture.

· Temperature Tolerance: Equipment should be capable of operating in ambient temperatures above 45°C without derating.

· Corrosion Resistance: Opt for enclosures made from stainless steel or coated with anti-corrosive materials to withstand coastal and desert environments.

Tip:

Ask for switchgear that has been tested and certified for desert and tropical climates to ensure long-term reliability.

2. Compliance with Local Regulations and Standards

Why It Matters:

Qatar’s construction and energy sectors are tightly regulated. Non-compliance with local codes can lead to project delays, penalties, or unsafe installations.

What to Consider:

· Kahramaa Regulations: Ensure the switchgear complies with Qatar General Electricity & Water Corporation (Kahramaa) specifications.

· International Standards: Equipment should meet IEC (International Electrotechnical Commission) or ANSI standards for design and performance.

· Vendor Certifications: Choose manufacturers and suppliers who are approved by local authorities and have a track record of regulatory compliance.

Tip:

Request documentation and third-party certification to verify compliance before purchase.

3. System Voltage and Current Ratings

Why It Matters:

Mismatched ratings can lead to equipment failure, increased downtime, or even safety hazards.

What to Consider:

· Voltage Level: Identify whether your application requires low-voltage (LV), medium-voltage (MV), or high-voltage (HV) switchgear.

· Short-Circuit Withstand Capacity: The switchgear must handle the maximum fault current expected in the system.

· Load Type and Growth: Consider both current and future load expansions when sizing the switchgear.

Tip:

Conduct a detailed load analysis with a qualified electrical engineer to ensure proper equipment sizing.

4. Reliability and Safety Features

Why It Matters:

Switchgear is central to ensuring electrical safety and minimizing power outages, especially in critical infrastructure.

What to Consider:

· Arc Flash Protection: Look for internal arc classification (IAC) and arc-resistant features.

· Automation and Remote Monitoring: Smart switchgear with SCADA integration can improve uptime and facilitate preventive maintenance.

· Redundancy and Segmentation: Ensure the switchgear design allows for maintenance without shutting down the entire system.

Tip:

Consider intelligent switchgear with diagnostic features to enable predictive maintenance and minimize human error.

5. Availability of Local Support and Spare Parts

Why It Matters:

Even the best switchgear can require maintenance or part replacement. Having quick access to support minimizes downtime and operational losses.

What to Consider:

· Local Service Network: Choose brands with authorized service centers or partners in Qatar.

· Spare Parts Availability: Ensure that spare parts can be sourced locally with minimal lead time.

· Training and Technical Support: Ask about operator training, maintenance contracts, and emergency response services.

Tip:

Opt for suppliers with a strong presence in the GCC region and a proven track record in Qatar’s market.

Conclusion

Choosing the right switchgear in Qatar requires a thoughtful evaluation of environmental, regulatory, technical, and logistical factors. With the right equipment, businesses and developers can ensure electrical safety, regulatory compliance, and long-term operational efficiency in one of the world’s most challenging climates.

When evaluating options, always consider:

· Local conditions and regulatory landscape

· Equipment ratings and design

· Vendor support and technical reliability

By focusing on these core considerations, stakeholders can make informed, cost-effective, and future-ready decisions for their electrical infrastructure projects in Qatar.

#electrical equipment#qatar#switchgear#electrical#911 abc#arcane#artists on tumblr#batman#cats of tumblr#cookie run kingdom

2 notes

·

View notes

Text

in trying to make another generic getaway porn post i’ve selfishly cooked up a really good one with my half oc/half sona n getaway

ok so basically getaway has one of those phasing devices like tfp smokescreen and he occasionally uses it to basically listen to people in the walls because being leader of a mutiny requires a lot of control and you always gotta be on your toes about information

but it malfunctions because getaway isn’t calibrating it as often as it should be (he’s not amazing with these types of devices anyway; we know this wrt his use of the nudge gun)

so he gets stuck in the wall and his little cat ears have materialized in part of a pipe and the pressure difference is sending signals to the SCADA and thus to the engineer in question who goes over to investigate and lil mr hottie is in the wall

and it’s like so what r u gonna give me to not tell people about your little invasion of privacy mr get a. way

and at first he tries to talk his way out but talk is cheap. especially his talk. so begin the little touches to his face plate and whispers in his audials until the teasing makes him drop the act and confess what he wants wants

and then after a little more teasing just to get him really restless, the phase device is taken from his hands and fixed. these devices get used all the time for engineers of this discipline anyway—so pipes and filters can be looked into for corrosion without having to cut in! the device is recalibrated, he steps out of the wall, and he’s so worked up he drags our protagonist by the wrist to his close by quarters and happy ending (fragged crazy style against the wall as soon as the door shuts)

5 notes

·

View notes

Text

Understanding MCC Panels: The Backbone of Motor Control Systems

In today’s fast-growing industrial sector, MCC panels play a crucial role in safely managing and operating multiple motors from a single control location. Whether you're in manufacturing, HVAC, or processing plants, choosing the right Motor Control Panel Manufacturer can help streamline operations, reduce downtime, and ensure equipment safety.

