#learn plc scada

Explore tagged Tumblr posts

Text

What Most People Miss When Picking an Aluminium Annealing Oven Supplier

A question people rarely ask upfront is, – What would be the long-term cost of a poorly made aluminium annealing oven?

Most would say it's just higher maintenance, but to be honest, this goes deeper. Poorly calibrated ovens can distort product consistency, eat up unnecessary energy, plus disrupt delivery cycles. That kind of inefficiency from an Aluminium Annealing Oven Manufacturer doesn’t just sting, but it bites. You don't need a fancy study to tell you that production downtime translates directly to lost business.

Investing in expensive aluminium, plus watching it get compromised due to unreliable heat control, is frustrating. That is why picking a solid manufacturer is not a checkbox but a critical business decision.

Quality Engineering = Reliable Results

A good aluminium annealing oven isn’t just a metal box with heat inside. It’s a calibrated system. Temperature uniformity, controlled atmosphere, even airflow—all of it needs to work together like a band that knows every beat. If your supplier cuts corners, you don’t get music, but noise.

Top manufacturers don't wing it. Rather, they engineer ovens based on real production needs. They offer specs tailored to your material thickness, loading capacity, plus throughput rates. That means fewer hot spots, better grain structure, as well as consistent mechanical properties across batches. That consistency shows in your end product. Whether you are in aerospace or cookware, those performance differences matter.

Customization Isn't Just a Fancy Option

Let us not pretend one-size-fits-all works here. If your oven can’t match your workflow, you are the one who will end up adjusting.

Reputable manufacturers take the time to understand your shop floor realities. Some offer PLC-based control panels with real-time diagnostics. Others go further—remote troubleshooting, integration with SCADA, or even hybrid heating systems for better energy control. If you want that, then don’t settle for someone who pushes catalogue models like discount furniture.

Also, consider space. Compact, vertical-load designs work better for smaller facilities. Large batch ovens with side-loading might suit high-volume operations. A good manufacturer won’t just know the options but walk you through them like a tech-savvy friend who cares.

Support Makes or Breaks the Deal

You get the oven, install it, and the supplier disappears. Months later, you are scrambling for replacement parts, or worse, training videos in a language your technicians can’t understand.

Look, machines break, even the well-made ones. What matters is how fast you get support. Manufacturers who value their clients have service teams, spare part availability, and real documentation. Not scanned PDFs from 2009.

Also, don’t underestimate the value of installation support or training. The learning curve for heat treatment systems can be steep. It is like owning a supercar. If you don’t know how to drive it right, you would not get the performance it is built for.

A Shortcut Is Not Really a Shortcut

So, why do people still go for the cheapest manufacturer? Price tags can be attractive. But once you factor in operating costs, quality control setbacks, plus replacement cycles, it doesn’t look like a deal anymore.

Sometimes, you have to think long game. That 15–20% you "save" upfront might cost double in missed deadlines and rejections. Good manufacturers provide meaningful warranties to support their goods. That type of certainty offers insurance against turmoil as well as peace of mind.

Final Thoughts

You don’t need the flashiest machine on the market. But you do need one that’s built right, plus comes from someone who’s not just trying to close a sale.

Choosing the right Aluminium Annealing Oven Manufacturer is about protecting your reputation, your timelines, as well as your sanity. If a supplier can’t keep your metal stable, how are they going to keep your operations stable?

0 notes

Text

usage of ARTIFICIAL INTELLIGENCE in sewer water treatment plants

Key Features and Technologies of Smart STPs

Advanced Monitoring and Instrumentation

– Sensors: Real-time monitoring of flow, pH, temperature, DO, ORP, ammonia, nitrate, turbidity, BOD, COD, TSS. – Level and flow transmitters: For influent, effluent, and sludge handling systems. – Smart flow meters and analyzers: Installed at critical points for continuous data acquisition.

Automation and Control

– PLC/SCADA Systems: Enables automatic process control, alarm management, and remote operations. – Distributed Control Systems (DCS): Used in large-scale plants for coordinated operations. – Variable Frequency Drives (VFDs): To optimize blower, pump, and motor operations. usage of ARTIFICIAL INTELLIGENCE in sewer water treatment plants

AI & Machine Learning

– Predictive modeling: For biological load changes and equipment failure. – Process optimization: AI adjusts aeration, dosing, and retention times in real-time. – Anomaly detection: Early identification of abnormal process behavior.

IoT and Cloud Integration

– Remote monitoring: Supervisors can access plant data from anywhere. – Cloud-based analytics: Long-term data storage, trend analysis, and performance benchmarking. – Mobile apps and dashboards: For operators, engineers, and municipal authorities.

Digital Twin Technology

– Virtual replication of the STP for simulation, fault analysis, and optimization. – Helps plan upgrades and test control strategies digitally before implementation.

0 notes

Text

Understanding MCC Panels: The Backbone of Motor Control Systems

In today’s fast-growing industrial sector, MCC panels play a crucial role in safely managing and operating multiple motors from a single control location. Whether you're in manufacturing, HVAC, or processing plants, choosing the right Motor Control Panel Manufacturer can help streamline operations, reduce downtime, and ensure equipment safety.

Modern MCC panels are engineered to enhance safety, reduce maintenance effort, and ensure seamless motor operation—all under one enclosure. This makes them an essential component for every plant where multiple motors are in use.

What Exactly is an MCC Panel?

MCC panels are widely used in industries for centralized motor control and protection. An experienced MCC manufacturer builds these panels with high-performance features that meet the dynamic demands of motor management. A trusted MCC Panels manufacturer ensures the panel includes every essential control and safety component, offering complete reliability for plant operations. Leading Motor Control Panel Manufacturers follow international standards for long service life.

