#danfoss controller

Explore tagged Tumblr posts

Text

The Danfoss EKE 347 080G5000 Liquid Level Controller is your solution for precise liquid level management. Designed by industry leader Danfoss, this controller ensures seamless operation and optimal performance in various liquid applications. With its advanced technology and user-friendly interface, managing liquid levels becomes effortless and efficient. Its robust construction guarantees durability and longevity, making it a trusted choice for professionals worldwide. Trust Danfoss EKE 347 080G5000 for liquid level control that meets your needs with precision and ease. Boost efficiency and accuracy with Danfoss today!

#automation#industrial and marine automation#industrial equipment#industrial#industrial spare parts#industrialautomation#industrial parts supplier#marine automation#industrial innovation#controller#danfoss

0 notes

Text

Buy Refurbished Danfoss Automation Products in Switzerland

The quest for high performance in automated systems is growing quickly in the market today. Advanced manufacturing and energy-efficient building systems are examples of industries where automation is the basis for modern advancements. For companies in Switzerland looking for solutions that also make sense economically, the refurbished route has emerged as a thoughtful and sustainable choice. Danfoss is one of the most trusted brands in the industry and a world leader in automated technologies that promote high performance and energy conservation. And now, for companies in Switzerland using platforms like `Automation-Warehouse,` Danfoss is offering Swiss industry access to extremely high-quality Danfoss automation products at greatly reduced prices.

The Growing Value of Industrial Automation

In Switzerland, we are known for being precise, innovative, and industrious—and not just in the watch or chocolate industry! Automation in many industries, such as pharmaceutical, food processing, mechanical engineering, and energy, has become an ingrained necessity rather than a luxury. Automated solutions create productive and scalable solutions while yielding fewer human errors in processes. But the upfront cost to outfit a facility with new technology can be significant, especially for small to medium-sized businesses.

Refurbished automation technology fills these gaps. Refurbished automation technology allows for access to high-quality technology at a fraction of the price while being more sustainable by extending product life cycles and reducing electronic waste. Refurbished Danfoss components provide plenty of opportunities through refurbished automation technology and components!

Why Choose Danfoss Automation Products?

Danfoss is a name synonymous with reliability, efficiency and high engineering quality. Danfoss’ automation portfolio includes numerous drives, controllers, sensors and soft starters designed to improve efficiencies in many applications in the industrial space. Danfoss components are designed to robust standards intended for long life expectancy, even beyond refurbishment.

Danfoss’ most commonly used automation products are:

VLT Drives: Used for energy efficiency and tight control of motors

Soft Starters: Creates an easier spike of mechanical stress on physical equipment and the power networks

Pressure & Temperature Sensors: Provide accurate data in critical systems

PLC Modules and Controllers: Provide thoughts around reliable process control and logic execution

The Danfoss automation products maintain a steady presence in HVAC, water treatment, manufacturing and heavy industries. Due to their durable physical build and modular design, these automation products are very suitable for refurbishment and ensure strong performance well beyond their first lifecycle.

Understanding Refurbished Automation Equipment

The word "refurbished" can be a troublesome word for many people. However, in the world of industrial automation, "refurbished" typically refers to used or previously owned equipment that has been inspected, repaired, tested, and cleaned by a professional inspection company. Many refurbished products are functionally and aesthetically just like new. Quality refurbished items are often just as good as brand new, particularly from reliable sources, like Automation-Warehouse. Each refurbished product is inspected for functioning and compatibility and has been checked for safety. For example, the refurbished Danfoss drive we have consistently tested for power output, programming, and motor control. All we are doing is assessing it to make sure it will function in the real world and if it will meet expectation levels. In Switzerland, where precision is paramount, having access to expertly refurbished automation parts provides an excellent opportunity for industries to expand or maintain operations without compromise.

Why Switzerland’s Industries Are Turning to Refurbished Solutions

Swiss industry is promoting the benefits of both cost and resource efficiencies. Refurbished automation equipment will enable businesses to: 1. Reduce CapEx costs with the same level of reliability 2. Provide sustainability by minimizing waste and the use of resources 3. Acknowledge compatibility with legacy systems which are still in operation 4. Affordably obtain obsolete or rare parts which enhance business continuity Businesses operating in environments which are heavily regulated, such as in pharmaceuticals or food processing, require that their control systems are consistent and reliable. All Danfoss automation products (products include obsolete versions of legacy products) provide this need, and refurbished versions continue to extend these products at affordable levels to a wider range of users. Automation-Warehouse: Your Trusted Source in Switzerland

Automation-Warehouse is a dominant source for surplus and refurbished industrial automation equipment. We are not authorized distributors for Danfoss; however, we have procured, with independent and verifiable sources, quality Danfoss products to sell to customers at a fair price. Their inventory includes hundreds of Danfoss automation products, from discontinued legacy models to current-generation systems, many of which are difficult to find elsewhere. Every product listed is marked for stock status, pricing, and technical specifications, ensuring transparency and ease of selection. Additionally, Automation-Warehouse ships worldwide from Switzerland and Hong Kong, making it an efficient and accessible partner for industries in Zürich, Basel, Bern, and beyond.

Benefits of Buying from Automation-Warehouse

When it comes to buying refurbished automation products, trust and service are as important as price. Here's how and why Swiss customers keep returning to Automation-Warehouse:

1. Full Testing and Quality Control

Every Danfoss unit is fully tested before it is available for sale. You can be assured of the quality of your investment, and the performance will last.

2. Competitive Price Including Warranty

Price points are often the driver of the selection, but also assurance. Automation-Warehouse offers up to a 3-year warranty on selected refurbished products, similar to warranties available with new equipment. That is assurance and a level of confidence that speaks volumes for their quality.

3. Global Express Delivery

Express delivery service and commitments are key attributes of our Swiss customers' selection. With FedEx and DHL services around the world, Swiss clients get their products when, where and how they want, with real-time order and delivery process updates. It is all about service.

4. Safe and Secure Payment Options

All payment processing is handled and completed through third-party gateway systems in compliance with PCI and ISO 27001 standards, which ensures that customer data is safe and secure when processing customer data.

5. Support and Customer Care

With trained staff available by email, Swiss customers get fast and accurate answers to business process, technical questions or supply chain clarification.

Tips for Buying Refurbished Danfoss Products

When making a purchase, it is important to remember this statement: 1. Determine your specifications: Make sure you are clear on the model number, voltage rating, firmware version, and connection type you require. 2. Ask for any documentation: Many refurbished units come with product manuals, wiring diagrams or tools used for configuration. In the case of automation-warehouse, it will include it if possible! 3. Verify compatibility; be sure that if you are integrating a refurbished unit into an older system, it is compatible with other components and software with it. 4. Understand warranty terms: make sure you know what is covered and how you claim the warranty or support if needed. 5. Remember your spare parts: Having critical spare parts will minimize downtime in case there are any issues in the future.

Industries That Benefit the Most

While almost any industrial operation can benefit from Danfoss automation products, some sectors in Switzerland are particularly suited for refurbished solutions: Pharmaceutical Manufacturing: High precision and process control Food & Beverage Processing: Consistency, hygiene, and compliance Renewable Energy Plants: Wind and hydro control systems Water & Wastewater Management: Sensor-driven process automation HVAC & Building Automation: Energy-efficient system optimisation For these applications, using high-grade yet affordable automation systems can make a significant impact on both performance and profit margins.

The Sustainability Advantage

With its dedication to sustainability, Switzerland makes upgraded automation products a green environmental choice because when companies reuse high-quality materials, they are hitting both green goals and circular economy markers, and are reducing their operational waste and carbon footprint. When companies can save Danfoss components from the landfill, they reduce the energy and materials needed to make new versions, while getting very good performance and reliability in the replacement components. Final Thoughts

Refurbished Danfoss automation equipment gives teams in the Swiss industry a practical, economical and environmentally friendly alternative to purchasing new equipment. Whether you are replacing older products, expanding existing systems, or looking for a more intelligent way to reduce automation costs, high-quality refurbished components should be considered. For example, if you choose Automation-Warehouse as your supplier, you will benefit from a deep inventory of tested Danfoss parts (some are even "tested to destruction"), industry-leading warranties, and worldwide shipping! A hassle-free way to add uncompromising automation technology to your portfolio, without the heavy price tag.

