#lyophile

Explore tagged Tumblr posts

Text

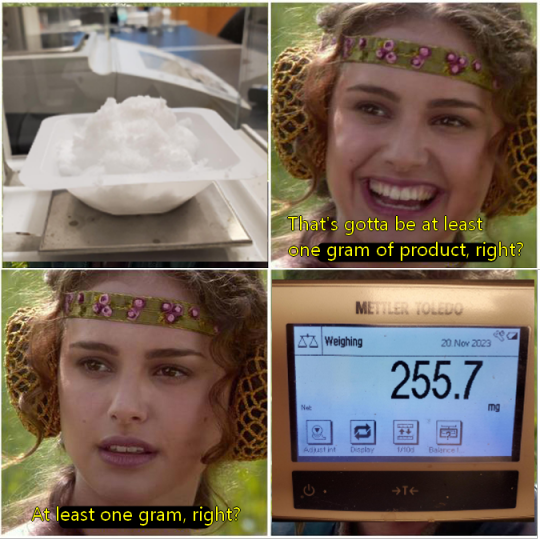

#Fluffy products fresh off the lyophilizer lie to my face all the time#I had to take product out of about 30 50 mL conicals for this little too#this sort of thing happens regularly and gives me trust issues#science#chemistry#organic chemistry#graduate school#graduate student#chemistry memes#organic chemistry memes#science memes

132 notes

·

View notes

Text

[Lyophilize.]

6 notes

·

View notes

Text

Lyophilizer Manufacturer in India: Trusted Freeze Drying Solutions by LyoGroup

In the rapidly evolving sectors of pharmaceuticals, biotechnology, research, and food processing, precision and product stability are non-negotiable. This is where lyophilization—also known as freeze drying—becomes essential. For businesses seeking dependable technology and long-term performance, finding the right Lyophilizer Manufacturer In India is crucial.

Enter LyoGroup – India’s Leading Lyophilizer Manufacturer

As a trusted name in the freeze-drying industry, LyoGroup specializes in designing, manufacturing, and supporting high-performance lyophilizers tailored to meet the stringent needs of Indian and global clients. With a focus on innovation, customization, and GMP compliance, we are empowering industries to achieve long-lasting product preservation and process efficiency.

What is a Lyophilizer?

A lyophilizer (or freeze dryer) is a specialized machine that removes water from perishable materials by freezing them and then using a vacuum to allow the ice to sublimate. This method retains the material's original structure, potency, and shelf life—making it ideal for:

Pharmaceuticals (e.g., vaccines, biologics)

Biotechnology (e.g., DNA, enzymes, antibodies)

Food & Nutraceuticals (e.g., fruit powders, herbal extracts)

Diagnostics and Chemical Reagents

Why Choose LyoGroup as Your Lyophilizer Manufacturer in India?

LyoGroup brings over a decade of engineering expertise and customer-first innovation to every project. Here's what makes us the preferred lyophilizer supplier across India:

Complete Range of Lyophilizers

We manufacture freeze dryers for every scale:

Laboratory Lyophilizers – Ideal for R&D and sample testing

Pilot Scale Freeze Dryers – For scale-up studies and pre-commercial runs

Industrial Lyophilizers – Fully automated GMP-compliant systems for large-scale production

Custom-Built Systems

Each lyophilizer is engineered to match your application, batch size, process requirements, and regulatory standards.

Advanced Automation & Monitoring

Our systems feature:

PLC/SCADA control panels

Touchscreen HMIs

Data logging and real-time monitoring

21 CFR Part 11 compliance (optional)

Local Manufacturing & Service

As an Indian manufacturer, we offer fast delivery, local support, and affordable pricing—without compromising on international quality standards.

Industries We Serve

LyoGroup’s lyophilizers are widely used across:

Pharmaceutical manufacturing units

Biotech R&D labs

Food processing plants

Veterinary medicine companies

Academic and government research institutions

We help clients reduce waste, improve shelf life, and meet global export requirements.

