#electrical and electronics components in pune

Explore tagged Tumblr posts

Text

Due to their excellent strength-to-weight ratio, strong corrosion resistance, electrical and thermal conductivity, and high flexibility,Aluminium Other Components in India are employed in most sand casting projects. To improve these qualities, these alloys include aluminum and minute amounts of metals, including copper, magnesium, silicon, and zinc.The most widely used aluminum alloys at Haworth Castings are LM25 and LM6, with the 'LM' prefix serving as a standard identifier to represent the chemical makeup and varied quantities of the various trace metals.

#Automobile Components in Pune#Automobile Parts in India#Home Appliances Components in India#Electrical and Electronics Components in Pune#Aluminium Other Components in India#Aluminium Other Components in Pune#Home Appliances Components in Pune

0 notes

Text

Access Control System Manufacturers: Enhancing Security with Advanced Solutions

Access control systems are integral to modern security infrastructure, enabling organizations to regulate and monitor entry to their premises. These systems encompass a range of technologies, including biometric scanners, card readers, keypads, and mobile access solutions, all designed to ensure that only authorized individuals can access specific areas.

Leading Manufacturers in Access Control Systems

Honeywell: A global leader in security solutions, Honeywell offers a comprehensive suite of access control systems known for their reliability and scalability. Their products cater to various sectors, including commercial, industrial, and residential applications.

Bosch: Bosch provides advanced access control system manufacturers solutions that integrate seamlessly with other security systems. Their offerings are designed to enhance operational efficiency and ensure robust security measures.

Paxton: Specializing in IP-based access control systems, Paxton offers user-friendly solutions that are easy to install and manage. Their systems are suitable for a wide range of applications, from small businesses to large enterprises.

HID Global: Known for pioneering contactless access technology, HID Global's systems are widely used in various industries, including education, healthcare, and government sectors.

SALTO Systems: SALTO's electronic locking solutions are designed for flexibility and scalability, making them ideal for facilities that require dynamic access control.

Cable Tray Manufacturers: Supporting Infrastructure with Quality Solutions

Cable Tray Manufacturers are essential components in electrical and data installations, providing support and protection for cables. They are widely used in industries such as construction, manufacturing, and telecommunications.

Prominent Cable Tray Manufacturers

Classic Engineering Solutions: Based in Bangalore, Classic Engineering Solutions offers a diverse range of cable trays, including perforated, ladder type, and wire mesh trays. Their products are known for their durability and compliance with international standards.

Elcon Cable Trays: Operating from Pune, Elcon specializes in stainless steel cable trays and accessories. Their products are designed to withstand harsh environmental conditions, making them suitable for industries like oil and gas, and power distribution.

Fixotech Engineering Systems: An ISO 9001-2015 certified company, Fixotech manufactures cable management systems and accessories, including ladder type and perforated cable trays. Their products are crafted using advanced technologies to meet the evolving needs of various industries.

Indmark Cable Trays: Located in Pune, Indmark offers a wide range of cable trays and accessories, including cable ducts and tray covers. Their products are designed for easy installation and maintenance, ensuring efficient cable management.

Harshdeep Cable Trays: Operating from Pune, Harshdeep specializes in high-load capacity cable trays suitable for industrial applications. Their products are known for their reliability and cost-effectiveness

Conclusion

Both access control systems and cable trays play pivotal roles in ensuring the safety and efficiency of modern infrastructures. Leading manufacturers in these sectors continue to innovate, providing solutions that meet the diverse needs of various industries. By selecting products from reputable manufacturers, organizations can enhance their security measures and streamline their cable management processes.

1 note

·

View note

Text

Kapoor Sales: Your Trusted Dealer for Valox™ PBT Resin in India

When performance matters, Kapoor Sales is India’s largest and most trusted distributor of high-grade engineering plastics including Valox™ PBT resins from SABIC. Known for durability, heat resistance, and electrical reliability, Valox resins are ideal for a wide range of demanding applications in the automotive, electrical, appliance, and industrial sectors.

With a wide product offering that includes VALOX 325, DR51, DR48, 420SE0, and 357X, Kapoor Sales delivers tailored material solutions to help manufacturers meet both functional and regulatory requirements.

What Is Valox™ PBT Resin?

Valox™ is SABIC’s line of polybutylene terephthalate (PBT) resins—high-performance thermoplastics that combine mechanical strength, chemical resistance, and dimensional stability. Often reinforced with glass fiber and flame-retardant additives, Valox resins are known for their reliability in harsh environments.

Kapoor Sales stocks a full range of Valox grades including:

VALOX 325, VALOX DR51, VALOX DR48

VALOX 420, VALOX 420SE0, VALOX 357, VALOX 357X

30% GF FR PBT, 15% GF FR PBT, VALOX RESIN DR51

SABIC 357X, VALOX FR RESIN ENH4560

Key Features of Valox PBT Resin and PC-PBT Granules

Durability & Mechanical Strength

Excellent tensile, impact, and flexural strength

High-performance grades like VALOX 357X and 420SE0 are ideal for structural parts

Superior Electrical Insulation

Outstanding dielectric properties

Trusted for electrical connectors, switchgear, and insulation applications

Chemical & Moisture Resistance

Withstands exposure to grease, fuels, acids, and humidity

Resins like VALOX DR51 excel in under-the-hood and outdoor environments

Flame Retardant Options

UL94 V-0 rated grades like VALOX 420SE0, ENH4560, and 30% GF FR PBT

Compliant with global fire safety standards in electronics and automotive

Dimensional Stability

Low shrinkage, excellent surface finish, and heat resistance make it ideal for precision parts

Applications of Valox PBT Resin

Automotive Components

Connectors, housings, sensor covers, and coil bobbins

Flame-retardant, glass-filled grades like VALOX 357 and DR51 SABIC support high-load, high-temperature zones

Electrical and Electronics

Circuit breakers, switches, sockets, and enclosures

Grades like VALOX 420SE0 provide electrical insulation with flame retardance

Consumer Appliances

Durable parts in washing machines, dryers, blenders, and kitchen appliances

Valox resins offer strength and surface quality, even under high heat

Industrial & Mechanical Applications

Used in valves, gear housings, relays, and control units

Grades like VALOX 505RU and 357X meet high-load operational demands

Why Choose Kapoor Sales for Valox PBT Resin in India?

India’s Largest Distributor

Over 25 years of excellence in engineering plastics with a nationwide presence and global sourcing capabilities.

Extensive Product Range

From PBT natural granules to PC-PBT blends and high-glass-content FR grades, Kapoor Sales has the material to meet your exact specifications.

Assured Quality

Only genuine SABIC-certified Valox resins with full traceability, COAs, and technical data support.