0 notes

Text

Investment Surge in Oil Infrastructure Drives Heat Tracing Market

The global electric heat tracing systems market was valued at US$ 2.8 Bn in 2022 and is projected to reach US$ 5.7 Bn by the end of 2031, expanding at a CAGR of 8.3% from 2023 to 2031. This robust growth is fueled by increasing investments in oil and gas infrastructure and rising global energy consumption. As industries seek reliable and energy-efficient thermal management systems, electric heat tracing is rapidly emerging as a preferred solution over conventional steam tracing.

Market Dynamics

1. Surge in Oil & Gas Infrastructure Development

One of the primary drivers of market expansion is the ongoing investment in oil and gas infrastructure, particularly in pipelines, tanks, and offshore facilities. The global demand for crude oil, as highlighted by the International Energy Agency, rose to 99.5 million barrels per day in 2022, a figure expected to rise further.

Electric heat tracing systems play a vital role in maintaining optimal temperature during hydrocarbon transportation and refining. These systems prevent pipelines from freezing or overheating, ensuring uninterrupted operations even in extreme environmental conditions, such as those found in arctic and polar regions.

2. Preference Over Steam Tracing

Electric systems are gaining ground over traditional steam tracing owing to their lower maintenance costs, superior energy efficiency, and advanced monitoring features. According to industry estimates, the installation cost of electric heat tracing can be up to 25% less than that of steam tracing.

Moreover, electric solutions offer precise control, automation, and integration with digital monitoring platforms, enabling users to detect faults, reduce energy wastage, and enhance safety. These benefits are unavailable in steam-based systems, which are bulkier and harder to regulate.

3. Technological Advancements and Product Innovation

Ongoing technological innovation is a key enabler of market growth. Self-regulating heating cables, for example, adjust their output based on ambient temperature. This dynamic wattage adjustment ensures consistent heating while preventing overheating—making the systems safer for use with flammable liquids and gases.

The April 2022 launch of the nVent RAYCHEM STS-HV cable is a testament to this trend. Designed for high-voltage, longline heating applications, it adds to the resilience and adaptability of electric tracing in large-scale industrial projects.

Regional Market Overview

North America dominated the electric heat tracing systems market in 2022, supported by an expansive oil and gas pipeline network. According to the U.S. Energy Information Administration, the country hosts more than 200 oil pipelines, surpassing Russia and China combined. This vast infrastructure demands efficient temperature maintenance solutions, creating a thriving market for heat tracing systems.

In Asia Pacific, the market is witnessing steady growth, driven by rapid urbanization and expanding energy networks in countries such as India and China. India, for instance, has over 17,000 kilometers of natural gas pipelines, and the government is investing in further network expansion.

Industry Outlook and Competitive Landscape

Key players in the electric heat tracing systems market are focusing on product development, mergers, and strategic collaborations to strengthen their market position. Companies such as Pentair PLC, Thermon Inc., Emerson Electric Co., Danfoss, Parker Hannifin Corp., BARTEC, and eltherm GmbH are leading the innovation curve.

Their strategies include the integration of IoT and smart monitoring, development of longer and more durable heating cables, and the creation of modular systems for easy scalability. These efforts aim to cater to both industrial heavyweights and emerging applications in commercial and residential segments.

Conclusion

The global electric heat tracing systems market is undergoing a transformative phase, fueled by the rising demand for energy, need for efficient thermal management, and the growing complexity of oil and gas operations. With advancements such as self-regulating cables and intelligent monitoring systems, electric heat tracing offers unmatched reliability, safety, and cost-effectiveness.As industries shift toward sustainable and digitally enabled infrastructure, electric heat tracing systems are expected to become an integral part of thermal process control, across sectors and geographies. With a projected value of US$ 5.7 Bn by 2031, the market holds significant promise for stakeholders looking to invest in the future of industrial efficiency.

0 notes

Text

Automotive MEMS Pressure Sensor Market: Innovations, Trends, and Market Size Forecast 2025-2032

Automotive MEMS Pressure Sensor Market, Trends, Business Strategies 2025-2032

Automotive MEMS Pressure Sensor Market was valued at 1336 million in 2024 and is projected to reach US$ 2456 million by 2032, at a CAGR of 9.3% during the forecast period

Our comprehensive Market report is ready with the latest trends, growth opportunities, and strategic analysishttps://semiconductorinsight.com/download-sample-report/?product_id=103038

MARKET INSIGHTS

The global Automotive MEMS Pressure Sensor Market was valued at 1336 million in 2024 and is projected to reach US$ 2456 million by 2032, at a CAGR of 9.3% during the forecast period.

Automotive MEMS pressure sensors are micro-electromechanical systems designed to measure pressure in various vehicle systems with high precision. These compact, low-power sensors play critical roles in applications like tire pressure monitoring (TPMS), fuel systems, airbags, and HVAC controls. The two dominant technologies in this space are piezoresistive sensors (which change resistance under pressure) and capacitive sensors (which measure changes in capacitance).

Market growth is being driven by increasing automotive production—which reached 81.6 million units globally in 2022 according to industry data—alongside stricter safety regulations mandating TPMS adoption. However, the industry faces challenges from packaging complexities (accounting for over 40% of production costs) and the need for miniaturization. The competitive landscape remains concentrated, with Bosch, NXP, and STMicroelectronics collectively holding significant market share through their advanced sensor portfolios tailored for automotive applications.

List of Key Automotive MEMS Pressure Sensor Companies

Robert Bosch GmbH (Germany)

Sensata Technologies (U.S.)

NXP Semiconductors (Netherlands)

STMicroelectronics (Switzerland)

Infineon Technologies (Germany)

Amphenol Corporation (U.S.)

Semikron Danfoss (Germany)

Continental AG (Germany)

Denso Corporation (Japan)

Fuji Electric (Japan)

Merit Sensor (U.S.)

OMRON Corporation (Japan)

TDK Corporation (Japan)

Teledyne DALSA (Canada)

NOBOSENSE (China)

Suzhou MEMSensing (China)

Jiangsu OLIVE (China)

Kunshan Shuangqiao Sensor (China)

Shenzhen Ampron (China)

Segment Analysis:

By Type

Piezoresistive Pressure Sensors Lead the Market Due to High Accuracy and Cost-Efficiency in Automotive Applications

The market is segmented based on type into:

Piezoresistive Pressure Sensor

Subtypes: Silicon-based, Thin-film, and others

Capacitive Pressure Sensor

By Application

Automotive Tires Segment Dominates Market Share Through Mandatory TPMS Regulations Globally

The market is segmented based on application into:

Automotive Tires

Automotive Fuel Oil System

Automotive Air Bag

Automotive Air Conditioner

By Technology

MEMS Technology Dominates Due to Superior Miniaturization and Integration Capabilities

The market is segmented based on technology into:

MEMS Technology

Non-MEMS Technology

Regional Analysis: Automotive MEMS Pressure Sensor Market

North America The North American region holds a significant share of the Automotive MEMS Pressure Sensor market, driven by stringent safety regulations and widespread adoption of Tire Pressure Monitoring Systems (TPMS). The U.S. is a major contributor due to the mandatory implementation of TPMS in passenger vehicles since 2007. Additionally, the push toward electric and autonomous vehicles is accelerating demand for high-precision MEMS sensors in battery management, cabin pressure monitoring, and fuel efficiency optimization. The market benefits from strong automotive R&D investments and early adoption of advanced driver-assistance systems (ADAS) by manufacturers like Bosch and Sensata.

Europe Europe is a high-growth market for Automotive MEMS Pressure Sensors, largely due to the region’s strict emission and fuel efficiency regulations, particularly under Euro 6 standards. German automotive giants, along with tier-1 suppliers such as Infineon and STMicroelectronics, are leading innovation in engine management and airbag pressure sensor technologies. EU mandates for TPMS in new vehicles since 2014 have also boosted demand. Furthermore, increasing production of hybrid and electric vehicles in countries like Germany and France is fueling market expansion, though supply chain disruptions post-pandemic remain a challenge.

