#cnc router for wood

Explore tagged Tumblr posts

Text

Top CNC Router In Ahmedabad, India | CNC Routers for Woodworking & Sign Making – Success Technologies

Ahmedabad's premier CNC Router Wood Engraving Machine manufacturer, delivering innovative and efficient machinery. Transform your woodworking experience with our premium range of products.

Success Technologies is proud to be recognized as a top CNC Router manufacturer in Ahmedabad, India, offering high-performance CNC Router machines designed for a wide range of applications.

Our CNC Routers are engineered to deliver precise, high-speed cutting, engraving, and milling solutions across industries like woodworking and the sign industry. If you're searching for reliable and cost-effective CNC Routers in Ahmedabad, Success Technologies has the perfect solution for your needs.

What is a CNC Router?

A CNC Router (Computer Numerical Control Router) is an advanced cutting machine that automates the cutting, drilling, carving, and engraving processes using computer software. Unlike traditional machines, CNC Routers can perform highly detailed tasks with exceptional speed and repeatability.

They are widely used in industries such as:

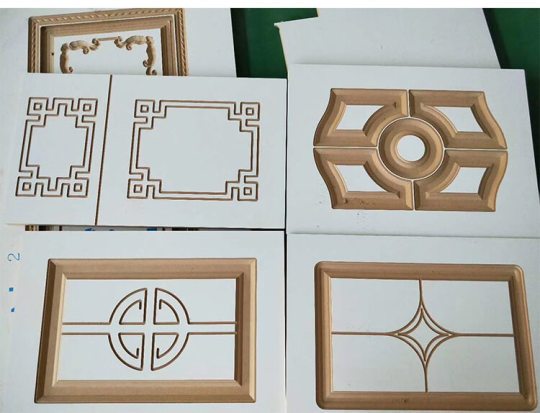

Woodworking: for crafting furniture, cabinets, decorative items, and more.

Sign making: for creating complex signboards, logos, and 3D signage.

Plastics and composites: for engraving and cutting materials like acrylic, PVC, and MDF.

Why Choose a CNC Router for Woodworking?

The woodworking industry demands machines that can work with softwoods, hardwoods, MDF, plywood, and more, without compromising on finish quality. A WoodWorking CNC Router Machine provides:

Precision: Accurate cuts and carvings, ensuring repeatable designs.

Versatility: Ability to handle various woodworking tasks including furniture making, door design, carving, and cabinetry.

Productivity: Automated operations reduce manual effort and save time.

Customization: Ideal for producing one-off or custom designs at scale.

At Success Technologies, our CNC Routers are designed specifically for woodworking professionals, combining durability with user-friendly controls.

CNC Router for Sign Industry

If you're in the business of sign making, investing in a CNC Router for the sign industry is essential. Signboards, architectural lettering, 3D logos, and backlit signs require fine detailing and consistency, which traditional manual tools can't provide.

Our CNC Router machines can process materials like:

Acrylic

PVC

Aluminum composite panels (ACP)

MDF

Whether you’re a small sign shop or a large-scale signage production company, our CNC Routers provide the speed, accuracy, and reliability you need to scale your operations.

Features of Success Technologies CNC Routers

As a reputed CNC Router manufacturer and supplier in India, we ensure our machines come equipped with top-of-the-line features:

Heavy-Duty Frame: The machine's robust structure ensures vibration-free operation and high-precision performance even during continuous, high-speed operations.

High-Speed Spindle: Our CNC Router machines are equipped with powerful spindles capable of operating at high RPMs, making them ideal for intricate cuts and engravings.

User-Friendly Interface: We provide machines with intuitive software interfaces and controllers, making them easy to operate even for beginners.

Customizable Sizes: From small table-top CNC Routers to large industrial-scale machines, we can customize machines based on your workspace and project needs.

Dust Collection System: Efficient dust collection keeps the workspace clean and protects components from debris, especially critical in woodworking environments.

Applications of CNC Routers

Success Technologies’ CNC Routers serve a wide range of applications across industries:

Wood carving

Sign Board manufacturing

Interior and exterior decor

Furniture production

Architectural millwork

Nameplates and number boards

Acrylic and plastic fabrication

Our CNC Router machines are designed to handle different materials with ease, including wood, plastic, foam, and metal.