Modern MCC panels are engineered to enhance safety, reduce maintenance effort, and ensure seamless motor operation—all under one enclosure. This makes them an essential component for every plant where multiple motors are in use.

What Exactly is an MCC Panel?

MCC panels are widely used in industries for centralized motor control and protection. An experienced MCC manufacturer builds these panels with high-performance features that meet the dynamic demands of motor management. A trusted MCC Panels manufacturer ensures the panel includes every essential control and safety component, offering complete reliability for plant operations. Leading Motor Control Panel Manufacturers follow international standards for long service life.

Each motor starter operates an individual motor, and multiple starters are mounted within one MCC, allowing centralized and organized motor control.

In simple words, an MCC panel lets you start, stop, monitor, and protect motors—safely and efficiently—from one place.

Key Components of an MCC Panel

An MCC Panel manufacturer designs MCC panels with top-grade circuit breakers, relays, busbars, and control transformers. A reputable Motor Control Panel Manufacturer ensures these components work together for efficient motor control and long-term reliability. When you choose a certified MCC Panel Supplier or MCC manufacturer, you’re assured of safe, scalable, and serviceable panel configurations.

A well-designed MCC panel consists of:

Incoming & Outgoing Feeders – For power entry and distribution

Busbars – Made of copper or aluminium (sizes like 25×5 mm or 100×10 mm)

Contactor & Overload Relay – Controls motor and prevents overheating

MCBs or MCCBs – Provide short-circuit and overload protection

Control Transformer / SMPS – Supplies control voltage (24VDC or 110VAC)

Push Buttons & Indicators – For manual control and status display

Digital Monitoring Units – Optional modules for load, voltage, and fault display

Auxiliary Relays & Timers – For automation and sequencing

These components are mounted on compartmentalized sections inside the MCC panel, which ensures safe maintenance and separation between circuits.

Key Technical Features of MCC Panels

MCC Panels manufacturers build panels based on standard and custom specifications. Voltage ratings, IP protection, busbar size, and short-circuit capacity vary based on the requirement. A reliable MCC manufacturer or MCC Panel Supplier will offer current ratings from 100A to 6300A and enclosure ratings up to IP65. Partnering with a professional Motor Control Panel Manufacturer helps you meet operational and safety compliance standards effectively. As a reliable MCC manufacturer would offer, the latest MCC panels come with a range of modern features designed for safety, ease of use, and durability:

Rated Voltage: 415V AC / 690V AC

Short Circuit Withstand: Up to 50kA for 1 second

Starter Types Supported: DOL, Star-Delta, Soft Starter, VFD

Protection Levels: IP42 to IP65

Operating Temperature: –5°C to +55°C

Busbar Rating: From 100A up to 6300A

Control Voltage: 24VDC / 110VAC / 230VAC

Design Type: Fixed, Semi-drawout, Fully Drawout

Communication Ready: Optional PLC/SCADA interface support

Certifications: Follows IEC 61439, IS 8623, UL, NEMA standards

Want a better way to manage your motors? Learn how choosing the right MCC Panels Manufacturer can help you reduce downtime and improve control.

Why Are MCC Panels So Important?

MCC Panels are critical for centralized motor control, ensuring safe and efficient operation of multiple motors in industrial environments. A professional MCC Panels manufacturer designs these panels to streamline maintenance, reduce electrical hazards, and offer seamless automation integration. Choosing a skilled MCC manufacturer or a reliable Motor Control Panel Manufacturer ensures your plant runs smoothly with minimized downtime. Trusted MCC Panel Suppliers provide robust, scalable, and custom-built MCC panels tailored for demanding applications.

The role of MCC panels extends beyond motor starting. They are critical for:

Centralized Control: Operate, monitor, and manage all motors from one place

Energy Management: Control motor usage and reduce wastage

Space Optimization: Compact, clean layouts minimize panel footprint

Downtime Reduction: Easy fault detection and quick isolation of faulty motors

Future Expandability: Modular designs make upgrades and additions simple

Operational Safety: Secure wiring, interlocking systems, emergency stop functions

In large industries where dozens or even hundreds—of motors are in use, having an MCC panel ensures system reliability, operational visibility, and long-term cost savings.

Where Are MCC Panels Commonly Used?

