#materialtest

Explore tagged Tumblr posts

Text

The Hidden ROI of Investing in High-Performance Temperature and Humidity Chambers

The Hidden ROI of Investing in High‑Performance Temperature and Humidity Chambers Discover how leading labs slash failure rates, accelerate product launches, and enhance quality control :-without breaking the bank.

#TemperatureChamber#HumidityChamber#EnvironmentalTesting#LabEquipment#MaterialTesting#QualityControl#ReliabilityTesting#ClimaticChamber#TestingSolutions#HighPerformanceEquipment#ProductDurability#TestChamber#ThermalTesting#IndustrialTesting#EnvironmentalChamber#LabTechnology#TestingInnovation#ChamberTesting#EngineeringExcellence#TestingStandards#Ask ChatGPT

0 notes

Text

Melt Flow Index Tester – Importance, Working, and Applications

Pacorr brings you a highly reliable and accurate Melt Flow Index Tester, specially designed to evaluate the melt flow properties of thermoplastic materials. In industries where plastic is used for molding, extrusion, or packaging, knowing how a material behaves when melted is essential. The Melt Flow Index (MFI), also known as Melt Flow Rate (MFR), is a standard measure that helps determine the viscosity and processability of polymers.

In this article, we will take a closer look at how a Melt Flow Index Tester works, why it is critical for quality control, and how manufacturers, exporters, and suppliers can benefit from using it.

What is a Melt Flow Index Tester?

A Melt Flow Index Tester is a laboratory instrument used to measure the flow rate of molten thermoplastic polymers. The test is conducted under specified conditions of temperature and load, and the result is expressed in grams of material flowing through a capillary die in ten minutes.

This value is known as the Melt Flow Index, and it provides key insights into the polymer’s molecular weight and flow behavior. A high MFI indicates low molecular weight and high fluidity, while a low MFI indicates a high molecular weight and lower flowability.

Why is MFI Testing Important?

The MFI test is critical for various reasons in the plastic and packaging industries:

1. Material Selection

Choosing the right polymer for injection molding, blow molding, or extrusion requires understanding its flow properties. MFI helps engineers and manufacturers select materials with appropriate characteristics.

2. Quality Control

Manufacturers can use MFI testing to ensure batch-to-batch consistency. Any deviation in MFI may indicate problems in material composition or blending.

3. Process Optimization

Knowing the melt flow rate helps set the correct processing parameters, reducing defects like warping, short shots, or poor surface finish.

4. Compliance with Standards

MFI testing is often required to meet international quality standards such as ASTM D1238 and ISO 1133. Many buyers and regulatory bodies demand this data.

Working Principle of Melt Flow Index Tester

The working of an MFI Tester is based on the movement of molten polymer under controlled temperature and pressure. Here’s how it works:

A sample of the polymer is placed inside the barrel of the tester.

The machine heats the sample to a specific temperature depending on the type of plastic (e.g., 190°C for polyethylene).

A standard weight (typically 2.16 kg or 5 kg) is applied to a piston or plunger.

The molten plastic is forced through a narrow capillary die.

The material that extrudes in 10 minutes is collected and weighed.

The result is expressed in g/10 min, which represents the Melt Flow Index.

This simple yet effective test provides accurate, repeatable data on a polymer's melt behavior.

Who Should Use a Melt Flow Index Tester?

The Melt Flow Index Testung is widely used by:

Plastic manufacturers producing components, containers, or sheets

Resin suppliers and exporters dealing in raw polymer materials

PET bottle and preform producers for ensuring strength and consistency

Masterbatch and compound manufacturers to evaluate flow uniformity

Research laboratories and quality control centers

Key Features of Pacorr Melt Flow Index Tester

At Pacorr Testing Instruments, we offer both manual and digital models of MFI Testers with industry-leading features:

Digital PID temperature controller for precise thermal management

Rugged, powder-coated body for corrosion resistance and long life

Standard-compliant barrel and die assembly

Interchangeable test loads (2.16 kg, 5 kg, 10 kg, etc.)