CNC Router Machine Price in Ahmedabad, India

One of the common queries we receive is about the CNC Router machine price in Ahmedabad, India. While prices vary depending on the size, features, and customization, Success Technologies offers competitive pricing without compromising on quality.

Our CNC Routers are available in a wide range of models to suit every budget and requirement — from startups and workshops to large manufacturing units.

Reach out to us for a personalized quote and know the best CNC Router machine price in India tailored for your specific application.

Why Choose Success Technologies?

Made in India Excellence: We take pride in being a leading CNC Router Manufacturer in Ahmedabad and contributing to the "Make in India" movement. All our machines are designed and built in-house using globally sourced components.

Experience and Expertise: With years of experience in manufacturing and support, our team understands your unique needs and provides tailored solutions.

Pan India Support: As a top CNC Router Supplier in India, we provide installation, training, and technical support across all major cities.

After-Sales Service: Our relationship doesn’t end at the sale. We provide comprehensive after-sales support and maintenance services to ensure your machine performs optimally throughout its lifespan.

CNC Routers in Ahmedabad – Local Trust, Global Standards

Ahmedabad is fast becoming a hub for machinery manufacturing, and Success Technologies is at the forefront as one of the most trusted CNC Router machine manufacturers in Ahmedabad.

Whether you're a business owner looking to enhance your manufacturing capabilities or a startup exploring CNC possibilities, Success Technologies has the right machine for you.

We offer:

In-stock models for quick delivery

Custom design options

On-site installation and training

Post-sale support and maintenance

CNC Router Machine – Manufacturers & Suppliers in India

Success Technologies is proud to be listed among the top Double Head WoodWorking CNC Router Machines And suppliers in India. Our focus on innovation, quality, and customer satisfaction sets us apart from others in the industry.

When it comes to buying the best CNC Router in Ahmedabad, India, Success Technologies stands as a trusted name for high-quality, performance-driven machines. Whether you need a CNC Router for woodworking or a sign making machine, we have solutions tailored to your needs.

Our goal is to help Indian manufacturers grow with world-class machines that deliver speed, precision, and profitability.

📞 Ready to Boost Your Productivity?

Get in touch with Success Technologies today!

✅ Explore our range of CNC Router Machines in Ahmedabad

✅ Know the latest CNC Router machine price in India

✅ Request a demo or quote tailored to your needs

✅ Partner with a reliable CNC Router manufacturer and supplier in India

Let Success Technologies be your partner in precision manufacturing!

For more information: https://www.successlaser.com/ Contact us: 9998961184 E-mail ID: [email protected] Location: 97, Barcelona Industrial Estate, Odhav Rd, Odhav, Kathwada, Ahmedabad, Gujarat 382415

#CNC Router#CNC Router for Wood#CNC Router for Sign Industry#CNC Machine#CNC Router Manufacturer#Woodworking Machine#Sign Making Machine#CNC Router Machine#CNC Router India#CNC Router Supplier#CNC Router Machine in Ahmedabad#CNC Router Machine - Manufacturers & Suppliers in India#CNC Router machine price in india

0 notes

Text

source

12 notes

·

View notes

Text

You won’t believe how easy it is to start a CNC Router Machine business! 🤯 If you’ve been dreaming of passive income and creative work—THIS is your sign. 💸 Hit follow for more business hacks that actually work! #CNCBusiness #SideHustleIdeas #viralbusiness

#business plan for cnc machine#business with a cnc router machine#cnc business#cnc business ideas#cnc machine#cnc machine business ideas#cnc machining business ideas#cnc router#cnc wood machine business#desktop cnc#full time cnc router business#how do i start a cnc business#how to make money with a cnc machine#how to make money with cnc router#make money with cnc router#new business ideas#small business#sucessful cnc business#woodworking#woodworking business

0 notes

Text

Cnc Wood Routers Market set to hit $2.9 billion by 2035

Industry revenue for Cnc Wood Routers is estimated to rise to $2.9 billion by 2035 from $1.3 billion of 2024. The revenue growth of market players is expected to average at 7.9% annually for the period 2024 to 2035.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/cnc-wood-routers-market-research-report

Cnc Wood Routers is critical across several key applications including furniture manufacturing, sign making, prototyping and musical instrument creation. The report unwinds growth & revenue expansion opportunities at Cnc Wood Routers’s Product Structure, Technology, Application Type, Product Complexity and Users including industry revenue forecast.

