#machine guarding Manufacturers in india

Explore tagged Tumblr posts

Text

Euchner Safety Relays & Safety Controllers Manufacturers in India

Euchner Safety Relays & Safety Controllers Manufacturers in India – Sanocs

In the industrial automation landscape, ensuring worker safety and machine protection is a top priority. Sanocs, a leading name in the industry, is recognized as one of the most trusted manufacturers of Euchner safety relays and safety controllers in India. We specialize in developing high-performance safety PLCs, machine safety relays, and safety controllers that cater to a wide variety of industries including automotive, manufacturing, robotics, packaging, and material handling.

Why Safety Controllers Are Essential in Industrial Environments

A safety controller is an essential component in any industrial setup where hazardous machinery and automated systems operate. It ensures that safety devices such as emergency stop switches, light curtains, interlocks, and two-hand controls are working efficiently to prevent accidents. With growing automation and complex machinery, using reliable and programmable safety controllers in India has become increasingly important for compliance, safety, and operational efficiency.

At Sanocs, we understand the critical need for dependable and intelligent safety solutions. That’s why we offer a wide range of safety controllers designed for integration with a variety of safety sensors and actuators.

Euchner Safety Relays – High-Quality Safety Relays You Can Trust

Euchner safety relays are designed to provide reliable performance and maximum protection. These safety relays monitor the signals from safety devices and control actuators to ensure safe shutdown of machinery during hazardous conditions. Sanocs offers machine safety relays that are compatible with multiple input devices, providing flexibility and enhanced safety functionality.

Our Euchner safety relays are known for:

Compact design and easy installation

Fast response time and precision

Durable components for long operational life

Compliance with international safety standards

Whether it’s for emergency stop circuits, safety gates, or light curtains, our safety relays offer reliable operation in the most demanding environments.

Sanocs – Leading Manufacturer of Safety Controllers in India

Sanocs is a pioneer in designing and manufacturing safety controllers in India that are robust, programmable, and highly adaptable to different safety applications. Our range of safety controllers includes both modular and compact models, suited for small to large-scale machinery and industrial automation systems.

We design our safety controllers keeping in mind:

Ease of integration with existing safety systems

Compatibility with various safety input devices

Real-time diagnostics and error reporting

Scalable architecture for future upgrades

We also provide safety PLCs that allow for complex logic programming, enabling users to configure custom safety responses based on the specific requirements of their facility.

Applications of Our Safety Relays and Controllers

Sanocs’ safety controllers and Euchner safety relays are widely used in:

CNC machines and robotic arms

Conveyor systems and material handling units

Packaging and bottling machines

Automotive assembly lines

Presses, cutters, and other high-risk machinery

These devices ensure operational safety, reduce downtime, and help companies comply with regulatory standards such as ISO 13849 and IEC 62061.

Why Choose Sanocs for Your Machine Safety Needs?

Trusted Brand – With years of expertise, Sanocs has built a reputation as a dependable manufacturer of safety controllers in India and Euchner safety relays.

Quality Assurance – All our products undergo strict quality checks and conform to global safety norms.

Competitive Pricing – Get the best value with high-performance products at industry-leading prices.

Technical Support – Our team of engineers provides end-to-end assistance, from product selection to implementation and troubleshooting.

Customization Available – We offer tailored safety solutions to suit specific industrial needs.

Safety First with Sanocs

When it comes to industrial safety, compromise is not an option. Sanocs is committed to delivering top-tier safety solutions that safeguard human lives and protect machinery. Our machine safety relays, Euchner safety relays, and programmable safety controllers are trusted across India by manufacturers who prioritize safety, performance, and reliability.

If you are looking for innovative, cost-effective, and certified safety solutions, Sanocs is the ideal choice for all your safety automation requirements.

For More Information

9879242755

Plot 21, Panchratna Green - Industrial Park, Nr. Pirana Village, Ahmedabad 382425

#Safety controller#safety controllers in india#euchner safety relays#safety relays#machine safety relays#machine guarding manufacturers in india

0 notes

Text

Business Insurance in India 2025 – Cost, Coverage, and Best Company Insurance Plans

Running a business in India—whether small or large—comes with its share of risks. From fire and property damage to employee-related liabilities or legal claims, even a single incident can disrupt your operations. That’s where business insurance in India becomes essential.

In this comprehensive guide, we’ll explain the types of business insurance, what it covers, how much business insurance costs in India, and how to buy the best plan online.

What is Business Insurance?

Business insurance is a type of financial protection that covers your company’s assets, operations, employees, and legal liabilities from unforeseen events like accidents, theft, lawsuits, or natural disasters. It applies to businesses of all sizes—startups, SMEs, corporates, and large enterprises.

Whether you’re a manufacturing unit, retail outlet, tech company, or service provider, having a business insurance plan ensures long-term sustainability.

🧾 Types of Business Insurance Plans in India

Here are the most common types of business insurance offered in India:

1. Commercial Property Insurance

Covers physical assets like office buildings, inventory, machines, and furniture from damage caused by fire, flood, earthquake, or vandalism.

2. Public Liability Insurance

Protects the business from third-party legal claims related to injury or property damage. Often required for factories and public-facing businesses.

3. Professional Indemnity Insurance

Covers businesses providing professional services (consulting, legal, accounting, tech) against errors or negligence.

4. Group Health Insurance & Accident Cover

Provides medical coverage for employees and is a key benefit in HR policy.

5. Directors & Officers (D&O) Liability Insurance

Safeguards company leadership from personal liability arising from managerial decisions.

6. Cyber Insurance

Protects digital businesses and companies from cyberattacks, data breaches, and hacking-related financial losses.

💸 Cost of Business Insurance in India

📊 Sample Business Insurance Premiums (2025)

💡 These are indicative prices. Get exact premiums by requesting a quote from trusted providers.

🛒 How to Buy Business Insurance Online in India

Buying commercial insurance online has never been easier. Here’s how:

Identify Your Business Risks: Start with understanding the threats specific to your sector.

Choose the Right Type of Insurance: Match your needs with the right policy—property, liability, cyber, etc.

Compare Plans Online: Visit insurer websites or aggregators for side-by-side comparisons.

Get Quotes: Enter your business details to get real-time premium estimates.

Buy Online: Select, pay, and receive your company insurance policy instantly via email.

🏆 Top Business Insurance Providers in India (2025)

Here are the best companies offering business insurance in India:

HDFC ERGO Business Shield

ICICI Lombard SME Insurance

Tata AIG Business Guard

Bajaj Allianz Commercial Protect

SBI General Business Package

Digit Business Insurance

Reliance General Corporate Shield

Each insurer offers customizable plans for different industries like logistics, IT, hospitality, manufacturing, and retail.

Why You Shouldn't Ignore Business Insurance

🔒 Risk Mitigation: Prevent heavy losses from fire, theft, or lawsuits

⚖️ Legal Compliance: Many industries require liability coverage by law

💼 Business Continuity: Insurance keeps operations running even after setbacks

👥 Employee Trust: Group insurance boosts retention and employee satisfaction

📈 Credibility: Investors and partners prefer insured businesses

Final Thoughts: Plan Now, Protect Always

The cost of business insurance in India is a small price for the peace of mind it offers. Whether you're a small business owner or running a large corporation, protecting your employees, assets, and reputation should be part of your core business strategy.

With tools available to buy commercial insurance online, you can compare, customize, and secure your business policy in just a few clicks.

#business insurance#business insurance india#cost of business insurance in India#commercial insurance#company insurance#insurance for corporations#company insurance policy#business insurance plan#commercial insurance online

1 note

·

View note

Text

Costa Power Industries Pvt. Ltd. is a having global exposure as Manufacturer, supplier, Distributor and dealers of Stabilizer system, V-Guard Voltage Stabilizer supplier, V-Guard Voltage Stabilizer power supplier, V-Guard Stabilizer dealers, voltage stabilizer ups, V-Guard stabilizer system in mumbai, v guard stabilizer vew 400 plus, V-Guard Stabilizer dealers in Mumbai. sinfle phase V-Guard Stabilizer dealers in Thane, V-Guard Stabilizer Supplier dealers in Mumbai. As headquarter is in economic capital of India, located in Mumbai and branches at PAN India.