Reliable Logistics

Pan-India supply network with fast and secure delivery to industrial hubs in Mumbai, Pune, Chennai, Bangalore, Delhi, and beyond.

Conclusion

When it comes to high-performance PBT resins, Kapoor Sales is the go-to source in India. Offering premium Valox™ grades like 420SE0, DR51, 357X, and ENH4560, we help industries achieve excellence in performance, safety, and production efficiency.

Partner with Kapoor Sales for top-quality PBT and PC-PBT solutions that meet global standards and local manufacturing needs.

Source: https://kapoorsalesindia.wixsite.com/kapoorsales/post/kapoor-sales-your-trusted-dealer-for-valox-pbt-resin-in-india

#ValoxPBTresin#PCpbtGranules#PBTgranules#PolybutyleneTerephthalatePBTresinsSuppliers#ValoxPBTgranule#PBTnatural

0 notes

Text

The Future of India’s Engineering Goods Export Market

India’s engineering goods export sector plays a pivotal role in the country’s economy, contributing significantly to national revenues and employment. Over the past few decades, this sector has evolved into one of the most promising areas for growth. As the global demand for engineering goods continues to rise, India is well-positioned to meet these needs and expand its footprint in international markets.

India’s Role in Global Engineering Goods Exports

India is home to a rapidly growing manufacturing sector that includes a wide range of engineering goods, such as electrical equipment, machinery, auto components, and industrial tools. These products are highly valued in global markets for their reliability, affordability, and quality. The country’s diverse range of engineering goods caters to industries such as automotive, construction, mining, and infrastructure.

Over the years, India has emerged as a competitive player in the engineering goods export market. Leading industrial hubs such as Pune, Chennai, and Ahmedabad have helped boost the production of high-quality machinery and equipment, positioning India as a key supplier for many countries worldwide. The sector has also gained traction due to strategic trade agreements, which have opened up new export markets for Indian products.

Key Factors Driving Engineering Goods Exports

The rise of India’s engineering goods export industry can be attributed to several factors:

Cost-Effectiveness: India offers competitive pricing for its engineering products, largely due to lower labor and production costs compared to other major manufacturing countries. This allows Indian exporters to remain competitive on the global stage while maintaining quality standards.

Skilled Workforce: India’s engineering workforce is among the largest and most skilled in the world. Highly trained engineers, technicians, and workers contribute to the development of cutting-edge products that meet international standards.

Technological Integration: The adoption of advanced technologies, including automation and robotics, has enhanced India’s manufacturing capabilities. By incorporating these innovations, Indian companies can produce high-precision and efficient engineering goods, making them more attractive to global buyers.

Strong Export Policies: The Indian government has taken several steps to promote the export of engineering goods, including simplifying export procedures, offering incentives, and establishing trade agreements with other countries. These efforts have helped boost India's position as a top exporter of engineering products.

To learn more about the factors driving the growth of India’s engineering goods export sector, read this in-depth article on engineering goods export from India.

Connecting with Other Key Sectors

India’s engineering goods export market is also closely linked with the electronics industry. As demand for electronic products increases globally, India’s engineering sector plays a crucial role in supplying the necessary components and machinery. To gain insights into how the electronics sector contributes to India’s export success, explore electronics manufacturing in India.

Conclusion

India’s engineering goods export sector is on a growth trajectory, fueled by competitive pricing, a skilled workforce, and continuous technological advancements. As the country strengthens its position in the global market, it is poised to become an even more significant player in the engineering goods export industry. By continuing to innovate and diversify its product range, India can ensure sustainable growth in this critical sector.

#engineering goods export from india#auto parts exporters in india#valve exporters in india#trade of engineering goods

0 notes

Text

CNC Machines Refurbishment Services Maharashtra – Restoring Precision and Performance

In the dynamic world of manufacturing, efficiency and precision are non-negotiable. Over time, even the most robust CNC (Computer Numerical Control) machines experience wear and tear, leading to reduced accuracy and productivity. However, purchasing new machinery is not always financially feasible. That’s where CNC Machines Refurbishment Services in Maharashtra come into play, offering a cost-effective solution to restore aging equipment to its original or even better performance.

Maharashtra, a hub of industrial activity with cities like Pune, Mumbai, Nashik, Aurangabad, and Nagpur, has emerged as a leader in the CNC refurbishment industry. Whether you operate in automotive, aerospace, die/mold, fabrication, or electronics — these services offer unmatched value and reliability.

What is CNC Machine Refurbishment?

CNC machine refurbishment involves restoring a used or worn CNC machine to its optimal working condition. This is done by overhauling mechanical components, upgrading control systems, recalibrating axes, and ensuring the machine performs like new.

Key Services Include:

🔧 Mechanical reconditioning

⚙️ Replacement of ball screws, guideways, and bearings

💡 Electrical rewiring and control panel upgrades

🖥️ CNC control system and software updates

📏 Axis alignment and geometric accuracy calibration

🔍 Functional testing and certification

With professional CNC machines refurbishment services in Maharashtra, businesses can significantly increase the lifespan and accuracy of their machines at a fraction of the cost of new purchases.

Why Choose CNC Machines Refurbishment Services in Maharashtra?

Maharashtra is India's industrial powerhouse with a highly developed engineering ecosystem. Choosing a CNC refurbishment provider in this region ensures:

✅ Technical Expertise:

Pune and Mumbai boast a dense cluster of skilled engineers and CNC specialists with decades of experience in servicing world-class machinery like Mazak, Haas, Siemens, Fanuc, DMG Mori, and more.

✅ Access to Latest Technology:

Service providers in Maharashtra use cutting-edge tools and diagnostic equipment to carry out precise refurbishments that meet global standards.

✅ Wide Industry Reach:

From automotive giants in Pune to fabrication units in Aurangabad, refurbishment services cater to every sector, ensuring tailored solutions.

✅ Cost-Efficiency:

Refurbishment is 40–70% more affordable than purchasing new CNC machines, offering maximum ROI.

Key Benefits of CNC Refurbishment

Partnering with a professional CNC machines refurbishment service provider in Maharashtra brings numerous advantages:

🔄 Extended Machine Life: Refurbished machines gain an additional 5–10 years of operation.

📈 Enhanced Productivity: Improved spindle speeds, feed rates, and axis response.

🛡️ Improved Safety and Compliance: Electrical and mechanical safety standards are re-evaluated and upgraded.

💰 Significant Cost Savings: No need for capital investment in new equipment.

⚙️ Up-to-date Technology: Integration of the latest CNC controllers and automation options.

Industries Served

Refurbishment services are widely used across Maharashtra’s diverse industrial base:

🚗 Automotive:

Engine component manufacturers refurbish their CNC machining centers to maintain tight tolerances.