MCC Panels are used in a wide range of industries such as cement, chemicals, water treatment, and HVAC systems. Every major MCC Panels manufacturer builds panels suitable for these sectors with customized feeders and starter combinations. A qualified Motor Control Panel Manufacturer offers scalable designs to meet plant-specific needs. Partnering with the right MCC Panel Supplier ensures safety and smooth motor operations.

Some top applications include:

Manufacturing Units: Motor control for assembly lines and machinery

Thermal & Hydroelectric Plants: Pump and turbine management

Water Treatment Facilities: Motorized valves and pump operations

Pharmaceutical & Chemical Plants: Precision control for production machinery

Cement Plants & Mining: High-torque motor systems

HVAC Systems in Commercial Buildings: Blower, chiller, and compressor control

Food & Beverage Processing: Timed and controlled automation

How MCC Panels Improve Safety

Safety is a major reason why industries invest in MCC panels. Every good Motor Control Panel Manufacturer focuses on building panels that reduce risks and protect both machinery and manpower.

Key safety features include:

Overload & Short Circuit Protection: Stops power supply to damaged motors

Interlock Mechanisms: Prevents access to live components

Emergency Stop Buttons: For immediate motor shutdown

Status Indicators: Shows live fault conditions

Insulated Busbars & Terminals: Prevent electrical shocks

Lockable Compartments: Ensures only trained staff can access sensitive areas

Proper Earthing and Grounding: Prevents fire and electrical hazards

These features ensure your operations run smoothly while staying within safety standards.

Conclusion

To conclude, MCC Panels are the backbone of safe, efficient, and centralized motor control. Whether you're expanding an existing setup or building a new plant, sourcing from a reliable MCC manufacturer or top-tier MCC Panel Supplier is essential. Choose an expert Motor Control Panel Manufacturer who provides tested solutions for your specific applications.

To sum it up, MCC panels are not just metal boxes filled with wires—they are strategically engineered systems that manage the lifeline of industrial operations: electric motors.

Need help selecting the right MCC panel for your plant? Consult with a trusted MCC manufacturer today and future-proof your motor control system.

#mcc#mcc panel#mcc panel manufacturer#motor control center#motor control center panel#electric control panel

0 notes

Text

Effluent Treatment Plant Manufacturer: Your Partner in Industrial Wastewater Management

In today’s environmentally conscious and regulation-driven world, wastewater treatment is more than just an operational requirement—it's a responsibility. Industries that generate large amounts of wastewater are under increasing pressure to comply with stringent environmental norms while maintaining cost-effective and efficient operations. That’s where Effluent Treatment Plants (ETPs) come in—and more importantly, choosing the right Effluent Treatment Plant Manufacturer can make all the difference.

Whether you operate in pharmaceuticals, textiles, chemicals, food processing, or any other industry, this guide will help you understand what ETPs are, why they are essential, and how to choose a manufacturer that delivers long-term value.

What is an Effluent Treatment Plant (ETP)?

An Effluent Treatment Plant is a system specifically designed to treat industrial wastewater—also known as effluent—before it is released into the environment or reused for industrial processes. Unlike domestic sewage, industrial effluent often contains complex contaminants such as heavy metals, oils, toxic chemicals, and biological waste, which require advanced treatment processes.

The goal of an ETP is to:

Remove harmful contaminants

Meet environmental and discharge norms

Reduce pollution load on municipal treatment systems

Enable water reuse and conservation

Industries That Require ETPs

Effluent Treatment Plants are critical across a wide range of industries, including:

Textile and Dyeing

Pharmaceuticals

Chemical Manufacturing

Oil & Gas

Food & Beverage

Paints and Coatings

Paper & Pulp

Tanneries

Automotive and Engineering

Each of these industries produces different types and levels of pollution, and therefore requires a customized ETP solution.

Why Choose a Reputed Effluent Treatment Plant Manufacturer?

Investing in an ETP is not just about installing a system—it’s about ensuring performance, compliance, and sustainability. A reputed manufacturer brings in the technical know-how, industry experience, and post-installation support needed to make your system efficient and reliable.

Here are the top reasons to choose a professional ETP manufacturer:

1. Customized Design & Engineering

No two industries have the same effluent characteristics. A trusted manufacturer begins with a comprehensive water analysis, then designs a custom treatment solution tailored to your effluent load, space availability, and compliance requirements.

2. Advanced Technology

Leading manufacturers offer modern treatment technologies such as:

Physico-Chemical Treatment

Biological Treatment (Aerobic/Anaerobic)

Sludge Dewatering Systems

Tertiary Treatment (Filtration, UV, RO)

Zero Liquid Discharge (ZLD)

These technologies are often integrated with smart control systems (PLC/SCADA) for automation and efficiency.