A Voltage Stabilizer is a Voltage motor controlled stabilization system that performs optimum voltage supplier using a Buck\Boost transformer booster that captures voltage fluctuations from input and regulates current to the correct output. Costa power Industries Pvt. Ltd. is top seller for 3-phase Voltage stabilizer in Mumbai, and VEW 500 PLUS, v guard stabilizer dealer in coimbatore, v guard vg 400 plus, v guard stabilizer for home from 500VA to 750KVA successfully. Due motor adjust voltage clockwise and anticlockwise direction with components like control card, dimmer, comparator, transistor and mocs etc.

V Guard Stabilizers Supplier in Mumbai | V Guard Stabilizers Distributors in Mumbai

Their specially fabricated design is sure to prevent cheap imitations. V-Guard Stabilizers come in different capacities for different applications like Air Conditioner, LCD TV, Music System, Refrigerator, Deep Freezer, Washing Machine, Microwave Oven, Treadmill and Mainline Stabilizers for general purposes. V-Guard provides a lot of variation in the voltage stabilizers dealers range so that you find a perfect fit for your appliance. It can protect devices and larger home appliances like television, air conditioner and music systems from voltage spikes and surges. V-Guard has a range of versatile stabilizers to suit all kinds of needs of major home appliances.

#Upsbattery#Upsbatterydealers#Upsbatterydistributor#Upsbatterysuppliers#Upsamc#Upsapc#Microtekinverter#Quatabattery#Luminousups#Emersonups#Onlineups#Digitalups#Offlineups#Bestups#Bestbattery#Servostabilizer#Vertivups#Exidebattery#Luminousinverter#Upsdealers#Upssuppliers#Upsdistributors

0 notes

Text

How to Prepare Your Farm with a Basic Rotavator equipment in india?

Buying a good tractor rotavator solely doesn’t provide you with good crop production. You also need to be aware of how this rotavator machine can be best used for a good crop production.

This blog highlights how better a tractor rotavator can be used to have its effective impact on crop production.

How to Prepare the Field?

Preparing your farm with a rotavator machine involves several steps of soil preparation to ensure the soil is properly tilled and ready for planting.

Compose the Field

Remove Debris: Clear the field of rocks, branches, and any large debris that could damage the rotavator machine.

Moisture Level: Ensure the soil has the right moisture level; too dry or too wet soil can be challenging to till.

Rotavate the Field

First Pass: Make the first pass over the field with the tractor rotavator at a shallow depth to break up the top layer of soil.

Second Pass: Increase the depth slightly and make a second pass to thoroughly mix and break down the soil.

Overlap Passes: Ensure each pass slightly overlaps the previous one to avoid missed strips of soil.

Final Preparation

Check for Clods: Break up any large clods of soil left after rotavating.

Level the Soil: Use a harrow or leveler to create a smooth and even seedbed.

Apply Fertilizer: If needed, spread fertilizer evenly across the tilled soil and lightly incorporate it with a shallow pass of the rotavator.

If you are new to mechanized farming, using basic rotavator equipment in India can be a good starting point for improving your soil preparation. These machines are affordable and efficient for various field sizes.

Tips to Consider when using the Rotavator

Safely rotavator use is significant to evade accidents and ensure efficient operation. Here are some essential safety tips:

Before Starting

Read the Manual: Always read the operator’s manual thoroughly before making rotavator use.

Inspect the Equipment: Check for any damage, loose parts or wear and tear before rotavator use. Certify all guards and shields are in place.

Wear Appropriate Gear: Utilize personal protective equipment (PPE) as gloves, safety glasses, sturdy footwear and hearing protection.

Check the Area: Clear the working area of rocks, debris and other obstacles that could be thrown by the rotavator.

Operating the Rotavator

Start Slowly: Begin at a low speed to get a feel for the machine and gradually increase speed as you gain control.

Maintain a Firm Grip: Keep both hands on the handles and maintain a firm grip at all times.

Stay Alert: Always be aware of your surroundings, especially if other people or animals are nearby.

Proper Posture: Stand straight and avoid bending over the rotavator machine. Maintain a stable stance to control the machine better.

Avoid Loose Clothing: Do not wear loose clothing or jewelry that could get caught in the machine.

During Operation

Avoid Slopes: Operate the tractor rotavator on flat ground whenever possible. If you must work on a slope, do so carefully and never across the slope.

Turn Off Before Adjusting: Always turn off the rotavator machine and disconnect the spark plug wire or power source before making any adjustments or clearing jams.

Not Once Leave Unattended: Not ever once leave the rotavator machine running while unattended. Always turn off the engine if you need to step away.

Steer Clear of Moving Parts: Retain your hands and feet at a distance from the rotating blades and other moving parts.

After Use

Cool Down: Allow the engine to cool down before performing any maintenance or storing the tractor rotavator.

Clean the Rotavator: Remove dirt, debris and plant material from the rotavator machine after each use to prevent buildup and ensure longevity.

Regular Maintenance: Follow the manufacturer’s maintenance schedule for oil changes, filter cleaning and other routine checks.

Emergency Situations

Stop Immediately: In case of any unusual noise, vibration or malfunction, turn off the rotavator machine immediately and inspect it.

First Aid: Hold on to a first aid kit close by in the event of minor injuries. Know the location of the nearest emergency services.

FINAL VERDICT

Considering these guidelines you can confirm that you use your tractor rotavator safely and effectively for good soil preparation. If you have any questions regarding the basic rotavator models you’re interested in, feel free to contact us.

#agricultural machinery#farming#agricultural equipment manufacturers#tractor rotavator#rotavator#basic rotavator equipment in india

0 notes

Text

Leading Safety Equipment Manufacturer in Ahmedabad -Sanocs

Industrial safety is more than just a protocol—it's a vital component of every successful manufacturing or processing facility. From small-scale workshops to large production units, protecting workers and machinery plays a key role in reducing operational hazards. This is where safety equipment becomes indispensable.

Sanocs, a trusted name in the industry, stands tall as a leading Safety Equipment Manufacturer in Ahmedabad. We specialize in delivering high-quality machine guarding, industrial guarding, and related solutions that help companies minimize risks and maintain compliance with safety norms. With innovative designs and a customer-first approach, we are reshaping industrial safety practices across India.

Why Safety Equipment is Essential in Industrial Environments

The use of safety equipment isn’t just about meeting regulations—it’s about protecting lives, reducing machine downtime, and increasing productivity. As industries grow more automated, moving parts and high-powered machinery pose greater risks. That’s why investing in products from a trusted Safety Equipment Manufacturer is essential.

Accidents can lead to severe injuries, expensive repairs, and business interruptions. With quality machine guarding systems in place, companies can:

Prevent access to dangerous parts of machines

Reduce injury rates and worker compensation claims

Protect infrastructure from accidental damage

Improve employee confidence and operational efficiency

Our products are crafted to meet these safety needs without compromising workflow or machine access.

Our Product Range

At Sanocs, we offer a complete line of industrial safety solutions. Our expertise as a Safety Equipment Manufacturer in Ahmedabad lies in building practical, durable, and customizable guarding systems for diverse industries.

1. Machine Guards and Safety Fences

Machine Guards and Safety Fences are essential for protecting operators from rotating parts, sharp tools, and high-speed systems. Whether it’s a CNC machine, lathe, press, or robotic assembly unit, these guards act as physical barriers while allowing visibility and easy maintenance access.

Our guards are modular, rust-resistant, and designed to suit specific machine models. They help reduce human error while meeting international safety standards.

2. Industrial Guarding Systems

Our industrial guarding solutions are designed for large-scale protection. We provide:

Perimeter fencing

Floor-to-ceiling guards

Workstation enclosures

Conveyor system barriers

These systems help control movement within industrial units, preventing unauthorized access and keeping machinery zones secure. As experienced machine guarding manufacturers in India, we ensure each guard fits its intended space precisely.