User-friendly interface with accurate timer and display

Available with automatic sample cutting in digital models

Benefits of Using Pacorr’s MFI Tester

✅ Reliable Results – Ensures accurate and repeatable MFI values ✅ Compliant with ASTM D1238 and ISO 1133 standards ✅ Durable Design – Built for industrial conditions ✅ Affordable and Efficient – High ROI for manufacturers ✅ Technical Support & Calibration Services available across India

Applications of Melt Flow Index Tester

Injection Molding – For parts like containers, caps, automotive components

Blow Molding – For PET bottles, jerry cans, and drums

Film and Sheet Extrusion – Ensuring consistent thickness and strength

Masterbatch Testing – Verifying flowability of colored resins

Recycling Plants – Monitoring quality of reprocessed polymers

Why Choose Pacorr?

Pacorr is one of India’s Top 10 Scientific Instrument Manufacturers (2023), with a strong reputation for delivering reliable, ISO-certified, and CE-marked testing machines. Our commitment to quality and innovation makes us the preferred choice among manufacturers, suppliers, and exporters across various industries.

We provide:

High-precision instruments

Customization options

Nationwide support and service

Expert consultation for choosing the right model

Conclusion

The Melt Flow Index Tester is an essential quality control tool for any company dealing with plastic and polymer materials. By providing accurate melt flow rate values, it helps ensure product consistency, optimizes production, and complies with international standards.

With Pacorr’s advanced MFI Tester, you not only test your materials—you build trust in your brand.

📞 Need Help Choosing the Right MFI Tester?

Call us at +91-8882149230 or email us at [email protected] Visit 👉 www.pacorr.com

#MeltFlowIndexTester#MFITester#PlasticTesting#PolymerTesting#QualityControl#PlasticManufacturers#PETPreformTesting#InjectionMolding#BlowMolding#ResinTesting#TestingInstruments#MaterialTesting#ASTMD1238#ISO1133#PlasticIndustry#TestingSolutions#ScientificInstruments#QualityAssurance#Manufacturers#Suppliers#Exporters#PacorrTestingInstruments

0 notes

Text

Digital Tensile Testing

To check how strong a product is, many industries use digital tensile testing to see how much it can stretch before breaking. This machine pulls the material slowly until it breaks, helping you know if it’s strong enough. It’s easy to use and gives quick, clear results. It’s helpful in labs, factories, and for checking product quality. Get simple and trusted testing equipment from Perfect Group India—your reliable partner for safe and easy strength testing

#DigitalTensileTesting#MaterialTesting#StrengthTesting#QualityControl#TestingEquipment#PerfectGroupIndia

0 notes

Text

Enhancing Precision with Ultrasonic Testing (UT) Solutions

Ultrasonic Testing (UT) is a highly effective non-destructive testing method used to detect internal flaws and material thickness in a wide range of industries. Known for its accuracy and depth penetration, UT plays a crucial role in maintaining the integrity of structures without causing any damage. From weld inspections to corrosion monitoring, this advanced technique ensures safety, compliance, and operational efficiency. Leveraging state-of-the-art equipment and experienced technicians, Ultrasonic Testing (UT) delivers reliable and repeatable results that support critical decision-making across sectors.

0 notes

Text

Metallurgical Microscope Manufacturer in Italy – FinelabUK

FinelabUK is a top Metallurgical Microscope Manufacturer in Italy, providing precision-engineered microscopes for industrial and research applications. Our microscopes deliver high-resolution imaging for metal analysis, material testing, and quality control. FinelabUK ensures superior performance and reliability for metallurgical investigations across Italy.

#MetallurgicalMicroscope#MicroscopeManufacturerItaly#FinelabUK#IndustrialMicroscope#MaterialTesting#MetallurgyEquipment#LabEquipmentItaly#ScientificInstruments

0 notes

Text

Eddy Current Testing Machine for Metal Parts - Magkraftndt

The Eddy Current Test quickly detects surface or subsurface cracks and defects in metal parts without any damage. It gives fast, accurate, and non-destructive results.

#magkraftndt#eddycurrenttesting#nondestructivetesting#materialtesting#inspectiontechnology#mpimachine#magneticparticletestingmachine#demagnetizermachine#magnafluxmachine#mpimachinemanufacturer

0 notes

Text

Comprehensive Mechanical Testing for Material Strength and Reliability

Mechanical testing evaluates the physical properties of materials, including tensile strength, hardness, impact, and fatigue resistance. Essential for ensuring safety, performance, and compliance across industrial applications.