✈️ Aerospace:

Precision milling and drilling machines used in aerospace part production are refurbished to achieve micron-level accuracy.

🔩 Die & Mould:

Toolmakers rely on refurbished CNC EDM and VMC machines to meet intricate mold design requirements.

🏗️ Heavy Engineering:

Lathes, boring machines, and horizontal machining centers are restored for large-scale operations.

🧰 General Manufacturing:

Job shops and MSMEs benefit from refurbished CNC routers, turning centers, and vertical machining centers.

CNC Machine Types Commonly Refurbished

🛠️ CNC Turning Centers

🧲 CNC Milling Machines (VMC/HMC)

🔧 CNC Boring Machines

🧵 CNC EDM/Wirecut Machines

📐 CNC Routers and Plasma Cutters

🪛 CNC Grinding Machines

Each refurbishment process is tailored to the machine type, application, and required performance level.

Top Cities Offering CNC Refurbishment in Maharashtra

1. Pune

Known for high-end CNC and automation industries.

Major hub for Fanuc, Siemens, and Mitsubishi system upgrades.

2. Mumbai

Offers full-scale refurbishment for CNC machines used in electronics, textiles, and aerospace.

3. Nashik

Specializes in machine calibration and high-precision spindle refurbishment.

4. Aurangabad

Industrial growth center with numerous refurbishment workshops for heavy-duty CNC machines.

5. Nagpur

Fast-growing location for CNC retrofitting, panel rewiring, and servo upgrades.

How to Choose the Right CNC Refurbishment Service Provider?

Before selecting a CNC machines refurbishment service in Maharashtra, evaluate these factors:

✅ Years of experience in CNC machine restoration

✅ Expertise in your specific machine brand (Fanuc, Haas, Siemens, etc.)

✅ Availability of genuine spare parts

✅ On-site diagnosis and breakdown support

✅ Post-refurbishment warranty and service contracts

Make sure to ask for a performance report and machine test results before approving the refurbished unit.

Conclusion

CNC machine refurbishment is a smart, sustainable, and cost-effective solution for manufacturers looking to optimize operations without investing in new machinery. Maharashtra stands out as a leader in this domain, offering technically sound and value-driven CNC Machines Refurbishment Services across its major industrial cities.

Whether you're facing issues with accuracy, system lag, or mechanical failures, a professional refurbishment can breathe new life into your CNC systems — restoring performance, boosting output, and saving costs.

If you're located in Maharashtra or planning to outsource your CNC refurbishment work, now is the perfect time to explore these services and partner with a trusted local expert.

Frequently Asked Questions (FAQs)

Q1: What is the typical cost of CNC machine refurbishment in Maharashtra? A: The cost can range between ₹75,000 to ₹8,00,000 depending on the machine model, age, and components required.

Q2: How long does it take to refurbish a CNC machine? A: A complete refurbishment usually takes 2 to 4 weeks, depending on the complexity and part availability.

Q3: Can refurbished CNC machines perform like new ones? A: Yes, when properly done, refurbished machines can deliver accuracy and performance similar to brand-new machines.

Q4: Is there a warranty on refurbished machines? A: Most reputed service providers offer a 6–12 month warranty on refurbished machines and components.

Q5: Do CNC refurbishment services include control system upgrades? A: Absolutely. Many providers upgrade the CNC controller, HMI, servo motors, and drives to modern standards.

#CNC Machines Refurbishment Services Maharastra#CNC Machine Reconditioning Service Maharastra#CNC Plano Milling Machine Maharastra#CNC Tube Sheet Drilling Machine Maharastra

0 notes

Text

Understanding Automotive Wiring Harnesses and BIM Training Institutes in Pune

Automotive Wiring Harness: The Nervous System of Vehicles

An automotive wiring harness is an essential component that acts as the nervous system of a vehicle. It consists of a complex network of wires, connectors, and terminals that transmit electrical signals and power throughout the automobile. These harnesses are responsible for connecting various electrical and electronic components such as lights, sensors, engine controls, and entertainment systems.

The design and manufacturing of wiring harnesses require precision and expertise to ensure safety, reliability, and durability under various operating conditions. Advances in automotive technology, including electric vehicles (EVs) and autonomous driving systems, have increased the complexity and importance of wiring harnesses. Modern harnesses are now designed to handle higher voltages, incorporate sophisticated routing, and meet stringent safety standards.

Professionals involved in the automotive wiring harness industry typically undergo specialized training in electrical systems, automotive electronics, and manufacturing processes. This knowledge ensures that they can produce harnesses that are efficient, safe, and compliant with industry standards.

Bim Training Institute in Pune: Building the Future with BIM Skills

In the construction and architecture sectors, BIM (Building Information Modeling) has revolutionized project planning, design, and management. The Bim Training Institute in Pune offers comprehensive courses that equip students and professionals with the necessary skills to excel in BIM technology. These courses cover essential topics such as 3D modeling, clash detection, project visualization, and construction management.

Pune has emerged as a hub for engineering and architectural education, making it an ideal location for Bim Software Classes in Pune. These institutes focus on hands-on training, providing learners with practical experience in popular BIM software tools like Revit, Navisworks, and Tekla Structures. The goal is to prepare students for the dynamic demands of the industry, where BIM professionals are highly sought after for their ability to streamline workflows, reduce costs, and improve project outcomes.

Structural Design Courses: Laying the Foundations

Complementing BIM training, structural design courses are vital for those interested in the structural engineering domain. These courses delve into the principles of designing safe and efficient structures, including buildings, bridges, and industrial facilities. Students learn about load calculations, material properties, seismic considerations, and sustainable design practices.

Structural design courses also incorporate software training, enabling students to create detailed structural models and analysis reports. Combining these skills with BIM expertise enhances a professional’s ability to contribute effectively to construction projects, ensuring structural integrity and compliance with safety standards.

The Intersection of Technology and Industry

Both the automotive wiring harness sector and the architectural/structural design fields are experiencing significant technological advancements. Automation, digital modeling, and computer-aided design tools have transformed how professionals approach their work. For instance, the integration of BIM in construction projects improves coordination and reduces errors, much like how advanced wiring harness designs optimize vehicle performance and safety.

Furthermore, educational institutions in Pune are adapting to these changes by offering specialized courses that blend traditional engineering principles with modern software skills. The Bim Training Institute in Pune and various structural design courses are examples of how education is evolving to meet industry needs.

Conclusion

Whether you're interested in the technical intricacies of automotive wiring harness manufacturing or aiming to enhance your skills through Bim Software Classes in Pune or structural design courses, Pune offers excellent opportunities for professional growth. Staying updated with the latest industry standards and technological advancements is crucial for success in these dynamic fields.