Advantages of Our Guarding Solutions

Choosing the right safety partner can make a massive difference to your operations. With Sanocs, you're getting more than just barriers—you’re investing in advanced machine guarding and industrial machine guarding that lasts.

Benefits of our products include:

Custom Fit Designs: Tailored to your space and workflow

Durable Materials: Weather-resistant, chemical-resistant, and corrosion-free

Quick Installation: Minimal disruption during setup

Low Maintenance: Built for long life and reliable performance

With our expertise as a Safety Equipment Manufacturer, we make safety simple and effective for industries nationwide.

Serving Multiple Sectors

We work with a wide range of industries across India. Our safety guards and fencing systems are used in:

Automotive plants

Pharmaceutical labs

Warehouses and logistics hubs

Food and beverage factories

Fabrication and metal workshops

Our clients rely on us for quick delivery, technical support, and products that meet both Indian and international safety guidelines. As trusted machine guarding manufacturers in India, our solutions are built for real-world use.

Why Choose Us?

Sanocs stands apart in the safety equipment market by combining quality craftsmanship with a deep understanding of industrial needs. As a leading Safety Equipment Manufacturer in Ahmedabad, we don’t just deliver products—we deliver peace of mind. Our design-first approach, commitment to quality, and after-sales support make us the preferred choice for businesses across the country. Whether you need simple machine guards or complete industrial guarding systems, Sanocs is your one-stop solution.

Conclusion

Safety is a smart investment—and with Sanocs, it’s a reliable one. As one of the top machine guarding manufacturers in India, we provide durable and efficient solutions tailored for modern industry. Backed by years of experience and a commitment to customer satisfaction, we’re proud to lead the way as a trusted Safety Equipment Manufacturer in Ahmedabad. Let us help you create a safer, more productive workplace with safety systems that work as hard as you do.

Want to upgrade your industrial safety game?

Reach out to Sanocs—your reliable partner in industrial safety. Call us at +91-987-924-2755 or email us at [email protected] for expert advice.

Sanocs, a leading Safety Equipment Manufacturer in Ahmedabad, offers high-quality machine guarding, industrial guarding, and safety solutions for various industries, built to withstand demanding operational conditions.

For More Information

9879242755

Plot 21, Panchratna Green - Industrial Park, Nr. Pirana Village, Ahmedabad 382425

https://www.sanocs.in/safety-equipment-manufacturer-in-ahmedabad

#Safety Equipment Manufacturer#Safety Equipment Manufacturer in ahmedabad#Machine Guards and Safety Fences#industrial guarding#machine guarding#industrial machine guarding#safety guards#machine guarding Manufacturers in india

0 notes

Text

Using Melt Flow Index Tester in Plastic Testing Labs

Source of Info: https://www.perfectgroupindia.co.in/blog/using-melt-flow-index-tester-in-plastic-testing-labsv

Introduction

The Melt Flow Index Tester is an important tool for plastics testing in labs because it finds how much a sample of molten plastic flows under specific conditions. By identifying whether the plastic is suitable for molding or extrusion this equipment gives manufacturers better assurance in their processing options. It guarantees the right materials are selected for a range of uses with specific results. Perfect Group India is a reputable company that provides reliable options that improve the testing process. This equipment is an important equipment in today's plastic testing labs that value high quality and productivity because it saves time, avoids manufacturing issues and improves product quality.

What is a Melt Flow Index Tester? A Melt Flow Index Tester is a testing device that measures the flow features of melted thermoplastic polymers. It will be used to analyze Melt Flow Rate the volume of plastic that will pass through a specific die in 10 minutes at a controlled temperature and pressure.

This test basically finds how easily it will flow once it is molten and at the proper temperature. This information is used by manufacturers to choose whether a material is suitable for injection molding or extrusion processes.

Why Is Melt Flow Index Important in Plastic Labs? Plastic testing labs work with different types of polymers. Each kind of plastic has a unique melting and behavior pattern. Maintaining consistent quality and choosing the right material require an understanding of this behavior. The Melt Flow Index Tester is useful for the following reasons:

Quality Control: Guarantee every batch of plastic meets flow standards.

Material Comparison: Helps compare different plastic grades.

Production Suitability: Checks if the material suits the intended molding or extrusion process.

Process Adjustment: Allows fine-tuning of machine settings based on the flow rate.

How Does a Melt Flow Index Tester Work? The working process of a device is simple but accurate. Here’s how it typically functions:

Sample Loading: A small amount of plastic is placed into the barrel of the tester.

Heating: The sample is heated to a specific temperature based on the polymer type.

Compression: The melted plastic is under pressure from a piston.

Measurement of Flow: The plastic is pushed through a narrow die at the bottom. The mass that flows out over 10 minutes is collected and weighed.

Calculation: The result is given in grams per 10 minutes.

Key Features of Modern Melt Flow Index Tester Modern testing labs use advanced Melt Flow Index Tester with the latest technology:

Digital Display: Real-time readings make analysis easy.

Touchscreen Interface: Simple navigation and control.

Temperature Control: Maintains steady heating for accurate results.

Timer Settings: Helps automate the testing process.

Detachable Parts: Makes cleaning and maintenance convenient.

Safe Design: Built with safety guards to avoid accidents.

All these features make it easier for lab technicians to perform regular tests without trouble.

Applications in Different Industries Melt Flow Index testing is not limited to just one type of plastic or industry. It has wide-ranging applications:

Packaging: Ensures films and containers have the right flow rate for shaping.

Automotive: Checks if the plastic parts can be molded with accuracy.

Consumer Goods: Validates that household plastic items meet standard quality.

Medical Devices: Verifies that plastic used in syringes and containers is safe and moldable.

Construction: Confirms that piping and fittings made from plastic flow as needed during manufacturing.

Every industry that uses thermoplastic materials depends on accurate flow testing to maintain product quality.

Benefits of Using Melt Flow Index Tester in Labs Labs that use this testing equipment enjoy multiple benefits:

Accurate Measurement: Offers accurate flow values which help maintain standards.

Quick Testing: Saves time with fast test cycles.

•Reliable Results: Removes guesswork in choosing materials.

Cost-Efficient: Helps reduce material wastage during manufacturing.

Better Planning: Supports data-driven decision-making in manufacturing.

Improved Quality: Leads to better high quality products and reduced rejections.

Tips for Using a Melt Flow Index Tester Effectively For best results labs should follow some best practices:

Preheat Properly: Allow the device to reach the required temperature before loading samples.

Use the Right Tools: Always use the specified die and piston weights.

Clean Regularly: Keep the barrel and die clean to avoid damage.

Record Data: Maintain proper logs to track batch performance over time.

Follow Standards: Use globally accepted testing standards like ASTM D1238 or ISO 1133.

These tips ensure that the test results remain consistent and dependable.

Choosing the Right Melt Flow Index Tester When selecting a right equipment for your lab consider the following:

Build Quality: Choose a durable model built with lab-grade materials.

Ease of Use: Find out controls and displays that are easy to use.

Support & Service: Guarantee the supplier provides training, service and spare parts.

Test Range: Check if it covers the range of polymers you handle.

Compliance: Make sure the tester follows international testing standards.

Making a smart choice saves time reduces errors and improves testing productivity.

Conclusion The Melt Flow Index Tester is an important instrument for plastic testing labs because it provides an accurate tool to identify the thermoplastics' flow rate. It helps to guarantee that the right processing conditions are being met by offering required details to industries including healthcare to packaging materials. Purchasing a reliable testing tool is a wise choice for companies trying to increase quality and improve manufacturing. Perfect Group India provides strong solutions that are made to satisfy international standards for labs that require reliability and accuracy. Having a proper tester on hand guarantees that you stay ahead of the competition in today's highly competitive marketplace no matter whether you're testing film, sheet, pipe or molded products.

0 notes

Text

How to Choose the Right Stringing Tools for Power Line Projects

Overview: The Foundation of All Effective Power Line Initiatives The most crucial factors in power infrastructure are installation speed, safety, and dependability. For every high-voltage line construction, experts rely on Power Transmission Stringing Tools to guarantee seamless operations. These tools are necessary for flawless execution, from tensioning to conductor positioning.