3. Regulatory Compliance

A reliable ETP manufacturer ensures that the treated water meets all required norms set by the Pollution Control Board (PCB) and Environmental Protection Agencies (EPA). This protects you from fines, legal actions, and reputational damage.

4. Robust Construction and Components

From corrosion-resistant tanks to energy-efficient blowers and pumps, a quality manufacturer uses durable, certified materials to ensure long-lasting performance.

5. Comprehensive Support

From installation and operator training to annual maintenance contracts and emergency repairs, a good manufacturer provides end-to-end service and support.

How to Select the Best Effluent Treatment Plant Manufacturer

Before selecting a manufacturer, consider the following:

✅ Experience and Industry Focus

Look for a company that has worked in your industry. Different sectors have different types of effluent, and experience matters.

✅ Certifications and Quality Standards

Ensure the company follows recognized standards like ISO 9001, ISO 14001, and has approval from environmental authorities.

✅ Customization and Scalability

Choose a manufacturer that can tailor the plant based on your wastewater volume and composition, and offers future scalability.

✅ Reference Projects

Ask for case studies or visit an existing plant. Testimonials and successful installations speak volumes about credibility.

✅ Cost Transparency

The best manufacturers offer a clear breakdown of capital expenditure (CAPEX) and operational expenditure (OPEX), so you understand the full cost of ownership.

Key Components of a Well-Designed ETP

An efficient ETP typically includes:

Screening Unit – Removes large solids

Equalization Tank – Balances flow and load

Coagulation & Flocculation – Prepares particles for sedimentation

Primary Clarifier – Settles suspended solids

Biological Reactor – Degrades organic matter

Secondary Clarifier – Removes biological sludge

Tertiary Treatment Unit – Polishes treated water for reuse or discharge

Sludge Handling System – Dewaters and disposes of sludge safely

A capable manufacturer will optimize these stages for performance, space, and cost.

Modern Trends in ETP Design

Leading ETP manufacturers are now integrating:

IoT-Based Monitoring – Real-time tracking of system health and performance

Energy-Efficient Equipment – Blowers, pumps, and motors that reduce operational costs

Automated Dosing Systems – Ensure precise chemical treatment

Modular and Compact Designs – For ease of installation and relocation

These innovations make systems more efficient, reliable, and easy to manage.

Questions to Ask Your ETP Manufacturer

What technology is best suited for my effluent type?

What will be the quality of treated water?

How much energy and chemicals will the system consume?

What is the average life of key components?

Do you provide operator training and annual maintenance?

Final Thoughts

An Effluent Treatment Plant is not just a technical solution—it’s a commitment to environmental responsibility and regulatory compliance. Choosing the right Effluent Treatment Plant Manufacturer ensures that you receive a system that’s efficient, durable, easy to operate, and tailored to your industry’s needs.

With growing emphasis on sustainable industrial practices, efficient effluent treatment is no longer optional—it’s essential. Partnering with a capable manufacturer will help your business stay compliant, minimize environmental impact, and even save on water and operational costs in the long run.

0 notes

Text

Pharmaceutical Engineering Services by Top Pharma Consultant in India

In the highly regulated and fast-evolving pharmaceutical industry, precision, safety, and compliance are paramount. From the development of robust manufacturing systems to ensuring facility layouts meet global regulatory standards, pharmaceutical engineering plays a critical role in transforming pharmaceutical ideas into real-world products.

As a Top pharmaceutical consultant in India, JD Pharma Consultant offers specialized pharmaceutical engineering services that help clients design, build, and optimize pharma facilities and processes. This article explores the core aspects of pharmaceutical engineering, its impact on the industry, and how expert consultants like JD Pharma ensure projects run smoothly and compliantly from concept to completion.

What Is Pharmaceutical Engineering?

Pharmaceutical engineering involves the application of engineering principles to the development, manufacturing, and packaging of pharmaceutical products. It encompasses a wide range of activities, from facility design and utility management to process optimization and validation.

Whether it's designing HVAC systems for cleanrooms or creating layouts for GMP-compliant production lines, pharmaceutical engineering ensures that both the product and process meet industry standards for quality, safety, and efficiency.

The Importance of Pharmaceutical Engineering Services

In the pharmaceutical sector, engineering isn't just about construction or machinery. It's a disciplined approach to achieving manufacturing excellence while staying compliant with stringent global standards.

Key Reasons Why Pharmaceutical Engineering Is Essential:

Ensures adherence to Good Manufacturing Practices (GMP)

Improves operational efficiency and product consistency

Supports cost-effective scale-up and technology transfer

Minimizes production downtime through optimized layouts and utilities

Enables safe, sterile, and compliant manufacturing environments

By leveraging professional pharmaceutical engineering services, companies can focus on core drug development while experts handle the technical complexities of plant design, construction, and validation.