Asia-Pacific Asia-Pacific dominates the global Automotive MEMS Pressure Sensor market, accounting for over 40% of demand, thanks to China, Japan, and South Korea’s thriving automotive sectors. China is the largest consumer due to its massive vehicle production and TPMS regulations introduced in 2020. Japanese manufacturers such as Denso and Omron are at the forefront of miniaturized, high-reliability MEMS sensors for fuel injection and HVAC systems. Meanwhile, India is emerging as a key growth market, supported by rising automobile sales and expanding EV infrastructure. However, cost sensitivity in lower-tier markets sometimes leads to preference for non-MEMS alternatives.

South America The South American market is moderately paced, with growth primarily driven by Brazil’s automotive industry. Adoption of TPMS and emissions control sensors is increasing, albeit slower than in other regions due to economic constraints and inconsistent regulatory enforcement. While the aftermarket for sensor replacements offers potential, reliance on imported components from China and Europe limits local production capabilities. Nevertheless, Brazil’s push for biofuel vehicles presents opportunities for fuel system pressure sensor demand.

Middle East & Africa The Middle East & Africa region shows nascent but promising growth, with UAE and Saudi Arabia leading due to luxury vehicle sales and infrastructure investments. The lack of stringent safety regulations curbs widespread MEMS adoption, though GCC countries are gradually aligning with global standards. Africa’s market remains underpenetrated, hindered by low vehicle electrification rates and economic volatility. Over the long term, industrialization efforts and rising awareness of vehicle safety could expand opportunities for MEMS pressure sensors.

MARKET DYNAMICS

The automotive MEMS pressure sensor market continues to face significant supply chain bottlenecks, particularly regarding semiconductor availability. The global chip shortage reduced automotive MEMS production by an estimated 18-22% during 2021-2022, with lead times for certain sensor components extending to 52 weeks. This situation is exacerbated by the industry’s concentration in specific geographic regions, where over 65% of MEMS fabrication capacity resides. While production capacities are gradually recovering, the market remains vulnerable to geopolitical tensions and trade restrictions that could disrupt the delicate balance between supply and demand.

Maintaining sensor accuracy across automotive operating temperatures ranging from -40°C to 150°C presents ongoing engineering challenges. Compensation algorithms add 15-20% to development costs, while failure rates in extreme conditions remain 3-5% higher than industrial specifications. These technical hurdles become increasingly critical as sensors are deployed in more demanding applications such as turbocharger monitoring and brake-by-wire systems.The integration of pressure sensors into vehicle communication networks introduces potential security risks. Recent vulnerability assessments indicate that up to 35% of automotive MEMS devices lack adequate encryption protocols, creating entry points for malicious attacks. As vehicles evolve into connected platforms, ensuring robust cybersecurity measures without compromising real-time performance remains a persistent challenge for sensor manufacturers.

The automotive industry’s stringent qualification requirements present substantial barriers to market entry for MEMS pressure sensor developers. Achieving ASIL-D compliance for safety-critical applications typically requires 18-24 months of validation testing, with development costs exceeding $2 million per sensor variant. These prolonged qualification cycles, combined with the need for redundant designs in autonomous vehicle applications, significantly increase time-to-market and R&D expenditures. Consequently, only established manufacturers with substantial financial resources can participate in cutting-edge automotive projects, potentially stifling innovation.

Automotive original equipment manufacturers (OEMs) continue to exert intense pricing pressure on component suppliers, with annual cost reduction targets typically ranging between 3-5%. This practice has compressed MEMS pressure sensor profit margins to approximately 12-15%, down from 20-25% a decade ago. Tier-1 suppliers are increasingly demanding integrated sensor solutions that combine multiple functionalities while maintaining aggressive pricing structures, forcing manufacturers to optimize production efficiencies continuously. Such market conditions create significant challenges for smaller players attempting to compete against vertically integrated semiconductor giants.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies https://semiconductorinsight.com/download-sample-report/?product_id=103038

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global Automotive MEMS Pressure Sensor Market?

Which key companies operate in Global Automotive MEMS Pressure Sensor Market?

What are the key growth drivers?

Which region dominates the market?

What are the emerging trends?

CONTACT US: City vista, 203A, Fountain Road, Ashoka Nagar, Kharadi, Pune, Maharashtra 411014 [+91 8087992013] [email protected]

0 notes

Text

Smart Cooling Tower Blowdown Controller Market: A USD 2.76 billion Opportunity by 2033

According to our latest research, the global smart cooling tower blowdown controller market size reached USD 1.42 billion in 2024, demonstrating robust momentum across diverse industrial sectors. The market is expanding at a CAGR of 7.6% and is forecasted to attain a value of USD 2.76 billion by 2033. This substantial growth is primarily driven by the increasing emphasis on water conservation, stringent regulatory norms regarding industrial water discharge, and the rising adoption of automation technologies in water treatment processes.

The integration of smart controllers in cooling towers is optimizing water usage, reducing operational costs, and supporting sustainability goals, which are key factors propelling market expansion.

Request a Sample Report: https://growthmarketreports.com/request-sample/9101

Why Smart Blowdown Controllers Matter

Cooling towers are essential components in many industrial processes, yet they often suffer from inefficiencies linked to manual or outdated control systems. Blowdown controllers are designed to regulate the amount of water removed from the tower to control the concentration of dissolved solids. Traditional systems lack the intelligence and adaptability that smart controllers now offer.

Smart blowdown controllers automatically assess water conductivity, temperature, and chemical levels to trigger the blowdown process precisely when needed. This ensures optimized performance, extending equipment lifespan and saving both water and energy in the process.

Market Drivers and Emerging Trends

The growth of the smart cooling tower blowdown controller market is fueled by several factors. A primary driver is the global push toward sustainable water management. Water-intensive industries are under increasing pressure to reduce consumption and comply with environmental regulations, making smart blowdown controllers an ideal investment.

Moreover, the integration of IoT and cloud-based monitoring systems into blowdown controllers enables real-time diagnostics, predictive maintenance, and remote management—key benefits that support operational efficiency. The rise of Industry 4.0 is also contributing to the adoption of these systems in both new and retrofit installations.

Regional Insights and Market Segmentation

North America leads the smart cooling tower blowdown controller market, driven by stringent water conservation laws and the presence of key players adopting advanced cooling technologies. The U.S. in particular continues to show strong demand across its power generation, data center, and petrochemical sectors.

Asia Pacific is another promising region, with countries like China and India investing heavily in industrial infrastructure and clean technologies. Meanwhile, Europe remains committed to eco-friendly industrial practices, creating a supportive environment for smart water-saving solutions.

Market segmentation typically includes standalone blowdown controllers and integrated systems, both of which are gaining ground across various industries depending on their needs and budget.

Check Out the Report: https://growthmarketreports.com/checkout/9101

Competitive Landscape and Innovation Trends

The smart cooling tower blowdown controller market features a blend of established players and innovative startups. Companies are focusing on user-friendly interfaces, enhanced sensor accuracy, and AI-driven analytics to differentiate their products. Partnerships between controller manufacturers and industrial automation firms are also on the rise, aiming to develop holistic solutions for cooling tower management.

Competitive Landscape: Key Players and Innovations

Several manufacturers and solution providers are shaping this market through innovation and strategic expansion. Some prominent companies include:

Danfoss

Siemens AG

Honeywell International Inc.

Emerson Electric Co.

Ecolab Inc.

SUEZ Water Technologies & Solutions

Xylem Inc.

Endress+Hauser Group

Future Outlook

Looking ahead, the smart cooling tower blowdown controller market is poised for consistent expansion. As climate challenges intensify and operational sustainability becomes a business imperative, industries are expected to invest more in intelligent water management tools. Innovations in wireless technology, machine learning, and adaptive algorithms are expected to unlock even more capabilities in next-generation blowdown controllers.