Key Features of Our Lyophilizers

High-efficiency vacuum pumps

Uniform shelf temperature distribution

Stainless steel chamber construction (SS304/316L)

Optional Clean-in-Place (CIP) & Sterilize-in-Place (SIP) systems

Low energy consumption

Minimal maintenance with long operational lifespan

Why Now is the Right Time to Invest in a Lyophilizer

India’s pharmaceutical and biotech sectors are growing rapidly, driven by exports, innovation, and government initiatives. Investing in a reliable lyophilizer from a reputed Indian manufacturer like LyoGroup ensures:

Regulatory readiness (GMP/FDA compliance)

Consistent product quality

Higher return on investment

Fast and reliable support network

Partner with the Leading Lyophilizer Manufacturer in India—At LyoGroup, we don’t just sell machines—we build long-term partnerships. From consultation and custom design to validation and technical support, our team is committed to your success.

Visit us: Lyophilizer Manufacturer in India – LyoGroup

0 notes

Text

Leadership in Pharmaceutical Preparations | Asence Pharma

Meet Asence Pharma's leadership driving innovation in synthetic active ingredients, lyophilized injections, and fermentation-based pharmaceutical preparations.

#Pharmaceutical Preparations#Synthetic Active Ingredients#Fermentation based plant#Lyophilized injections#Anti Allergics

0 notes

Text

Food lyophilization equipment market is expected to reach USD 2.12 billion by 2034, growing at a CAGR of 5.7% over the forecast period.

Global Food Lyophilization Equipment Market size and share is currently valued at USD 1.22 billion in 2024 and is anticipated to generate an estimated revenue of USD 2.12 Billion by 2034, according to the latest study by Polaris Market Research. Besides, the report notes that the market exhibits a robust 5.7% Compound Annual Growth Rate (CAGR) over the forecasted timeframe, 2025 – 2034 Market…

#Food lyophilization equipment market#Food lyophilization equipment market Growth#Food lyophilization equipment market Size#Food lyophilization equipment market Trends

0 notes

Text

pharmaceutical manufacturing company | lyophilized injection manufacturers in india | Alde Medi

As one of the top lyophilized injection manufacturers in India, we cater to both domestic and international markets, delivering excellence in every dose. Our experienced R&D team ensures strict quality control, advanced formulation processes, and timely delivery to meet your specific contract manufacturing requirements.

Whether you are a pharma brand looking to outsource manufacturing or a startup seeking affordable injection manufacturing services in Delhi, Alde Medi is your trusted partner. We maintain compliance with global standards and serve across therapeutic segments like antibiotics, anti-infectives, and critical care.

Website www.aldemedi.com/home

Email: [email protected] Phone: +91 114165 2813

Address: 71/2C, First Floor, Rama Road, Najafgarh Road Industrial Area, New Delhi – 110015

#pharmaceutical manufacturing company#injection manufacturing company in Delhi#lyophilized injection manufacturers in India#third-party pharma manufacturing#pharma companies in India#sterile injectable manufacturer#contract manufacturing pharma#Alde Medi

0 notes

Text

Sermorelin Injection 5mg Lyophilized Powder GHRH Analog – A2Z RX

At A2Z RX, we understand the growing demand for effective, science-backed hormone therapies. One standout option is Sermorelin Injection 5mg Lyophilized Powder GHRH Analog, a synthetic peptide that mimics Growth Hormone-Releasing Hormone (GHRH). This treatment stimulates the pituitary gland to naturally increase human growth hormone (HGH) production—ideal for individuals experiencing age-related HGH decline or hormone imbalance.

Sermorelin injection 5mg lyophilized powder GHRH analog is widely appreciated for its safety profile and regenerative benefits. When reconstituted and administered properly, it can support improved sleep quality, enhanced metabolism, increased lean muscle mass, and better recovery.

A2Z RX provides high-quality sermorelin formulations, ensuring purity and efficacy for optimal results. As always, consult a licensed healthcare professional before starting any hormone therapy. Whether you’re seeking anti-aging support or recovery enhancement, sermorelin injection 5mg lyophilized powder GHRH analog may be a valuable addition to your wellness routine.