Core Areas of Pharmaceutical Engineering in Practice

1. Facility Design and Layout Planning

Proper plant layout is critical to ensuring clean, logical material flow and avoiding cross-contamination. Pharmaceutical engineers work closely with architects and regulatory experts to create GMP-compliant facility designs that meet local and global regulatory norms (USFDA, WHO, MHRA, etc.).

Key aspects include:

Cleanroom classification and airflow design

Personnel and material movement optimization

Segregation of sterile and non-sterile zones

Future scalability and expansion planning

2. HVAC System Design

HVAC (Heating, Ventilation, and Air Conditioning) systems are vital in controlling temperature, humidity, and airborne contamination in pharmaceutical environments. An optimized HVAC system ensures product safety and energy efficiency.

3. Utility Systems Engineering

Utilities like purified water, WFI (Water for Injection), compressed air, and clean steam are essential in pharma manufacturing. Engineers design and validate these systems to ensure uninterrupted, contamination-free supply.

4. Process Equipment Selection and Integration

From tablet presses to bioreactors, engineers help select and integrate process equipment that aligns with the manufacturing goals and regulatory requirements of the facility.

5. Automation and Control Systems

Modern pharmaceutical facilities incorporate automation for better control, accuracy, and compliance. Engineers implement SCADA and PLC systems for monitoring critical process parameters in real-time.

Project Management in Pharmaceutical Engineering

Project management in the pharmaceutical industry is inseparable from engineering. An experienced consultant ensures that all engineering tasks are completed on schedule and within budget without compromising compliance.

JD Pharma Consultant offers end-to-end project oversight—from concept planning to commissioning.

Our Project Management Services Include:

Project scope and feasibility assessment

Engineering design coordination

Equipment procurement and vendor management

Validation and qualification

Budget tracking and risk management

Regulatory audit readiness

Role of Pharmaceutical Engineering in Regulatory Compliance

Meeting compliance is not optional in the pharmaceutical industry—it's a mandate.

Pharmaceutical engineering ensures that facilities and processes conform to regulatory standards such as:

USFDA (United States Food & Drug Administration)

EU-GMP (European Union Good Manufacturing Practice)

WHO-GMP (World Health Organization Guidelines)

Schedule M (India-specific GMP standards)

Engineering Services Offered by JD Pharma Consultant

Our Pharmaceutical Engineering Services Include:

Facility and process design

HVAC and cleanroom design

Utility systems engineering (WFI, steam, air, water)

Process flow mapping and layout optimization

Equipment specification and selection

Qualification and validation protocols

Automation and control system design

Safety and energy audits

Environmental engineering and waste management

Industries We Serve

JD Pharma Consultant provides specialized engineering services to:

Pharmaceutical formulation units

Active Pharmaceutical Ingredient (API) plants

Biotech and biosimilar manufacturing facilities

Nutraceuticals and herbal product facilities

Cosmetic manufacturing plants

Veterinary medicine units

Future of Pharmaceutical Engineering: Trends to Watch

1. Digitization and Smart Manufacturing

Pharmaceutical engineering is evolving with Industry 4.0 technologies like IoT, AI, and machine learning to monitor systems in real time and predict failures before they occur.

2. Sustainable Engineering Solutions

Green building concepts, energy-efficient HVAC systems, and eco-friendly waste management are being integrated into pharma engineering for a cleaner future.

3. Modular Facility Design

To reduce time-to-market, companies are embracing modular setups that can be built and validated faster and offer flexibility for expansion or reconfiguration.

Conclusion

Pharmaceutical engineering is the foundation of safe, efficient, and compliant drug manufacturing. From facility design to utility systems and process optimization, every element must be engineered with precision and aligned with regulatory expectations.

As a Top pharmaceutical consultant in India, JD Pharma Consultant brings years of hands-on experience in delivering tailored pharmaceutical engineering services that meet the highest quality and compliance standards. Our integrated approach combines technical expertise with regulatory insight, ensuring that your pharma projects are built for long-term success.

Contact us:

07314043825

5th floor, Fortune Business Centre, 501, RNT Marg, South Tukoganj, Indore, Madhya Pradesh 452001

#PharmaceuticalEngineering#PharmaConsulting#GMPCompliance#PharmaFacilityDesign#TopPharmaceuticalConsultant

0 notes

Text

Aluminum Annealing Furnace – Enhancing Ductility, Strength & Surface Finish

Aluminum and its alloys are widely used in industries like automotive, aerospace, construction, packaging, and electronics due to their lightweight, corrosion resistance, and excellent thermal conductivity. However, processes such as rolling, extrusion, or forming introduce internal stresses and reduce ductility. To restore their original properties, annealing is essential.