By reducing water usage, minimizing energy costs, and automating system maintenance, these smart systems are emerging as essential components of a greener and more efficient industrial ecosystem.

View Full Report: https://growthmarketreports.com/report/smart-cooling-tower-blowdown-controller-market

About Growth Market Reports:

Growth Market Reports excels in creating tailored Market research reports across various industry verticals. With in-dept Market analysis, creative business strategies for new entrants, and insights into the currents Market scenario, our reports undergo intensive primary and secondary research, interviews, and consumer surveys.

Contact Us:

Name: Alex Mathews

Phone No: +1 909 414 1393

Email: [email protected]

Website: https://growthmarketreports.com/

Address: 500 East E Street, Ontario, CA 91764, United States.

#Smart Cooling Tower Blowdown Controller Market#Smart Cooling Tower Blowdown Controller#Smart Cooling Tower Blowdown Controller Market Size#Smart Cooling Tower Blowdown Controller Market Share#Cooling Tower

1 note

·

View note

Text

🏭🛑 Industrial Brakes Market: Growth, Innovation & Future Trends! 🌏

The global industrial brakes market is gaining traction! Valued at USD 1.72 billion in 2024, it’s projected to reach USD 2.30 billion by 2032 at a CAGR of 3.8%. Asia Pacific led the market with a 36.04% share in 2024.

🔎 What Are Industrial Brakes? Industrial brakes are robust devices designed to stop or control the movement of heavy machinery by friction, handling extreme inertial loads and operating under harsh conditions. Unlike automotive brakes, they are engineered for manufacturing, mining, marine, construction, oil & gas, and more.

⚙️ Market Segmentation:

By Type:

Disc

Drum

By Actuation:

Hydraulic

Mechanical

Electrical

Pneumatic

Others (Electromagnetic, etc.)

By Application:

Manufacturing

Metal & Mining

Marine & Shipping

Construction

Oil & Gas

Others (Food Processing, Energy, etc.)

🏆 Top Companies: Dellner Bubenzer, AKEBONO BRAKE INDUSTRY, AMETEK Inc., Danfoss, Kendrion N.V., Regal Rexnord, Sibre Siegerland Bremsen, The Hilliard Corporation, TMD Friction Holding, Wabtec Corporation

🚀 Key Industry Developments:

May 2023: Kendrion opened a new facility in Suzhou, China, for industrial brakes and controls.

Mar 2023: Wabtec supplied advanced brake systems for India’s Pune Metro, enhancing rail safety and efficiency.

Mar 2023: Regal Rexnord acquired Altra Industrial Motion, expanding its powertrain and brake product portfolio.

🔮 Future Trends:

Rise of industrial automation & smart control systems

Use of advanced, durable materials

Expansion in Asia Pacific’s manufacturing sector

Focus on energy efficiency & safety

👉 Explore the full report: https://www.fortunebusinessinsights.com/industrial-brakes-market-107341

#IndustrialBrakes#Manufacturing#Automation#MarketTrends#AsiaPacific#Mining#Construction#SmartIndustry#Engineering#Innovation

0 notes

Text

Global Pressure Transmitter Market Size, Share, and Future Outlook

The Global Pressure Transmitter Market Size is expected to reach USD 4.63 Billion By 2032, at a CAGR of 4.7% during the forecast period 2022 to 2032.

Pressure Transmitters: Precision Tools Driving Industrial Automation

Pressure transmitters, or transducers, convert physical pressure from gases or liquids into electrical signals for monitoring and control. Featuring pressure-sensitive surfaces made from materials like steel or silicon, these instruments are essential in applications requiring high accuracy, such as fluid control, leak detection, and pump systems. Widely used across industrial settings, they support automation by interfacing with controllers and data systems. Market growth is fueled by rising industrial automation, increased energy sector investments, and a shift toward advanced, electronically integrated transmitters that reduce human error and enhance operational efficiency.

This study gives a detailed analysis of drivers, restrains, opportunities and challenges limiting the market expansion of Pressure Transmitter market. The survey included a diverse set of players, including a balance of leading and growing manufacturers for business profiling, such as;

Emerson ABB Schneider Electric Yokogawa Endress+Hauser Fuji Electric Danfoss Hitachi Siemens Honeywell WIKA Instruments Omega Engineering, Inc. Dwyer Instruments SensorONE Ltd.

Our expert team is consistently working on updated data and information on the key player's related business processes that value the market for future strategies and predictions

Get Access to a Free Copy of Our Latest Sample Report - https://www.sphericalinsights.com/request-sample/2447

Market Segmentation:

Type Analysis

Absolute

Gauge

Differential Pressure

Multivariable

Fluid Type Analysis

Liquid

Gas

Steam

Covered in this Report:

1. Go-to-market Strategy. 2. Neutral perspective on the market performance. 3. Development trends, competitive landscape analysis, supply side analysis, demand side analysis, year-on-year growth, competitive benchmarking, vendor identification, QMI quadrant, and other significant analysis, as well as development status. 4. Customized regional/country reports as per request and country level analysis. 5. Potential & niche segments and regions exhibiting promising growth covered. 6.Analysis of Market Size (historical and forecast), Total Addressable Market (TAM), Serviceable Available Market (SAM), Serviceable Obtainable Market (SOM), Market Growth, Technological Trends, Market Share, Market Dynamics, Competitive Landscape and Major Players (Innovators, Start-ups, Laggard, and Pioneer).

Buy this report now:- https://www.sphericalinsights.com/checkout/2447

Industry Developments:

On May 2023, Dwyer Instruments announces the Series IDPT, a water-resistant industrial differential pressure transmitter with highly stable accuracy for long service life in most industrial applications. The Series IDPT has a consistent accuracy even at low ranges, assisting in the maintenance of process quality and the elimination of downtime.

Regional Analysis for Pressure Transmitter Market:

✫ North America: (U.S., Canada, Mexico) ✫ Europe: (U.K., Italy, Germany, Russia, France, Spain, The Netherlands and Rest of Europe) ✫ Asia-Pacific: (India, Japan, China, South Korea, Australia, Indonesia Rest of Asia Pacific) ✫ South America: (Colombia, Brazil, Argentina, Rest of South America) ✫ Middle East & Africa: (Saudi Arabia, U.A.E., South Africa, Rest of Middle East & Africa)

Benefits of the Report:

⏩ A descriptive analysis of demand-supply gap, market size estimation, SWOT analysis, PESTEL Analysis and forecast in the global market. ⏩ Top-down and bottom-up approach for regional analysis ⏩ Porter’s five forces model gives an in-depth analysis of buyers and suppliers, threats of new entrants & substitutes and competition amongst the key market players. ⏩ By understanding the value chain analysis, the stakeholders can get a clear and detailed picture of this Market

Insightful inquiry before buying:- https://www.sphericalinsights.com/inquiry-before-buying/2447

Frequently asked questions:

➥ What is the market size of the Pressure Transmitter market? ➥ What is the market growth rate of the Pressure Transmitter market? ➥ What are the Pressure Transmitter market opportunities and threats faced by the vendors in the global Pressure Transmitter Industry? ➥ Which application/end-user or product type may seek incremental growth prospects? What is the market share of each type and application? ➥ What focused approach and constraints are holding the Pressure Transmitter market? ➥ What are the different sales, marketing, and distribution channels in the global industry?

Unlock the full report now! @ https://www.sphericalinsights.com/reports/pressure-transmitter-market

About the Spherical Insights

Spherical Insights is a market research and consulting firm which provides actionable market research study, quantitative forecasting and trends analysis provides forward-looking insight especially designed for decision makers and aids ROI.

which is catering to different industry such as financial sectors, industrial sectors, government organizations, universities, non-profits and corporations. The company's mission is to work with businesses to achieve business objectives and maintain strategic improvements.