0 notes

Text

Lyophilizer Machine In Maintaining Product Quality

A Lyophilizer Machine also known as a freeze dryer, is a vital piece of system applied in a method called lyophilization or freeze-drying. This approach includes freezing a product and then eliminating the ice via sublimation, in which the strong ice without delay turns into vapor without passing through the liquid segment. The number one characteristic of a lyophilizer is to maintain perishable substances, specially the ones which might be sensitive to warmth or moisture, through drying them at low temperatures. This approach is particularly essential for preserving the quality, integrity, and potency of touchy substances like prescription drugs, food, and natural materials.

The working precept of a Lyophilizer Machine in China revolves across the 3 most important tiers of freeze-drying: freezing, number one drying (sublimation), and secondary drying (desorption). First, the cloth to be freeze-dried is frozen to a very low temperature, regularly around -40°C to -80°C. This is commonly achieved in a freezing chamber wherein the cloth is subjected to fast cooling. Once frozen, the cloth is moved into a vacuum chamber. In the vacuum chamber, stress is decreased notably, which lowers the boiling element of water, causing the ice to transition at once into vapor without becoming liquid. This method is known as sublimation, and it gets rid of most of the water content material from the fabric. After the primary drying phase, the product undergoes a secondary drying section, where any last moisture is removed via desorption. This final degree guarantees the product is freed from moisture and stable for long-time period storage.

Lyophilizer Machine Supplier in China are broadly used throughout various industries, especially in which the protection of sensitive merchandise is vital. In the pharmaceutical industry, lyophilization is important for maintaining drugs, vaccines, and biologics that would lose their efficacy if uncovered to excessive temperatures. Freeze-drying permits for the garage and transportation of vaccines and other temperature-touchy prescribed drugs at room temperature, without compromising their effectiveness. Lyophilizers also are important inside the production of injectable medicinal drugs, wherein keeping sterility and bioactivity is a pinnacle precedence.

In the meals organisation, Lyophilizer Machine is used to hold food products like end result, greens, meats, and prepared-to-devour food. Freeze-dried food preserves a good deal of their specific flavor, nutritional rate, and texture. One of the key blessings of lyophilization in meals safety is its functionality to maintain food mild-weight and compact at the identical time as extending shelf life, making it quality for emergency elements, camping, and long-term meals garage. Freeze-dried food may be rehydrated fast, making them convenient for clients who want nutritious meals without the want for refrigeration.

In biotechnology and studies, lyophilizers play an essential characteristic in retaining organic materials including enzymes, proteins, and cellular cultures. These substances are frequently sensitive to warmness and moisture, and lyophilization is one of the best techniques to maintain their stability. Freeze-drying lets researchers store organic samples for prolonged periods without refrigeration, that is mainly critical for prolonged-time period research or for delivery samples at some stage in the globe without compromising their integrity.

The cloth used inside the construction of a lyophilizer is also essential. Most lyophilizers are made from exceptional stainless-steel, this is long lasting, evidence in opposition to corrosion, and clean to easy. The machines typically encompass a freezing chamber, a vacuum chamber, and a condenser, which captures the sublimated vapor. Some superior lyophilizers are ready with automated controls and monitoring systems to make sure specific temperature, strain, and humidity conditions during the procedure.

Lyophilizer Machine Manufacturer in China are a big investment, however they provide a big number of benefits for industries that rely upon top notch maintenance strategies. From food merchandise to pharmaceutical drugs, the ones machines assist make sure that substances remain solid, safe, and powerful for extended periods. Their ability to preserve the physical and chemical houses of a product makes them a useful device in the safety of sensitive substances.

0 notes

Text

Eye, Ear, Nasal Drops Manufacturers in India - Grecian

Grecian Pvt. Ltd is highly known as one of the leading Eye, Ear, Nasal Drops Manufacturers in India. Our accessibility to a complete range of eye, ear, and nasal products makes us one of the finest manufacturing companies in the country. We adopt the latest technologies emerging in the pharmaceutical sector. Grecian Pvt. Ltd. is achieving all-round success compared to other pharma companies in the same domain, thanks to our precise delivery schedules and dedicated teams. We are also proudly recognized as one of the Best Pharma Drops Manufacturers in India.