0 notes

Text

Top Manufacturers Trust India's BIS & NABL Certified Product Testing Lab

Product testing is not merely a formality in today's quality-driven and compliance-focused marketplace; rather, it is an essential component of success. To assist manufacturers in meeting regulatory requirements quickly and confidently, House of Testing provides NABL-accredited testing services as well as end-to-end BIS certification support.

Our knowledgeable staff makes sure your products are tested, certified, and prepared for the market, whether you're introducing a new product or growing an existing line.

✅ What We Test:

LED Lights & Luminaries – IS 10322 & photometric testing

Cell & Batteries – IS 16046, UN 38.3 compliance

Fans (Ceiling, Table, Pedestal) – IS 302 & IS 374 standards

Home & Kitchen Appliances – Mixers, toasters, cooktops, etc.

Consumer Electronics – Chargers, power banks, and more

🧪 Key Services:

BIS Certification Testing (CRS & Compulsory Registration)

NABL Lab Testing under ISO/IEC 17025:2017

Electrical Safety & Performance Testing

Photometry Testing for LED Products

Mechanical, Vibration & Environmental Testing

Customized Testing Solutions for Startups & OEMs

🚀 Why Top Brands Choose House of Testing:

NABL Accredited & BIS Recognized Laboratory

Fast Turnaround Time with accurate reporting

PAN-India Service – Delhi NCR, Mumbai, Pune, Bangalore, Hyderabad & more

Transparent Pricing with expert support at every stage

Comprehensive Testing for Domestic & Export Requirements

📌 Who Should Partner With Us?

LED & lighting manufacturers

Battery & electronics manufacturers

Fan & appliance producers

Consumer goods startups

Importers & exporters requiring BIS certification

🌐 Ready to Get Certified?

House of Testing is your go-to source for dependable, certified, and effective product testing in India. Make sure your products fulfill all safety and quality requirements. 🔗 Visit us at: www.houseoftesting.com 📞 +91-9899994387 🗺️ Sec 5, Noida, (U.P.)

0 notes

Text

Why Is Luxury Car Repair in Pune Crucial for Premium Vehicle Owners?

Owning a luxury car is a dream for many, and those who live that dream understand the level of responsibility it comes with. Whether it's a sleek BMW, a powerful Audi, or a sophisticated Mercedes-Benz, these machines require far more than just regular servicing. In Pune—a city known for its fast-paced lifestyle and rising luxury car market—the demand for expert luxury car repair is rapidly growing. But why is this so important, and what should you know about choosing the right repair service?

Luxury Cars Need Specialized Attention

Luxury vehicles are engineered with precision and advanced technology. These aren’t your average cars—they come with complex electronic systems, turbocharged engines, adaptive suspensions, and high-performance components. Any issue in such a system can’t be fixed by a regular mechanic. The tools, knowledge, and techniques used in repairing luxury cars differ greatly from those used for standard vehicles.

If you're in Pune and own a luxury car, trusting a general repair shop could be a costly mistake. Instead, opt for repair centers that specialize in luxury brands. These service centers often have brand-certified technicians who are trained to handle your specific vehicle model.

The Pune Luxury Car Market Is Booming

In recent years, Pune has seen a significant rise in the number of luxury vehicles on its roads. With IT parks, business hubs, and an affluent population, Pune is now one of India's top markets for luxury car sales. This growing trend has also created a need for dedicated luxury car repair services across the city.

From Koregaon Park and Kalyani Nagar to Baner and Hinjewadi, you’ll find several high-end repair centers that cater exclusively to luxury vehicles. They not only handle routine servicing but also complex repairs, diagnostic scans, and advanced component replacements.

Common Repairs Luxury Cars May Need

While luxury cars are built to last, they aren’t immune to problems. Some of the common issues that demand specialized attention include:

Transmission Repairs: Many luxury cars use advanced automatic or dual-clutch transmissions that require brand-specific diagnostic tools and parts.

Suspension Issues: Adaptive or air suspension systems are common in high-end cars and need expert handling.

Electrical Faults: Modern luxury cars come packed with tech—infotainment systems, parking sensors, lane assist features, and more—all of which require skilled troubleshooting.

Engine Performance Problems: Turbochargers, fuel injection systems, and ECU (Engine Control Unit) require expert calibration and repair techniques.

Why Choose Certified Luxury Car Repair Services in Pune?

There are numerous reasons to choose a certified and trusted luxury car repair workshop in Pune:

Trained Technicians: Certified technicians are trained by the car brands themselves and know your vehicle inside out.

Genuine Parts: These centers use OEM (Original Equipment Manufacturer) parts to maintain your vehicle’s performance and value.

Advanced Diagnostics: Specialized scanning tools are essential for identifying faults in luxury cars accurately.

Brand-Specific Expertise: Whether you drive a Porsche, Volvo, Jaguar, or Lexus, you need a team that understands the brand-specific engineering.

What to Look for in a Luxury Car Repair Center

Not all repair centers are created equal. Here are a few things to check before handing over your vehicle:

Reputation and Reviews: Look for online reviews, word-of-mouth recommendations, and client testimonials.

Certifications: Make sure the workshop is authorized or certified by luxury car brands.

Transparency: You should receive clear estimates, breakdowns, and progress updates on your repair.

Customer Service: A premium car deserves premium service. Look for centers that offer pickup/drop-off, lounge facilities, and quick turnaround time.

Cost vs. Quality: The Trade-Off

Luxury car repair in Pune may come at a premium price, but it’s worth every rupee when your car’s performance and safety are on the line. Avoid cutting corners with cheaper, unqualified repair shops that might do more harm than good. Remember, maintaining the value and integrity of your luxury vehicle starts with quality repairs.

The Future of Luxury Car Servicing in Pune

With the rise of electric and hybrid luxury vehicles, the need for specialized technicians and equipment will only increase. Many new service centers in Pune are now investing in EV-compatible tools and training to stay ahead of the curve.

As more people invest in high-end vehicles, the demand for expert, trustworthy, and technologically advanced repair services will continue to grow. If you’re a luxury car owner in Pune, staying ahead of maintenance and repairs through the right service provider is not just a choice, it's a necessity.

FAQs

Q1. How often should I get my luxury car serviced in Pune?

Most luxury cars require servicing every 10,000 km or once a year, whichever comes first. However, it’s best to follow the maintenance schedule recommended by the car manufacturer.

Q2. Are luxury car repairs more expensive than regular cars?

Yes, due to advanced engineering, imported parts, and specialized labor, luxury car repairs typically cost more than standard vehicle repairs.

Q3. Can I take my luxury car to a local garage?

It's not recommended. Luxury cars need brand-specific tools and trained technicians. Visiting an unauthorized garage may void your warranty or cause further damage.