Industry Leadership and Competitive Landscape

The Cnc Wood Routers market is characterized by intense competition, with a number of leading players such as Biesse Group, Homag Group, SCM Group, Anderson Industrial Corporation, Felder Group, Thermwood Corporation, Holz-Her, AXYZ Automation Group, Multicam Inc., Shop Sabre, ArtClip3D and Haas Automation Inc..

The Cnc Wood Routers market is projected to expand substantially, driven by increased demand for precision woodworking and technological advancements in cnc machines. This growth is expected to be further supported by Micro industry trends.

Moreover, the key opportunities, such as exploiting the underserved custom furniture segment, harnessing technological innovations and penetrating emerging markets, are anticipated to create revenue pockets in major demand hubs including U.S., Germany, China, Japan and Italy.

Regional Shifts and Evolving Supply Chains

North America and Europe are the two most active and leading regions in the market. With challenges like high initial investment and lack of skilled personnel, Cnc Wood Routers market’s supply chain from raw material providers / hardware & component manufacturers / cnc wood router manufacturer to end-use industry is expected to evolve & expand further; and industry players will make strategic advancement in emerging markets including Brazil, India and South Africa for revenue diversification and TAM expansion.

About DataString Consulting

DataString Consulting offers a complete range of market research and business intelligence solutions for both B2C and B2B markets all under one roof. We offer bespoke market research projects designed to meet the specific strategic objectives of the business. DataString’s leadership team has more than 30 years of combined experience in Market & business research and strategy advisory across the world. DataString Consulting’s data aggregators and Industry experts monitor high growth segments within more than 15 industries on an ongoing basis.

DataString Consulting is a professional market research company which aims at providing all the market & business research solutions under one roof. Get the right insights for your goals with our unique approach to market research and precisely tailored solutions. We offer services in strategy consulting, comprehensive opportunity assessment across various sectors, and solution-oriented approaches to solve business problems.

0 notes

Text

#cnc router wood#cnc router machine#laser#laser welding machine#machinery#laserengraving#cnc router#laser dentistry#laser marking machine#metal engraving

1 note

·

View note

Text

CNC Routers: Best for wood and sign Industries | Success Technologies

India’s largest CNC router manufacturer, Success Technologies, is leading innovation with a diverse range of machines for woodworking, sign-making, and more. Discover how our CNC routers are transforming the wood and signage industries. Our high-precision machines are engineered for cutting, carving, and engraving wood, MDF, acrylic, and other materials with ease. Buy a CNC router machine at the best price today!

Visit: https://www.successlaser.com/cnc-router-machine.html Location: 97, Barcelona Industrial Estate, Odhav Rd, Odhav, Kathwada, Ahmedabad, Gujarat 382415

Call Now: 9998961184

#CNC Router#CNC Router for Wood#CNC Router for Sign Industry#CNC Machine#CNC Router Manufacturer#Woodworking Machine#Sign Making Machine#CNC Router Machine#CNC Router India#CNC Router Supplier#CNC Router Machine in Ahmedabad#CNC Router Machine - Manufacturers & Suppliers in India#CNC Router machine price in india

0 notes

Text

1325 CNC Wood Cutting Machine 4×8

The CNC wood cutting machine is also known as cnc wood cutting machine,CNC nesting machine, cnc router machine for wood, cnc machine for wood cutting, cnc machine wood cutting , CNC machine for cabinet making, cabinet door cutting machine for sale, etc.CNC wood cutting machines have revolutionized woodworking by automating and streamlining the cutting process. They are widely used in various woodworking applications, including furniture manufacturing, cabinetry, woodworking workshops, and architectural millwork.

Our 1325 CNC machine is one of our popular and best-selling machines. It is good at cutting, carving, engraving, drilling, routing, grooving, and pocketing of wood, MDF, acrylic, PVC, plastic, foam, stone, soft metal, and other materials.

CNC Wood Cutting Machine 4×8

This 1325 cnc wood cutting machine can change 12 different tools automatically. It is very suitable for the people who do complex work and change different tools frequently. This machine is provided with a push device and can push materials after cutting or engraving.

High Precision Cutting Best Selling CNC Machine For 4×8 Small CNC Machine

The 4×8 CNC machine XYZ axis Taiwan Hiwin square rail makes the gantry and spindle moving at high speed with high precision. CNC kit 4×8 adopts Hiwin square rail with high rigidity and very durable. XY axis German Helical rack and pinion are directly coupled to the stepper motor and pinion. This 4×8 CNC router cheap configuration ensures that the accuracy is less than ±0.03mm when the max 4×8 work table speed is 20,000mm/min.