Contact us Today.

#Nasal Drops Manufacturers#Lyophilized injection manufacturers#Ayurvedic product manufacturer in India#Herbal Manufacturers#Ointments#Creams & Lotions manufacturers#Anti-cancer drug exporters#Contract manufacturing pharma

0 notes

Text

Top-Rated Lyophilizer Machine For Scientific Use

A Lyophilizer Machine also referred to as a freeze dryer, eliminates moisture from products by freezing them after which using vacuum sublimation. It preserves biological materials, prescription drugs, and food without detrimental structure or nutrients. Lyophilizers are essential in labs, clinical manufacturing and meals processing for a long-time period, strong garage of sensitive objects.

0 notes

Text

Freeze Drying Equipment Market Size, Trends & Forecast 2025–2032

Meticulous Research®—a leading global market research company, published a research report titled ‘Freeze Drying Equipment Market—Global Opportunity Analysis and Industry Forecast (2025-2032)’. According to this latest publication from Meticulous Research®, the freeze drying equipment market is projected to reach $8.4 billion by 2032, at a CAGR of 7.9% from 2025–2032.

The growing use of the lyophilization process for food preservation, advancements in automation within the lyophilization method, and the rapid expansion of the cosmetics and personal care products sector are key factors driving the growth of the freeze drying equipment market. However, market growth is hindered by high capital costs and stringent regulatory compliance requirements.

Additionally, the rising demand for lyophilized products in the pharmaceutical industry and increasing investments in R&D laboratories present significant opportunities for market players. However, the market faces challenges such as complex operating procedures and competition from alternative drying methods. Moreover, miniature & portable freeze drying units and customized freeze drying solutions are prominent technology trends in the freeze drying equipment market.

Key Players:

The freeze drying equipment market is characterized by a moderately competitive scenario due to the presence of many large- and small-sized global, regional, and local players. The key players operating in the freeze drying equipment market are GEA Group Aktiengesellschaft (Germany), Tofflon Science and Technology Co., Ltd (China), Labconco Corporation (U.S.), Azbil Corporation (Japan), Millrock Technology, Inc. (U.S.), Cuddon Freeze Dry (New Zealand), HOF Sonderanlagenbau GmbH (Germany), I.M.A. Industria Macchine Automatiche S.p.A. (Italy), ZIRBUS technology GmbH (Germany), MechaTech Systems Ltd (U.K.), BÜCHI Labortechnik AG (Switzerland), OPTIMA packaging group GmbH (Germany), Scala Scientific B.V. (Netherlands), Martin Christ Gefriertrocknungsanlagen GmbH (Germany), and Biopharma Process Systems Ltd. (U.K.).

The freeze drying equipment market is segmented based on component, type, scale of operation, and application. The report also evaluates industry competitors and analyzes the freeze drying equipment market at the regional and country levels.

Among the components studied in this report, the loading & unloading systems segment is anticipated to hold the dominant position, with a large share of the freeze drying equipment market in 2025. The increased utilization of laboratory and pilot-scale freeze drying equipment, automation in loading and unloading systems to minimize manual labor, and higher production rates in the industrial sector are key factors contributing to the segment's dominant position in the freeze drying equipment market.

Among the types studied in this report, the tray freeze dryers segment is anticipated to hold the dominant position, with a large share of the freeze drying equipment market in 2025. The increased use of tray freeze dryers to enhance drying efficiency and reduce processing time, their cost-effectiveness compared to other types, and the growing demand for freeze-dried products across industries such as pharmaceuticals, food, and biotechnology are key factors contributing to the segment's dominant position in the freeze drying equipment market.