Each motor starter operates an individual motor, and multiple starters are mounted within one MCC, allowing centralized and organized motor control.

In simple words, an MCC panel lets you start, stop, monitor, and protect motors—safely and efficiently—from one place.

Key Components of an MCC Panel

An MCC Panel manufacturer designs MCC panels with top-grade circuit breakers, relays, busbars, and control transformers. A reputable Motor Control Panel Manufacturer ensures these components work together for efficient motor control and long-term reliability. When you choose a certified MCC Panel Supplier or MCC manufacturer, you’re assured of safe, scalable, and serviceable panel configurations.

A well-designed MCC panel consists of:

Incoming & Outgoing Feeders – For power entry and distribution

Busbars – Made of copper or aluminium (sizes like 25×5 mm or 100×10 mm)

Contactor & Overload Relay – Controls motor and prevents overheating

MCBs or MCCBs – Provide short-circuit and overload protection

Control Transformer / SMPS – Supplies control voltage (24VDC or 110VAC)

Push Buttons & Indicators – For manual control and status display

Digital Monitoring Units – Optional modules for load, voltage, and fault display

Auxiliary Relays & Timers – For automation and sequencing

These components are mounted on compartmentalized sections inside the MCC panel, which ensures safe maintenance and separation between circuits.

Key Technical Features of MCC Panels

MCC Panels manufacturers build panels based on standard and custom specifications. Voltage ratings, IP protection, busbar size, and short-circuit capacity vary based on the requirement. A reliable MCC manufacturer or MCC Panel Supplier will offer current ratings from 100A to 6300A and enclosure ratings up to IP65. Partnering with a professional Motor Control Panel Manufacturer helps you meet operational and safety compliance standards effectively. As a reliable MCC manufacturer would offer, the latest MCC panels come with a range of modern features designed for safety, ease of use, and durability:

Rated Voltage: 415V AC / 690V AC

Short Circuit Withstand: Up to 50kA for 1 second

Starter Types Supported: DOL, Star-Delta, Soft Starter, VFD

Protection Levels: IP42 to IP65

Operating Temperature: –5°C to +55°C

Busbar Rating: From 100A up to 6300A

Control Voltage: 24VDC / 110VAC / 230VAC

Design Type: Fixed, Semi-drawout, Fully Drawout

Communication Ready: Optional PLC/SCADA interface support

Certifications: Follows IEC 61439, IS 8623, UL, NEMA standards

Want a better way to manage your motors? Learn how choosing the right MCC Panels Manufacturer can help you reduce downtime and improve control.

Why Are MCC Panels So Important?

MCC Panels are critical for centralized motor control, ensuring safe and efficient operation of multiple motors in industrial environments. A professional MCC Panels manufacturer designs these panels to streamline maintenance, reduce electrical hazards, and offer seamless automation integration. Choosing a skilled MCC manufacturer or a reliable Motor Control Panel Manufacturer ensures your plant runs smoothly with minimized downtime. Trusted MCC Panel Suppliers provide robust, scalable, and custom-built MCC panels tailored for demanding applications.

The role of MCC panels extends beyond motor starting. They are critical for:

Centralized Control: Operate, monitor, and manage all motors from one place

Energy Management: Control motor usage and reduce wastage

Space Optimization: Compact, clean layouts minimize panel footprint

Downtime Reduction: Easy fault detection and quick isolation of faulty motors

Future Expandability: Modular designs make upgrades and additions simple

Operational Safety: Secure wiring, interlocking systems, emergency stop functions

In large industries where dozens or even hundreds—of motors are in use, having an MCC panel ensures system reliability, operational visibility, and long-term cost savings.

Where Are MCC Panels Commonly Used?

MCC Panels are used in a wide range of industries such as cement, chemicals, water treatment, and HVAC systems. Every major MCC Panels manufacturer builds panels suitable for these sectors with customized feeders and starter combinations. A qualified Motor Control Panel Manufacturer offers scalable designs to meet plant-specific needs. Partnering with the right MCC Panel Supplier ensures safety and smooth motor operations.

Some top applications include:

Manufacturing Units: Motor control for assembly lines and machinery

Thermal & Hydroelectric Plants: Pump and turbine management

Water Treatment Facilities: Motorized valves and pump operations

Pharmaceutical & Chemical Plants: Precision control for production machinery

Cement Plants & Mining: High-torque motor systems

HVAC Systems in Commercial Buildings: Blower, chiller, and compressor control

Food & Beverage Processing: Timed and controlled automation

How MCC Panels Improve Safety

Safety is a major reason why industries invest in MCC panels. Every good Motor Control Panel Manufacturer focuses on building panels that reduce risks and protect both machinery and manpower.

Key safety features include:

Overload & Short Circuit Protection: Stops power supply to damaged motors

Interlock Mechanisms: Prevents access to live components

Emergency Stop Buttons: For immediate motor shutdown

Status Indicators: Shows live fault conditions

Insulated Busbars & Terminals: Prevent electrical shocks

Lockable Compartments: Ensures only trained staff can access sensitive areas

Proper Earthing and Grounding: Prevents fire and electrical hazards

These features ensure your operations run smoothly while staying within safety standards.

Conclusion

To conclude, MCC Panels are the backbone of safe, efficient, and centralized motor control. Whether you're expanding an existing setup or building a new plant, sourcing from a reliable MCC manufacturer or top-tier MCC Panel Supplier is essential. Choose an expert Motor Control Panel Manufacturer who provides tested solutions for your specific applications.

To sum it up, MCC panels are not just metal boxes filled with wires—they are strategically engineered systems that manage the lifeline of industrial operations: electric motors.

Need help selecting the right MCC panel for your plant? Consult with a trusted MCC manufacturer today and future-proof your motor control system.