Contact Us:

Company Name: Spherical Insights

Email: [email protected]

Phone: +1 303 800 4326 (US)

Follow Us: LinkedIn | Facebook | Twitter

#Pressure Transmitter Market#Global Pressure Transmitter Market#Pressure Transmitter Market Size#Pressure Transmitter Market Share#Pressure Transmitter Market Analysis

0 notes

Text

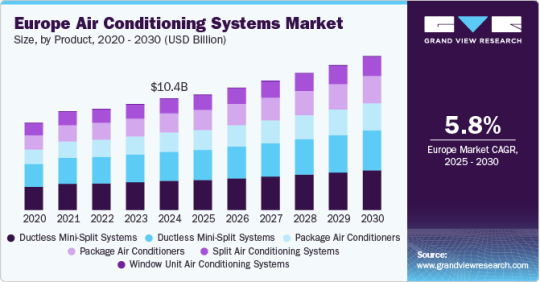

Europe Air Conditioning Systems Market Rises With Demand for Clean Cooling

The Europe air conditioning systems market was valued at USD 10.38 billion in 2024 and is projected to reach USD 14.25 billion by 2030, growing at a CAGR of 5.8% from 2025 to 2030. This growth is driven by strict energy efficiency regulations and the growing demand for advanced cooling technologies. Industries across Europe are adopting modern air conditioning systems to enhance production efficiency, reduce energy consumption, and meet environmental compliance standards.

Manufacturers are increasingly focusing on energy efficiency, sustainability, and smart technologies to align with evolving consumer preferences and regulatory frameworks. In particular, the European Union’s F-Gas Regulation and EcoDesign Directive have prompted HVAC companies to develop systems that utilize low-GWP refrigerants, deliver higher energy performance, and contribute to reduced carbon emissions.

Key Market Insights:

By Type: Ductless mini-split systems led the market in 2024, accounting for 46.1% of the market share. Their popularity continues to grow, particularly in retrofit and renovation projects, where the installation of traditional ductwork is impractical or cost-prohibitive.

By Application: The residential segment was the dominant application in 2024, holding 42.1% of the market share. The surge in residential demand is largely due to rising temperatures across Europe, driven by climate change, leading to increased adoption of cooling systems in homes.

By Technology: Inverter technology held the largest share of 67.3% in 2024. This segment's growth is primarily fueled by the rising need for energy-efficient and cost-saving solutions, making inverter-based systems a preferred choice across both residential and commercial sectors.

Order a free sample PDF of the Europe Air Conditioning Systems Market Intelligence Study, published by Grand View Research.

Market Size & Forecast

2024 Market Size: USD 10.38 Billion

2030 Projected Market Size: USD 14.25 Billion

CAGR (2025-2030): 5.8%

Key Companies & Market Share Insights

Some of the key players operating in the market include Carrier, DAIKIN INDUSTRIES, Ltd, and Mitsubishi Corporation, among others.

Carrier specializes in providing healthy, safe, sustainable, and intelligent solutions for buildings and cold chains. Originally acquired by United Technologies Corporation in 1979, Carrier became an independent entity following a spin-off in April 2020. The company operates through key business segments including HVAC, refrigeration, and fire & security. Its diverse product portfolio includes heat pumps, air conditioners, boilers, furnaces, air purifiers, humidifiers, dehumidifiers, ventilators, air scrubbers, thermostats, UV lamps, energy services, and building controls, serving retail, commercial, transport, and food service industries. Notable HVAC brands under Carrier include Arcoaire, Beretta, Bryant, Carlyle, Comfortmaker, CIAT, Day & Night, Heil, Keeprite, and Payne.

DAIKIN INDUSTRIES, Ltd. is a global manufacturer and supplier of air conditioning systems and chemical products, with a network of 313 consolidated subsidiaries worldwide. The company offers a comprehensive range of products including air-conditioning systems, room heating and heat pumps, hot water supply systems, packaged air-conditioning units, and air conditioning systems for industrial plants, commercial facilities, and office buildings. Additionally, Daikin provides low- and medium-capacity air conditioning systems, water chillers, air purifiers, humidity control air processors, marine container refrigeration systems, and air handling units, catering to diverse environmental and operational needs.

Key Players

DAIKIN INDUSTRIES, Ltd

Johnson Controls Inc.

LG Electronics

Mitsubishi Corporation

Panasonic Holdings Corporation

Midea

Danfoss

Robert Bosch GmbH

Electrolux

Explore Horizon Databook – The world's most expansive market intelligence platform developed by Grand View Research.

Conclusion

The European air conditioning systems market is steadily growing, propelled by strict environmental regulations, rising demand for energy-efficient and smart cooling solutions, and innovations like inverter technology. Both established manufacturers and agile niche players will continue thriving by addressing evolving market and regulatory needs.

0 notes

Text

Heating Engineer in Parsons Green: Trusted Repairs for Efficient, Safe Homes

A Midwinter Breakdown in Parsons Green When Charlotte’s radiators remained cold despite her boiler running, she suspected a circulation fault. A quick call to a heating engineer in Parsons Green brought immediate results. The technician arrived the same day, flushed the system, balanced the radiators, and restored full warmth across her home.

Why Heating Engineers Are Essential in Parsons Green Parsons Green features a mix of Victorian terraces and contemporary flats, each with unique heating configurations. A certified heating engineer provides:

Accurate diagnosis of central heating issues

Safe installation of radiators, valves, and pumps

Full compliance with UK heating and safety standards

Longtail keywords: heating engineer Parsons Green, central heating repair SW6, Gas Safe heating technician Fulham

Book a heating engineer in Parsons Green

Services Provided by Local Heating Engineers

Radiator repairs, power flushing, and system balancing

Installation of smart thermostats and heating controls

Replacement of faulty pumps and valves

Diagnostic repairs for boiler heating circuits

All services are performed by Gas Safe registered and DBS-checked professionals.

Why SW6 Residents Trust Their Local Engineers

Quick response times in Parsons Green and Fulham

Knowledge of heating layouts in older and newer properties

Clear pricing with detailed repair documentation

What’s the difference between a heating engineer and a plumber?

Heating engineers specialise in boilers and central heating systems, while plumbers generally handle water-related plumbing.

Do heating engineers need to be Gas Safe registered?

Yes, registration is legally required for any work involving gas-powered heating equipment.

FAQs for Heating Services in Parsons Green

Q: Do engineers install smart thermostats? A: Yes — integration with systems like Hive and Nest is included.

Q: What does a typical heating inspection involve? A: Radiators, valves, pumps, pipework, and boiler response are assessed.

Q: Are weekend and evening slots available? A: Yes — flexible appointments are offered throughout the week.

Q: Which brands are used for replacement parts? A: Parts from trusted manufacturers such as Grundfos, Honeywell, and Danfoss are fitted.

Q: Do engineers handle communal systems? A: Yes — services extend to multi-unit heating systems managed by landlords and agents.Charlotte’s Home — Warm and Balanced Again With prompt support from a local heating engineer in Parsons Green, Charlotte’s home was quickly restored to a comfortable temperature. For efficient heating repairs, visit kewgasparsonsgreen.co.uk.

#KewGasEngineers#ParsonsGreenBoilerRepair#BoilerServiceKew#GasSafeLondon#EmergencyHeatingRepair#BoilerInstallationParsonsGreen

0 notes

Text

Brass Solenoid Valves Market Size, Share, Trends, Opportunities, Key Drivers and Growth Prospectus

"Executive Summary Brass Solenoid Valves Market : Data Bridge Market Research analyses that the brass solenoid valves market was valued at USD 1.21 billion in 2021 and is expected to reach the value of USD 1.63 billion by 2029, at a CAGR of 3.80% during the forecast period.

Brass Solenoid Valves Market report is the outcome of continual efforts guided by knowledgeable forecasters, innovative analysts and brilliant researchers. They work with respect to detailed and thorough research on different markets, trends and emerging opportunities in the consecutive direction for the business needs. The Brass Solenoid Valves Market report is a window to the industry which explains what market definition, classifications, applications, engagements and market trends are. To accomplish something great in this competitive market place, businesses must look for a better solution to refine their business strategies and that’s where this Brass Solenoid Valves Market report seems very helpful.