Q4. Do repair centers in Pune use genuine parts for luxury cars?

Authorized and reputed luxury car repair centers in Pune use OEM (Original Equipment Manufacturer) parts to ensure the vehicle’s performance and longevity.

Q5. Which areas in Pune are known for luxury car repair services?

Areas like Koregaon Park, Baner, Aundh, and Kalyani Nagar have reputed workshops that specialize in luxury car servicing and repairs.

0 notes

Text

How Excel Heaters Delivers Precision-Engineered Nozzle Heating Solutions

Plastic injection moulding requires very precise control of temperature. Even a small variation can lead to defects in the moulded product. If the plastic is too cold, it won’t flow properly. If it’s too hot, it might burn or degrade. That’s why a reliable heater is essential.

At Excel Heaters, we understand this need and have focused our designs on accuracy, uniform heating, and long life.

Our Design Philosophy: Quality First

Every heater at Excel Heaters is built with a commitment to quality, safety, and performance. Here’s how we ensure that:

1. Material Selection

We use high-grade brass for the outer body of our sealed nozzle heaters. Brass offers excellent thermal conductivity and corrosion resistance, making it perfect for tough industrial conditions.

2. Advanced Heating Elements

Inside every heater is a high-quality nichrome wire, wound in a way that ensures even heating across the surface. We take great care in selecting insulation materials that improve heat transfer while keeping electrical components safe.

3. Sealed Construction

One of the standout features of our nozzle heaters is the sealed construction. This prevents moisture or plastic residue from entering the heater and damaging the coil. As a result, the heaters last longer and perform better in damp or dusty environments.

Customization as per Industry Needs

We know that every machine and moulding setup is different. That’s why we offer customization options for:

Diameter and Length

Wattage and Voltage

Lead wire exit direction

Mounting method (clamp or band)

Whether you need an 8mm heater or an 8.5mm, high wattage or standard, we can manufacture it as per your machine's requirements.

Key Benefits of Excel Heaters' Nozzle Heaters

Our sealed brass nozzle heaters are designed to provide several practical benefits:

Uniform Heat Distribution – No cold spots, resulting in better flow of plastic.

Energy Efficiency – Quick heat-up and recovery times save electricity.

Longer Life – Moisture-proof design protects the inner coil.

Easy to Install – Lightweight and compact design.

Consistent Performance – Suitable for long production cycles.

These features make our heaters suitable for plastic processing, packaging, printing, and more.

Industries We Serve

Excel Heaters supplies to a wide range of industries including:

Plastic Injection Moulding

Blow Moulding Machines

Thermoforming

Automotive Component Manufacturing

Consumer Goods & Electronics

Our heaters are used across India, including major hubs like Mumbai, Delhi, Pune, Ahmedabad, and Chennai.

Customer Support & After-Sales Service

Buying from Excel Heaters doesn’t end with delivery. We are committed to supporting our customers every step of the way. Our technical team can help you with:

Choosing the right heater

Installation guidance

Troubleshooting

Replacements and spares

Our goal is to build long-term relationships based on trust and performance.

Why Choose Excel Heaters?

With over a decade of experience, Excel Heaters has become a reliable name in the industrial heating segment. Here’s why manufacturers prefer us:

Made in India, Trusted Worldwide

Quick Turnaround Time

Stringent Quality Control

Affordable Prices

Custom Manufacturing Capabilities

When you choose Excel Heaters, you choose consistency, durability, and peace of mind.

Final Thoughts

In a fast-paced manufacturing environment, you can’t afford to take chances with heating elements. With Excel Heaters’ sealed brass nozzle heaters, you get reliable performance, precise temperature control, and long-lasting service — all in one compact, efficient product.

If you are upgrading your moulding machines or starting a new production line, trust Excel Heaters. They will power your process accurately.

0 notes

Text

Shot Blasting of Components

The Shot Blasting of Components in India is critical. If you're looking for the best saddle service, we're here to help. Even while you go through our assortment, you can be confident that the saddles we provide are of the greatest possible quality. For your enjoyment, we've assembled just the best. For more details visit our Website today

#automobile components#shot blasting of components in pune#electrical components#advanvcetechnologiespune#electrical and electronics components in pune

0 notes

Text

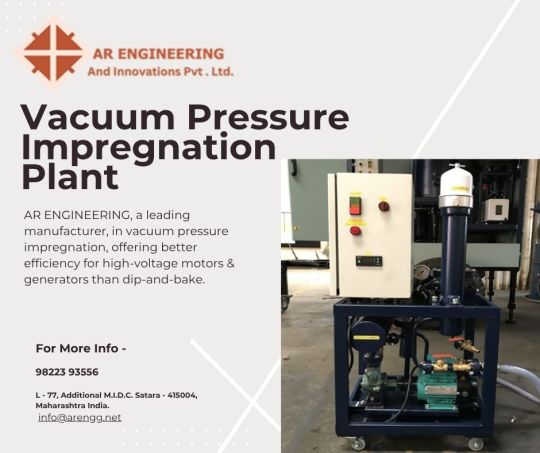

🏭 Vacuum Pressure Impregnation Plant Manufacturers & Exporters – AR Engineering, Satara, Maharashtra

AR Engineering is one of the leading Vacuum Pressure Impregnation Plant manufacturers in India, providing advanced solutions for insulation and resin treatment in electrical and industrial components. We are trusted exporters and suppliers of Pressure Impregnation Plants in India, offering durable and high-performance systems for a wide range of applications.

Whether you're looking for Vacuum Impregnation Plants manufacturer in Pune or require large-scale plants anywhere in India, AR Engineering ensures precision, consistency, and performance in every system.

⚙️ Our Specialized Range Includes:

Fully automated Vacuum Pressure Impregnation Plant

Custom-engineered Pressure Impregnation Plant systems

Compact and scalable Vacuum Impregnation Plants

Batch Type Trickle Impregnating Machine for consistent results

Index Type Trickle Impregnating Machine for high-speed production

Advanced Varnishing Machines for motor coil protection

As an experienced Vacuum / Pressure Impregnation Plants manufacturer, exporter, and supplier in Satara, Maharashtra, we serve industries across India and abroad with top-quality impregnation systems.

🌐 Serving Domestic & International Markets:

Vacuum pressure impregnation plant supplier in Pune

Vacuum pressure impregnation plant supplier in India

Vacuum pressure impregnation plant exporter in India

Vacuum pressure impregnation plant exporter in Pune

Wholesale Pressure Impregnation Plant suppliers for B2B orders

Trusted Indian Vacuum Pressure Impregnation Plant manufacturers

Our commitment to innovation and quality makes us the preferred choice for clients seeking Vacuum Impregnation Plant manufacturers in India or exporters of Pressure Impregnation Plants globally.