#mcc#mcc panel#mcc panel manufacturer#motor control center#motor control center panel#electric control panel

0 notes

Text

Data Historian Market to Witness Strong Growth Backed by Digital Transformation Initiatives

Data Historian Market was worth USD 1.29 billion in 2023 and is predicted to be worth USD 2.26 billion by 2032, growing at a CAGR of 6.54% between 2024 and 2032.

Data Historian Market is evolving as industries increasingly rely on time-series databases to capture, store, and analyze large volumes of operational data. These systems play a pivotal role in sectors such as manufacturing, oil & gas, energy, and utilities by providing real-time visibility into process performance, predictive maintenance, and long-term trend analysis.

Data Historian Market continues to witness strong traction driven by the shift towards digital transformation and Industry 4.0 adoption. Businesses across the USA and Europe are leveraging these tools to ensure accurate data logging, seamless integration with SCADA and PLC systems, and faster decision-making based on historical trends.

Get Sample Copy of This Report: https://www.snsinsider.com/sample-request/3569

Market Keyplayers:

Amazon Web Services, Inc.

Google LLC

Duolingo, Inc.

Mojang Studios

Kahoot! ASA

Epic Games

Age of Learning, Inc.

Breakaway Games

Bublar Group

Frontier Developments

Playgen

Spin Master

Idnusgeeks

Gamelearn

Recurrence

Stratbeans

Tangible Play, Inc.

Simulearn

Raptivity

Banzai Labs

Cognitive Toybox

VR Education Holdings

Fundamental

Market Analysis

The market is experiencing substantial growth as organizations demand reliable systems to manage historical process data. Data historians offer the ability to store high-frequency data over long periods, allowing stakeholders to gain actionable insights for operational efficiency and compliance. The deployment of cloud-based historian solutions and the integration of AI and machine learning further enhance the usability of this technology across industries.

Market Trends

Rising adoption of cloud-native historian platforms

Integration with advanced analytics and AI for predictive insights

Increased demand in energy, oil & gas, and process manufacturing sectors

Focus on cybersecurity and secure data transmission

Enhanced mobile access and visualization features

Growing preference for edge-based historian solutions

Real-time data synchronization with enterprise applications

Market Scope

The Data Historian Market is expanding its footprint across critical industrial verticals, offering robust and scalable solutions to track and analyze plant data in real time. As industries prioritize operational intelligence, the scope of data historians is more vital than ever.

Seamless integration with legacy control systems

High-frequency data logging and storage optimization

Long-term historical data retention with minimal latency

Scalable solutions for plant-level to enterprise-wide deployment

Support for compliance reporting and audit trails

Centralized dashboards for visual analytics

Access Complete Report: https://www.snsinsider.com/checkout/3569

Forecast Outlook

The future of the Data Historian Market appears promising, fueled by the need for data-driven operational efficiency. As organizations in the USA and Europe continue to modernize their industrial ecosystems, demand for intelligent historian platforms will rise. Cloud-enabled infrastructure, enhanced data interoperability, and intelligent data modeling will define the next phase of market growth, offering smarter, more responsive systems for industrial users.

Conclusion

The Data Historian Market is no longer a niche domain—it's becoming central to modern industrial operations. With an increasing emphasis on automation, transparency, and performance optimization, businesses are turning to historian systems to turn raw data into strategic value. From smart factories in Germany to energy grids in the U.S., the role of data historians is expanding—making them a cornerstone in the journey toward intelligent industry transformation.

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Related Reports:

U.S.A Learning Management System Market sees rising demand for remote learning solutions

Contact Us:

Jagney Dave - Vice President of Client Engagement

Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

Mail us: [email protected]

0 notes

Text

High-Efficiency Reverse Osmosis Plants – Engineered for UAE Demands

When your operations rely on consistent, cost-effective water purification, trust Aqua Experts UAE—a leading name among Reverse Osmosis Plant Manufacturers in the UAE.

Our RO systems are purpose-built to handle brackish water, seawater, and complex industrial sources, delivering performance backed by smart automation and sustainable engineering.

⚙️ Why Choose Aqua Experts’ RO Plants?

✅ Energy-Efficient Designs – Reduce power consumption with high-recovery configurations ✅ Smart Automation – Integrated PLC/SCADA systems for real-time control and diagnostics ✅ Tailored Configurations – Custom-built to match your water source and industry needs ✅ Consistent Purity – Designed to meet UAE and international water quality standards

🏭 Ideal for Applications In:

• Industrial Manufacturing & Processing • Seawater Desalination Projects • Bottled Water Production • Infrastructure & Utility Water Systems

At Aqua Experts, we don’t just build RO systems—we deliver reliable, future-ready solutions that support sustainability, reduce operating costs, and ensure water purity where it matters most.

🔗 Learn More: Reverse Osmosis Plant Manufacturers in UAE

0 notes

Text

The Future of Industrial Growth with Automation Contractors in UAE

With the help of intelligence technologies and economic vision oriented toward the future, the United Arab Emirates (UAE) is fast becoming one of the world leaders in industrial innovation. Automation is one of the most dominant drivers towards this change. The automation contractors in UAE are not just enhancing efficiency in the operations of different industries today, but also reshaping industrial developments with smart and technology-driven solutions.

Automation in Increasing Dominance

Oil and gas, as well as the logistics sector to power generation and water treatment, industries in the UAE are welcoming automation as a way of remaining competitive and sustainable. The increased demand has also resulted in an increased number of specialized automation companies in UAE that provide end-to-end solutions, including system design and programming, maintenance, and support.

