#metal fabrication

Explore tagged Tumblr posts

Text

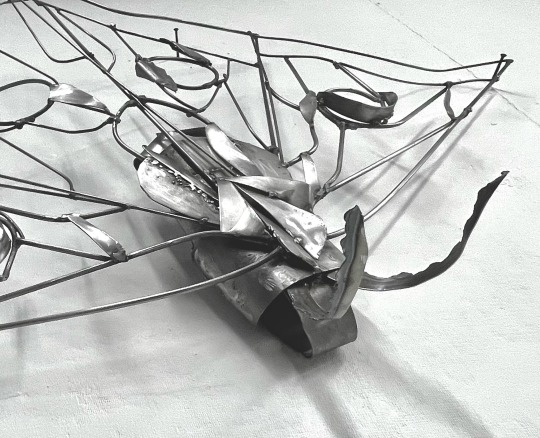

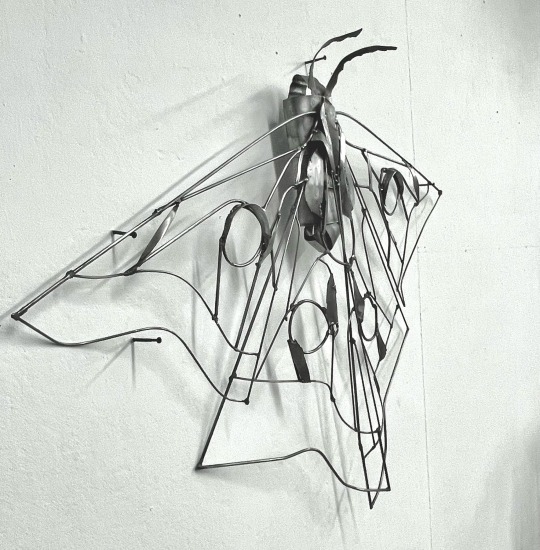

Metal moth COMPLETE!

#metalworking#welding#metal#art#artists on tumblr#artists of tumblr#sculpture#metal fabrication#moth#moon moth#my art#this was for a class and I’m actually pleasantly surprised with how it turned out#yippe

393 notes

·

View notes

Text

For the love of the 80series

#land cruiser#toyota#prado#jdm#japanese cars#japan travel#offroad#overland travel#trails#go outside#turbo#metal fabrication#lovers#the amazing digital circus#4x4

11 notes

·

View notes

Text

im making my own fold out table for camping. i just re-used a stool seat for the table part, its lookin good!

14 notes

·

View notes

Text

completely hand fabricated ✨

#i’m excited to do more customs!!!#silversmith#silver#jewelry#metal fabrication#amethyst#ring#artists an tumblr#jewerly

5 notes

·

View notes

Text

my recent art I’ve been working on 🏎️🪁

2 notes

·

View notes

Text

U-Tubes

At Heavy Metal & Tubes, we use advanced U-bending machines for precision cold bending with three-dimensional accuracy. Our U-Tubes are ideal for heat exchangers, condensers, and boilers, available in carbon, alloy, and stainless steel (seamless & welded). Custom bends & shapes available!

What are Boiler and Heat Exchanger Tubes, and Why Are They Essential for Industrial Applications?

#HeavyMetalTubes#UTubes#precisionbending#steel tubes#heat exchanger tubes#alloy steel#stainless steel#CarbonSteel#tube manufacturing#metal fabrication#industrial solutions#seamless tubes

2 notes

·

View notes

Text

Look at my dope af paint job guys

Two other guys put it together, but I was the chosen one to paint it

#metal fabrication#spacey lives on#yippee#spacey doesn't weld this time#but she paints#fireplace#spray paint#it isn't too ugly lmaoo

4 notes

·

View notes

Text

Our Powder Coating services produce long-lasting, corrosion-resistant finishes that are perfect for industrial and commercial applications. With a diverse choice of colors and patterns, we guarantee a high-quality, long-lasting coating that protects metal surfaces from severe environments while improving their beauty. Ideal for machinery, equipment, architectural parts, and structural steel. To get more information in detail about Powder Coating, visit: https://www.metalskills.co.nz/powder-coating

#hardware insertion#welding engineering#steel fabrication#metal fabrication#Steel Fabrication#Powder Coating#Deburring

1 note

·

View note

Text

Top 5 Automotive Companies and How Metalman Auto Ltd. Supports Them

The automotive industry is dominated by several key players that lead the market in terms of innovation, production, and market share. The top five automotive companies globally are typically considered to be Toyota, Volkswagen Group, Daimler AG (Mercedes-Benz), Ford Motor Company, and General Motors (GM).