Stable, Stronger And More Durable Structural Design Of CNC Machine Table 4×8

The Heavy structure adopts thicken steel square which improves the stability of wood CNC 4×8. This Stronger structure is necessary for cutting solid materials such as hardwood. During the 4×8 wood CNC machine cutting and carving process, the XYZ axis remains stationary against external cutting forces.

Long Time Operation With High-Power Stepper Motor Of Cheap CNC Router

Stepper motor and driver do not require regular maintenance. This not only reduces maintenance downtime but also spindle is able to run normally for a long time. Coupled with the fast working speed, the CNC machine 4×8 efficiency is greatly improved.

Compatible With Any Advanced Software For 4×8 CNC Wood Router

Software including Vectric Aspire, Type3, Ucancam, Artcam, AlphaCam, Powermill, Solidworks is run on the system of CNC table 4×8. You can use the CNC wood router 4×8 quickly without wasting the cost of training labor. This is simple and efficient for you.

Features CNC Wood Cutting Machine

1. Heavy duty frame. The frame is longer and much stronger than normal CNC routers.

2.Taiwan 1000w SYNTEC servo motor with Japan SHIMPO reducer. It adopts full closed loop and has brake function on Z axis. It provides constant position feedback, bigger power and smooth contentious motion.

3. Linear type tool change magazine under gantry. It can change 12 different tools fast.

4. Y axis adopts #30 Taiwan square linear guide. While X and Z axis adopt #25 square linear guide. 2M helical rack is used to ensure the high-speed and stable operation of the machine, and also ensure a higher processing accuracy.

5. ATC air cooling spindle. Max. speed can be 24000RPM. With ISO30 tool holder, it can use 20mm bits at max.

What can a 4X8 CNC Router do?

A 4X8 CNC Router is the ideal wood cutting and carving machine that imparts excellent efficacy in manufacturing doors, furniture designs, etc.

It runs on the CAD software that enables a user to cut detailed designs with utmost precision on a preferred material. The process of producing complex designs manually demands a lot of time and other resources. Just opposite, this wonder machine can perform carving and cutting in three axes to come up with the design you want.

Usually, it is cumbersome for manual processes to offer such precision and they incur huge material loss as well. With the aid of the driving software, you can convert complicated designs into a reality with the aid of 4X8 CNC Router.

Heavy duty CNC router is good for complex processes and long time work, such as:

Wood door, furniture making; MDF, Poly wood cutting;

Hardwood engraving & carving;

Big scale woodworking;

Soft metal, plastic, acrylic, foam engraving & cutting, etc.;

Automatic Wood CNC Router Cutting & Engraving Machine

A CNC wood router is an automatic machine tool for wood cutting, relief carving, drilling & slotting, which works with 2D/3D designed files by CAD/CAM software. A CNC wood router machine is composed of bed frames, spindles, T-slot table or vacuum table, vacuum pump, CNC controller, motor driver, guide rail, rack and pinion, ball screw, power supply, limit switch, collets, tools & bits, and other parts & accessories. The most common types of wood routers include 3 axis, 4th axis, 4 axis, 5 axis CNC woodworking machines.

Here is our collection of most popular CNC machines for woodworking, from single-spindle to multi-spindle kits, from small footprint to large format tables, from desktop to gantry styles, from hobby to industrial models, from primary 3 axis to professional 5 axis, from entry-level for beginners to high-end ATC series for experts, all types of CNC wood routers are available.Just discover what you need, plan your budget, compare features and costs, find and buy the best one to start or upgrade your woodworking business.

0 notes

Text

Are you a dynamic professional with a passion for sales and coordination? Unistar Industries, a leader in CNC router production, is looking for a dedicated Sales Coordinator to join our team. You’ll manage client interactions, streamline sales processes, and support our sales team in achieving targets. If you have strong organizational skills and a background in sales, this is your opportunity to grow with us. Apply now and take the next step in your career!