Adaptable Instruments Designed for Control and Performance High-quality transmission line stringing tools are made to preserve proper conductor alignment, guard against cable breakage, and increase field efficiency. We provide reel stands, tensioners, anti-twisting ropes, stringing tools and accessories, and alternatives for Stringing Machine Cleaning Tool Kits. These products guarantee consistently precise, safe, and clean cable laying.

The Importance of High-Quality Stringing Equipment Purchasing dependable stringing tools and cable laying tools will result in fewer malfunctions, quicker installation, and less rework. Our cutting-edge transmission line stringing tools and equipment satisfy performance and accuracy standards set by the industry. Our expertise in producing stringing equipment in India guarantees that our instruments can effortlessly manage the most demanding job site circumstances.

In conclusion, Power Line Tools is your reliable partner. Being one of India's leading manufacturers of stringing equipment, we are well aware of how important these instruments are to the success of infrastructure. Our equipment exemplifies true workmanship in both design and longevity. Always select tried-and-true tools that yield tangible results, regardless of the size of the project or transmission task.

#Stringing Tools Manufacturer in India#Stringing Tools Supplier in India#Stringing Tools Exporter in India#Overhead Line Stringing Tools India#Conductor Stringing Tools India#Transmission Line Stringing Equipment India#Power Line Stringing Tools Manufacturer India

0 notes

Text

Mankoo Drop Forge Hammer Press – Precision Forging Power

Mankoo Presses is a name that resonates with engineering excellence, unmatched durability, and high-performance machinery in the field of metalworking. Among their diverse product range, the Drop Forge Hammer Press Machine stands out as a powerful solution for heavy-duty forging applications.

With decades of experience and a reputation for delivering top-of-the-line power presses, Mankoo Engineering Works has established itself as a leading manufacturer in India and across global markets. This blog explores the features, benefits, and industrial applications of the Mankoo Drop Forge Hammer Press, emphasizing why it remains a preferred choice among modern manufacturers and forging units.

The Legacy of Mankoo Presses

Established with a mission to provide robust, reliable, and technologically advanced power press solutions, Mankoo Presses has grown to become a trusted brand in the machine tools industry. From mechanical and hydraulic power presses to high-speed precision machines, Mankoo has engineered a complete portfolio of equipment that caters to small workshops as well as large-scale industries. With a strong presence in sectors such as automotive, aerospace, defense, agriculture, and railway, Mankoo has earned recognition not only for its machine quality but also for its excellent after-sales support.

What is a Drop Forge Hammer Press Machine

A Drop Forge Hammer Press Machine is a heavy-duty forging machine used to shape metal through repeated, high-impact hammering. The machine operates by lifting a massive hammer and dropping it on the workpiece to deform and mold it into the desired shape. This process is essential in producing high-strength metal components such as crankshafts, axles, gears, connecting rods, and various structural parts that require superior durability and precision. The drop forging method enhances grain structure, reduces porosity, and improves mechanical properties, making it ideal for critical load-bearing parts.

Features of Mankoo Drop Forge Hammer Press

1. High-Impact Forging Power Mankoo’s drop forge hammer is designed to deliver consistent, high-impact blows that ensure deep penetration and accurate shaping of the material. The forging force is calibrated to handle both ferrous and non-ferrous metals, making it versatile for a wide range of applications.

2. Rigid and Durable Frame Construction Built with a heavy-duty steel frame, the Mankoo Drop Forge Hammer Press offers excellent stability during operations. The robust design eliminates vibrations and ensures long-term durability even under continuous usage in demanding environments.

3. Precision Engineering Each Mankoo hammer press is precisely engineered using CNC and automated technologies. This allows for accurate alignment, superior balance, and repeatable performance, which are critical factors in high-quality forging operations.

4. Efficient Ram Movement The vertical ram or hammer head is designed to move smoothly with minimum resistance, ensuring maximum energy transfer on every strike. The result is a powerful impact with reduced energy loss, contributing to the machine’s overall efficiency.

5. Customization and Automation Options Mankoo provides the option of customizing the drop forge hammer based on customer requirements. Features like programmable automation, die cooling systems, safety guards, and digital stroke counters can be integrated to enhance productivity and user safety.

6. Easy Maintenance and Accessibility With a focus on user-friendly design, Mankoo ensures that all parts of the machine are easily accessible for routine maintenance. The use of high-grade components also means that wear and tear is minimized, reducing downtime and increasing machine life.

Industrial Applications of Mankoo Drop Forge Hammer Press

Automotive Industry Used to forge critical parts like crankshafts, axles, steering knuckles, and suspension arms, the Mankoo drop hammer ensures high mechanical strength and fatigue resistance, which is vital for automotive applications.

Railway and Aerospace Forging components for railway coaches and aircraft structures demands the highest levels of precision and strength. Mankoo machines are capable of producing such components with exact dimensional accuracy and metallurgical integrity.

Agricultural Equipment From plowshares to couplings and gear parts, the Mankoo Drop Forge Hammer Press helps create durable, weather-resistant parts used in heavy agricultural machinery and tools.

Defense Manufacturing The machine is ideal for manufacturing armor plates, weapon components, and other critical defense parts that must withstand extreme conditions and operational stress.

Tool and Die Making Precision dies and hammers can be forged using the Mankoo press, ensuring durability and resistance to repetitive strain, which is essential for tool manufacturing industries.

Advantages of Choosing Mankoo Drop Forge Hammer Press

Made in India, Trusted Worldwide Mankoo machines are manufactured in India under strict quality standards but are designed to compete with global counterparts. They are exported to countries across Asia, Africa, and the Middle East, proving their reliability on international platforms.

Cost-Efficient Solution Compared to imported machinery, Mankoo offers a highly cost-effective alternative without compromising on quality or performance. The return on investment is high due to the machine’s productivity and low maintenance.

Strong Service Network Mankoo’s wide service network ensures that customers receive prompt assistance, installation support, and genuine spare parts. Their engineering team is always ready to guide and resolve technical issues.

Environment-Friendly Forging Solution The machine is built with energy efficiency in mind. With improved energy transfer, minimal vibration, and optional oil-lubrication systems, Mankoo helps industries meet their environmental compliance goals.

Customer Success Stories

Over the years, numerous clients have trusted Mankoo Drop Forge Hammer Press for their forging needs. From leading auto part manufacturers to government railway units, Mankoo machines have played a vital role in helping businesses scale their production while maintaining quality. Several clients have also reported significant reductions in cycle time and material wastage after switching to Mankoo presses.

Conclusion

When it comes to forging precision, power, and durability into one machine, Mankoo Drop Forge Hammer Press stands tall as a leader. Built with cutting-edge technology, engineered for perfection, and backed by decades of trust, it is an indispensable asset for any industry involved in heavy metal forging. Whether you're a manufacturer looking to expand capacity or a startup exploring reliable forging solutions, Mankoo has the machine and the support you need to succeed.

Mankoo Presses continues to set new standards in metal forming technology, and the Drop Forge Hammer Press is a perfect reflection of their commitment to quality and performance.

0 notes

Text

JUGMUG Electric Panel Enclosure Roll Forming Machine for Mass Production

Introduction

In today’s fast-paced manufacturing landscape, efficiency and precision are key to staying competitive. One area where this is especially true is in the production of electric panel enclosures and electrical cabinets. As demand for smart infrastructure and industrial automation grows, so does the need for high-quality, durable, and precisely shaped electrical enclosures. Enter JUGMUG RollForming, a trusted name in the roll forming industry, known for providing cutting-edge solutions that drive mass production without compromising on quality.

Why Roll Forming for Electrical Panel Enclosures

Roll forming is the most efficient method for producing long lengths of metal profiles with uniform cross-sections. It ensures minimal material wastage, higher production speeds, and dimensional accuracy—making it the preferred process for manufacturing electric panel enclosures. Traditional methods such as bending and stamping often fall short in terms of speed and consistency, especially when scaled to industrial levels.