How Metalman Auto Ltd. Supports These Automotive Giants

As a leading supplier of high-quality automotive components, Metalman Auto Ltd. is well-positioned to support these top automotive companies. Our expertise in metal fabrication and assembly allows us to provide critical components that meet the specific needs of these manufacturers.

Our Value Proposition:

High-Precision Components: We provide parts that are essential for the safety and performance of vehicles, adhering to the exact specifications required by these top manufacturers.

Collaborative Approach: We work closely with OEMs to understand their needs and provide innovative solutions that enhance vehicle performance and safety.

Sustainable Manufacturing: Our commitment to sustainable practices ensures we contribute positively to the automotive industry’s environmental goals.

By partnering with Metalman Auto, these top automotive companies can enhance their supply chain efficiency and maintain their competitive edge in the global market.

#EV components supplier#Electric car parts manufacturer#Battery components supplier for EVs#Electric vehicle drivetrain parts supplier#EV charging components manufacturer#Electric motor parts supplier#EV battery management system supplier#Electric scooter parts manufacturer#general motors#vintage automobiles#chevrolet#Volkswagen Group#automotive industry#automotive#automotive components#metal fabrication#oems#oemparts#oem manufacturing#oem#metal parts supplier#India automotive components manufacturer#Automobile parts production in India#OEM parts manufacturing in India#Indian automotive parts supplier#Vehicle parts manufacturing industry in India#Made in India automotive components#Indian car parts production#India-based automotive parts manufacturer"

2 notes

·

View notes

Text

#architecture#contractors#design#metal fabrication#tig welder#mig welder#roofing#welder#welder wings

2 notes

·

View notes

Text

Three representatives from the National Federation of Women Workers – Julia Varley, who had started work as a 13-year-old mill girl; Mary Macarthur, a draper's daughter; and Charles Stitch, who had started chainmaking at the age of eight – visited the chainmakers: 'We went into the forges, talking to the women as they hammered away, awakening their consciousness to their responsibilities, appealing to their pride and their motherhood,' said Varley.

"Normal Women: 900 Years of Making History" - Philippa Gregory

#book quote#normal women#philippa gregory#nonfiction#union representative#representation#national federation of women workers#julia varley#miller#mary macarthur#draper#charles stitch#chainmaker#forge#ironwork#metal fabrication#hammering#awakened#consciousness#responsibility#pride#motherhood

2 notes

·

View notes

Text

#press machines#industrial manufacturing#Inerrant Robotomation Pvt. Ltd.#India#automotive industry#metal fabrication#sustainability#hydraulic presses#mechanical presses#quality assurance#manufacturing technology

0 notes

Text

STEFFIN’s 5th gen

#4runner#toyota#5th generation#metal fabrication#offroad#4x4#trails#overland travel#california#japanese cars#tacoma#land cruiser

8 notes

·

View notes

Text

How 3-Roll Plate Bending Machines Enhance Precision in Metal Fabrication

In today’s competitive manufacturing landscape, achieving accuracy in metal forming processes is more than a goal—it’s a necessity. Among the wide range of machinery used in fabrication workshops, 3-roll plate bending machines stand out for their unmatched ability to deliver precise and consistent results. These machines are the backbone of industries that demand perfect curves, such as shipbuilding, pressure vessel manufacturing, windmill towers, and more.

Let’s explore how these machines work, their advantages, and why they are essential in modern metal fabrication.

Understanding 3-Roll Plate Bending Machines

A 3-roll plate bending machine uses a trio of rollers—two at the bottom and one at the top—to bend flat metal sheets into cylindrical or conical shapes. The machine operates by pinching the metal plate between the top and bottom rolls and then adjusting the rolls to apply force, guiding the metal into the desired curvature.