Tekzone, a market leader in the field, is offering customised EPC (Engineering, Procurement and Construction) and automation solutions to accommodate the emerging requirements of the projects in both the government and non-government sectors. Through the incorporation of sophisticated control systems, sensors, and software, Tekzone enables companies to complete an operation with ease and long-term productivity.

Per the UAE Vision 2030

A clear plan towards a diversified and knowledge-based economy is spelt out in the UAE Vision 2030. This can only be realized through the introduction of smart systems in the industrial sectors that enhance productivity but lower energy consumption rates and pollutant-emitting activities. The automation contractors in UAE work extensively towards this mission as well and provide solutions that can perfectly fit into the vision of the country, directed towards sustainable development.

Through the usage of smart technologies such as the SCADA, PLC, and IoT-equipped systems, vendors of automation can facilitate industries to keep track of their performance in real-time, mitigate operational risks, and make calculated decisions that result in cost savings and increased production.

Helping Smart Infrastructure and Mega Projects

The UAE has a reputation for possessing world-class infrastructure, and the prosperity of smart cities, industrial zones, and energy facilities depends largely on automation. Some of the infrastructure projects entail the skill of leading automation companies in UAE because of the effective implementation of the project, system integration, and maintenance.

An example of the same is that Tekzone has played a critical role in assuring ADNOC-approved projects and major developments in the region. This is because of their extensive knowledge of the industry and devotion to innovativeness, which enables them to provide scalable and reliable automation systems that can be used in complex industry settings.

Training Local People and Skills

Besides the technical implementation, the automation contractors in UAE are involved in the development of the national workforce. There is an increasing demand for automation, which is in turn necessitating a rise in the requirement for trained engineers, programmers, and technicians. Firms such as Tekzone are also spending their resources in training up the local talent by rolling out specialized training programs, workshops, as well as on-the-job learning opportunities.

Making Industrial Futures

Automation is also essential as the UAE is on the way toward becoming a global center of innovation. Alliances between the industries and automation companies in the UAE are spearheading quantifiable growth in productivity, sustainability, and competition. Of course, automation contractors in the UAE will continue being the foundation of industrial development in the country as long as its leading providers, such as Tekzone, maintain the trend towards thinking forward.

0 notes

Text

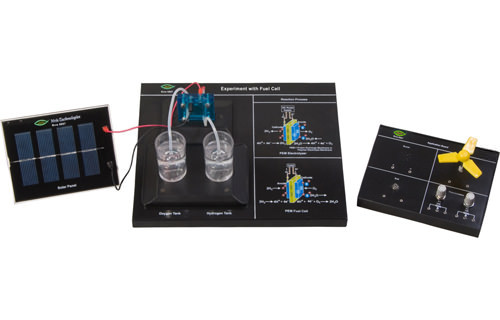

Best Lab Training Systems for Practical Learning in Engineering

In today’s rapidly advancing technical education landscape, hands-on training is no longer optional—it's essential. Whether you're an educator, institution, or student, integrating the Best Lab Training Systems into your curriculum is key to building future-ready skills. From embedded systems to communication labs and industrial automation, practical experience with real equipment bridges the gap between theory and industry requirements.

Let’s dive into how to choose the best lab training systems, their benefits, applications, and why sourcing from trusted electronic lab equipment providers in Indore can give you an edge.

What Are Lab Training Systems?

Lab training systems are structured educational setups that simulate real-world technical environments for students to learn and practice various engineering concepts. These systems include:

Microcontroller/Embedded System trainers

Electrical machines and power electronics labs

Communication lab kits (Analog, Digital, Optical, etc.)

IoT, Robotics, and PLC-based automation platforms

They are commonly used in engineering colleges, polytechnics, vocational institutes, and technical universities to enhance student employability.

Why Choose the Best Lab Training Systems?

Selecting the best lab training systems ensures:

Industry-aligned skill development

Increased student engagement through interactive learning

Long-term usability and safety

Support for NEP 2020 and other modern curriculum standards

Here’s what defines a great lab training system:

Key Features:

Modular Design: Expandable systems for flexible experiments

Real-Time Monitoring: Display outputs and waveform analysis

Compatibility: Supports multiple software and hardware platforms

Safety Measures: Fuse protection, current limiters, and more

Documentation: Comes with manuals, experiment sheets, and software

Applications Across Engineering Domains

The best lab training systems cover a broad spectrum of disciplines:

1. Electronics & Communication Engineering

Analog/Digital communication labs

Satellite & antenna trainers

Fiber optic kits

2. Electrical Engineering

DC & AC machine trainers

Power electronics experiment boards

Renewable energy integration modules

3. Embedded Systems & IoT

ARM/PIC/AVR microcontroller kits

IoT-based automation with cloud connectivity

Arduino/Raspberry Pi interfacing

4. Mechatronics & Industrial Automation

Pneumatic & hydraulic simulation platforms

SCADA & PLC-based labs

Smart factory simulation units

Why Buy from Electronic Lab Equipment Providers in Indore?

Indore has become a hub for high-quality electronic lab equipment manufacturing and innovation. Partnering with reliable electronic lab equipment providers in Indore offers:

Customization based on institutional syllabus

Reliable delivery and installation

Complete training and documentation

On-demand support and AMC (Annual Maintenance Contracts)

Advanced R&D-backed systems compliant with AICTE & NAAC norms

These suppliers not only understand local academic needs but also offer internationally competitive products.

How to Choose the Right Electronic Lab Equipment?

Here are essential factors to consider when selecting a lab training solution:

Technical Checklist:

Does it cover all required experiments?

Is the system upgradeable or modular?

Are the components industry-grade and durable?

Is software integration available (e.g., MATLAB, LabVIEW)?

Is there training support for faculty?