0 notes

Text

#cncrouter1325#cncroutermachine#woodcarving#woodworking#cncwoodworkingmachine#woodstarcncrouter#youtube#cnc router#3d wood carving machine#cncwoodrouter#bestqualitycncrouter#lowinvestmentbusinessidea#3dcncrouter

0 notes

Text

ATC CNC Router for Wood Cutting and Engraving

Woodworking ATC (automatic tool changer) CNC router is a type of machine that is used to automate woodworking processes and increase efficiency. This type of router is equipped with an automatic tool changer, which allows for the rapid and precise changing of cutting tools during the routing process.

ATC Wood CNC Router

In the world of woodworking, precision, efficiency, and versatility are paramount. Enter the Automatic Tool Change (ATC) Wood CNC Router – a cutting-edge solution that revolutionizes woodworking processes. This comprehensive guide is your key to understanding the capabilities and benefits of ATC Wood CNC routers. From exploring the fundamentals of ATC technology to uncovering its diverse applications in woodworking, this guide equips you with the knowledge to optimize your woodworking operations and unleash your creativity.

It can be equipped with 6, 8, 10, 12 tools according to the different production process requirements of customers. There are two tool change modes for inline tool change and disc tool change. Widely used, including engraving, milling, chamfering, side milling, drilling, cutting, grooving, etc.

An Automatic Tool Change (ATC) Wood CNC Router is a sophisticated machining tool equipped with a tool magazine and a mechanism for automatically changing cutting tools during the machining process. Unlike manual tool changes, which require operator intervention and downtime, ATC routers streamline production by seamlessly switching between different tools as needed, enhancing efficiency and productivity.

Product Recommend

Linear ATC CNC Router with Oscillating Knife Cutting

3d Atc Auto Tool Changer Wood Woodworking Machine

Wood CNC Router Rotation Head With Rotation Table

Atc CNC Router Wood Carving Machine with Pinch Roller

ATC Linear CNC Wood Machine for Sale

3 Axis Swing Head ATC CNC Router Woodworking Machine

Linear ATC CNC Router Woodworking Machine

Atc CNC Router With Automatci Tool Changer

ATC CNC Router With Automatic Tool Changer

Step into a world of limitless possibilities with our state-of-the-art Woodworking ATC CNC Router with Tool Changer. Designed to revolutionize your woodworking experience, this cutting-edge machine combines precision, efficiency, and versatility to bring your creative visions to life like never before.

Unparalleled Precision

Experience woodworking at its finest with the Woodworking ATC CNC Router’s exceptional precision. Equipped with advanced technology and high-precision components, this machine ensures every intricate detail of your designs is flawlessly executed. From intricate carvings to intricate joinery, achieve perfection with ease.

Automatic Tool Changer

Say goodbye to time-consuming manual tool changes. Our Woodworking ATC CNC Router comes with an Automatic Tool Changer (ATC) that allows seamless and efficient transitions between different cutting, carving, and shaping tools. This feature not only saves you valuable time but also enables uninterrupted workflow, maximizing productivity.

Versatility Redefined

With the Woodworking ATC CNC Router’s tool-changing capabilities, you can explore a wide range of woodworking applications. Whether you’re crafting fine furniture, intricate cabinetry, decorative moldings, or even intricate wood engravings, this machine empowers you to push the boundaries of your creativity with ease.

Efficient Workflow

Boost your efficiency and optimize your workflow with the Woodworking ATC CNC Router. Its user-friendly interface and intuitive controls make operation effortless, allowing you to focus on unleashing your creativity. The machine’s rapid cutting speed, coupled with the automatic tool changer, ensures quick turnarounds and seamless production.

Enhanced Material Compatibility

The Woodworking ATC CNC Router is designed to accommodate a variety of materials, expanding your woodworking capabilities. From hardwoods to softwoods, plywood to MDF, this machine delivers exceptional results on various materials, enabling you to tackle diverse woodworking projects with confidence.

Reliable and Durable

Invest in a woodworking machine that stands the test of time. Our Woodworking ATC CNC Router is built with durability and reliability in mind. The robust construction and high-quality components ensure consistent performance, minimizing downtime and maximizing your return on investment.

Unmatched Customer Support:

We are committed to providing exceptional customer support throughout your woodworking journey. Our team of experts is available to assist you with any queries, technical support, or training needs, ensuring a smooth and seamless experience with our Woodworking ATC CNC Router.

Applications of ATC CNC Router Machine

The applications of ATC Wood CNC routers span a wide range of woodworking disciplines and industries. In furniture manufacturing, ATC routers excel at producing custom cabinetry, decorative panels, intricate carvings, and complex joinery with precision and efficiency.