Know More At:- https://mpplstandards.com/mechanical-testing/

#mpplstandards#qualitycontrol#materialtesting#proficiencytesting#testingstandards#qualityassurance#certifiedreferencematerials#industrialtesting#metaltesting

0 notes

Text

FREE WEBINAR: Foam Fundamentals – Measurement Methods & Industry Applications

📅 Date: Thursday, June 26, 2025 🕙 Time: 10:00 AM IST & 7:30 PM IST 📍 Duration: 60 Minutes (with Live Q&A) 🔗 [https://www.orbitind.com/event/live-webinar-on-understanding-foam-measurement-and-industry-applications/]

Foam isn't just froth — it’s science.

From shampoos to beer, detergents to emulsions, the behavior of foam impacts performance, shelf life, and user experience.

🔬 What You’ll Learn:

How foam forms and decays

How to measure foamability, stability & bubble structure

Why tools like the DFA100 Dynamic Foam Analyzer from KRÜSS are transforming lab workflows

👩🔬 Speaker: Dr. Fiona Mary Antony, Laboratory Manager (APAC), KRÜSS – expert in surface science and foam mechanics.

💼 Who Should Attend? Professionals in:

Research & Development

Product Formulation

Quality Control

Analytical Chemistry

Process Engineering

Brought to you by Orbit Research, your partner in precision surface & interfacial testing.

#FoamAnalyzer#SurfaceTensionMeasurement#KRUSS#OrbitResearch#LabTesting#CosmeticScience#MaterialTesting#DropShapeAnalyzer#DFA100#Webinar2025

1 note

·

View note

Text

Vibratory Sieve Shaker VS1100

Vibratory Sieve Shaker VS1100 can be used for sieving any kind of inorganic and organic substances such as sand, rocks, clay, granite, feldspar, coal, soil, various powder, grains, seeds, and other solid particles. It is suitable for both dry & Wet samples. Standard Features of Vibratory Sieve Shaker VS1100 • Electromagnetic Drive with Unique sieving with 3D motion • Built-In Colour LED 5” Touch screen, intelligent control. • Digital setting of all sieving parameters can be preset viz. amplitude (vibration height), Sieving time, interval time & Pause time operation • Dry & Wet sieving Modes • Sieving Aids according to the mesh size and vibration strength in MOC’s of Agate, Rubber, Nylon etc. for proper separation • Measuring Range from 20 μm to 25 mm • Sieves (ASTM/ISO) of Diameters of 100, 150, 200, 203 (8”) mm and length 25, 50 mm can be used with the fractions of 17 / 9 • Adjustable Amplitude from 0.2 to 3.0 mm • Sieving Time selectable from 01 to 999 Min. • Interval Operation & Pause Time selectable from 01 to 99 Sec. • Reliable, repeatable, and highly efficient sieving result. • Low noise, maintenance-free ≤ 60 dB • 9 Standard Operating Procedures (SOP’s) can be stored • ISO, CE & IP30 certified • Can be connected to the computer and controlled by the Smart screen software to perform data processing and analysis, Screening evaluation. visit www.technovalue.in for more detail

#MaterialTesting#SoilAnalysis#PowderProcessing#FoodTesting#PharmaceuticalTesting#ConstructionMaterials#MiningTechnology#GranularMaterials

0 notes

Text

🔬Building Materials Testing Chennai🏗

Worried about material quality compromising your project? 🔍 Don't risk delays or failures! Falcon Industrial Testing Laboratory ensures your building materials meet the highest standards in Chennai.

We test for:

Strength & Durability

Safety & Compliance

Long-term Performance

Safeguard your investment with certified testing! 📱 Call Now: +91 80561 59517 / +91 72000 96379 💻 Learn More: www.fitpl.in

#MaterialTesting#ConstructionChennai#BuildReliable#QualityAssurance#Infrastructure#FalconTestingLab#Fitpl#BuildWithConfidence

0 notes

Text

Quality footwear starts with trusted testing. Ensure your shoes meet global durability, safety, and performance standards with certified footwear testing services in Delhi NCR.

#FootwearTestingLab#ShoeTestingLabInDelhiNCR#MaterialTesting#SoleDurabilityTesting#ProductQuality#ComplianceTesting#LeatherTesting#AtharvaLaboratories#FootwearStandards#IS17043

0 notes

Text

Achieve Unmatched Accuracy in Pipe Testing

When failure is not an option, precision becomes non negotiable. At Testron Group, we engineer pipe testing instruments that deliver consistent results, ensuring your systems meet every compliance and durability standard.

From pressure integrity to performance validation, our cutting edge solutions are designed for specialists who demand reliability and speed without compromise.