This configuration provides smooth and controlled bending with minimal material deformation, making it ideal for medium to heavy-duty applications.

Why Precision Matters in Metal Fabrication

Precision in metal forming determines the structural integrity, appearance, and fit of the final product. In industries like aerospace or energy, even the smallest inconsistency can result in performance failure or non-compliance with regulatory standards.

Here’s how 3-roll bending machines elevate precision:

Uniform Pressure Distribution: The symmetrical arrangement of the rolls ensures even pressure throughout the sheet, minimizing distortions.

Controlled Rolling Process: Fine-tuned adjustments can be made during bending, allowing exact control over the radius and shape.

CNC Integration: Modern 3-roll machines come with CNC controls that automate settings and reduce human error, enhancing repeatability and accuracy.

Key Advantages of Using 3-Roll Bending Machines

1. Versatility in Applications

Whether it’s a tank shell, a steel pipe, or a component for wind turbines, 3-roll plate bending machines can handle various thicknesses and diameters, adapting easily to complex project needs.

2. Smooth Surface Finish

Due to their gradual bending motion and consistent pressure, these machines produce superior surface finishes compared to traditional press brakes or manual methods.

3. Reduced Material Waste

Precision means fewer errors, and fewer errors mean less scrap material. This directly translates into cost savings and more sustainable production.

4. Enhanced Operator Safety

Many modern systems are equipped with safety features like automatic material centering, emergency stop systems, and hydraulic clamping—making operations safer and more efficient.

Where 3-Roll Plate Bending Machines Are Used

You’ll find these machines in a wide range of industries that demand consistent, high-quality bends:

Shipbuilding – For forming hull sections and pressure bulkheads

Aerospace – For producing cylindrical fuel tanks and structural elements

Energy – Windmill towers, boilers, and heat exchangers

Construction – Fabricating curved steel elements for architecture and infrastructure

Manual vs. CNC-Controlled 3-Roll Bending

Traditional machines required significant operator experience to achieve desired results. Today, CNC-integrated 3-roll plate bending machines simplify the process through programmable bending sequences, automatic calibration, and real-time monitoring.

This not only boosts precision but also improves consistency across large production batches.

The Role of Energy Mission in Metal Fabrication

Companies like Energy Mission are leading the charge by providing advanced plate bending solutions that meet the evolving needs of modern fabrication units. With a strong focus on innovation, build quality, and operator-friendly features, their 3-roll plate bending machines are engineered for reliability and long-term value.

Final Thoughts

In an industry where every millimeter matters, investing in 3-roll plate bending machines offers a strategic advantage. They not only ensure precision but also improve productivity, reduce waste, and enhance the quality of end products. Whether you’re upgrading an existing fabrication line or setting up a new one, these machines are a worthwhile addition that can redefine your metal forming capabilities.

0 notes

Text

What Are the Most Common Bending Techniques Used in Press Work?

A sheet metal bending press is a machine used to bend, fold, or shape flat metal sheets into specific angles or forms. It does this by applying pressure through special tools, often called punches and dies. These tools press down on the metal to create a precise bend, giving it the shape needed for construction, manufacturing, or custom parts.

This type of press is widely used in industries like automotive, construction, and furniture. It's perfect for making brackets, panels, frames, or any part that needs a clean, accurate fold. Because it uses force and precision, it helps workers and businesses get repeatable results with minimal effort.

Why It’s a Key Tool in Modern Workshops

Today’s sheet metal bending press machines are much more advanced than older manual versions. Many are now automated or use digital controls to follow detailed instructions. This means less guesswork, less waste, and a faster process overall.

With the right setup, a press can handle different materials—like steel, aluminium, and stainless steel—and bend them at various angles without cracking or damaging the metal. Thanks to their reliability and efficiency, bending presses have become essential in almost every metalworking shop.

How Does a Sheet Metal Press Brake Work in Fabrication?

Bending Angles with Power and Precision

A sheet metal press brake is the most common tool used in metal bending. It works by using a top tool (the punch) and a bottom tool (the die). The sheet metal is placed between them. When the punch is pressed down into the die, it bends the sheet to the required angle.