✅ Why AR Engineering?

ISO-certified production facility in Satara, Maharashtra, India

Precision-built plants using latest vacuum and pressure technology

Export-ready solutions with customization and technical support

Used in transformers, motors, windings, and electronic insulation

📍 Manufacturing & Export Locations:

Satara

Pune

Maharashtra

Pan India

International Exports

🔗 Learn more about our full range of impregnation and varnishing systems: https://hydraulicoilfiltrationmachine.com/vacuum-pressure-impregnation-plant.html

#Vacuum Pressure Impregnation Plant manufacturers - AR Engineering exporters#suppliers of Pressure Impregnation Plant india#indian Vacuum Pressure Impregnation Plant#Vacuum Impregnation Plant manufacturer#wholesale Pressure Impregnation Plant suppliers#Vacuum Pressure Impregnation Plant#Pressure Impregnation Plant#Vacuum Impregnation Plant#Vacuum Impregnation Plants#Pressure Impregnation Plants#Varnishing Machines#Batch Type Trickle Impregnating Machine#Index Type Trickle Impregnating Machine#Vacuum / Pressure Impregnation Plants Manufacturer Exporter#Supplier#Satara#Maharashtra#India#Vacuum Impregnation Plants manufacturer in pune#Vacuum Impregnation Plants manufacturer in india#vacuum pressure impregnation plant supplier in pune#vacuum pressure impregnation plant supplier in india#vacuum pressure impregnation plant exporter in india#vacuum pressure impregnation plant exporter in pune

0 notes

Text

Always On Numeric UPS Systems in India is an industry leading global brands ups manufacturers of UPS systems and power conditioning equipment. Our engineered solutions protect sensitive electronics against surges, blackouts, electrical noise, and transients. We provide complete, customized ups battery solutions to meet customer needs. Always On takes great pride in providing complete ups battery backup solutions. This includes all modes and levels of protection being designed into every system we build, eliminating the need for additional equipment to be added to address the total system requirements. We do not cobble together standard products like some of our larger competitors do, but instead provide a customized engineered solution to meet customer needs. Ensuring protection and power quality through every mode of operation requires coordination between all system components. This includes surge protection devices, inverters, ups battery, battery chargers, bypass systems, transfer switches and power distribution units.

Today’s Technology has been changed and advanced so taking this into consideration Costa Power plays a vital role as ups battery dealers in Mumbai which are connected into a global ups battery suppliers chain and borderless markets. Being a reason Costa power is best Numeric ups dealers in Mumbai and available PAN India associated with Numeric ups manufacturers in India, Numeric online ups dealers in Mumbai, Numeric ups suppliers in India, Numeric modular ups dealers in Mumbai, Numeric Digital ups dealers in Pune and chain of technician & experts. This is just like now homes have become entertainment and social hubs. All of which demand seamless quality power ranging from 6kVA to 21 MV. Top-off-the-line, they come with several innovative features like front-end access, remote operation capabilities and modularity which make them thoughtful and ideal for a variety of uses and industries. And for it Costa power is ups battery dealers of Numeric ups dealers in Thane as well Numeric online ups dealers in Mumbai for the quality power use taking consideration of ROI. Costa power have expertise in providing solution for Numeric ups distributors in India with the products are available across Numeric Line Interactive UPS, Numeric Single Phase UPS and Numeric 3 Phase industrial UPS, etc and are customizable at every scale.

#Upsbattery#Upsbatterydealers#Upsbatterydistributor#Upsbatterysuppliers#Upsamc#Upsapc#Microtekinverter#Quatabattery#Luminousups#Emersonups#Onlineups#Digitalups#Offlineups#Bestups#Bestbattery#Servostabilizer#Vertivups#Exidebattery#Luminousinverter#Upsdealers#Upssuppliers#Upsdistributors

0 notes

Text

Top 10 Items Exported From India To The USA

Wondering what India sends the most to the U.S.? The top 10 items exported from India to USA reflect how India has become a global supplier across tech, health, and consumer markets. From smartphones to home furnishings, here’s a quick look at what’s driving billions in exports.

Electronics & Electricals India shipped $14.4B worth of electronics to the U.S., led by smartphones (including iPhones), PCBs, and EV parts.

Pharmaceuticals At $12.73B, India remains the top source of generic drugs and APIs for the U.S. healthcare system.

Precious Metals Jewelry, diamonds, and silver exports reached $11.88B—thanks to India’s strong gem-cutting and design industry.

Machinery Industrial and farm equipment valued at $7.10B is built in hubs like Pune and Coimbatore.

Fuel & Oil India exported $3.23B in refined petroleum and light oils, supported by top-tier refineries.

Chemical Products Dyes, pigments, and specialty chemicals made up $3.63B in exports to U.S. industries.

Textiles (Home) From bed linens to rugs, home textile exports hit $3.10B, led by Panipat and Karur.

Iron & Steel Goods Pipes, castings, and more added up to $2.83B in exports for construction and manufacturing.

Vehicles & Auto Parts India shipped $2.80B worth of cars, two-wheelers, and EV components to the U.S.

Apparel Garments like woven fashionwear and ethnic apparel reached $2.52B in U.S. markets.

India’s export engine is a mix of scale, skill, and policy support—making it a rising force in global trade.

0 notes

Text

Common Mistakes to Avoid When Using DC-DC Converters

DC-DC converters are devices crucial in electronic systems, to step up or step down voltage efficiently in devices that run on batteries or other DC power sources. These are used in smartphones, laptops, electric vehicles, solar panels, and other electronic devices.

Do you know that even a minor mistake in setting up a DC-DC converter can lead to complete failure? When misused, sensitive components can be damaged due to overvoltage and overheating, resulting in a device failure, or reduced performance.

In this blog, we will discuss the common mistakes users make with DC-DC converters and how to avoid them to maintain high efficiency.

Let’s dive in!

Neglecting Load Requirements

Choosing a converter without fully knowing about the load requirement can lead to problems. Under sizing can lead to overheating and failure, whereas oversizing can result in inefficiency and unwanted costs. Always measure your maximum and average loads to support the correct equipment choice.

Unreliable Thermal Performance

DC-DC Converters generate a lot of heat sometimes. An improper implementation of heat skins, airflow, and other cooling methods can affect the life span of the device. Do not wait for the thermal breakdown to realize your mistake.

Incorrect Input Voltage

Plugging in voltages that are too high or too low for the converter specifications can damage both the converter and the connected gadgets. Always check for the input voltage ranges and ensure consistency in the power supply.