JUGMUG RollForming has designed its Electric Panel Enclosure Roll Forming Machine to meet the exacting demands of mass production. Whether you're producing switchgear boxes, electrical cabinets, or control panels, JUGMUG machines offer unparalleled consistency and reliability.

Features of JUGMUG Electric Panel Enclosure Roll Forming Machine

JUGMUG’s roll forming machines are the result of years of engineering expertise and real-world manufacturing experience. Here are some standout features:

High-Speed Production: The machine is engineered for continuous operation, making it ideal for large-volume production. With line speeds ranging from 10 to 25 meters per minute, you can meet bulk orders efficiently.

Fully-Automatic Operation: The entire line is PLC-controlled, from material feeding to cut-to-length, punching, and final stacking. This reduces the need for manual intervention and lowers labor costs.

Servo Feeding and Hydraulic Punching: Precision is critical when producing electric enclosures. JUGMUG integrates servo feeder technology and CNC hydraulic punching units to ensure holes and cut-outs are made with millimeter-level accuracy.

Durable Tooling and Die Systems: Built with hardened alloy steel rollers, chrome-plated shafts, and high-precision dies, JUGMUG machines are designed for long operational life and minimal maintenance.

Customizable Profile Design: Whether you need cabinets with knockouts, door openings, or ventilation slots, JUGMUG machines can be customized to create any design with consistency.

Integrated Safety Systems: Operator safety is a top priority. The machines come with emergency stop mechanisms, protective guards, and overload protection features.

Applications of the Machine

The Electric Panel Enclosure Roll Forming Machine by JUGMUG is suitable for a wide range of applications:

Electrical distribution boxes

Power control centers

Switchgear cabinets

Telecom and network enclosures

HVAC control boxes

Solar inverter enclosures

Why Choose JUGMUG RollForming

Trusted Brand with Proven Expertise: With decades of experience in roll forming technology, JUGMUG is a name trusted by thousands of businesses across India and abroad. From design to installation, JUGMUG ensures complete support.

Precision Engineering: Each JUGMUG machine is built with German-grade CNC components and follows international quality standards. Every batch is rigorously tested before dispatch.

High ROI Machines: Designed for mass production, JUGMUG machines help reduce production time and material wastage. This leads to faster ROI and increased profitability.

Tailored Solutions: No two businesses are the same. That’s why JUGMUG offers custom roll forming machines tailored to your specific panel dimensions, punching needs, and automation level.

Comprehensive After-Sales Support: JUGMUG believes in building long-term relationships. Their after-sales support includes machine installation, training, preventive maintenance, and quick spare part availability.

Serving India and Global Markets

JUGMUG RollForming is proud to be an export-ready manufacturer, supplying roll forming solutions to the Middle East, Southeast Asia, Africa, and Europe. With a strong logistic network and international quality certifications, JUGMUG ensures that clients worldwide get Conclusion

In the competitive world of electrical enclosure manufacturing, choosing the right machine can make or break your production efficiency. The JUGMUG Electric Cabinet Box Roll Forming Machine is purpose-built for mass production, offering speed, precision, and durability all in one package. Whether you’re a small-scale manufacturer or a large industrial unit, JUGMUG provides a solution that grows with your business.

Invest in JUGMUG RollForming – Where Innovation Meets Productivity

For demo videos, technical specifications, or a personalized quote, reach out to the JUGMUG RollForming team today. Take the first step towards automated, efficient, and profitable enclosure production.

0 notes

Text

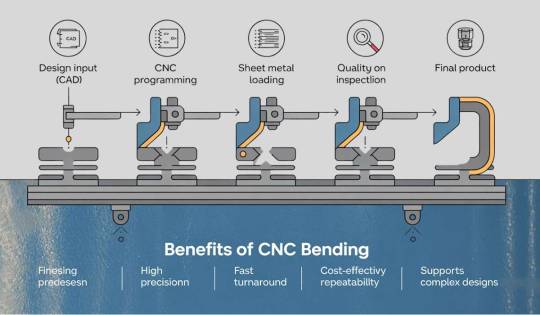

Why We Offer the Best CNC Bending Services in India – Precision, Speed, and Excellence

In the fast-paced world of manufacturing, precision, speed, and reliability are the cornerstones of success. One of the key processes that makes this possible is CNC bending—a technique that turns flat sheet metal into perfectly formed components. Whether it’s for automotive frames, electrical enclosures, or industrial brackets, CNC bending delivers unmatched accuracy.

At Sawant Group, we’ve built our reputation by offering the Best CNC Bending Services in India. From advanced technology to expert teams, we ensure every project is handled with the highest standards of quality and care.

What Is CNC Bending?

CNC (Computer Numerical Control) bending is a metal fabrication process where sheet metal is bent using a programmable press brake. The process is computer-controlled, which ensures precision and repeatability in each bend.

It is widely used to manufacture:

Car body parts

Electrical boxes

HVAC systems

Furniture frames

Machine guards

Why Precision Matters

In industries like automotive and electrical, even a slight variation in dimensions can lead to major issues. That’s why precision is not optional—it’s essential.

With CNC bending:

Every angle is calculated.

Every movement is controlled.

Every component fits just right.

We invest in state-of-the-art CNC machines that offer tight tolerance bending (±0.1 mm), ensuring components meet the highest specifications.

Speed That Meets Deadlines

Time is money. Our CNC bending services are designed to keep your production line moving. With automated systems and efficient workflows, we offer quick turnaround times without sacrificing quality.

Whether it’s a low-volume prototype or a high-volume batch, our team works to deliver your order on time, every time.

What Makes Us the Best CNC Bending Services in India?

Delivering the best is about more than just machines—it’s about experience, commitment, and trust.

1. Advanced Machinery

We use high-performance CNC press brake machines with:

Multi-axis control

Programmable sequences

Real-time monitoring

Compatibility with CAD/CAM software

These features allow us to handle complex geometries and different materials, including stainless steel, aluminum, and mild steel.

2. Skilled Team

Behind every machine is a trained operator and an experienced engineer. Our team understands not just the bending process, but also:

Material behavior

Design for manufacturability (DFM)

Industry-specific requirements

3. Custom Solutions

Each client has different needs. We provide tailor-made solutions that match your exact requirements—whether you need thick aluminum bends or precision stainless steel panels.

4. Integrated Fabrication Services

We offer more than just CNC bending. Our facility also provides:

CNC laser cutting

Welding (MIG/TIG/spot)

Powder coating

Assembly and packaging

This end-to-end solution helps clients save time and coordinate less.

Where Quality Meets Volume

As a trusted provider of the Best CNC Bending Services in India, we handle both:

Small-batch prototypes

High-volume production runs

Our factory setup is optimized for scaling orders quickly, without compromising consistency or quality.

Attention to Every Detail

From the moment we receive your design file, our quality team:

Reviews technical specifications

Checks compatibility with tooling

Tests first pieces before bulk bending

We also offer Design for Manufacturing (DFM) assistance to reduce material usage and improve the fit of your parts.

Serving Multiple Industries

We proudly serve various sectors with our CNC bending capabilities:

Automotive

Brackets, dash supports, chassis components

Electrical

Distribution boxes, switchboards, control panels

Architecture

Decorative sheet panels, metal facades, signboards

Industrial Equipment

Machine frames, cabinets, safety guards

HVAC

Mounts, enclosures, ducting support systems

Each sector demands its own set of standards, and we’re equipped to meet them all.

Location Advantage: Based in Chakan, Pune

Our facility is located in Chakan, Pune—India’s major industrial hub. With excellent transport access, we serve clients from:

Mumbai

Nashik

Aurangabad

Hyderabad

And pan-India via logistics support

This strategic location helps us reduce delivery times and serve you faster.

Sustainability in Fabrication

We are committed to environment-friendly practices, including:

Material optimization to reduce waste

Energy-efficient CNC machines

Recycling of scrap material

This reduces cost and supports clients looking to meet green manufacturing standards.

What Our Clients Say

“We needed a reliable CNC bending partner for our automotive parts. The precision and service we received were outstanding. Easily the Best CNC Bending Services in India we’ve come across.”