Among the scale of operations studied in this report, the production freeze drying equipment segment is anticipated to hold the dominant position, with a large share of the freeze drying equipment market in 2025. The rising demand for freeze dryers across industries such as pharmaceuticals, food, and biotechnology, driven by the need for larger-scale production capabilities, continuous advancements in freeze drying technology, and a heightened focus on product quality and safety, are key factors contributing to the segment's dominant position in the freeze drying equipment market.

Among the applications studied in this report, the food processing & packaging segment is anticipated to hold the dominant position, with a large share of the freeze drying equipment market in 2025. The growing need to preserve nutrients and flavors, extend the shelf life of food products, and meet the rising demand for healthy and natural food options are key factors contributing to the segment's dominant position in the market.

This research report analyzes major geographies and provides a comprehensive analysis of North America (U.S., Canada), Europe (Germany, U.K., France, Italy, Spain, Netherlands, Switzerland, and Rest of Europe), Asia-Pacific (Japan, China, India, South Korea, Australia & New Zealand, Indonesia, and Rest of Asia-Pacific), Latin America (Brazil, Mexico, and Rest of Latin America), and the Middle East & Africa (UAE, Israel, and Rest of Middle East & Africa).

Among the geographies studied in this report, Asia-Pacific is anticipated to hold the dominant position, with a large share of the freeze drying equipment market in 2025. Asian countries are experiencing rapid growth in the food and pharmaceutical industries, driven by stringent government regulations for food safety and quality, increased consumer awareness regarding quality food products, and the expansion of market players in India and China. These factors collectively contribute to the region's dominant position in the freeze drying equipment market. Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=6033

Key Questions Answered in the Report-

What is the value of revenue generated by the sale of components, type, scale of operation, and application?

At what rate is the global demand for freeze drying equipment projected to grow for the next five to seven years?

What is the historical market size and growth rate for the freeze drying equipment market?

What are the major factors impacting the growth of this market at global and regional levels?

What are the major opportunities for existing players and new entrants in the market?

Which offering segments create major traction in this market?

What are the key geographical trends in this market? Which regions/countries are expected to offer significant growth opportunities for the manufacturers operating in the freeze drying equipment market?

Who are the major players in the freeze drying equipment market? What are their specific product offerings in this market?

What recent developments have taken place in the freeze drying equipment market? What impact have these strategic developments created on the market?

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Freeze Drying Equipment Market#Freeze Dry Machine#Freeze Dryer#Commercial Freeze Dryer#Industrial Freeze Dryer#Lyophilizer#Small Freeze Dryer#Lyophilizer Freeze Dryer

0 notes

Text

Lyophilizer Freeze Dryers in India: Revolutionizing Freeze Drying Technology

In today’s rapidly evolving pharmaceutical, biotech, and research industries, lyophilizer freeze dryers have become essential equipment for product stability, shelf life enhancement, and efficient moisture removal. If you’re seeking high-quality Lyophilizer Freeze Dryers In India, you’re likely aware of their critical role in preserving sensitive materials without compromising their structure or efficacy.

What is a Lyophilizer Freeze Dryer?

A lyophilizer, also known as a freeze dryer, is a machine that removes moisture from materials by freezing them and then reducing the surrounding pressure to allow the frozen water to sublimate directly from solid to gas. This process, known as lyophilization, is widely used in:

Pharmaceuticals & Vaccines

Biotechnology Research

Food & Nutraceuticals

Diagnostic Kits

Tissue & Biological Sample Preservation

Why Choose Lyophilizer Freeze Dryers from LyoGroup India?

LyoGroup is a recognized leader in the Indian freeze dryer market, known for delivering customized, energy-efficient, and GMP-compliant lyophilizers that meet international quality standards. Here’s why industries across India trust LyoGroup:

Wide Range of Freeze Dryers

From laboratory-scale lyophilizers to full-scale production freeze dryers, LyoGroup offers a broad spectrum of models tailored to specific needs—whether it’s for R&D labs or large-scale pharmaceutical manufacturing.

Advanced Automation & Controls

Equipped with PLC-based control systems, data logging, and touchscreen interfaces, our freeze dryers ensure ease of operation, real-time monitoring, and process repeatability.