Real-World Outcomes of Lab Training Systems

Implementing the best lab training systems leads to:

Faster concept grasping through visual and tactile learning

Research and innovation by students and faculty

Increased placement rates due to hands-on exposure

Institutional ranking improvement through enhanced infrastructure

Institutions that emphasize experiential learning through training systems tend to produce more industry-ready engineers.

0 notes

Text

Industrial RO Plant Manufacturer In Ghaziabad

A sudden increase in the demand & requirement fulfilments for clean water solutions in Ghaziabad, which is an industrial hub in a well-located geographic location that has given way for Industrial RO plants to be installed & operated to resolve all water-related issues. Commercial RO Plant, the biggest & most important industrial RO plant manufacturer in Ghaziabad, is currently spearheading this water purification revolution. Commercial RO Plant's contemporary industrial RO plant systems serve customers in a range of residential as well as commercial environments, including small businesses & large manufacturing facilities.

The manufacturer of Industrial RO plants in Ghaziabad along with other water treatment industries will be thoroughly discussed. We will go over all the advantages of our systems, the cutting-edge technological advancements that Commercial RO Plant provides with top-notch amenities, & the way staffs at Commercial RO Plant are rewriting the water treatment industry's history in this particular field.

The steady & strong development of Industrial RO plants, particularly those made by Commercial RO Plant

The industrial atmosphere within the surroundings of Ghaziabad has been changed significantly in the last several decades. More effective water treatment technologies, such as these Industrial RO plants, are being installed as a result of increased legal requirements & public awareness of environmental protection along with water quality issues.

When they are performing at their best, Commercial RO Plant experts have witnessed this change on their own. Order lists are more comprehensive than ever before as commercial enterprises, especially those in the fabric textile, eateries, & pharmaceutical industries, have come to understand the value of having high-quality purified water. Because RO technology is configurable & customizable, it can be applied to eliminate impurities while decreasing total dissolved solids while maintaining a high standard of water quality.

Commercial RO Plant Description

The team of highly qualified professionals who work at this company such as Commercial RO Plant works tirelessly to develop & build industrial RO systems that satisfy our clients' demanding specifications.

Our ability to adapt allows us to offer the highest level of services to a wide range of commercial enterprises, from large power plants to tiny processing companies. Being the top noble Industrial RO plant manufacturer in Ghaziabad has gained itself a national reputation; Commercial RO Plant has significantly earned recognition for its unwavering dedication to quality & innovation through numerous accolades.

Crucial Features Commercial RO Plant designs & manufactures Industrial RO plants.

1) Better Membrane Integration: The most advanced thin-film membranes available, known for their long lifespan & significant rejection rate, are commonly employed by Commercial RO Plant or any other branches.

2) Technical Approaches for Automated Software Control: SCADA PLC-based control panels guarantee seamless operation with real-time, live data monitoring.

3) Systems for Pre-treatment: To preserve & prolong the service life of the RO membranes, pre-treatment modules & its processes are implemented.

4) Various Additional Treatments available with many options: In addition to various treatment methods for a variety of purposes, Commercial RO Plant provides restoration or many mineral contents & pH balancing systems, depending on the particular characteristics of the water.

The principal sequence of events that must be followed by for fabricating Industrial RO plants are as follows:

Procedures implemented in the manufacturing process to provide all of its customers with the highest quality of Industrial RO plants:

1) Design Development Stage: Our engineers collaborate directly with clients to learn about their needs, then figure out distinctive designs for RO plants.

2) Purchasing Parts or Other Related Components for the RO Plants: Commercial RO Plant buys instruments, pumps, including valves from reputable suppliers in addition to other premium parts.

Various Applications of Industrial RO Plants

Industries such as textiles, manufacturing of medicines, food & beverage production, power plants, along with other medical facilities including hospitals or hotels are just a few of the Ghaziabad industries that depend on our RO plant systems.

The advantages of utilizing Commercial RO Plant as Industrial RO plant manufacturer In Ghaziabad consist of:

Based on our long history of practical knowledge in the water treatment industry, we tackle every task with unparalleled expertise.

1) Flexibility in the Event of Change Depending on what the client expects: We can offer distinctive solutions that meet client requirements thanks to our most recent creative designs along with revisions or modifications.

2) Helps with the ultimate buying decision: We provide thorough maintenance agreements along with rapid technical assistance.

3) Economical: Reduced operating costs are the direct result of energy-efficient structures along with enhanced processes.

4) Enforcement & Implementation by Regulatory Terms: By ensuring that our methods meet & exceed regulatory requirements, we provide our clients with stability by meeting their needs.

Conclusion

Due to rising industrial demand along with concerns about water quality, the number of industrial RO plant manufacturer in Ghaziabad is rapidly increasing. Commercial RO Plant, the leading exporter or provider in this quickly evolving sector, has continuously pushed the limits of quality with imaginative thinking.

Commercial RO Plant is totally dedicated to providing the most specialized, reliable, as well as successful Industrial RO solutions, which might have propelled this business to the top of Ghaziabad's water treatment facilities.

#industrial ro plant#industrial ro plant manufacturer in ghaziabad#water treatment plant#save water#water is life#netsol water

0 notes

Text

The Role of Siemens PLC in Modern Packaging and Textile Automation

In the Industry 4.0 era, industries are swiftly opining for the advent of smarter and more efficient interconnected manufacturing setups. In such an array of gears to bring about a change, Siemens PLC finds itself as the foremost means of automating all industrial processes, particularly in the packaging and textile sectors.

Faster processing of goods, reductions in downtime, and enhancement in product quality: Siemens PLC has really changed the ways in which textile plants and packaging plants operate.

Learn more, Why Siemens PLC is a Smart Investment for Packaging and Textile Plant Automation

What Is Siemens PLC and Why Is It So Important?