“Their team helped us redesign our electrical panels to reduce bending time and material cost. Fast delivery, great results!”

Value-Added Services

Beyond bending, we also offer:

Design file review (DXF, DWG)

Prototype development

Material procurement support

Finishing options like polishing, deburring, and coating

This makes the journey from concept to product smoother and faster.

Let’s Build Something Precise

If you’re looking for a CNC bending partner that understands accuracy, timelines, and cost-efficiency, we’re ready to help. From small startups to large OEMs, we bring the same level of professionalism and care.

We believe in building long-term relationships by consistently delivering the Best CNC Bending Services in India—and the results speak for themselves.

Frequently Asked Questions (FAQs)

Q1: What thickness of sheet metal can you bend?

We handle materials up to 6 mm thick, depending on the type (steel, aluminum, etc.).

Q2: Do you provide sample bends or prototypes?

Yes, we can produce sample pieces before full production, especially for custom or complex designs.

Q3: How soon can I expect delivery?

Depending on the order size and complexity, we usually deliver within 5–10 working days.

Q4: Can you work with stainless steel and aluminum?

Absolutely. We specialize in stainless steel, aluminum, and mild steel CNC bending.

Q5: Is there a minimum order quantity?

No. We accept both one-off prototypes and bulk production orders.

Final Thoughts

In today's competitive world, only those who value precision and speed will lead. Our CNC bending services are not just about bending metal—they’re about shaping ideas, solving challenges, and delivering excellence.

When you partner with us, you choose more than a vendor—you choose the Best CNC Bending Services in India, backed by commitment, technology, and passion for perfection.

Want to explore more? Learn more about CNC bending technology and its role in modern manufacturing from a global perspective.

#Sawant Groups#Best CNC Bending Services in India#CNC bending technology#automotive#cnc services#automation

0 notes

Text

Machine Guards and Safety Fences Manufacturers in India - Sanocs

Sanocs is a trusted name in India when it comes to Machine Guards and Safety Fences. We specialize in delivering innovative and robust solutions designed to enhance workplace safety and protect equipment from accidental damage. Our high-quality guarding systems are suitable for various industrial applications, ensuring compliance with safety standards while boosting productivity.

Why Choose Sanocs for Machine Guards and Safety Fences?

Comprehensive Safety SolutionsSanocs offers a wide range of industrial guarding products, including machine guards and safety fences.

Durable and High-Quality MaterialsOur machine guards and safety fences are built using top-grade materials like steel, aluminum, and durable composites.

Customizable DesignsAt Sanocs, we understand that every industrial setup has unique requirements. That’s why we offer customizable machine guarding solutions, tailored to fit your specific needs.

Enhanced Workplace SafetyWith Sanocs' machine guards and safety fences, you can create a safe working environment by preventing unauthorized access to hazardous zones.

Applications of Industrial Machine Guarding

Our products are widely used in industries such as:

Automotive manufacturing

Pharmaceutical production

Food processing

Electronics assembly

Heavy machinery operations

Machine Guarding Manufacturers in India

Sanocs is among the leading machine guarding manufacturers in India, delivering safety solutions that meet global standards. Our products are meticulously designed to cater to diverse industries, ensuring robust protection for both workers and machinery.

Additional Safety Products from Sanocs

In addition to machine guards and safety fences, we also offer:

Safety Switches: Reliable switches to enhance operational control and safety.

Liquid Particle Counters: Advanced devices for monitoring contamination levels in industrial liquids.

Benefits of Choosing Sanocs

High Durability: Engineered for extended use in challenging environments.

Compliance: Designed to meet international safety regulations.

Cost-Effective: Affordable safety solutions with minimal maintenance.

Custom Support: Tailored solutions for every industrial need.

Contact Sanocs for Reliable Safety Solutions

For premium-quality machine guards, safety fences, and industrial guarding solutions, trust Sanocs. As a leading manufacturer in India, we are committed to creating safer workplaces with our cutting-edge products. Reach out to us today to learn more or to request a quote!

For More Information

9879242755

Plot 21, Panchratna Green - Industrial Park, Nr. Pirana Village, Ahmedabad 382425

#Machine Guards and Safety Fences#industrial guarding#machine guarding#industrial machine guarding#safety guards#machine guarding Manufacturers in india

0 notes

Text

Costa Power Industries Pvt. Ltd. is a having global exposure as Manufacturer, supplier, Distributor and dealers of Stabilizer system, V-Guard Voltage Stabilizer supplier, V-Guard Voltage Stabilizer power supplier, V-Guard Stabilizer dealers, voltage stabilizer ups, V-Guard stabilizer system in mumbai, v guard stabilizer vew 400 plus, V-Guard Stabilizer dealers in Mumbai. sinfle phase V-Guard Stabilizer dealers in Thane, V-Guard Stabilizer Supplier dealers in Mumbai. As headquarter is in economic capital of India, located in Mumbai and branches at PAN India.

A Voltage Stabilizer is a Voltage motor controlled stabilization system that performs optimum voltage supplier using a Buck\Boost transformer booster that captures voltage fluctuations from input and regulates current to the correct output. Costa power Industries Pvt. Ltd. is top seller for 3-phase Voltage stabilizer in Mumbai, and VEW 500 PLUS, v guard stabilizer dealer in coimbatore, v guard vg 400 plus, v guard stabilizer for home from 500VA to 750KVA successfully. Due motor adjust voltage clockwise and anticlockwise direction with components like control card, dimmer, comparator, transistor and mocs etc.

V Guard Stabilizers Supplier in Mumbai | V Guard Stabilizers Distributors in Mumbai

Their specially fabricated design is sure to prevent cheap imitations. V-Guard Stabilizers come in different capacities for different applications like Air Conditioner, LCD TV, Music System, Refrigerator, Deep Freezer, Washing Machine, Microwave Oven, Treadmill and Mainline Stabilizers for general purposes. V-Guard provides a lot of variation in the voltage stabilizers dealers range so that you find a perfect fit for your appliance. It can protect devices and larger home appliances like television, air conditioner and music systems from voltage spikes and surges. V-Guard has a range of versatile stabilizers to suit all kinds of needs of major home appliances.

#Upsbattery#Upsbatterydealers#Upsbatterydistributor#Upsbatterysuppliers#Upsamc#Upsapc#Microtekinverter#Quatabattery#Luminousups#Emersonups#Onlineups#Digitalups#Offlineups#Bestups#Bestbattery#Servostabilizer#Vertivups#Exidebattery#Luminousinverter#Upsdealers#Upssuppliers#Upsdistributors

0 notes

Text

Yamuna Engineering: Trusted Finger Jointer Machine Manufacturer Driving Precision and Performance

When it comes to high-quality finger jointing solutions, Yamuna Engineering stands out as one of the most reliable Finger Jointer Machine Manufacturers in India. Based in the industrial city of Yamunanagar, Yamuna Engineering has consistently delivered precision-engineered machinery that meets the growing demands of the plywood and woodworking industries.

Finger jointing is a crucial process in woodworking that involves joining small lengths of wood to form longer, stronger, and defect-free timber. Yamuna Engineering has mastered the art of creating high-performance Finger Jointer Machines that offer seamless operation, strong bonding, and efficient production. These machines are widely used for manufacturing block boards, flush doors, panel boards, and other engineered wood products.

What makes Yamuna Engineering a preferred choice in the market is their commitment to quality, innovation, and customization. Each Finger Jointer Machine is designed using advanced technology to ensure accurate cutting, perfect alignment, and superior adhesive application. The result is a joint that is both durable and aesthetically flawless.

The machines are equipped with user-friendly features such as automatic feeding systems, high-speed spindles, safety guards, and precision control panels. Whether it is a small-scale workshop or a large plywood plant, Yamuna Engineering offers finger jointing solutions that can be tailored to meet diverse production needs.

Yamuna Engineering also emphasizes robust construction and long service life, using only high-grade raw materials and components. Their machines undergo strict quality checks and testing to ensure reliable performance under continuous operation. This durability, coupled with low maintenance requirements, makes their machines a cost-effective investment for any manufacturer.