As a leading aluminum annealing furnace manufacturer in India, JR Furnace & Ovens delivers advanced, high-precision thermal systems specifically designed for annealing aluminum and non-ferrous metals. Our furnaces ensure accurate temperature control, uniform heating, and energy-efficient performance—making them ideal for mass production and critical applications.

What Is an Aluminum Annealing Furnace?

An aluminum annealing furnace is a thermal processing unit designed to heat aluminum sheets, billets, coils, extrusions, or castings to a controlled temperature (usually between 300°C and 450°C) and then cool them slowly. This process:

Relieves internal stresses

Improves ductility and formability

Restores electrical conductivity

Enhances surface finish

Prepares material for further forming or machining

Unlike steel, aluminum requires lower annealing temperatures and more precise control to avoid overheating or surface oxidation.

Applications of Aluminum Annealing Furnaces

Aluminum annealing is a crucial process in various industries, such as:

Automotive – Body panels, frames, and battery enclosures

Aerospace – Aircraft skins, structural components

Packaging – Foil, cans, and containers

Construction – Panels, extrusions, and facades

Electrical – Busbars, wires, and connectors

Furniture & Appliances – Frames, extruded sections, trims

JR Furnace – Advanced Aluminum Annealing Furnace Solutions

At JR Furnace & Ovens, we specialize in custom-designed furnaces optimized for aluminum heat treatment. Our systems are engineered for temperature accuracy, low energy consumption, and operational safety.

Key Features:

Temperature Range: 150°C to 600°C (precisely controlled)

Heating Options: Electric or Gas-Fired

Control System: Digital PID / PLC-SCADA with HMI

Construction: Rigid steel body with high-density ceramic fiber or refractory lining

Atmosphere: Air or Inert Gas (Nitrogen) to avoid oxidation

Cooling Options: Forced air or controlled natural cooling

Loading Systems: Manual, trolley, or automated roller conveyor

Types of Aluminum Annealing Furnaces We Offer

Box-Type Annealing Furnace Suitable for batch annealing of aluminum castings, billets, or fabricated parts.

Bell-Type Annealing Furnace Sealed design used for oxidation-free annealing of aluminum coils or sheets under controlled atmosphere.

Bogie Hearth Annealing Furnace Heavy-duty solution for large and heavy aluminum parts; ideal for extrusion industries.

Chamber Type Furnace Designed for high-throughput annealing processes with excellent temperature uniformity.

Continuous Conveyor Furnace Automated annealing line for large-scale operations in foil and packaging industries.

Benefits of JR Aluminum Annealing Furnaces

✅ Uniform Heating – Even temperature distribution across all zones ✅ Accurate Control – PLC-based operation ensures consistent annealing cycles ✅ Energy Efficiency – Advanced insulation and burner/heater design reduce energy consumption ✅ Surface Protection – Optional inert gas purging prevents oxidation or discoloration ✅ Flexible Design – Custom-built to fit your space, material size, and productivity goals ✅ Long Equipment Life – Industrial-grade materials and craftsmanship ensure durability

Industries We Serve

✔ Aluminum Extrusion & Rolling Plants ✔ Automotive Component Manufacturers ✔ Aerospace Suppliers ✔ Metal Packaging & Foil Producers ✔ Electrical Equipment Manufacturers ✔ General Metalworking & Foundries

Why Choose JR Furnace & Ovens?

30+ Years of Manufacturing Expertise

ISO-Certified Production & Testing Facility

Fully Customizable Furnace Designs

Global Export Presence

End-to-End Service: Design → Commissioning → AMC

Innovative Solutions with Proven Thermal Engineering

We help manufacturers improve product quality, reduce scrap, and meet international metallurgical standards through advanced aluminum annealing furnaces.

Ready to Upgrade Your Heat Treatment Line?

Whether you're looking to install a new aluminum annealing furnace or retrofit your current setup, JR Furnace & Ovens provides reliable, high-efficiency systems backed by expert service and support.

0 notes

Text

Understanding the Basics of Industrial Control Panels & How Artificial Intelligence is Emerging as an Enabler for Panel Manufacturers

In the heart of every modern industrial facility lies an unsung hero — the industrial control panel (ICP). These panels are the backbone of industrial automation, silently managing and coordinating complex processes across sectors like manufacturing, energy, HVAC, pharmaceuticals, water treatment, logistics, and more. Whether it’s starting a motor, activating a safety interlock, or communicating with SCADA systems, ICPs ensure that industrial processes run smoothly, safely, and efficiently.