The Siemens PLC controller is a digitally enhanced computer for automation of industrial processes, machinery control, line automation, and monitoring. Unlike traditional control systems, the Siemens PLCs are modular, scalable, and developed for real-time applications. They allow a plant operator to define automation for repetitive tasks, thus enhancing productivity and reducing human error.

In packaging and textile industries, where speed, precision, and reliability are keys, the PLC Siemens solution is the backbone of operations.

Packaging Industry: Rapid, Smart, and Safe by Siemens PLC

There are quick-changeovers, accurate measurements, and faultless operations that must be fulfilled by the packaging industry. Siemens PLC supports the following ways to satisfy these expectations:

Motion Control: Where milliseconds matter in packaging lines, the Siemens PLC controller provides for the smooth and synchronous movement of conveyor belts, robotic arms, and filling stations.

Testing for Flaws and Quality Control: Real-time monitoring lets Siemens PLC detect packaging faults or errors, thus removing defective units automatically and decreasing product recalls.

Flexibility and Changeover: Nowadays, packaging lines change product sizes and packaging materials. A Siemens PLC allows for easy changeovers and reprogramming with minimal downtime.

Integration with Sensors and Vision Systems: Siemens PLC can integrate with sensors, barcode scanners, and camera systems to assure product integrity.

Learn more, The Impact of Siemens PLC on Mining and Heavy Equipment

Textile Industry: Seamless Automation to Maintain Output Consistency

Textile production is a multi-stage process consisting of weaving, dyeing, printing, and cutting. These processes are subjected to requirements of uniform quality and speed. Siemens PLC technology provides a great solution, handling this challenge efficiently.

Process Control with Precision: In dyeing, temperature control is considered, whereas in weaving machines, pressure and speed must be controlled, and the Siemens PLC controller ensures these operations are set within their parameters.

Real-Time Monitoring: PLC Siemens supports operators to prevent bottlenecks from hindering their performance metrics and thus measures performance.

Downtime Reduction: Predictive maintenance aids in reducing failures induced by unexpected malfunctions with the implementation of Siemens PLC.

Energy Efficiency: During plant operation, energy consumption is on the higher side. On this aspect, Siemens PLC helps in machine operations so that the power wastage gets minimized, and the plants are in tune with sustainability.

Why Should Siemens PLC Be Considered for Your Plant-Impartment Needs?

Modular and Scalable: Whatever it be, a small setup or a completely integrated smart factory, Siemens PLC will be customized to fit your requirements.

Proven Reliability: Being in use for decades and well known across the globe, Siemens PLCs uphold the highest standards of track records in durability and longevity.

Advanced Connectivity: Siemens PLC supports modern communication protocols such as PROFINET and MODBUS, which allow it to integrate smoothly with HMI and SCADA systems and with ERP systems.

Remote Access and Control: Using the Siemens TIA Portal and other tool software, operators and managers have the ability to monitor and control operations remotely.

Explore our detailed post on Siemens PLC: Benefits of Using it in Industrial Automation

Conclusion

With growing requirements for efficiency, quality, and automation within the packaging and textile sectors, having a reliable control system is not an option anymore; it is a necessity. Naksh Technology Solutions LLP recognizes this need and offers solutions by Siemens. By equipping themselves with a Siemens PLC, companies keep the industrial landscape evolving toward a competitive realm where greater control and cost reduction are regarded as benchmarks.

Whether you are setting up a new automation line or retrofitting existing machinery, the Siemens PLC controller presents a forward-looking, flexible, and scalable solution genuinely in support of the goals of modern manufacturing.

0 notes

Text

Are you familiar with Mitsubishi’s FX5‑OPC module?

It transforms the FX5 PLC into an OPC UA server, enabling secure, direct SCADA/HMI/MES access no gateway computer needed

Learn how to connect and configure this module here:

0 notes

Text

Diploma in Electrical Engineering in Pune – Empower Your Future in Core Engineering

Looking for a career in the power, automation, or electrical sector? The Diploma in Electrical Engineering in Pune offered by Adarsh Paramedical Institute is the ideal stepping stone for students aspiring to join core industries.

Our Electrical Engineering course is a skill-based polytechnic program designed to equip students with both theoretical knowledge and hands-on training in electrical circuits, systems, and technologies. With a growing demand for technicians and engineers, this course is a smart career choice.

⚡ Why Choose Electrical Engineering?

Electrical engineers are vital across industries like construction, power plants, manufacturing, maintenance, and renewable energy. Our course covers:

Electric circuits and wiring systems

Electrical machines and transformers

Power generation and distribution

Safety, troubleshooting, and maintenance

PLC, SCADA, and automation basics

Graduates are well-prepared for jobs or further technical studies.

📍 Electrical Engineering in Hadapsar, Bhosari & Wadki

We offer the Electrical Engineering Diploma across major learning hubs in Pune:

Electrical Engineering Diploma in Hadapsar – Access modern labs, real-time practicals, and expert faculty in East Pune.

Diploma in Electrical Engineering in Bhosari – Located near major industrial zones, this center focuses on job-ready training and placement support.

Electrical Engineering Diploma in Wadki – Ideal for students in and around Wadki who want affordable and quality education close to home.

Whether you're in an urban or semi-urban area, Adarsh brings industry-standard training to your doorstep.

🔌 Polytechnic Diploma in Electrical Engineering Pune

Our Diploma in Electrical Engineering in Pune is part of our polytechnic stream and is perfect for students who’ve completed their 10th or 12th grade. With a duration of 3 years, the program emphasizes practical learning and industry exposure.

Job roles after this course include:

Electrical Technician

Site Engineer

Maintenance Engineer

Control Panel Designer

Electrical Draftsman

We also guide students who wish to pursue a B.Tech/B.E. later.