Apart from delivering top-notch machinery, Yamuna Engineering is known for its excellent customer support and technical service. Their experienced team provides end-to-end assistance—from installation and setup to training and troubleshooting—ensuring that clients get the most out of their equipment.

With a vision to support sustainable manufacturing, Yamuna Engineering designs their machines to minimize wood waste and optimize material utilization. This eco-friendly approach not only supports environmental goals but also enhances profitability for users.

In summary, Yamuna Engineering is more than just a Finger Jointer Machine Manufacturer—it is a trusted partner for businesses looking to improve efficiency, quality, and output in the plywood and woodworking sectors. Their cutting-edge machinery, industry expertise, and customer-first philosophy continue to set new benchmarks in the market.

Visit:- https://www.yamunaengineeringindustries.com/finger-jointer-machine.html

#plywood machinery manufacturer#finger jointer machine manufacturer#best plywood machinery manufacturer#glue spreader machine

0 notes

Text

Using Melt Flow Index Tester in Plastic Testing Labs

Source of Info: https://www.perfectgroupindia.co.in/blog/using-melt-flow-index-tester-in-plastic-testing-labs

Introduction

The Melt Flow Index Tester is an important tool for plastics testing in labs because it finds how much a sample of molten plastic flows under specific conditions. By identifying whether the plastic is suitable for molding or extrusion this equipment gives manufacturers better assurance in their processing options. It guarantees the right materials are selected for a range of uses with specific results. Perfect Group India is a reputable company that provides reliable options that improve the testing process. This equipment is an important equipment in today's plastic testing labs that value high quality and productivity because it saves time, avoids manufacturing issues and improves product quality.

What is a Melt Flow Index Tester?

A Melt Flow Index Tester is a testing device that measures the flow features of melted thermoplastic polymers. It will be used to analyze Melt Flow Rate the volume of plastic that will pass through a specific die in 10 minutes at a controlled temperature and pressure.

This test basically finds how easily it will flow once it is molten and at the proper temperature. This information is used by manufacturers to choose whether a material is suitable for injection molding or extrusion processes.

Why Is Melt Flow Index Important in Plastic Labs?

Plastic testing labs work with different types of polymers. Each kind of plastic has a unique melting and behavior pattern. Maintaining consistent quality and choosing the right material require an understanding of this behavior. The Melt Flow Index Tester is useful for the following reasons:

• Quality Control: Guarantee every batch of plastic meets flow standards.

• Material Comparison: Helps compare different plastic grades.

• Production Suitability: Checks if the material suits the intended molding or extrusion process.

• Process Adjustment: Allows fine-tuning of machine settings based on the flow rate.

How Does a Melt Flow Index Tester Work?

The working process of a device is simple but accurate. Here’s how it typically functions:

• Sample Loading: A small amount of plastic is placed into the barrel of the tester.

• Heating: The sample is heated to a specific temperature based on the polymer type.

• Compression: The melted plastic is under pressure from a piston.

• Measurement of Flow: The plastic is pushed through a narrow die at the bottom. The mass that flows out over 10 minutes is collected and weighed.

• Calculation: The result is given in grams per 10 minutes.

Key Features of Modern Melt Flow Index Tester

Modern testing labs use advanced Melt Flow Index Tester with the latest technology:

• Digital Display: Real-time readings make analysis easy.

• Touchscreen Interface: Simple navigation and control.

• Temperature Control: Maintains steady heating for accurate results.

• Timer Settings: Helps automate the testing process.

• Detachable Parts: Makes cleaning and maintenance convenient.

• Safe Design: Built with safety guards to avoid accidents.

All these features make it easier for lab technicians to perform regular tests without trouble.

Applications in Different Industries

Melt Flow Index testing is not limited to just one type of plastic or industry. It has wide-ranging applications:

• Packaging: Ensures films and containers have the right flow rate for shaping.

• Automotive: Checks if the plastic parts can be molded with accuracy.

• Consumer Goods: Validates that household plastic items meet standard quality.

• Medical Devices: Verifies that plastic used in syringes and containers is safe and moldable.

• Construction: Confirms that piping and fittings made from plastic flow as needed during manufacturing.

Every industry that uses thermoplastic materials depends on accurate flow testing to maintain product quality.

Benefits of Using Melt Flow Index Tester in Labs

Labs that use this testing equipment enjoy multiple benefits:

• Accurate Measurement: Offers accurate flow values which help maintain standards.

• Quick Testing: Saves time with fast test cycles.

•Reliable Results: Removes guesswork in choosing materials.

• Cost-Efficient: Helps reduce material wastage during manufacturing.

• Better Planning: Supports data-driven decision-making in manufacturing.

• Improved Quality: Leads to better high quality products and reduced rejections.

Tips for Using a Melt Flow Index Tester Effectively

For best results labs should follow some best practices:

• Preheat Properly: Allow the device to reach the required temperature before loading samples.

• Use the Right Tools: Always use the specified die and piston weights.

• Clean Regularly: Keep the barrel and die clean to avoid damage.

• Record Data: Maintain proper logs to track batch performance over time.

• Follow Standards: Use globally accepted testing standards like ASTM D1238 or ISO 1133.

These tips ensure that the test results remain consistent and dependable.

Choosing the Right Melt Flow Index Tester

When selecting a right equipment for your lab consider the following:

• Build Quality: Choose a durable model built with lab-grade materials.

• Ease of Use: Find out controls and displays that are easy to use.

• Support & Service: Guarantee the supplier provides training, service and spare parts.

• Test Range: Check if it covers the range of polymers you handle.

• Compliance: Make sure the tester follows international testing standards.

Making a smart choice saves time reduces errors and improves testing productivity.

Conclusion

The Melt Flow Index Tester is an important instrument for plastic testing labs because it provides an accurate tool to identify the thermoplastics' flow rate. It helps to guarantee that the right processing conditions are being met by offering required details to industries including healthcare to packaging materials. Purchasing a reliable testing tool is a wise choice for companies trying to increase quality and improve manufacturing. Perfect Group India provides strong solutions that are made to satisfy international standards for labs that require reliability and accuracy. Having a proper tester on hand guarantees that you stay ahead of the competition in today's highly competitive marketplace no matter whether you're testing film, sheet, pipe or molded products.

0 notes

Text

Using Melt Flow Index Tester in Plastic Testing Labs

Source of Info:https://www.perfectgroupindia.co.in/blog/using-melt-flow-index-tester-in-plastic-testing-labs

Introduction

The Melt Flow Index Tester is an important tool for plastics testing in labs because it finds how much a sample of molten plastic flows under specific conditions. By identifying whether the plastic is suitable for molding or extrusion this equipment gives manufacturers better assurance in their processing options. It guarantees the right materials are selected for a range of uses with specific results. Perfect Group India is a reputable company that provides reliable options that improve the testing process. This equipment is an important equipment in today's plastic testing labs that value high quality and productivity because it saves time, avoids manufacturing issues and improves product quality.

What is a Melt Flow Index Tester? A Melt Flow Index Tester is a testing device that measures the flow features of melted thermoplastic polymers. It will be used to analyze Melt Flow Rate the volume of plastic that will pass through a specific die in 10 minutes at a controlled temperature and pressure.

This test basically finds how easily it will flow once it is molten and at the proper temperature. This information is used by manufacturers to choose whether a material is suitable for injection molding or extrusion processes.

Why Is Melt Flow Index Important in Plastic Labs? Plastic testing labs work with different types of polymers. Each kind of plastic has a unique melting and behavior pattern. Maintaining consistent quality and choosing the right material require an understanding of this behavior. The Melt Flow Index Tester is useful for the following reasons:

Quality Control: Guarantee every batch of plastic meets flow standards.

Material Comparison: Helps compare different plastic grades.

Production Suitability: Checks if the material suits the intended molding or extrusion process.

Process Adjustment: Allows fine-tuning of machine settings based on the flow rate.

How Does a Melt Flow Index Tester Work? The working process of a device is simple but accurate. Here’s how it typically functions:

Sample Loading: A small amount of plastic is placed into the barrel of the tester.