This method is popular in fabrication because it gives great control over the bend. Whether you need a small fold or a wide curve, a sheet metal press brake can be adjusted to do the job right. It also allows for clean edges, which is important in high-quality manufacturing.

Tools That Make Bending More Accurate

For accurate results, these machines also use a part called a back gauge. This helps position the metal at the exact spot needed for each bend. It acts like a stop guide and ensures that every part is bent in the same place, over and over again.

When combined with trained operators or digital programming, a press brake becomes a powerful tool for shaping metal parts. It’s a key part of the engineering manufacturing and fabrication capabilities used by professionals today.

What Is Air Bending and Why Is It So Common?

Forming Metal Without Full Contact

Air bending is the most widely used method on a sheet metal bending press. In this technique, the punch doesn’t press the metal all the way into the bottom of the die. Instead, the punch pushes the metal partway, and the angle is formed by the position of the punch and the space between the die walls.

This method doesn’t need full contact with the bottom surface, which makes it more flexible. You can make different angles with the same set of tools, simply by adjusting how far the punch moves down.

Why Air Bending Is a Popular Choice

There are many reasons why shops and manufacturers use air bending. It requires less force, so it reduces wear on tools. It also allows faster bending and makes it easier to adjust for different jobs. Plus, it works well with different metal types and thicknesses.

Air bending is especially useful in cnc sheet metal fabrication, where precision and efficiency are critical. Thanks to digital programming, the bending depth can be controlled perfectly, helping you create accurate parts with minimal setup.

How Does Bottom Bending Differ from Air Bending?

Using More Force for Better Contact

Bottom bending is another method used on a sheet metal bending press, but it works a bit differently from air bending. In this process, the punch pushes the metal all the way into the die. This creates full contact between the metal and the tooling.

Because of that full contact, bottom bending usually needs more force than air bending. The benefit is that the final angle tends to be more consistent, especially when you're working with thicker or harder metal.

When to Use Bottom Bending for Better Accuracy

While air bending is faster, bottom bending offers more stability. It’s a better option when high repeatability is needed and there’s no room for variation. This technique is also great for parts that will go into precise assemblies or frames.

In many engineering manufacturing and fabrication capabilities, bottom bending is used when the final product needs tight control over dimensions. It's a little slower, but the accuracy and strength of the bend can be worth it.

What Is Coining and When Should It Be Used?

Coining for Sharp, Accurate Bends

Coining is the most forceful bending method used in a sheet metal bending press. It uses extreme pressure to press the metal tightly between the punch and die, which changes the structure of the metal slightly. This results in a sharp, clean bend that stays exactly as designed.

Unlike air or bottom bending, coining doesn’t spring back. That’s because the metal has been compressed at the bend line. This makes it ideal for very precise parts where angle variation is not allowed.

Trusted in High-Precision Manufacturing

Coining is a common practice in advanced engineering manufacturing and fabrication capabilities, especially when small parts or electronic enclosures are involved.

If you're looking for a provider that offers a full range of services—including coining, laser cutting, cnc punching, turret punching services, Metal punching services, as well as Shelving Units and Storage Cabinets and Machining—you can turn to Premier Engineering & Storage Solutions. They combine expert tools and experienced staff to help you get reliable results every time.

How CNC Sheet Metal Fabrication Enhances Bending Precision

Digital Control Means More Consistency

Cnc sheet metal fabrication is all about accuracy and speed. With CNC (computer numerical control), machines follow digital instructions. This removes the need for manual adjustments and cuts down on errors.

When a press brake is CNC-controlled, each bend can be programmed for exact depth, position, and angle. That means parts come out nearly identical, even in large production runs.

Less Setup Time, More Productivity

Another benefit of cnc sheet metal fabrication is how easy it is to switch between jobs. Instead of changing tools or settings manually, you just upload a new program. This saves time and increases output, especially for businesses with custom orders or short lead times.

Whether you're making a few brackets or hundreds of panels, CNC control keeps every bend sharp and in line with your design.

Can Laser Cutting Be Used with Bending for Better Results?