Let your testing speak quality. Let your quality define your brand.

Testron Group – Trusted by engineers. Preferred by industries.

#PipeTestingMachines#MaterialTesting#QualityControlEquipment#IndustrialTesting#NDT#PipeInspection#PipelineTesting#ManufacturingQuality#EngineeringSolutions#TestingMachines#OilAndGasIndustry#ConstructionIndustry#AutomotiveIndustry#IndiaManufacturing#USAManufacturing#UAEIndustry#UKManufacturing#GlobalTestingSolutions#LabEquipment#TestronGroup

0 notes

Text

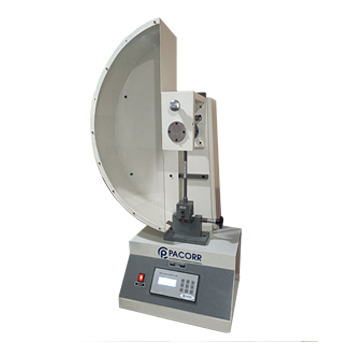

Understanding the IZOD/Charpy Impact Tester – Essential Tool for Material Toughness Testing

In today’s competitive manufacturing environment, the mechanical performance of materials under stress is critical to product quality, safety, and reliability. One of the most important parameters in material testing is impact resistance, and this is precisely where the IZOD/Charpy Impact Tester from Pacorr plays a vital role.

What is an IZOD/Charpy Impact Tester?

The IZOD/Charpy Impact Tester is a highly specialized testing instrument used to measure the impact strength or toughness of materials. It helps determine how much energy a material can absorb before it fractures when subjected to sudden or shock loading.

Pacorr’s Impact Testers are designed to support both IZOD and Charpy methods, allowing users to comply with international standards like ASTM D256, ISO 180, and ISO 179 with a single machine.

Difference Between IZOD and Charpy Tests

Though similar in purpose, the IZOD and Charpy test differ in configuration:

IZOD Test: The specimen is clamped vertically and struck at the upper tip.

Charpy Test: The specimen is placed horizontally and supported at both ends, with the impact at the center.

Having a tester that can perform both ensures flexibility, especially in laboratories and industries serving multiple global markets.

Key Features of Pacorr’s IZOD/Charpy Impact Tester

Pacorr is known for designing highly reliable and durable testing instruments. Our IZOD/Charpy Impact Tester includes:

Dual Configuration: Easily switch between IZOD and Charpy testing

Digital Display: Real-time impact energy readout in Joules or ft-lbs

Rugged Frame: Built with industrial-grade materials for long-term durability

High-Precision Pendulum: Provides accurate and repeatable results

Adjustable Impact Energy Levels: For testing a wide range of materials

Applications Across Industries

The IZOD/Charpy Impact Tester is indispensable for industries such as:

Automotive: Ensuring material durability under crash conditions

Plastic and Polymer: Verifying the quality of injection-molded parts

Aerospace: Evaluating materials used in high-stress environments

Construction: Testing building materials for shock resistance

Research & Academia: Fundamental tool for studying material behavior

Why Choose Pacorr?

With years of experience in material testing equipment, Pacorr delivers unmatched accuracy, build quality, and after-sales support. Our IZOD/Charpy Impact Tester Price is trusted by top-tier manufacturers, laboratories, and academic institutions across the globe.

We not only offer the product but also assist with installation, training, and calibration services, ensuring your team gets maximum value.

Request a Quote Today

Enhance your quality control and material research capabilities with a world-class impact testing solution from Pacorr.

👉 Explore now at: www.pacorr.com 📧 Email us: [email protected]

#IZODCharpyImpactTester#MaterialTesting#Pacorr#ImpactStrength#QualityControl#ASTMTesting#PlasticsTesting#MechanicalTesting

0 notes

Text

Haze Tester , Clarity Tester , Alat uji kabut dan kejernihan , Pengukur haze dan clarity , Haze meter , Clarity meter , Prinsip kerja haze tester , Cara mengukur haze dan clarity , Alat uji transparansi plastic , Pengukuran light scattering , Alat uji transmittance cahaya , Pengukur dispersi cahaya pada material , Instrumen pengujian optical clarity , Alat quality control material transparan

Haze Tester dan Clarity Tester adalah alat uji presisi yang digunakan untuk mengukur tingkat kabut (haze) dan kejernihan (clarity) pada material transparan seperti plastik, kaca, film kemasan, dan produk lainnya. Alat ini bekerja berdasarkan prinsip optik dengan standar internasional ASTM D1003, ISO 13468, dan ISO 14782, memastikan hasil pengukuran akurat dan konsisten. Haze Tesser mengukur persentase cahaya yang terhambur saat melewati material, sementara Clarity Tester menilai ketajaman visual untuk menentukan seberapa jelas suatu objek terlihat melalui sampel.