Heating: The sample is heated to a specific temperature based on the polymer type.

Compression: The melted plastic is under pressure from a piston.

Measurement of Flow: The plastic is pushed through a narrow die at the bottom. The mass that flows out over 10 minutes is collected and weighed.

Calculation: The result is given in grams per 10 minutes.

Key Features of Modern Melt Flow Index Tester Modern testing labs use advanced Melt Flow Index Tester with the latest technology:

Digital Display: Real-time readings make analysis easy.

Touchscreen Interface: Simple navigation and control.

Temperature Control: Maintains steady heating for accurate results.

Timer Settings: Helps automate the testing process.

Detachable Parts: Makes cleaning and maintenance convenient.

Safe Design: Built with safety guards to avoid accidents.

All these features make it easier for lab technicians to perform regular tests without trouble.

Applications in Different Industries Melt Flow Index testing is not limited to just one type of plastic or industry. It has wide-ranging applications:

Packaging: Ensures films and containers have the right flow rate for shaping.

Automotive: Checks if the plastic parts can be molded with accuracy.

Consumer Goods: Validates that household plastic items meet standard quality.

Medical Devices: Verifies that plastic used in syringes and containers is safe and moldable.

Construction: Confirms that piping and fittings made from plastic flow as needed during manufacturing.

Every industry that uses thermoplastic materials depends on accurate flow testing to maintain product quality.

Benefits of Using Melt Flow Index Tester in Labs Labs that use this testing equipment enjoy multiple benefits:

Accurate Measurement: Offers accurate flow values which help maintain standards.

Quick Testing: Saves time with fast test cycles.

•Reliable Results: Removes guesswork in choosing materials.

Cost-Efficient: Helps reduce material wastage during manufacturing.

Better Planning: Supports data-driven decision-making in manufacturing.

Improved Quality: Leads to better high quality products and reduced rejections.

Tips for Using a Melt Flow Index Tester Effectively For best results labs should follow some best practices:

Preheat Properly: Allow the device to reach the required temperature before loading samples.

Use the Right Tools: Always use the specified die and piston weights.

Clean Regularly: Keep the barrel and die clean to avoid damage.

Record Data: Maintain proper logs to track batch performance over time.

Follow Standards: Use globally accepted testing standards like ASTM D1238 or ISO 1133.

These tips ensure that the test results remain consistent and dependable.

Choosing the Right Melt Flow Index Tester When selecting a right equipment for your lab consider the following:

Build Quality: Choose a durable model built with lab-grade materials.

Ease of Use: Find out controls and displays that are easy to use.

Support & Service: Guarantee the supplier provides training, service and spare parts.

Test Range: Check if it covers the range of polymers you handle.

Compliance: Make sure the tester follows international testing standards.

Making a smart choice saves time reduces errors and improves testing productivity.

Conclusion The Melt Flow Index Tester is an important instrument for plastic testing labs because it provides an accurate tool to identify the thermoplastics' flow rate. It helps to guarantee that the right processing conditions are being met by offering required details to industries including healthcare to packaging materials. Purchasing a reliable testing tool is a wise choice for companies trying to increase quality and improve manufacturing. Perfect Group India provides strong solutions that are made to satisfy international standards for labs that require reliability and accuracy. Having a proper tester on hand guarantees that you stay ahead of the competition in today's highly competitive marketplace no matter whether you're testing film, sheet, pipe or molded products.

0 notes

Text

10 Reasons Every Fabrication Shop Needs a Power Press – Featuring Mankoo Presses

In today’s competitive manufacturing environment, staying ahead means more than just working harder — it means working smarter. For fabrication shops aiming to scale production, enhance precision, and reduce waste, one machine has proven indispensable: the Power Press. And when it comes to reliable, high-performance presses in India and abroad, Mankoo Presses leads the way.

With over 60 years of manufacturing excellence, Mankoo Presses has become synonymous with rugged durability, cutting-edge technology, and consistent output. In this blog, we’ll explore 10 powerful reasons why every fabrication shop should have a power press — and why Mankoo should be your go-to brand.

1. Unmatched Efficiency and Speed

Power press machines are designed for high-speed, repetitive tasks — punching, shearing, bending, or forming metal sheets — with minimal downtime. Unlike manual or semi-automated processes, power presses can deliver thousands of strokes per hour with consistent force.

Mankoo Presses are engineered with heavy-duty components and smooth drive systems, enabling maximum productivity and cycle times that optimize throughput in any fabrication setting.

2. High Precision and Repeatability

Accuracy is everything in fabrication. Whether you’re making automotive parts or electrical enclosures, each component must match specifications down to the last millimeter.

Mankoo’s power presses are built with precisely machined dies, tight tolerances, and well-aligned rams to ensure perfect repeatability across large volumes. This ensures fewer rejections, less scrap, and better client satisfaction.

3. Versatile Metal Forming Capabilities

A power press isn’t just a one-trick machine. It can perform a wide range of operations including:

Blanking

Punching

Deep drawing

Coining

Bending and flanging

Mankoo offers C-type, H-type, and pneumatic clutch presses, making it easy to match the press type with your specific fabrication task. Whether you need light-duty precision work or heavy-duty bulk operations, Mankoo has the right press to fit your shop.

4. Durability That Lasts Decades

In fabrication, machine failure equals lost money. That’s why durability is non-negotiable.

Mankoo’s presses are built from high-tensile steel, cast iron frames, and heat-treated components to withstand continuous industrial use. With proper maintenance, Mankoo power presses can operate smoothly for decades, making them a long-term investment rather than a recurring expense.

5. Customizable to Shop Requirements

No two fabrication shops are alike. Some deal with intricate lightweight components, while others handle thick plates and structural metal.

Mankoo understands this and offers custom-built power presses tailored to your workload, material type, die design, and automation needs. Whether it’s stroke length, tonnage capacity, or ram size, you can get a machine that’s perfectly suited to your operations.

6. Advanced Safety Features

Safety in fabrication environments is crucial — especially when dealing with powerful, fast-moving equipment.

Mankoo Presses are equipped with:

Two-hand control systems

Emergency stop switches

Overload protection

Guarding and enclosure options

Interlock mechanisms

These features not only ensure operator safety but also help in maintaining compliance with international safety standards like ISO and CE.

7. Low Operational Cost

Though a power press involves an upfront investment, the operational costs are surprisingly low. Since Mankoo presses are designed for energy efficiency, low maintenance, and high productivity, the cost-per-piece produced becomes extremely economical over time.

Their robust build reduces breakdowns, while the wide availability of spares and technical support further brings down maintenance costs — making Mankoo presses a cost-effective choice for fabrication shops of all sizes.

8. Support for Automation and Integration

As the fabrication industry moves toward Industry 4.0, Mankoo is keeping pace. Their machines can be seamlessly integrated with:

Automatic feeders

PLC systems

Servo drives

Conveyor lines

Sensor-based safety systems

This helps in automating production lines, reducing manual handling, improving speed, and boosting quality — a critical advantage in high-volume or export-oriented units.

9. Trusted by Top Industries

Mankoo Presses are used by leading names in:

Automotive

Appliances

Aerospace

Electrical

Agriculture

Defense

The reason is simple — reliability and performance under pressure. Whether it’s manufacturing body panels for vehicles or deep-drawn enclosures for electrical systems, Mankoo’s presses deliver results that meet global standards.

By adding a Mankoo power press to your fabrication shop, you're joining a network of elite manufacturers who value excellence.

10. Excellent After-Sales Support

A great machine is only as good as the support that backs it. Mankoo provides:

On-site installation

Operator training

Preventive maintenance guidance

Quick delivery of spare parts

Responsive customer care

Their engineers and service technicians are well-trained to address any technical challenge, helping your shop maintain minimal downtime and maximum efficiency.

Conclusion: Power Up with Mankoo Presses

In the dynamic world of metal fabrication, where quality, speed, and cost efficiency matter more than ever, a power press machine is not a luxury — it’s a necessity. And when you invest in a Mankoo Power Press, you’re not just buying a machine — you’re gaining a strategic manufacturing advantage.