Lack of EMI and noise mitigation planning Electromagnetic interference can cause significant disruption. Not using proper filtering methods with a DC-DC converter can result in unstable operation or interference with other devices. That’s why planning EMI from the beginning is essential.

Skipping Datasheet Details Going straight to installation by skipping the data sheet can lead to malfunctioning or failure of the system. To avoid misunderstanding in configurations and damaging errors it is necessary to read the sheet, it saves both time and money.

Final Thought Avoid this common mistake and start using high-quality components from trusted suppliers. Yonderh2 offers high-efficiency, reliable, and precision-engineered DC-DC Converters for real-world applications.

CTA

Don’t let mistakes drain your system and budget. Explore Yonderh2’s DC-DC Converters today!

Contact us or visit— https://yonderh2.com/ to get the performance and reliability you need!

About the Author: Yonder, a division of the Ador Group, has been a leader in Power Electronics since 1908. Specializing in advanced Power Conversion Units for hydrogen generation, we integrate Alkaline, PEM, SOEC, and AEM electrolyzers to ensure high efficiency and minimal power consumption. Headquartered in Mumbai with state-of-the-art facilities in Pune, Yonder is committed to global decarbonization. Our 500-MW manufacturing facility for hydrogen power sources is poised to deliver cutting-edge solutions that thrive in unique and demanding deployment contexts.

0 notes

Text

Top Electronics Manufacturing Companies in India: Powering the Future of Global Tech

India’s electronics manufacturing industry is witnessing a phenomenal rise, transforming from a major importer to a self-reliant, export-driven powerhouse. As the global demand for electronics continues to surge, India’s strategic position in the global supply chain, favorable policies, and growing innovation ecosystem have placed it in the spotlight. In this article, we explore the landscape of electronics manufacturing in India, the driving factors behind its growth, and a detailed look at the top companies shaping its future.

Introduction: The Rise of Electronics Manufacturing in India

India is undergoing a remarkable shift in its electronics landscape. Once dependent on imported devices and components, the country now produces millions of consumer electronics, mobile phones, and embedded systems domestically. This transformation is driven by a combination of government initiatives, private sector innovation, and global demand.

What is Electronics Manufacturing?

Electronics manufacturing involves the design, assembly, and production of electronic components and finished products. This includes everything from printed circuit boards (PCBs), microprocessors, and semiconductors to televisions, smartphones, and industrial control systems. The Indian electronics ecosystem spans a wide array of industries, including telecom, automotive, medical devices, aerospace, and defense.

India’s Journey from Import-Dependent to Manufacturing Hub

Historically, India relied heavily on imported electronic goods and raw materials. However, the introduction of policies such as the National Policy on Electronics (NPE) and initiatives like Make in India have paved the way for rapid domestic growth. In the past decade, India has emerged as the second-largest manufacturer of mobile phones globally, with a vision to become a global hub for Electronics System Design and Manufacturing (ESDM).

Market Size and Growth Projections

The Indian electronics manufacturing market was valued at over $100 billion in 2023 and is projected to reach $300 billion by 2026, supported by a compound annual growth rate (CAGR) of 15-20%. Key growth sectors include smartphones, consumer electronics, industrial automation, automotive electronics, and medical devices.

India’s share in global electronics exports is steadily rising, with key partners including the United States, UAE, Germany, and Southeast Asian countries.

Government-Led Initiatives Accelerating Growth

1. Make in India

This flagship campaign encourages global and domestic companies to manufacture within India. Electronics is a priority sector under this initiative.

2. Production Linked Incentive (PLI) Scheme

Introduced to boost large-scale manufacturing, the PLI scheme offers financial incentives to electronics companies based on incremental output and exports. The scheme has attracted investments from leading global brands such as Apple, Samsung, and Foxconn.

3. EMC 2.0 (Electronics Manufacturing Clusters)

India has established dedicated electronics manufacturing zones in regions like Noida, Chennai, Pune, and Bengaluru, providing infrastructure, logistics, and tax incentives to companies.

Key Segments within the Indian Electronics Manufacturing Ecosystem

India’s electronics manufacturing spans across various verticals, including:

Consumer Electronics

Televisions, refrigerators, washing machines, and smart home devices are now being largely manufactured within India, with increasing export volume.

Mobile Phone Manufacturing

With over 200 mobile manufacturing units, India has become a global hub. Companies like Xiaomi, Samsung, and Apple assemble smartphones and components at scale.

Automotive Electronics

The rise of electric vehicles (EVs) and autonomous driving systems has created demand for battery management systems (BMS), infotainment, and ADAS components.

PCB and Semiconductor Assembly

India is ramping up PCB manufacturing capabilities and working on developing its own semiconductor fabrication infrastructure, with projects already announced in Gujarat and Karnataka.

Top Electronics Manufacturing Companies in India

Let’s take a closer look at the most prominent players in India’s electronics manufacturing sector:

1. Dixon Technologies

Dixon is India’s leading EMS (Electronics Manufacturing Services) provider. It partners with global brands like Samsung, Philips, and Xiaomi to manufacture:

Smartphones

LED TVs

Lighting solutions

Wearables and security systems

Dixon has multiple manufacturing plants across India and is a key beneficiary of the PLI scheme.

2. Bharat Electronics Limited (BEL)

A government-owned company, BEL specializes in electronics for defense and aerospace. It plays a critical role in India’s self-reliance efforts in defense tech and manufactures:

Radars

Avionics

Surveillance systems

Electronic warfare equipment

3. VVDN Technologies

VVDN is a design-led electronics manufacturer offering end-to-end solutions. It is known for:

Embedded product design

IoT solutions

Networking and telecom equipment

Cloud and AI-enabled hardware

VVDN operates multiple design and manufacturing centers across India.

4. Kaynes Technology

Kaynes offers integrated EMS solutions across:

Automotive

Aerospace

Medical electronics

Consumer and industrial electronics

With strong R&D and a focus on Industry 4.0 practices, Kaynes has expanded its footprint globally.

5. SFO Technologies (NeST Group)

SFO provides end-to-end solutions, from product design to system integration, serving industries such as:

Healthcare

Aerospace

Energy

Industrial automation

Their multi-disciplinary engineering capabilities set them apart in high-precision manufacturing.

Role of EMS Providers in India’s Growth

Electronics Manufacturing Services (EMS) companies are the backbone of the electronics industry. They handle everything from procurement and assembly to testing and packaging, allowing OEMs to focus on core design and branding. Indian EMS providers have expanded capacity and capabilities significantly, attracting projects from Europe, the U.S., and Asia-Pacific regions.

Importance of PCB Assembly and SMT Technologies

Surface Mount Technology (SMT) and advanced PCB assembly lines are central to India’s electronics boom. These allow for:

High-speed production

Automated soldering and inspection

Cost-effective prototyping

Compliance with international standards (RoHS, IPC-A-610)

Several Indian companies now offer multi-layer PCB manufacturing and full turnkey solutions with in-house testing and packaging.