🏫 Why Adarsh Paramedical Institute?

ISO-certified polytechnic institute in Pune

Industry-experienced trainers and lab assistants

100% job assistance after course completion

Practical workshops and electrical safety training

Affordable fees and easy admission process

We take pride in shaping future-ready professionals across Hadapsar, Bhosari, and Wadki.

📞 Apply now at 👉 https://adarshparamedical.com/electrical-engineering.html and join the best Diploma in Electrical Engineering Pune to power up your career!

#Diploma in Electrical Engineering Pune#Electrical Engineering#Electrical Engineering Diploma in Hadapsar#Diploma in Electrical Engineering Bhosari#Electrical Engineering Diploma Wadki#Electrical Engineering course

0 notes

Text

RDEC vs. Other Engineering Colleges in Ghaziabad – What Sets It Apart?

Ghaziabad, a rapidly growing educational hub in the Delhi–NCR region, hosts numerous institutions vying for recognition as a top engineering college in Ghaziabad. Among them, R.D. Engineering College (RDEC) distinguishes itself—not only as a reliable engineering college in Ghaziabad, but also as a notable option for those seeking a low fees engineering college in India without compromising quality.

RDEC: A Blend of Quality and Affordability

Modern campus: Spread across 12–15 acres near NH‑58, RDEC features air‑conditioned labs, a vast library, gym, sports facilities, Wi‑Fi, and separate boys' and girls' hostels.

In-house training: RDEC’s “Industrial Training and Corporate Resource Center” offers free, expert-led training in technologies like ML, AI, IoT, Python, Java, PLC/SCADA, AutoCAD, and more—tightening the curriculum-to-industry gap.

Strong placements: Recruiters include Wipro, Infosys, NIIT, and Ericsson.

Research exposure: Over 70 papers published

Recognitions: Multiple awards like “Best Emerging College of Western UP” and high AKTU percentile rankings .

Fee structure: Approximately ₹85k/year fees for B.Tech, making it more affordable than many peers.

How RDEC Stacks Up Against Other Ghaziabad Colleges

When compared to other engineering colleges in Ghaziabad, RDEC offers a highly competitive value proposition.

In contrast, RDEC provides quality technical education at a significantly lower cost, with annual fees of approximately ₹85,000 and good placement packages. This positions RDEC as a standout low fees engineering college in India, especially when paired with its unique in-house training in technologies like AI, IoT, Python, and Data Science—offered at no extra cost from the first year. With over 70 student research papers, national-level awards, and consistent industry partnerships, RDEC holds its ground firmly among the top engineering colleges in Ghaziabad.

Why RDEC Stands Out

Affordability: As a low fees engineering college in India, RDEC's ~₹85k/year makes it one of the most cost-effective in Ghaziabad.

Comprehensive training: Few colleges offer such extensive, free in‑house tech training from Year 1—a key differentiator.

Early academic start: Sessions begin in July, giving students crucial prep time post-12th grade.

Research edge and awards: With 70+ papers, innovation labs, and noteworthy accolades, RDEC fosters both learning and innovation .

Student Feedback

Feedback on RDEC is generally positive:

“Faculty … friendly … campus … beautiful… provide us in campus training about mern stack…”

Conclusion

If you're searching for a top engineering college in Ghaziabad that offers hands-on tech training, solid placements, and research exposure—all at low fees—RDEC is a standout option. Peers like KIET or ABES may offer slightly higher salaries but at significantly higher annual costs. Ultimately, RDEC strikes an ideal balance, offering a compelling blend of educational quality and affordability in Ghaziabad’s engineering landscape.

To begin your journey with RDEC, apply for admission here.

1 note

·

View note

Text

Trusted RO Plant Manufacturers in the UAE – Built for Performance, Engineered for Purity

When water quality directly impacts your operations, choosing the right RO system provider becomes a critical business decision.

At Aqua Experts UAE, we design and manufacture advanced Reverse Osmosis (RO) plants tailored to the specific demands of industrial and commercial sectors across the UAE.

⚙️ What Makes Our RO Plants Stand Out:

✅ High Recovery Rates – Engineered to minimize water wastage and maximize yield ✅ Custom-Built Configurations – Designed for brackish, seawater, and municipal water sources ✅ Integrated Automation – PLC & SCADA systems for smart control and real-time monitoring ✅ Full Regulatory Compliance – Built to meet UAE and international water quality standards

🏭 Industries We Support:

• Manufacturing & Processing Plants • Hospitality & Commercial Establishments • Bottled Water Production Facilities • Power & Utility Infrastructure

From compact RO units to turnkey industrial plants, Aqua Experts delivers purity, performance, and peace of mind—every time.

🔗 Learn More: Reverse Osmosis Plant Manufacturers in UAE

#ROPlants #ReverseOsmosisUAE #WaterPurification

0 notes

Text

Sunflame PAC-3 NEP 16T 94V-0 Programmable Analog Controller | Industrial Automation Parts

Introducing the Sunflame PAC-3 NEP 16T 94V-0 Programmable Analog Controller, the perfect solution for enhancing your industrial automation systems. This highly efficient, durable, and precise controller is designed for a wide range of applications across industrial and process automation sectors.

At Ram Automations, we provide high-quality industrial automation parts from leading brands to ensure your systems perform at their peak. The Sunflame PAC-3 NEP 16T 94V-0 is ideal for precision control, offering flexibility and reliability, making it a crucial component in any automation setup.