Alat ini banyak digunakan di industri otomatif, kemasan, elektronik, dan manufaktur untuk memastikan kualitas material. Dengan fitur seperti pengukuran cepat, kalibrasi otomatis, dan tampilan digital, Haze & Clarity Tester membantu produsen memenuhi standar kualitas produk. Penggunaannya sangat penting untuk mengontrol transparansi, ketahanan optik, dan estetika material, sehingga meningkatkan keandalan produk di pasaran.

PT. Valtekindo Global Intertek Distributor Mesin Industri, Alat Uji, dan Peralatan Laboratorium Perusahaan kami hadir untuk kemajuan teknologi dan layanan terbaik untuk mendukung efisiensi dan produktivitas bisnis Anda.

Untuk Info Lebih Lanjut Bisa Mengunjungi Website Kami : www.valtekindo.co.id

#HazeTester#ClarityTester#OpticalTesting#QualityControl#MaterialTesting#PlasticTesting#PackagingIndustry#AutomotiveTesting#FilmManufacturing#GlassQuality

1 note

·

View note

Text

Magnetic Particle Testing (MT): Enhancing Surface Crack Detection in Industrial Components

Magnetic Particle Testing (MT) is a widely used non-destructive testing (NDT) method designed to identify surface and slightly subsurface discontinuities in ferromagnetic materials. This inspection technique plays a crucial role in industries such as aerospace, automotive, oil & gas, and manufacturing by ensuring the structural integrity of components without causing damage. By using finely milled iron particles and magnetic fields, MT testing effectively detects cracks, seams, laps, and other flaws that are invisible to the naked eye. Compared to other NDT methods, magnetic particle inspection is cost-effective, fast, and highly reliable. Engineers and quality control professionals rely on magnetic testing to maintain safety standards and extend equipment life.

#MagneticParticleTesting#MagneticTesting#NonDestructiveTesting#NDT#MTTesting#SurfaceInspection#IndustrialInspection#QualityControl#WeldTesting#MaterialTesting

0 notes

Text

Convection oven

Product Description

Our convection ovens are specifically designed for general drying, heating, and thermal applications where a gentle airflow is required. These ovens rely on natural air circulation, providing even heat distribution without the need for a fan. This makes them ideal for processes involving sensitive samples, as the absence of forced airflow minimizes the risk of sample disturbance, contamination, or dehydration.

Key Features:

Temperature Range: Designed to operate efficiently at temperatures ranging from ambient +10°C to 250°C, these ovens provide precise thermal control for a wide variety of applications.

Uniform Heat Distribution: The natural airflow ensures consistent temperature throughout the chamber, making it suitable for drying glassware, sample curing, and testing that requires stable, low-turbulence heating conditions.

Sizes: Available in a variety of chamber sizes, from compact benchtop models starting at 30 liters, to larger, more spacious units up to 180 liters, catering to both small-scale laboratory work and more demanding industrial applications.

Ideal Applications:

Drying and curing delicate materials

Heat treatment processes

Slow and gentle heating of samples in life sciences, material testing, and chemical research

Each oven is equipped with intuitive controls for precise temperature settings, durable stainless steel interiors, and multiple safety features, making them a reliable and essential tool in laboratories, quality control environments, and industrial processes.

M-Kube Enterprise is an Australian company catering customized laboratory products, laboratory consumables and laboratory solutions in Australia, Dubai, India, Indonesia, Malaysia, New Zealand, Philippines, Singapore, South Korea, USA, and Vietnam. We can supply wide range of ovens. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us on [email protected] or call us on +61478594746 to discuss your projects

#convectionoven#laboratoryequipment#dryingoven#heatingoven#scientificequipment#thermalprocessing#labtech#materialtesting#lifesciences#chemicalresearch#mkube#mkubeaustralia#customlabsolutions#stainlesssteeloven#gentleairflow#sampledrying#heatdistribution#qualitycontrol#industrialoven#labfurnace#labappliances#researchtools#labsolutions#ovenforscience#mkubelabs

1 note

·

View note