While traditionally grounded in electrical engineering and logic-based control systems, the game is evolving — and evolving fast. The rapid rise of Artificial Intelligence (AI) is rewriting the rules, enabling smarter, more agile, and more cost-effective solutions across the control panel lifecycle. From automating design and estimation to predictive maintenance and virtual support, AI is transforming the role of panel manufacturers from hardware builders to tech-enabled solution providers.

This blog dives into the fundamentals of industrial control panels and explores how AI is not just a buzzword, but a strategic enabler for panel manufacturers aiming for speed, precision, quality, and profitability in an increasingly competitive and digital-first world.

What is an Industrial Control Panel?

At its core, an industrial control panel is an assembly of electrical devices — such as relays, switches, circuit breakers, PLCs (Programmable Logic Controllers), transformers, power supplies, and structured wiring — all housed within an enclosure. These components work together to control, monitor, and regulate machinery, processes, and safety mechanisms in industrial environments.

Depending on the application, control panels may also include devices for automation logic, analog and digital signal processing, communications, and human interaction. They can range from simple on-off motor control panels to highly complex, multi-section panels with remote I/O, touchscreens, cloud connectivity, and safety interlocks.

Key Components:

Power Distribution Units – These manage how electricity is distributed to internal devices and external loads, ensuring energy is delivered safely and efficiently.

Control Devices – This includes PLCs, relays, timers, VFDs, and controllers that form the brain of the operation by processing logic and managing sequences.

Interface Units – HMIs (Human Machine Interfaces), push-button stations, and touchscreen panels allow human operators to visualize operations, control equipment, and monitor system health.

Wiring and Protection – Fuse blocks, terminal blocks, circuit breakers, surge protectors, and ground fault devices are essential for structured connectivity, protection, and compliance with safety standards.

Control panels must be designed according to international safety and performance standards, such as UL508A (United States), IEC 61439 (Europe), and others, depending on geographic and sectoral requirements. Environmental considerations — like temperature, humidity, vibration, and ingress protection (IP rating) — also influence component selection and enclosure design.

Challenges Faced by Panel Manufacturers Today

Despite the increasing demand for industrial control systems, panel manufacturers face a variety of challenges that limit their growth and operational efficiency:

Lengthy Design Cycles: Manual schematic generation, layout planning, and approvals slow down project delivery timelines, especially for custom-built panels.

Customization Pressure: Every industrial customer has unique system requirements, which forces manufacturers to tailor designs frequently — increasing engineering time and chances of error.

Skilled Manpower Shortage: The industry is experiencing a shortage of skilled panel designers, electrical engineers, and trained wiring technicians, making scalability difficult.

Tight Margins: With rising prices for raw materials, pressure from competition, and frequent scope changes, maintaining healthy profit margins has become challenging.

After-Sales Troubleshooting: Diagnosing faults post-installation often requires physical site visits, which adds cost, delays, and affects customer satisfaction — especially in geographically dispersed installations.

These issues call for intelligent, automated, and scalable solutions, and this is precisely where Artificial Intelligence is stepping in — not as a futuristic concept, but as a practical toolkit to tackle real-world bottlenecks.

AI as an Enabler for Panel Manufacturers

Artificial Intelligence is enabling panel manufacturers to optimize workflows, minimize rework, enhance accuracy, and deliver faster — giving them a much-needed edge in today’s demanding landscape. Here’s how:

1. AI in Panel Design Automation

AI-powered design tools can analyze previous projects and generate optimized panel layouts within minutes. These tools learn from design rules, space constraints, and component configurations, allowing engineers to:

Auto-suggest electrical schematics based on user inputs and project templates.

Optimize component placement to minimize wiring length, heat build-up, and enclosure size.

Detect and flag non-compliant or risky designs early in the development stage.

Seamlessly integrate with popular CAD/E-CAD platforms for quick revisions.

This significantly reduces engineering time, shortens the design review cycle, and minimizes human errors — especially in high-mix, low-volume environments.

2. AI-Driven Smart BOM and Cost Estimation

AI algorithms can read project specs and instantly generate a Smart Bill of Materials (BOM), complete with up-to-date pricing, availability, and lead times.

This empowers:

Sales teams to respond to RFQs faster with high-accuracy quotations.

Procurement teams to make informed decisions and avoid last-minute shortages.

Project managers to reduce buffer costs and manage delivery timelines efficiently.

One of the most effective tools in this space is Quoteplan, an AI-powered platform that automates estimation and BOM generation. With features like OEM catalogue integration and configurable pricing logic, Quoteplan helps manufacturers quote smarter, faster, and more competitively — often reducing quotation turnaround by 30–50% and improving win rates significantly.