This Brass Solenoid Valves Market research report provides clients with the information on their business scenario with which they can build business strategies to thrive in the market. Systemic gathering of company profiles that are driving the market is also performed in this report. This report has forecasted compound annual growth rate (CAGR) in % value for specific period that will help industry to take decision based on futuristic chart. Brass Solenoid Valves Market research report works as a best solution to know the trends and opportunities in the industry. This report not only offers actionable market insights but also lend a hand to create sustainable and money-spinning business strategies.

Discover the latest trends, growth opportunities, and strategic insights in our comprehensive Brass Solenoid Valves Market report. Download Full Report: https://www.databridgemarketresearch.com/reports/global-brass-solenoid-valves-market

Brass Solenoid Valves Market Overview

**Segments**

- On the basis of type, the Global Brass Solenoid Valves Market can be segmented into 2-way solenoid valves, 3-way solenoid valves, 4-way solenoid valves, and 5-way solenoid valves. The 2-way solenoid valves segment is expected to dominate the market due to their widespread application in various industries. - By application, the market can be divided into industrial, commercial, and residential sectors. The industrial segment is anticipated to hold the largest market share attributed to the growing industrial automation across different sectors. - Based on geography, the market is segmented into North America, Europe, Asia-Pacific, South America, and the Middle East & Africa. The Asia-Pacific region is projected to witness significant growth due to the rapid industrialization and increasing demand for automation in countries like China and India.

**Market Players**

- Some of the key players in the Global Brass Solenoid Valves Market include Emerson Electric Co., Parker Hannifin Corp, Danfoss, IMI plc, Christian Bürkert GmbH & Co. KG, Rotex Automation, CKD Corporation, and Aventics GmbH, among others. These companies are focusing on strategic initiatives like product launches, partnerships, and acquisitions to strengthen their market position and expand their customer base. - The market players are also investing in research and development activities to innovate new technologies and enhance the efficiency of brass solenoid valves. Additionally, partnerships with technology providers and distributors are helping these companies to reach a wider audience and improve their sales channels.

In conclusion, the Global Brass Solenoid Valves Market is poised for significant growth driven by factors such as increasing industrial automation, rising demand for efficient fluid control systems, and advancements in valve technologies. With key players continuously investing in R&D and strategic partnerships, the market is expected to witness fierce competition and innovations in the coming years.

The global brass solenoid valves market is witnessing a notable shift towards enhanced efficiency and innovation as key players like Emerson Electric Co., Parker Hannifin Corp, and Danfoss are intensifying their focus on research and development activities. These companies are striving to introduce cutting-edge technologies that can cater to the evolving needs of industries across industrial, commercial, and residential sectors. The emphasis on product launches, strategic partnerships, and acquisitions underscores the competitive landscape of the market, where companies are vying to strengthen their market presence and expand their customer base.

In terms of geographical segmentation, the Asia-Pacific region is emerging as a significant market player, buoyed by the rapid industrialization in countries like China and India. The growing demand for automation solutions in various industries is propelling the adoption of brass solenoid valves, presenting ample growth opportunities for market players in this region. With the Middle East & Africa region also showing promise due to increasing infrastructural development and industrial activities, the global brass solenoid valves market is poised for substantial growth in the foreseeable future.

Furthermore, the industrial segment is expected to retain its dominance in the market, driven by the escalating need for efficient fluid control systems and the integration of automation technologies across different sectors. The versatility of 2-way solenoid valves in various industries is poised to sustain their market leadership, as these valves find extensive applications in diverse industrial processes. Alongside, the focus on enhancing operational efficiency, reducing downtime, and optimizing fluid control processes is fueling the demand for brass solenoid valves in both established and emerging markets worldwide.

As market players continue to invest in technological advancements and strategic collaborations, the competitive landscape of the global brass solenoid valves market is likely to witness further dynamism. The pursuit of innovative solutions, coupled with an emphasis on customer-centric approaches, is reshaping the market dynamics and setting the stage for disruptive changes in the industry. In conclusion, the market's growth trajectory remains optimistic, propelled by a confluence of factors such as industrial automation trends, technological advancements, and a diverse range of applications across different sectors.The Global Brass Solenoid Valves Market is experiencing a significant evolution towards enhanced efficiency and innovation, driven by key players such as Emerson Electric Co., Parker Hannifin Corp, and Danfoss. These industry leaders are heavily investing in research and development endeavors to introduce cutting-edge technologies tailored to meet the evolving requirements of industrial, commercial, and residential sectors. By focusing on strategic initiatives like product launches, partnerships, and acquisitions, market participants are intensifying the competition to consolidate their market positions and broaden their customer base.

In terms of geographical segmentation, the Asia-Pacific region is emerging as a prominent player in the global brass solenoid valves market, propelled by the rapid industrialization observed in countries like China and India. The escalating demand for automation solutions in various industries is driving the adoption of brass solenoid valves, presenting abundant growth opportunities for companies operating in this region. Moreover, with the Middle East & Africa region exhibiting promise due to the increasing infrastructural development and industrial activities, the overall market for brass solenoid valves is poised for substantial expansion in the foreseeable future.

Furthermore, the industrial segment is forecasted to maintain its dominance in the market, underpinned by the rising need for efficient fluid control systems and the integration of automation technologies across diverse sectors. The versatility of 2-way solenoid valves in multiple industries is expected to sustain their market leadership position, given their extensive utility in various industrial processes. Additionally, the industry's focus on boosting operational efficiency, reducing downtime, and optimizing fluid control procedures is fueling the demand for brass solenoid valves in both established and emerging markets worldwide.

As market players persist in their investments in technological advancements and strategic collaborations, the competitive landscape of the global brass solenoid valves market is poised to witness further dynamics. The quest for innovative solutions, coupled with a dedication to customer-centric approaches, is reshaping market dynamics and paving the way for disruptive changes in the industry. In conclusion, the market's growth trajectory remains optimistic, propelled by a convergence of factors such as industrial automation trends, technological advancements, and a diverse range of applications across different sectors.

The Brass Solenoid Valves Market is highly fragmented, featuring intense competition among both global and regional players striving for market share. To explore how global trends are shaping the future of the top 10 companies in the keyword market.

Learn More Now: https://www.databridgemarketresearch.com/reports/global-brass-solenoid-valves-market/companies

DBMR Nucleus: Powering Insights, Strategy & Growth

DBMR Nucleus is a dynamic, AI-powered business intelligence platform designed to revolutionize the way organizations access and interpret market data. Developed by Data Bridge Market Research, Nucleus integrates cutting-edge analytics with intuitive dashboards to deliver real-time insights across industries. From tracking market trends and competitive landscapes to uncovering growth opportunities, the platform enables strategic decision-making backed by data-driven evidence. Whether you're a startup or an enterprise, DBMR Nucleus equips you with the tools to stay ahead of the curve and fuel long-term success.

Reasons to Consider This Report

To understand the Brass Solenoid Valves Market landscape and identify market segments that are most likely to guarantee a strong return

Stay ahead of the race by comprehending the ever-changing competitive landscape for Brass Solenoid Valves Market

Efficiently plan M&A and partnership deals in Brass Solenoid Valves Market by identifying market segments with the most promising probable sales

Helps to take knowledgeable business decisions from perceptive and comprehensive analysis of market performance of various segments of cannabis seeds market

Obtain market revenue forecasts for the Brass Solenoid Valves Market by various segments in regions.