Pre-Cut Parts Improve the Bending Process

Laser cutting is often used before bending to shape metal sheets to the right size. When done properly, it prepares the metal for bending with smooth edges and perfect dimensions. This helps the press brake perform better and reduces chances of misalignment.

For parts with cut-outs, slots, or tabs, laser cutting is especially helpful. It ensures everything is in the right place before the sheet ever touches a sheet metal press brake.

Combining Techniques for a Smoother Workflow

By combining laser cutting with bending on a sheet metal bending press, manufacturers get the best of both worlds—speed and precision. It’s a smart way to streamline production and reduce the number of machines or manual steps needed.

Many modern workshops rely on this combo to handle complex parts and meet tight deadlines. It’s a popular approach in industries that require quality and speed in every job.

#laser#cnc machining#cnc punching#engineering#welding#metal fabrication#metal press#metal punching#sheet metal fabrication#metal bending press#bending press australia

0 notes

Text

Custom Metal Fabrication v/s Off-the-Shelf: What Engineers Are Choosing in 2025

In a world where precision engineering and fast delivery are often in conflict, the question of whether to go with custom metal fabrication or stick to off-the-shelf components has become more relevant than ever.

As 2025 unfolds, engineering and procurement teams are rethinking the way they approach metal parts — from flanges and pipe fittings to structural steel and pressure-rated assemblies. What was once a question of cost is now a decision about fit, performance, and long-term efficiency.

So, what’s driving this shift, and what are engineers choosing?

Off-the-shelf parts still have their place. For standardised requirements, common sizes, and repeat orders, they remain the go-to solution.

a. Speed: These parts are ready to ship, reducing lead times. b. Cost Efficiency: Standardisation enables economies of scale. c. Interchangeability: Engineers know what they’re getting. No surprises.

In industries with conventional requirements like basic plumbing systems or general-purpose piping, off-the-shelf often works just fine. But as systems become more complex, those advantages start to fade.

Today’s infrastructure isn’t always built around what’s available on the shelf. It’s built around performance, environmental conditions, space limitations, and compliance. That’s where custom metal fabrication steps in.

Here’s why engineers are choosing custom in 2025:

1. Precision That Matches Project Demands

Modern industrial systems are not forgiving. Whether it’s matching an old legacy pipeline or integrating equipment sourced internationally, the tolerances are tighter and the margin for error is lower.

Custom fabrication allows you to specify:

a. Exact flange dimensions b. Bolt patterns and gasket grooves c. Material grades based on pressure or chemical compatibility

The result? A perfect fit — every time.

2. Solving Space and Design Constraints

Every inch matters in industries like marine, aerospace, and compact factory lines. Off-the-shelf fittings often don’t account for tight corners, custom angles, or unique installation paths.

Custom pieces are tailored to:

a. Fit into pre-existing equipment layouts b. Reduce weight and space c. Optimise flow with smoother transitions

3. Compliance and Certification

With industries governed by strict standards like ASME, ASTM, ISO, and PED, one wrong component could derail an audit or even a full shipment.

Custom fabrication gives engineers control over:

a. Traceability of raw materials b. Mill Test Certificates (MTCs) c. Surface finish for hygienic or high-purity applications

4. Better Long-Term ROI

Custom parts may cost more upfront, but they often reduce:

a. Installation time b. Maintenance issues c. Pressure drop and flow disruptions

When evaluated over the life of a project, custom solutions often outperform their stock counterparts in both durability and reliability.

So, What Are Engineers Choosing?

In 2025, engineers are prioritising performance over convenience. While off-the-shelf still serves its purpose, custom fabrication is no longer a luxury; it’s often a necessity.

Whether it’s matching a non-standard joint on a retrofit project or sourcing flanges that meet dual global certifications, engineers are demanding more, and fabricators are rising to meet that demand with better lead times, digital modelling support, and precision machining.

At Online Fittings, We Make Custom Simple

You don’t need to compromise anymore. Whether you’re an MEP consultant, project manager, or industrial buyer, Online Fittings delivers precision-engineered, certified fittings built around your project’s needs.

From custom flanges and elbows to reducers and caps, we craft solutions that integrate seamlessly and perform reliably.

Your project deserves the right fit. Not just the nearest one.

0 notes