Artistic woodworking thrives with ATC routers, allowing craftsmen to explore creative designs, sculptures, and intricate patterns with ease and precision.

ATC Wood CNC routers offer a multitude of benefits for woodworking professionals and businesses. Firstly, they significantly reduce setup times and tool changeovers, maximizing uptime and throughput. This results in faster production cycles and shorter lead times, ultimately increasing profitability and competitiveness in the market.

Moreover, ATC routers enhance versatility by enabling the use of a wide range of cutting tools, including end mills, drills, saw blades, and specialty tools. This versatility allows woodworkers to tackle diverse projects with varying requirements, from intricate carving and engraving to precision cutting and shaping.

Furthermore, ATC technology improves accuracy and consistency by eliminating human error associated with manual tool changes. This ensures uniformity in finished products and minimizes waste, leading to higher quality and customer satisfaction.

Key Considerations when Choosing an ATC Wood CNC Router

Selecting the right ATC Wood CNC Router is vital to ensure optimal performance and productivity. Here are some essential factors to consider:

a. Machine Size and Work Area: Assess your workspace and determine the appropriate machine size and work area to accommodate your woodworking projects.

b. Spindle Power and Speed: Consider the type of wood materials and cutting requirements you will be working with. Choose a machine with an adequate spindle power and speed range to achieve desired results efficiently.

c. Tool Magazine Capacity: Evaluate the tool magazine capacity of the ATC Wood CNC Router. Ensure that it can accommodate the range and quantity of cutting tools you typically use for your projects.

d. Control System and Software: Look for a machine with a user-friendly control system and compatible software. The software should support your design needs and provide ease of use for programming and toolpath generation. e.Continuation:

e. Machine Durability and Build Quality: Consider the durability and build quality of the ATC Wood CNC Router. Look for machines constructed with robust materials and components that can withstand the demands of continuous use.

f. Support and Training: Ensure that the manufacturer or supplier provides comprehensive support and training for the machine. This will help you maximize the capabilities of the ATC Wood CNC Router and troubleshoot any issues efficiently.

g. Budget and Return on Investment (ROI): Determine your budget and evaluate the potential return on investment. While ATC Wood CNC Routers may require a significant initial investment, their efficiency and productivity gains can lead to long-term cost savings and improved profitability.

ATC Wood CNC Routers offer a multitude of benefits and applications for woodworkers and manufacturers in the woodworking industry. Their automatic tool changing capability, versatility, precision, and efficiency make them indispensable tools for creating intricate designs, producing custom woodworking projects, and streamlining production processes. By considering key factors when choosing a machine and implementing proper maintenance, woodworkers can harness the full potential of an ATC Wood CNC Router to achieve exceptional results and stay at the forefront of the woodworking industry.

0 notes

Text

Mastering Woodworking with Precision: The Ultimate Guide to CNC Wood Routers

In the world of woodworking, precision and efficiency are paramount. CNC wood routers have emerged as indispensable tools for achieving intricate designs and flawless cuts. These advanced machines, controlled by computer numerical control (CNC) technology, offer unparalleled accuracy and versatility, revolutionizing the woodworking industry. This comprehensive guide explores the various aspects and benefits of CNC wood routers, providing insights into their functionality and applications.

Precision Engineering: The Power of CNC Wood Router

The CNC wood router stands at the forefront of modern woodworking technology. By automating the routing process, these machines enable woodworkers to execute complex designs with exceptional precision. The CNC wood router is capable of handling various tasks, from simple cuts to intricate patterns, ensuring that each piece is crafted to perfection. The precision of these machines eliminates the margin for error, enhancing both the quality and efficiency of woodworking projects.

Versatility in Crafting: CNC Machine Wood Router

When it comes to versatility, the CNC machine wood router is unparalleled. This equipment is designed to cater to a wide range of woodworking needs, from furniture making to intricate carvings. The CNC machine wood router can work with different types of wood, allowing artisans to explore their creativity without limitations. Whether crafting custom cabinetry or decorative wood panels, this machine delivers consistent results that meet the highest standards of craftsmanship.