Robust Design & Materials

Each lyophilizer is constructed with stainless steel chambers, clean-in-place (CIP) options, and vacuum integrity, making them ideal for sterile environments.

Local Support & Installation

Being based in India, LyoGroup provides prompt after-sales support, training, and spare parts availability, reducing downtime and increasing productivity.

Applications Across Indian Industries

India’s growing demand for high-performance lyophilizer freeze dryers is driven by rapid advancements in the following sectors:

Pharmaceutical Manufacturing

Stabilizing vaccines, antibiotics, and biologics with extended shelf life and zero contamination risk.

Biotech and Life Sciences

Preserving DNA, enzymes, and cell cultures for research and development.

Food and Nutraceuticals

Drying fruit, herbs, and supplements while retaining their flavor, color, and nutritional value.

Medical and Diagnostic Kits

Storing reagents, antibodies, and diagnostic components without refrigeration.

Why the Indian Market is Embracing Lyophilization

India is emerging as a global hub for pharmaceutical exports and research innovation. With increasing regulatory requirements and a shift towards high-quality manufacturing, lyophilization is no longer optional—it’s essential. Freeze drying ensures longer product life, easier transport, and reduced waste—key factors for any competitive manufacturing setup.

Looking for the Best Lyophilizer Freeze Dryer in India?

At LyoGroup, we help you choose the right model, offer installation and training, and provide reliable after-sales service—all tailored to your industry’s requirements. Whether you need a lab-scale bench-top unit or a full-scale automated system, we deliver solutions that boost efficiency and ROI.

Request a Quote Today

If you're looking to invest in cutting-edge Lyophilizer Freeze Dryers In India, now is the time. Partner with LyoGroup for quality, reliability, and innovation in freeze drying.

1 note

·

View note

Text

Buy Pharmaceutical Preparations & APIs Online in India

Purchase synthetic active ingredients, lyophilized injections, and anti-allergics from our fermentation-based plant. Trusted online source in India for pharma needs.

#Pharmaceutical Preparations#Synthetic Active Ingredients#Fermentation based plant#Lyophilized injections#Anti Allergics in india

0 notes

Text

Lyophilization Equipment and Services Market Future of Hybrid Freeze-Drying

The world of pharmaceuticals and biotechnology is in the midst of a silent revolution, one that revolves around safeguarding the delicate integrity of life-saving molecules. At the heart of this revolution lies lyophilization—better known as freeze-drying—a process that removes water from temperature-sensitive products under low pressure, locking in potency and extending shelf life. According to…

0 notes

Text

pharmaceutical manufacturing company | lyophilized injection manufacturers in india | Alde Medi

Looking for a reliable pharmaceutical manufacturing company? Alde Medi Impex Ltd stands as a leading name in the pharmaceutical sector, offering high-quality formulations and specialized injection manufacturing services. With a state-of-the-art GMP-WHO-certified facility, we specialize in the production of sterile injectables, including lyophilized injections, dry powder injections, and liquid ampoules.

As one of the top lyophilized injection manufacturers in India, we cater to both domestic and international markets, delivering excellence in every dose. Our experienced R&D team ensures strict quality control, advanced formulation processes, and timely delivery to meet your specific contract manufacturing requirements.

Whether you are a pharma brand looking to outsource manufacturing or a startup seeking affordable injection manufacturing services in Delhi, Alde Medi is your trusted partner. We maintain compliance with global standards and serve across therapeutic segments like antibiotics, anti-infectives, and critical care.

Website www.aldemedi.com/home

Email: [email protected] Phone: +91 114165 2813

Address: 71/2C, First Floor, Rama Road, Najafgarh Road Industrial Area, New Delhi – 110015

#pharmaceutical manufacturing company#injection manufacturing company in Delhi#lyophilized injection manufacturers in India#third-party pharma manufacturing#pharma companies in India#sterile injectable manufacturer#contract manufacturing pharma#Alde Medi

0 notes