3. Predictive Maintenance & Remote Diagnostics

AI is also playing a crucial role in monitoring panel performance in real time. By combining AI with IoT sensors, manufacturers can:

Monitor load cycles, current spikes, and heat signatures to detect abnormal patterns.

Predict component failure (e.g., overheating relays or degrading capacitors) before it occurs.

Send automated alerts or maintenance instructions via remote dashboards.

This drastically reduces the cost of unplanned downtime, minimizes site visits, and enhances customer trust in the system’s long-term reliability.

4. AI in Quality Assurance

AI-powered machine vision systems and smart checklists can be integrated during panel assembly to:

Inspect wiring paths, terminal tightness, and component placement visually.

Compare panel builds against digital twins to detect errors in real-time.

Automatically generate QA reports for client records or compliance purposes.

This ensures repeatable quality and enables manufacturers to meet rigorous industry standards — without overburdening the QA team.

5. Training & Knowledge Management

AI assistants such as ChatGPT-based bots or proprietary LLMs can support technicians, wiring staff, and engineers by:

Answering design questions in real time.

Offering step-by-step wiring assistance based on manufacturer data.

Troubleshooting configuration issues without needing to escalate support.

This is especially useful for new hires or less experienced technicians, helping bridge the skill gap while reducing training overhead.

Case in Point: AI in Action

A mid-sized panel manufacturer in India recently integrated AI-driven design automation, BOM generation, and quoting tools into their standard workflow. The results were remarkable:

50% reduction in design cycle time through auto-schematic generation.

30% faster quotation turnaround by eliminating manual Excel-based estimates.

20% improvement in win rate due to faster, more professional client responses.

Fewer reworks, improved client satisfaction, and faster delivery timelines.

This transformation allowed the company to take on more projects without increasing headcount, clearly demonstrating the value of integrating AI into everyday operations.

What Lies Ahead?

The future of industrial control panels is intelligent, connected, and autonomous. The convergence of AI, IoT, cloud computing, and digital twins is giving rise to a new generation of “smart panels” that will:

Self-configure based on application parameters or system changes.

Conduct real-time diagnostics and self-healing operations.

Seamlessly collaborate across devices and facilities, enabling Industry 4.0 and smart factory use cases.

In the coming years, we’ll see AI not just assist but take decision-making roles in power management, fault isolation, and remote optimization — drastically changing how systems are managed in real time.

Final Thoughts

Industrial control panels may appear to be just a box of wires and switches to the untrained eye, but they are the brains and nervous system of industrial operations. As demands for customization, speed, and digital integration grow, panel manufacturers must evolve — and AI is the key catalyst in that transformation.

Adopting AI is no longer a futuristic investment — it is a present-day competitive advantage. Those who embrace this technology early will not only thrive but redefine the very benchmarks of innovation, quality, and efficiency in the control panel industry.

#product management system#project management software#inventory management software#stock management software#product management software#quotation management software

0 notes

Text

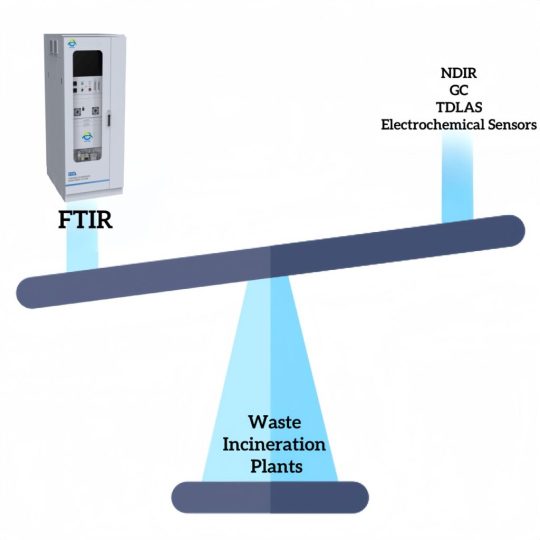

Why FTIR Gas Analyzers Are a Game-Changer for Waste Incineration Emission Monitoring

The Hidden Dangers of Waste Incineration Emissions

Waste incineration plants are essential for reducing landfill usage and generating energy from waste. But there’s a catch—they emit harmful gases like CO, NOx, SO₂, HCl, HF, VOCs, and even dioxins. These pollutants can harm air quality, human health, and the environment if left unchecked. That's why emission monitoring in these plants isn’t just regulatory—it’s critical.

Traditional gas analyzers often fall short. Many can only detect a single gas, require complex setups, and have slower response times. That means you might miss dangerous spikes or spend more on maintenance and compliance issues. Enter a new solution: FTIR gas analyzers.

What Makes FTIR the Smarter Choice?