Transforming Woodwork: CNC Router Wood Applications

The applications of CNC router wood machines are vast and varied. These machines are used in industries ranging from furniture manufacturing to architectural millwork. With the ability to produce repetitive, high-precision cuts, CNC router wood machines are ideal for mass production as well as custom projects. They are essential for creating detailed engravings, intricate inlays, and precise joinery, ensuring that each piece is both functional and aesthetically pleasing.

Enhancing Efficiency: CNC Wood Router Machine

Efficiency is a key advantage of the CNC wood router machine. By automating the cutting and shaping processes, these machines significantly reduce the time and labor required for woodworking projects. The CNC wood router machine is equipped with advanced features such as multi-axis movement and tool-changing capabilities, allowing for continuous operation without manual intervention. This results in faster turnaround times and increased productivity, making it an invaluable asset for any woodworking shop.

Innovations in Woodworking: The Evolution of CNC Technology

The evolution of CNC technology has brought about significant advancements in woodworking. Modern CNC wood routers are equipped with sophisticated software that allows for precise control over the cutting process. This technology enables woodworkers to design complex patterns and execute them with high accuracy. The integration of CNC technology in woodworking has not only improved the quality of the finished products but also expanded the possibilities for creative expression.

Precision and Creativity: Benefits of CNC Wood Routers

The benefits of using CNC wood routers are numerous. These machines provide a level of precision that is unmatched by traditional woodworking tools. They also offer greater flexibility, allowing woodworkers to create intricate designs and complex shapes with ease. Additionally, CNC wood routers enhance productivity by streamlining the production process and reducing the need for manual labor. This combination of precision, versatility, and efficiency makes CNC wood routers an essential tool for modern woodworking.

0 notes

Text

https://aaradhanatech.com/product/fiber-welding-machine/

Get your hands on the ultimate Fiber Welding Machine, designed to provide precision and efficiency in welding and cutting applications.

#wood cnc machine price#co2 laser machine price in india#cnc router machine price#cnc wood carving machine price in india

0 notes

Text

Garage Progress!!

A workshop is born!

View from outside:

Right half of the garage is my pottery, 3d printers, cnc, and laser cutter.

Left half is wood working storage and tools (band saw, table saw, all the routers and sanders.

I tend to only do woodworking with the garage door and side door open so hopefully the dust will stay mostly contained to that side. If it starts causing a problem with pottery I'll try creating a partition with a curtain and positive pressure.

I've got two walking paths at the moment, but I'm going through do a test patch of resin tonight and if that turns out pretty good tomorrow then I'll play Tetris one last time to shuffle things about and hopefully be able to arrange everything in a final way that makes everything I work with frequently accessible.

25 notes

·

View notes

Text

Mastering Woodworking with a CNC Router Machine: Unlocking Precision and Efficiency

The CNC router machine for wood has emerged as an indispensable tool for modern woodworking. Whether crafting intricate designs or scaling up production, this advanced technology brings precision, speed, and creativity to the forefront. Among its many variations, the 5x10 CNC router stands out for its large working area and robust functionality. This article delves into the transformative impact of CNC router machines on woodworking and why they are a must-have in today’s workshops.

What is a CNC Router Machine for Wood?

A CNC (Computer Numerical Control) router machine for wood is a sophisticated device that automates cutting, engraving, and carving processes. By using computer-aided designs (CAD), it translates digital plans into precise physical creations. This machine eliminates the challenges of manual craftsmanship, ensuring flawless results even for the most complex patterns.

Key Benefits:

Unmatched Accuracy: Create intricate details with pinpoint precision.

Time-Saving: Reduce production times significantly without compromising quality.

Versatility: Handle diverse projects, from furniture making to decorative carvings.

Consistency: Deliver identical results across multiple pieces, perfect for bulk production.

Exploring the 5x10 CNC Router

The 5x10 CNC router is a preferred choice for professionals who handle large-scale projects or work with oversized wooden sheets. Its generous 5-foot by 10-foot workspace allows for seamless execution of expansive designs, such as furniture panels, doors, and signage.

Features of the 5x10 CNC Router:

Ample Work Area: Ideal for cutting and engraving large materials without the need for piecing.

Precision Mechanics: Designed to maintain accuracy over extended working hours.

Tool Flexibility: Compatible with various attachments for added functionality, such as automated tool changers or multiple spindles.

This model is particularly useful in industries where size and detail matter, such as interior design and furniture manufacturing.

Applications of CNC Router Machines in Woodworking

CNC router machines have diverse applications across various woodworking domains, including:

Furniture Production: Create tables, chairs, cabinets, and other custom pieces with intricate designs.