Browse More Reports:

Global Algae Fertilizers Market Global Construction Film Market Global Antimicrobial Agent Market Global Benchtop Laboratory Water Purifier Market Asia-Pacific Feed Flavours and Sweeteners Market Global Catenary Infrastructure Market Global Bus Public Transport Market Latin America Point of Care Infectious Disease Market Global Innovation Management Market Middle East and Africa Indium Market Global Antibiotics Market Global Potassium Humate Biostimulants Market Africa MDI, TDI, Polyurethane Market Global Dental Diode Lasers Market Middle East and Africa Artificial Turf Market Global Hematologic Malignancies Market Latin America Ostomy Devices Market Asia-Pacific Rotomolding Market Philippines Microgrid Market Global Automated Beverage Carton Packaging Machinery Market Global Surgical Power Tools Market Europe Intensive Care Unit (ICU) Ventilators Market Global Vasodilators Market Global Methylene Diphenyl Diisocyanate (MDI), Toluene Diisocyanate (TDI) and Polyurethane Market Global Constrictive Pericarditis Market Middle East and Africa q-PCR Reagents Market Global Artificial Turf Market Global Styrene Butadiene Latex Market Global Digital Farming Software Market Global Alpha Linolenic Acid Market Global Head and Neck Cancer Drug Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us: Data Bridge Market Research US: +1 614 591 3140 UK: +44 845 154 9652 APAC : +653 1251 975 Email:- [email protected]

Tag

"

0 notes

Text

Electric Heat Tracing Systems Market Set to Double by 2031

The global electric heat tracing systems market was valued at US$ 2.8 Bn in 2022 and is projected to reach US$ 5.7 Bn by the end of 2031, expanding at a CAGR of 8.3% from 2023 to 2031. This robust growth is fueled by increasing investments in oil and gas infrastructure and rising global energy consumption. As industries seek reliable and energy-efficient thermal management systems, electric heat tracing is rapidly emerging as a preferred solution over conventional steam tracing.

Market Dynamics

1. Surge in Oil & Gas Infrastructure Development

One of the primary drivers of market expansion is the ongoing investment in oil and gas infrastructure, particularly in pipelines, tanks, and offshore facilities. The global demand for crude oil, as highlighted by the International Energy Agency, rose to 99.5 million barrels per day in 2022, a figure expected to rise further.

Electric heat tracing systems play a vital role in maintaining optimal temperature during hydrocarbon transportation and refining. These systems prevent pipelines from freezing or overheating, ensuring uninterrupted operations even in extreme environmental conditions, such as those found in arctic and polar regions.

2. Preference Over Steam Tracing

Electric systems are gaining ground over traditional steam tracing owing to their lower maintenance costs, superior energy efficiency, and advanced monitoring features. According to industry estimates, the installation cost of electric heat tracing can be up to 25% less than that of steam tracing.

Moreover, electric solutions offer precise control, automation, and integration with digital monitoring platforms, enabling users to detect faults, reduce energy wastage, and enhance safety. These benefits are unavailable in steam-based systems, which are bulkier and harder to regulate.

3. Technological Advancements and Product Innovation

Ongoing technological innovation is a key enabler of market growth. Self-regulating heating cables, for example, adjust their output based on ambient temperature. This dynamic wattage adjustment ensures consistent heating while preventing overheating—making the systems safer for use with flammable liquids and gases.

The April 2022 launch of the nVent RAYCHEM STS-HV cable is a testament to this trend. Designed for high-voltage, longline heating applications, it adds to the resilience and adaptability of electric tracing in large-scale industrial projects.

Regional Market Overview

North America dominated the electric heat tracing systems market in 2022, supported by an expansive oil and gas pipeline network. According to the U.S. Energy Information Administration, the country hosts more than 200 oil pipelines, surpassing Russia and China combined. This vast infrastructure demands efficient temperature maintenance solutions, creating a thriving market for heat tracing systems.

In Asia Pacific, the market is witnessing steady growth, driven by rapid urbanization and expanding energy networks in countries such as India and China. India, for instance, has over 17,000 kilometers of natural gas pipelines, and the government is investing in further network expansion.

Industry Outlook and Competitive Landscape

Key players in the electric heat tracing systems market are focusing on product development, mergers, and strategic collaborations to strengthen their market position. Companies such as Pentair PLC, Thermon Inc., Emerson Electric Co., Danfoss, Parker Hannifin Corp., BARTEC, and eltherm GmbH are leading the innovation curve.

Their strategies include the integration of IoT and smart monitoring, development of longer and more durable heating cables, and the creation of modular systems for easy scalability. These efforts aim to cater to both industrial heavyweights and emerging applications in commercial and residential segments.

Conclusion

The global electric heat tracing systems market is undergoing a transformative phase, fueled by the rising demand for energy, need for efficient thermal management, and the growing complexity of oil and gas operations. With advancements such as self-regulating cables and intelligent monitoring systems, electric heat tracing offers unmatched reliability, safety, and cost-effectiveness. As industries shift toward sustainable and digitally enabled infrastructure, electric heat tracing systems are expected to become an integral part of thermal process control, across sectors and geographies. With a projected value of US$ 5.7 Bn by 2031, the market holds significant promise for stakeholders looking to invest in the future of industrial efficiency.

0 notes

Text

Danfoss PVG 32 Inlet Sections

Neilson Hydraulics & Engineering Ltd supplies high-quality Danfoss PVG 32 inlet sections designed for precise hydraulic flow control in demanding applications. These inlet sections serve as the interface between the hydraulic pump and the PVG 32 valve system, offering options for both open- and closed-centre configurations. Built for reliability and flexibility, they support various control functions and flow capacities. Trust Neilson Hydraulics for expert support and genuine Danfoss components tailored to your hydraulic system needs.

0 notes

Text

Top Hydraulic Accessories Every Industrial Setup Needs

In the world of industrial operations, hydraulic systems are the driving force behind heavy machinery, precision tools, and automation lines. To ensure peak performance and operational efficiency, it's crucial to equip your setup with the right hydraulic accessories. These components not only boost performance but also enhance durability, safety, and cost-efficiency.

In this blog, we’ll explore the top hydraulic accessories every industrial setup needs, and why choosing high-quality hydraulic system components from trusted suppliers like Tech Hydro can make all the difference.

1. Hydraulic Pumps – The Heart of the System

No hydraulic system can function without a reliable hydraulic pump. Whether you're using gear pumps, vane pumps, or piston pumps, this component is responsible for converting mechanical energy into hydraulic energy. It's important to select a pump that suits your system's pressure, flow rate, and fluid type.

Pro Tip: If your existing pump is obsolete, look for a supplier that offers replacement hydraulic pumps with OEM-level performance.

2. Hydraulic Motors – Delivering Mechanical Power

Paired with pumps, hydraulic motors convert hydraulic energy back into mechanical force. They're essential in mobile machinery, conveyors, and industrial automation. Look for motor parts that are interchangeable with your existing setup to avoid costly replacements.

At Tech Hydro, we provide durable hydraulic motors and motor assemblies engineered for both heavy-duty and precision tasks.

3. Hydraulic Regulators – Precision Pressure Control

Maintaining consistent pressure is vital for the safety and performance of your system. Hydraulic regulators ensure that pressure levels are controlled and consistent, preventing system overloads and ensuring smooth operation. These are essential in systems that experience fluctuating loads or require precise output.

4. Hydraulic Controllers – Operational Accuracy

Hydraulic controllers manage flow, direction, and pressure throughout the hydraulic system. High-quality controllers help automate complex operations, reduce manual intervention, and improve energy efficiency. For advanced systems, electronic-hydraulic controllers offer even better control over performance variables.

5. Gear Pumps – Compact and Cost-Effective Power

Gear pumps are popular for their compact design and low cost. They’re ideal for fixed-displacement applications in both mobile and industrial systems. Tech Hydro offers a wide range of gear pump replacements that are compatible with leading OEMs.

6. Hydraulic Spare Parts – For Maintenance and Longevity

Downtime is expensive. That’s why it’s smart to stock essential hydraulic spare parts like seals, pistons, casings, and gaskets. These parts ensure fast repairs and minimal disruption. Always choose OEM-quality spares to maintain system integrity and avoid mismatches.

7. Filters, Hoses & Fittings – Supporting Components that Matter

While often overlooked, accessories like filters, hoses, and couplings play a critical role in maintaining system cleanliness and leak-free operation. Contaminants can severely reduce the lifespan of hydraulic components, so never skimp on filtration.

Final Thoughts: Choose a Trusted Supplier

When it comes to sourcing hydraulic accessories, always prioritize compatibility, quality, and performance. At Tech Hydro, we specialize in providing premium hydraulic system components, including hard-to-find or discontinued parts for top brands like Caterpillar, Danfoss, Kayaba, and more.