🛒 Purchase Now from Ram Automations 👉 https://ramautomations.com/products/sunflame-pac-3-nep-16t-94v-0-programmable-analog-controller-used

🌐 Explore Thousands of Automation Components 👉 https://ramautomations.com

🧩 Product Specifications

• 🔹 Brand: Sunflame • 🔹 Model: PAC-3 NEP 16T 94V-0 • 🔹 Type: Programmable Analog Controller • 🔹 Category: Industrial Automation Controller / Analog Controllers / Process Automation Parts • 🔹 Applications: Industrial Automation, Process Control, Robotics, Control Systems

✅ Key Features

✔️ Programmable analog control for precise operations ✔️ High reliability and long-lasting performance ✔️ Seamless integration into industrial automation systems ✔️ Flexibility in configuring and programming to specific needs ✔️ Compact design with high operational efficiency ✔️ Supports advanced control and monitoring in industrial setups

💡 Applications Include:

• Industrial Process Control Systems • SCADA and PLC Control Systems • Process Automation for Manufacturing Plants • Robotics and Mechatronics Control • Power Control and Distribution Systems • Energy Monitoring and Management • Automated Testing Systems

🌟 Why Choose Ram Automations?

✅ Trusted Supplier of High-Quality Automation Components ✅ Competitive Prices for Industrial Parts ✅ Fast Delivery & Customer Support ✅ One-Stop Shop for Reliable, Hard-to-Find Automation Parts

🎥 In This Video You Will Learn:

🔎 Close-Up of the Sunflame PAC-3 NEP 16T 94V-0 Controller 🔧 How to Integrate the PAC-3 Controller into Your Systems 💡 The Benefits of Programmable Analog Controllers 🌍 Why Choose Ram Automations for Industrial Components

📣 Stay Connected!

🔔 Subscribe for more Industrial Automation Insights 👍 Like if You Value High-Performance Automation Solutions 💬 Leave a Comment – We’re Happy to Assist

1 note

·

View note

Text

Best Industrial Automation Courses in 2025

Introduction

Industrial automation is becoming a vital part of modern manufacturing and production. In 2025, as industries move towards smarter technologies, learning automation skills has become important for students, engineers, and technicians. If you are planning a career in this field, choosing the right course is the first step toward success.

What is Industrial Automation?

Industrial automation involves using machines, control systems, and software to operate processes with minimal human involvement. This includes the use of PLCs (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition), robotics, and sensors. These systems help improve efficiency, safety, and productivity in industries.

Why Learn Industrial Automation in 2025?

In today’s competitive job market, industries are looking for professionals who understand automation systems. Companies are shifting to smart factories and using advanced tools to monitor, control, and improve their operations. Learning industrial automation gives you the skills needed for jobs in manufacturing, production, maintenance, and system design.

Top Course Features to Look For

When choosing an industrial automation courses in 2025, here are the key features to consider:

1. Beginner to Advanced Levels

Look for a course that suits your experience level. Beginners can start with the basics of PLC programming, wiring systems, and sensors. Advanced learners should look for topics like SCADA systems, robotics, and industrial IoT.

2. Hands-on Training

Good courses offer practical sessions using real or simulated automation systems. These labs help you understand how automation works in real-life industrial settings.

3. Industry-Relevant Tools

Make sure the course includes popular software and tools used in the industry such as Siemens TIA Portal, Allen Bradley PLCs, HMI design, and robotic arms.

4. Flexible Learning Options

Courses that are available in online, offline, or hybrid formats are best suited for different learning needs. Online courses are great for self-paced learning, while classroom sessions offer better interaction and direct support.

5. Certifications and Placement Support

Courses that provide a certificate of completion or industry-recognized credentials can help boost your resume. Some institutes also offer placement assistance or internship opportunities.

Who Should Enroll?

Diploma or engineering students interested in electrical, mechanical, or instrumentation fields

Working professionals looking to upgrade their skills

Anyone interested in the future of smart manufacturing

Conclusion

2025 is the perfect time to learn industrial automation as industries continue to evolve with new technologies. Choose a course that matches your learning goals and provides hands-on experience with real-world tools. By gaining the right skills and knowledge, you can build a strong career in the growing field of industrial automation.

0 notes

Text

Industrial Cybersecurity Solutions: Protecting Critical Infrastructure and Operations

Industrial cybersecurity solutions are essential for safeguarding critical infrastructure, manufacturing facilities, and industrial control systems (ICS) from cyber threats. As industries become increasingly digitized and interconnected, the risk of cyberattacks targeting operational technology (OT) grows exponentially.

These cybersecurity solutions are designed to protect SCADA systems, PLCs, DCS, and IoT devices that control machinery, production lines, energy grids, and other essential industrial processes. Unlike traditional IT security, industrial cybersecurity focuses on maintaining operational uptime, safety, and data integrity within complex industrial environments.

Key components of industrial cybersecurity solutions include network segmentation, intrusion detection and prevention systems (IDPS), endpoint protection, vulnerability management, and real-time threat monitoring. Specialized firewalls for OT networks help isolate and protect critical systems from external and internal threats.

One major concern in industrial environments is the risk of ransomware, malware, or targeted attacks that can disrupt production, damage equipment, or compromise safety. Cybersecurity solutions deploy anomaly detection powered by AI and machine learning, allowing operators to identify unusual activities before they escalate into major incidents.

Additionally, industrial cybersecurity includes secure remote access controls, ensuring that vendors, technicians, and engineers can access systems safely without exposing the network to unnecessary risks.

Regular risk assessments, compliance checks, and employee cybersecurity training are crucial parts of a complete solution, helping organizations meet standards like NIST, IEC 62443, and ISO 27001.

In summary, industrial cybersecurity solutions are critical for ensuring the safety, reliability, and continuity of industrial operations. They protect against evolving cyber threats while enabling businesses to embrace digital transformation confidently and securely.

0 notes