Interior Décor: Produce unique wooden wall panels, decorative moldings, and ceiling details.

Architectural Designs: Craft custom doors, frames, and staircases with precision.

Artisanal Creations: Design engraved artwork, personalized gifts, and one-of-a-kind decorative items.

Sign Making: Build durable and aesthetically pleasing wooden signs with precision engravings.

Why Choose a CNC Router Machine for Wood?

Ease of Use: With user-friendly software and automated processes, CNC routers make complex projects manageable.

Material Optimization: Reduce waste with precise cutting and carving.

Scalable Production: Adaptable for one-off creations or large-scale manufacturing.

Cost Efficiency: While an initial investment is required, long-term savings are achieved through reduced material waste and increased productivity.

Conclusion

The CNC router machine for wood is a technological marvel that combines precision, versatility, and efficiency to revolutionize woodworking. Its ability to automate complex tasks while maintaining artistic integrity makes it an invaluable asset for both seasoned professionals and hobbyists. The 5x10 CNC router, with its expansive workspace, is especially suited for tackling large and detailed projects. Whether you aim to craft fine furniture or intricate designs, investing in a CNC router ensures that your woodworking ventures achieve excellence with every cut and carve.

2 notes

·

View notes

Text

Drawings have been unsatisfactory and gone absolutely nowhere but here's a table I made this week.

Made out of sapele, ash and khaya mahogany. Lovely woods, altough using khaya wasn't part of the original plan but had to substitute due material restrictions. The acrs are cnc machined but can of course be done with a hand router. The angle of the leg is achieved by the wood block attached to the corner brace being slanted, and the leg itself is glued to it, so nothing too complicated.

#woodworking#design#furniture#furniture maker#furniture design#wood furniture#wood#I worked so fast the whole week help

3 notes

·

View notes

Text

Multi-Head CNC Router for Wood, Plywood, Soft Wood, Hard Wood, MDF, Chipboard

Multi-head CNC router for wood is a computer-controlled cutting machine that is capable of cutting, carving, and shaping wood with multiple cutting heads. This type of router is commonly used in the woodworking industry for mass production of furniture, cabinetry, and other wooden products.The multi-head feature of the router allows for increased efficiency and productivity by allowing multiple cutting heads to work simultaneously on different areas of the same workpiece. This can significantly reduce the time it takes to complete a project and also improve the accuracy and precision of the cuts.

MATERIAL:

Wood: Plywood, Soft Wood, Hard Wood, MDF, Chipboard

Plastic: Acrylic, ABS, HDPE, PVC, UHMW, HDPE

Stone: Granite, Marble, Slate, Basalt, Pebbles, Natural Stone, Ceramic, Porcelain

Metal: Aluminium, Brass, Copper, Mild Steel, Stainless Steel

Composite: Aluminium Composite, Copper Composite, Titanium Composite, Zinc Composite.

The multi-head CNC router for wood is a computer-controlled cutting machine that is capable of cutting, carving, and shaping wood with multiple cutting heads. This type of router is commonly used in the woodworking industry for mass production of furniture, cabinetry, and other wooden products.

Pneumatic Tool Change CNC Router is very easy to use. Users only need to save the position of the cutters in the tool path, then the system could realize the cutter auto changing according to the cutter code. And the user does not need to worry tool changing failed or spindle changing speed etc, also will not feel pity using the 8.5kw spindle to drill 6mm holes.

This series support spindle integrated control for multi-head from 2 to 8pcs, can delivery command to spindles to work in tandem, also can work similarly as CNC router with an auto tool changer. Pneumatic Tool Change CNC Router allows users to set different tool path for different spindles (cutters), similar working mode as an auto tool changer. When the first spindle complete its work, the second spindle (cutter) can go on its own work automatically.

Multi-head CNC routers for wood come in different sizes and configurations, depending on the specific needs of the user. They can have two or more cutting heads, which can work together on the same workpiece or on different pieces simultaneously. The cutting heads can be arranged in a variety of configurations, such as side-by-side, stacked vertically, or in a combination of both.

Pneumatic Tool Change CNC Router proves to you that time is money. High efficiency, easier operation, low maintenance fee. You only need to install the extra spindle (ATC spindle is very expensive, while the common spindle is only 30%-60% around of it at the price.

0 notes