Whether you’re upgrading your system, replacing old components, or building from scratch, Tech Hydro has the expertise and inventory to support your industrial needs.

🛠️ Need Help Finding the Right Hydraulic Accessories?

Explore our catalog or contact our experts at Tech Hydro to find the perfect match for your equipment.

0 notes

Text

Servo Valve Market Outlook: Size, Share, and CAGR of 3.61% to 2031

The "Servo Valve Market" Report 2024 by Astute Analytica offers a detailed analysis of major regions, including North America, Europe, Asia Pacific, and LAMEA. This comprehensive report provides an in-depth examination of end users and types within the Servo Valve market, enabling stakeholders to understand the landscape better.

Global servo valve market generated a revenue of US$ 2,349.13 million in 2022 and is estimated to reach a valuation of US$ 3,177.48 million by 2031 at a CAGR of 3.61%.

A Request of this Sample PDF File@- https://www.astuteanalytica.com/request-sample/servo-valve-market

Market Overview

The Servo Valve market report delivers a thorough analysis that combines both qualitative and quantitative insights. It incorporates SWOT (Strengths, Weaknesses, Opportunities, and Threats) and PESTLE (Political, Economic, Social, Technological, Legal, and Environmental) analyses to present a holistic view of the industry. This combination of methodologies helps in identifying key factors that influence market dynamics.

Included in the report are essential industry statistics, which examine emerging business landscapes. The report also offers valuable insights on growth strategies, business tactics, customer acquisition, and collaborations. Furthermore, it emphasizes governance, risk, and compliance, vertical classification, business revolution, and technological advancements that are shaping the industry.

Industry Statistics and Emerging Business Landscapes

The report provides vital industry statistics that shed light on market trends, growth rates, and overall market size. These insights equip businesses with a clear understanding of the current state of the industry, allowing for informed decision-making.

Additionally, the analysis of emerging business landscapes highlights new trends, technologies, and market dynamics. This information is crucial for businesses aiming to stay ahead of the competition and adapt to the rapidly changing market conditions.

Importance of the Servo Valve Market in 2024

In 2024, having a comprehensive understanding of the market landscape is essential for businesses. It empowers them to identify growth opportunities in terms of strategies, services, and potential customer bases. By considering economic factors that may impact operations, businesses can also mitigate risks effectively.

Staying informed about market trends, including the latest developments, consumer preferences, emerging technologies, and competitor dynamics, provides valuable insights that facilitate strategic decision-making. This knowledge enables businesses to adjust their strategies and offerings to align with market demands.

For Purchase Enquiry: https://www.astuteanalytica.com/industry-report/servo-valve-market

Competitive Breakthrough

Competitive analysis serves as a vital tool for businesses to assess their market position and understand the competition targeting their main customers. By examining Servo Valve market share and analyzing detailed company profiles, businesses can gain insights into their competitors' strategies, revenue, gross margins, product offerings, recent developments, and historical data.

List of Prominent Players

Atos spa

Aviation industry AVIC Nanjing Servo Control System Co., Ltd.

Bosch Rexroth AG

Danfoss

DUPLOMATIC MS Spa

Eaton

HAWE Hydraulik SE

Honeywell International Inc.

JASC

MTS Systems

PARKER HANNIFIN CORP

SCHNEIDER SERVOHYDRAULICS

SG SERVO

Star Hydraulics Limited

Voith GmbH & Co. KGaA

Woodward, Inc.

YUKEN KOGYO CO., LTD

Other Prominent Players

Segmentation Outline

By Type

Electrohydraulic

Single-Stage

Two-Stage

Three-Stage

Mechanical Hydraulic

By Mount

Manifold

Sandwich

Sectional/Stacking

Slip-in Cartridge

Sub base

By End User

Aerospace & Defence

Steel Industry

Power Industry

Chemical Industry

Marine

Construction

Other (Oil & Gas)

By Country

North America

The U.S.

Canada

Mexico

Europe

Western Europe

The UK

Germany

France

Italy

Spain

Rest of Western Europe

Eastern Europe

Poland

Russia

Rest of Eastern Europe

Asia Pacific

China

India

Japan

Australia & New Zealand

South Korea

ASEAN

Rest of Asia Pacific

Middle East & Africa

Saudi Arabia

South Africa

UAE

Rest of MEA

South America

Argentina

Brazil

Rest of South America

Download Sample PDF Report@- https://www.astuteanalytica.com/request-sample/servo-valve-market

About Astute Analytica:

Astute Analytica is a global analytics and advisory company that has built a solid reputation in a short period, thanks to the tangible outcomes we have delivered to our clients. We pride ourselves in generating unparalleled, in-depth, and uncannily accurate estimates and projections for our very demanding clients spread across different verticals. We have a long list of satisfied and repeat clients from a wide spectrum including technology, healthcare, chemicals, semiconductors, FMCG, and many more. These happy customers come to us from all across the globe.

They are able to make well-calibrated decisions and leverage highly lucrative opportunities while surmounting the fierce challenges all because we analyse for them the complex business environment, segment-wise existing and emerging possibilities, technology formations, growth estimates, and even the strategic choices available. In short, a complete package. All this is possible because we have a highly qualified, competent, and experienced team of professionals comprising business analysts, economists, consultants, and technology experts. In our list of priorities, you-our patron-come at the top. You can be sure of the best cost-effective, value-added package from us, should you decide to engage with us.

Get in touch with us

Phone number: +18884296757

Email: [email protected]

Visit our website: https://www.astuteanalytica.com/

0 notes

Text

Europe Heat Exchanger Market Trends, Size, Segment and Growth by Forecast to 2030

The European heat exchanger market, valued at US$ 7,918.70 million in 2022, is projected to reach US$ 15,269.64 million by 2030, exhibiting a robust CAGR of 8.6% during this period. This growth is primarily fueled by increasing industrialization and significant investments in manufacturing and power generation across the continent. 📚Download Full PDF Sample Copy of Market Report @ https://wwcw.businessmarketinsights.com/sample/BMIRE00029743

Industrial Growth and Innovation Drive Demand

The rise of Industry 4.0 is a key driver for the European heat exchanger market. Governments and private entities are heavily investing in transforming manufacturing processes to improve product quality, minimize errors, and enhance safety. A prime example is the "Made in Europe" initiative, a seven-year (2021-2027) public-private collaboration under Horizon Europe with a budget of approximately US$ 2 billion. This initiative, spearheaded by the European Factories of the Future Research Association (EFFRA), aims to make Europe's industrial sector more resilient, digital, green, competitive, and human-centered.

This push for industrialization is leading to the construction of new manufacturing facilities across various sectors, including chemical, food & beverages, and automotive. Heat exchangers are crucial in these facilities to maintain optimal temperatures for efficient workflow, ensuring productivity and preventing safety hazards. To meet this escalating demand, market players are actively investing in new product developments:

In February 2023, Sanhua introduced stainless steel brazed plate heat exchangers (BPHEs) designed for enhanced heat transfer efficiency and lower pressure drops in applications like chillers, heat pumps, and boilers.

In March 2022, Sweden-based Alfa Laval unveiled the AC540 series, a new brazed-plate heat exchanger ideal for multiple-scroll chillers. Its unique asymmetric plate design helps reduce refrigerant charge and minimize pressure drop.

Power Generation Sector Bolsters Market Expansion

The European heat exchanger market also benefits from the region's focus on building new power plants to address the increasing electricity demand from residential, commercial, and industrial sectors. There's a growing emphasis on renewable electricity sources. For instance, in February 2022, the French President announced plans to construct 14 new nuclear reactors to achieve carbon neutrality by 2050. Such projects necessitate the use of liquid-to-liquid heat exchangers for moderator cooling, which improves plant efficiency and safety, thereby further boosting the heat exchanger market in Europe.

The European heat exchanger market encompasses countries such as Germany, France, Italy, Spain, the UK, Russia, Poland, Sweden, Norway, Denmark, Czech Republic, Hungary, Belgium, the Netherlands, Luxembourg, Finland, and the Rest of Europe.

Europe Heat Exchanger Strategic Insights