Supply Chain Dynamics and Local Sourcing Trends

India is gradually reducing its reliance on imports by localizing more components:

Passive components (resistors, capacitors)

Plastics and mechanical parts

Wire harnesses and connectors

However, critical semiconductor parts still depend on international suppliers. With the launch of India’s Semiconductor Mission, this gap is expected to shrink in the coming decade.

Challenges Facing Indian Electronics Manufacturers

Despite rapid progress, some challenges remain:

1. Import Dependence for Semiconductors

Semiconductors are still largely imported from Taiwan, South Korea, and China. Although India is investing in domestic fabs, the road to chip independence is long.

2. Infrastructure and Logistics

Power supply, last-mile logistics, and export logistics are inconsistent in Tier-2 cities, affecting delivery timelines and operational costs.

3. Talent Shortage in Advanced Tech

While India has a strong engineering base, there is a shortage of professionals with hands-on experience in VLSI design, embedded systems, and AI-integrated electronics.

The Future Outlook: India’s Role in the Global Electronics Supply Chain

India is actively positioning itself as a credible China+1 alternative for global electronics production. With rising global geopolitical uncertainty, multinational corporations are diversifying their manufacturing operations. India stands out due to its:

English-speaking technical talent

Competitive production costs

Expanding infrastructure

Business-friendly reforms

How to Choose the Right Electronics Manufacturing Company in India

Before partnering with an Indian manufacturer, consider the following:

1. Certifications and Quality Standards

Look for ISO 9001, IATF 16949, ISO 13485, and RoHS compliance depending on your industry.

2. Technical Capabilities

Check if the company offers:

Full turnkey EMS solutions

Prototyping and NPI support

High-speed SMT lines

Design-for-manufacturability services

3. Scalability

Evaluate the company's ability to handle low- to high-volume orders, rapid scaling, and long-term support.

How FindingMFG Simplifies Supplier Discovery

FindingMFG.com is a global B2B platform connecting manufacturers and buyers. It helps businesses:

Compare Indian EMS and electronics manufacturers

View profiles, certifications, and factory capabilities

Send RFQs directly through the platform

Build long-term supplier relationships

Whether you're a startup or an enterprise, FindingMFG makes it easy to access India’s electronics manufacturing ecosystem.

Conclusion

India’s electronics manufacturing sector is not just growing — it’s evolving. The combination of policy support, skilled talent, and global partnerships is positioning India as a central node in the global electronics supply chain. Whether you're sourcing mobile phones, PCBs, IoT devices, or defense-grade systems, Indian electronics manufacturers are ready to deliver world-class solutions.

With platforms like FindingMFG.com, finding the right manufacturing partner has never been easier. The future of electronics is being built — and it's being built in India.

FAQs

1. What is the current size of the electronics manufacturing industry in India?

As of 2023, the market is valued at over $100 billion and is expected to grow to $300 billion by 2026.

2. Which are the best cities in India for electronics manufacturing?

Top cities include Noida, Bengaluru, Pune, Chennai, and Hyderabad due to their cluster infrastructure and skilled workforce.

3. Can Indian electronics companies handle international orders?

Yes, many companies are already serving clients in the U.S., Europe, and Southeast Asia with ISO-certified processes and scalable capacity.

4. What are the key advantages of sourcing from India?

Lower production costs, government incentives, skilled labor, and diversification from China are major advantages.

5. How do I connect with electronics manufacturers in India?

Use platforms like FindingMFG.com to find verified manufacturers, post RFQs, and initiate conversations directly.

0 notes

Text

Electronics shop in karanjade

Walia Electronics – Electronics Shop in Karanjade, Navi Mumbai

As Navi Mumbai’s tech-savvy population grows, demand for high-quality electronics and reliable service continues to rise. Among the emerging localities, Karanjade has rapidly evolved from a quiet village to a thriving residential hub. Amidst this transformation, Walia Electronics has established itself as the go-to electronics store—offering expert guidance, genuine products, and a personalized touch.

This comprehensive guide explores:

📍 Karanjade’s electrifying development

🔍 Why Walia Electronics is at the forefront

🛍️ Services and product range

🤝 What sets them apart

🗣️ Customer feedback and testimonials

🚀 Tips for choosing an electronics store

📈 Future growth outlook for Walia Electronics

Karanjade: A Growing Electronics Market

Thanks to infrastructure improvements like the upcoming Navi Mumbai International Airport and access via the Mumbai–Pune Expressway, Karanjade has seen a surge in residential demand With schools, banks, and hospitals opening up, tech essentials have become essential for new homeowners .

Residents in sectors like 1–30 prioritize convenient access to appliances, gadgets, repairs, and accessories. Walia Electronics meets this need locally—no more trips to distant malls or big-city hubs.

Meet Walia Electronics: Your Neighborhood Tech Specialist

Located in the heart of Karanjade, Walia Electronics offers:

📱 A wide range of gadgets and home appliances

🛠️ On-site repairs and installation

🧰 Genuine-brand products and accessories

🤝 Friendly advice and transparent pricing

Why Choose Walia Electronics in Karanjade?

Specialist Knowledge Tech-trained staff help you choose the right products and troubleshoot issues.

Genuine Brands & Warranty Only BR-certified products with full guarantees.

On-Site Repairs Minor fixes and part replacements are handled directly, often within hours.

Competitive Pricing Fair rates and price matching for local competitors.

Personalized Customer Interaction Custom recommendations based on your budget and lifestyle.

Products & Services Offered

Consumer Electronics

Smartphones, tablets

Bluetooth speakers & headphones

Smartwatches & wearables

Cables, chargers, memory cards, and accessories

Home Appliances

Mixer grinders, blenders

Electric kettles, irons

Fans, heaters, lighting equipment

Electronics Components

Wiring kits, switches, sockets

Connectors, resistors, fuses Similar to small-component sourcing on Lamington Road reddit.com+4en.wikipedia.org+4reddit.com+4.

Repair & Maintenance

Screen replacements

Gadget troubleshooting

Kitchen appliance servicing

Spare part replacements

After-Sales Support

Help with installation

Warranty servicing

Product replacement advice

Store Walkthrough: What to Expect at Walia Electronics

Warm Welcome – Friendly reception and instant availability.

Needs Assessment – In-depth questioning ensures the right solution.

Product Demos – Test devices firsthand (e.g., speaker quality, features).

Expert Advice – Honest insights on product pros and cons.

Quick Service – Repairs done professionally and promptly.

Transparent Billing – Marked invoices and clear cost breakdowns.

0 notes